Patents

Literature

63results about How to "Promote cooling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

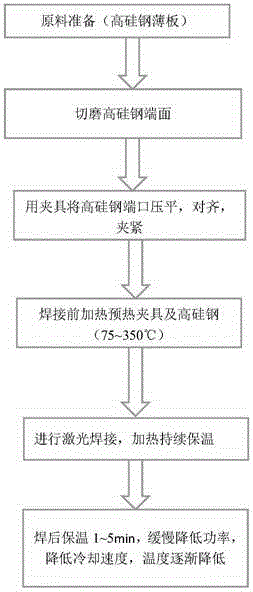

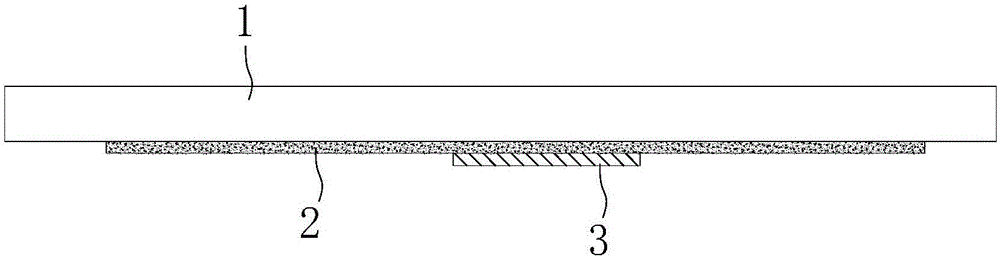

Laser welding method of high silicon steel

ActiveCN106041305ARealize welding formingImprove cooling conditionsWelding/soldering/cutting articlesLaser beam welding apparatusAlloySlow cooling

The invention belongs to the field of the metallurgy technology and material science, and aims at providing a laser welding process method of brittle high silicon steel. Quick welding of strip tension rolling in the rolling preparation process of a high silicon steel thin strip is met. According to the mass ratio, an adopted alloy is prepared from 93%-96.5% of Fe and 3.5%-7% of Si; and the thickness ranges from 0.1 mm to 3.5 mm. According to the method, laser welding and a supplementary heat source are combined, and double-face or single-face welding is adopted; preheating carried out before welding is utilized for controlling the temperature rise speed, and heat preservation during welding and heat preservation carried out after welding are utilized for slow cooling to control the temperature reduction speed; and the temperature gradient and welding stress in the weld joint cooling process are reduced, and welding forming of the brittle high silicon steel is achieved. By means of the adoption of the method, cracks generated by the too high welding stress of the brittle high silicon steel can be avoided well, and the yield and the mechanical performance of the brittle high silicon steel are increased.

Owner:UNIV OF SCI & TECH BEIJING

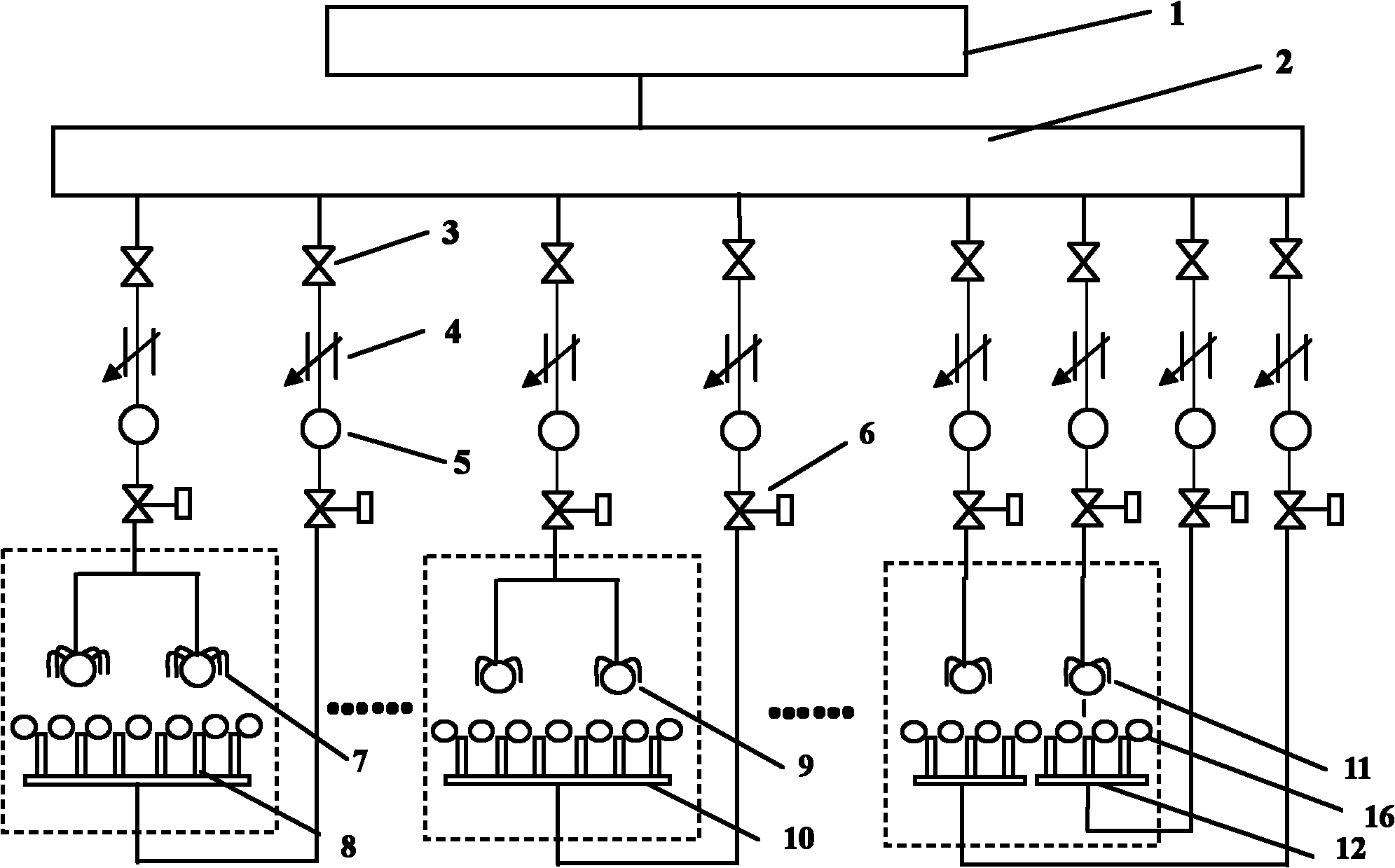

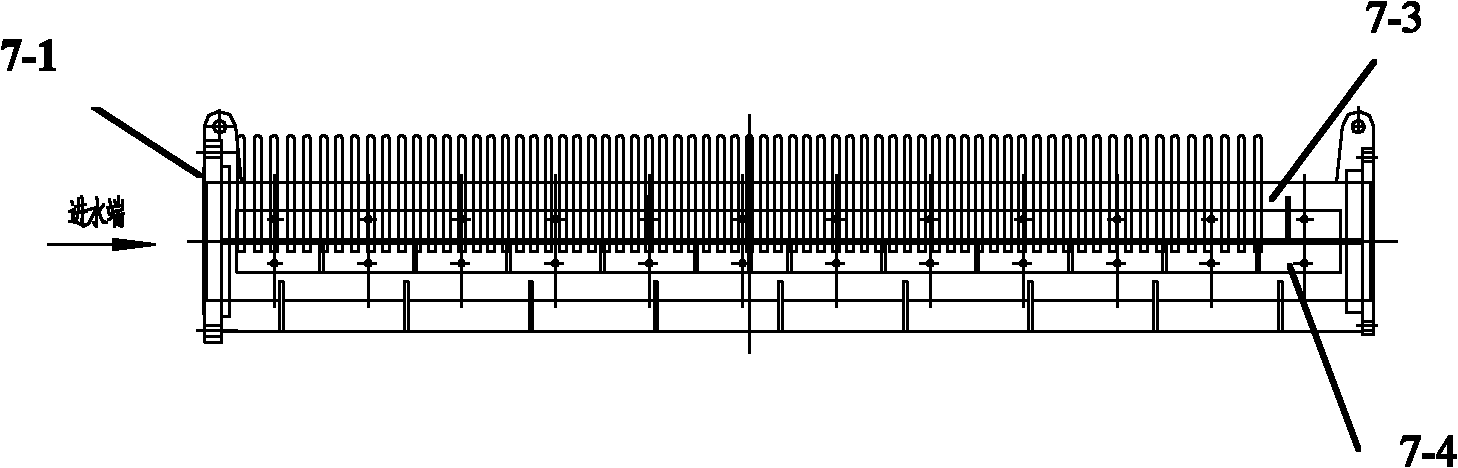

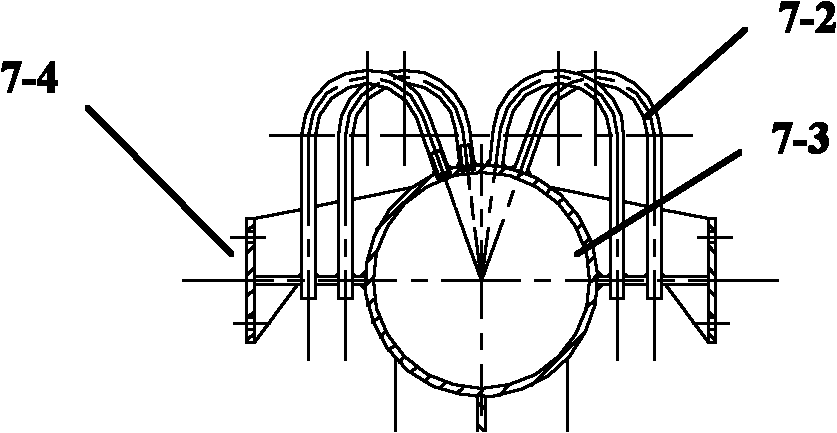

Direct quenching device for medium plate and quenching process thereof

InactiveCN102061363AReduce processShorten the production cycleQuenching devicesTemperature controlDistributor

The invention provides a direct quenching device for a medium plate and a quenching process thereof. The device comprises a high-level water tank, a water quantity distributor, upper quenching coolers, upper accelerating coolers, upper fine-tuning coolers, lower quenching coolers, lower accelerating coolers, lower fine-tuning coolers, edge shielding devices, side spraying devices and a purging device. The quenching method comprises the following steps: carrying out controlled rolling, and controlling the finished rolling temperature at 780-850 DEG C; calculating the speed of a roller way, the group number of the coolers to be started, the water quantity of the coolers and the edge shielding quantity according to the plate thickness and the steel grade by utilizing a computer, and then transferring the plate to a controlled cooling area according to a predetermined speed; and starting the coolers and the corresponding side spraying devices according to the position sequence of the plate, wherein, the finished cooling temperature range is 150-450 DEG C. The direct quenching device has the characteristics of low fabrication cost, and fast and uniform cooling speed, and can stably produce the flat quenching plate with the quenching thickness of 9-60mm, and is simple and convenient in maintenance; and compared with the traditional out-line quenching method, the quenching process provided by the invention has the characteristics of short process flow and less energy consumption.

Owner:UNIV OF SCI & TECH BEIJING +1

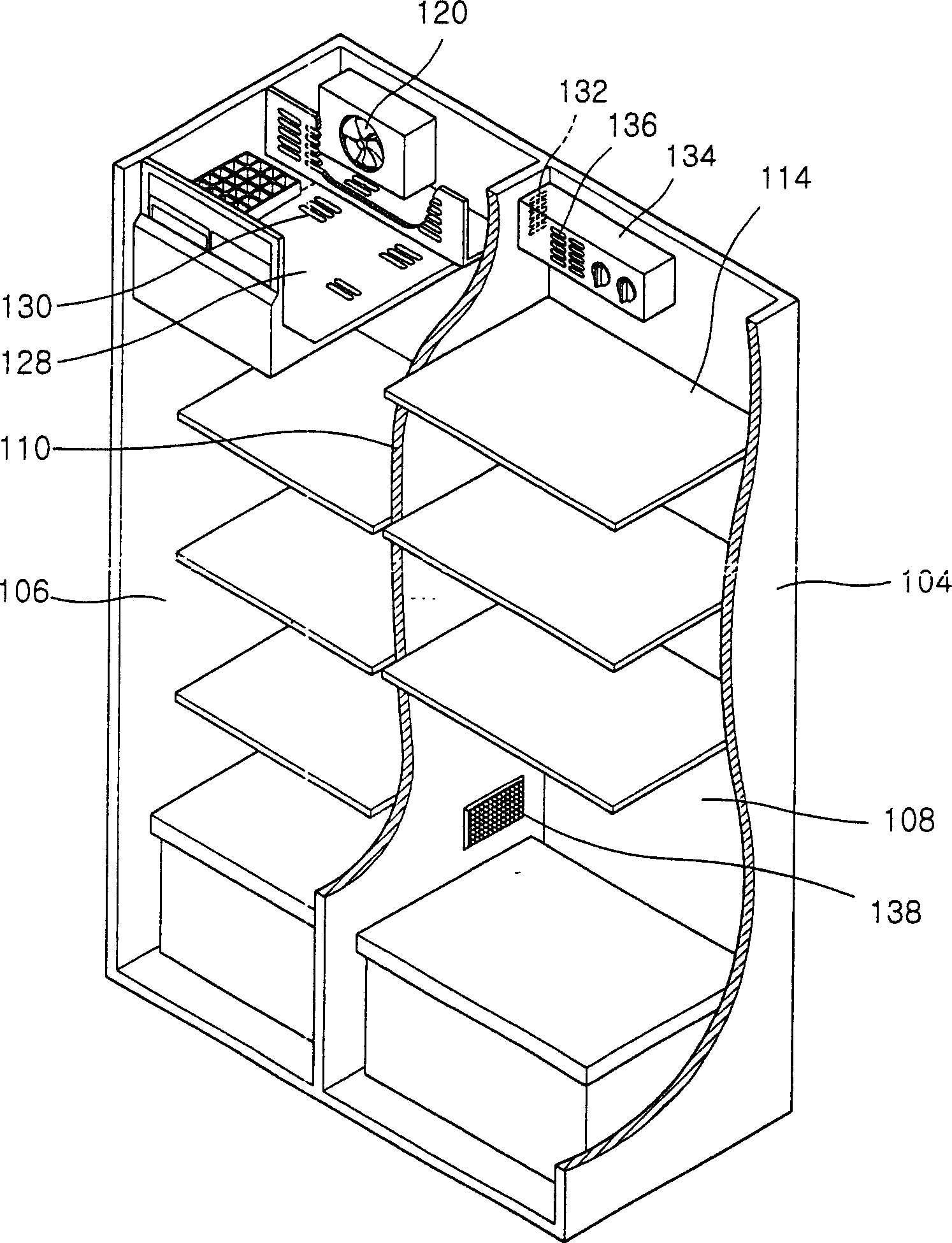

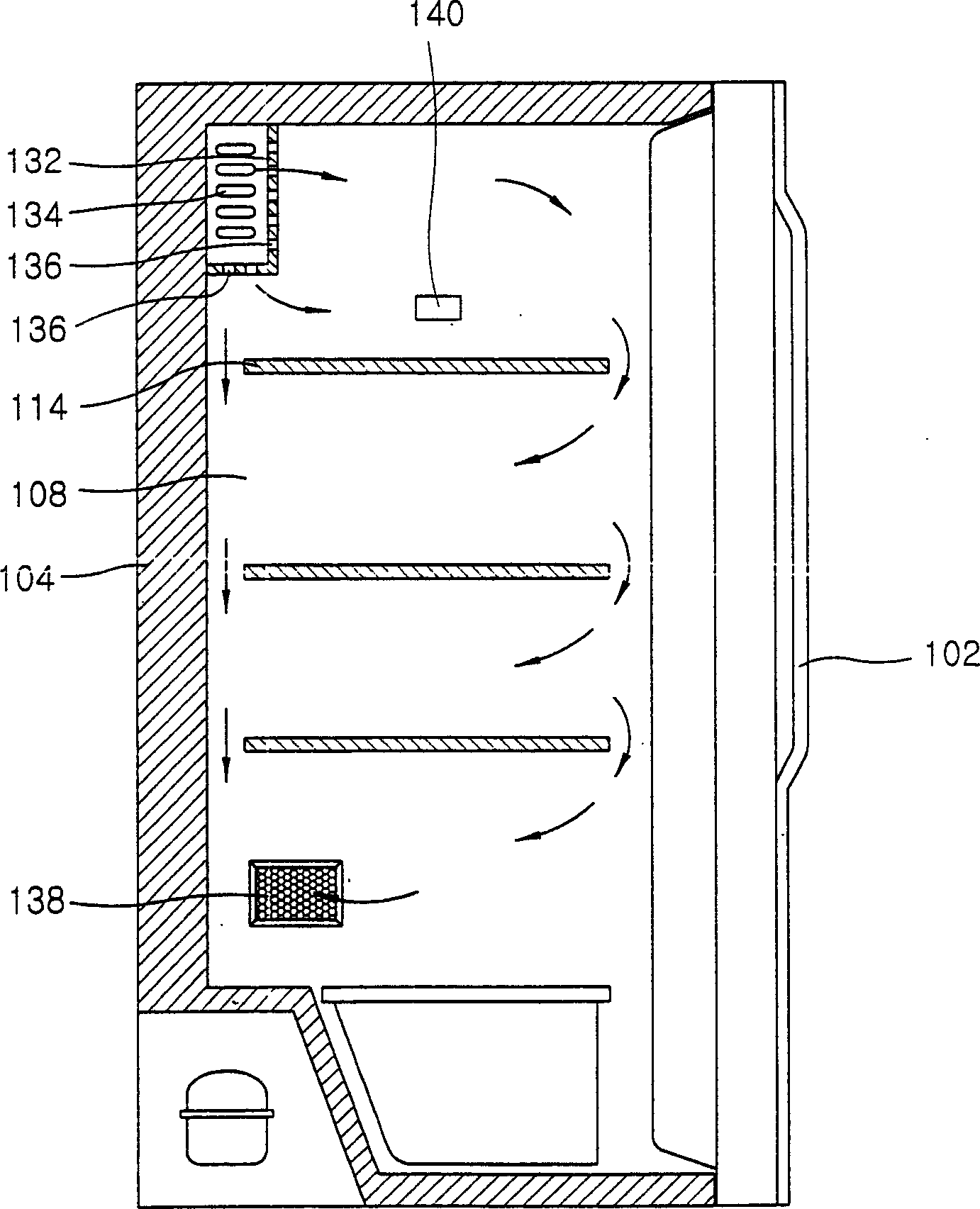

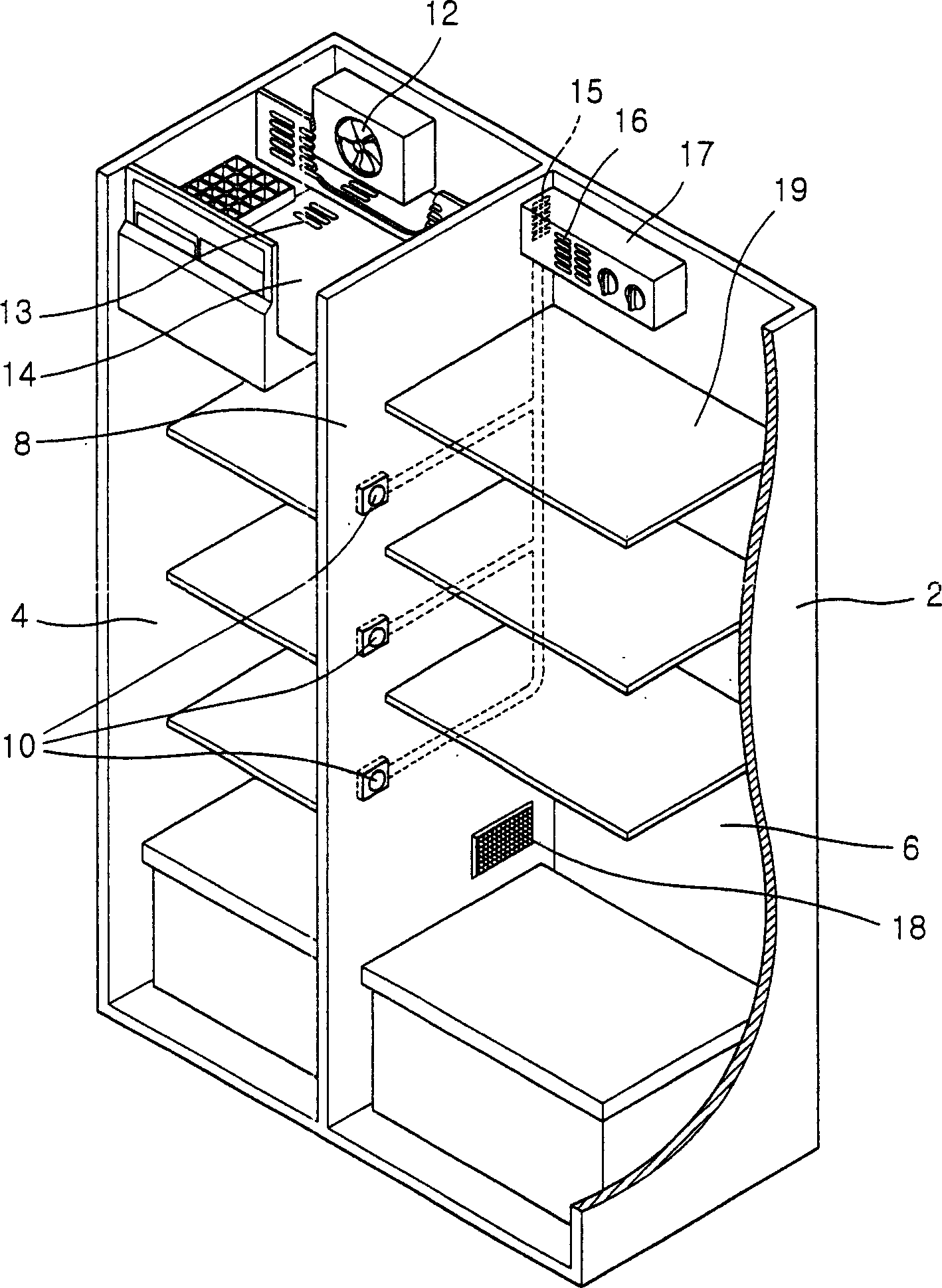

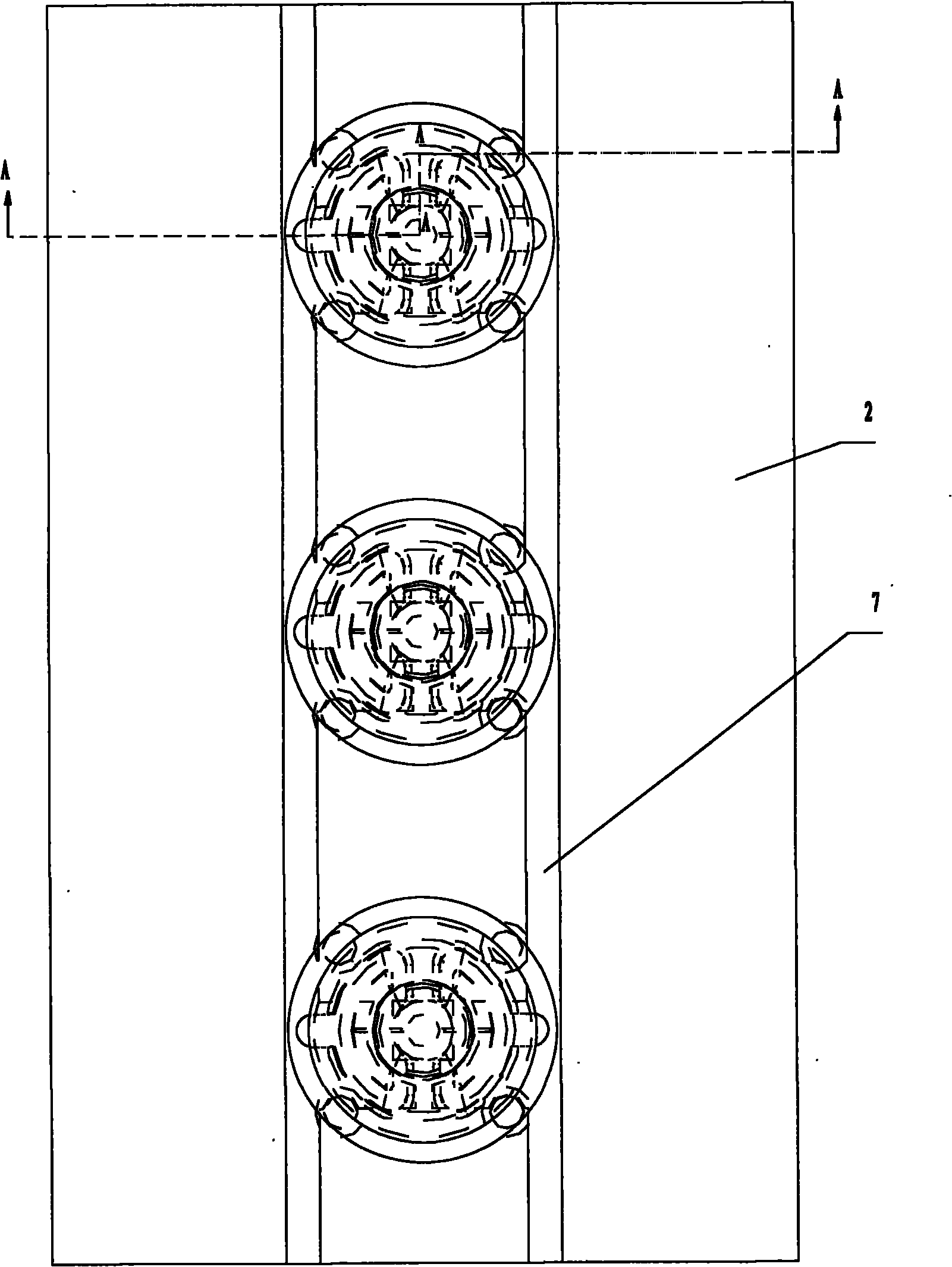

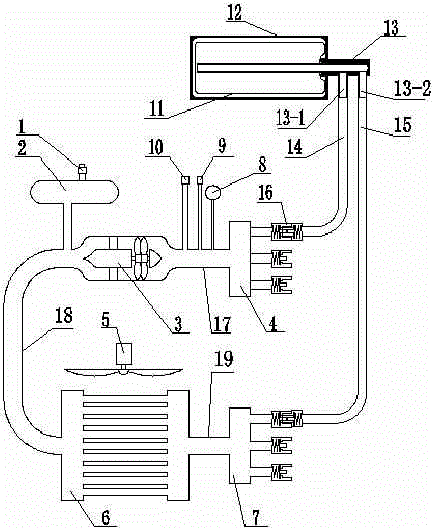

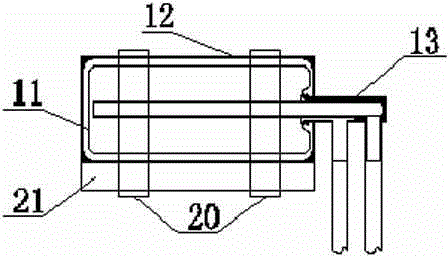

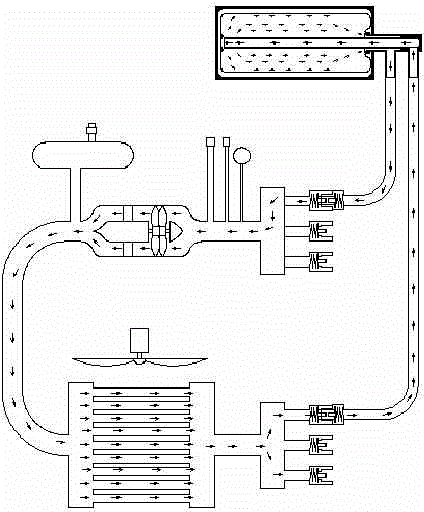

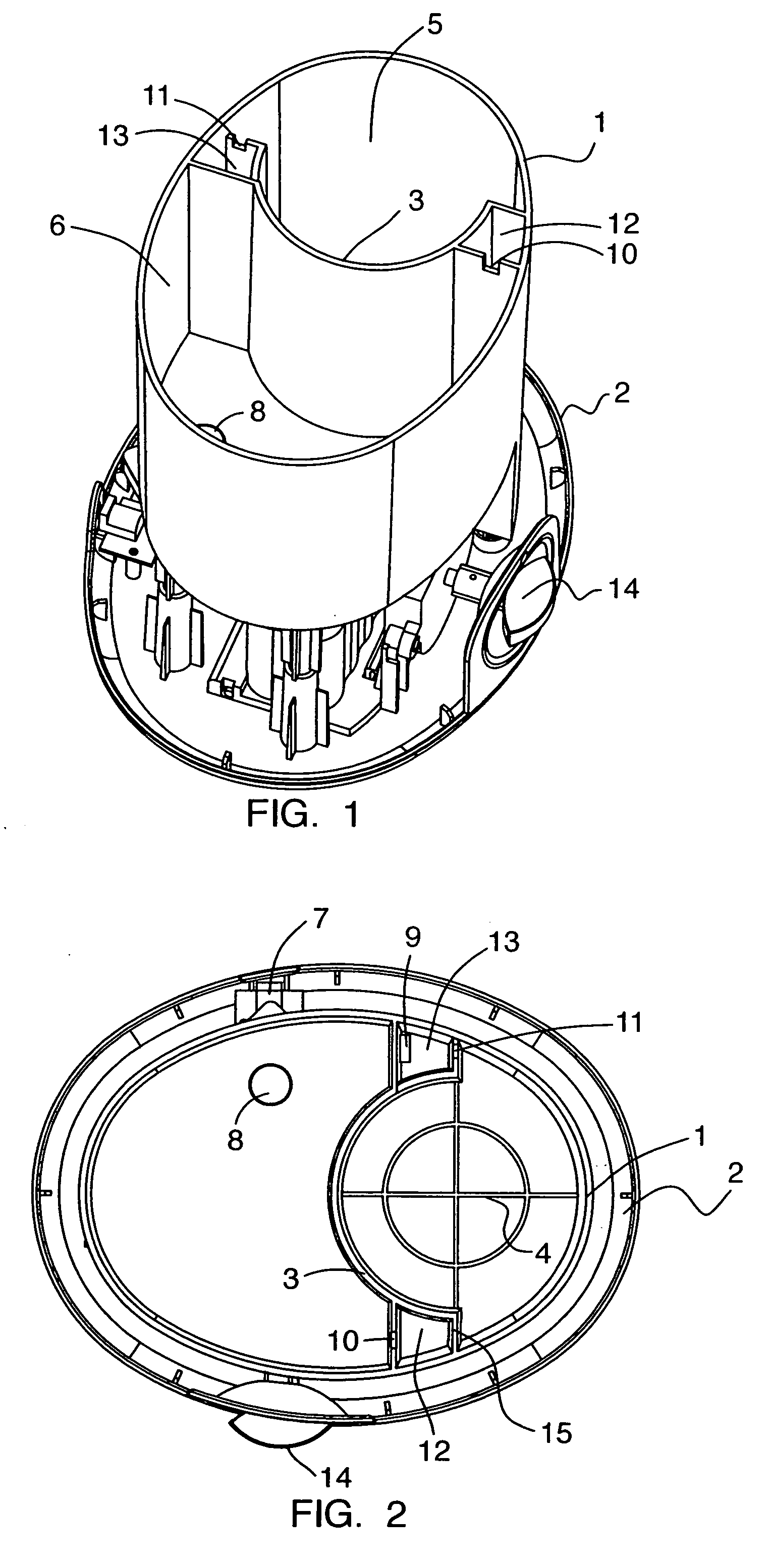

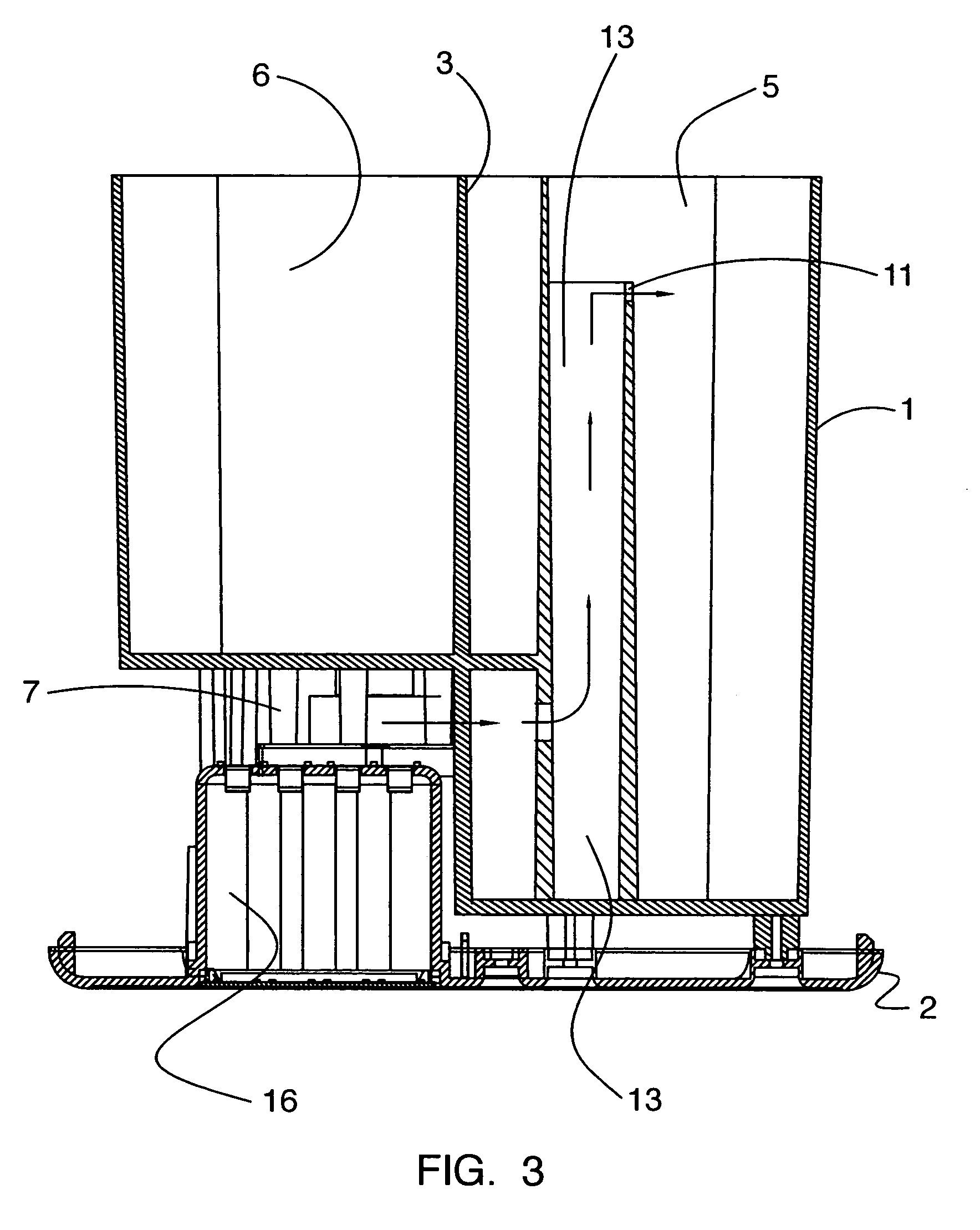

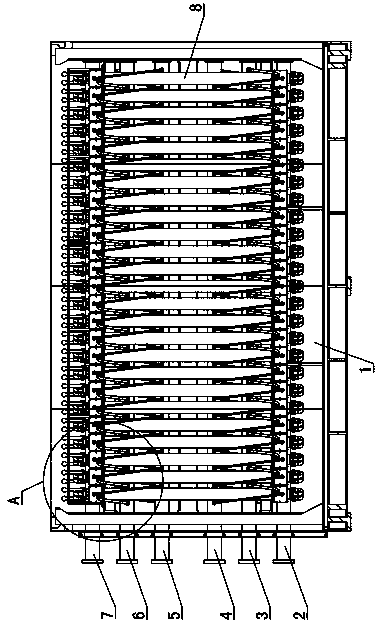

Integrated cooling device and refrigerator having same

InactiveCN1470829AUniform temperaturePromote cooling speedLighting and heating apparatusCooling fluid circulationCold airCold store

In a concentrated cooling apparatus and a refrigerator having the same capable of performing cooling operation instantly by discharging intensively cold air to a high-temperature load occurred region inside a chilling chamber, a concentrated cooling apparatus of a refrigerator includes housings respectively installed to at least one cold air guide path formed at the side wall of a chilling chamber in order to guide cold air to the side wall of the chilling chamber; a nozzle rotatively supported by the housings and jetting cold air intensively to a high-temperature load occurred region inside the chilling chamber when the high temperature load occurs at the certain region; a temperature sensor installed on the front of the nozzle, rotating with the nozzle and sensing the high-temperature load occurred region; and a nozzle driving unit installed at a certain side of the housings to rotate the nozzle.

Owner:LG ELECTRONICS INC

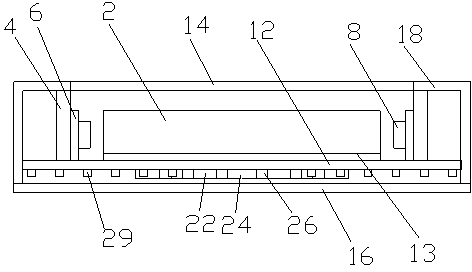

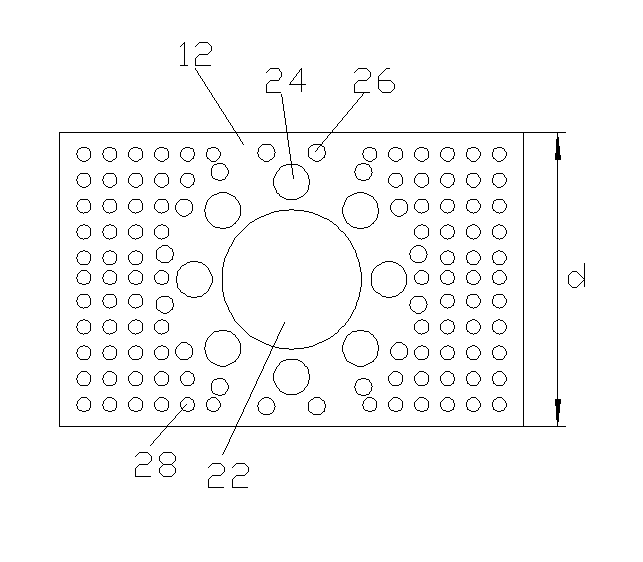

Manufacture method of LED integrated structure

InactiveCN101963296AWorking temperature is suitableReduce thermal resistancePlanar light sourcesPoint-like light sourceHeat resistanceEngineering

The invention discloses a manufacture method of an LED integrated structure, comprises the following process steps: molding a heat dissipation substrate; molding a layout circuit conducting layer; molding a position lens or the plastic part of the lens; carrying out die bonding; electrically connecting an LED chip with the layout circuit conducting layer; and packaging the LED chip and wires. Themethod has the advantages of less process, simple technology, low manufacturing cost, small heat resistance and good heat dissipation of the intermediate link of manufacturing the LED chip and accurate position relation of the lens and the chip, and the LED integrated structure has the advantages of high luminous flux, simple structure, simple assembling, good heat dissipation effect and good optical effect.

Owner:杨东佐

Large-scale self-aligning roller bearing ring quenching and cooling method

ActiveCN101654735AReduce quenching stressCool evenlyFurnace typesHeat treatment furnacesEngineeringHardness

The invention discloses a large-scale self-aligning roller bearing ring quenching and cooling method. In the method, a bearing ring is in flat suspension above a cooling mechanism in quenching oil ina cylinder by a toplift; the cooling mechanism comprises two concentric circuit blowpipes provided with a plurality of air outlets; the two circuit blowpipes are respectively connected with a first blast pipe and a second blast pipe which are connected with a pressured air source. When the bearing ring is quenched, air under the pressure of 5-10kMPa is ejected from the air outlets of the two circuit blowpipes to form a strong recycled oil stream so as to lead the self-aligning roller bearing ring to realize cooling and quenching. In the invention, the cooling speeds of the inner surface and the outer speed have little difference, the cooling is even, the quenching stress is reduced, the tendency of deformation and cracking is reduced, the hardness is improved and product quality is also greatly enhanced.

Owner:DALIAN METALLURGICAL BEARING

Noise reduction and heat dissipation motor

InactiveCN107919761AReduce noiseExtended service lifeCooling/ventillation arrangementSupports/enclosures/casingsEngineeringNoise reduction

The invention provides a noise reduction and heat dissipation motor. The motor includes an inner shell body, an outer shell body and an end cover; the outer shell body is of a cylindrical structure with one open end, and the end cover is arranged at the open end of the outer shell body and connected with the outer shell body in a sealed mode; the inner shell body is hollow and is of a cylindricalstructure with two open ends, the inner shell body is arranged in the outer shell body, and the two ends of the inner shell body are coaxially arranged with the outer shell body separately; the two ends of the inner shell body abut against the outer shell body and the end cover respectively, a gap is reserved between the inner shell body and the outer shell body to form a noise reduction cavity, and the noise reduction cavity is internally provided with a noise absorbing sleeve sleeving the inner shell body; multiple annular noise absorbing cavities are axially formed in the noise absorbing sleeve at intervals, each annular noise absorbing cavity is filled with noise absorbing cotton, multiple noise absorbing hole rows are axially distributed on the inner shell body at intervals and correspond to the annular noise absorbing cavities in a one-to-one mode, and each noise absorbing hole row comprises multiple noise absorbing through holes communicated with the corresponding annular noiseabsorbing cavity. The noise reduction and heat dissipation motor is great in noise reduction effect, high in heat dissipation speed and longer in service life.

Owner:傅皓衍

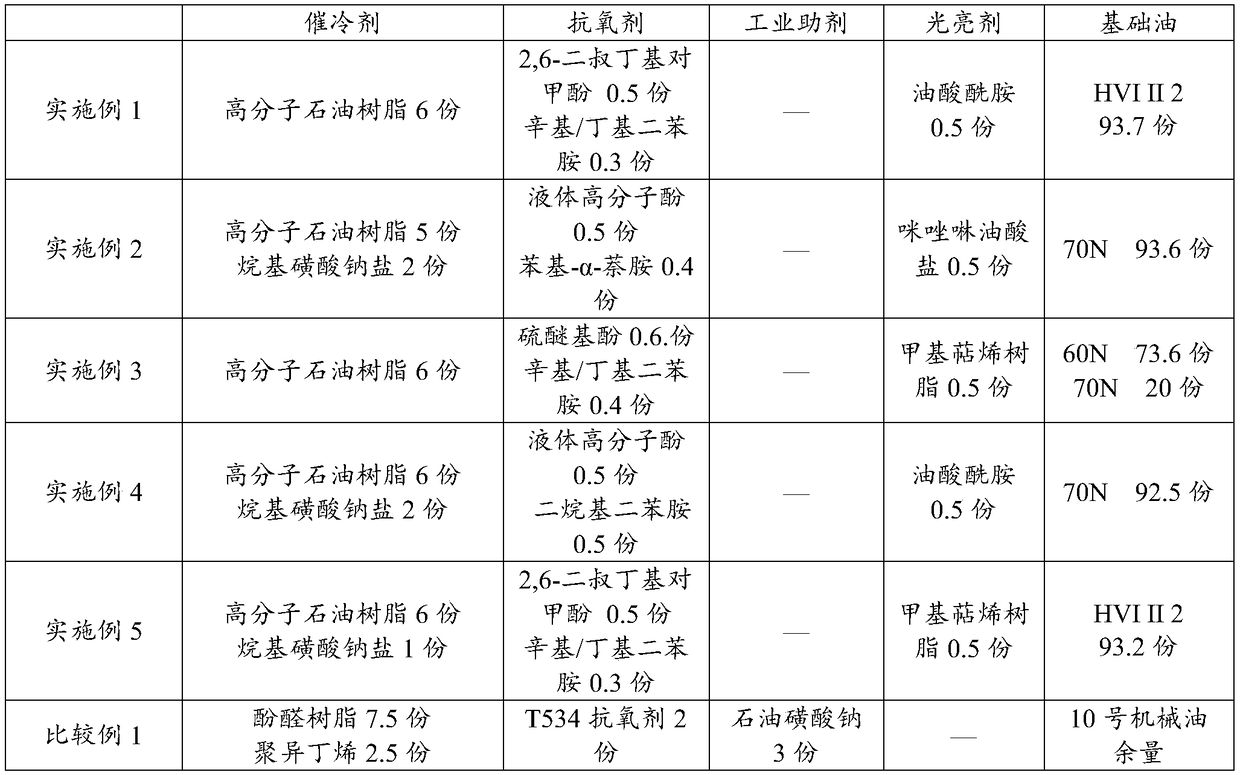

Anti-emulsification type overspeed quenching oil composition and application thereof

The invention relates to an anti-emulsification type overspeed quenching oil composition and application thereof, and mainly relates to overspeed quenching oil with good oil-water separation and excellent cooling performance. The anti-emulsification performance of the overspeed quenching oil in the prior art is improved, and the oil-water separation performance is enhanced so as to solve the problem of emulsification of the overspeed quenching oil in the cleaning process of quench workpieces in the prior art. The anti-emulsification type overspeed quenching oil composition comprises, by weight, (a) 0.5-10 parts of cooling agents, (b) 0.1-3 parts of antioxidants, (c) 0.05-1 part of brightener and (d) 75-95 parts of base oil. The anti-emulsification type overspeed quenching oil composition can be used for quenching workpieces which require high emulsifying performance and have high thickness, large cross section and low hardenability, such as automobile fasteners, gears, bearings and seamless steel pipes.

Owner:CHINA PETROLEUM & CHEM CORP

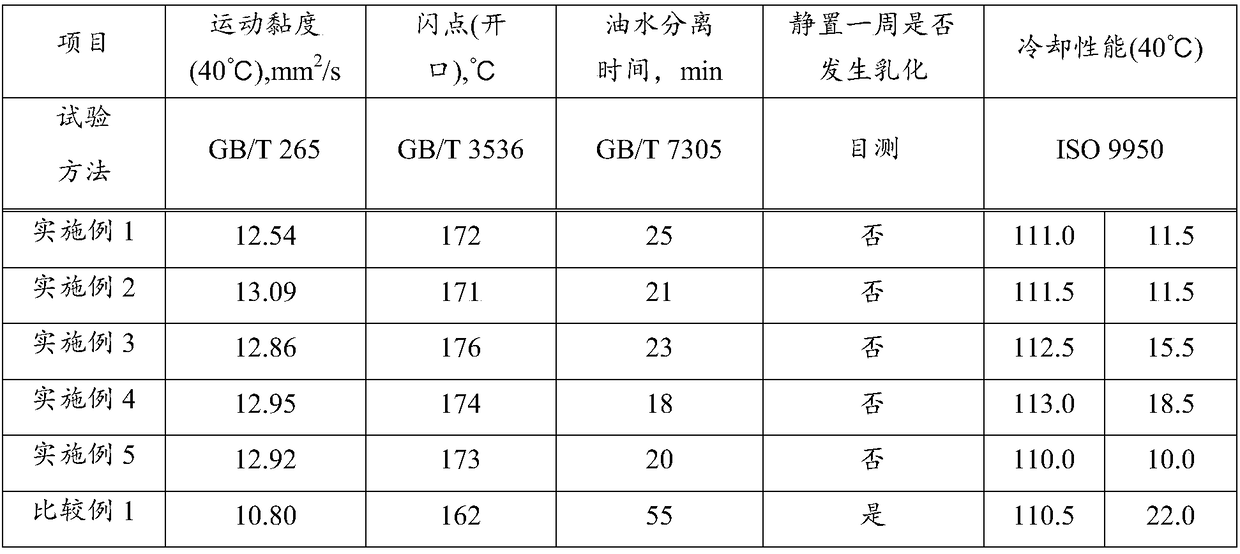

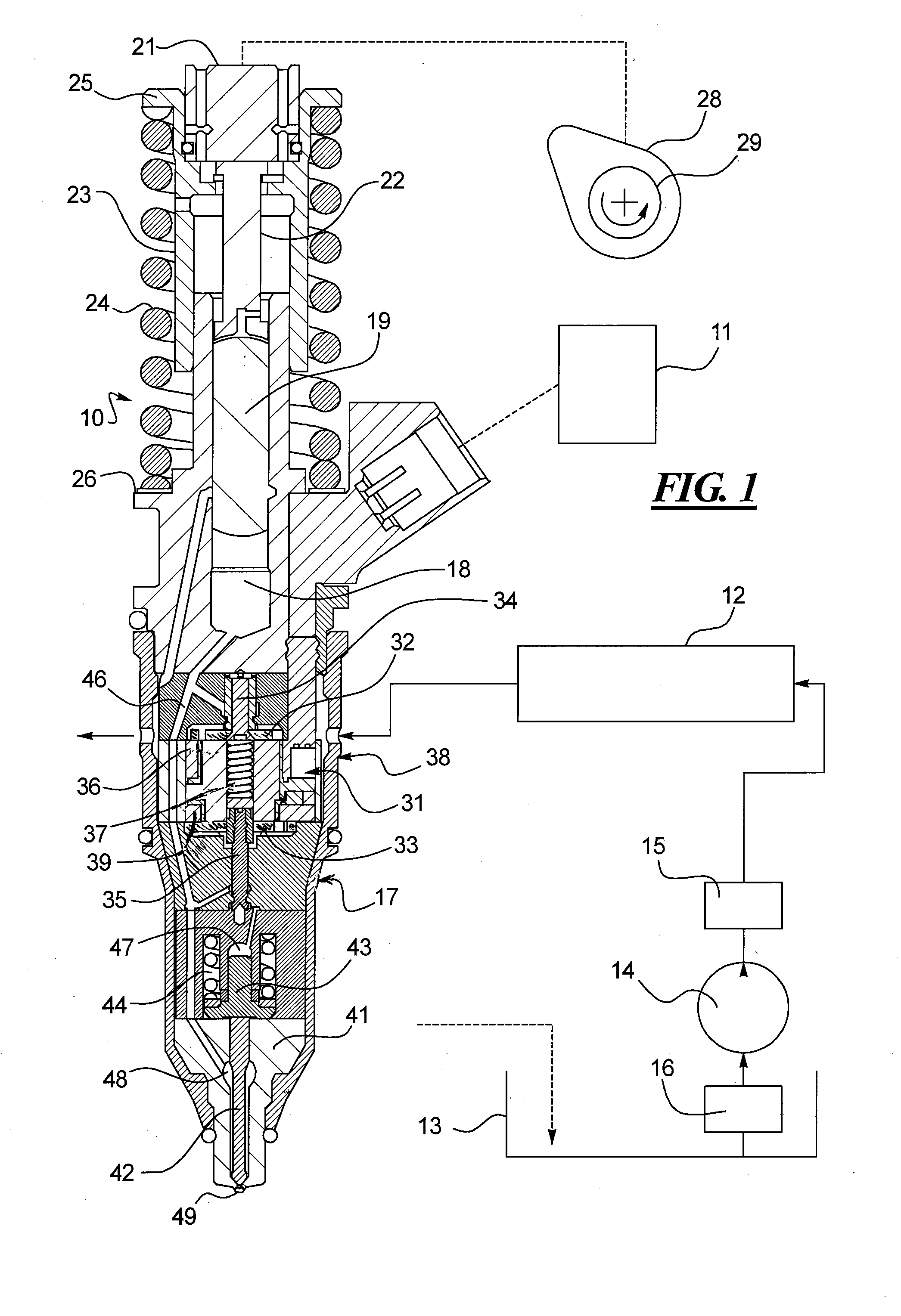

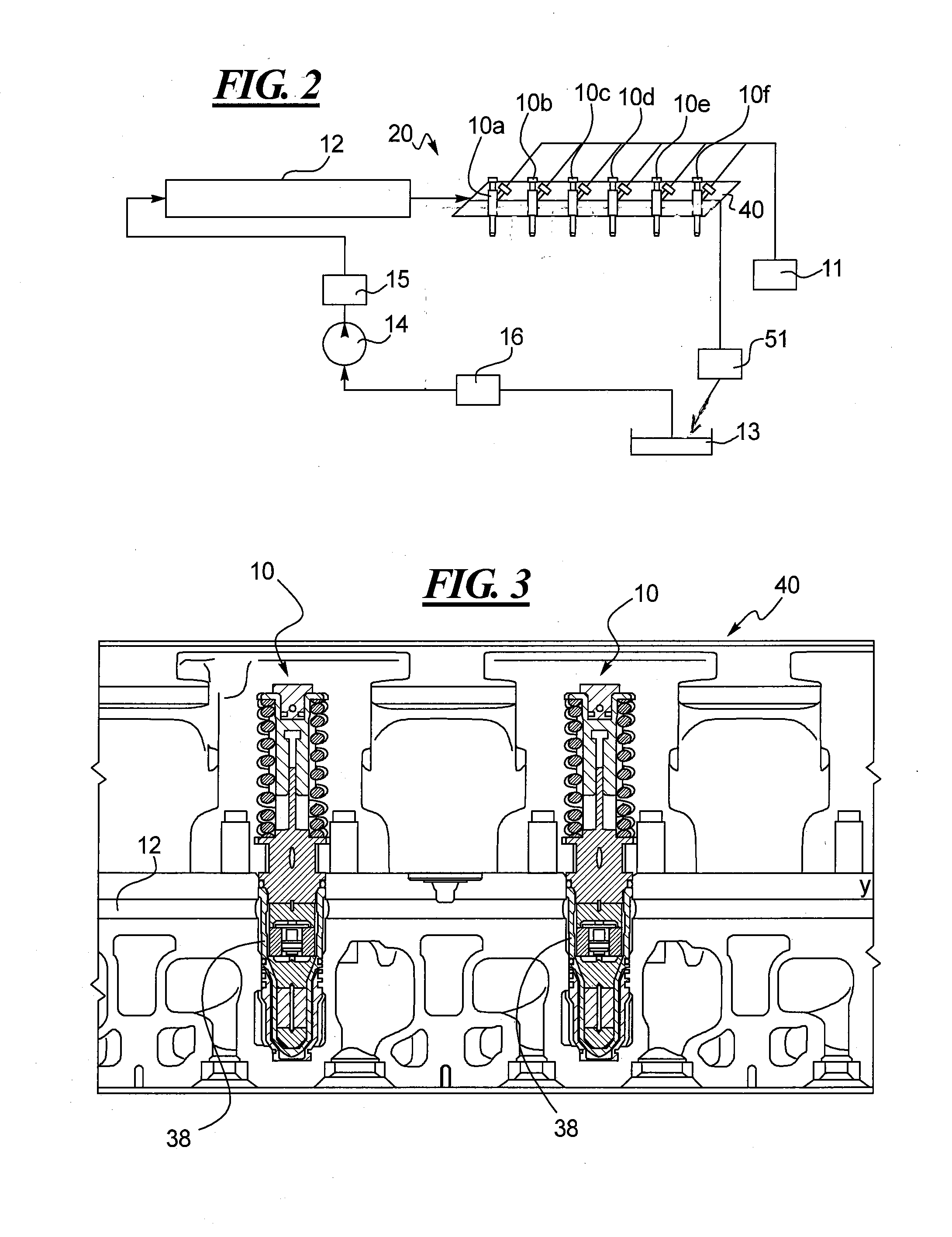

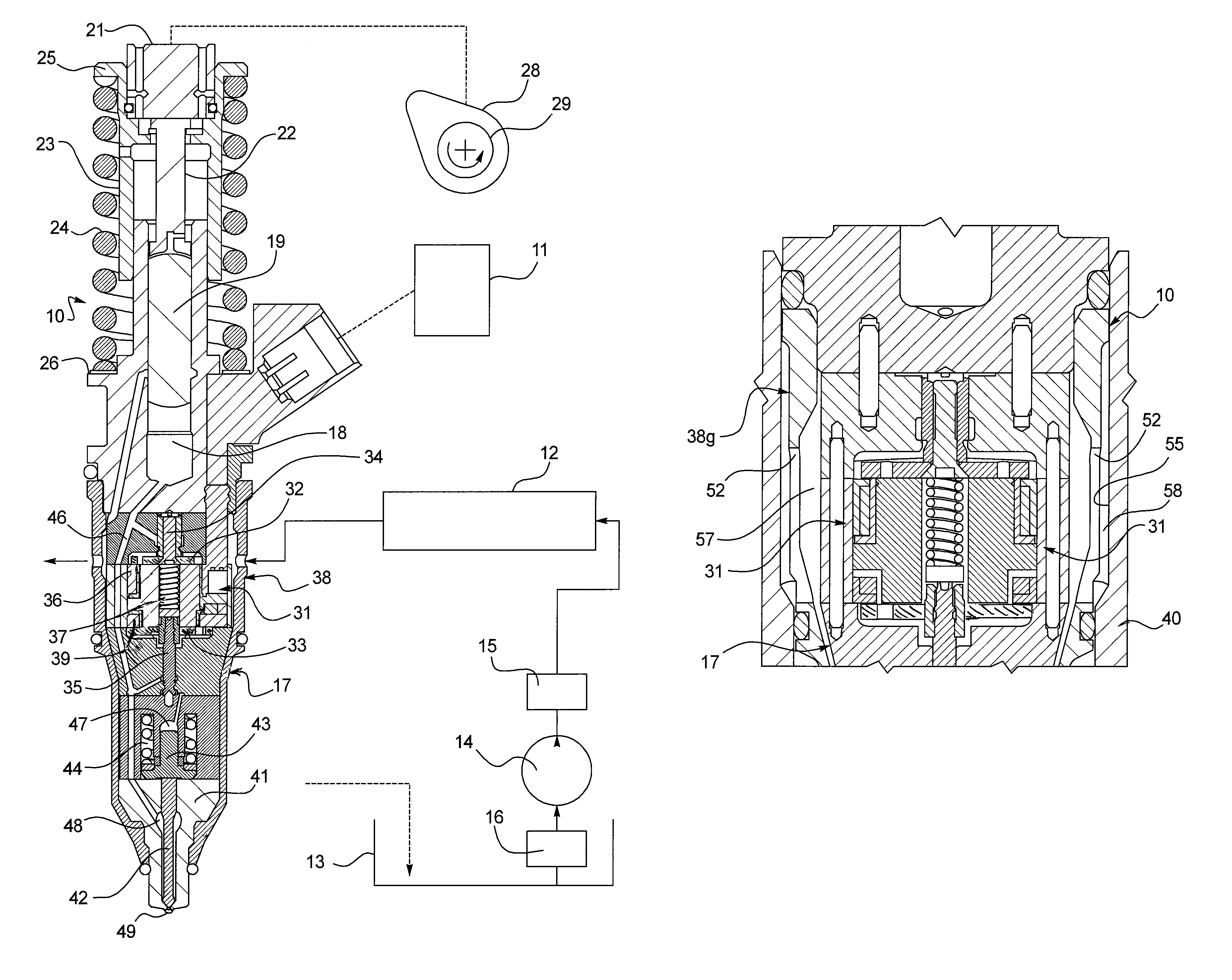

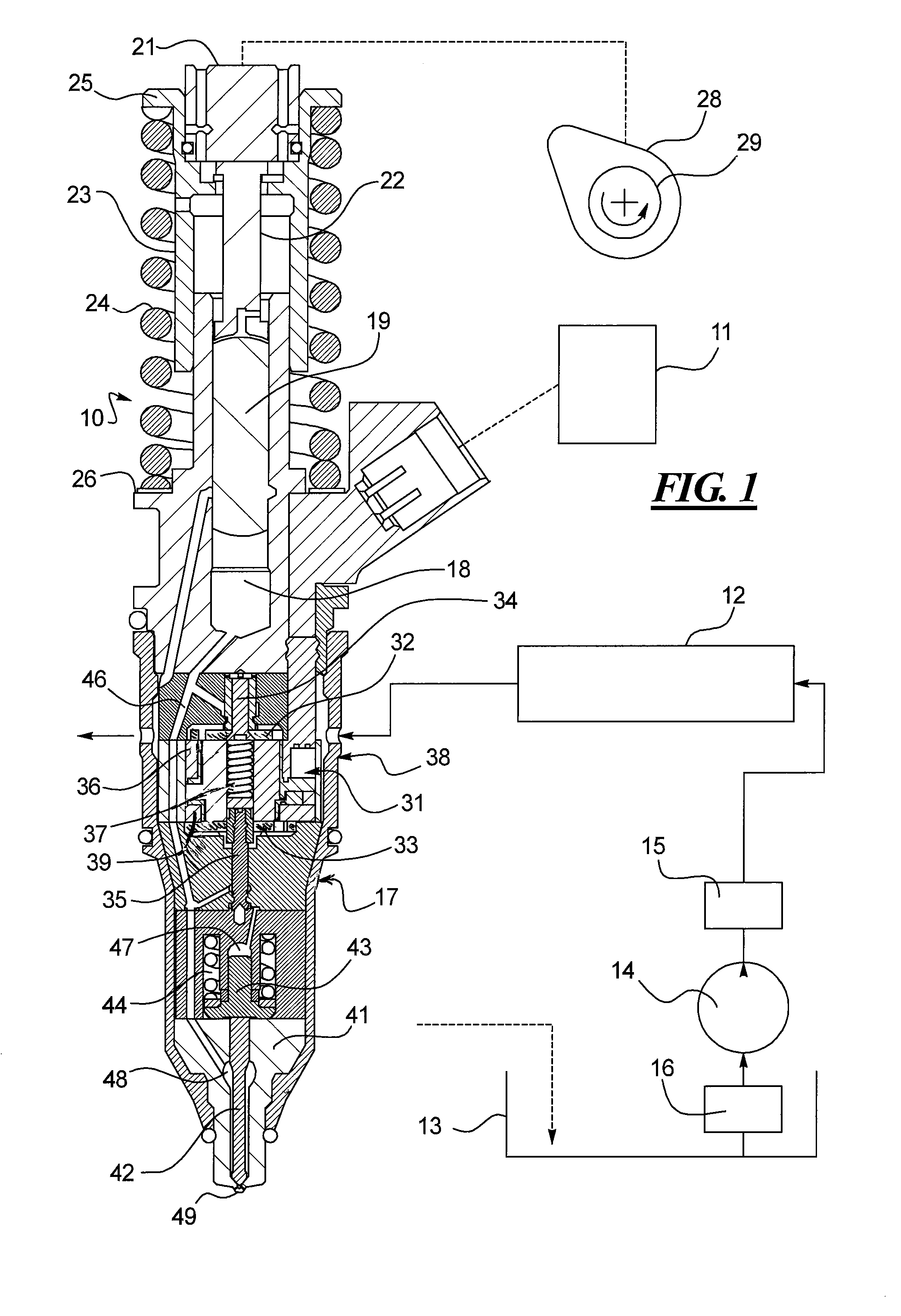

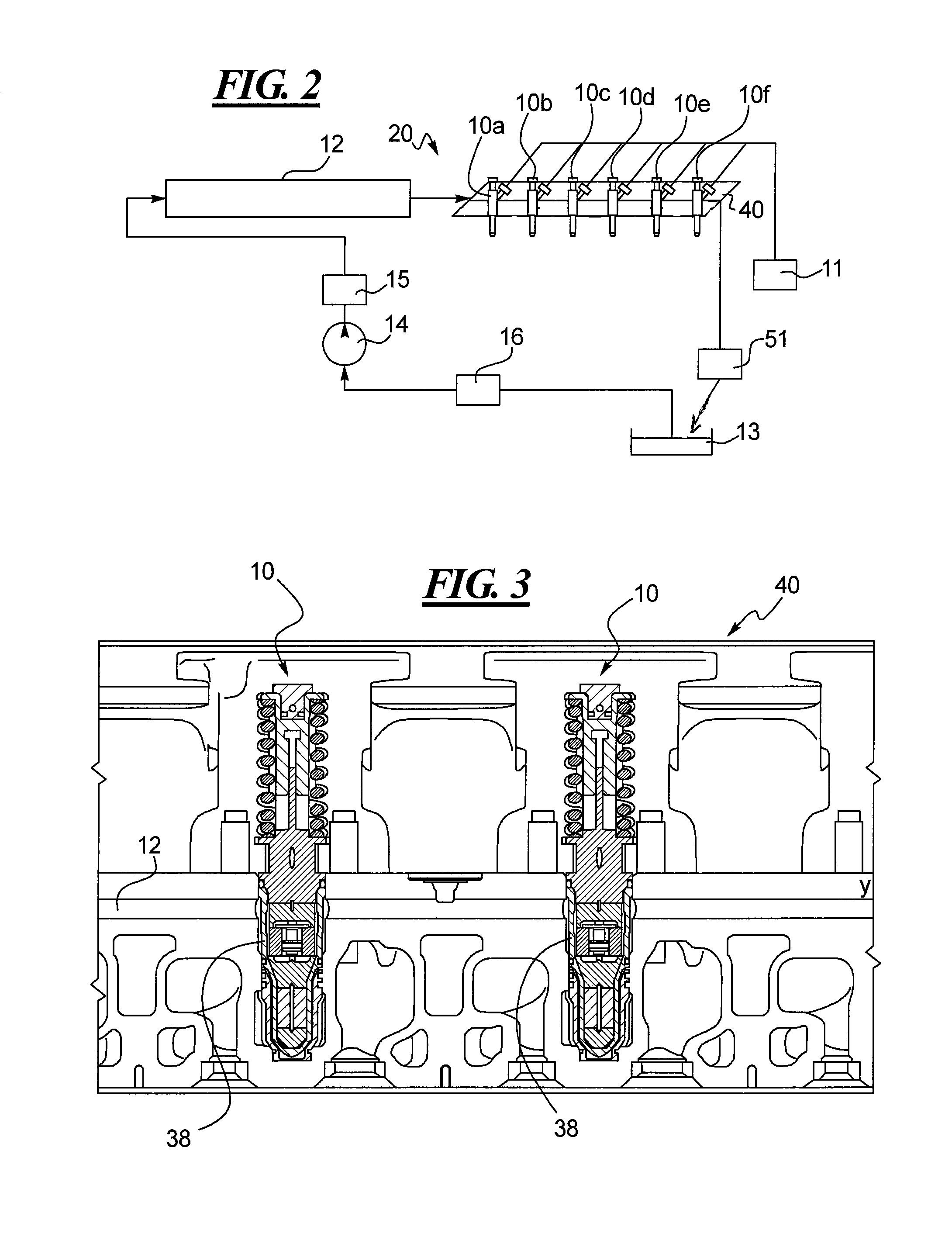

System and Method for Cooling Fuel Injectors

Various fuel injection systems and fuel injectors are disclosed that provide varying cooling rates for fuel injectors connected in series to fuel supply and drain rail. The local cooling rate for each injector is manipulated to balance the heat flux or heat transfer across the injectors disposed along the rail. The cooling rates may be manipulated by varying sizes of openings or slots in the nozzle case, by varying annular spaces disposed between the nozzle case and the portion of the injector body that houses the actuator and solenoid assembly, and by varying the size of annular spaces disposed between the nozzle case and the cylinder head. Strategic placement of slots in the nozzle case that direct more flow at the portion of the injector body that houses the actuator and solenoid assembly may also be employed. As a result, the operating temperatures of fuel injectors connected in series to a fuel rail can be manipulated and moderated so the downstream injectors are not prone to overheating.

Owner:CATERPILLAR INC

System and method for cooling fuel injectors

Various fuel injection systems and fuel injectors are disclosed that provide varying cooling rates for fuel injectors connected in series to fuel supply and drain rail. The local cooling rate for each injector is manipulated to balance the heat flux or heat transfer across the injectors disposed along the rail. The cooling rates may be manipulated by varying sizes of openings or slots in the nozzle case, by varying annular spaces disposed between the nozzle case and the portion of the injector body that houses the actuator and solenoid assembly, and by varying the size of annular spaces disposed between the nozzle case and the cylinder head. Strategic placement of slots in the nozzle case that direct more flow at the portion of the injector body that houses the actuator and solenoid assembly may also be employed. As a result, the operating temperatures of fuel injectors connected in series to a fuel rail can be manipulated and moderated so the downstream injectors are not prone to overheating.

Owner:CATERPILLAR INC

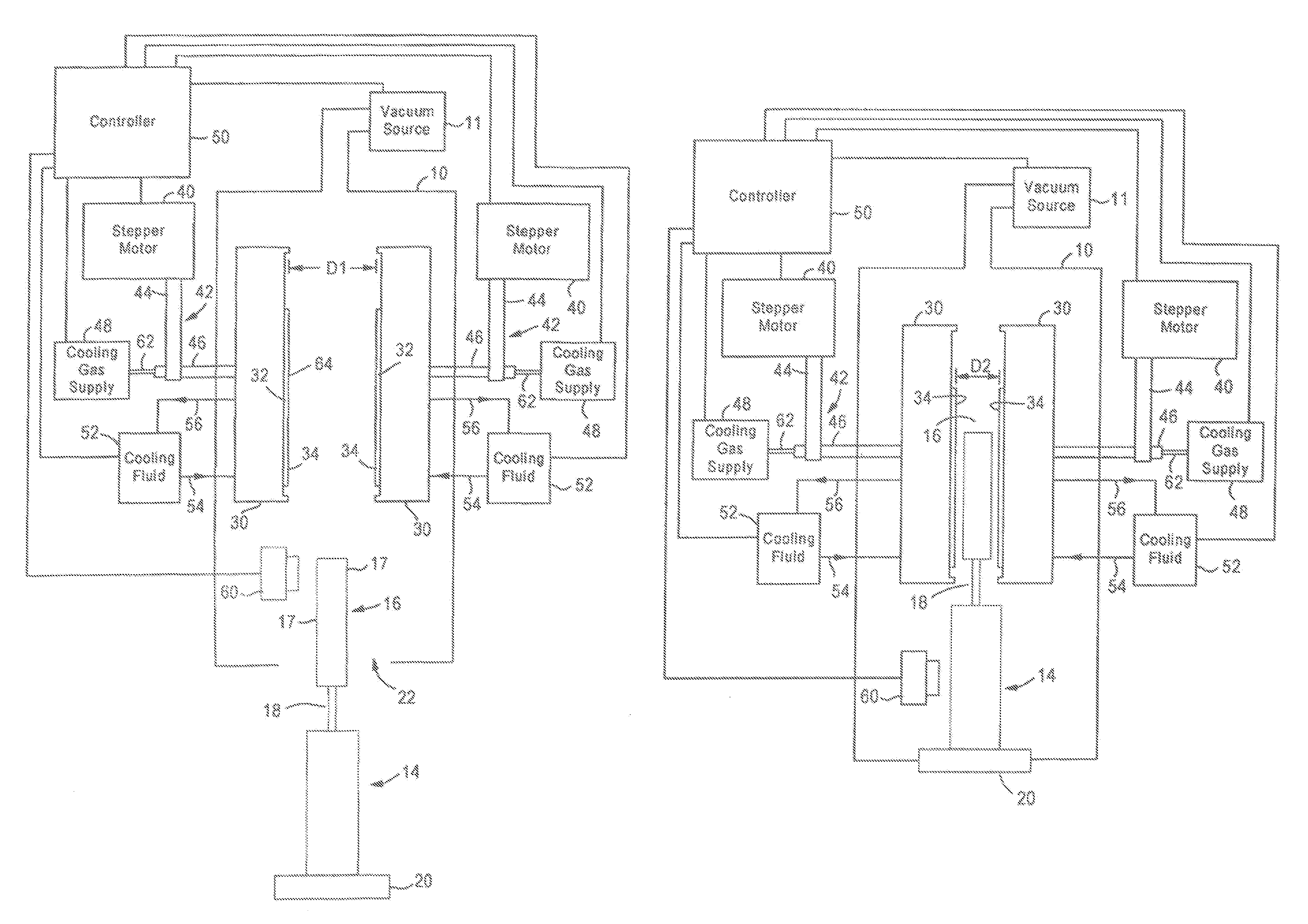

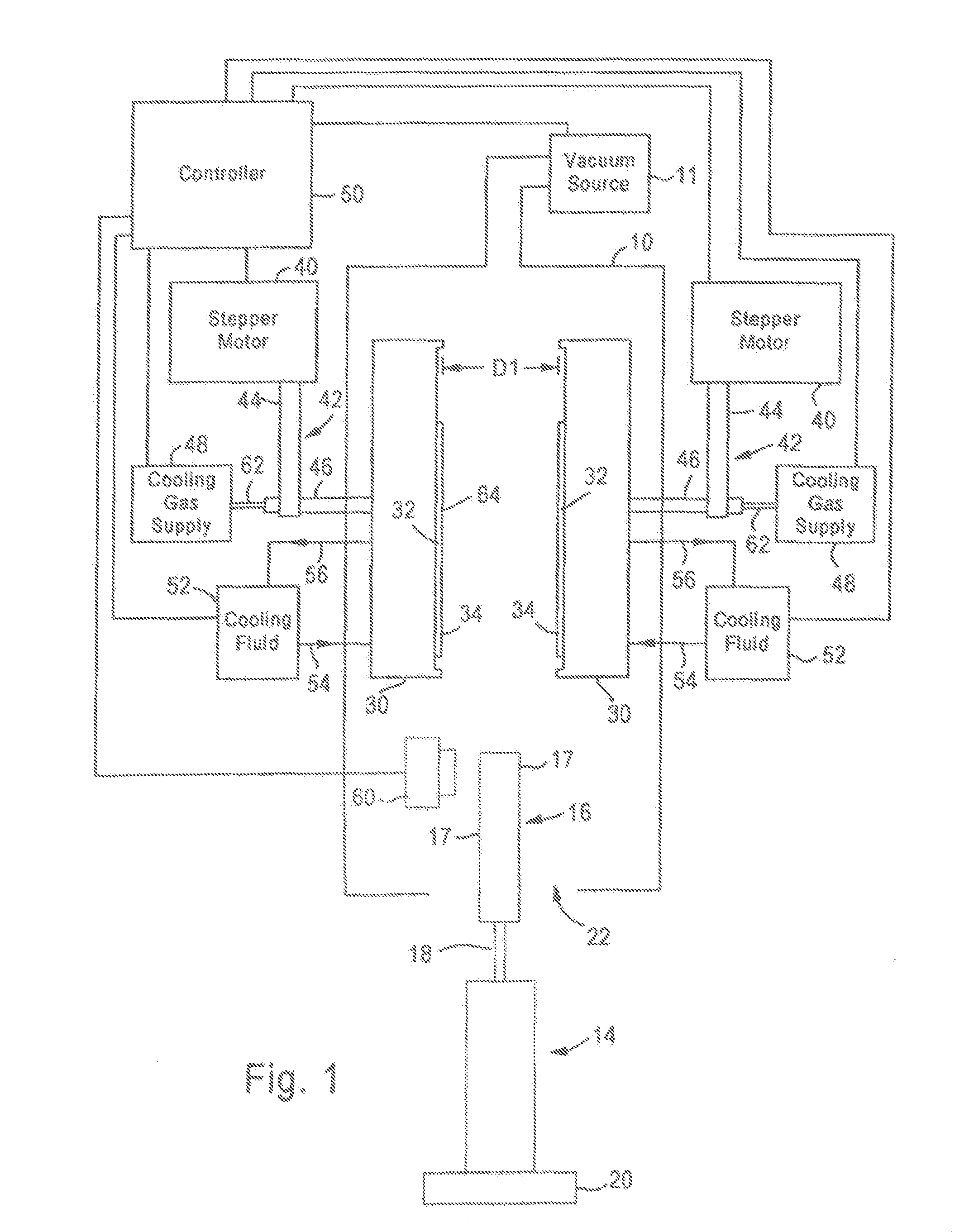

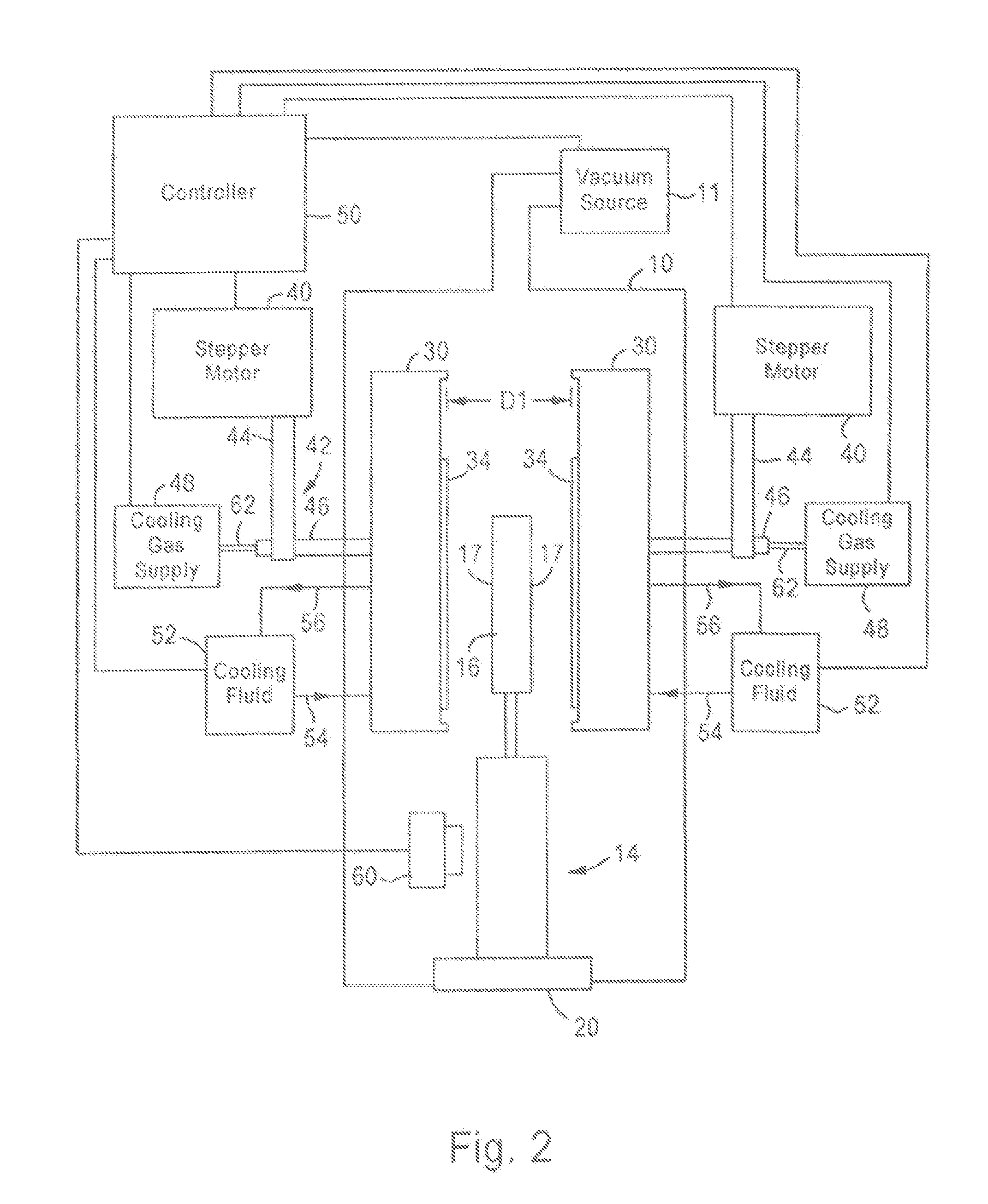

Method and apparatus for cooling a planar workpiece in an evacuated environment with dynamically moveable heat sinks

InactiveUS8701753B2High throughputHigh rateCellsVacuum evaporation coatingHeat spreaderVacuum chamber

An apparatus and method for cooling a planar workpiece, such as a substrate of a recording disk, in an evacuated environment has a heat exchanging structure with at least two heat sinks having substantially parallel facing surfaces disposed within a vacuum chamber. A drive arrangement is connected to the heat sinks to controllably and dynamically drive the parallel facing surfaces of the heat sinks towards and away from each other.

Owner:SEAGATE TECH LLC

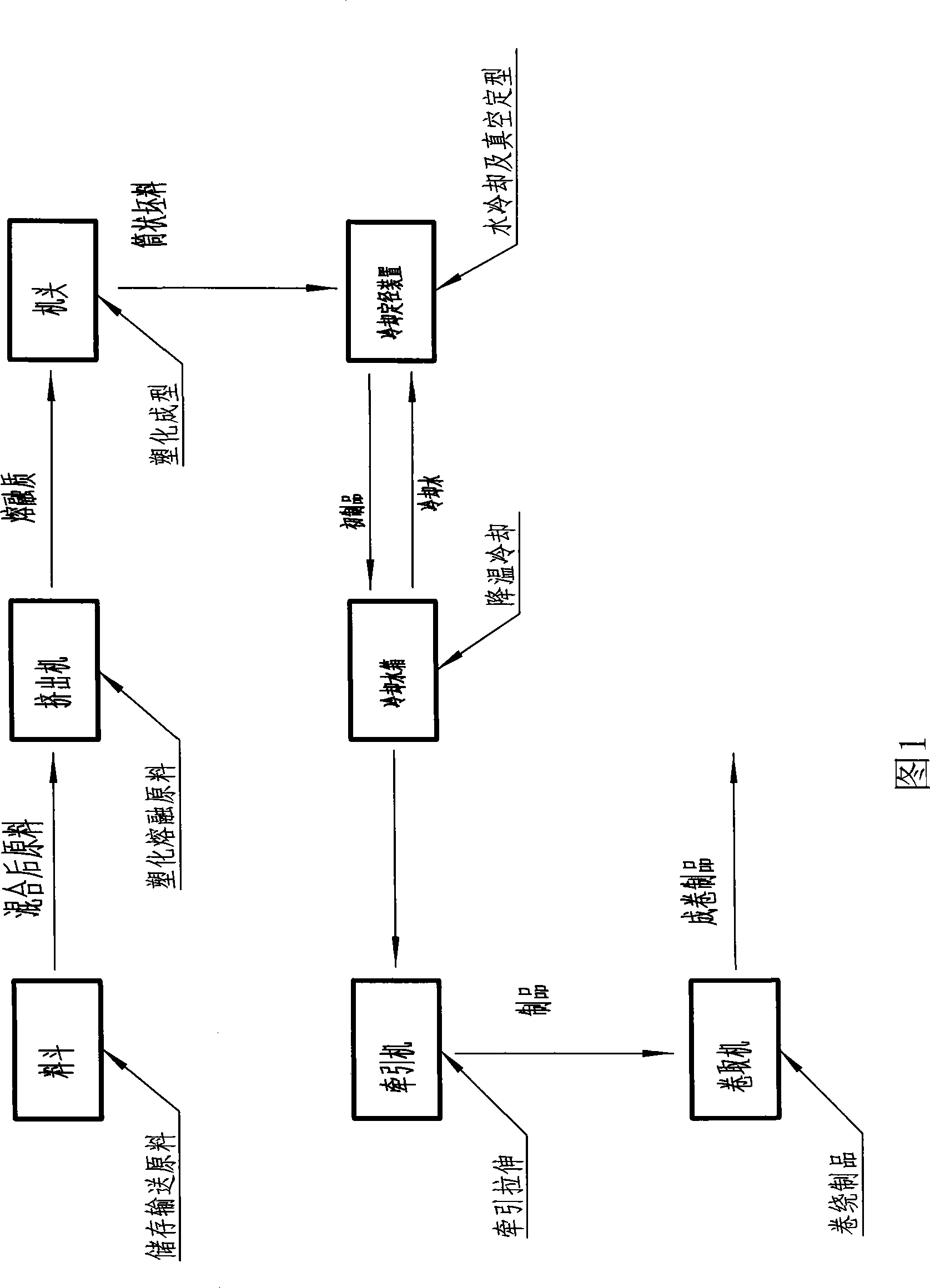

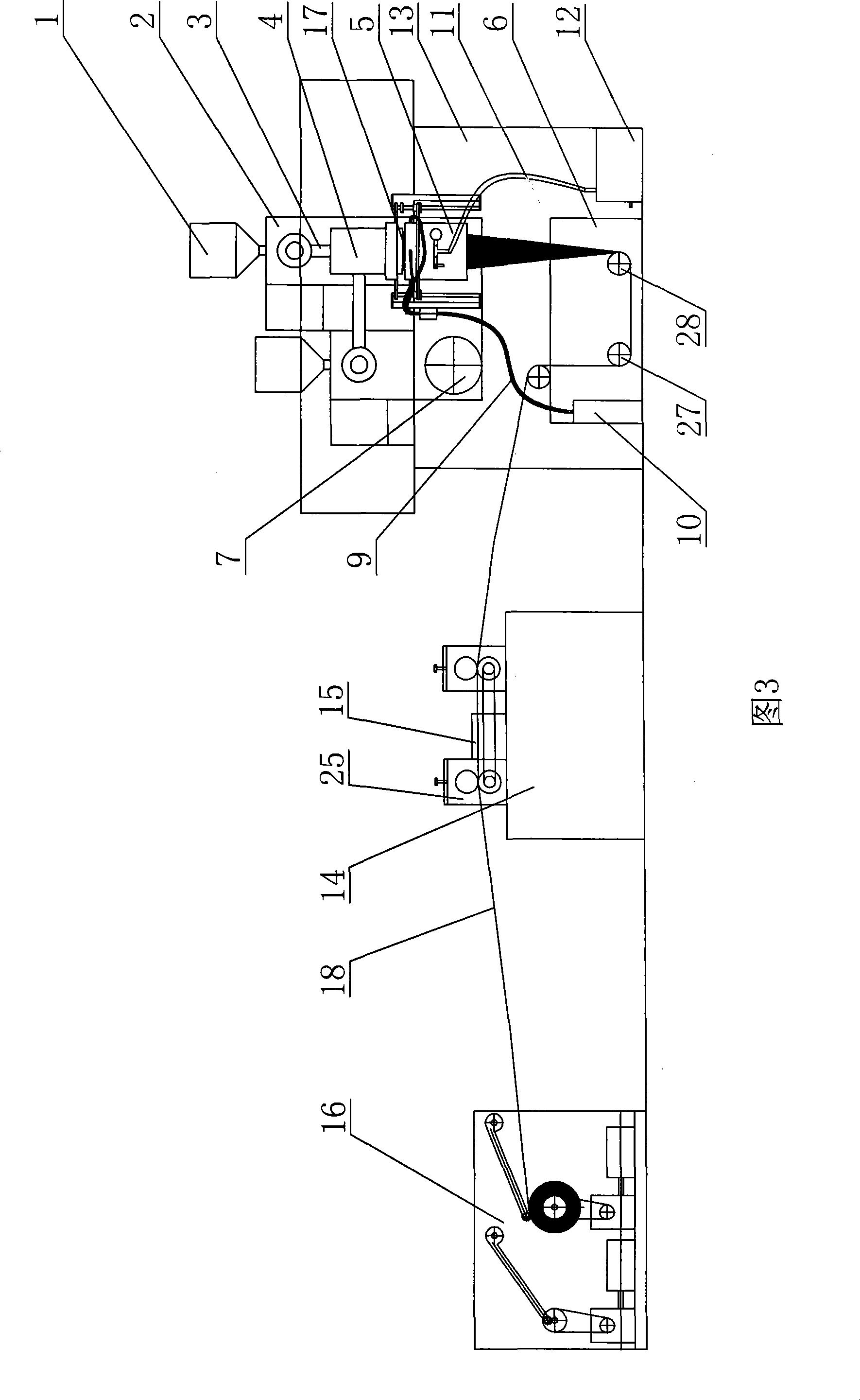

Method and equipment for manufacturing fire engine hose

InactiveCN101249717AGood molding effectImprove molding abilityHollow articlesVacuum pumpingMixed materials

The invention discloses a manufacturing method of a water hose and manufacturing equipment of the water hose. The invention comprises the following processes: firstly, selected materials, color master batches and batches are fully mixed and then put into a container; secondly, the mixed materials are arranged into an extrusion device, the plasticization and melting are performed to the mixed materials to form molten substance, and the molten substance is continuously extruded from the clearance of a shaping mould by the extrusion device, so as to form continuous cylindrical blanks; thirdly, one ends of the cylindrical blanks are hauled by a hauling machine to evenly get into a cooling sizing device, and then the cooling is performed to the walls of the cylindrical blanks through cooling water; fourthly, vacuum pumping is performed to a sizing sleeve in the cooling sizing device, and the cylindrical blanks are sized to form primary products; fifthly, the primary products are hauled into a cooling water tank, the water cooling is performed to the primary products to form finished products. The manufacturing equipment of the water hose realizes the vacuum shaping by being equipped with the devices of a sizing cooling tank and a vacuum pump, etc. The manufacturing method and the manufacturing equipment of the water hose have the advantages of good shaping effect, high cooling speed, low production cost, greatly enhanced product quality and high pressure resistance of the finished products, etc.

Owner:李建国

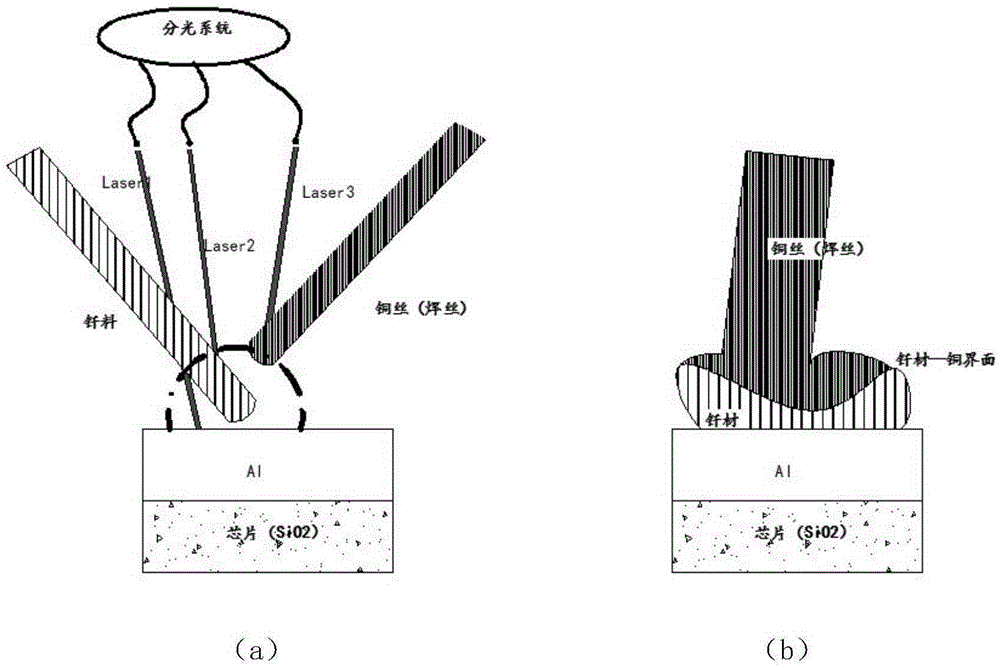

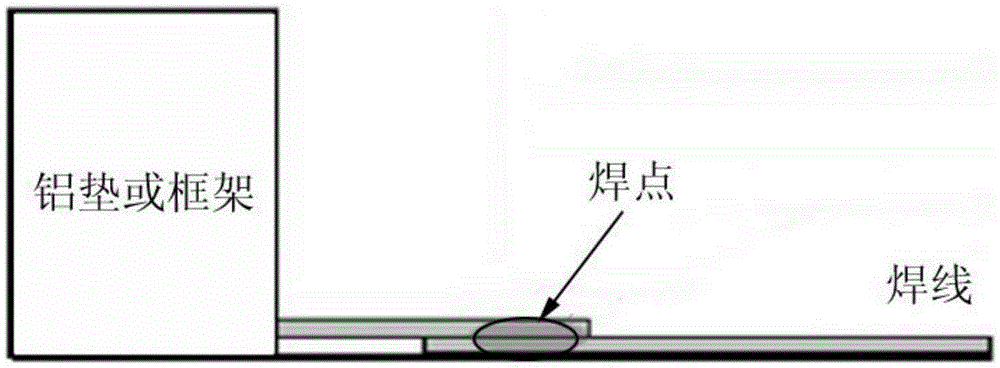

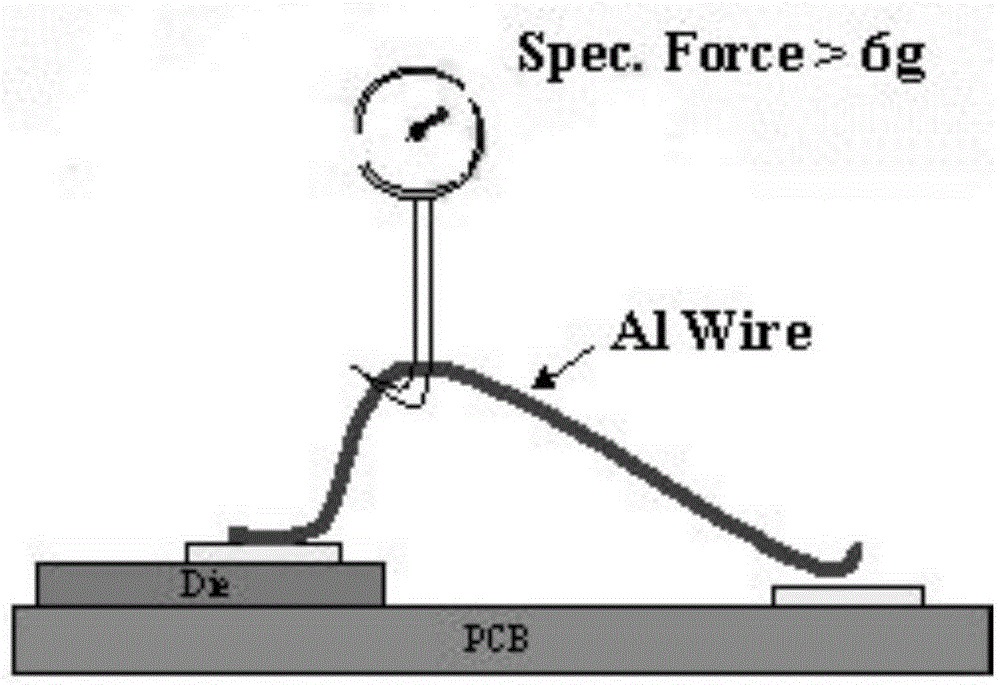

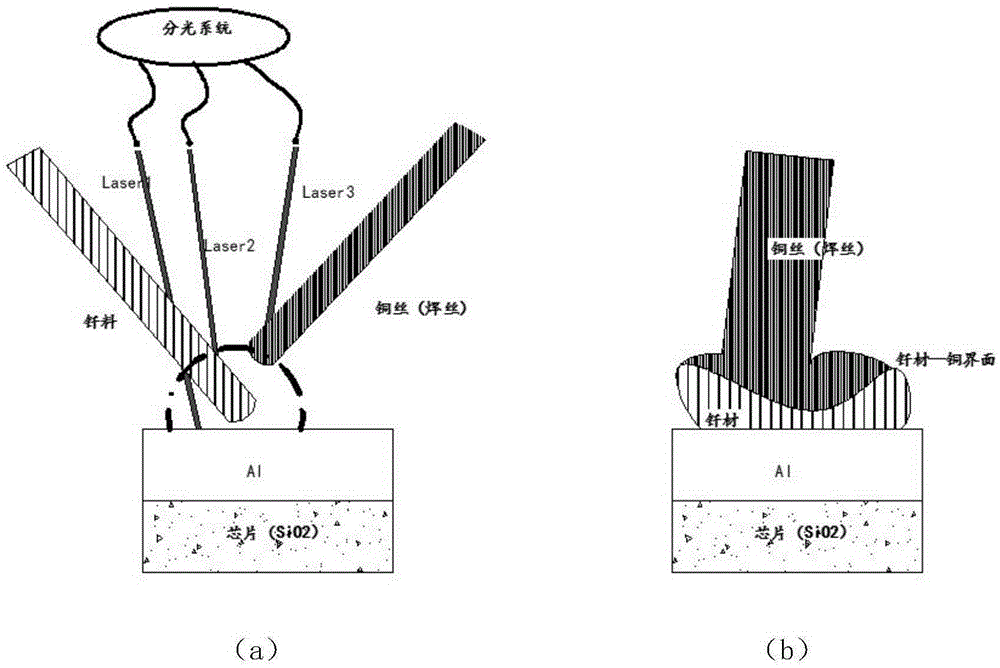

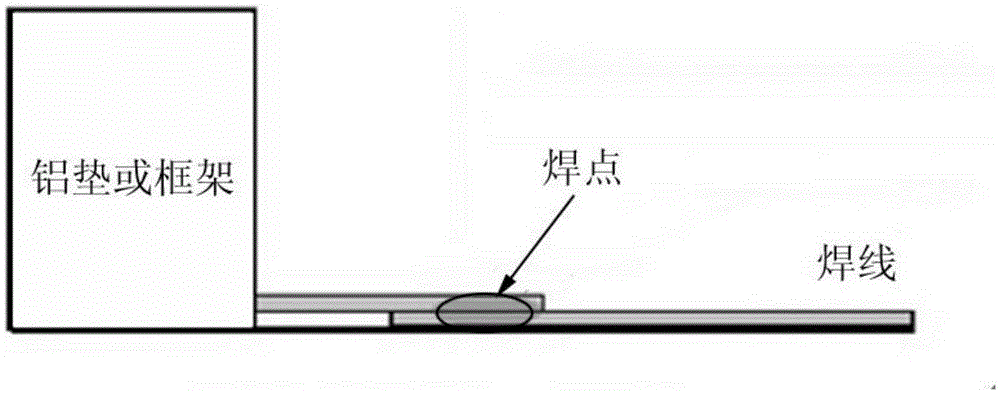

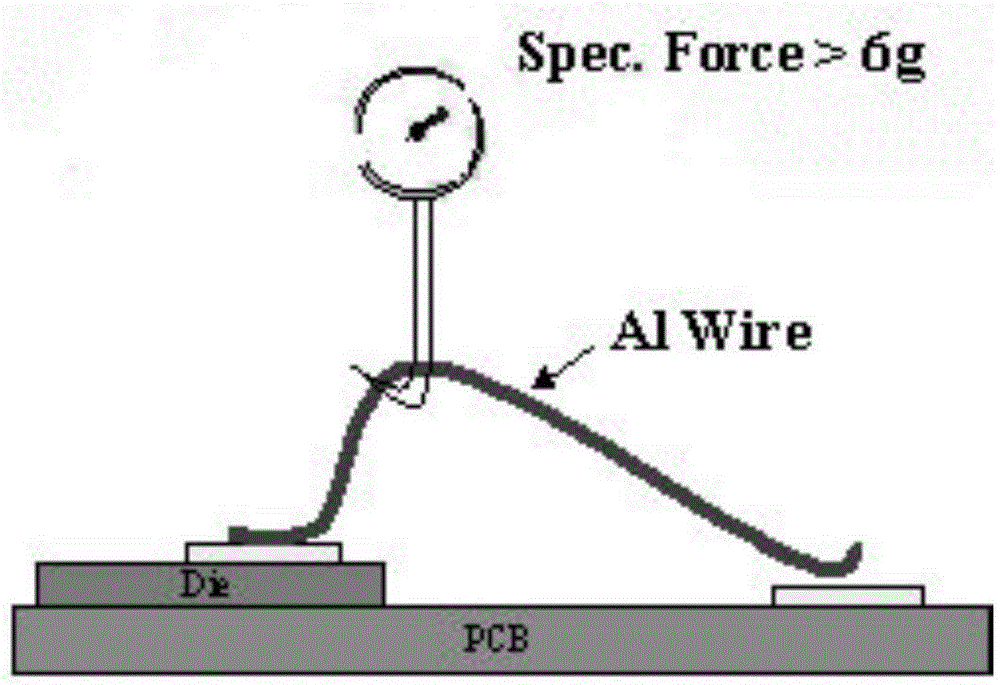

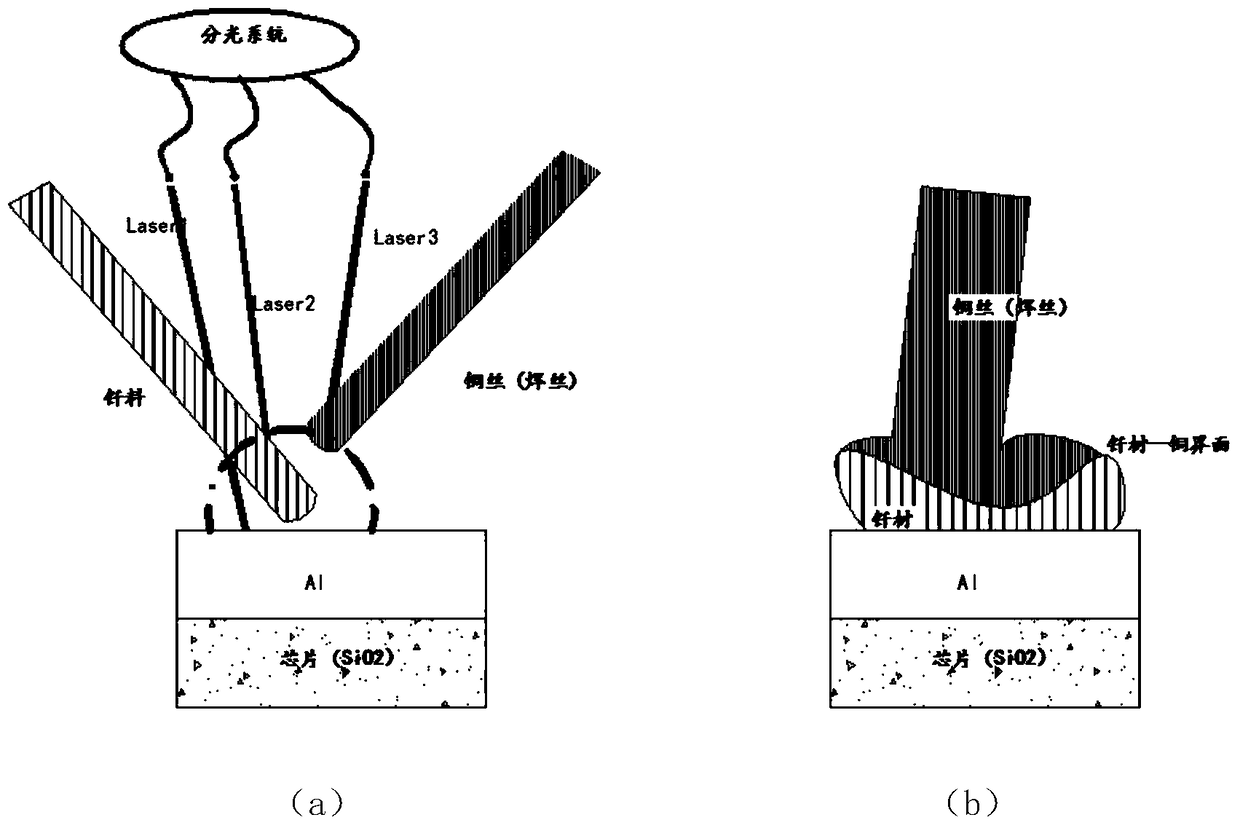

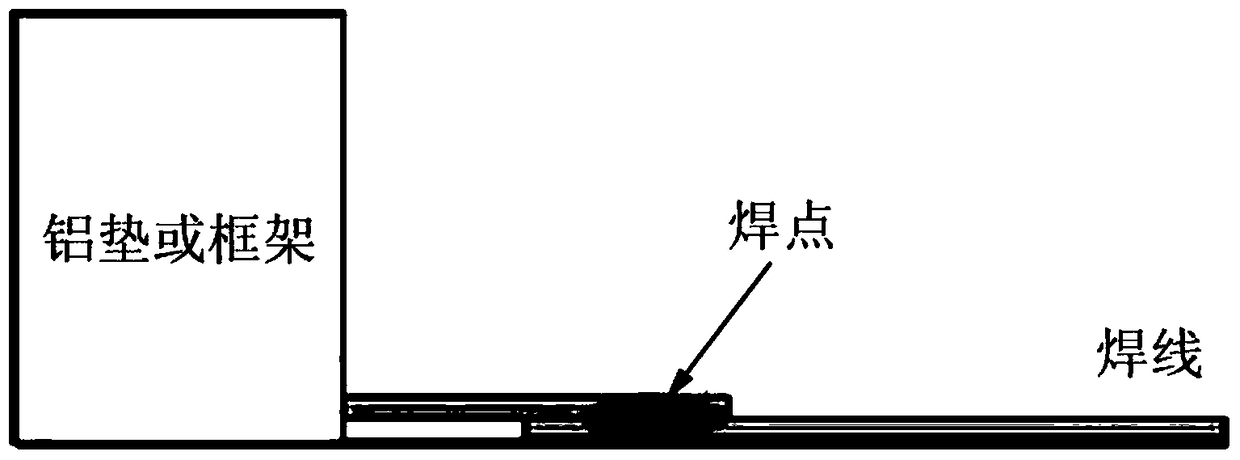

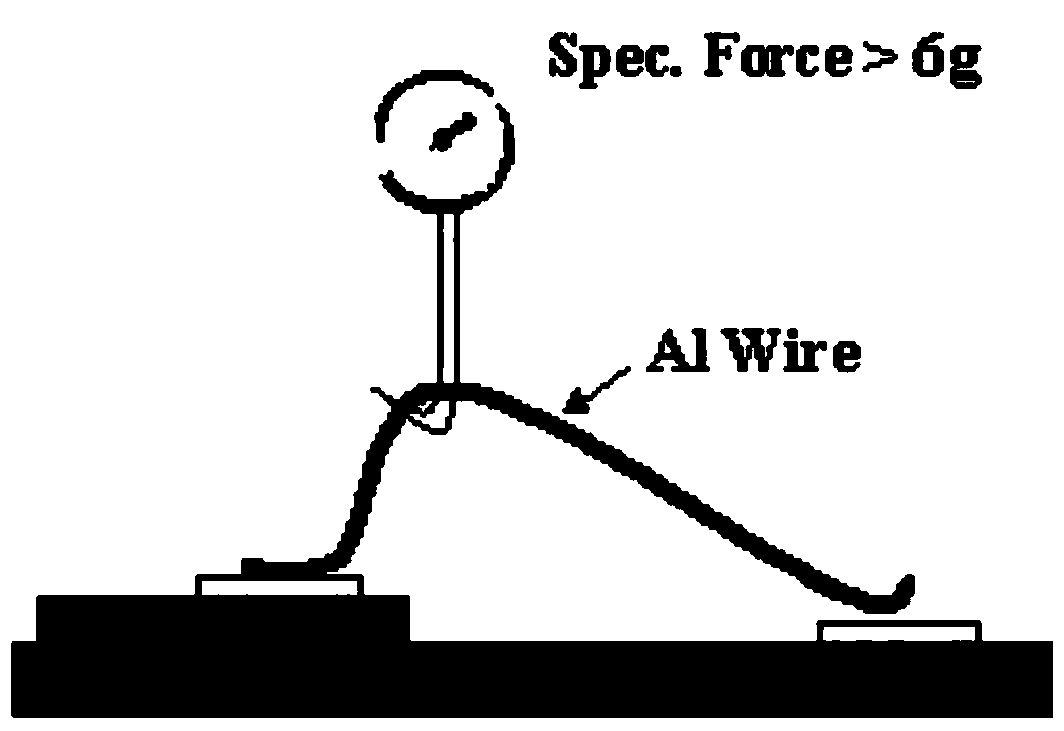

Lead welding technique for packaging semiconductor power device

ActiveCN105458434ANo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

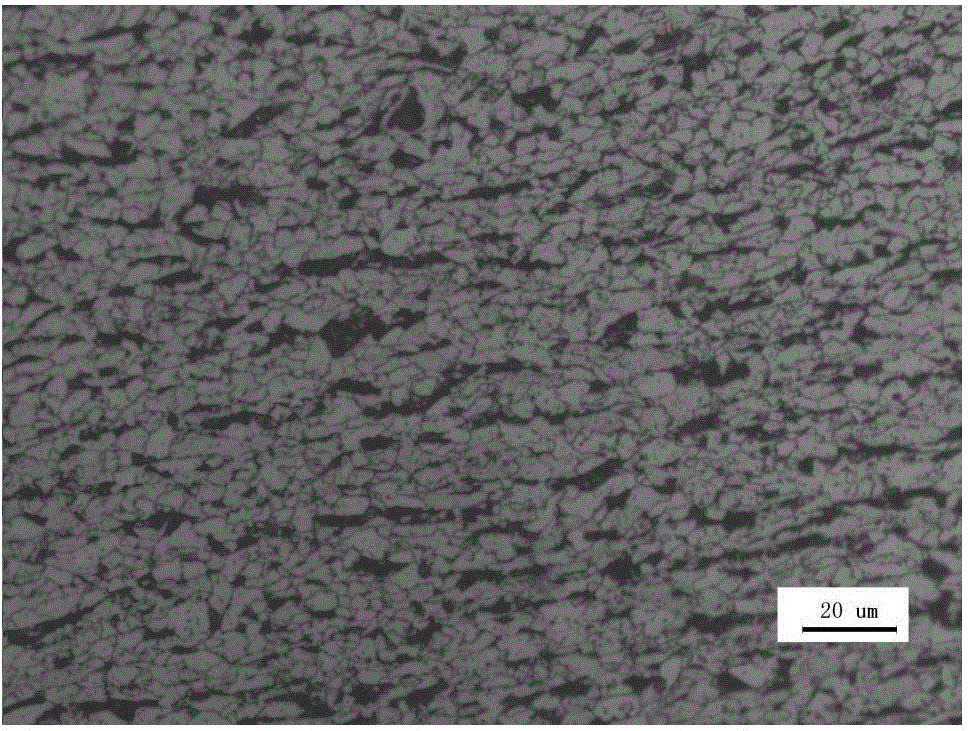

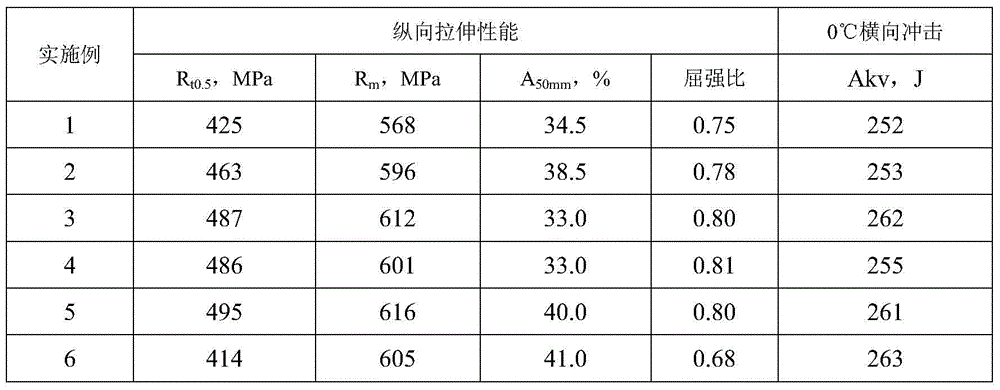

J55-grade low-yield-ratio steel for electric resistance welding casing pipe and manufacturing method of J55-grade low-yield-ratio steel

The invention discloses J55-grade low-yield-ratio steel for an electric resistance welding casing pipe and a manufacturing method of the J55-grade low-yield-ratio steel. The J55-grade low-yield-ratio steel comprises chemical components including, by weight percent, 0.090%-0.128% of C, 0.10%-0.35% of Si, 1.02%-1.25% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S, 0.01%-0.03% of Nb, 0.010%-0.030% of Ti, 0.30%-0.40% of Cr, 0.02%-0.06% of Als, smaller than or equal to 0.008% of N and the balance Fe and inevitable elements. The method is characterized in that a continuous casting sheet billet is heated to 1160-1200 DEG C through a heating furnace, and the final rolling temperature in the first stage is larger than 980 DEG C; the rolling starting temperature in the second stage ranges from 980 DEG C to 1020 DEG C, and the final rolling temperature ranges from 810 DEG C to 865 DEG C; laminar flow intermittent cooling is adopted for a rolled steel strip, and the cooling speed ranges from 12 DEG C / s to 18 DEG C / s; and coiling is conducted at the temperature ranging from 590 DEG C to 680 DEG C. The J55-grade low-yield-ratio steel has the beneficial effects that the carbon content is relatively low, and weldability and the impact toughness are good; and a proper number of Cr alloy is added, the safety of a steel pipe is good, and it is ensured that the yield strength and the tensile strength meet the standard requirement.

Owner:ANGANG STEEL CO LTD

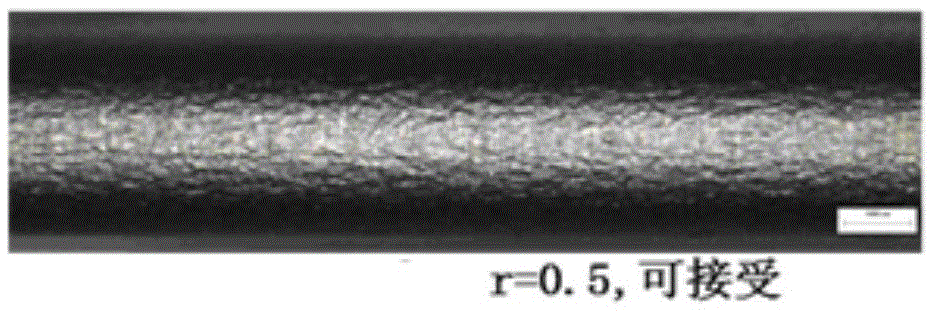

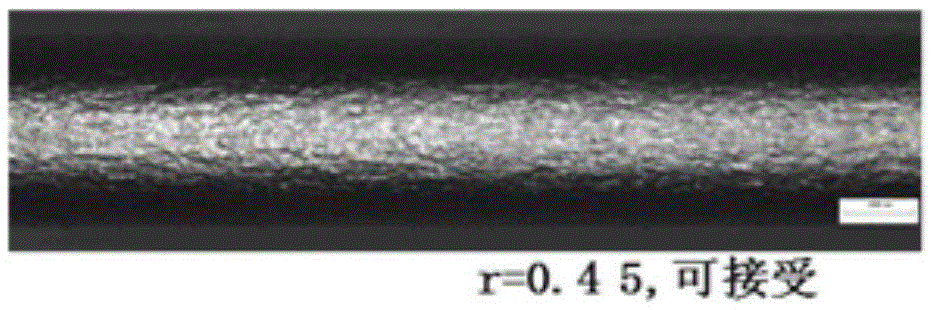

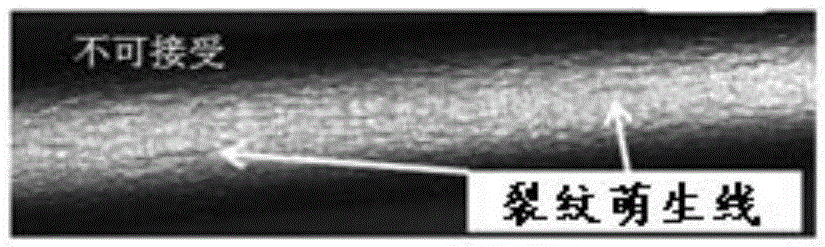

Intermediate annealing process of aluminum alloy and aluminum alloy for automobile covering part

The invention provides an intermediate annealing process of an aluminum alloy. The intermediate annealing process comprises the step of carrying out intermediate annealing on a cold-rolled aluminum alloy to obtain the aluminum alloy subjected to intermediate annealing, wherein the temperature of intermediate annealing is 450-550 DEG C, and the time of intermediate annealing is 2-20 minutes. A continuous annealing mode is adopted, annealing temperature of an intermediate annealing process is increased, and morphology of the annealed aluminum alloy is improved, so that the effect of improving flangability of products is achieved. Experiment results show that the aluminum alloy which is prepared by the intermediate annealing process has smooth surfaces after being subjected to flanging, does not have crack initiation lines or cracks, and can be applied to the automobile industry. The invention further provides an aluminum alloy for an automobile covering part.

Owner:SOUTHWEST ALUMINUM GRP

Electronic equipment, housing assembly, and circuit board assembly

InactiveCN107529320ASolve the problem of limited cooling areaSolve the pain points of heat dissipationCooling/ventilation/heating modificationsHeat conductingGraphite

The invention is suitable for the technical field of electronic equipment, and provides electronic equipment, a housing assembly, and a circuit board assembly. The housing assembly comprises a plastic housing, and the circuit board assembly comprises a substrate which is provided with a heating element. The substrate is disposed in the plastic housing, and the inner side surface of the plastic housing is covered by a metal layer. A graphite part is fixed on the metal layer, and the heating element is fixedly provided with heat-conducting glue. The graphite part makes contact with the heat-conducting glue. When the electronic equipment is assembled, the heat-conducting glue makes contact with the graphite part, and the heat on the heating element is transferred to the heat-conducting glue. The heat-conducting glue can achieve the quick transfer of heat to the graphite part. The graphite part has the good performances of heat conduction and heat dissipation, and the heat on the graphite part can be transferred to the metal layer. The metal layer covers the plastic housing, is larger in area, and facilitates the quick dissipation of heat. Compared with a mode of dissipating the heat of the heating element through a shielding cover, the electronic equipment is larger in heat dissipation area, is high in speed of heat dissipation, and is good in performance of heat dissipation.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

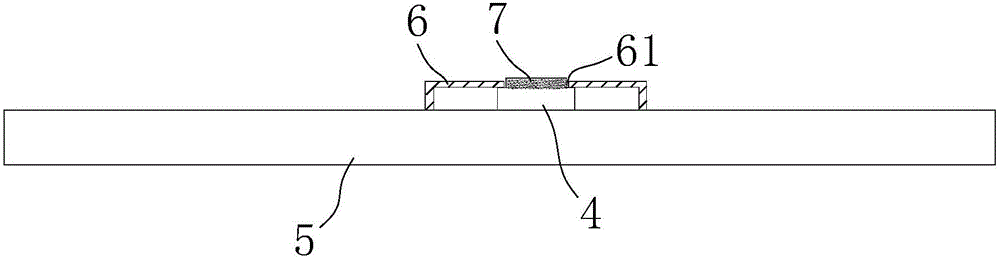

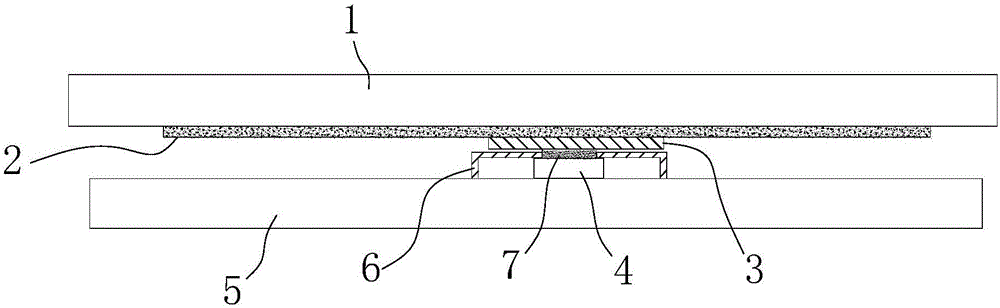

Lead welding device and technique for packaging semiconductor power device

ActiveCN105458435AImprove efficiencySmall heat affected zoneWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding device and technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. The device is a laser wire welding machine and comprises a computer main board, a laser generator, a chip and frame image identification system, a feeding system and an XY workbench. The computer main board is used for controlling all the actions of the laser wire welding machine to achieve the whole automatic and accurate wire welding technique process; the laser generator is used for outputting laser spots of the required power and the required diameter; and the feeding system is used for accurately conveying a frame, a lead and a brazing wire to the work position before welding actions are executed. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers. By the adoption of the device and technique, a wet aluminum pad and a frame are directly melted to achieve the stable and reliable connection of the lead, a chip and the frame, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

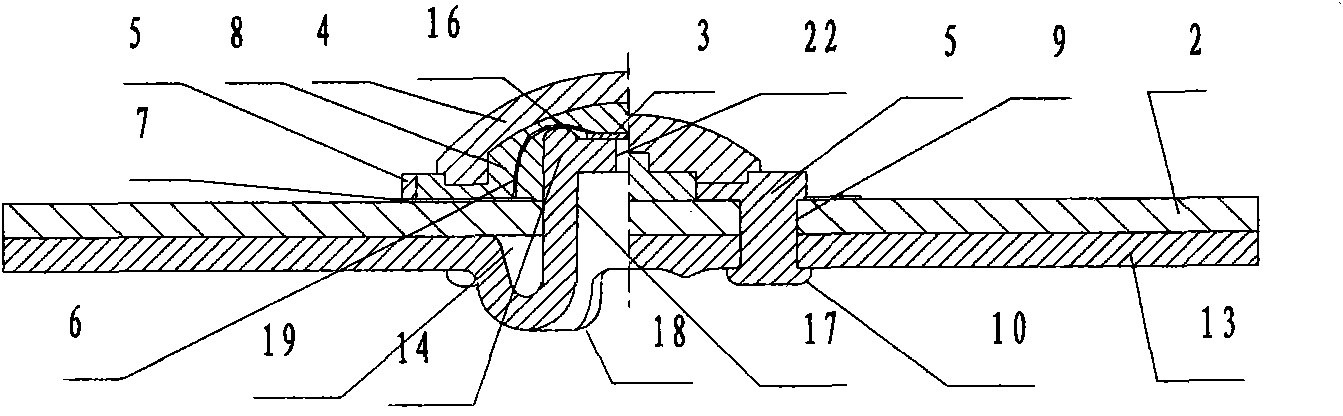

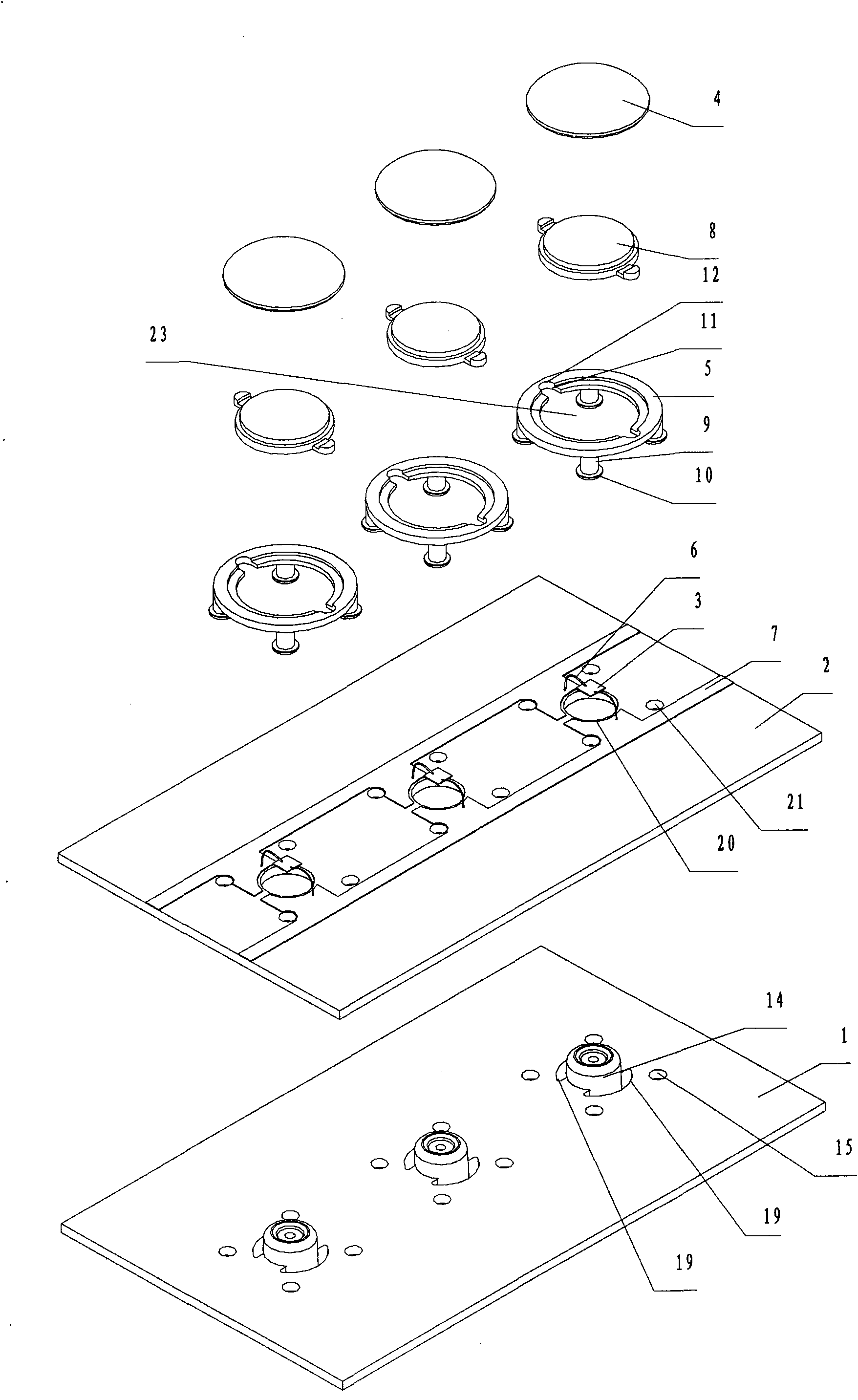

Self-adapting saccule surface cooling device

ActiveCN104697261AQuick exchangeSoft materialLighting and heating apparatusElectrical apparatus contructional detailsSurface coolingSaccule

The invention relates to a self-adapting saccule surface cooling device. The cooling device comprises a saccule cooler and a working medium heat dissipation circulator; the saccule cooler comprises a cooling saccule, a shape limiting housing and a liquid separating device; a hot liquid outlet and a cold liquid inlet are formed in the liquid separating device; the working medium heat dissipation circulator comprises a heat exchanger, a pressure compensation device, a sealed molecular pump, a liquid outlet separator, a return liquid separator and a liquid adding valve; the liquid outlet separator is connected with the sealed molecular pump through a first pipeline; the sealed molecular pump is connected with the heat exchanger through a second pipeline; the heat exchanger is connected with the return liquid separator through a third pipeline; the pressure compensation device is arranged on the second pipeline; the saccule cooler and the working medium heat dissipation circulator are connected with a liquid return pipe through a liquid outlet pipe. The cooling device is ingenious in conception, simple in structure, high in heat dissipation speed, good in effect and broad in application fields, and can be applied to the fields of battery heat dissipation, electronic product heat dissipation, industrial product heat dissipation and exchange, and the like.

Owner:GUANGDONG HI 1 NEW MATERIALS TECH RES INST CO LTD

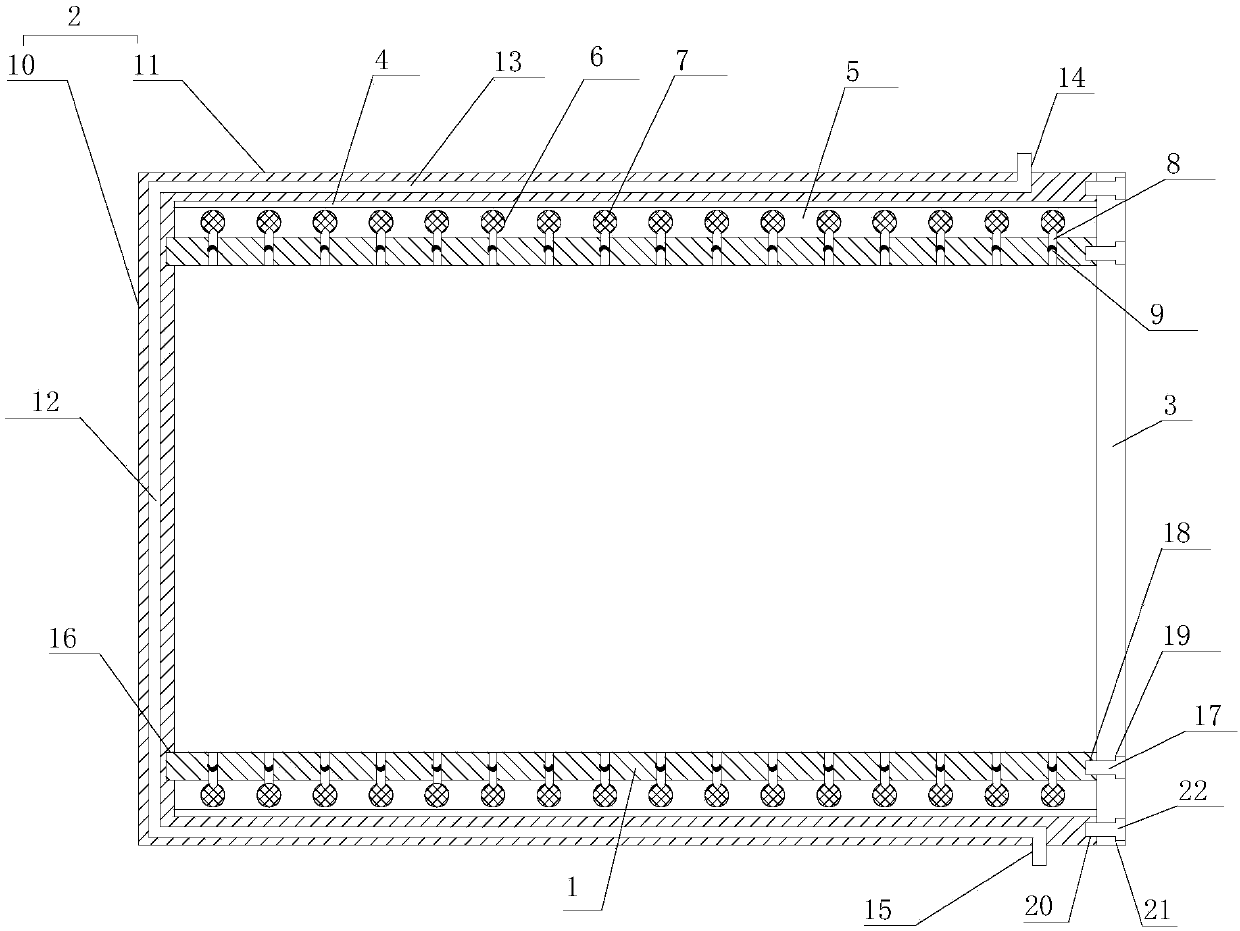

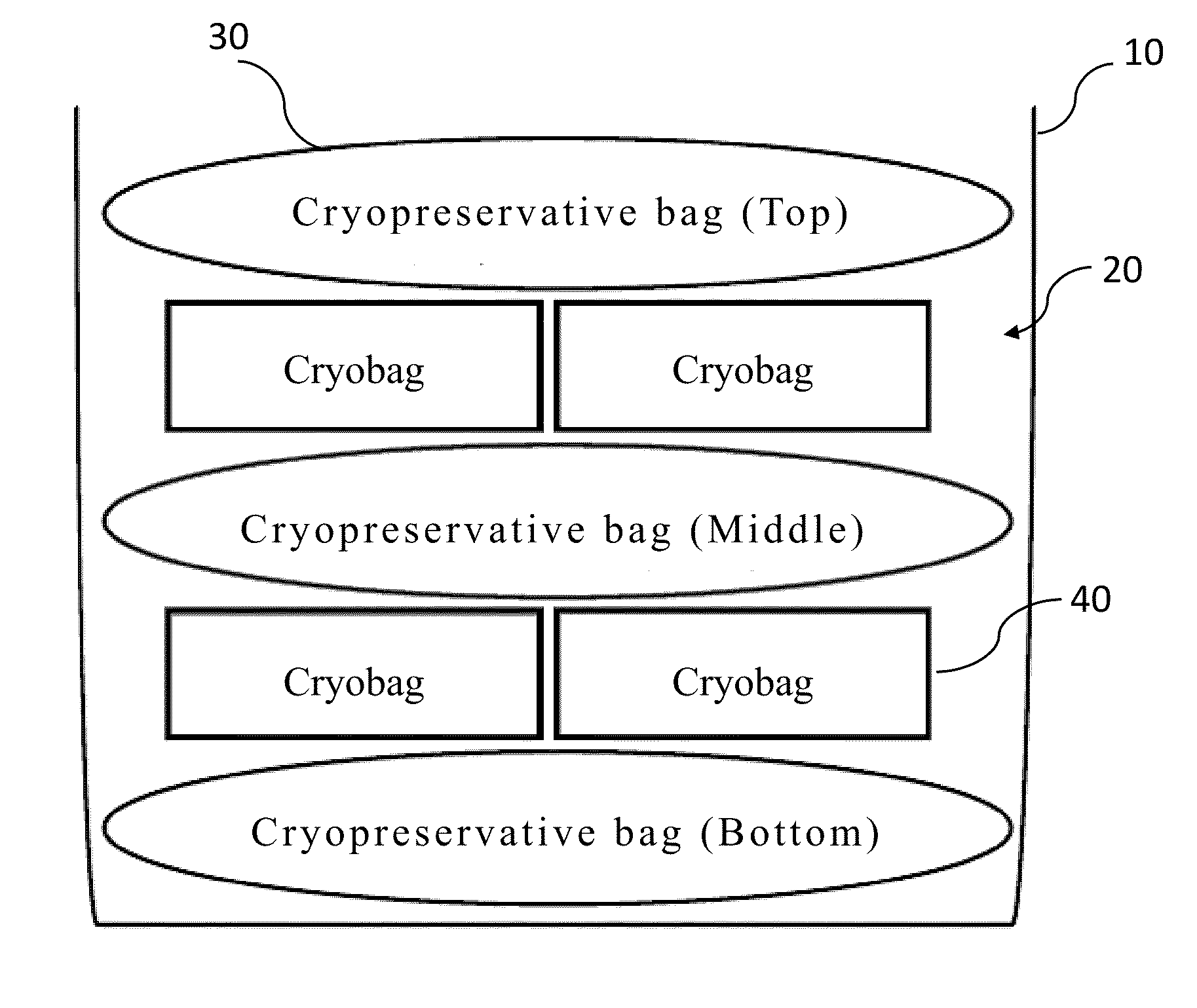

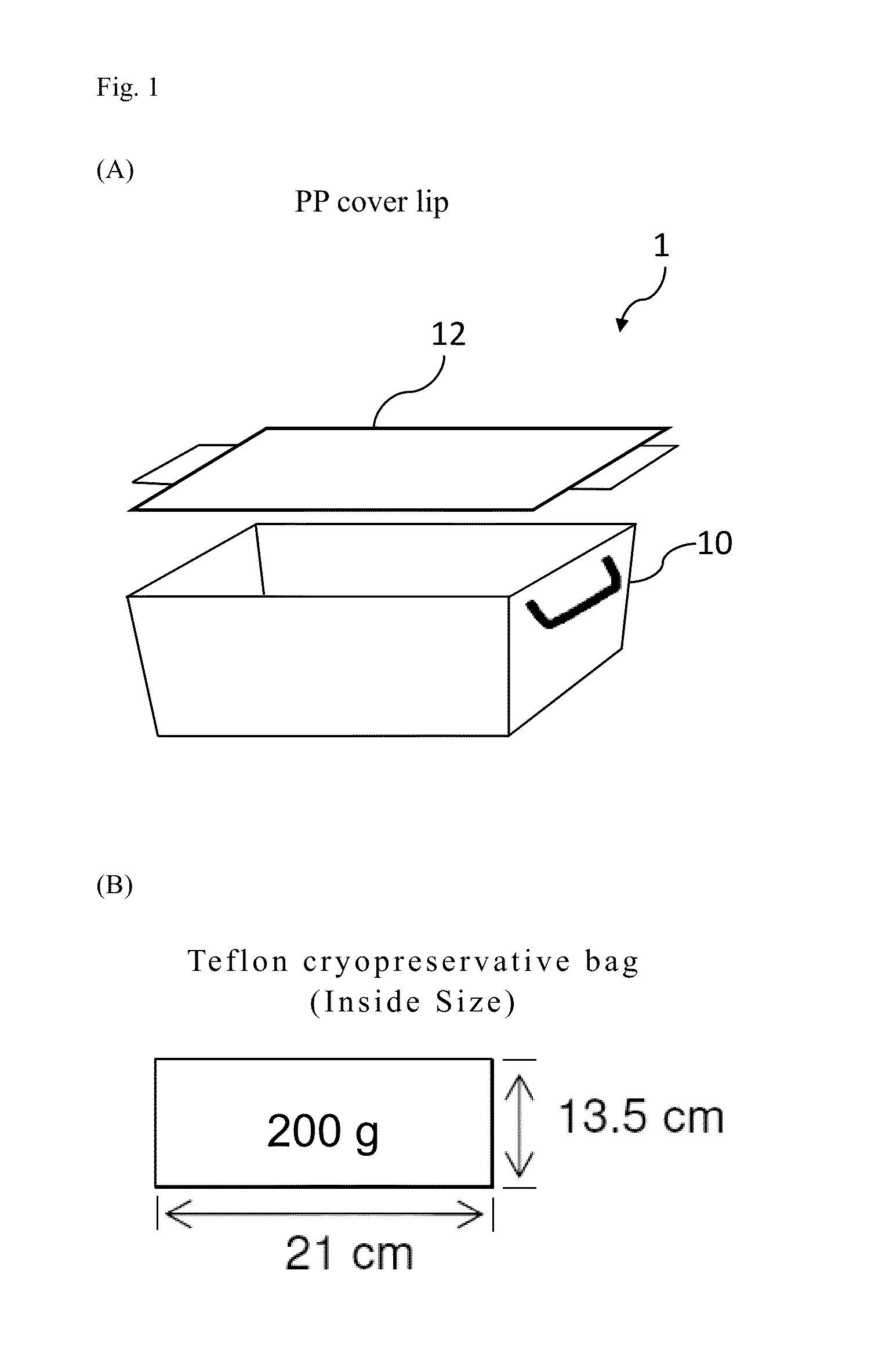

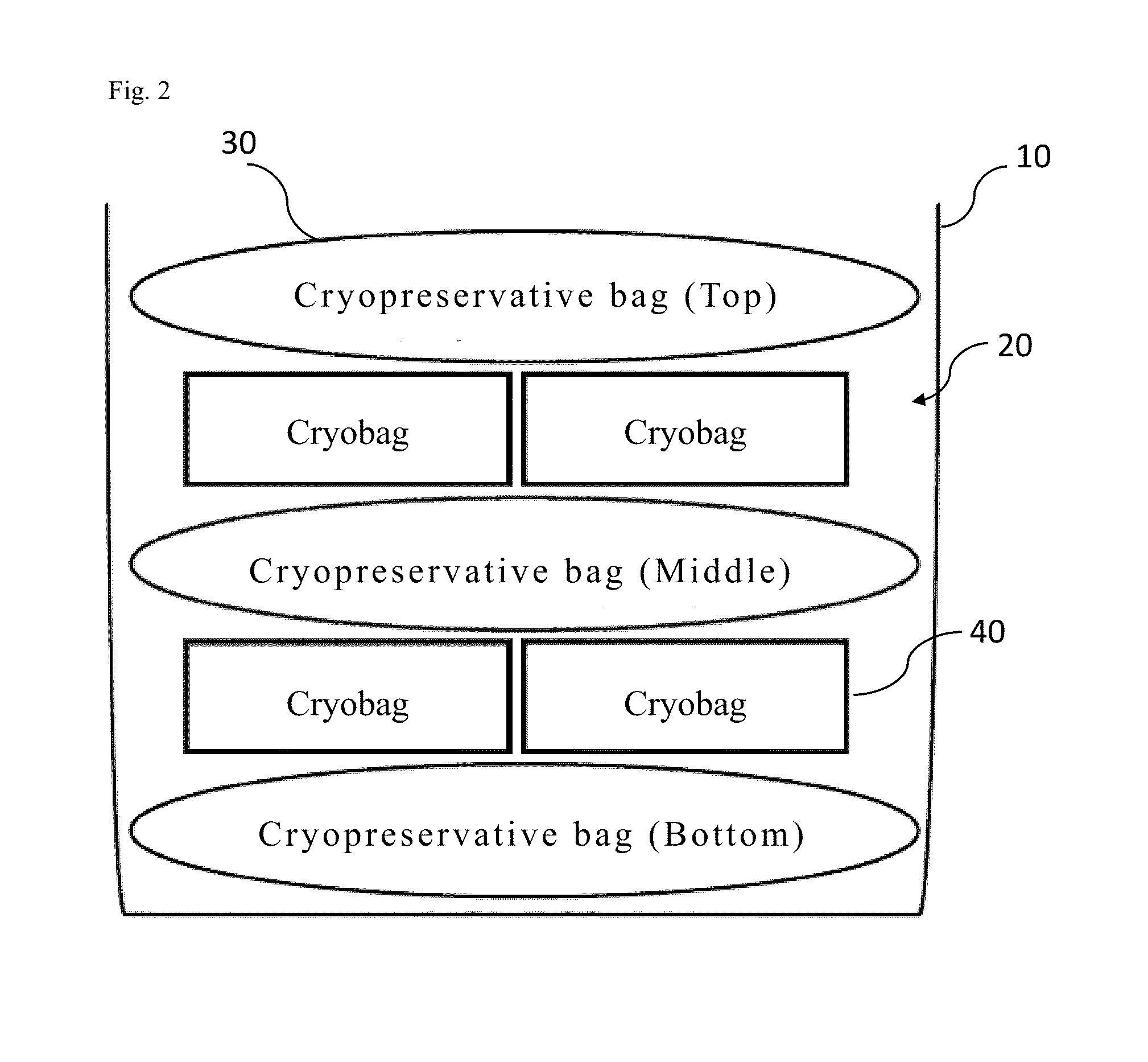

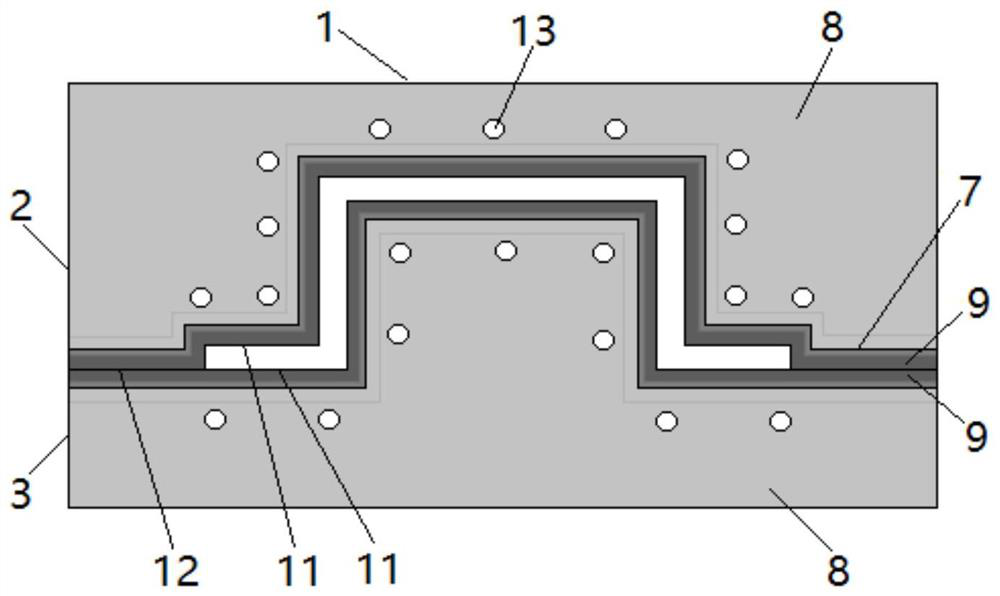

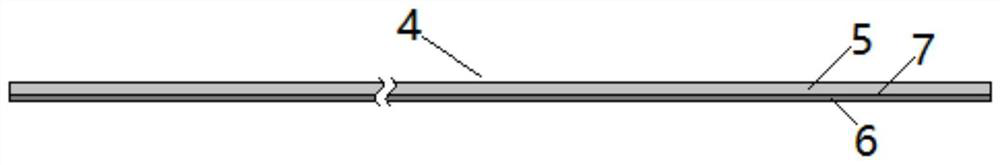

Cryopreservation storage device for cell collection bag, and using method thereof

InactiveUS20150024487A1Low costPromote cooling speedBioreactor/fermenter combinationsBiological substance pretreatmentsCryopreservationEngineering

The present invention relates to a cryopreservative device comprising an outer case, one or more layers of space for the cryo-bags, and two or more Teflon cryopreservative bags. The outer case has a cover lip for opening and closing. The Teflon cryopreservative bags are filled with a freezing resistant. In the present invention, the cryo-bags and the Teflon cryopreservative bags are crossly stacked in the cryopreservation device. The Teflon cryopreservative bags are designed to directly contact with the cryo-bags in order to obtain the effect of slow cell freezing.

Owner:STEMINENT BIOTHERAPEUTICS

High-elasticity high-nickel-alloy card clothing steel wire rod and preparation method thereof

The invention discloses a high-elasticity high-nickel-alloy card clothing steel wire rod. The wire rod comprises the following chemical components of, in percentage by weight, 0.6%-1.2% of C, 0.1%-0.6% of Si, 0.4%-0.7% of Mn, 2%-3.2% of Ni, 0.1%-0.28% of Cr, 0.005%-0.02% of rare earth element, less than or equal to 0.005% of S, less than or equal to 0.005% of P and the balance Fe and inevitable impurity elements. According to an elastic card clothing made of the wire rod, the tensile strength is larger than or equal to 2350 + / - 50 MPa, the total breaking elongation is larger than or equal to 6.0%, the one-direction torsion is larger than or equal to 6000 times / 360 degrees, the yield ratio is larger than or equal to 90%, and the adhesive force is larger than or equal to 1750 N.

Owner:江阴市钧益特种钢丝科技有限公司

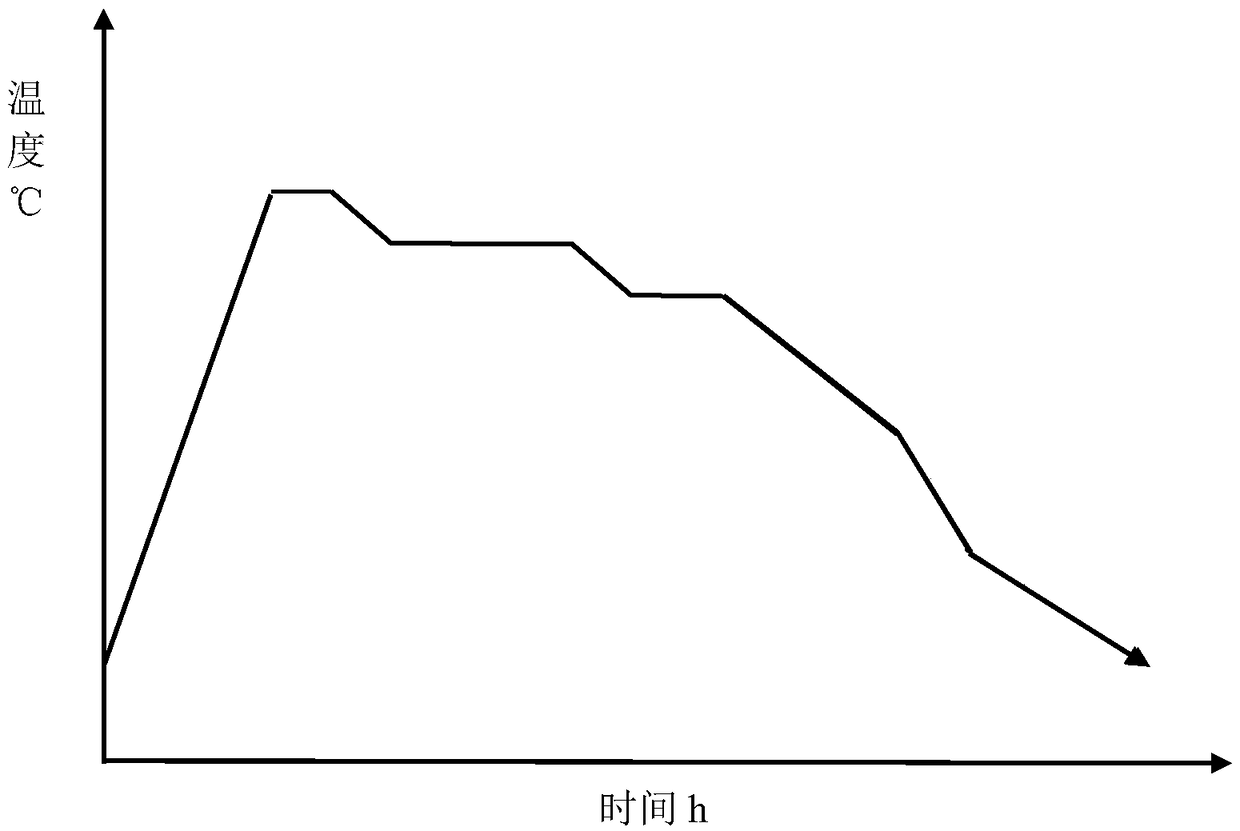

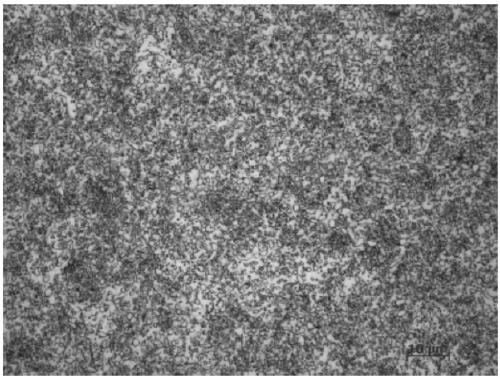

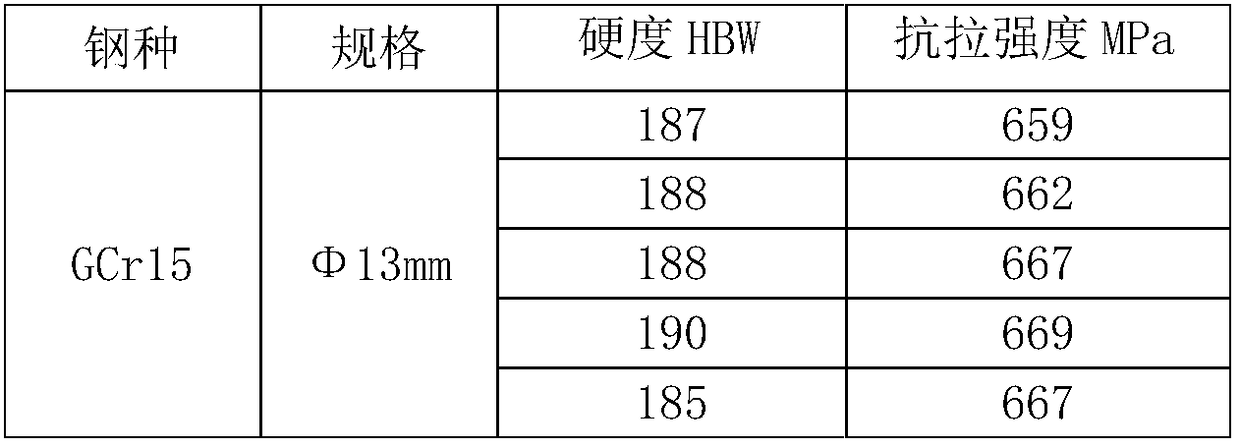

Novel spheroidizing annealing technology for bearing steel wire

PendingCN109402345AShorten the annealing cycleIncreased annealing throughputFurnace typesHeat treatment furnacesHydrogenMetallurgy

The invention relates to a novel spheroidizing annealing technology for a bearing steel wire. The novel spheroidizing annealing technology comprises the steps that the bearing steel wire is arranged in a cover-type furnace, a heat treatment furnace is filled with nitrogen, then nitrogen filling is stopped, the heat treatment furnace is filled with hydrogen, the heat treatment furnace is heated tothe high temperature T0 firstly, T0 is 780 to 800 DEG C, heat preservation is conducted for 0.5-5 h, meanwhile, technology nitrogen filling is stopped, then the temperature is controlled at the heat preservation stage, uniform heating is controlled at 780+ / -2 DEG C, and heat preservation treatment is conducted for 5-7 h; first-stage cooling is conducted, specifically, the interior of the furnace is cooled to 700- 720 DEG C at the speed of 50+ / -4 DEG C / h, and heat preservation is conducted for 1 h; second-stage cooling is conducted, specifically, the interior of the furnace continues being cooled to 650 DEG C at the speed of 12.5+ / -2 DEG C / h, and heat preservation is not conducted; third-stage cooling is conducted, specifically, the interior of the furnace continues being cooled to 300 DEGC at the speed of 230+ / -10 DEG C / h, meanwhile, water spraying for cooling is started, and heat preservation is not conducted; and fourth-stage cooling is conducted, specifically, the interior of the furnace continues being cooled to 150 DEG C at the speed of 70+ / -10 DEG C / h, and a product is taken from the furnace. According to the novel spheroidizing annealing technology, the annealing period ofthe bearing steel wire is shortened, and the annealing capacity is increased.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

Metal surface gradient coating cladding method

InactiveCN106435442AAdapt to wideLower technical barriersMolten spray coatingSurface gradientPlasma generator

The invention discloses a metal surface gradient coating cladding method, and belongs to the technical field of metal surface heat treatment. The metal surface gradient coating cladding method comprises four steps of matrix surface pretreatment, coating material setting, coating cladding treatment and coating inspection; and in the coating cladding process, through specific setting of coating cladding equipment, a laminar flow plasma generator and a cladding spraying gun are adopted to provide a heat source to laminar flow plasma to perform gradient treatment for a metal surface. After at least two times of classing treatment, a coating layer with a gradient is formed, so that the cracking or stripping damage in an ultrahard coating layer is prevented, and the application range of the coating layer is wider; the laminar flow plasma is fast in heating speed, and the matrix temperature is convenient to control, and is not higher to prevent generation of annealing deformation; and meanwhile, as the laminar flow plasma continuously works to cause relatively slow cooling of a machine body, and a formed transition area is higher, the stress release is better for hard surface material cladding.

Owner:CHENGDU PLASMAJET SCI & TECH

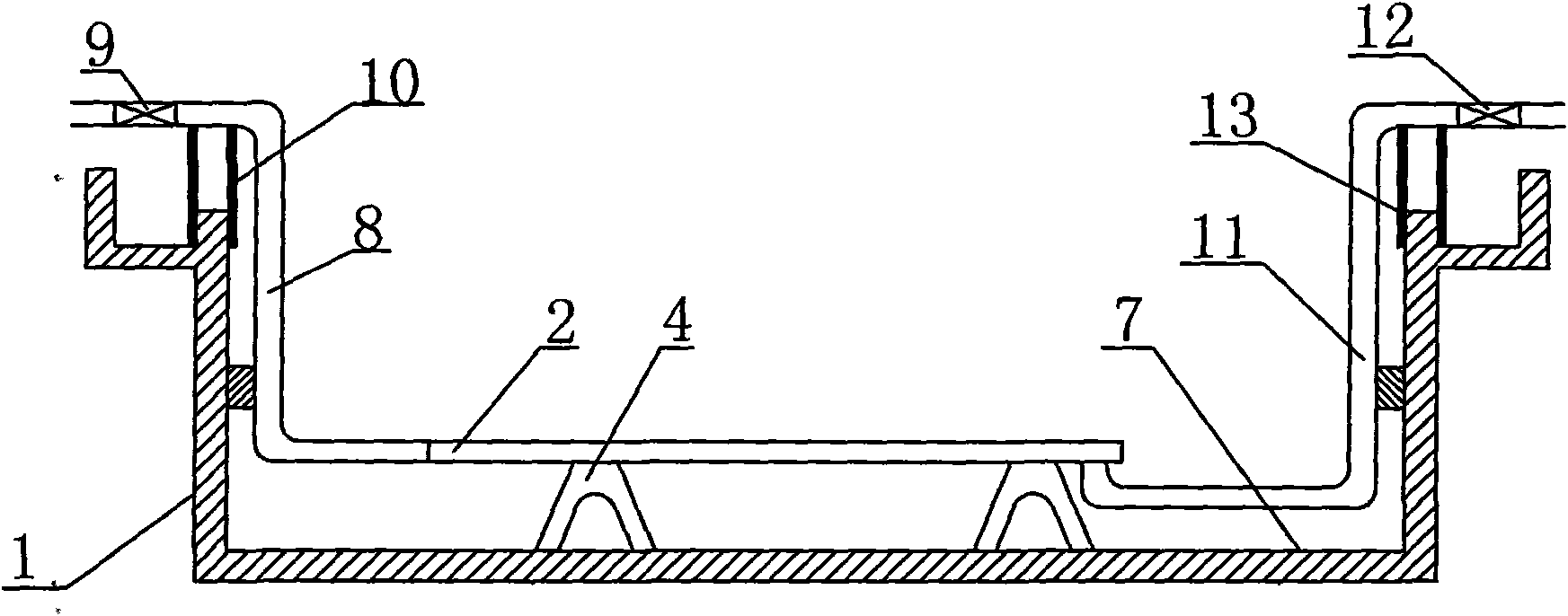

Bottle cooler

InactiveUS20070068192A1Prevent floatingReduce riskLighting and heating apparatusDomestic refrigeratorsEngineeringBottle

A bottle cooler comprising an upwardly opening chamber having a base upon which a bottle may be located, the neck of the bottle extending from an opening of the chamber, an upwardly opening reservoir adjacent the chamber, a pump, a passage from the reservoir communicating with the chamber so that water may be pumped in use from the reservoir to the chamber, the chamber including a further passage communicating with the reservoir arranged so that water may be circulated in use from the reservoir to the chamber and from the chamber to the reservoir, the cooler including a plurality of overflow conduits, a first conduit having an inlet from the reservoir and an outlet to the chamber, and a second conduit having an inlet from the chamber and outlet to the reservoir.

Owner:NG YIU WING

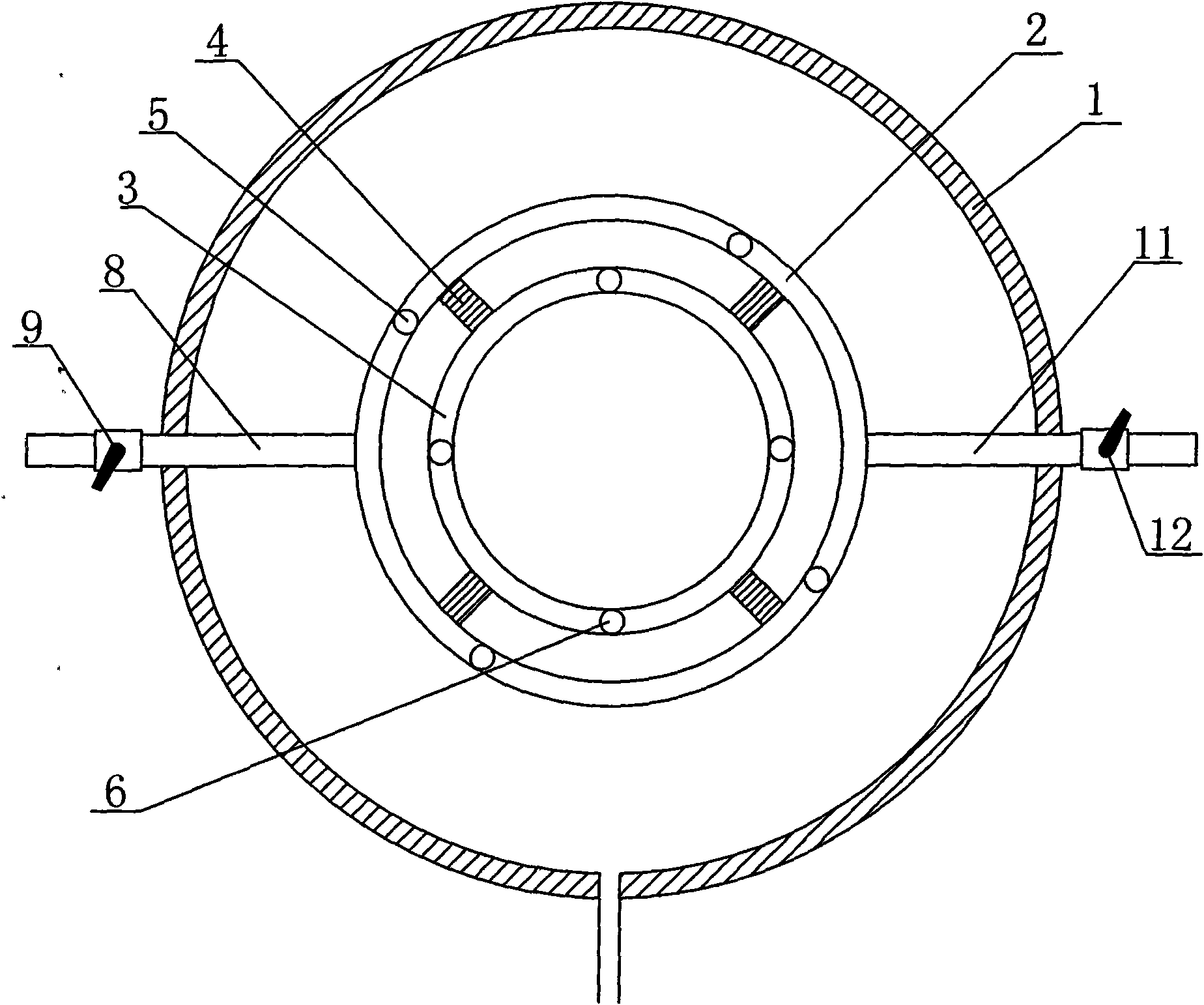

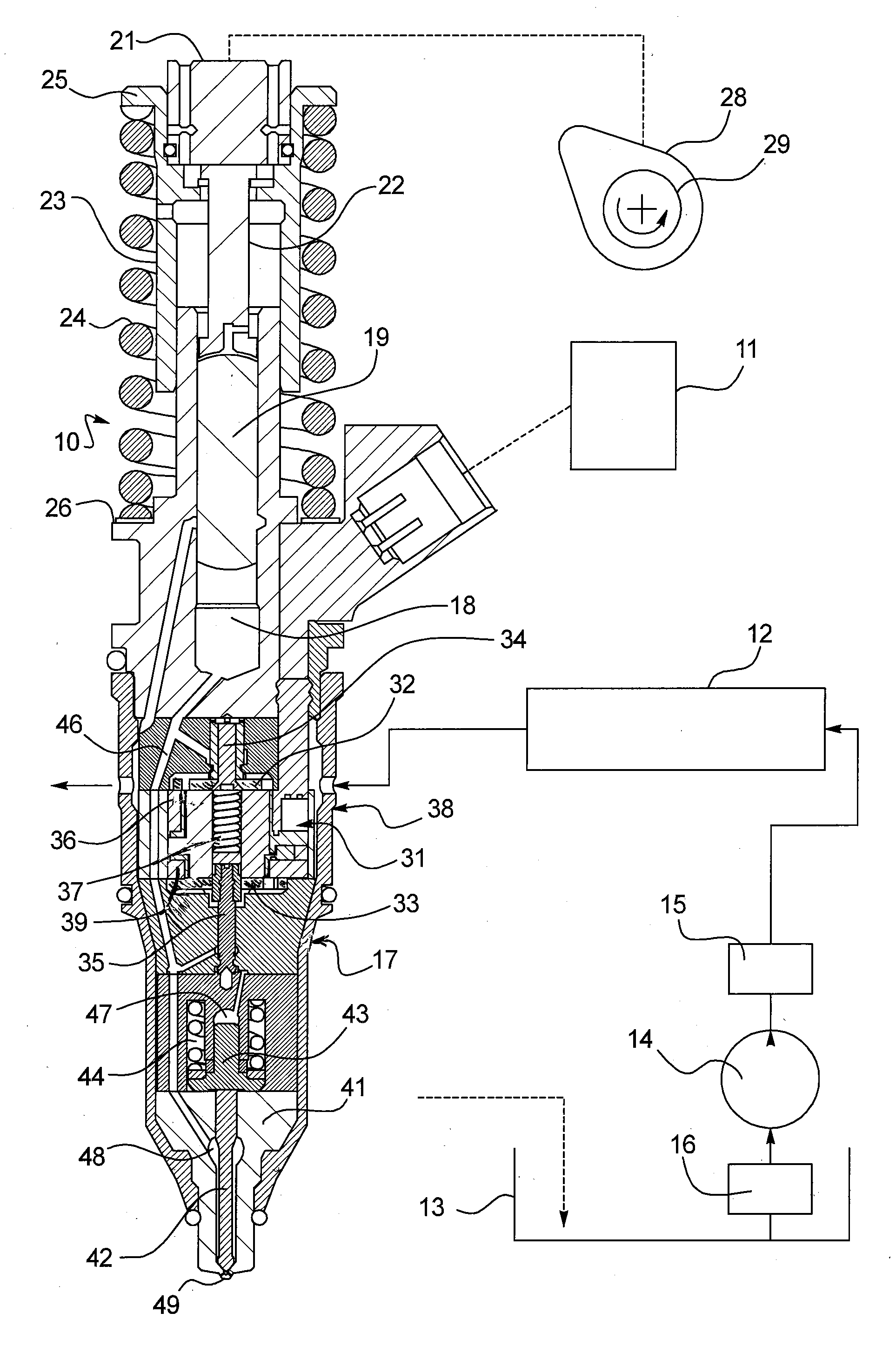

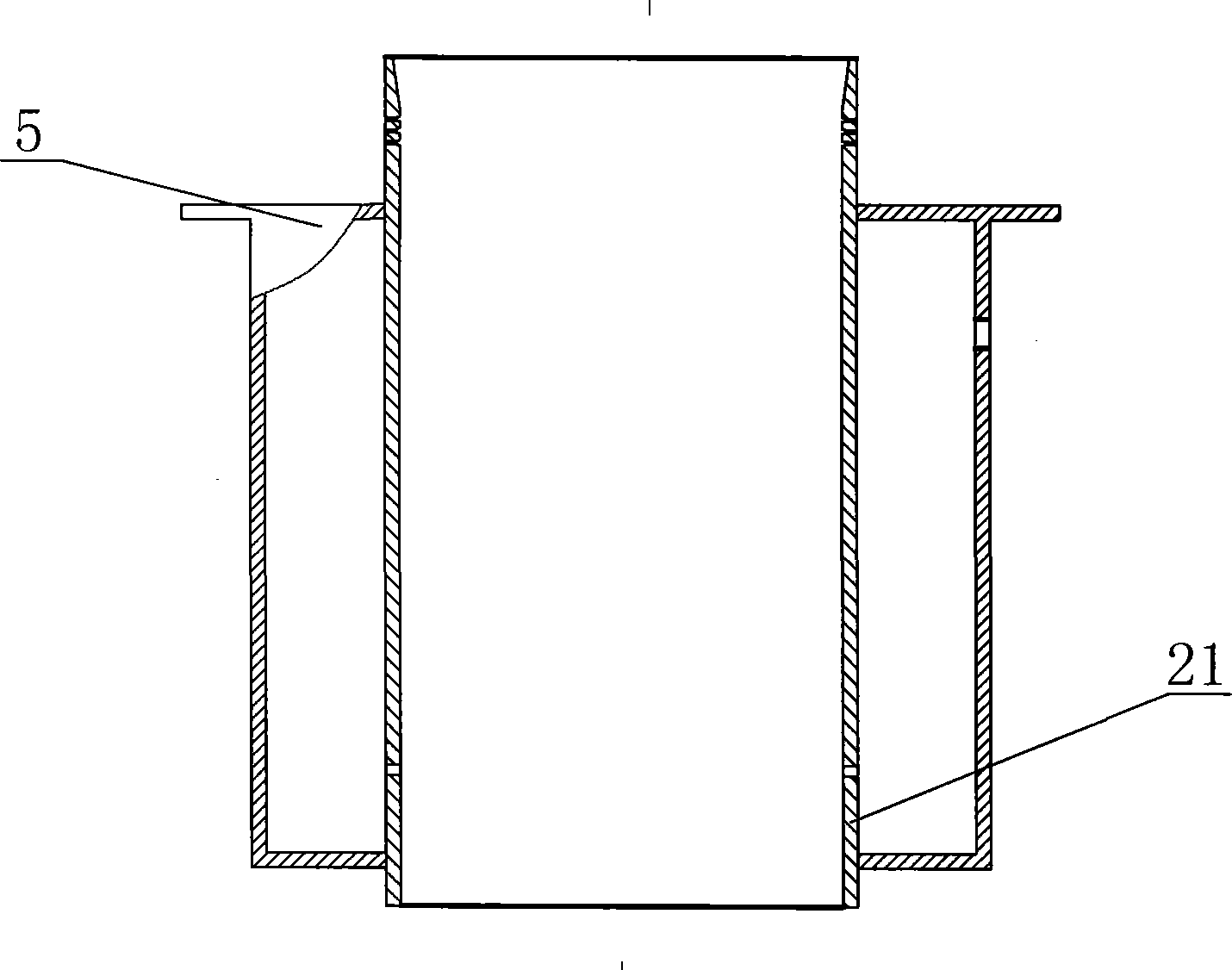

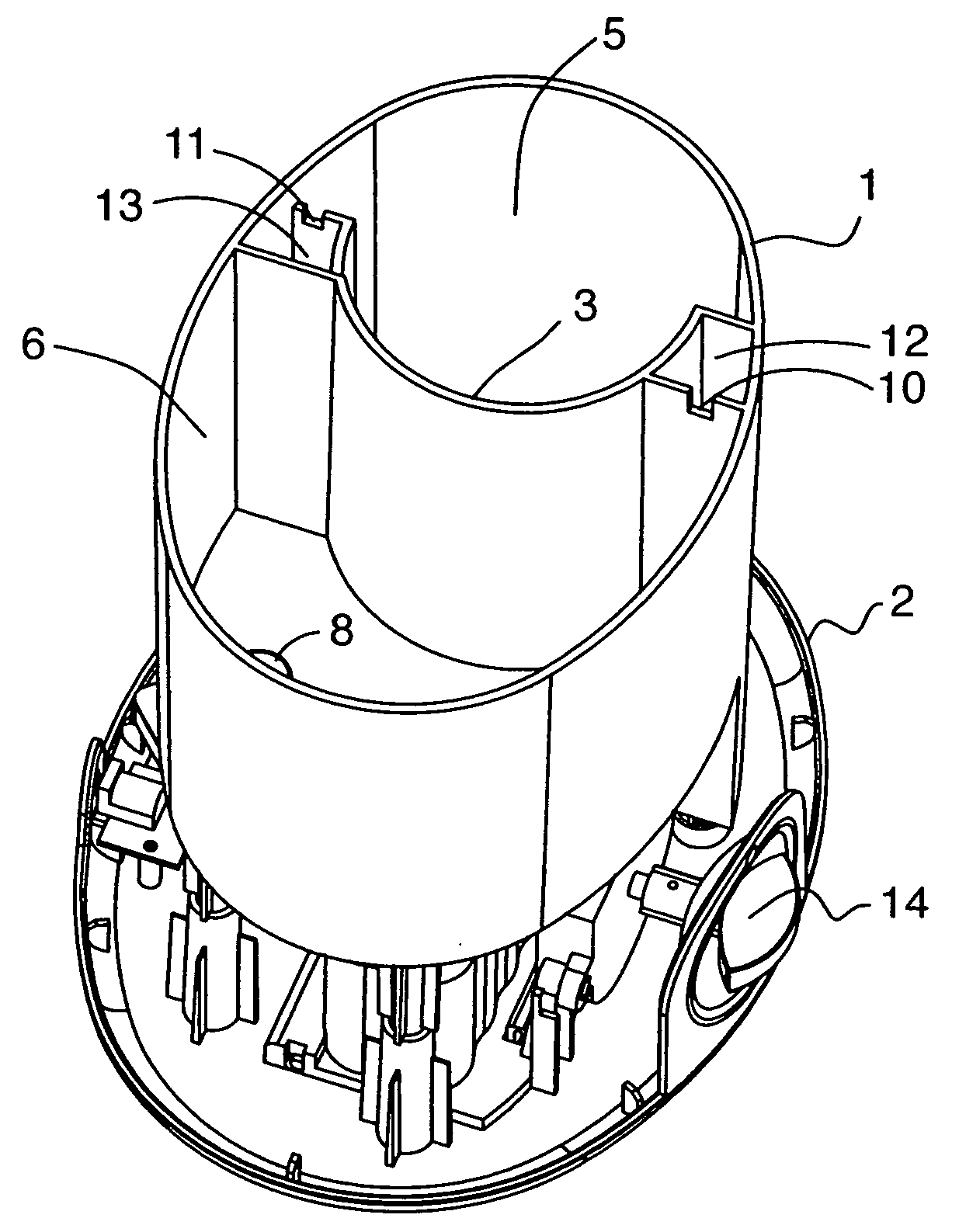

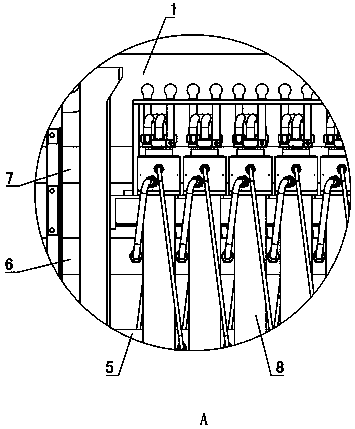

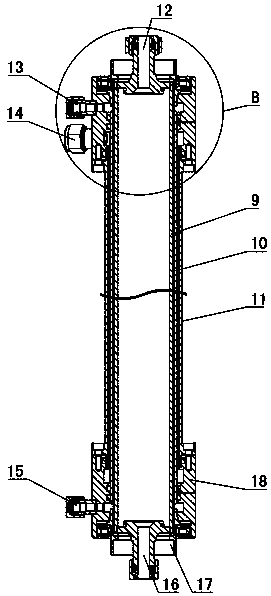

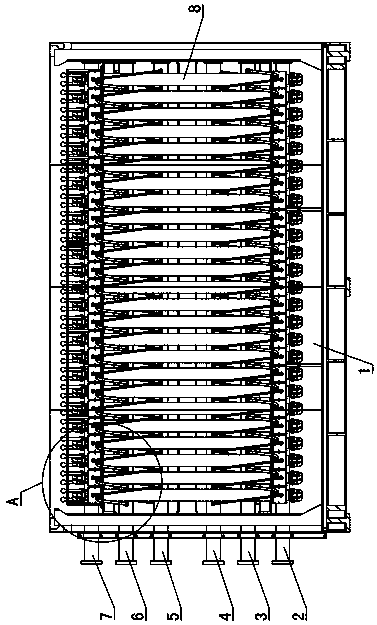

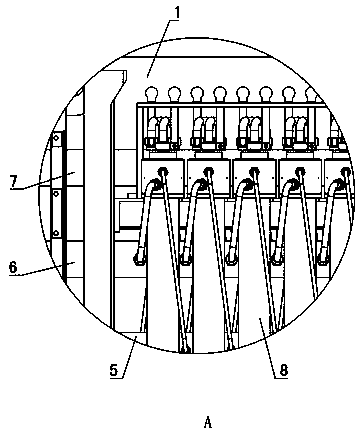

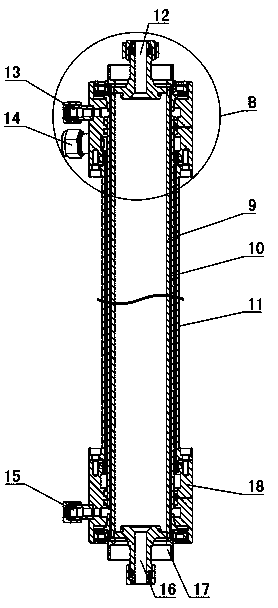

Ozone generation device

InactiveCN108147370AMeet production requirementsAdjust the quantityOzone preparationOzone generatorComputer module

The invention discloses an ozone generation device, and belongs to the technical field of ozone generators. The ozone generation device is characterized in that the device comprises a generator body (1) and at least one ozone generation module, the ozone generation modules are arranged in the generator body (1), the ozone output of each ozone generation module is 0.5-3kg / h, each ozone generation module comprises a plurality ozone pipes (8), two ends of a cooling liquid channel of each ozone pipe (8) are connected with a liquid inlet pipe and a liquid outlet pipe, two ends of a gas channel of each ozone pipe (8) are connected with a gas inlet pipe (5) and a gas outlet pipe (4), the inner side and the outer side of each gas channel are insulated, discharge electrodes of power supplies are connected on the inner sides of the gas channels, and ground electrodes of the power supplies are connected on the outer sides of the gas channels. The ozone generation device can adjust ozone output bydirectly increasing or decreasing the number of the ozone generation modules in the generator body, the ozone output of each ozone generation module is 0.5-3kg / h, and most ozone output requirements can be met.

Owner:恒天摩尔科技(山东)有限公司

Detection method of gas reaction concentration and detection device

ActiveCN108375651AReal-time detectionDoes not affect accuracyAnalysing gaseous mixturesAir quality improvementChemical reactionDelta-v

The invention provides a detection method of gas reaction concentration and a detection device and belongs to the technical field of concentration detection. The detection method is characterized by comprising the following steps: step 1), measuring total volume flows Q1 and Q2 of gas reactants before reaction in real time; step 2), calculating a real-time volume flow difference delta Q of gas before and after a chemical reaction; step 3), determining a relation between a volume change value delta V and a volume V of gas to be detected of the gas before and after the reaction and calculating avolume flow Q3 of the gas to be detected; step 4), equalizing each gas reactant into an equivalent reactant according to a ratio of corresponding stoichiometric numbers; step 5), calculating the gasmass percent of the gas to be detected. According to the detection method of the gas reaction concentration, through gas volume change relation before and after the chemical reaction, the difficulty in the prior art that the gas needs to be detected through a sampling manner is overcome, and the detection accuracy and the detection stability are improved; an ozone generation device can be used formonitoring the concentration of produced ozone in real time.

Owner:惟能科技(常州)有限公司

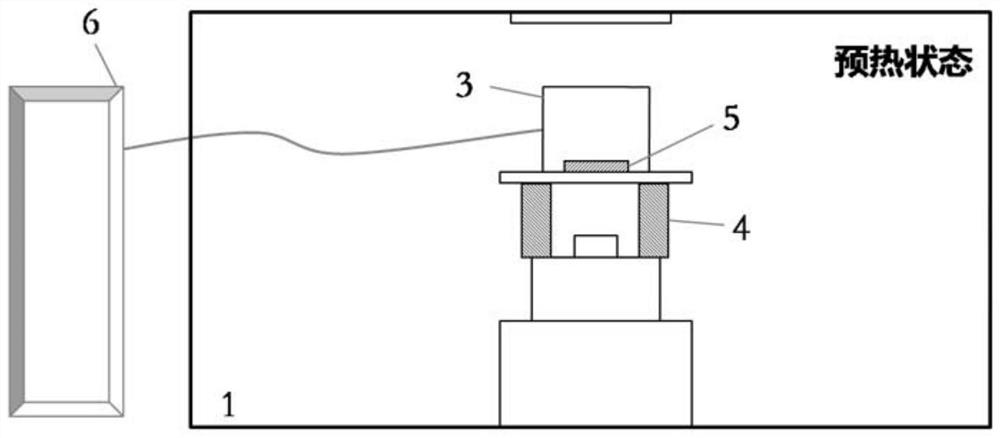

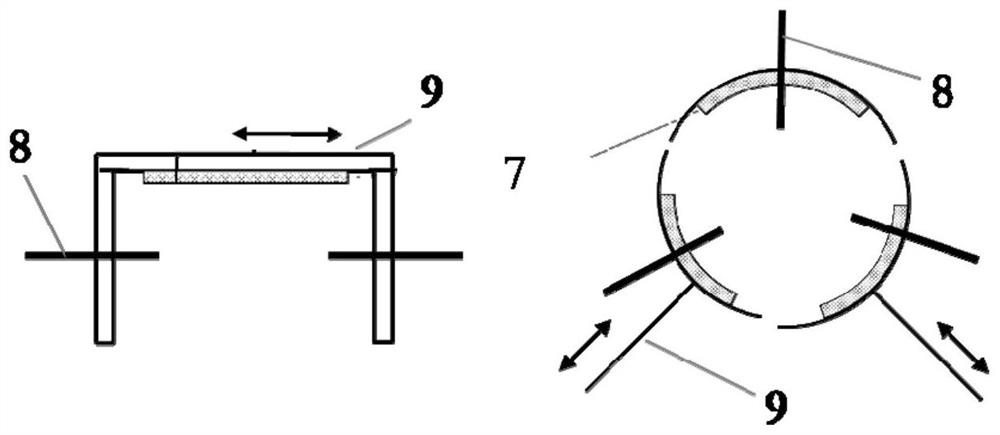

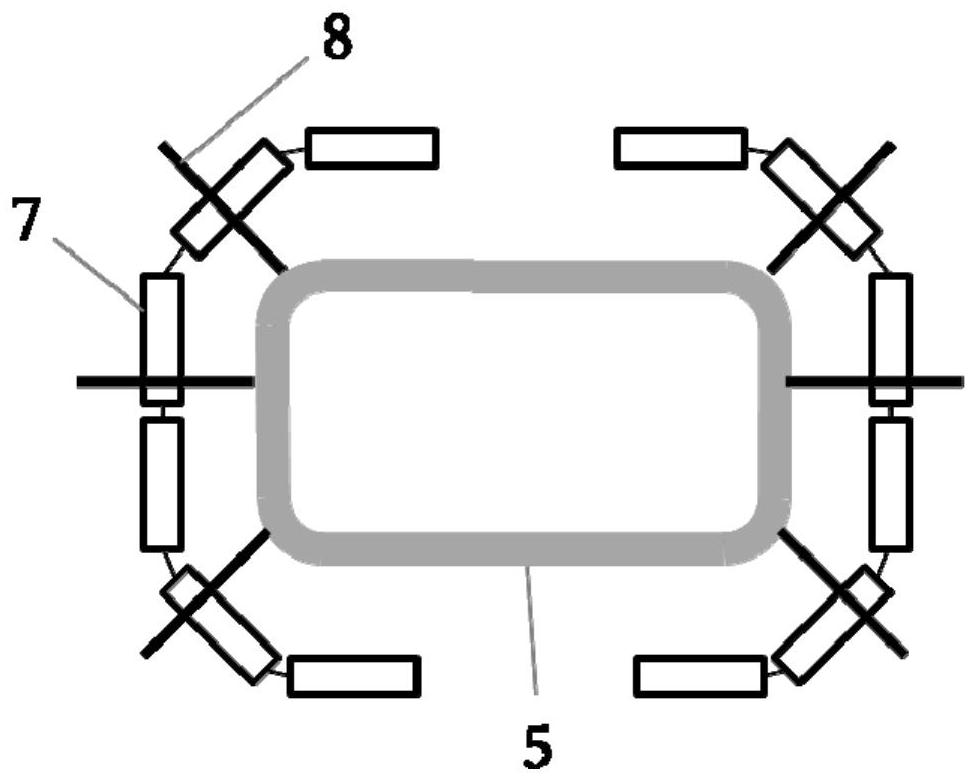

Auxiliary heating system and electron beam welding thermal cycle method

ActiveCN112958898AFulfill heating requirementsEasy to shapeElectron beam welding apparatusThermal insulationHeat stress

The embodiment of the invention provides an auxiliary heating device and an electron beam welding thermal cycle method. The auxiliary heating device comprises a heating cover, a control device and a thermal insulation layer, and the heating cover is used for being arranged above a workpiece in a sleeving manner. The thermal insulation layer is fixed between a rotary table and the workpiece, and a top cover plate of the heating cover is movably arranged. The auxiliary heating device is designed in electron beam welding equipment, a stable and uniform preheating temperature field is provided for welding materials and the workpiece before welding, the heating requirements of planar, annular and complex workpiece structures can be met, the use requirements of frequent and transient vacuum circulation heating can be met, and preconditions can be provided for subsequent reduction of welding heat input; and the control device is arranged, under the preheating condition, electron beam welding parameters are adjusted, heat cycle regulation and control of electron beam welding are achieved, the cooling speed and the temperature gradient of welding are reduced, surface forming of a weld joint is improved, welding heat stress and residual stress are reduced, and the probability of crack generation is reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

A wire bonding process for semiconductor power device packaging

ActiveCN105458434BNo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

Novel LED panel light with modified heat dissipation for clean rooms

InactiveCN103277699ASimple structureAvoid accumulationPoint-like light sourceLighting heating/cooling arrangementsLight guideEngineering

The invention relates to a novel LED panel light with modified heat dissipation for clean rooms. The novel LED panel light with the modified heat dissipation comprises two LED light bars, a heat-dissipation body and a shell shaped in a flat box. The two LED light bars are parallelly arranged, the heat-dissipation body is used for dissipating heat of the LED light bars, and the shell shaped in the flat box is used for holding the LED light bars and the heat-dissipation body. A light guide panel is arranged between two LED light bars. The heat-dissipation body comprises two first heat-dissipation panels arranged on two sides of the light guide panel, each LED light bar comprises a PCB (printed circuit board) and an LED light bead arranged on the PCB, and the PCBs and the LED light beads which correspond to two LED light bars are sequentially arranged on the first heat-dissipation panels and face to the light guide panel. The novel LED panel light with the modified heat dissipation is characterized in that the heat-dissipation body further comprises a second heat-dissipation panel which is perpendicular to the two first heat-dissipation panels and arranged at the back of the light guide panel and the inner side of a back panel, and heat-dissipation columns are arranged on the second heat-dissipation panel and face to one side of the back panel. By the arrangement of a novel cylindrical heat-dissipation structure on the outer side of the second heat-dissipation panel, directions and angles of the heat dissipation are enlarged, and speed and effect of the heat dissipation are improved. Since the shell is of a sealed structure less prone to accumulation of dust, the novel LED panel light is especially adaptable to using of the clean rooms.

Owner:SUZHOU NEWASIA SCI & TECH

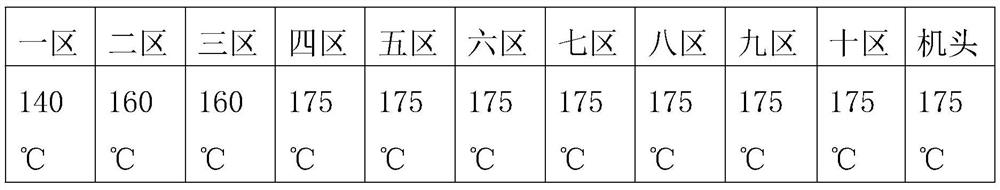

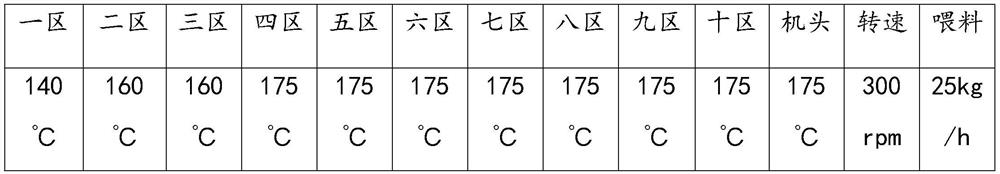

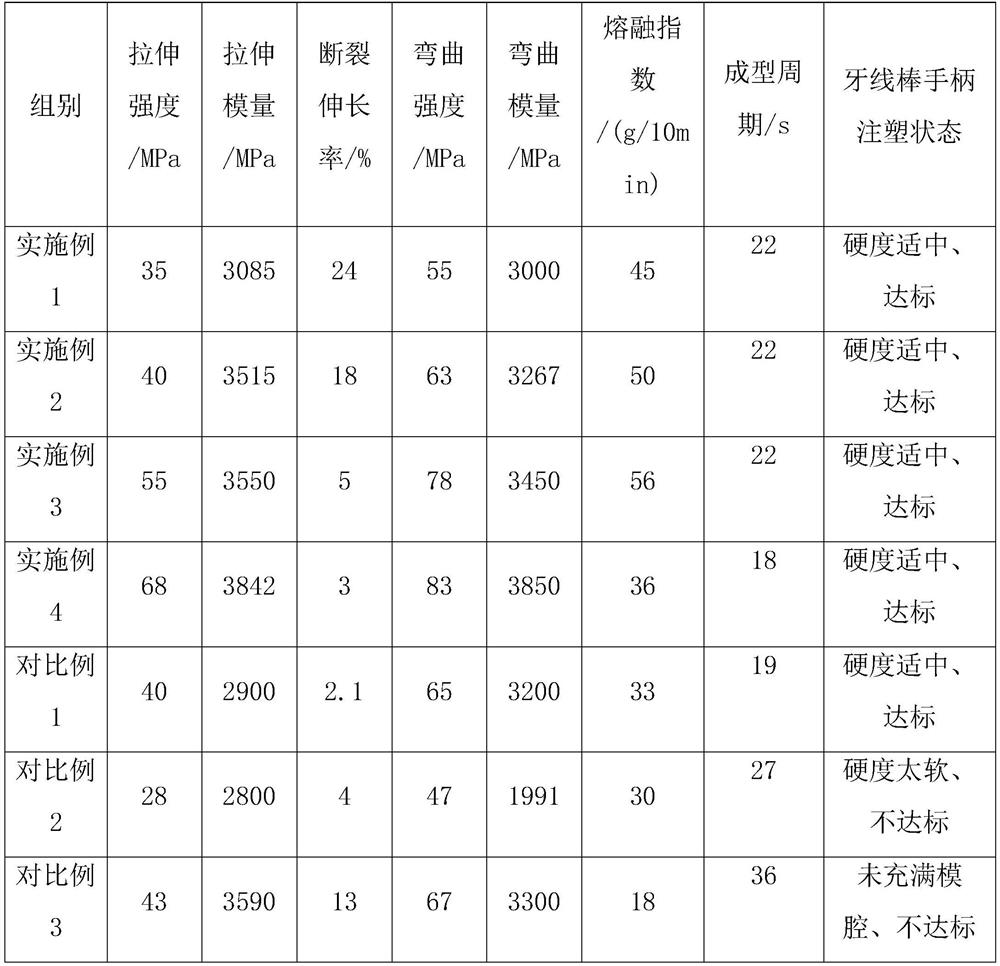

Biodegradable material for dental floss pick handle and preparation method of biodegradable material

The invention discloses a biodegradable material for a dental floss pick handle and a preparation method of the biodegradable material. The biodegradable material is prepared from the following substances in parts by weight: 45-95 parts of polylactic acid, 5-25 parts of poly(butylene succinate-co-terephthalate), 0-35 parts of an inorganic filler, 0.1-0.5 part of a lubricant, 0.1-0.5 part of a dispersing agent, 0.5-5 part of a plasticizer, 0.3-2 part of a nucleating agent and 0.1-0.4 part of an antioxidant. The dental floss rod handle has the characteristics of good fluidity, high cooling speedand short forming period during processing, and after being used and discarded, the dental floss rod handle made of the material can be decomposed into small molecular substances through bacteria inthe natural environment and finally decomposed into substances such as water and carbon dioxide, so that environmental pollution is avoided, meanwhile, the preparation method provided by the inventionis simple and feasible, has no complex equipment requirements, and is beneficial to large-scale production and application in the market.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

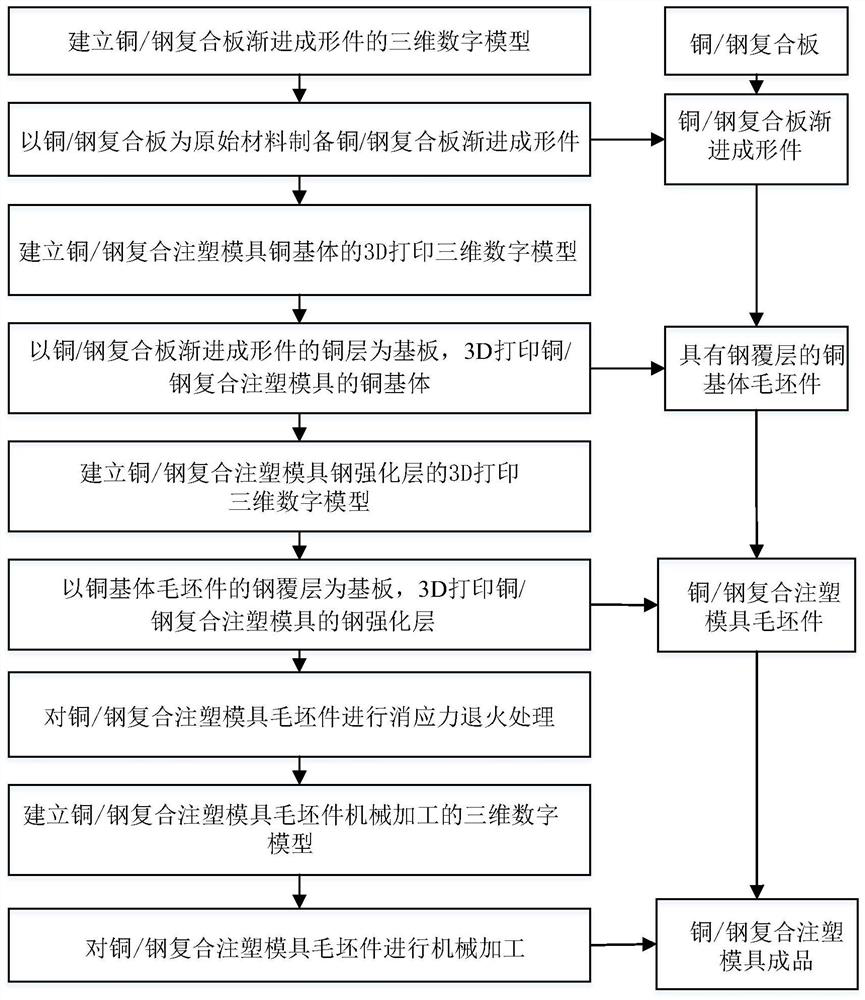

Additive manufacturing method for copper/steel composite injection mould

ActiveCN111715983ASolve the difficult problem of high-strength bondingUniform thicknessAdditive manufacturing apparatusPlasma welding apparatusLayer thicknessComposite plate

The invention discloses an additive manufacturing method for a copper / steel composite injection mould. The additive manufacturing method comprises the following steps of preparing a copper / steel composite plate incrementally formed part through an incremental forming method by taking a copper / steel composite plate as raw forming materials, and 3D-printing a copper base blank of the copper / steel composite injection mould by taking a copper layer of the copper / steel composite plate incrementally formed part as a baseplate; and finally 3D-printing a steel strengthened layer of the copper / steel composite injection mould by taking the copper base blank as a steel cladding. According to the additive manufacturing method, a high-strength copper / steel bonding interface of the copper / steel composite plate is transplanted into the copper / steel composite injection mould, and the problem that the copper base is hard to combine with the steel strengthened layer in the composite injection mould is solved; meanwhile, the contour of the copper / steel bonding interface in the copper / steel composite injection mould remains similar to the curved surface of a mould cavity, and the thickness of the steel strengthened layer is uniform; the whole manufacturing process is dieless forming, and the process is simple; and the high-quality and low-cost additive manufacturing of the copper / steel composite injection mould is achieved.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

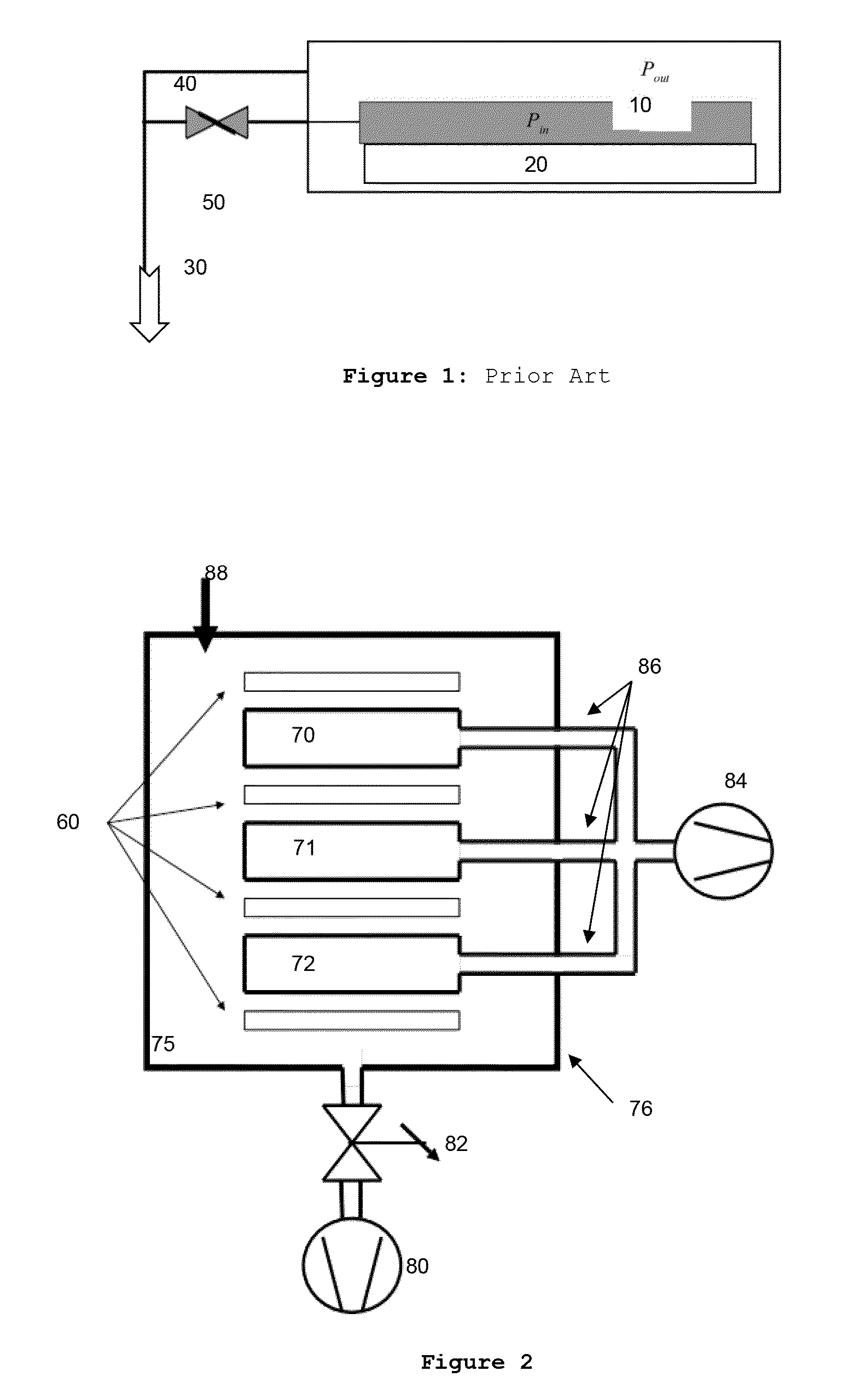

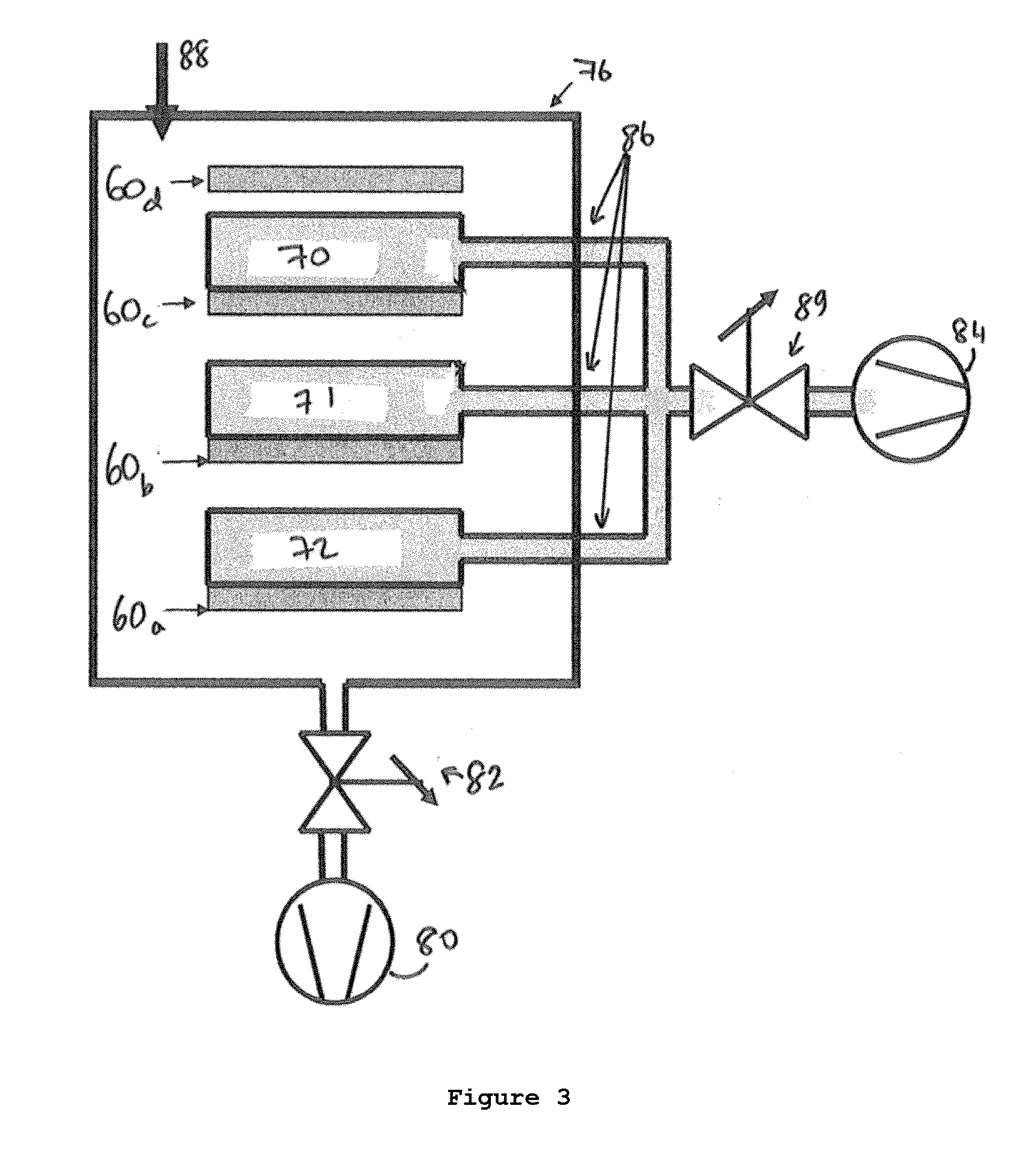

Heat transfer control in pecvd systems

InactiveUS20150010718A1Improve heat transfer performanceImprove thermal conductivityChemical vapor deposition coatingPlasma techniqueProduct gasEngineering

The invention relates to a method for manufacturing thin films on substrates, the method comprising providing a deposition system, said system comprising an inner non-airtight enclosure for containing at least one substrate and an outer airtight chamber completely surrounding said enclosure, and providing at least one substrate in the inner non-airtight enclosure. The inner non-airtight enclosure is maintained at a pressure lower than the pressure within said outer airtight chamber, and a backfilling gas comprising at least hydrogen or helium is introduced into the outer airtight chamber volume.

Owner:OERLIKON SOLAR AG (TRUEBBACH)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com