Detection method of gas reaction concentration and detection device

A technology of gas reaction and detection method, which is applied in measurement devices, analysis of gas mixtures, and air quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

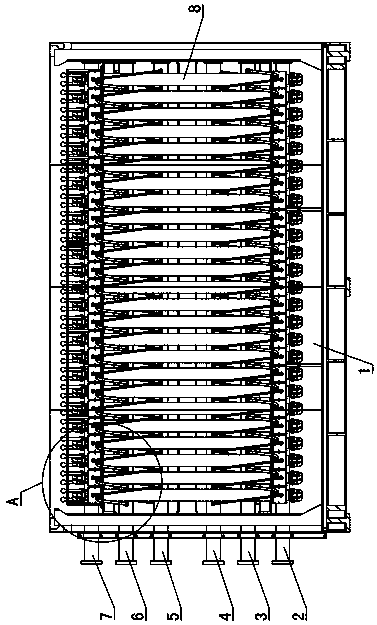

[0050] In this embodiment, the chemical reaction that takes place is that oxygen is converted into ozone through corona, and the chemical equation of the reaction is: 3O 2 =2O 3 .

[0051] The detection method of gas reaction concentration comprises the steps:

[0052] Step 1), under the same conditions, measure the total volume flow Q of the gas reactant before the reaction in real time 1 , where each gas reactant is input according to the ratio of the corresponding stoichiometric numbers in the chemical equation, and the total volume flow Q of the gas mixture after the reaction is measured in real time 2 ;

[0053] In this embodiment, the chemical reaction that occurs is a chemical reaction in which oxygen is converted into ozone. Under the same temperature and pressure conditions, the volume flow Q of the incoming gas is measured in real time 1 , real-time measurement of the volume flow Q of the discharged gas 2 . It can also measure the mass flow of the gas before t...

Embodiment 2

[0104] In this embodiment, the chemical reaction that takes place is that nitrogen and hydrogen are converted into ammonia through corona, and the chemical equation of the reaction is:

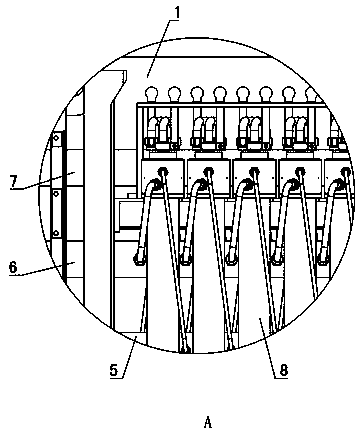

[0105] N 2 + 3H 2 ⇌2NH 3 . The mixed gas of nitrogen and hydrogen is led in through the inlet pipe 5, and the gas discharged from the outlet pipe 4 is a mixed gas of nitrogen, hydrogen and ammonia.

[0106] The detection method of gas reaction concentration comprises the steps:

[0107] Step 1), under the same conditions, measure the total volume flow Q of the gas reactant before the reaction in real time 1 , where each gas reactant is input according to the ratio of the corresponding stoichiometric numbers in the chemical equation, and the total volume flow Q of the gas mixture after the reaction is measured in real time 2 ;

[0108] In this embodiment, the chemical reaction that takes place is the conversion of nitrogen and hydrogen into ammonia by corona. Under the same temperature ...

Embodiment 3

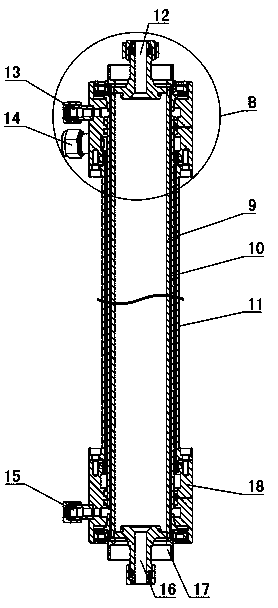

[0124] The difference between embodiment 3 and embodiment 1 is that the voltage inside and outside the gas channel is 2000V, and the gas flow rate is 4m 3 / h, so that the ozone concentration contained in the oxygen through the reaction tube 8 is at 500g / m 3 above. The inner coolant is cooling water, and the outer coolant is cooling oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com