Additive manufacturing method for copper/steel composite injection mould

A technology of injection mold and additive manufacturing, which is applied in the direction of manufacturing tools, additive processing, plasma welding equipment, etc., can solve the problems of high-strength bonding, copper/steel interface bonding strength is difficult to meet the requirements, etc., and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

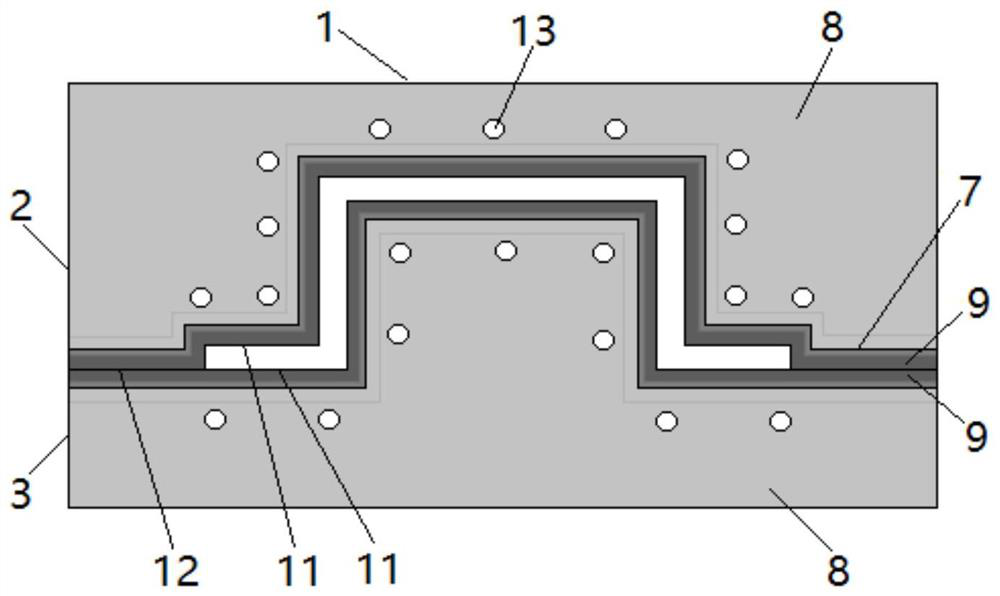

[0032] The present invention will be further described below in conjunction with accompanying drawing.

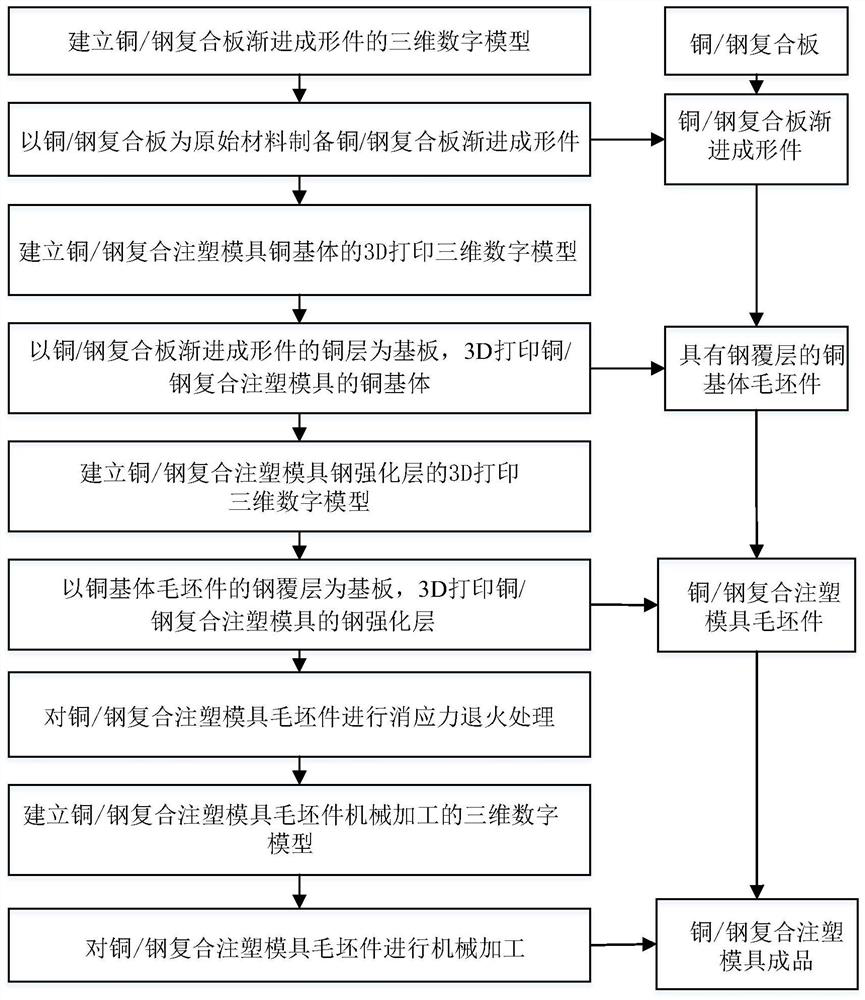

[0033] The invention provides a method for additive manufacturing of a copper / steel composite injection mold based on the progressive forming technology of composite plates. The manufacturing process is as follows figure 1 As shown, the high-strength bonding of the copper / steel interface in the copper / steel composite injection mold is achieved, and the profile of the copper / steel interface remains similar to the surface of the mold cavity.

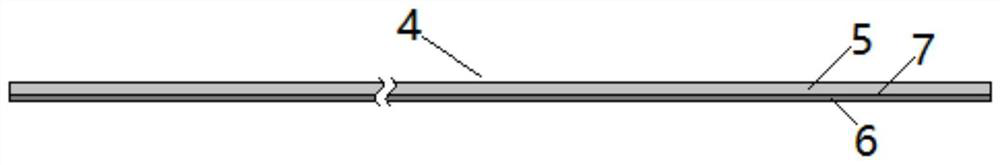

[0034] The invention adopts the copper / steel composite plate whose bonding strength of the copper / steel interface is close to or exceeds that of the copper base material as the original forming material to solve the problem that the copper matrix and the steel reinforcement layer are difficult to form a high-strength interface bond in the manufacture of the copper / steel composite injection mold. The copper / steel composite plate is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com