Biodegradable material for dental floss pick handle and preparation method of biodegradable material

The technology of biodegradable material and dental floss stick is applied in the field of biodegradable material of dental floss stick handle and its preparation field, which can solve the problems of increasing product production cycle, reducing production efficiency, poor melt fluidity, etc. The effect of improving athletic ability and short molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

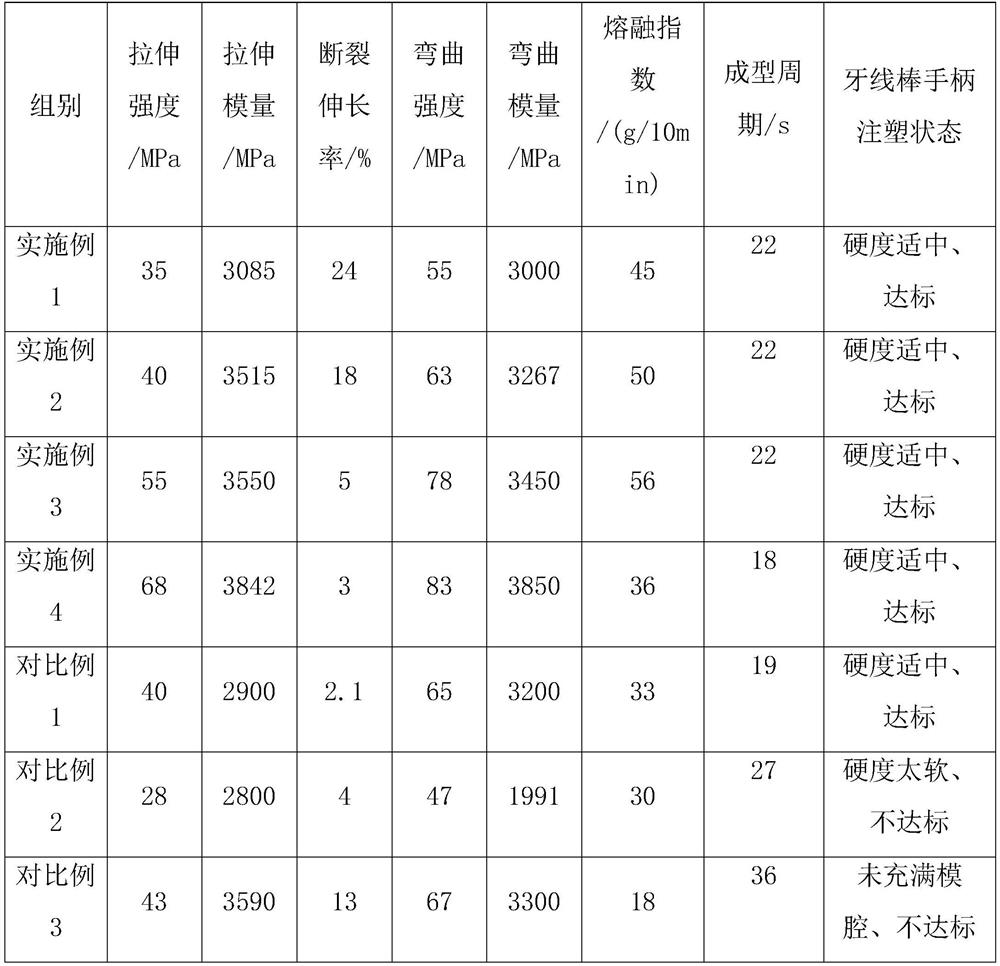

Examples

Embodiment 1

[0030] Step 1: Weigh 45kg polylactic acid, 25kg polyterephthalic acid-succinic acid-butylene glycol ester T, 0.05kg white oil, 0.4kg interacid amide, 0.3kg calcium stearate, 5kg citric acid according to the proportion Tributyl ester, 2kg potassium benzenesulfonate, 0.3kg phenolic antioxidant, 30kg talcum powder;

[0031] Step 2: Send polylactic acid, polybutylene terephthalate-succinate-butylene glycol ester and white oil into the mixer and stir evenly Step 2;

[0032] Step 3: Continue to add interacid amide, calcium stearate, tributyl citrate, phenolic antioxidant and potassium benzenesulfonate to the mixer, and stir until uniform;

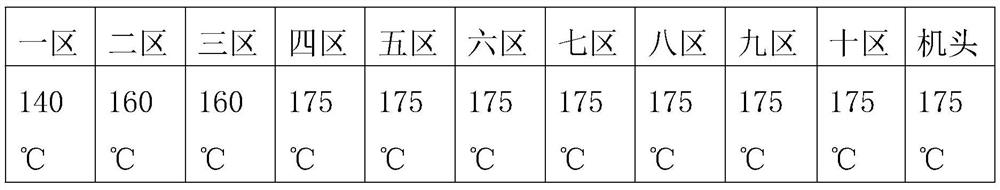

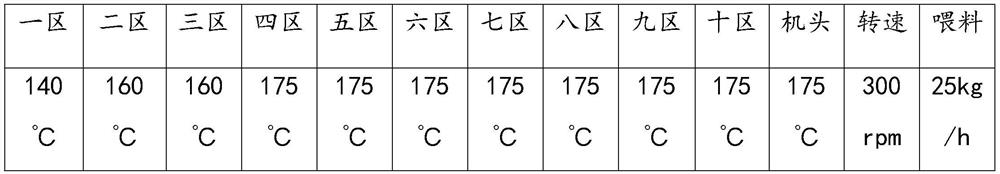

[0033] Step 4: Add talcum powder to the mixer, continue to stir until uniform, and then send it to the twin-screw extruder for extrusion and granulation. The temperature, rotation speed and feeding speed of the twin-screw extruder are set as follows:

[0034]

[0035] Step 5: After the raw material mixture is melted and extruded, it is sequen...

Embodiment 2

[0037] Step 1: Weigh 50kg polylactic acid, 20kg polyterephthalic acid-succinic acid-butylene glycol ester T, 0.05kg white oil, 0.4kg interacid amide, 0.3kg calcium stearate, 3kg citric acid according to the proportion Tributyl ester, 1kg potassium benzenesulfonate, 0.3kg phenolic antioxidant, 30kg talcum powder;

[0038] Step 2: Send polylactic acid, polybutylene terephthalate-succinate-butylene glycol ester and white oil into the mixer and stir evenly Step 2;

[0039] Step 3: Continue to add interacid amide, calcium stearate, tributyl citrate, phenolic antioxidant and potassium benzenesulfonate to the mixer, and stir until uniform;

[0040] Step 4: Add talcum powder to the mixer, continue to stir until uniform, and then send it into a twin-screw extruder for extrusion and granulation. The subsequent preparation method is the same as in Example 1.

Embodiment 3

[0042] Step 1: Weigh 60kg polylactic acid, 5kg polyterephthalate-succinate-butylene glycol T, 0.05kg white oil, 0.4kg interacid amide, 0.3kg calcium stearate, 1.5kg lemon Acetate tributyl ester, 0.8kg potassium benzenesulfonate, 0.3kg phenolic antioxidant, 35kg talcum powder;

[0043] Step 2: Send polylactic acid, polybutylene terephthalate-succinate-butylene glycol ester and white oil into the mixer and stir evenly Step 2;

[0044] Step 3: Continue to add interacid amide, calcium stearate, tributyl citrate, phenolic antioxidant and potassium benzenesulfonate to the mixer, and stir until uniform;

[0045] Step 4: Add talcum powder to the mixer, continue to stir until uniform, and then send it into a twin-screw extruder for extrusion and granulation. The subsequent preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com