Semiconductor underlay and production method and its application on silicon and extension of insulator

A semiconductor and substrate technology, applied in the field of microelectronics and solid-state electronics, and silicon-based integrated optoelectronic device materials, can solve problems such as harmful device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

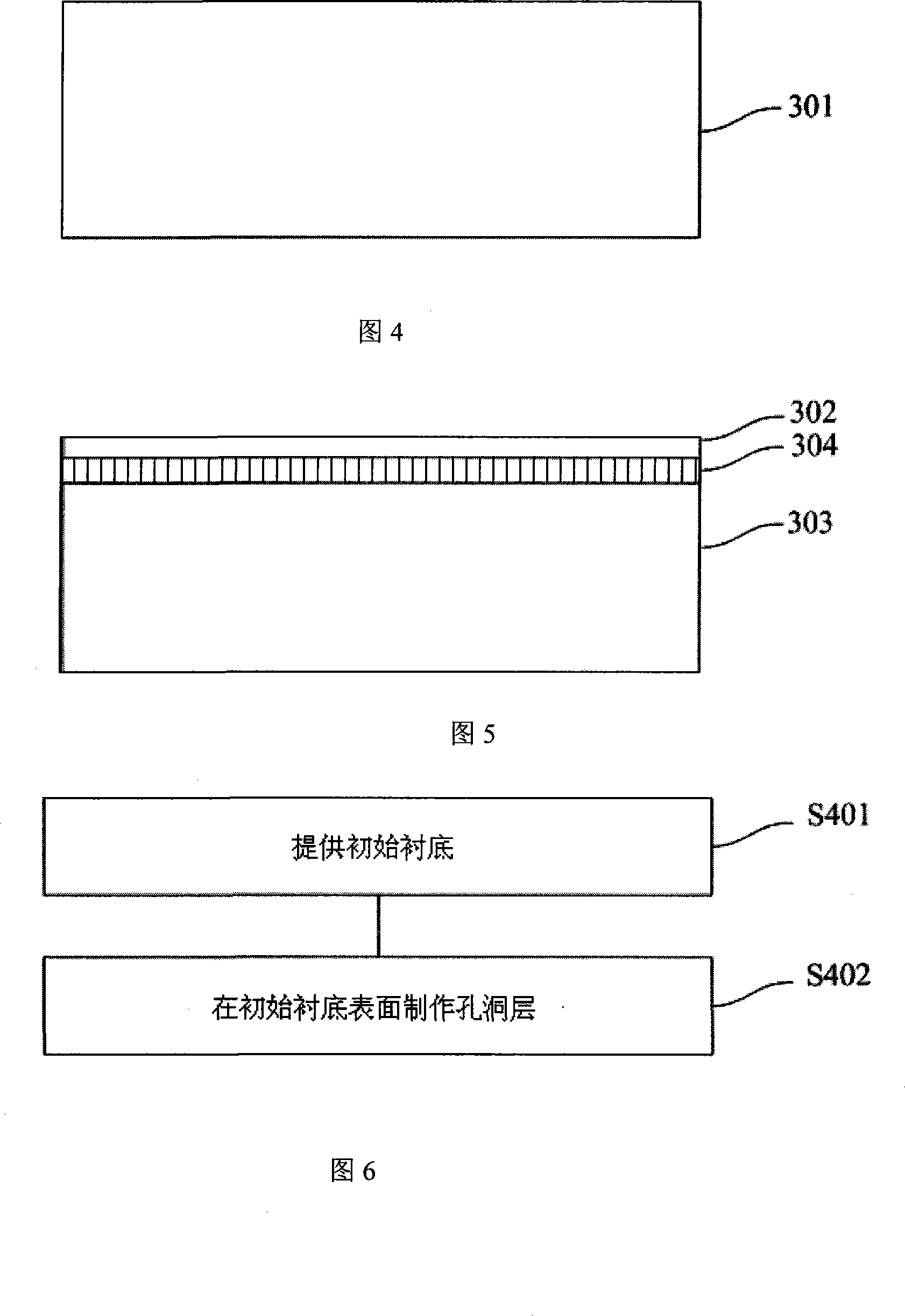

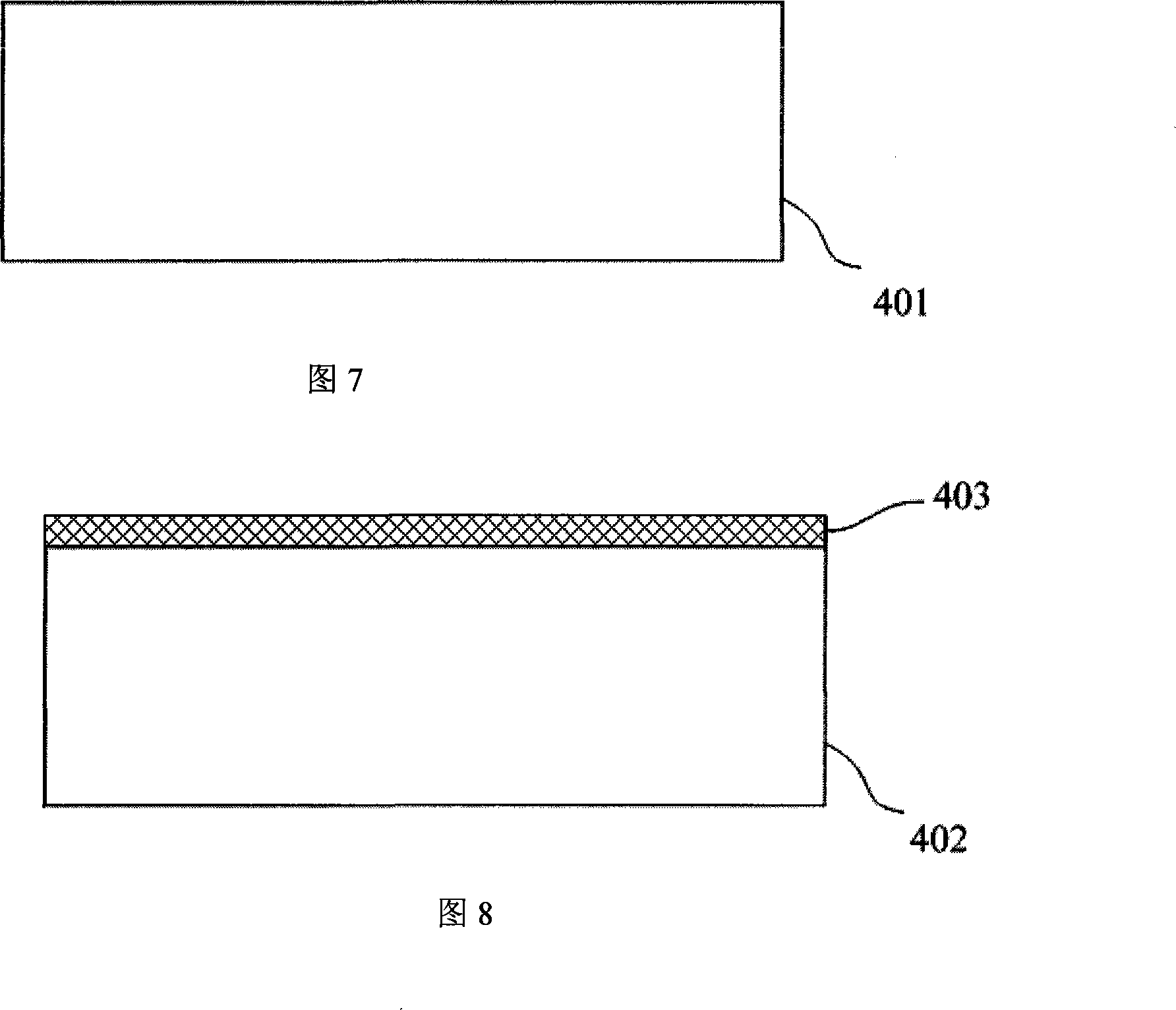

[0076] Below in conjunction with accompanying drawing, the semiconductor substrate described in the present invention, the preparation method of semiconductor substrate and the silicon material on thinning insulator and adopting this semiconductor substrate as the epitaxial substrate The specific implementation of the epitaxial gallium nitride material will be described in detail.

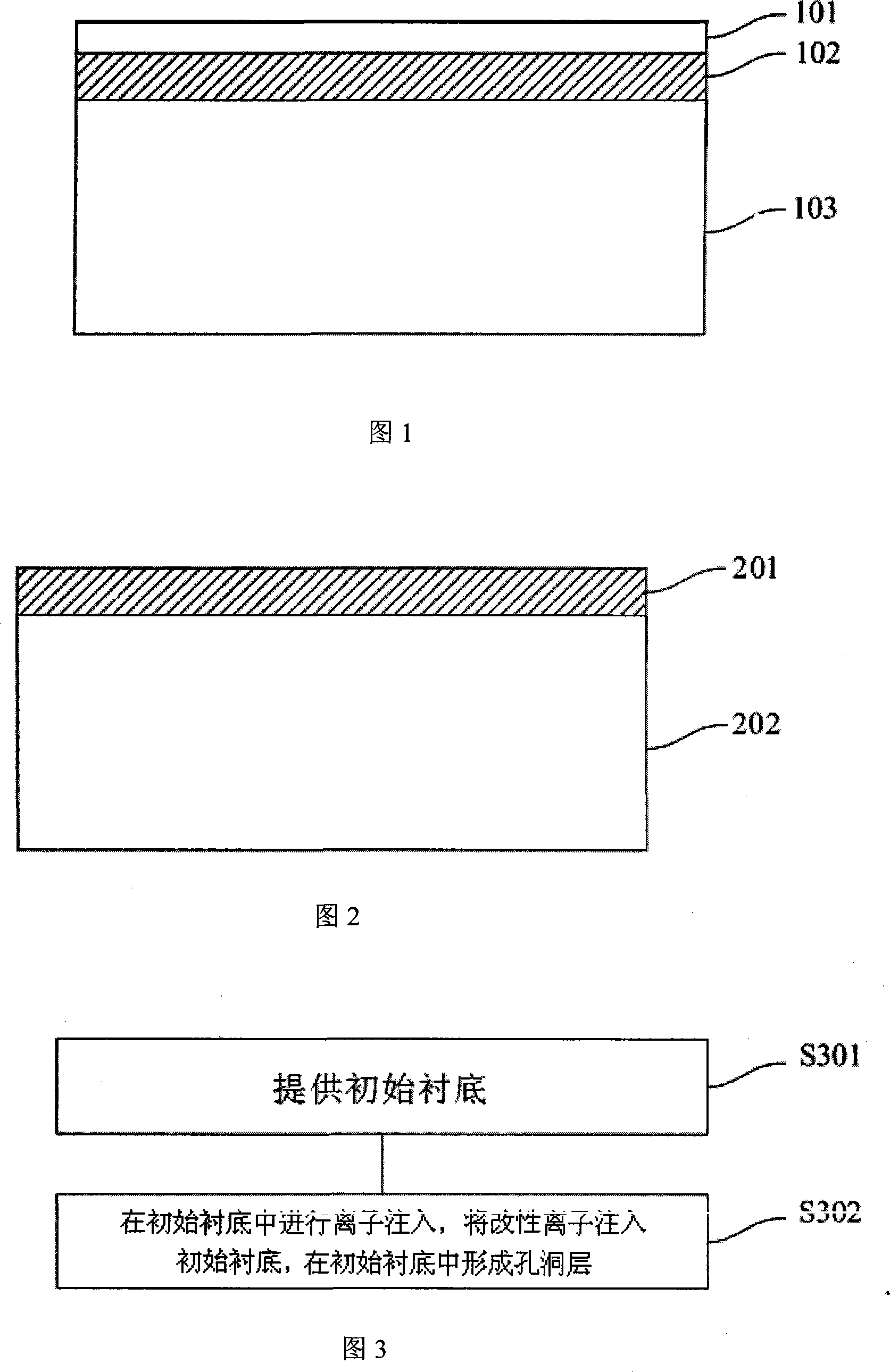

[0077] Firstly, the specific implementation manner of the semiconductor substrate described in the present invention will be introduced. FIG. 1 is a schematic diagram of a first embodiment of a semiconductor substrate, including a cover layer 101 , a hole layer 102 below the cover layer, and a support layer 103 below the hole layer.

[0078] The material of the hole layer 102 is porous silicon or single crystal silicon containing bubbles, the material of the covering layer 101 is single crystal silicon, and the material of the supporting layer 103 is single crystal silicon,

[0079] FIG. 2 is a sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com