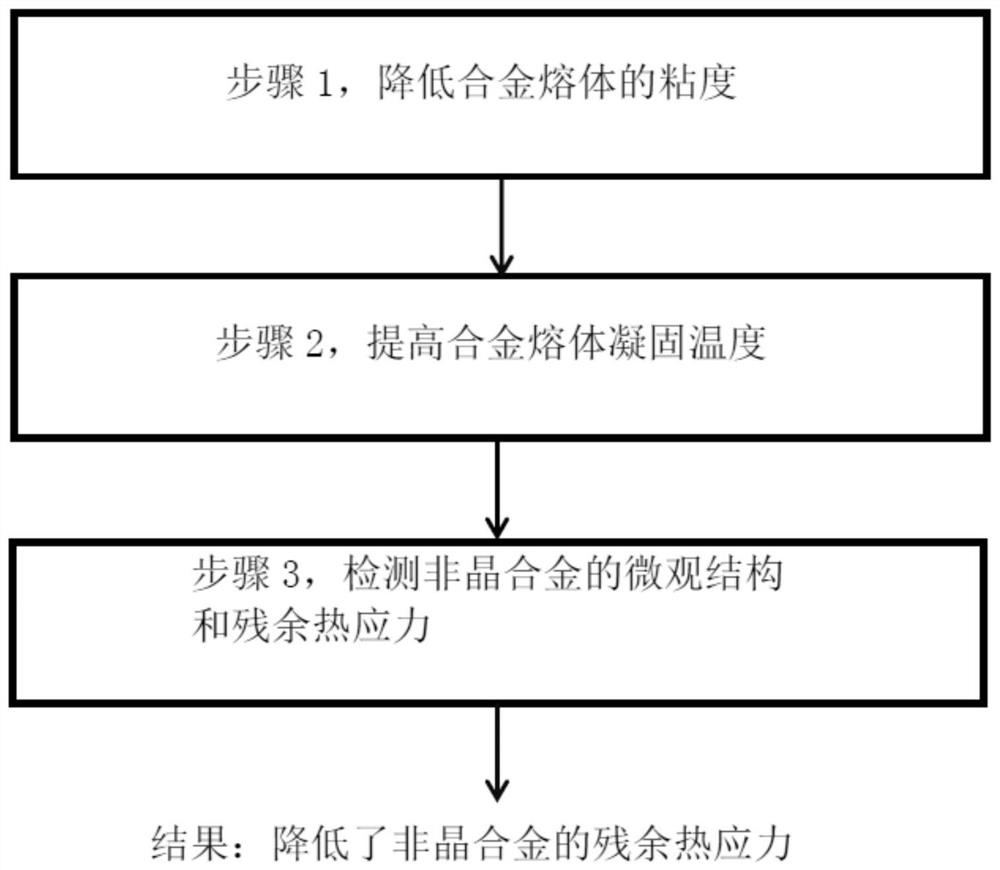

A process for preparing low residual thermal stress amorphous alloy

A technology of amorphous alloy and process method, applied in the field of preparing low residual thermal stress amorphous alloy, can solve the problems of not reducing the difference between the melt casting temperature and solidification temperature, reducing the residual thermal stress of amorphous alloy, etc. High maneuverability and repeatability, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

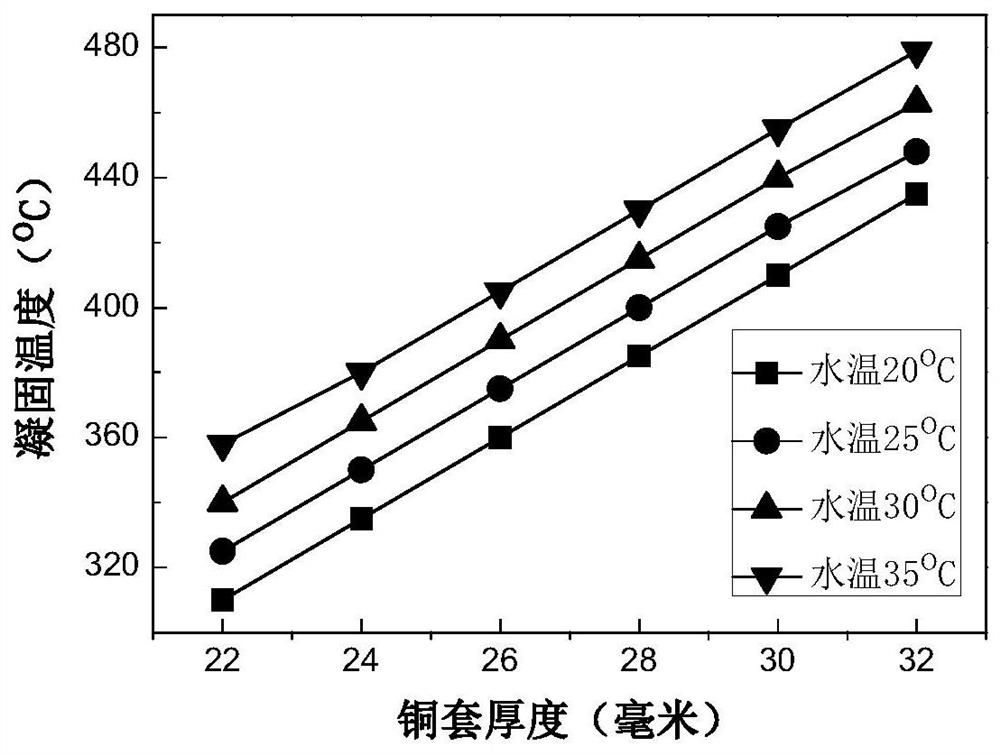

[0067] to prepare Fe 80 P X Si 15-X B 5 Amorphous alloy thin strip is example (the subscript number in the chemical formula is atomic percentage content at%), and the specific operation steps of a kind of processing method that the present invention proposes to reduce amorphous alloy thin strip thermal stress are as follows:

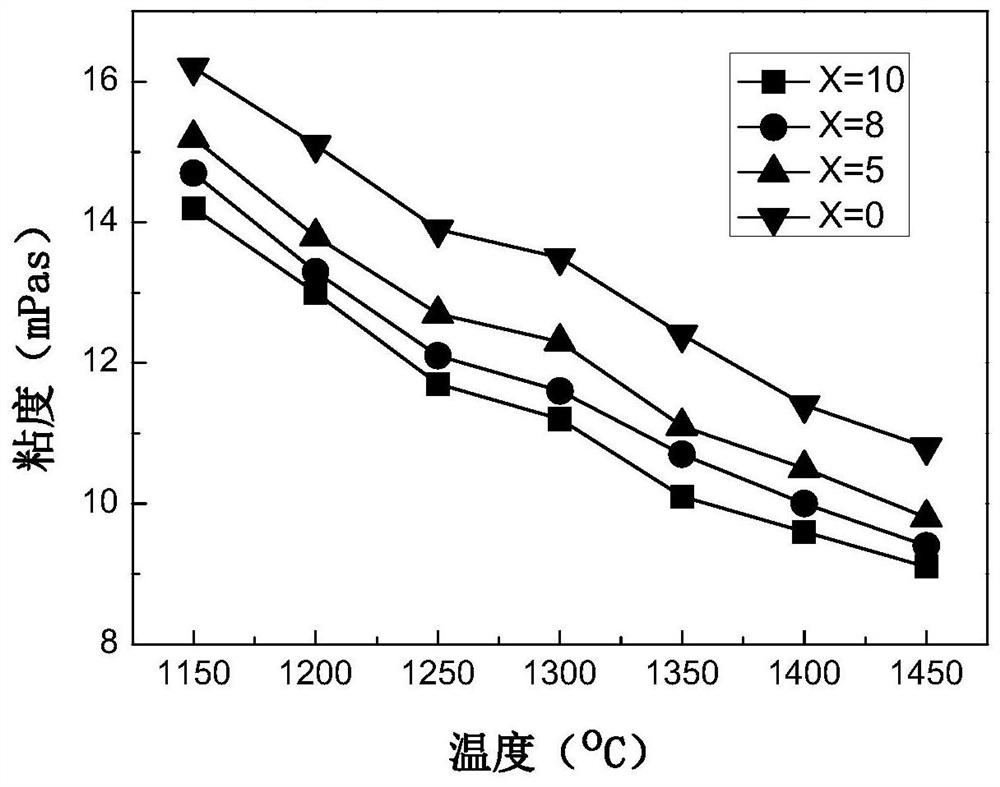

[0068] Step 1, reduce the viscosity of amorphous alloy melt:

[0069] (1) First prepare Fe according to the actual situation 80 Si 15 B 5 The requirements for the casting temperature of the alloy melt in the case of amorphous alloys determine that the casting temperature of the alloy melt is 1300°C. Will Fe 80 Si 15 B 5 The alloy melt was heated up to 1450°C, held for 1 hour, then cooled to 1300°C, held for another 1 hour, and then the viscosity of the alloy melt was measured by a high-temperature viscosity measuring instrument (product of GBX company, model: Viscodrop 2000) to obtain the alloy melt The viscosity value at the casting temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com