Patents

Literature

114 results about "Borazine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

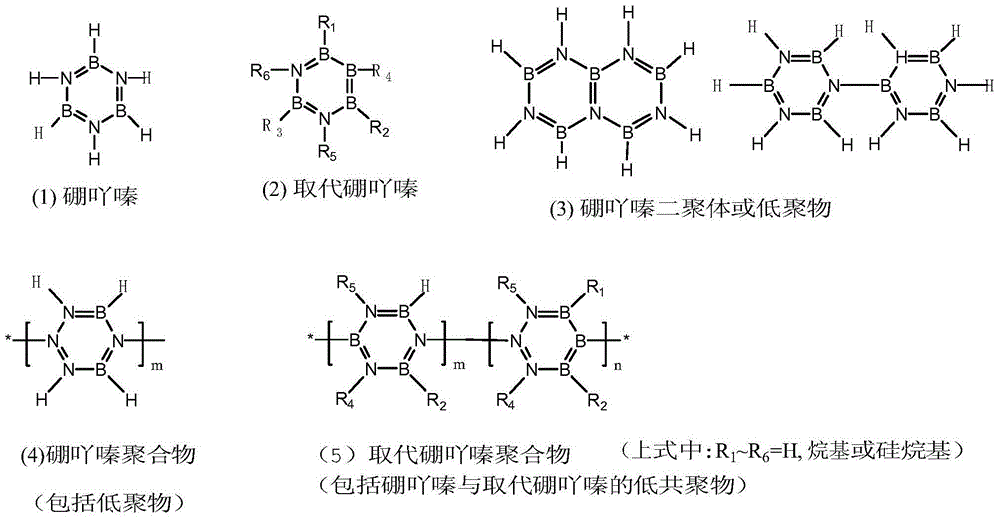

Borazine is a polar inorganic compound with the chemical formula B₃H₆N₃. In this cyclic compound, the three BH units and three NH units alternate. The compound is isoelectronic and isostructural with benzene. For this reason borazine is sometimes referred to as “inorganic benzene”. Like benzene, borazine is a colourless liquid.

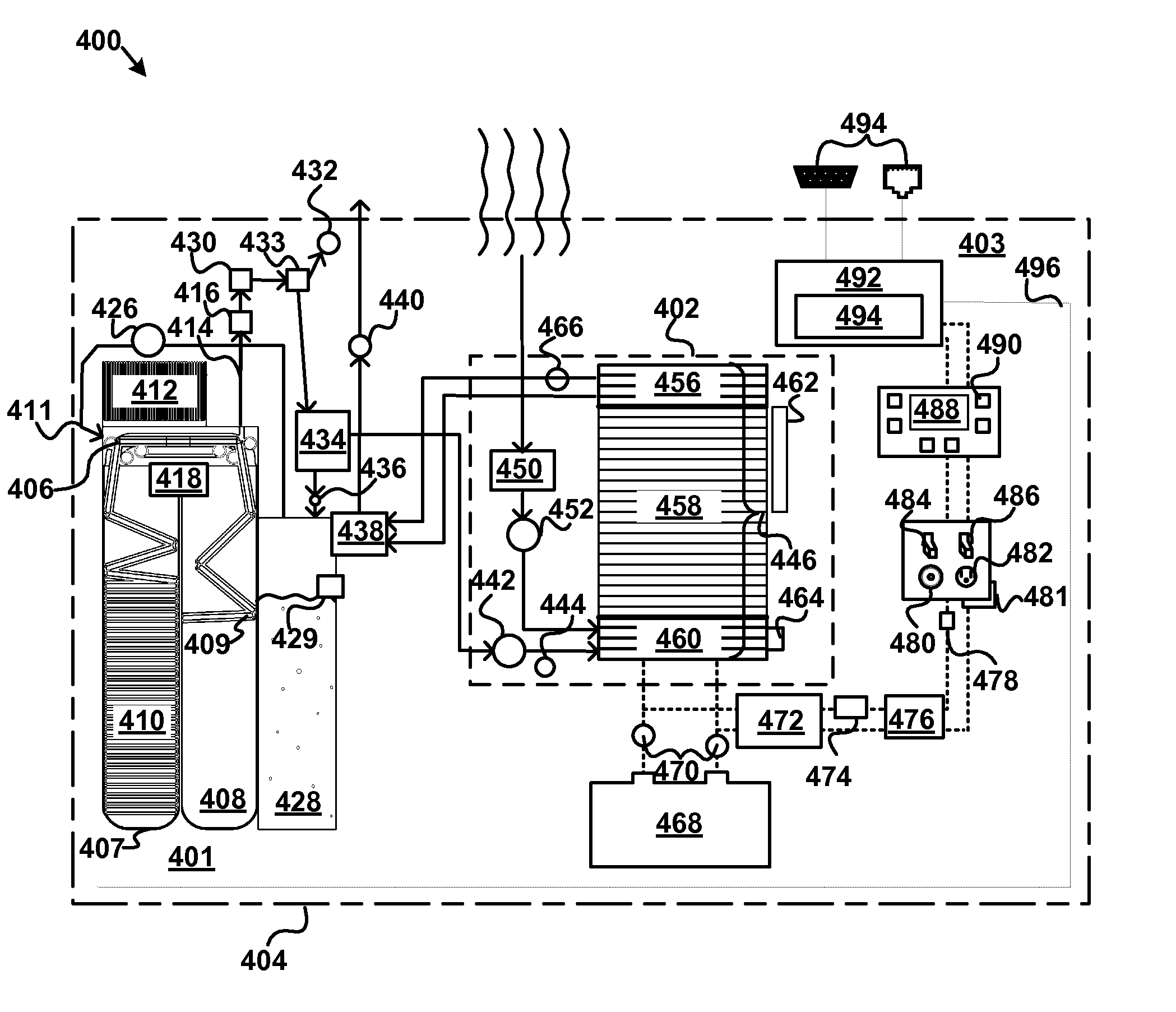

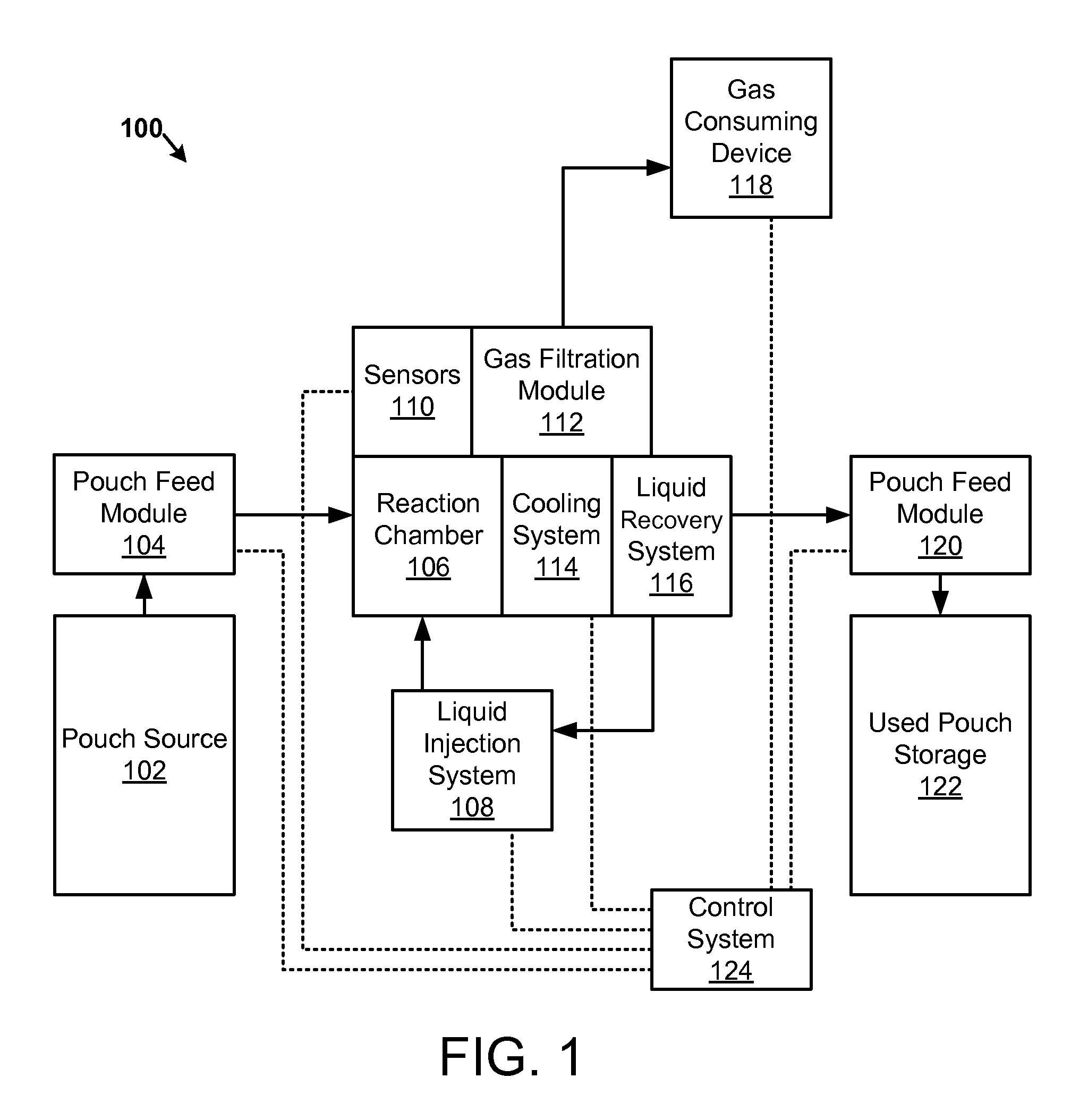

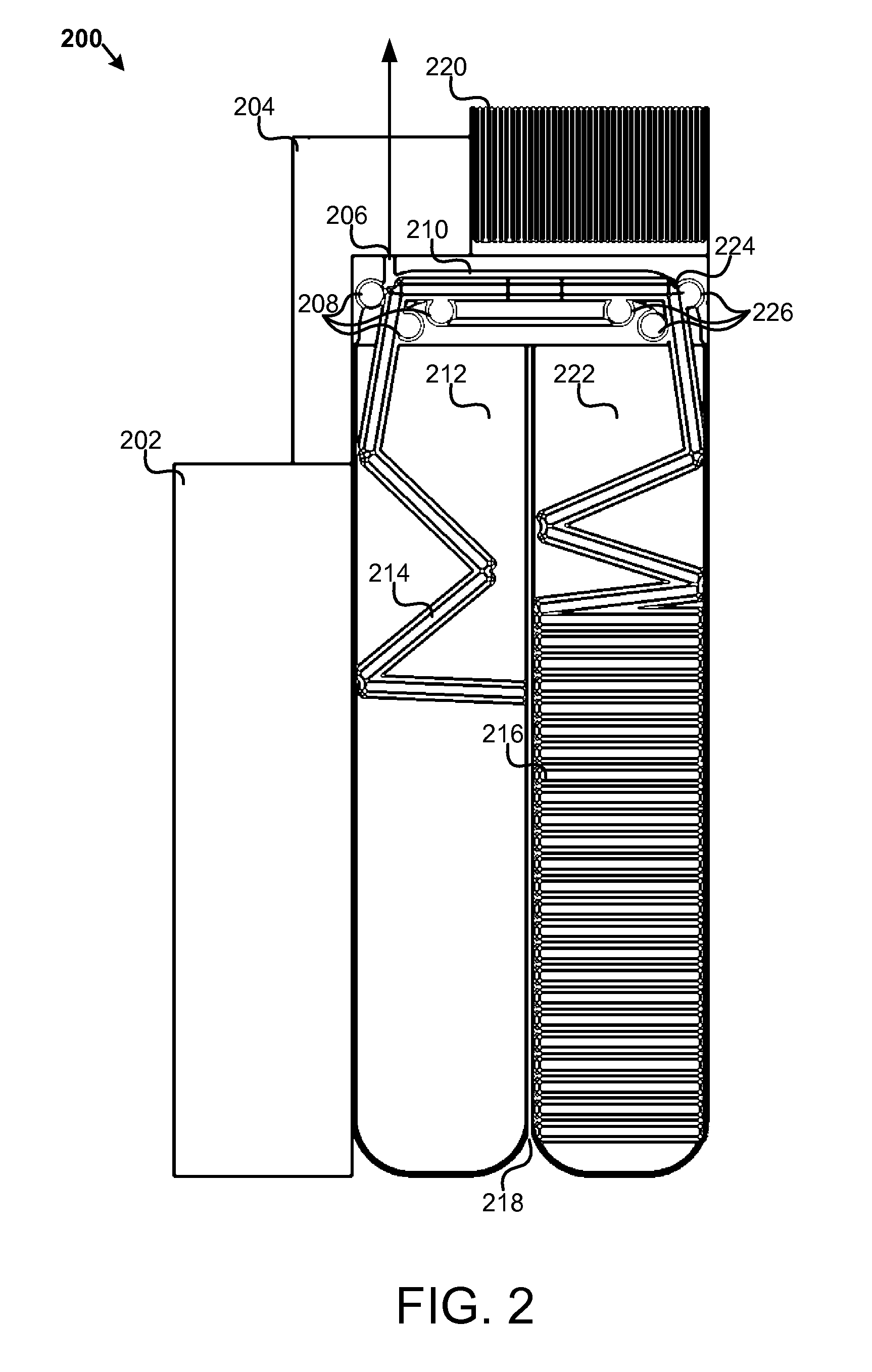

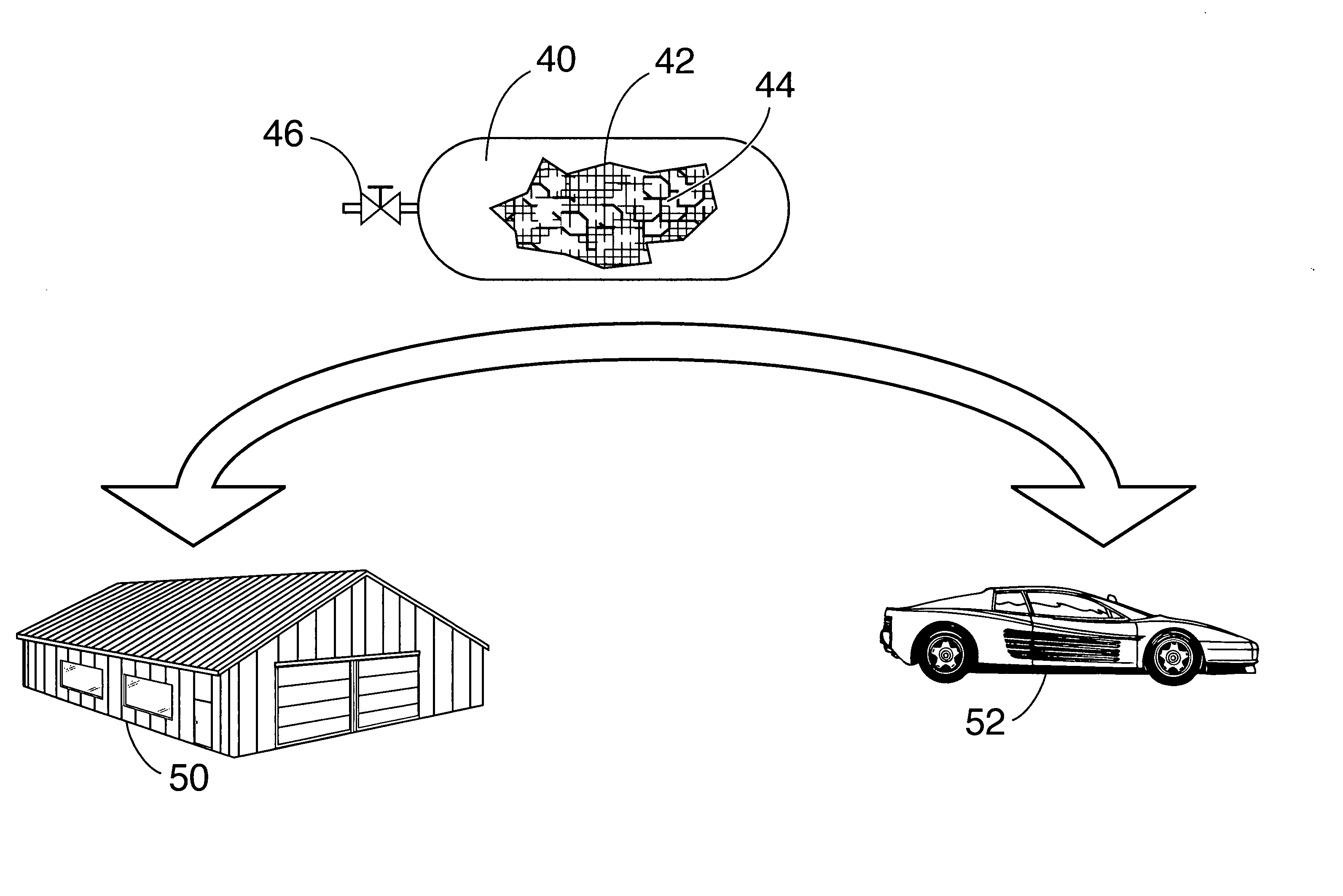

Apparatus, system, and method for generating a gas from solid reactant pouches

An apparatus, system, and method are disclosed for generating a gas. One or more liquid permeable pouches each define a cavity that contains a solid anhydrous reactant, such as a chemical hydride. A reaction chamber made of a heat, chemical and / or pressure resistant material receives the one or more pouches from a pouch feeder that transfers the one or more pouches into the reaction chamber successively at a feed rate. One or more liquid sources inject a liquid reactant into the reaction chamber so that the liquid reactant contacts a portion of the one or more pouches. The one or more liquid sources inject the liquid reactant at an injection rate that corresponds to the feed rate. A gas outlet releases a gas, such as hydrogen, oxygen, ammonia, borazine, nitrogen, or a hydrocarbon, that is produced by a reaction between the solid reactant and the liquid reactant.

Owner:TRULITE INC

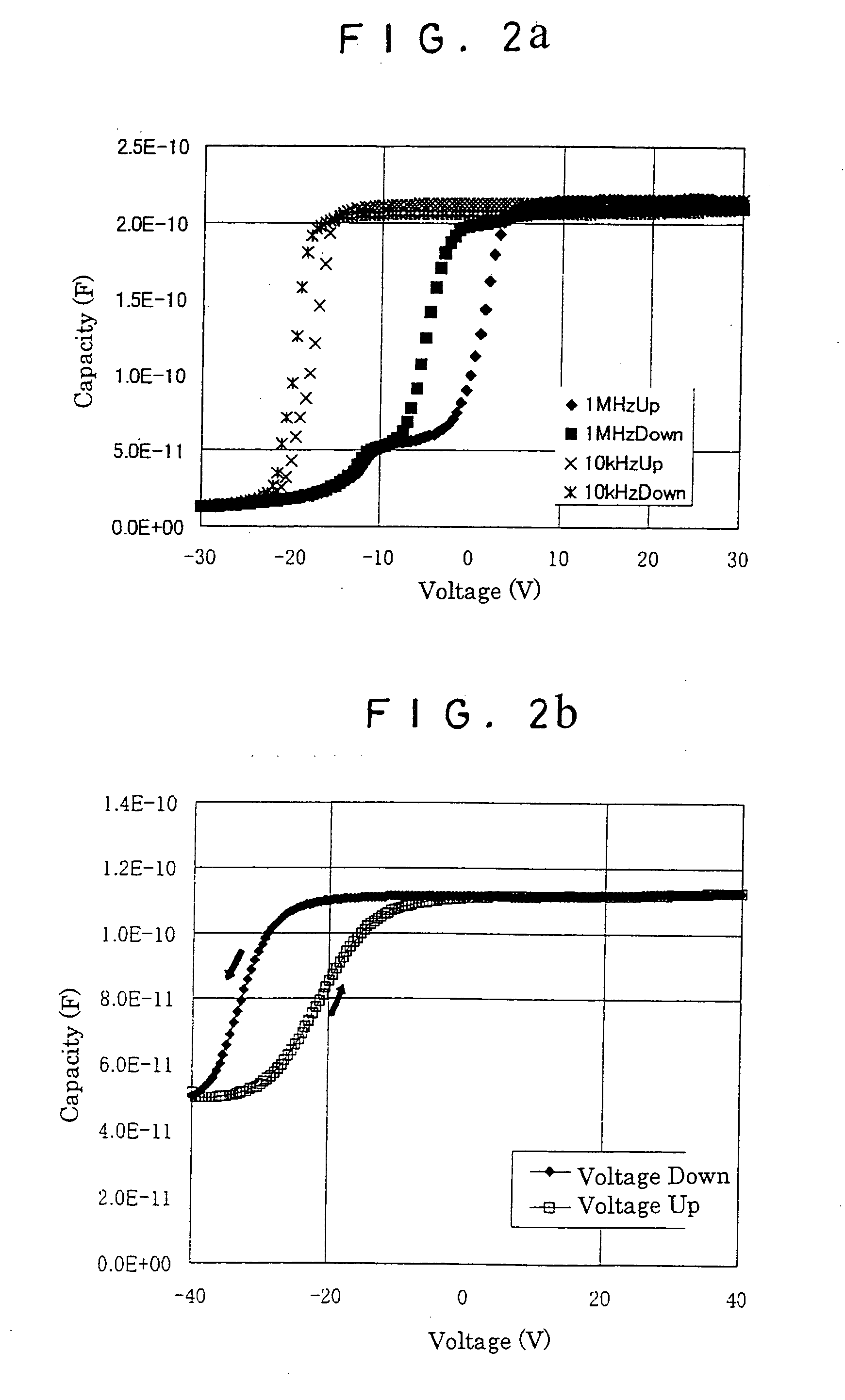

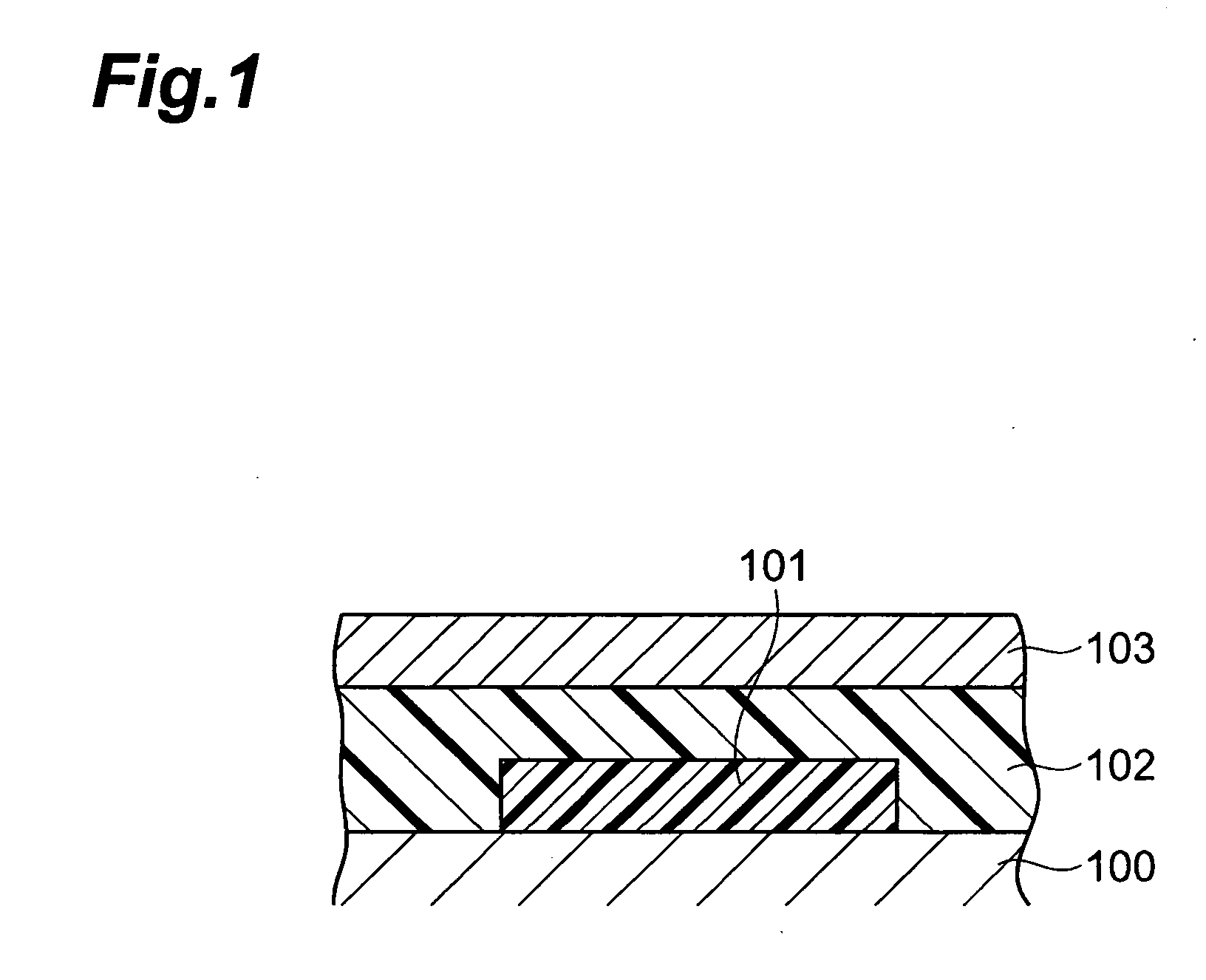

Low dielectric constant insulating material and semiconductor device using the material

ActiveUS20060097393A1Increase in parasitic capacityDecrease of throughput speed can be preventedLayered productsSemiconductor/solid-state device detailsElectricityParasitic capacitance

The use of a material possessing a six-member borazine ring consisting of at least boron and nitrogen elements in the form of a low dielectric constant insulating film in a hard mask, a Cu diffusion barrier layer and an etching stopper which are necessary when low dielectric constant interlayer insulating films and Cu wiring in the multilayer interconnection of an LSI allows the parasitic capacity between the multilayer wirings to be suppressed and enables the ULSI to produce a high-speed operation.

Owner:HITACHI CHEM CO LTD

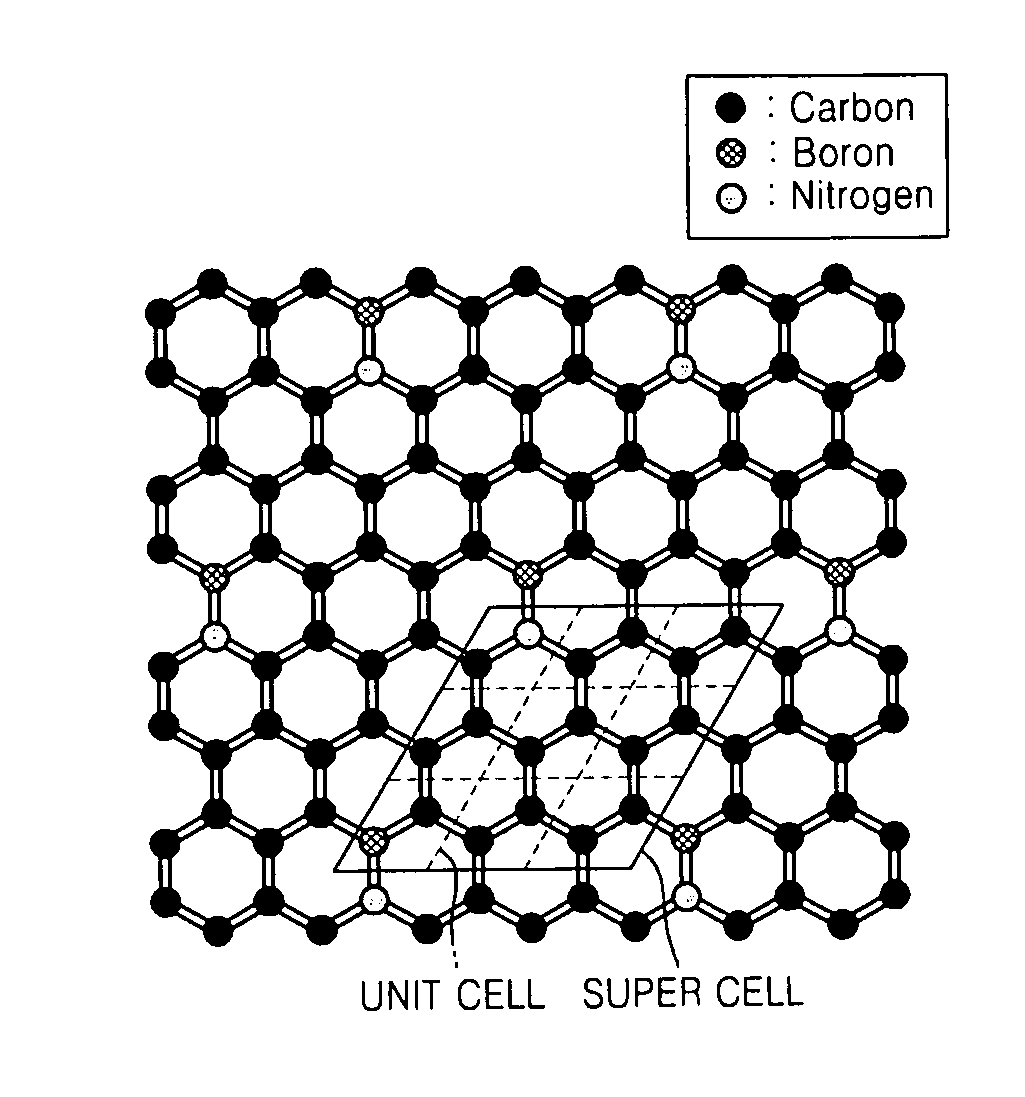

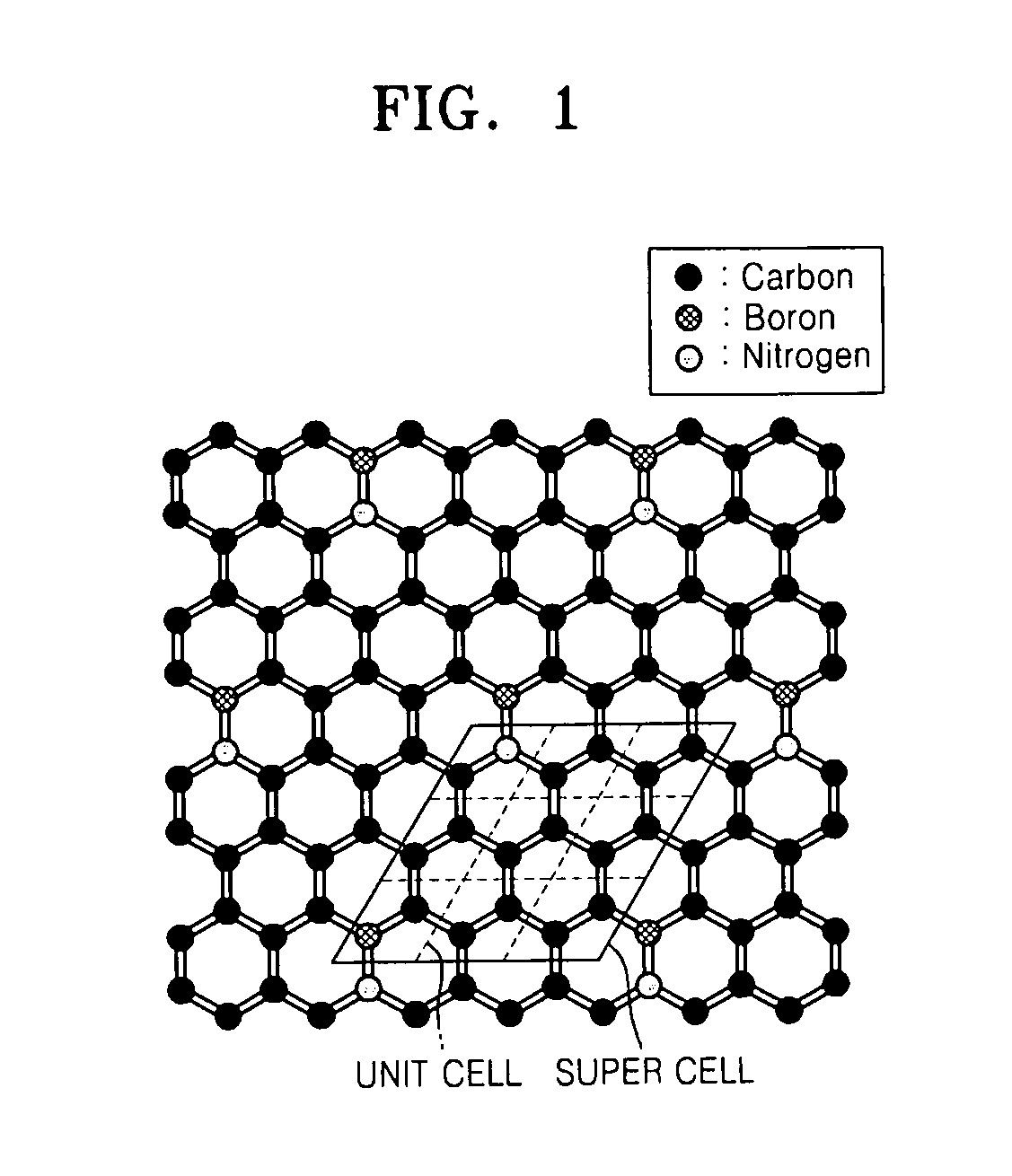

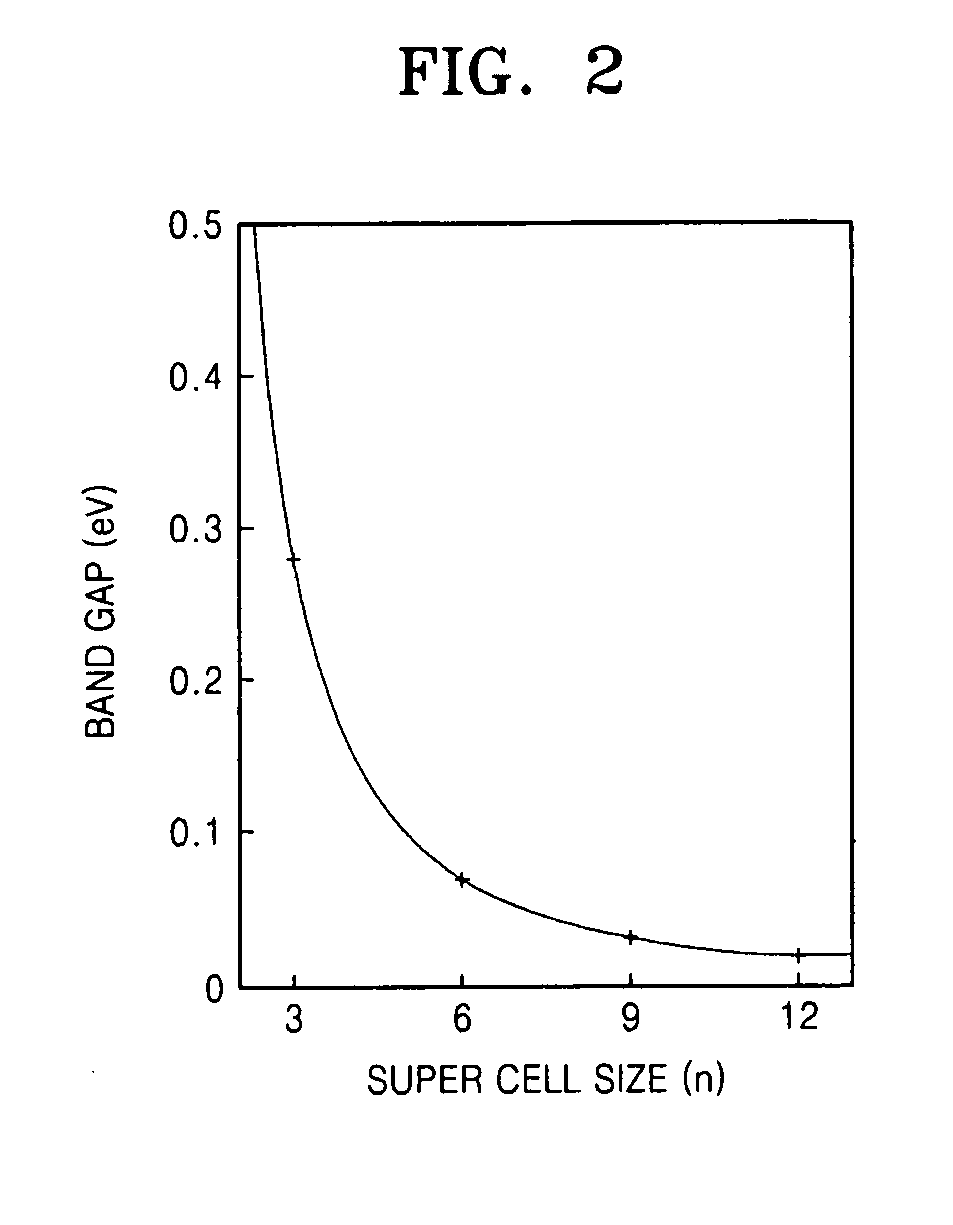

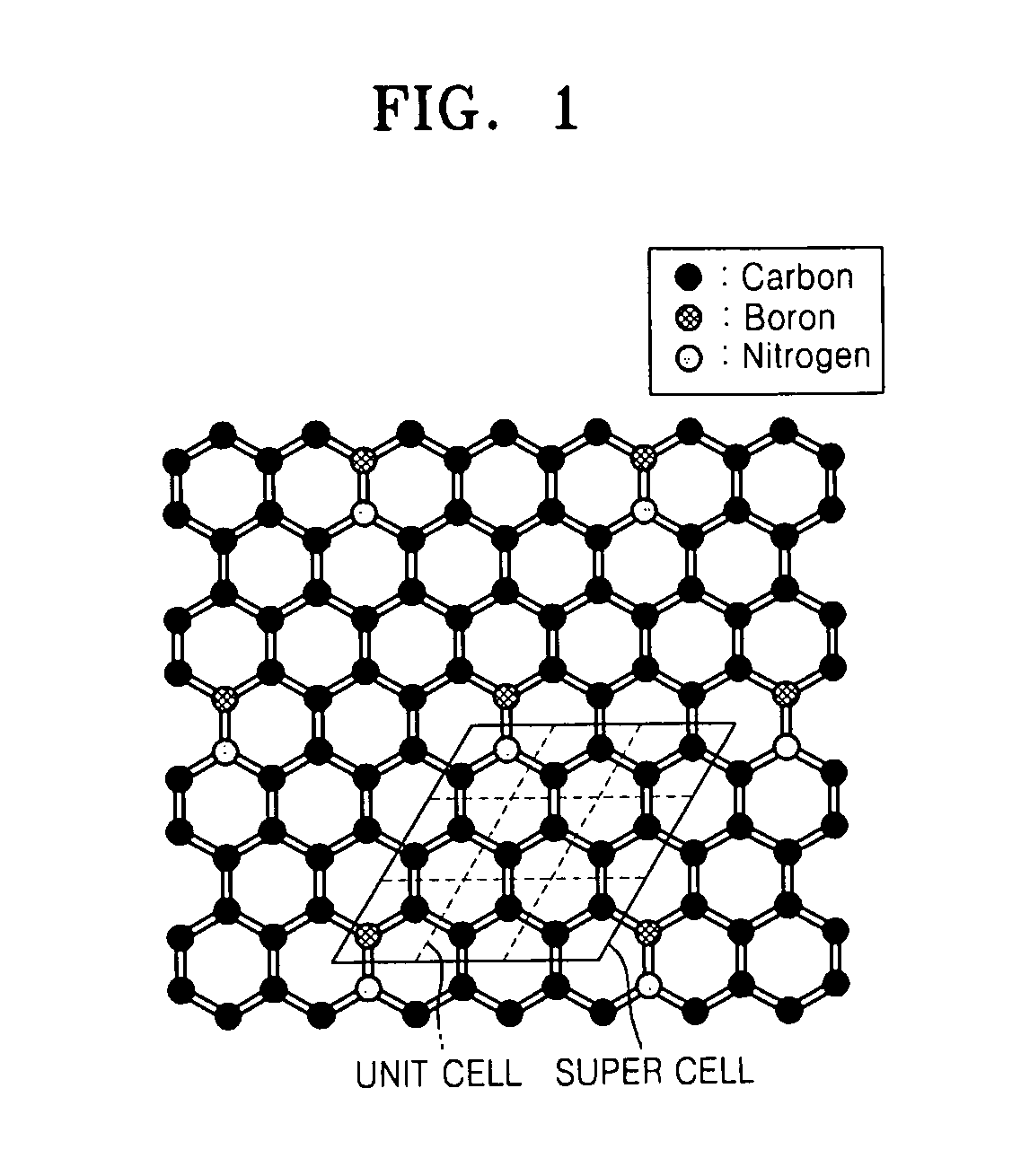

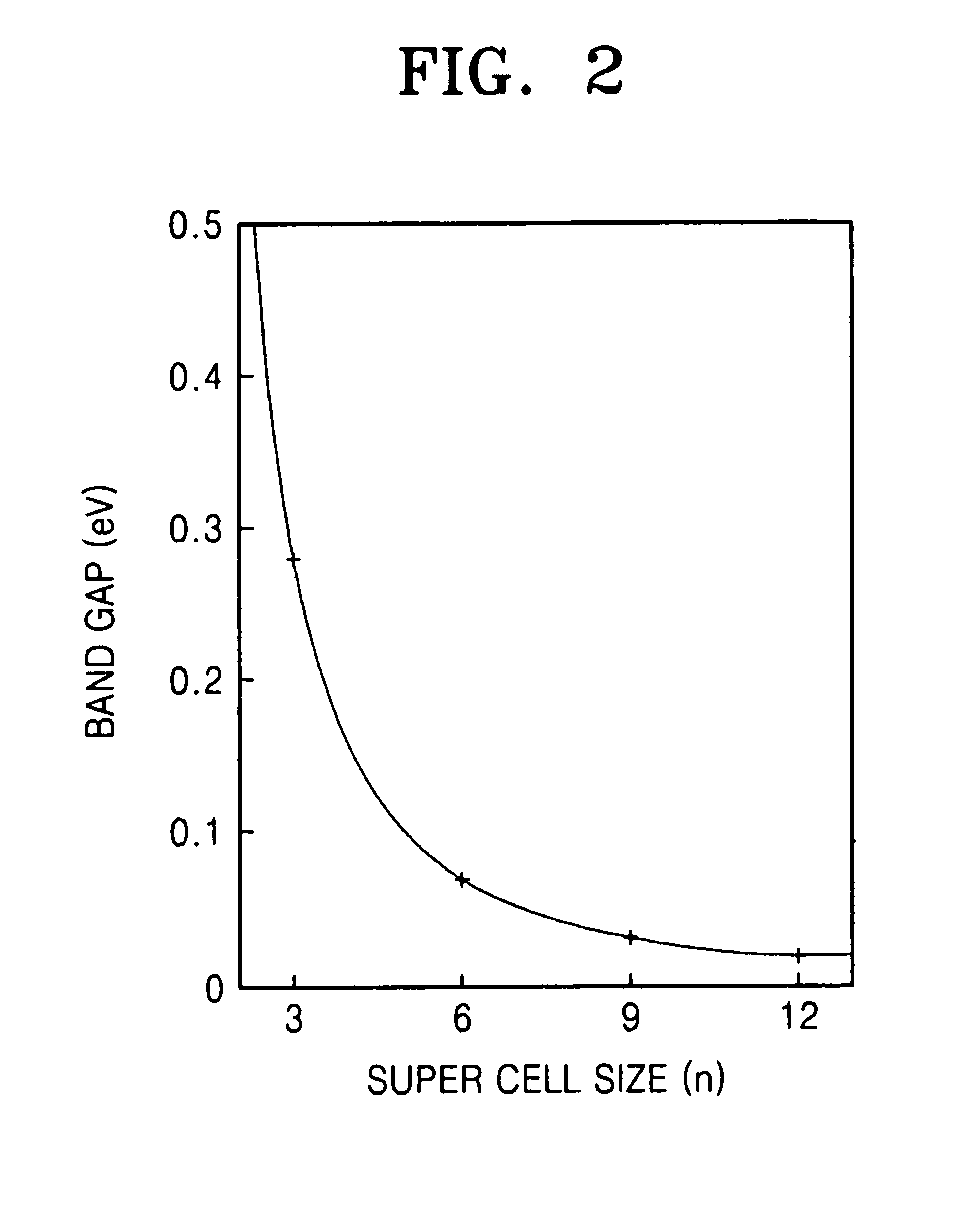

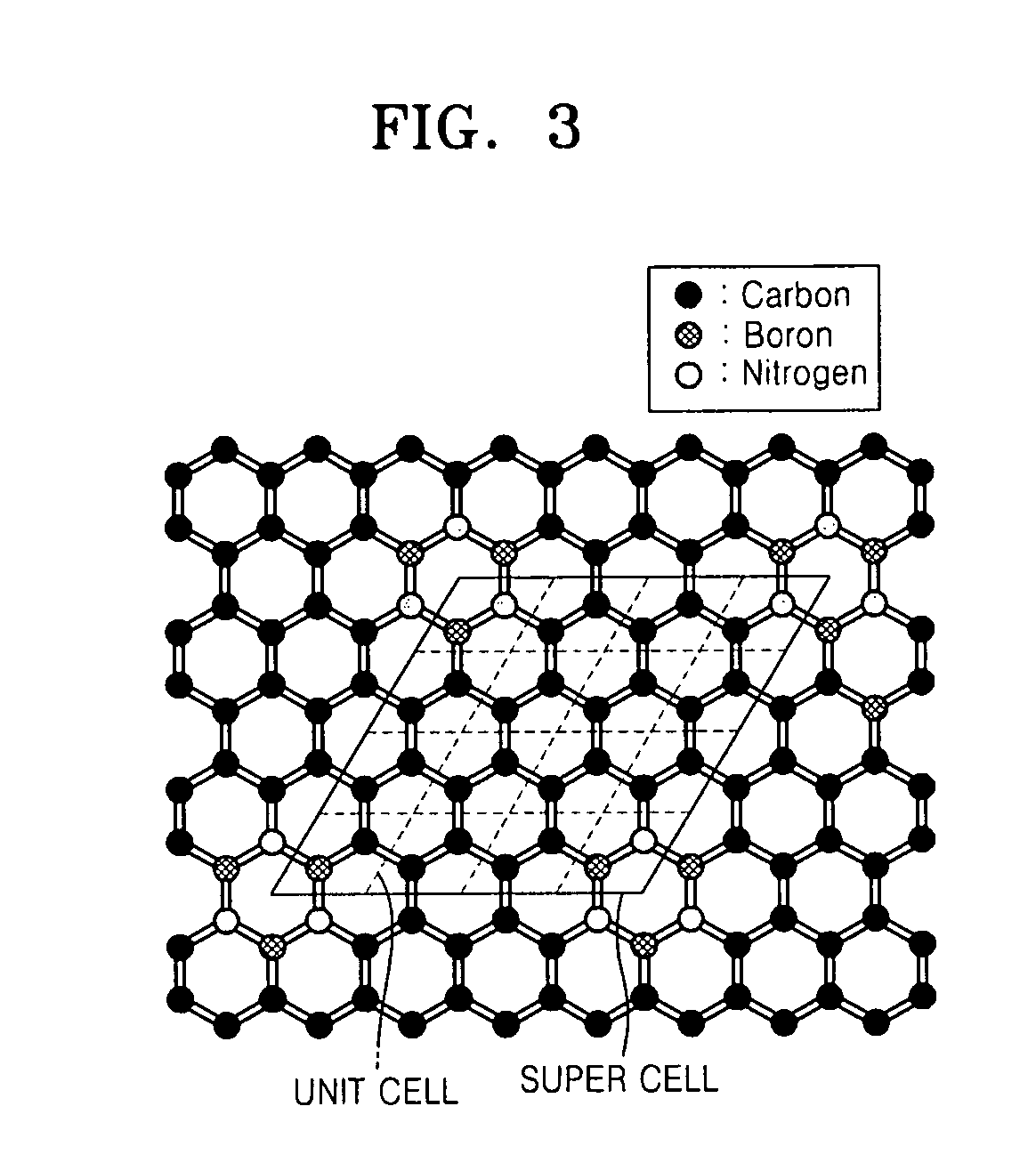

Graphene substituted with boron and nitrogen , method of fabricating the same, and transistor having the same

Graphene, a method of fabricating the same, and a transistor having the graphene are provided, the graphene includes a structure of carbon (C) atoms partially substituted with boron (B) atoms and nitrogen (N) atoms. The graphene has a band gap. The graphene substituted with boron and nitrogen may be used as a channel of a field effect transistor. The graphene may be formed by performing chemical vapor deposition (CVD) method using borazine or ammonia borane as a boron nitride (B—N) precursor.

Owner:SAMSUNG ELECTRONICS CO LTD

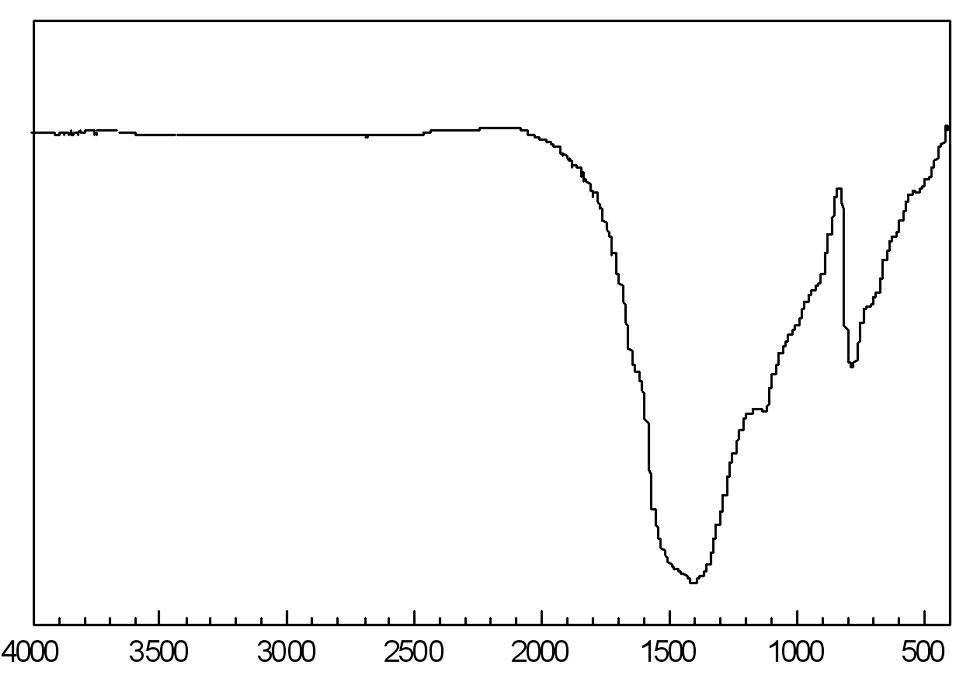

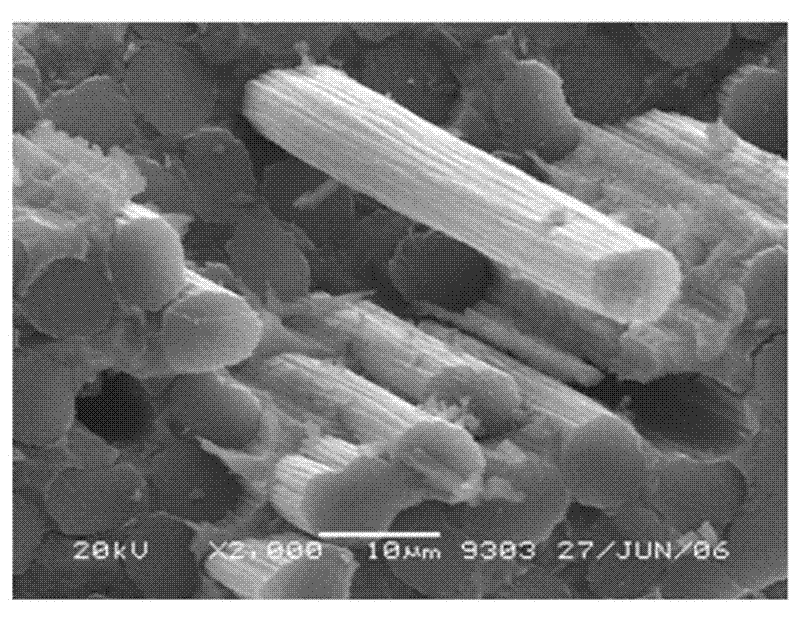

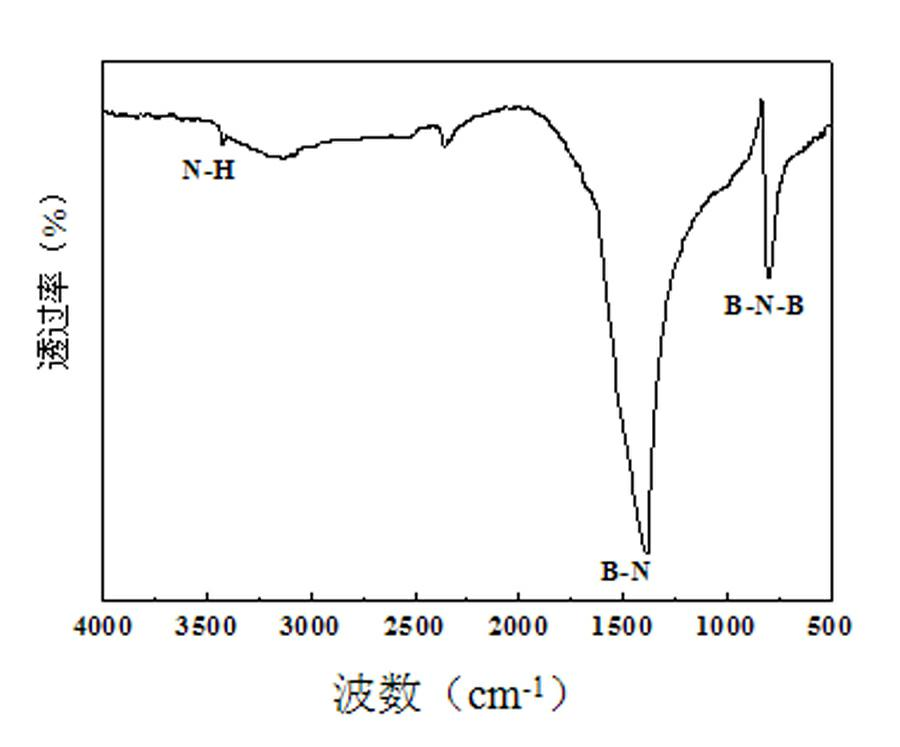

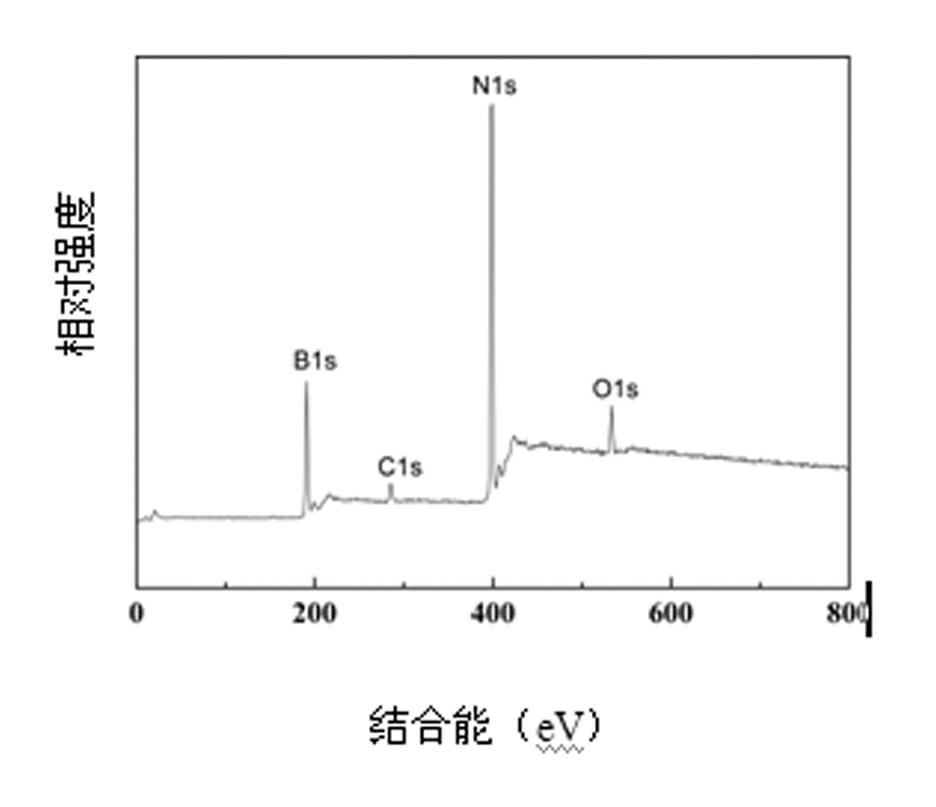

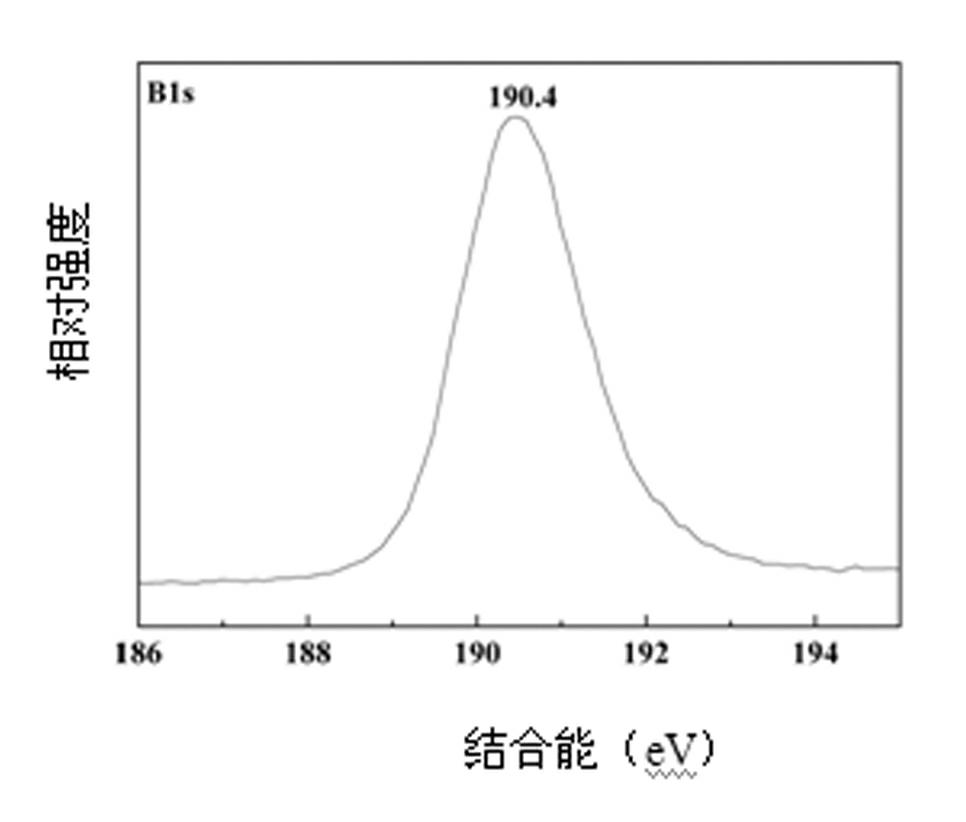

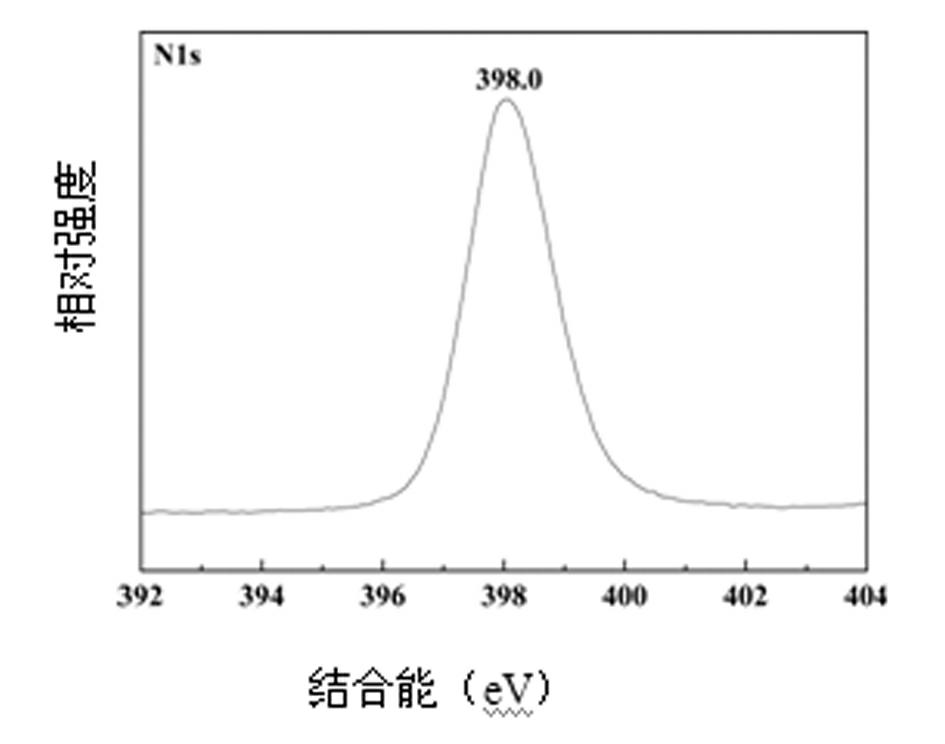

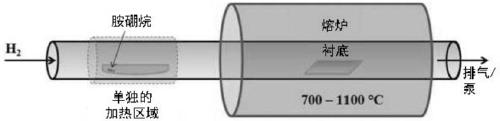

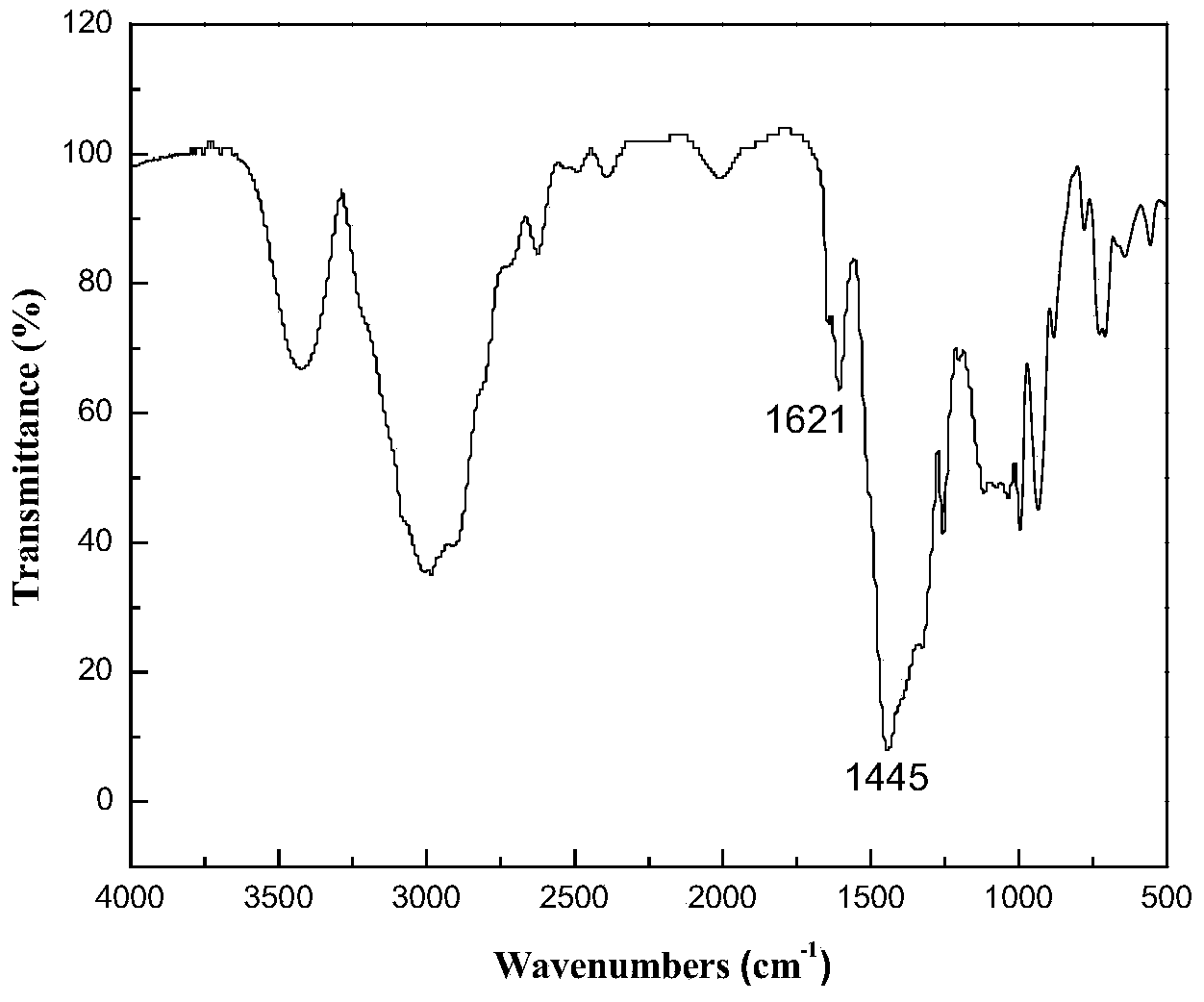

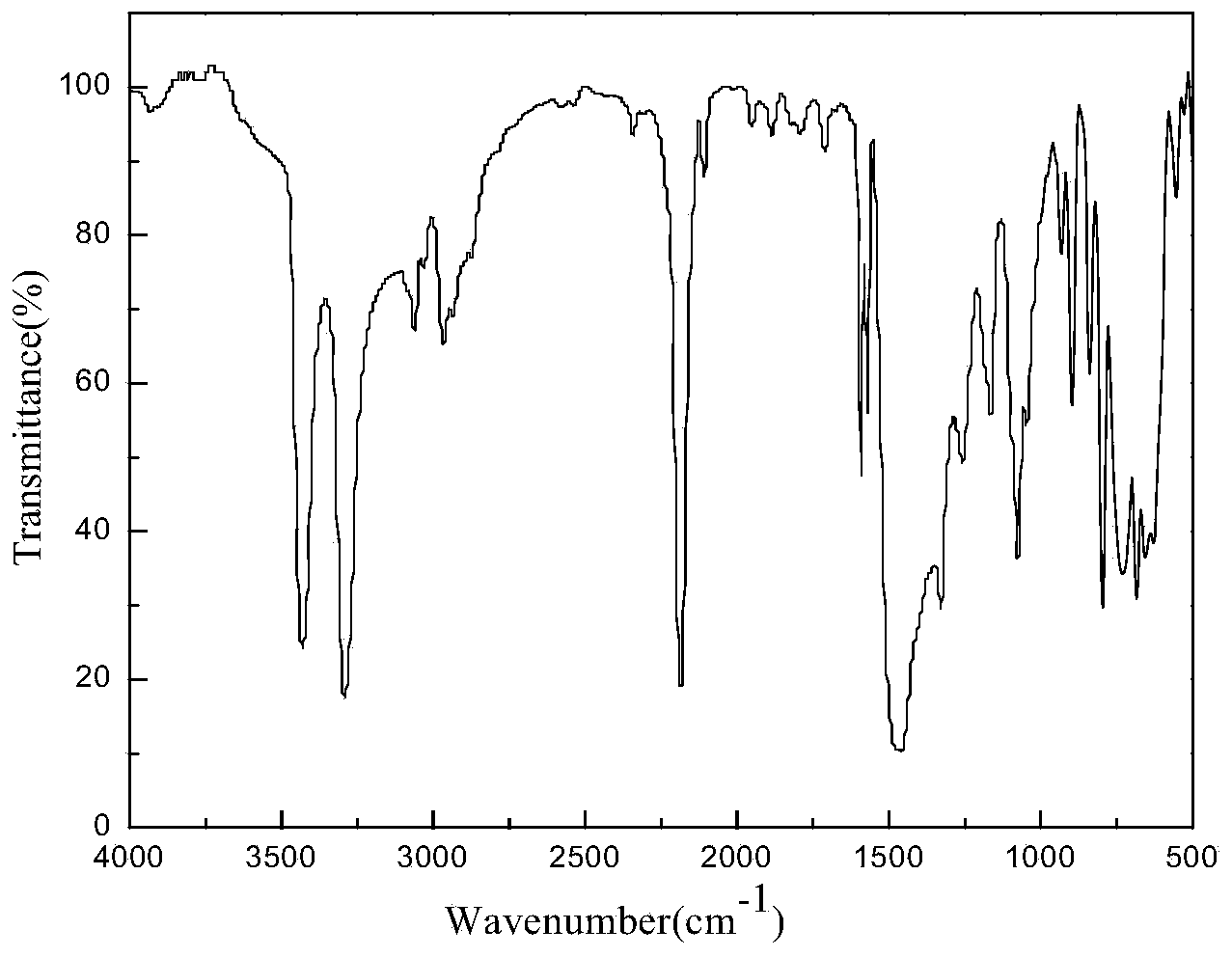

Preparation method of boron nitride coating on fiber surface

The invention provides a preparation method of a boron nitride coating on a fiber surface, comprising the following steps: (1) ultrasonically cleaning a fiber braid in acetone to remove contaminants on the surface, drying and placing the fiber braid in a deposition furnace; (2) evacuating the deposition furnace, and introducing nitrogen gas; (3) evacuating the deposition furnace to 0.01-1 Pa, and heating to 500-1,800 DEG C; (4) introducing carrier gas and dilute gas in such a manner that the carrier gas can carry borazine into the deposition furnace in a bubbling manner to ensure boron nitride to deposit on the fiber surface so as to form a boron nitride coating; and (5) stopping the introduction of the carrier gas and the dilute gas after the deposition finishes, closing the heating system, and cooling to the room temperature along with the furnace. According to the method, the boron nitride can be well deposited on the surface, inside and crossing points of the fiber braid, and the boron nitride coating with uniform, smooth and dense surface and uniform thickness can be deposited on the surface of each fiber in a fiber bundle.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of Cf/BN-SiC composite material

Owner:NAT UNIV OF DEFENSE TECH

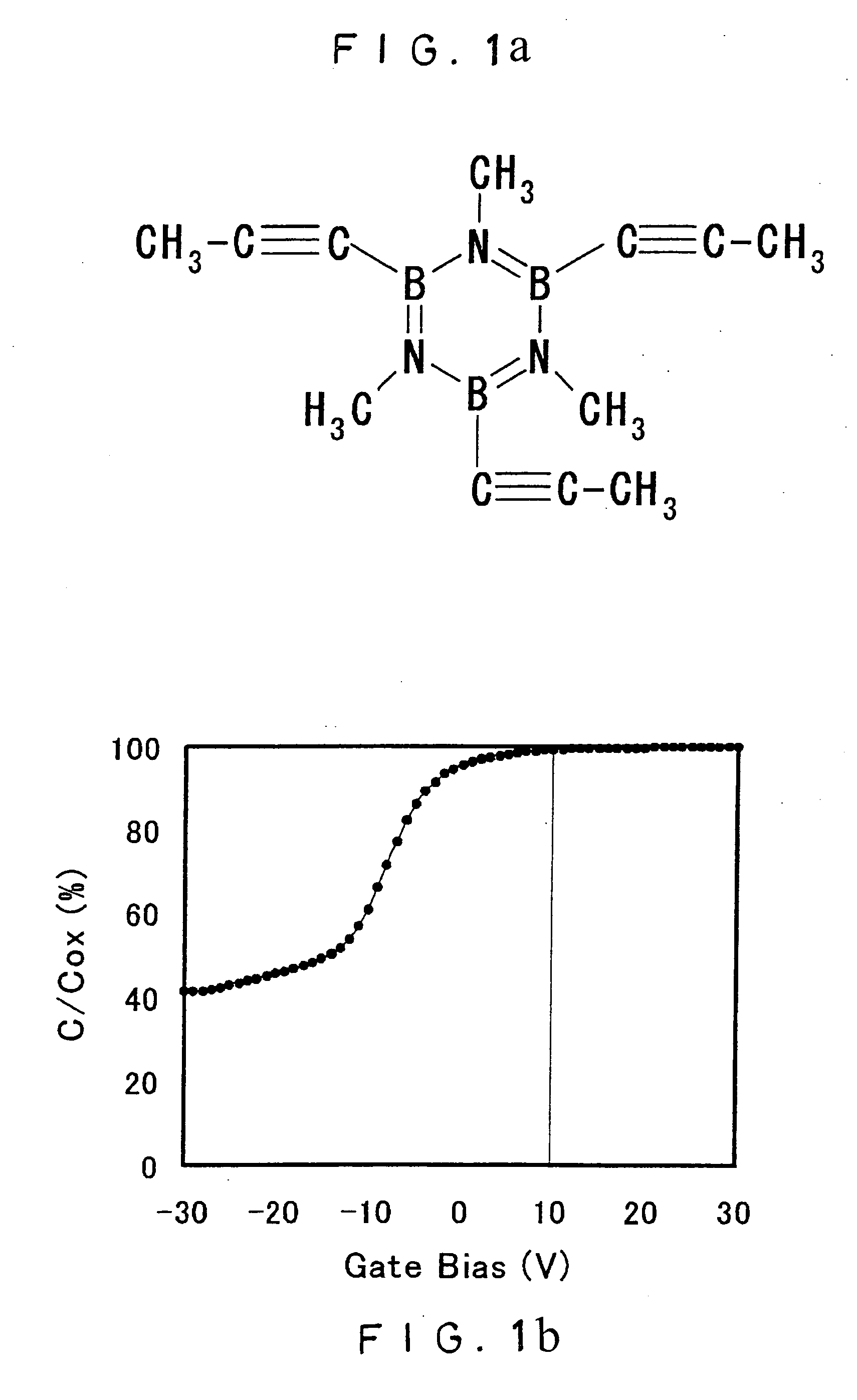

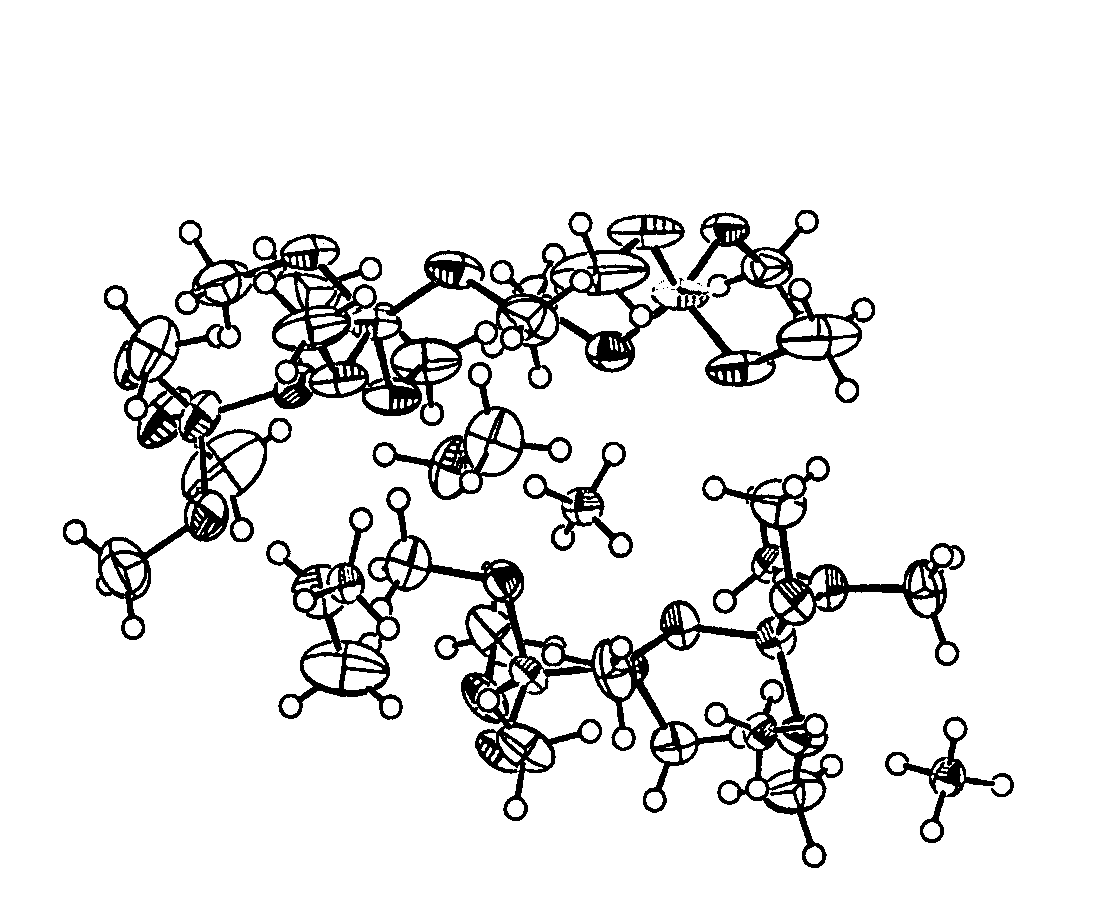

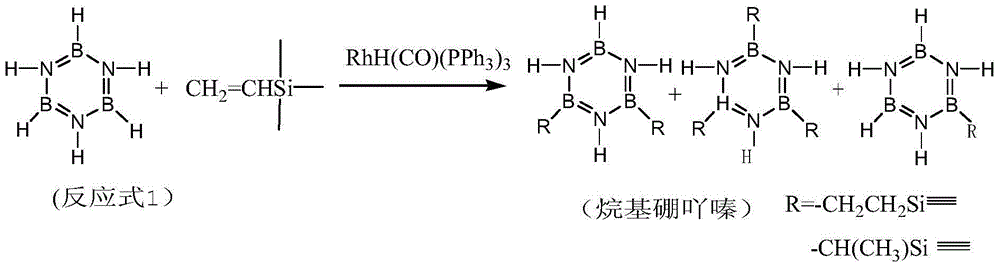

Alkylborazine compound and production method for the same

InactiveUS20050177002A1Boiling pointImprove flammabilitySilicon organic compoundsGroup 3/13 element organic compoundsHalogenDistillation

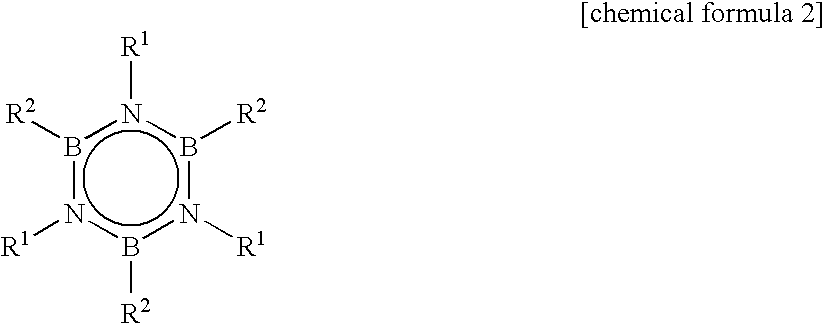

In the process of synthesizing alkylborazine compound represented by the chemical formula 2, by a reaction of a halogenated borazine compound represented by the chemical formula 1 with a Grignard reagent, thus synthesized alkylborazine compound is washed with water, or subjected to sublimation purification or distillation purification at least three times, and / or subjected to distillation purification at least twice. In the formulas, R1 independently represents alkyl group; R2 independently represents alkyl group; and X represents halogen atom.

Owner:NIPPON SHOKUBAI CO LTD

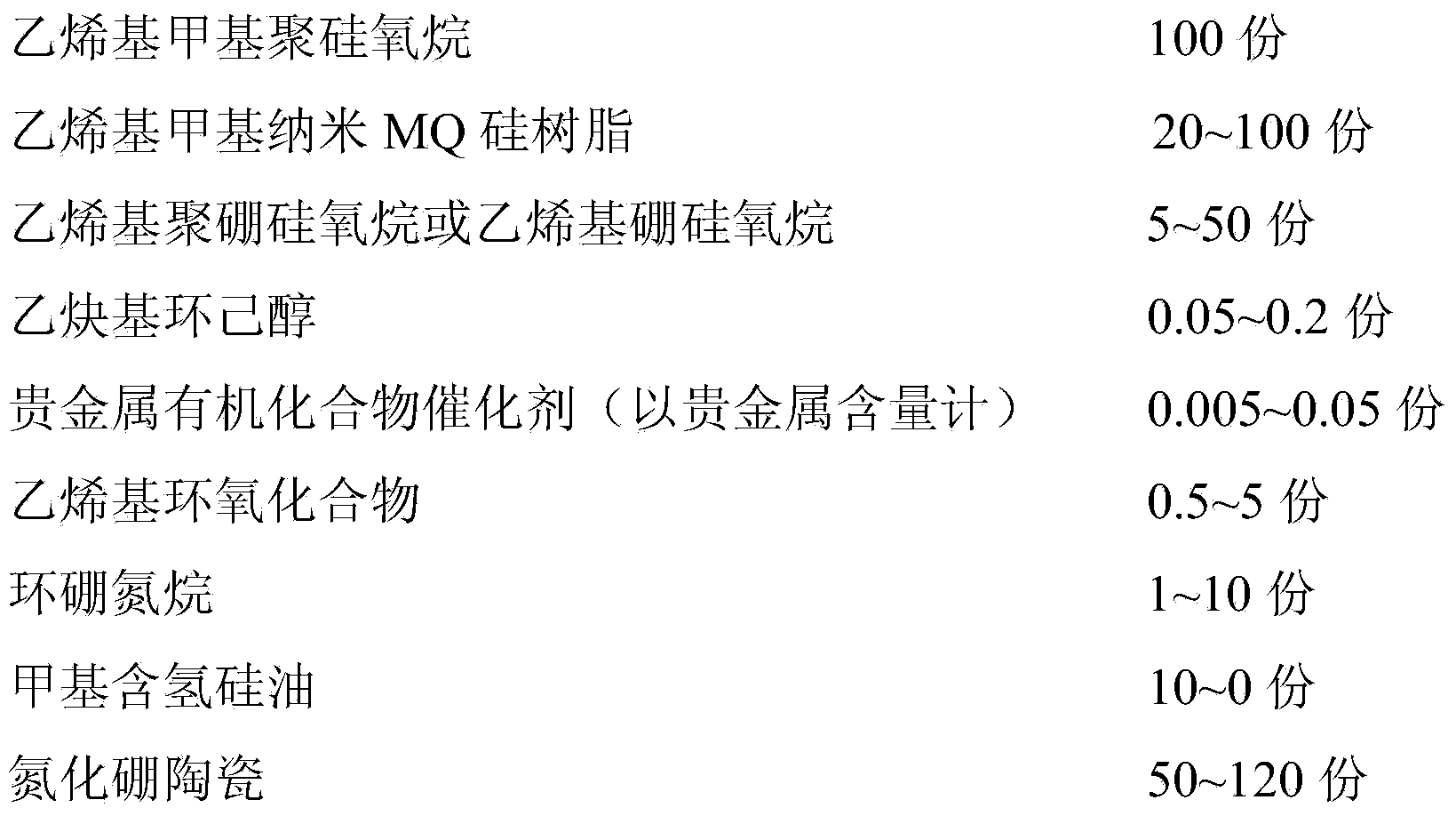

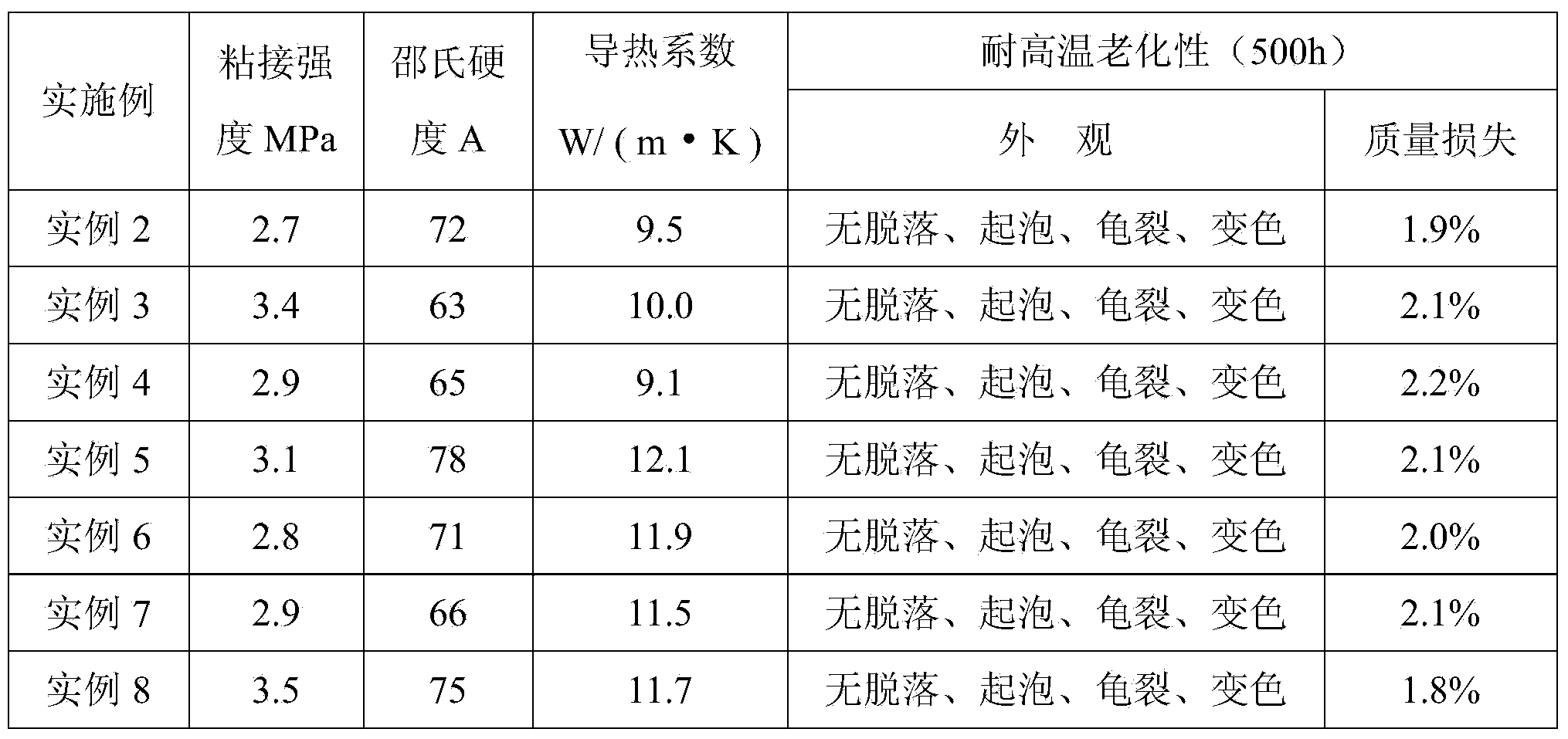

High-heat-conductivity boroheteropolysiloxane potting adhesive and preparation method thereof

ActiveCN104031603ALow shrinkageImprove shrinkageNon-macromolecular adhesive additivesModified epoxy resin adhesivesEpoxyAdhesive

The invention belongs to the field of potting materials, and discloses a high-heat-conductivity boroheteropolysiloxane potting adhesive and a preparation method thereof. The potting adhesive is composed of the following components in parts by mass: 100 parts of vinylmethyl polysiloxane, 20-100 parts of vinylmethyl nano MQ silicon resin, 5-50 parts of vinyl polyborosiloxane or vinyl borosiloxane, 0.05-0.2 part of acetylenyl cyclohexanol, 0.005-0.05 part of noble metal organic compound catalyst, 0.5-5 parts of vinyl epoxy compound, 1-10 parts of borazine, 10-0 part of methyl hydrogen-containing silicon oil and 50-120 parts of boron nitride ceramic. The high-heat-conductivity boroheteropolysiloxane potting adhesive has the advantages of high heat conductivity, favorable sealing property, high bonding force, favorable elasticity, water and moisture resistance, electric insulation, shock absorption, high temperature resistance and excellent aging resistance, and has wide application prospects in packaging of high-power electronic information components, semiconductor communication and illumination components and other components.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

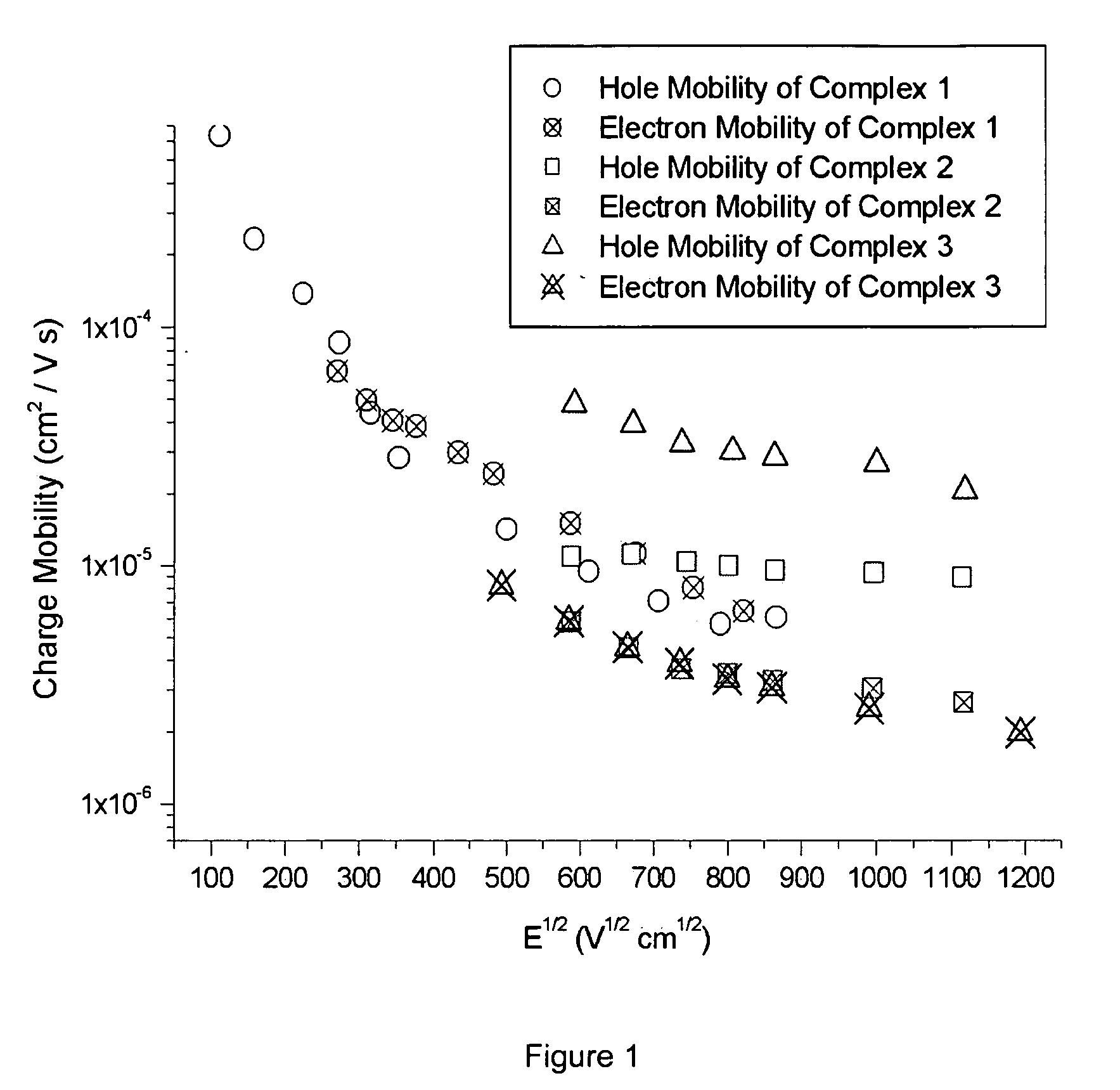

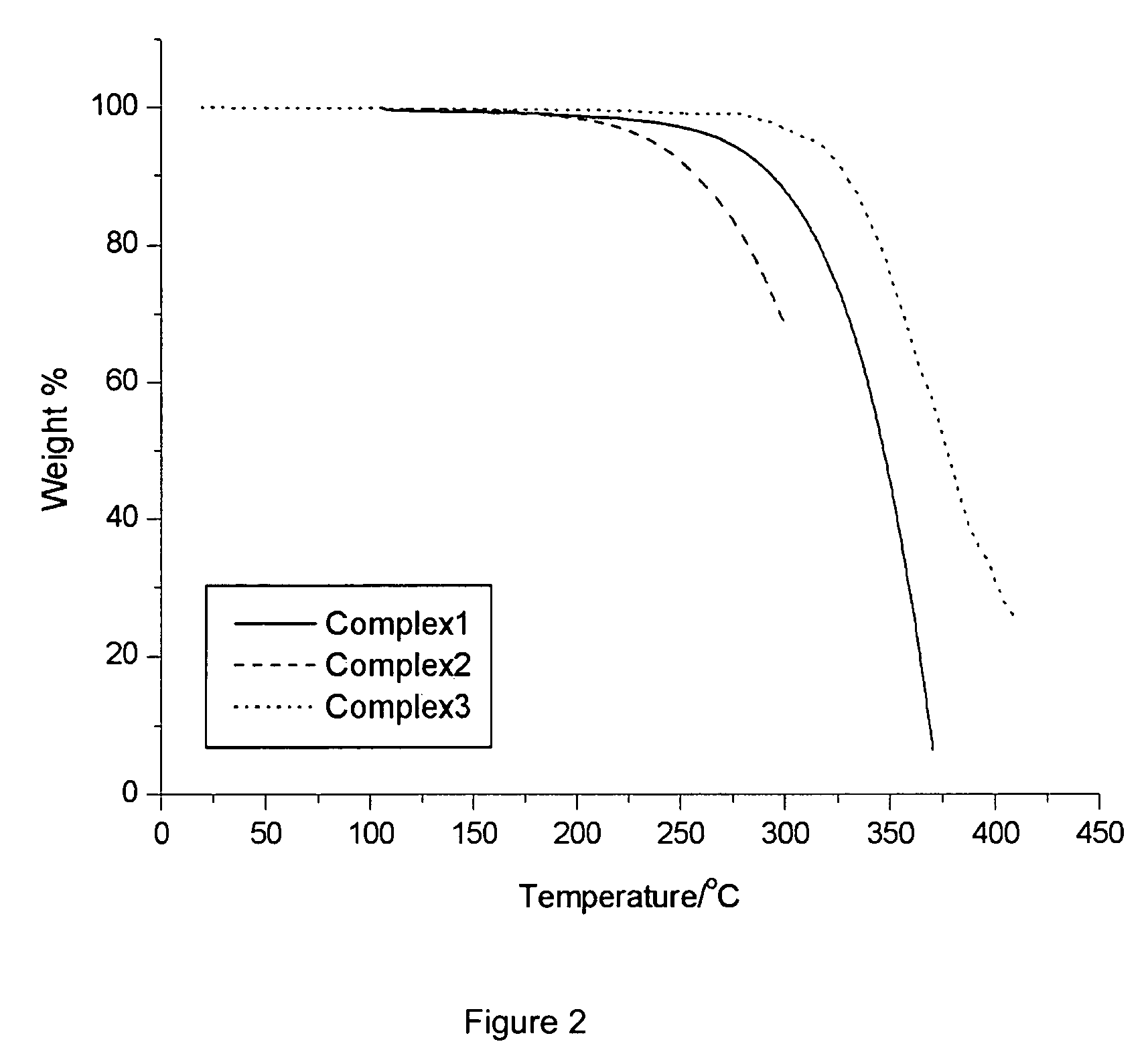

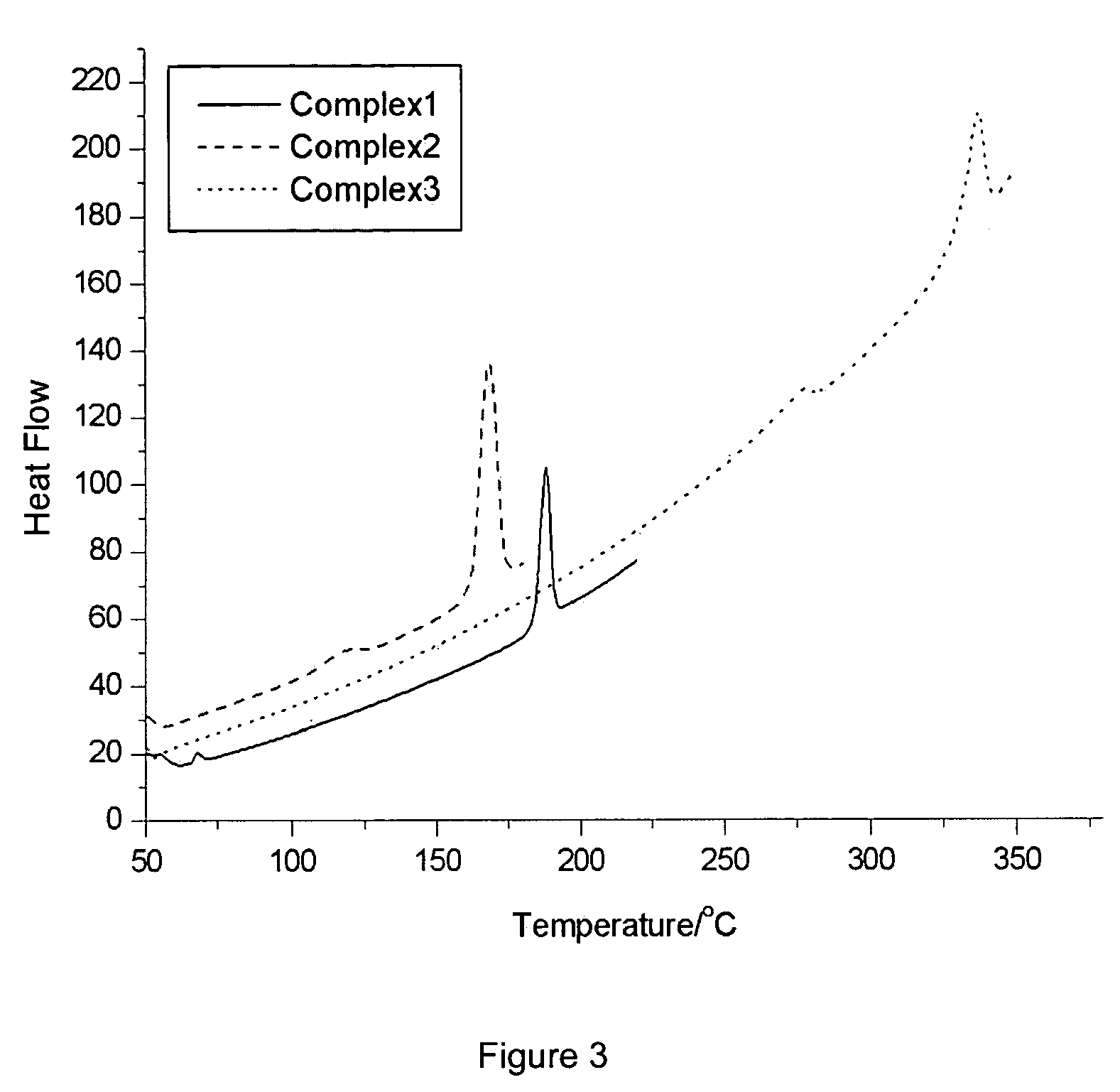

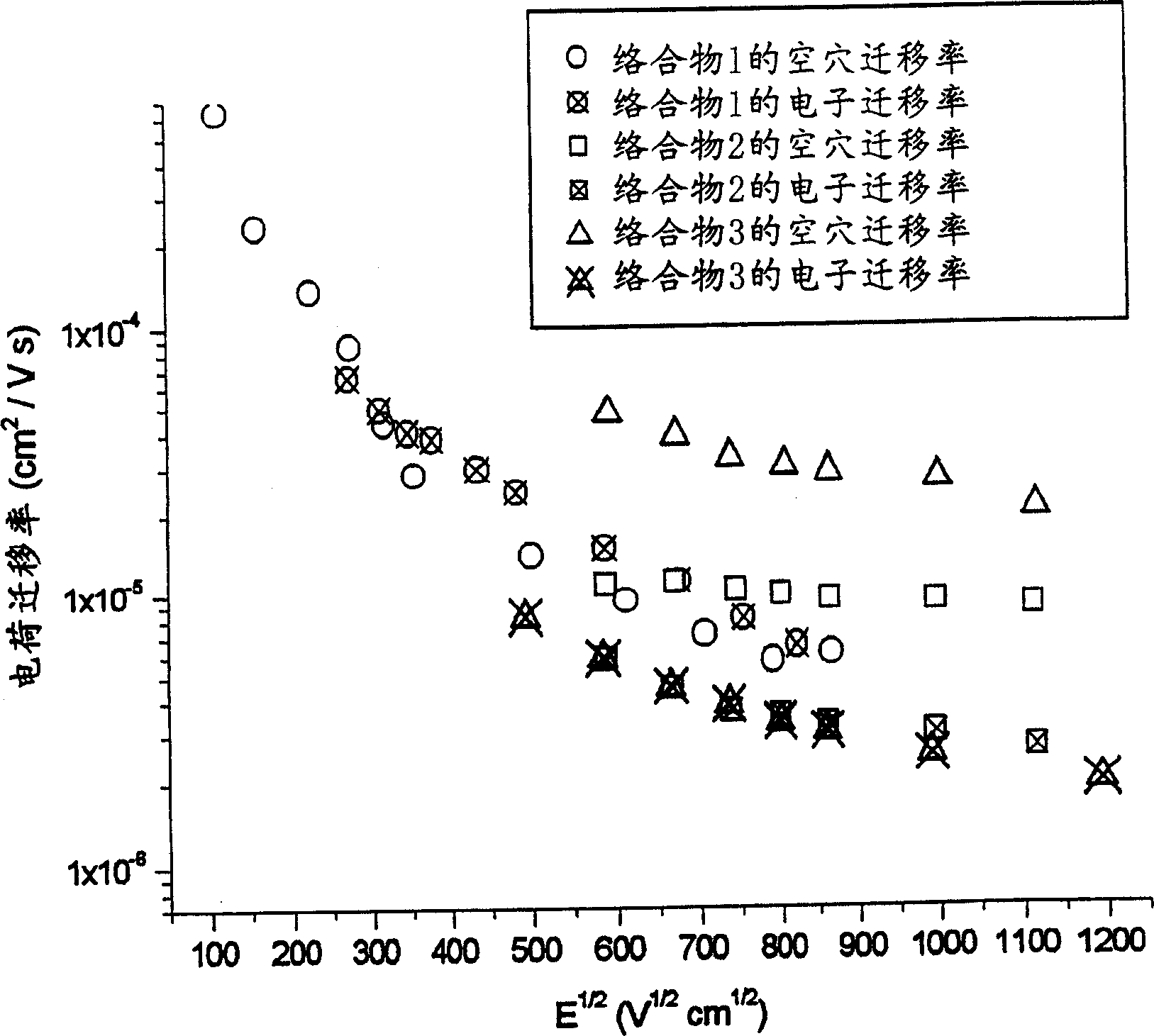

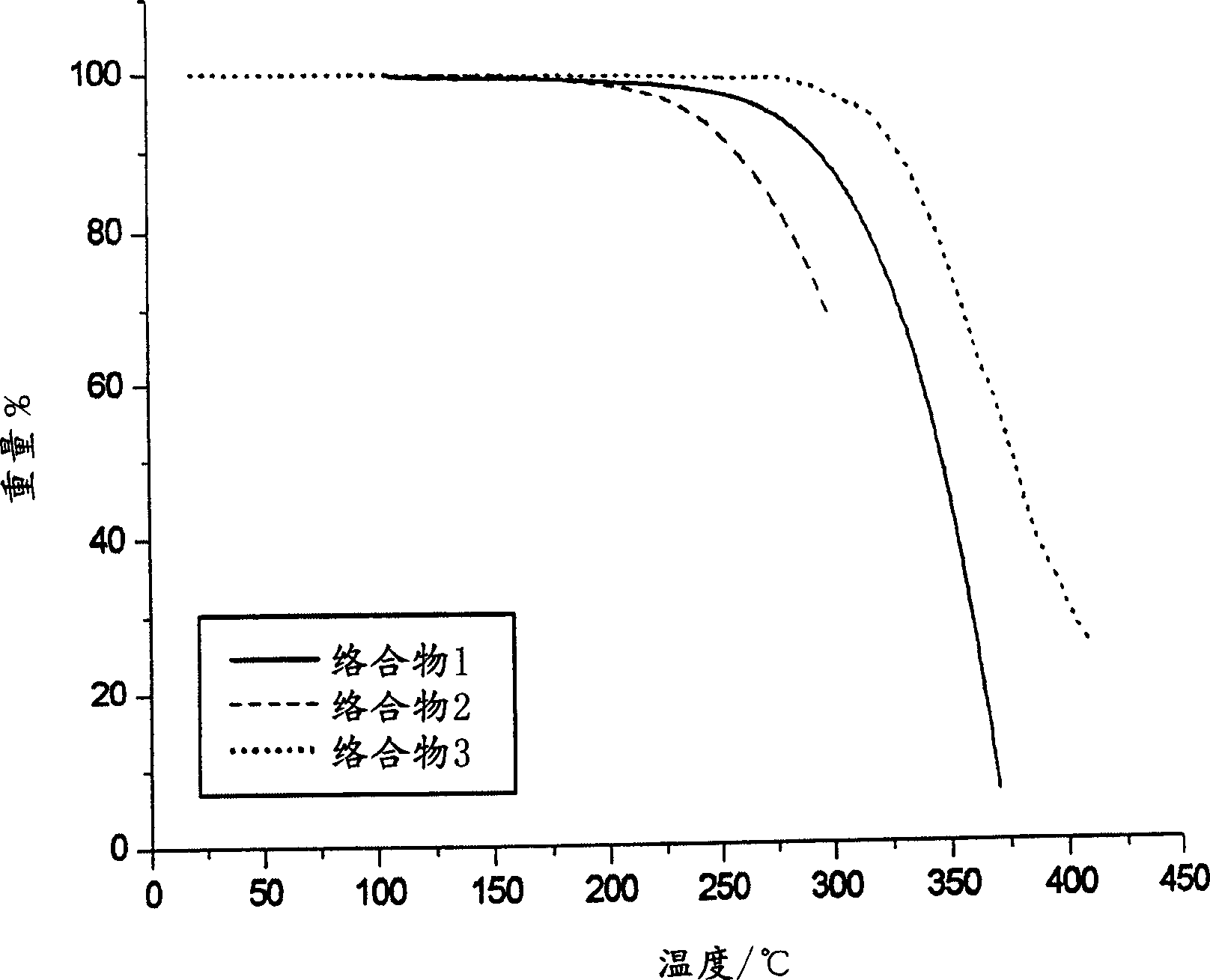

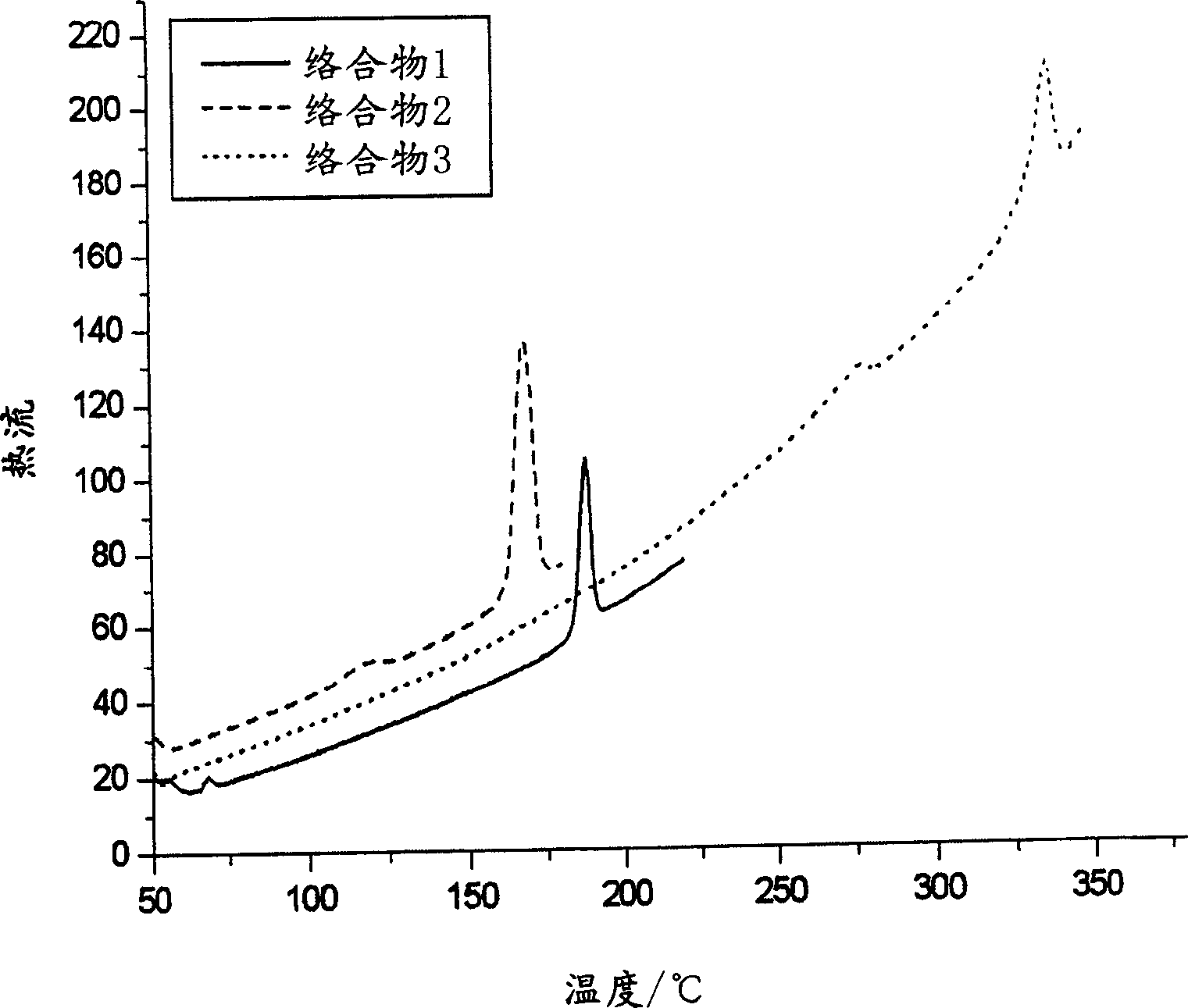

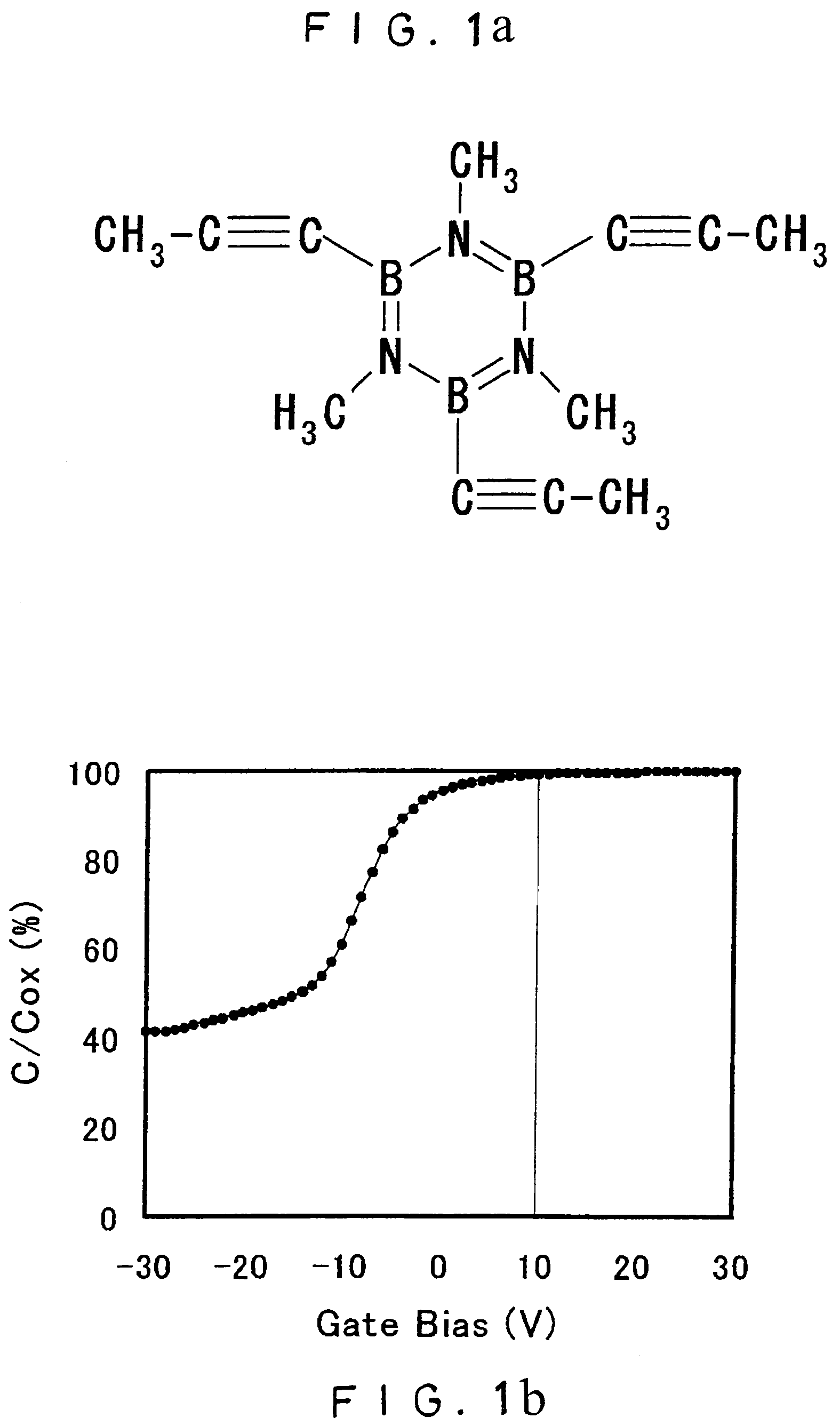

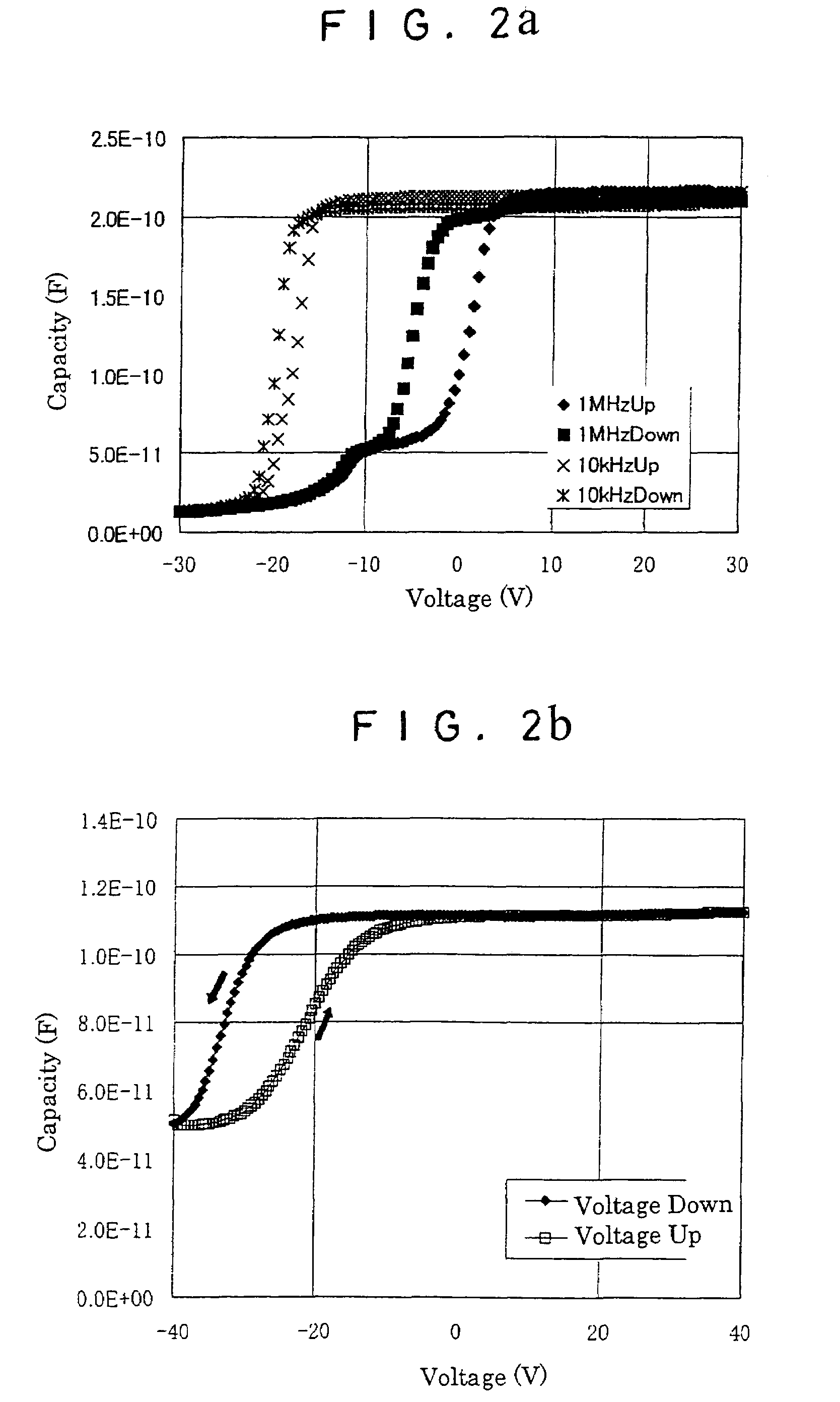

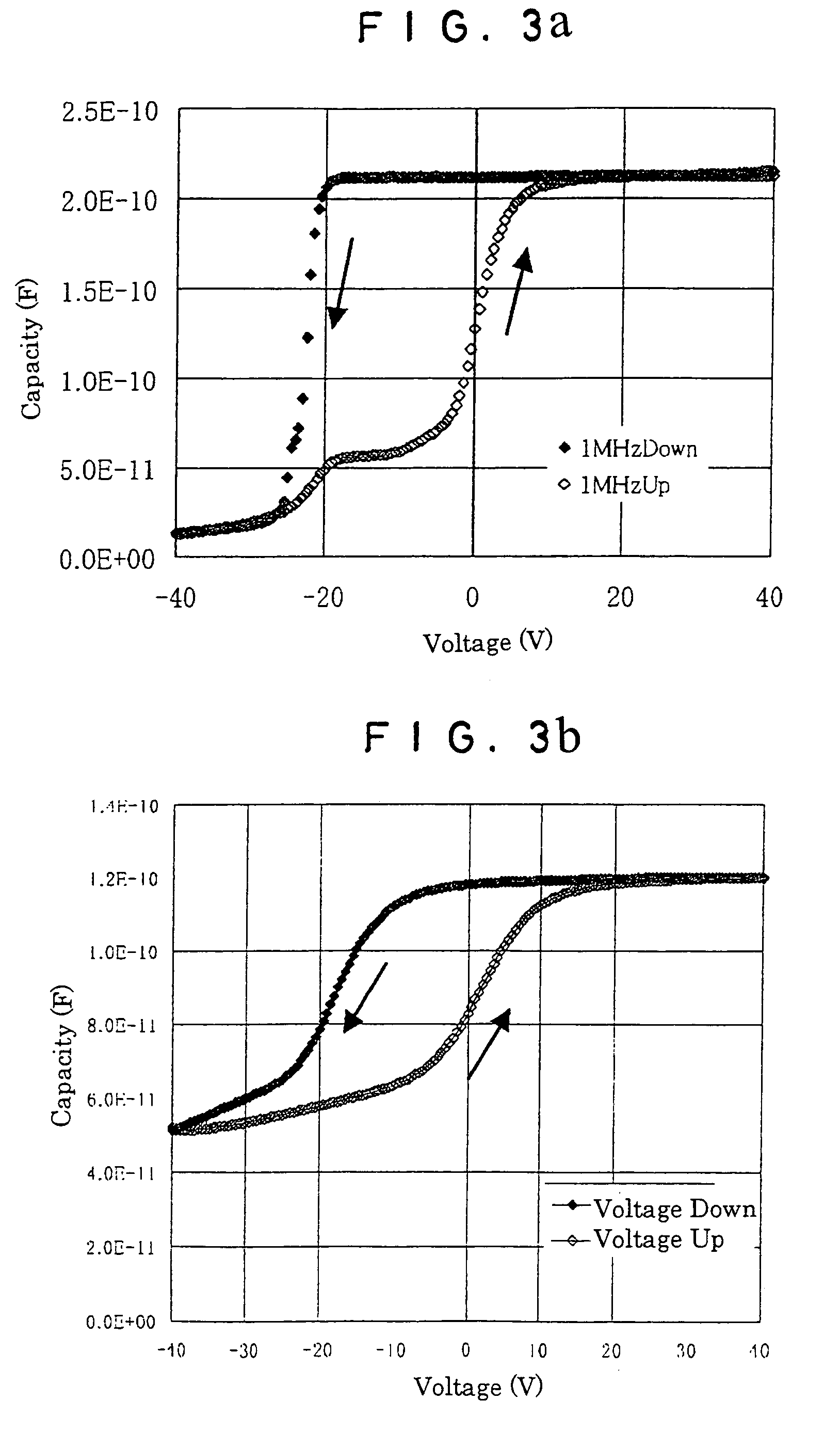

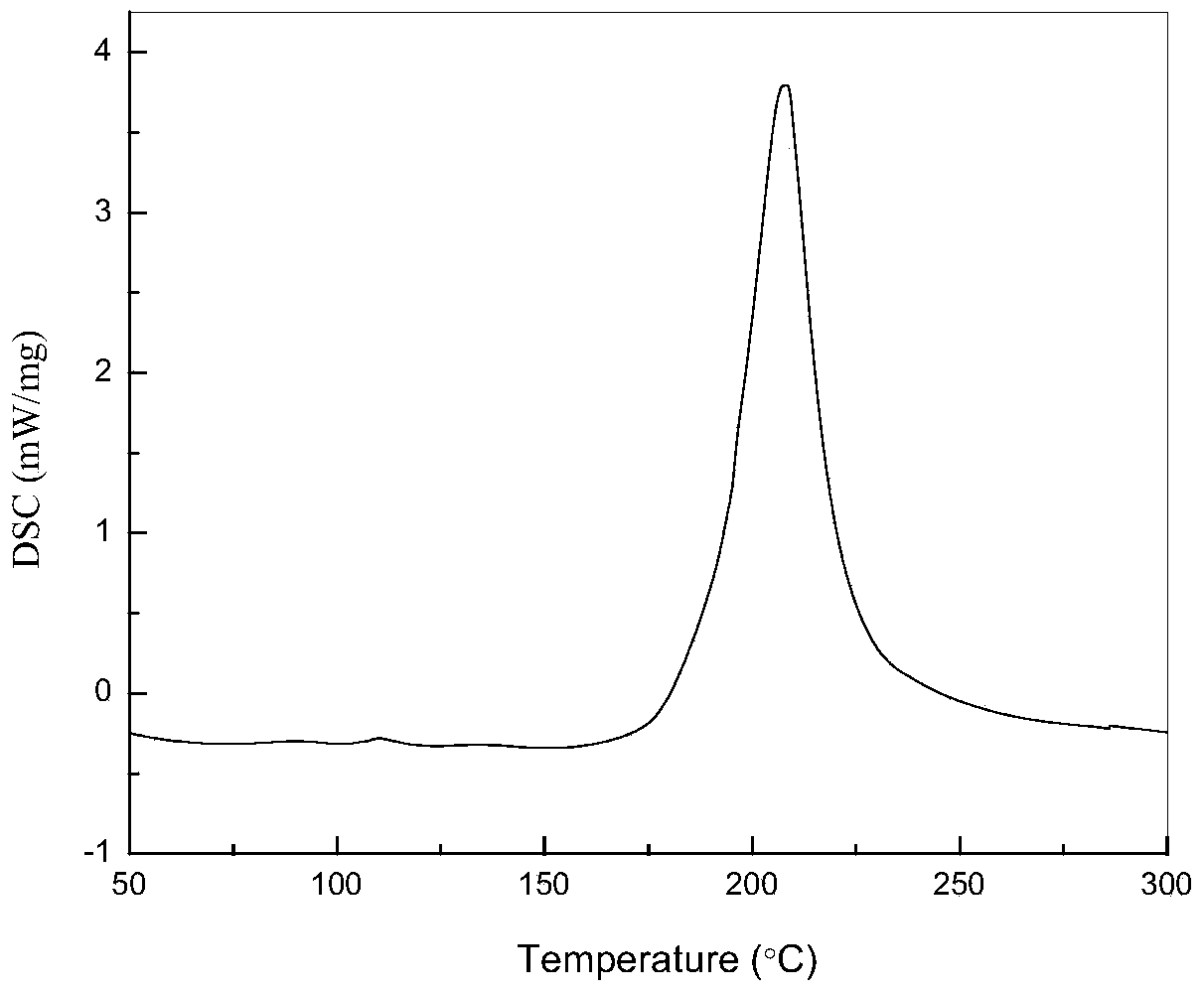

Materials for electroluminescent devices

ActiveUS20050153164A1Improve performanceImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesArylHydrogen

Materials containing one or more borazine rings are employed as materials for electroluminescent devices. The compounds have molecular structures represented by the following formula: in which R1—R6 are independently a metal; a whole or part of an optionally substituted borazine ring; hydrogen; halogen; hydroxyl; optionally substituted alkyl, cycloalkyl, aryl, acyl, alkoxy, acyloxy, amino, acylamino, aralkyl, cyano, carboxyl, thio, vinyl, styryl, aminocarbonyl, carbamoyl, aryloxycarbonyl, phenoxycarbonyl, or alkoxycarbonyl, as well as recognized donor and acceptor groups. The compounds have high thermal stability as well as hole and electron mobilities.

Owner:VERSITECH LTD

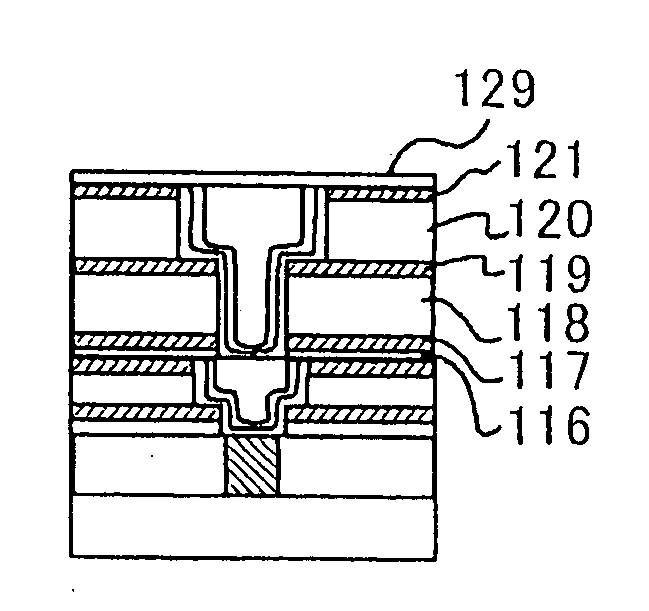

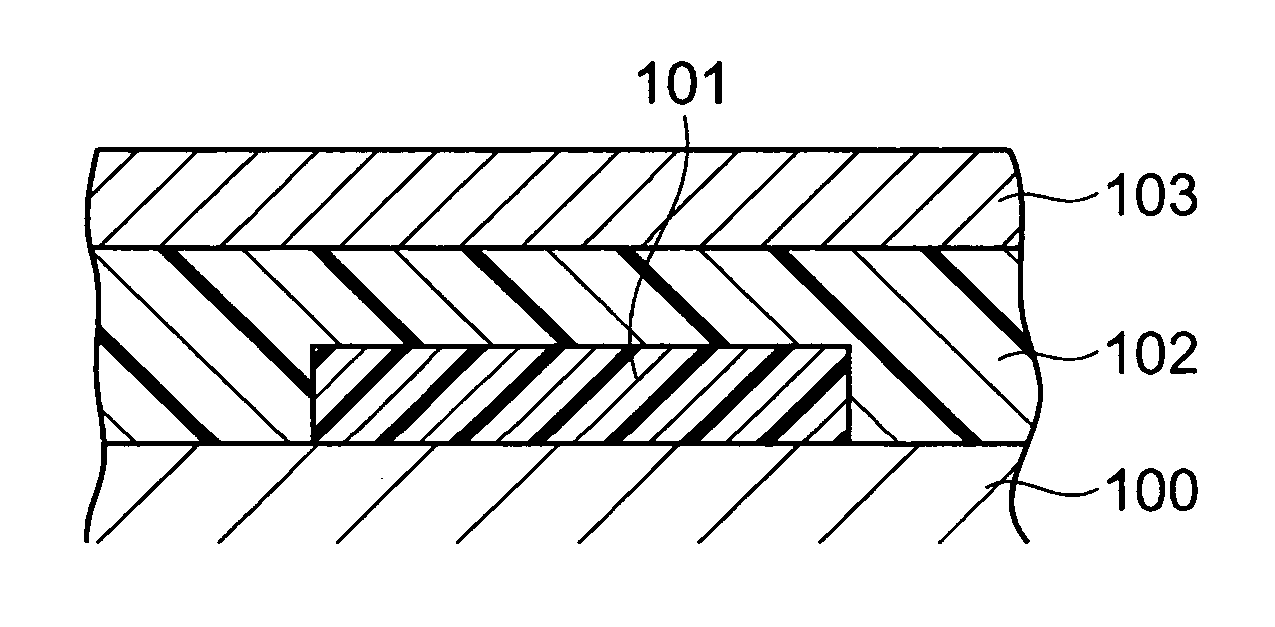

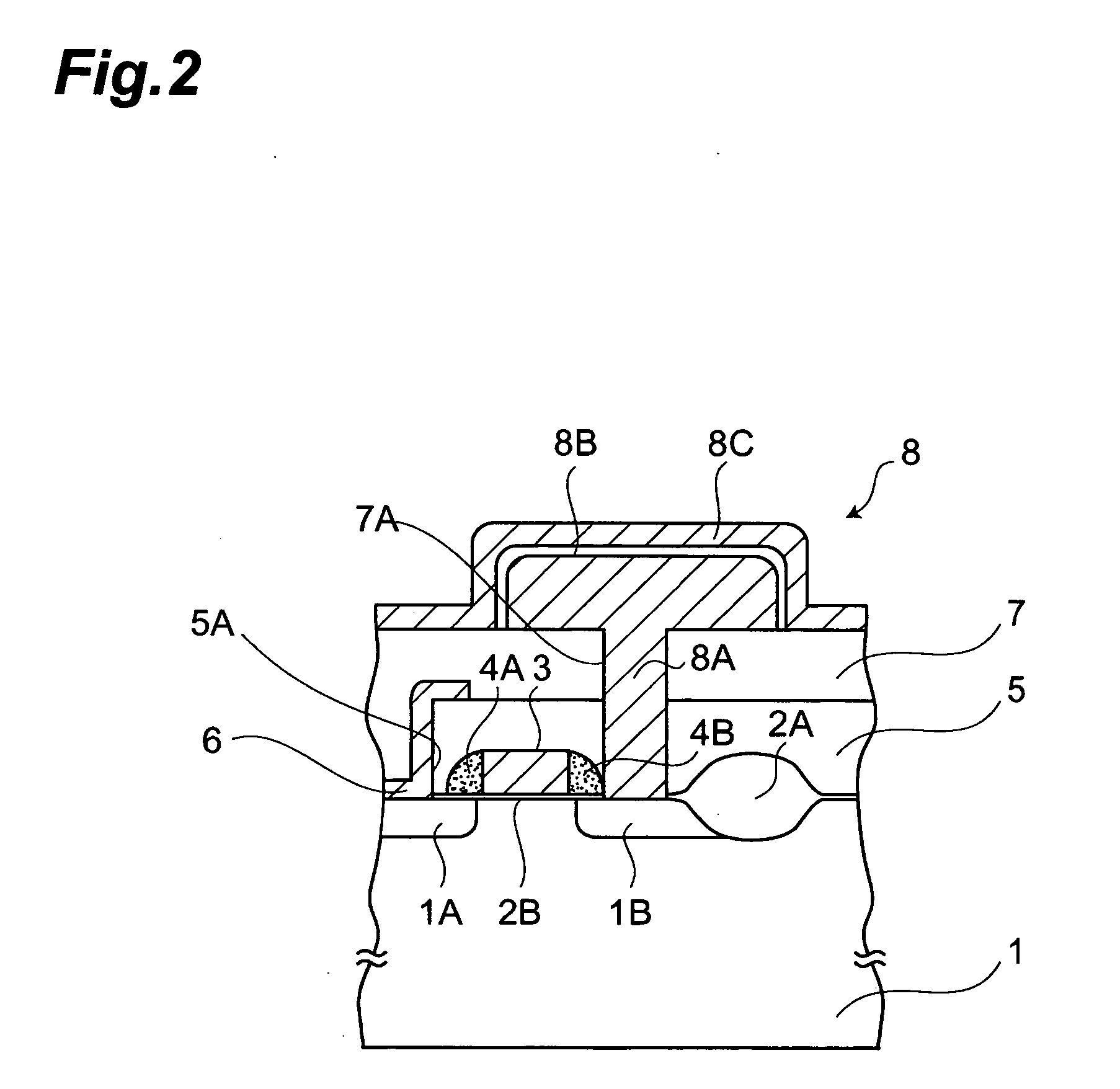

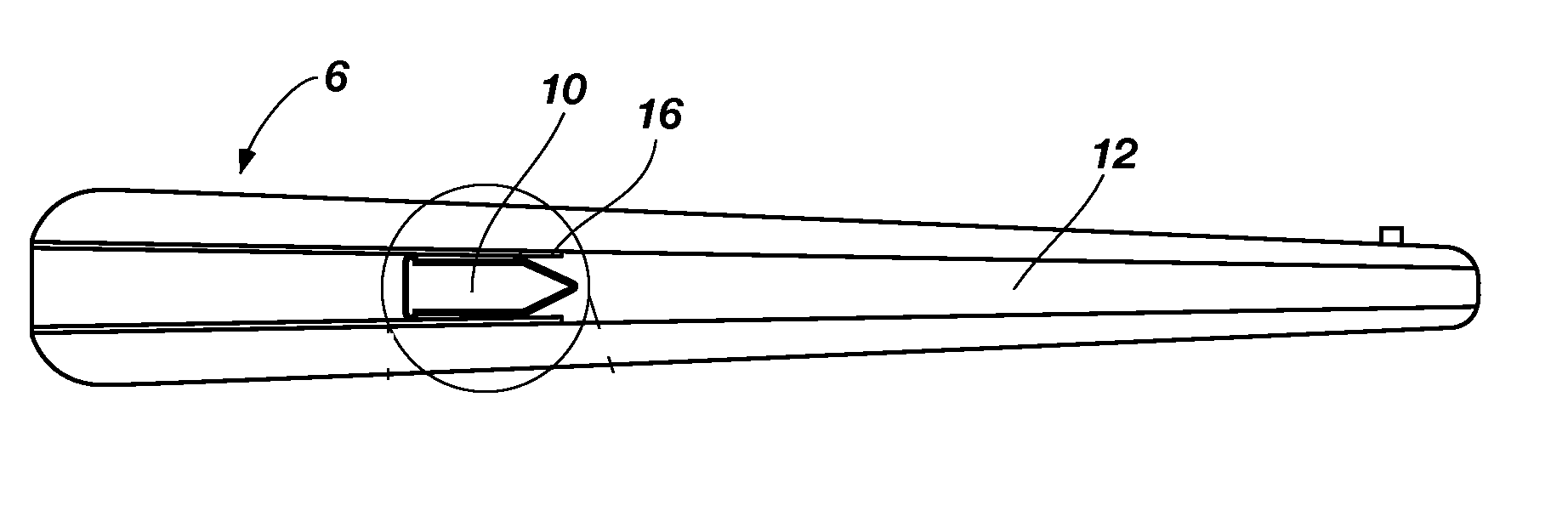

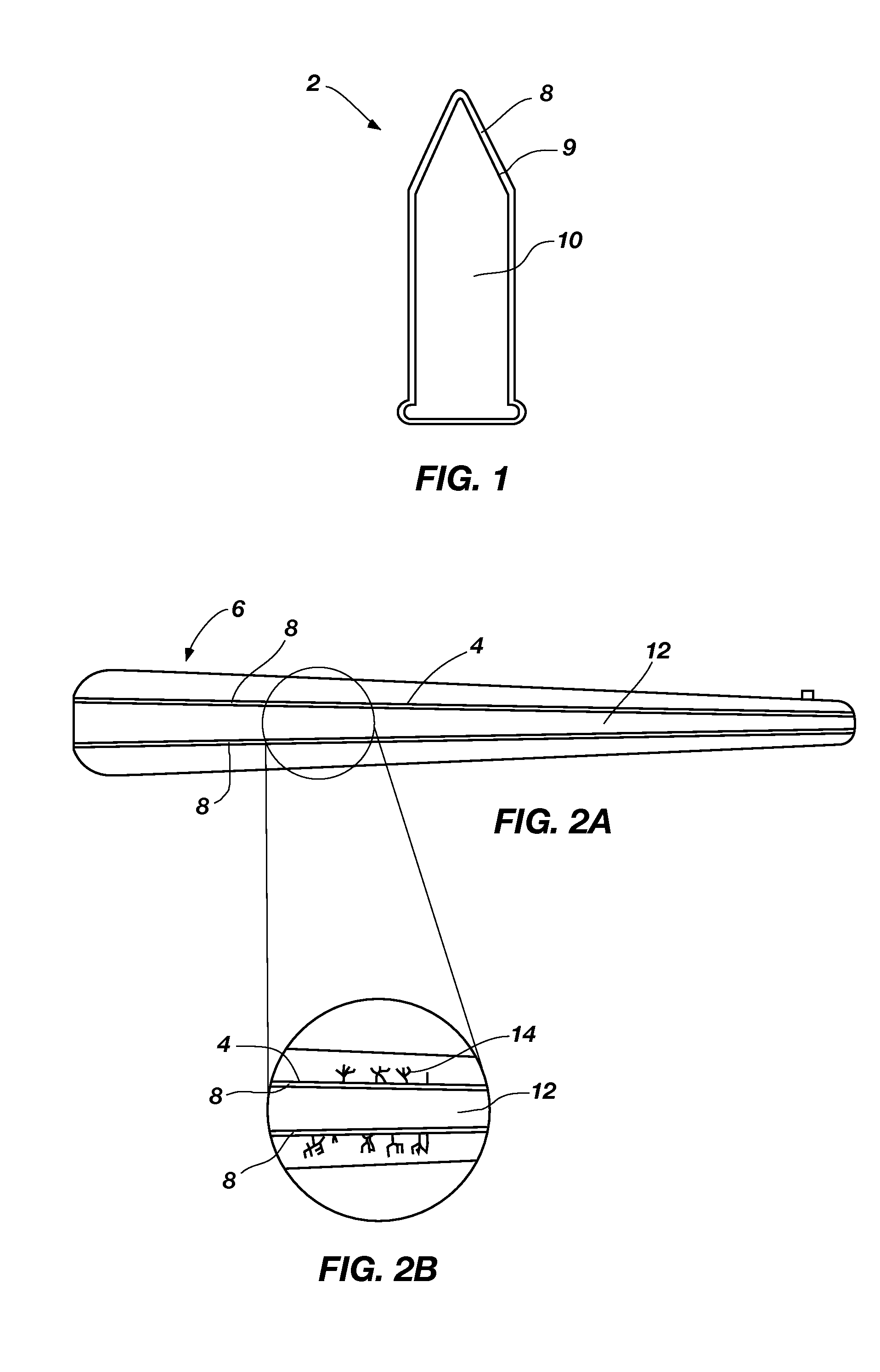

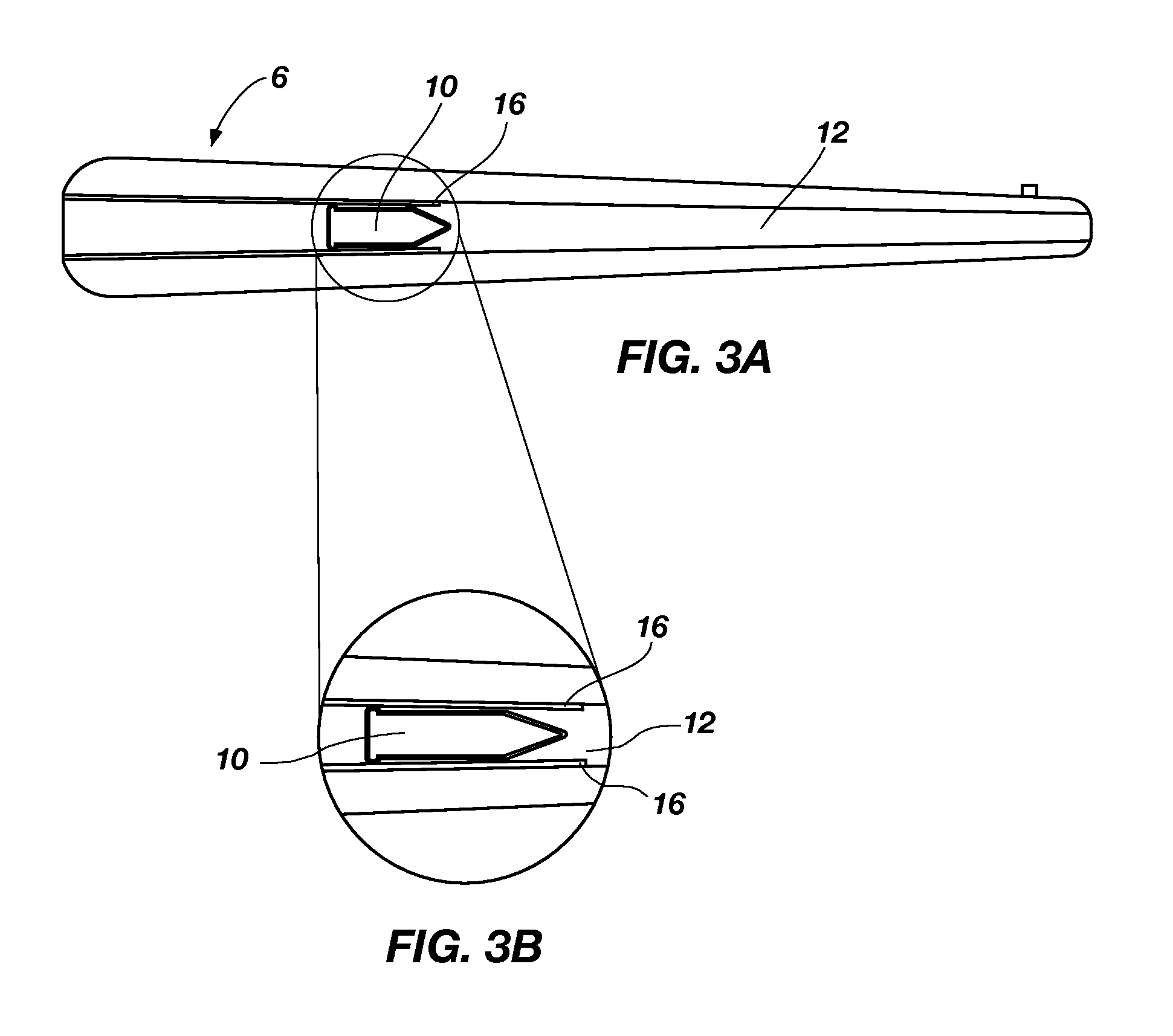

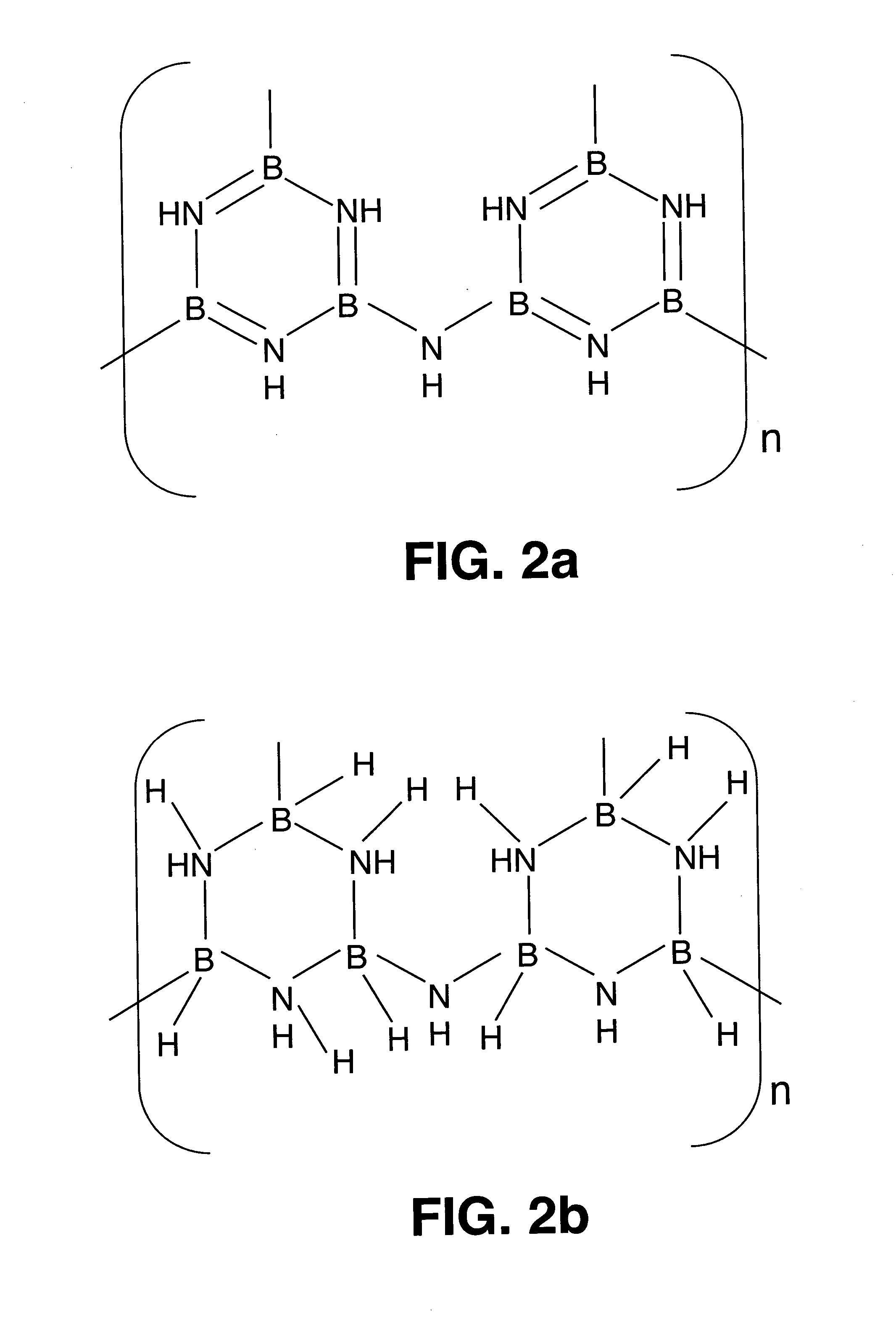

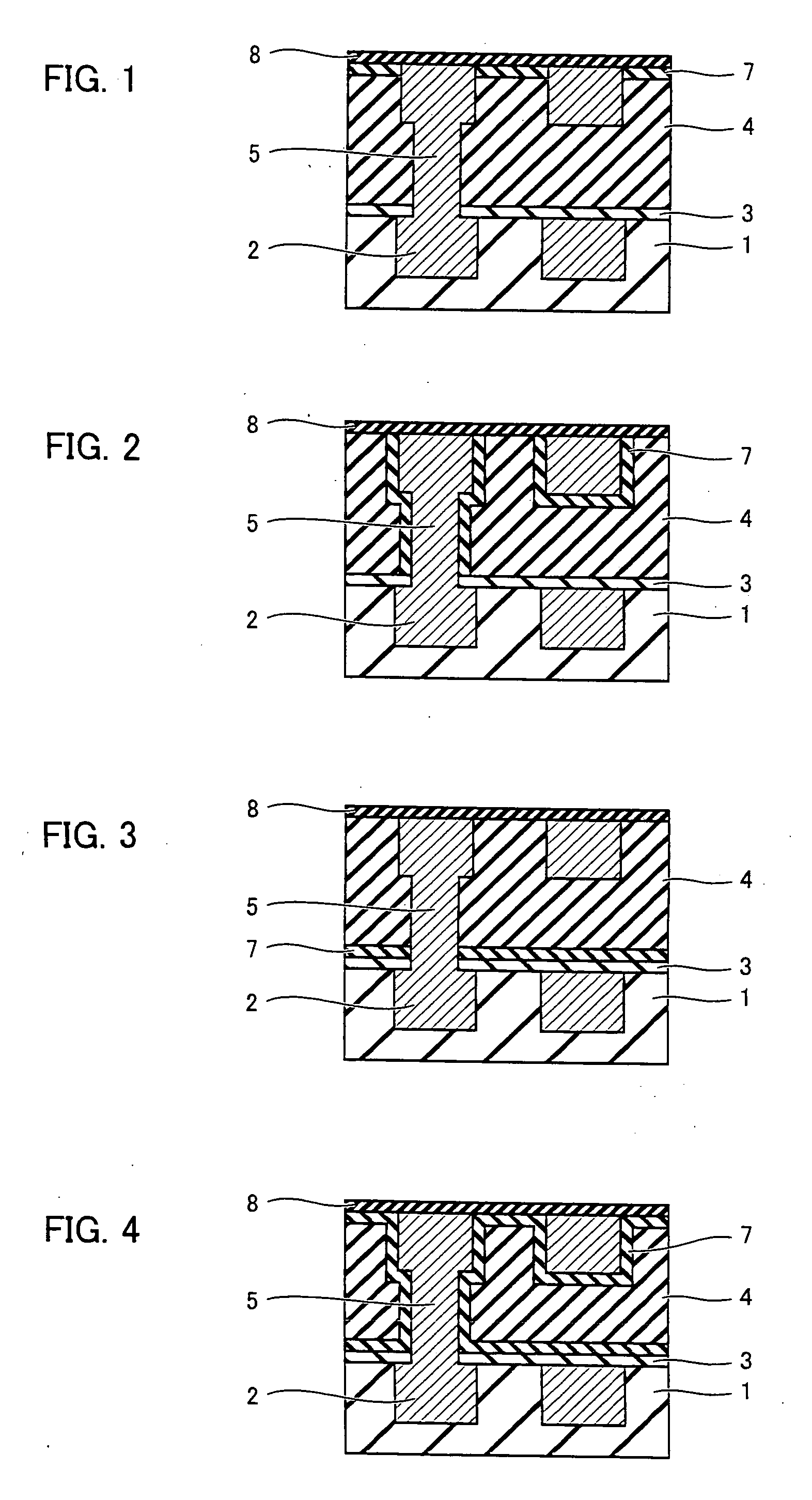

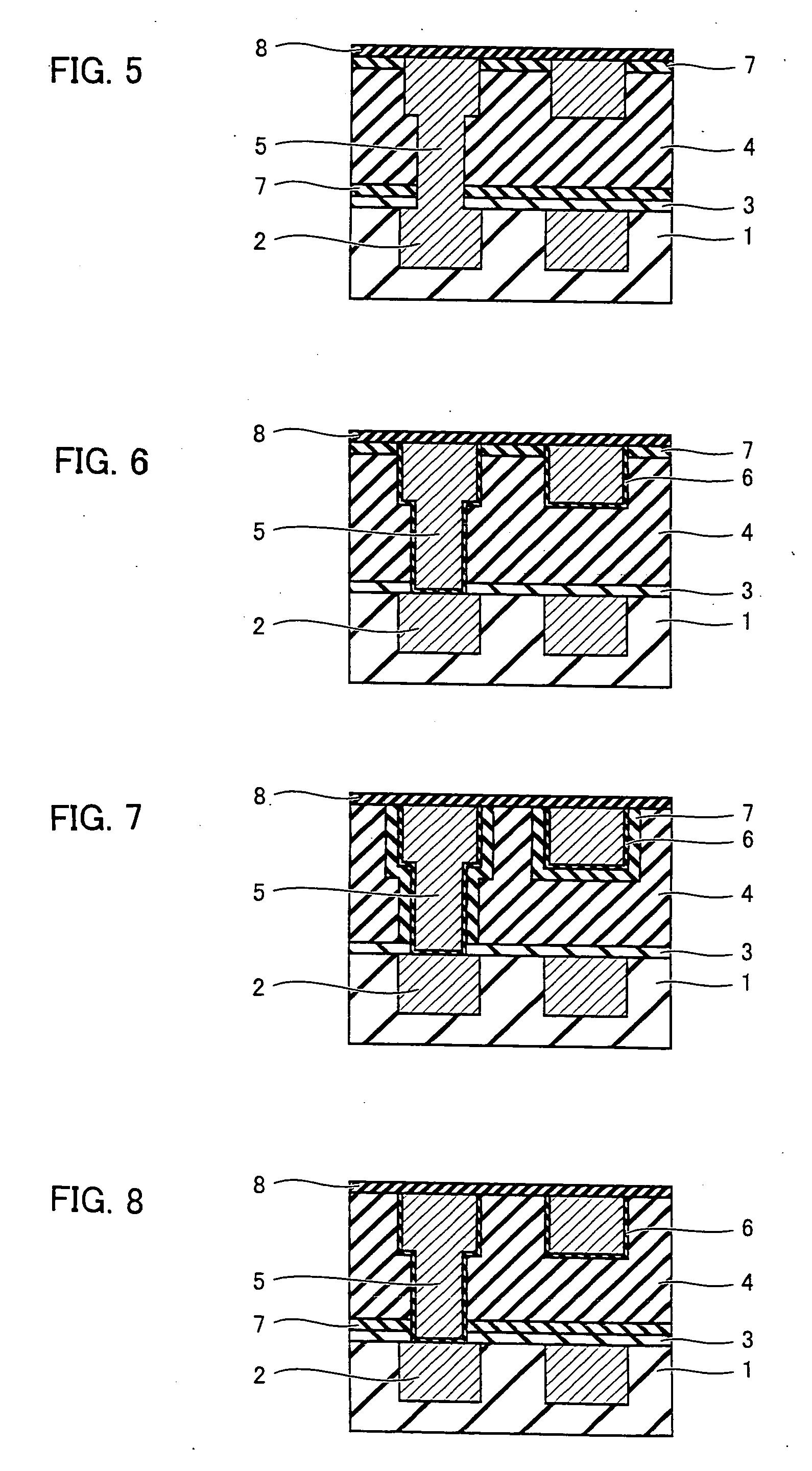

Borazine-based resin, and method for production thereof, borazine based resin composition, insulating coating and method for formation thereof, and electronic parts having the insulating coating

InactiveUS20060110610A1Easily filtered outEffective recoverySynthetic resin layered productsSemiconductor/solid-state device manufacturingYoung's modulusEngineering

Interlayer insulating films 5,7 (insulating films) provided in a memory capacitor cell 8 are formed between a gate electrode 3 and a counter electrode 8C formed on a silicon wafer 1. The interlayer insulating films 5,7 comprise a borazine-based resin, having a specific dielectric constant of no greater than 2.6, a Young's modulus of 5 GPa or greater and a leak current of no greater than 1×10−8 A / cm2.

Owner:HITACHI CHEM CO LTD +1

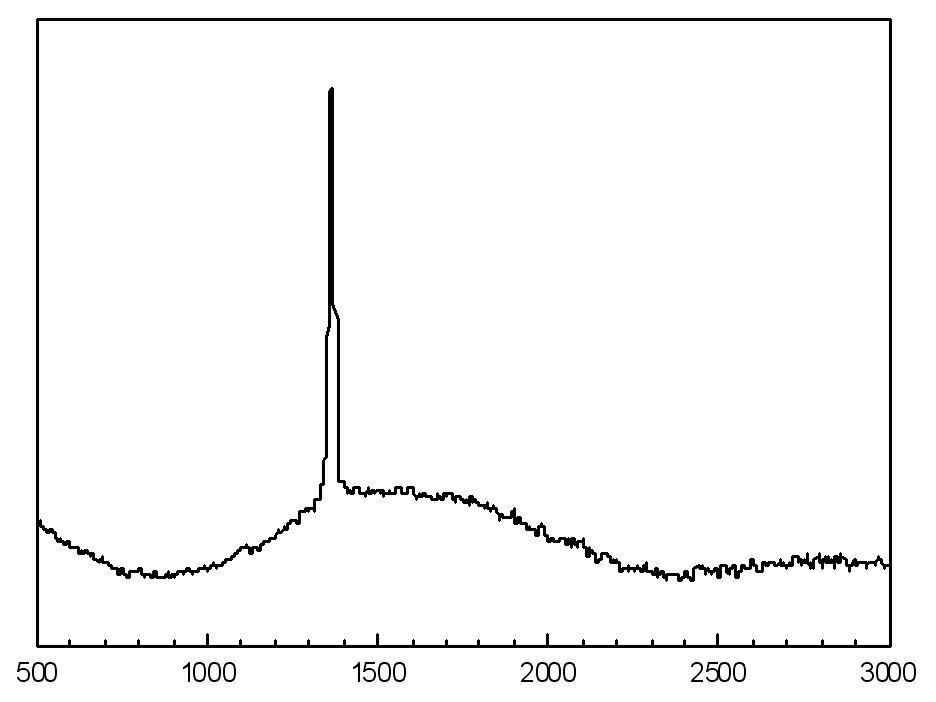

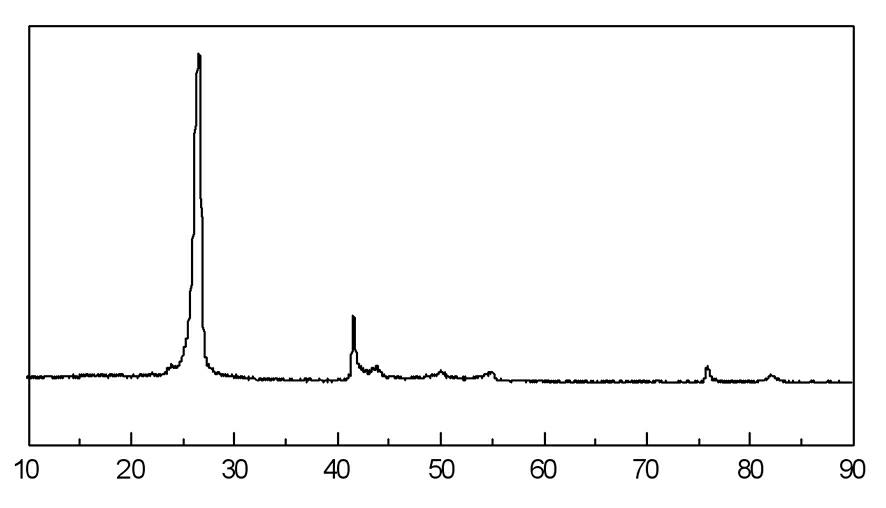

Carbon fiber reinforced boron nitride composite and preparation method thereof

ActiveCN102173844AImprove high temperature resistanceImprove antioxidant capacityCarbon fibersOxidation resistant

A carbon fiber reinforced boron nitride composite and a preparation method thereof belong to the field of the ceramic-based composites. The carbon fiber reinforced boron nitride composite uses a carbon fiber as a reinforcement body; and the liquid borazine precursor of which the B / N atomic ratio is 1:1 is converted to a boron nitride matrix. The preparation method comprises the following steps: the carbon fiber is weaved into a three-dimensional fabric, the liquid borazine of which the B / N atomic ratio is 1:1 is completely soaked in the carbon fiber fabric at 80-120 DEG C under 1-15MPa, the temperature is kept for 10-70 hours to crosslink and solidify the liquid borazine; and the product obtained through solidifying is cracked, soaked, crosslinked and cracked again for 2-6 times to prepare the finished product. The carbon fiber reinforced boron nitride composite is a new structure / function integrating material suitable for the aviation and aerospace field and has good high temperatureresistance, oxidation resistance and ablation resistance.

Owner:NAT UNIV OF DEFENSE TECH

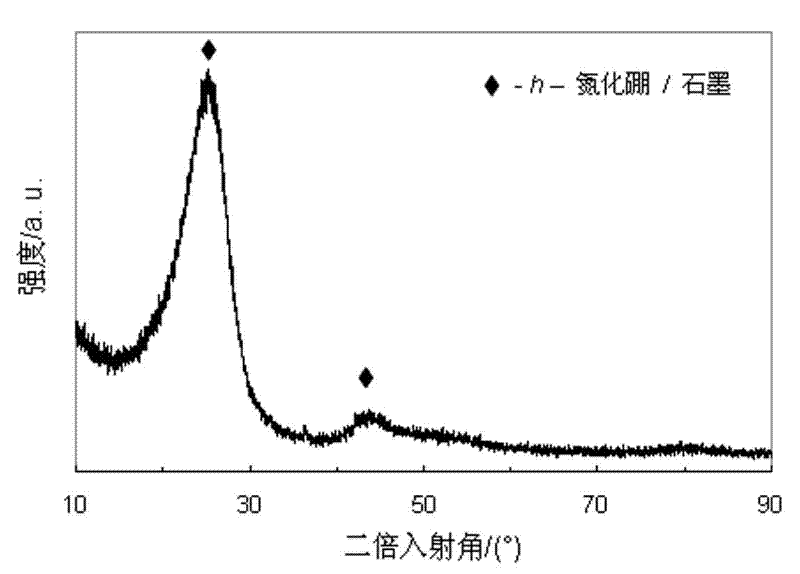

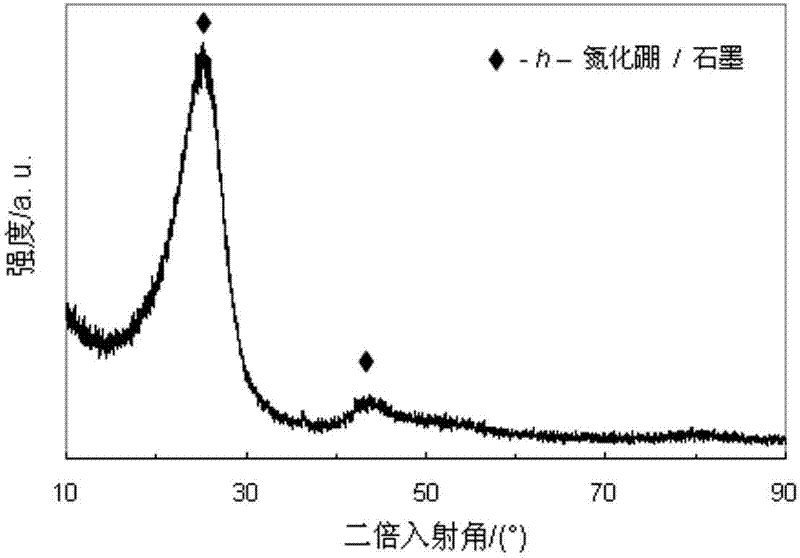

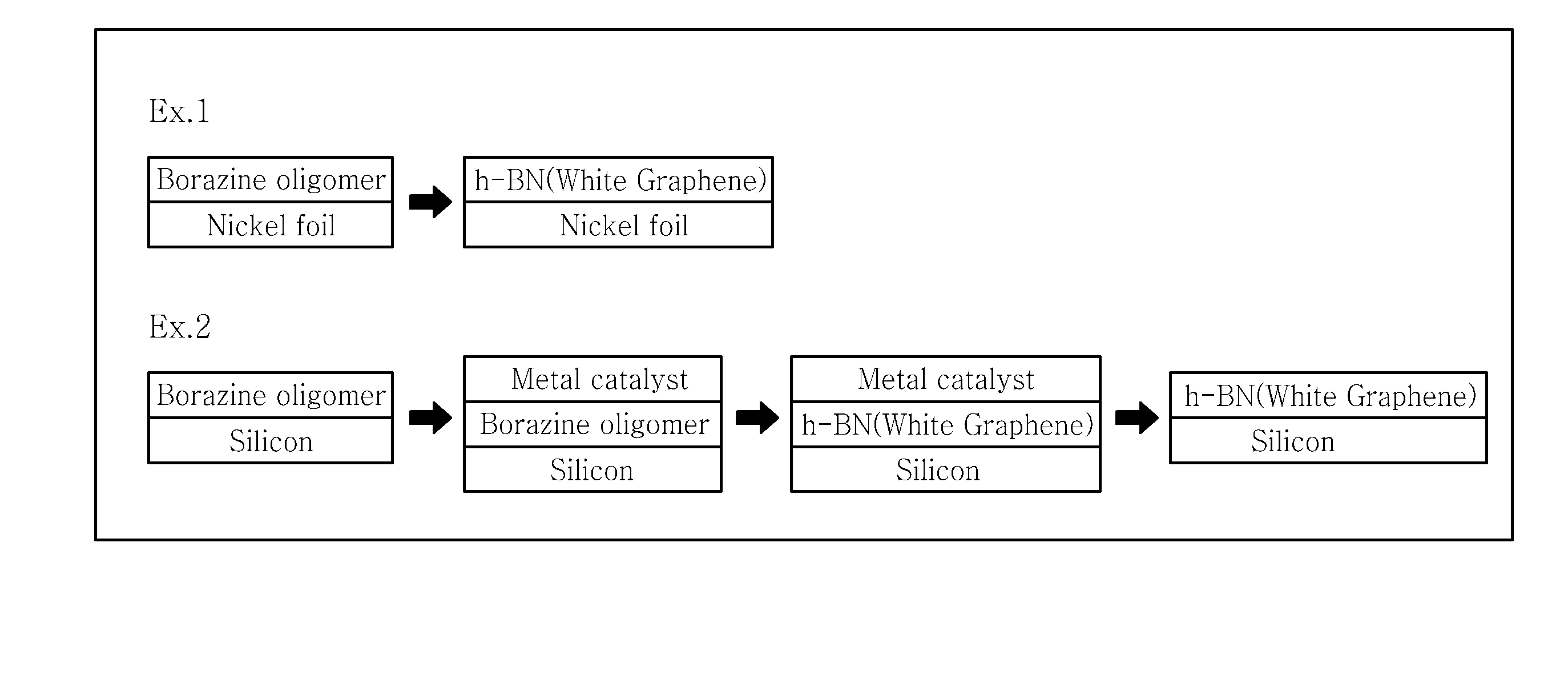

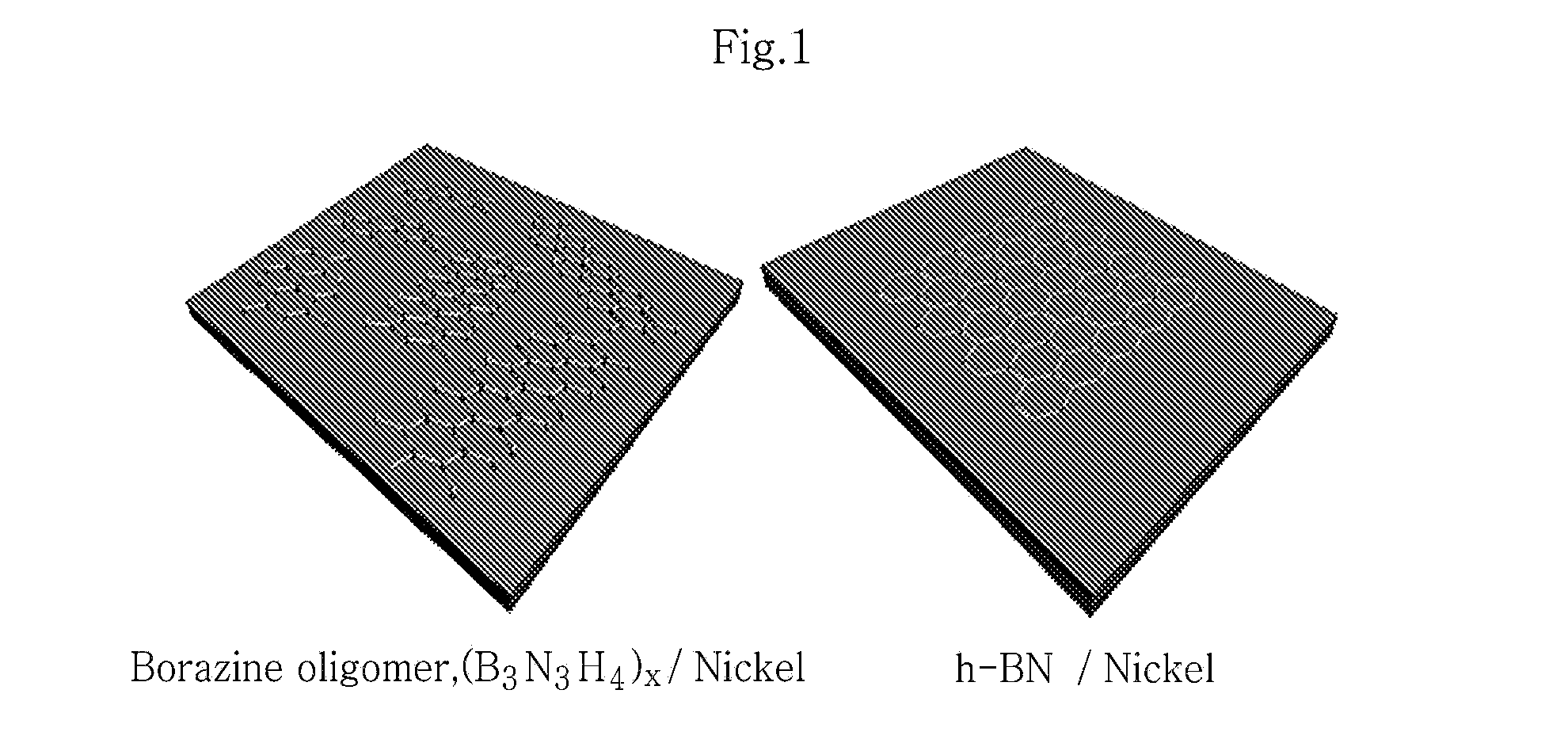

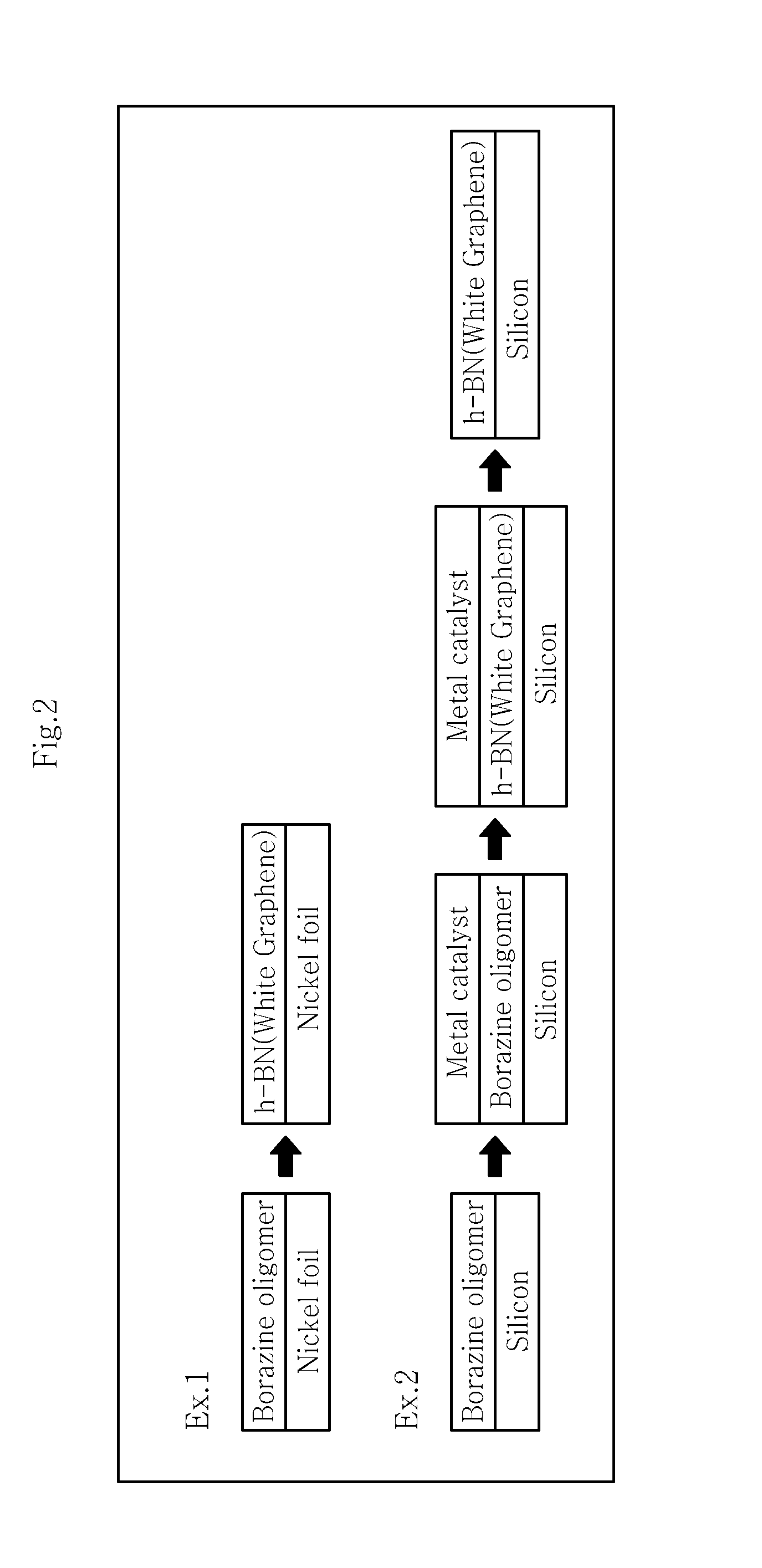

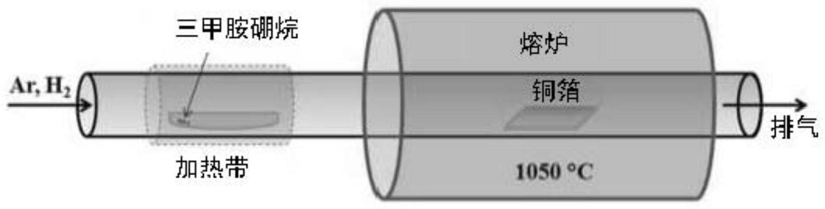

Method for producing hexagonal boron nitride film using borazine oligomer as a precursor

ActiveUS20150086460A1Low costSimple processNitrogen compoundsElectric discharge heatingOligomerMetal catalyst

Provided is a method for producing a high-quality boron nitride film grown by using a borazine oligomer as a precursor through a metal catalyst effect. The method solves the problems, such as control of a gaseous precursor and vapor pressure control, occurring in CVD(Chemical vapor deposition) according to the related art, and a high-quality hexagonal boron nitride film is obtained through a simple process at low cost. In addition, the hexagonal boron nitride film may be coated onto various structures and materials. Further, selective coating is allowed so as to carry out coating in a predetermined area and scale-up is also allowed. Therefore, the method may be useful for coating applications of composite materials and various materials.

Owner:KOREA INST OF SCI & TECH

Methods of forming a boron nitride, a method of conditioning a ballistic weapon, and a metal article coated with a monomeric boron-nitrogen compound

A method of forming a boron nitride. The method comprises contacting a metal article with a monomeric boron-nitrogen compound and converting the monomeric boron-nitrogen compound to a boron nitride. The boron nitride is formed on the same or a different metal article. The monomeric boron-nitrogen compound is borazine, cycloborazane, trimethylcycloborazane, polyborazylene, B-vinylborazine, poly(B-vinylborazine), or combinations thereof. The monomeric boron-nitrogen compound is polymerized to form the boron nitride by exposure to a temperature greater than approximately 100° C. The boron nitride is amorphous boron nitride, hexagonal boron nitride, rhombohedral boron nitride, turbostratic boron nitride, wurzite boron nitride, combinations thereof, or boron nitride and carbon. A method of conditioning a ballistic weapon and a metal article coated with the monomeric boron-nitrogen compound are also disclosed.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Preparation method of SiBN(C) ceramic fiber

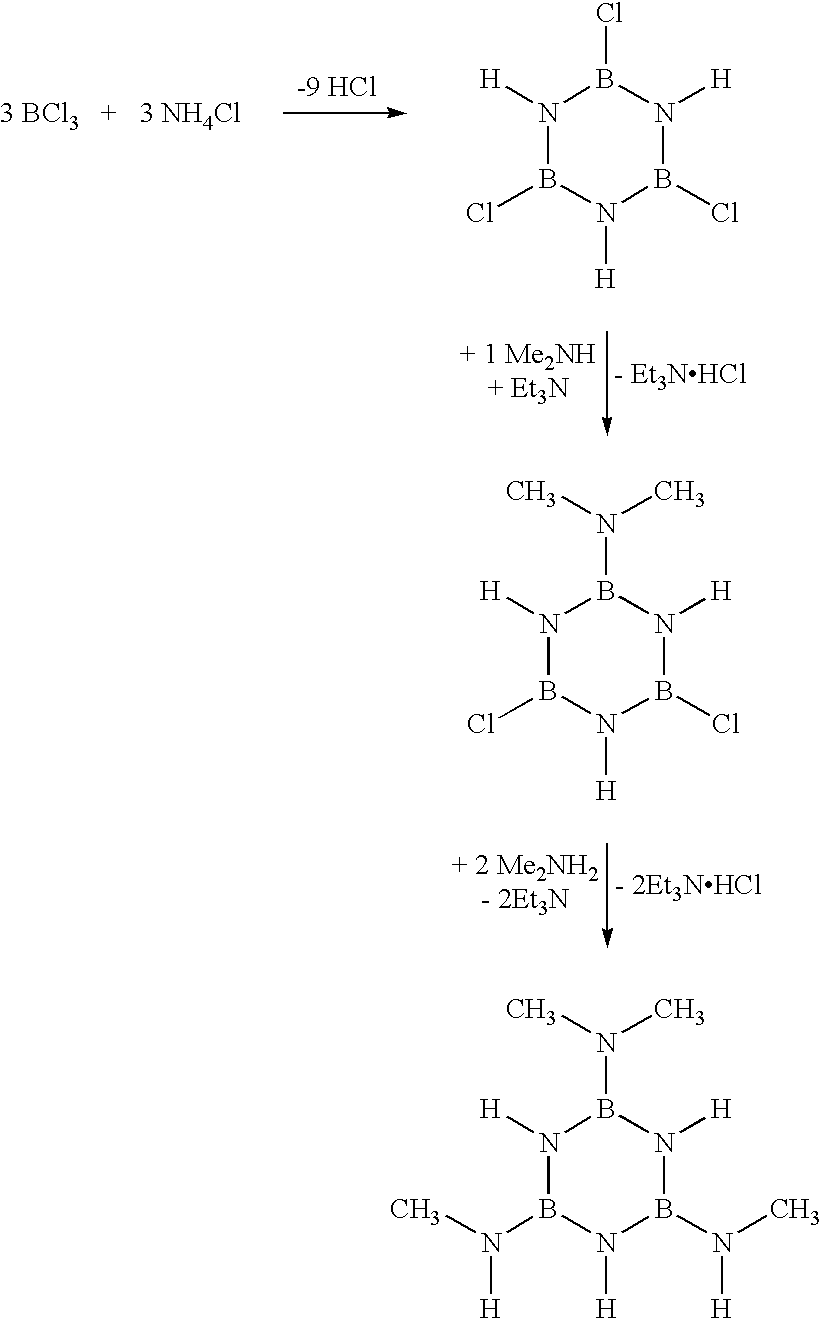

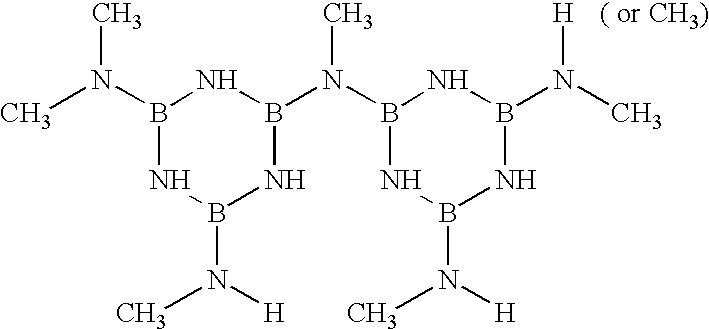

The invention discloses a preparation method of a SiBN(C) ceramic fiber. The method comprises the following steps of: using alkyl amine and B-trichloroborazine as initial raw materials, and triethylamine as a precipitating agent; adding alkyl amine and TCB in a mo;ar ratio of 3:1, and an excess amount of triethylamine into a reactor for reaction; filtering products after the reaction and obtaining a filtrate which is an alkyl amino borazine monomer; carrying out polymerization to the monomer with heating; cooling to obtain a poly alkyl amino borazine precursor; adding the poly alkyl amino borazine precursor and polycarbosilane in a mass ratio of 1:15-15:1 into a toluene or a xylene solution; depriving a solvent by reduced pressure distillation and carrying out melt spinning to a hybrid precursor; and carrying out curing treatment and pyrolysis to obtain a SiBN(C) ceramic fiber. The method of the invention has a high synthesis yield and a technology thereof is simple; and the melt spinning of the precursor is completed in a general melt spinning equipment environment and without protection of expensive inert atmosphere, and has low coats and high efficiency; so as to realize large scale production.

Owner:NAT UNIV OF DEFENSE TECH

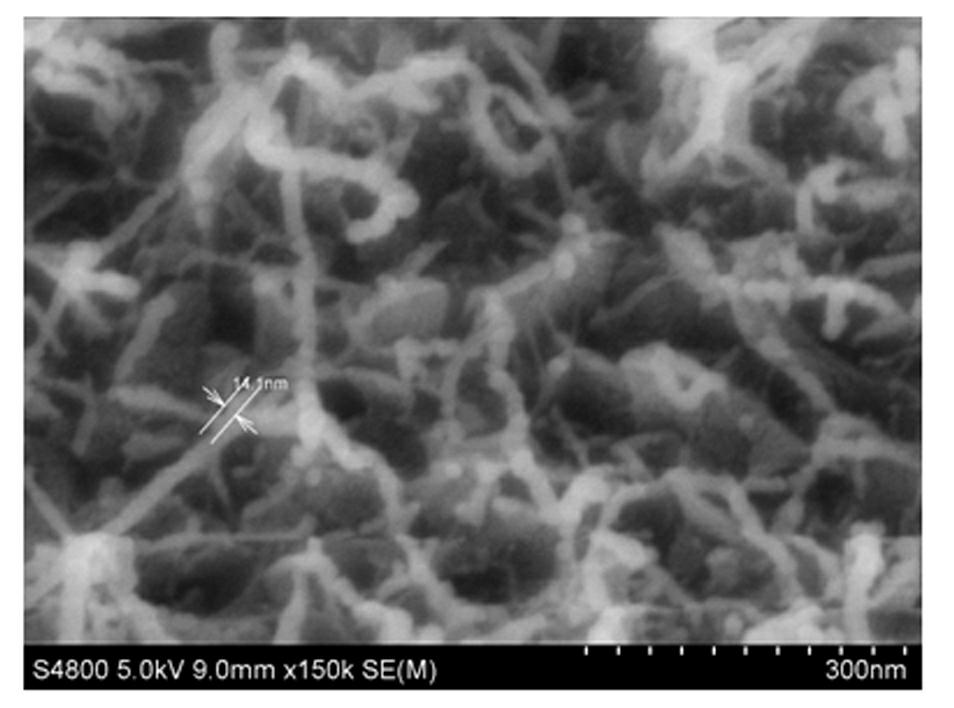

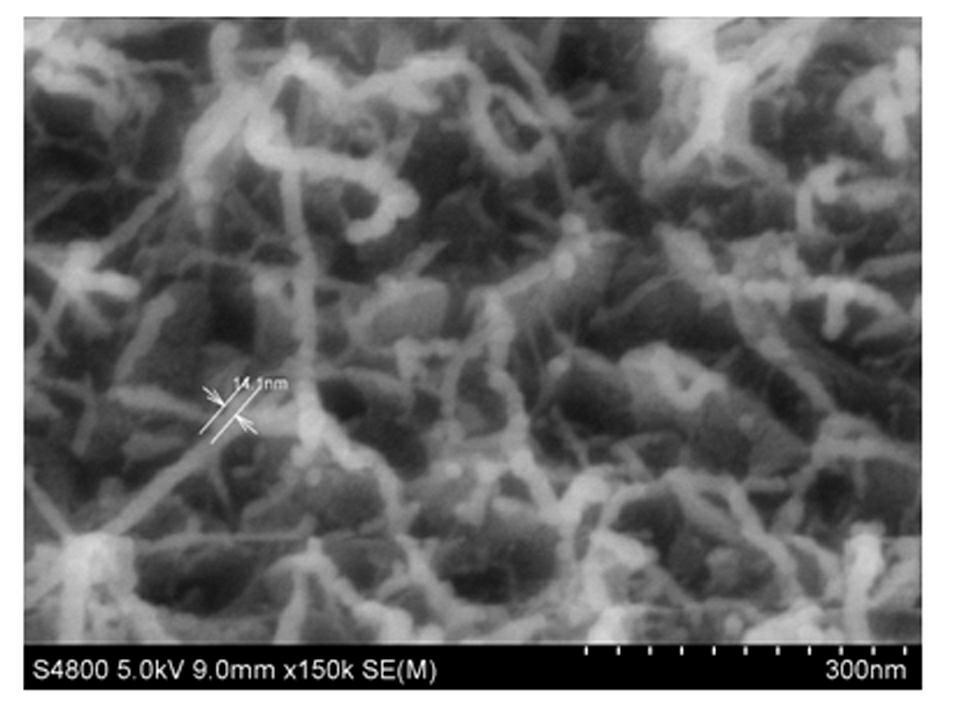

Method for preparing boron nitride nanowire by cracking of polymer

ActiveCN102126710AUniform diameter distributionIncrease contact areaNitrogen compoundsChemical industrySemiconductor materialsNanowire

The invention provides a method for preparing a boron nitride nanowire by cracking of a polymer. The method comprises the following steps: synthesizing a polyalkylamino borazine precursor according to the prior art: grinding the precursor under the protective condition of inert gas and screening the grinded precursor through a 1000-mesh sieve; placing the precursor powder in a graphite boat, rising the temperature to 100-200 DEG C at the speed of 3-10 DEG C / min in the presence of high-pure nitrogen in a tubular furnace, and then insulating for 1-3 hours; rising the temperature to 500-700 DEG C at the speed of 3-10 DEG / min, and then insulating for 1-3 hours; at the atmosphere of nitrogen, heating to 1000-1600 DEG C at the rising speed of 3-10 DEG C / min, then insulating for 0.5-5 hours, and then cooling along with the furnace so as to obtain the boron nitride nanowire. The diameter of the nanowire prepared by the method is about 13-18 nm and is evenly distributed, no catalyst is used, preparation temperature is low, and energy is saved, thereby reducing the cost; and the method is simple in process, is convenient for operation and is easy to achieve large scale; and as a structure reinforced material, a semiconductor material, a wave-transparent material and the like, the prepared boron nitride nanowire has a good prospect of application.

Owner:NAT UNIV OF DEFENSE TECH

Process for preparing low dielectric constant material

InactiveUS20050181628A1Easy to produceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesArylSilylene

A process for preparing a low dielectric constant material comprising heat-treating a compound containing a borazine skeleton structure of the formula: wherein at least one of R1 to R6 is a bond which binds said borazine skeleton structure to a molecule of a inorganic or organic compound, and / or R1 to R6 are independently a hydrogen atom, an alkyl group having 1 to 20 carbon atoms, an aryl group, a substituted aryl group, an alkenyl group, an amino group, an alkylamino group, an alkoxyl group, a thioalkoxyl group, a carbonyl group, a silyl group, an alkylsilyl group, a phosphino group, an alkylphosphino group or a group of the formula: Si(OR7)(OR8)(OR9), and at least one of R1 to R6 is not a hydrogen atom.

Owner:MITSUBISHI ELECTRIC CORP

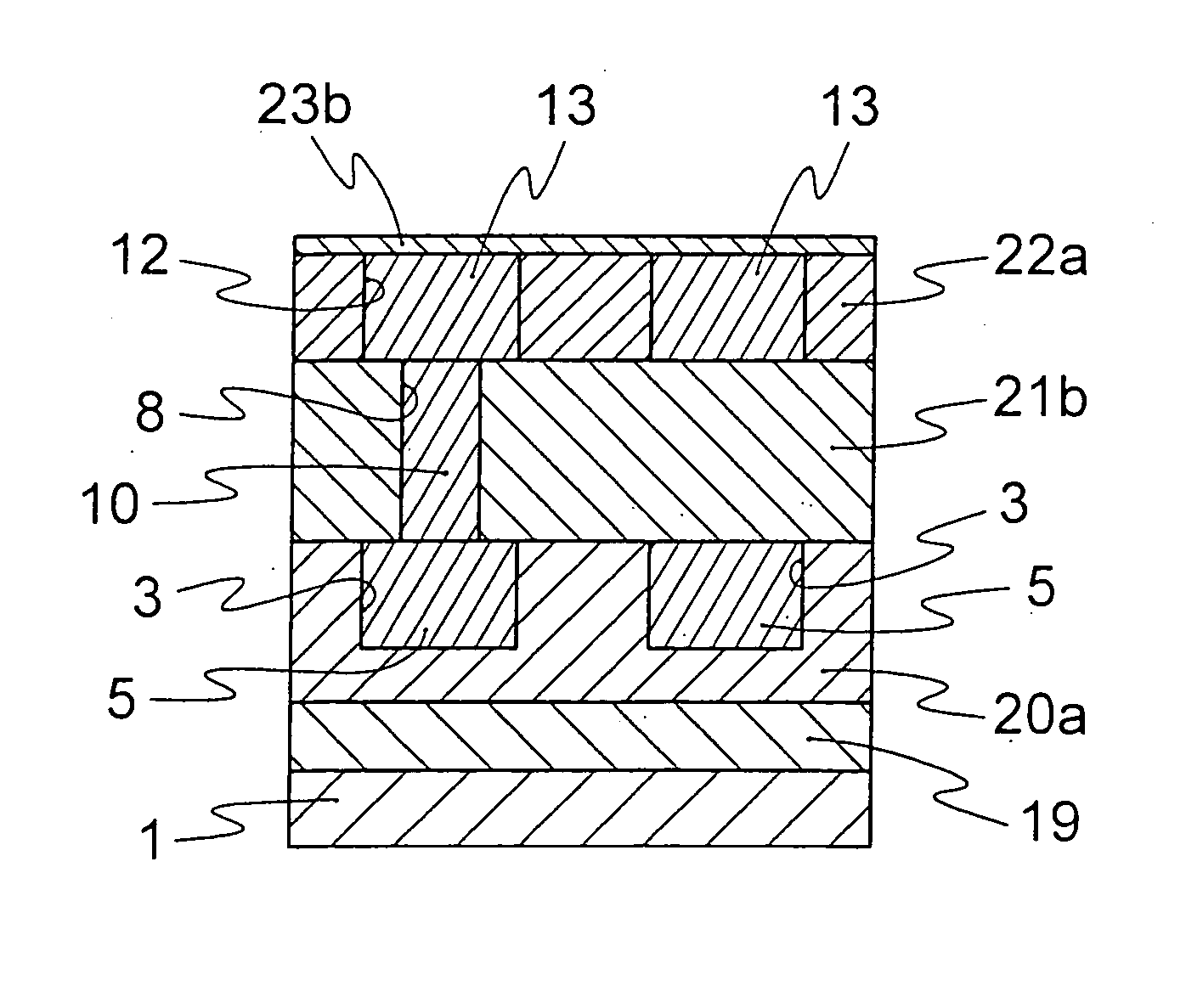

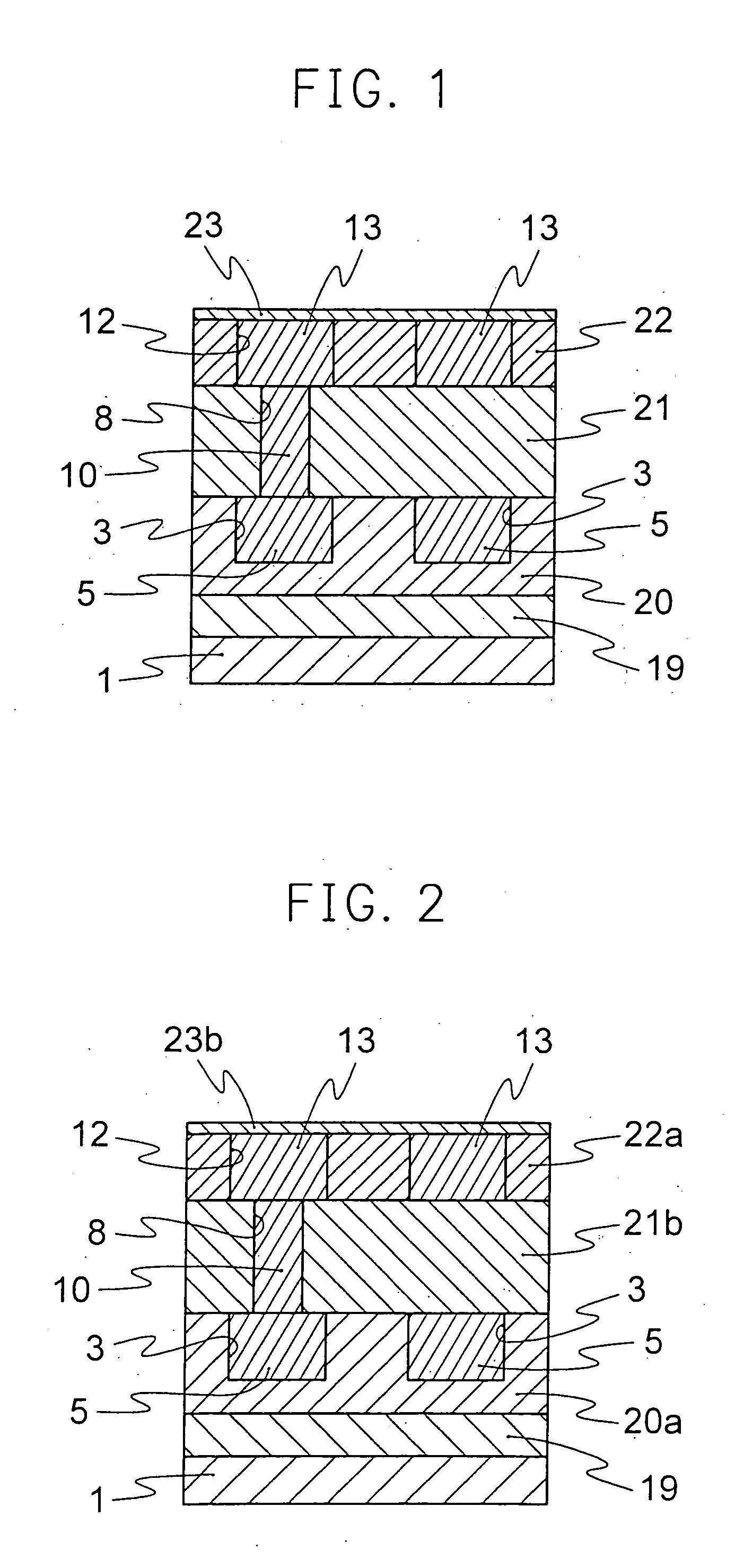

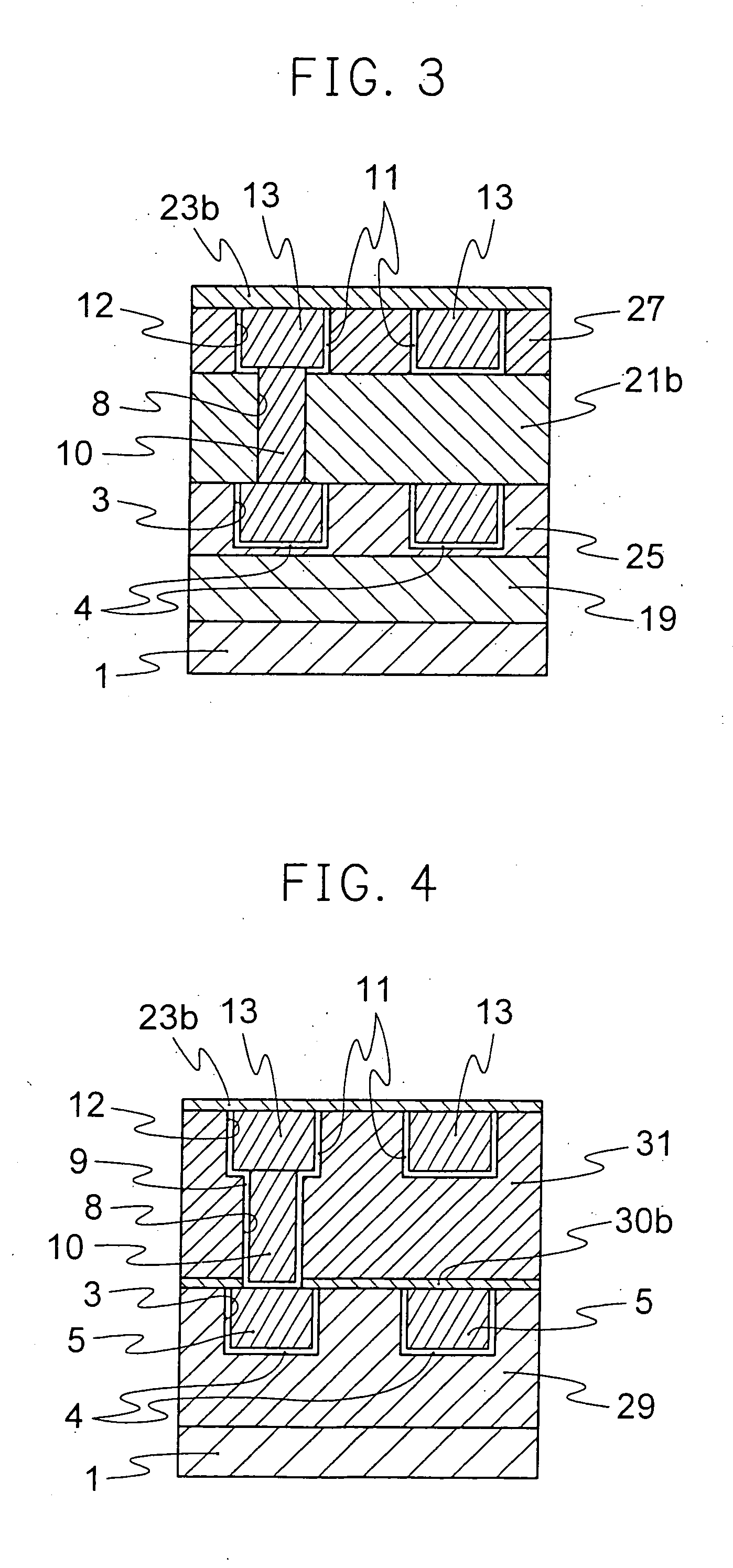

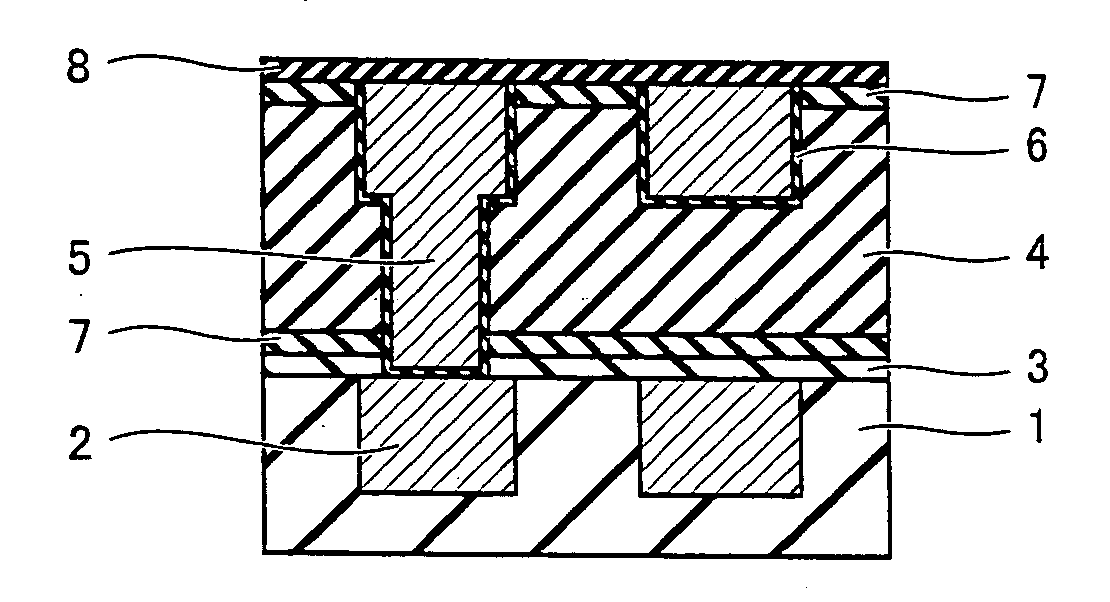

Semiconductor device and method of fabricating the same

ActiveUS20060286814A1Smooth connectionExcellent characteristicsSemiconductor/solid-state device detailsSolid-state devicesInsulation layerElectrical conductor

There is provided a semiconductor device and method of fabricating the same that employs an insulation film of a borazine-based compound to provided enhanced contact between a material for insulation and that for interconnection, increased mechanical strength, and other improved characteristics. The semiconductor device includes a first insulation layer having a recess with a first conductor layer buried therein, an etching stopper layer formed on the first insulation layer, a second insulation layer formed on the etching stopper layer, a third insulation layer formed on the second insulation layer, and a second conductor layer buried in a recess of the second and third insulation layers. The second and third insulation layers are grown by chemical vapor deposition with a carbon-containing borazine compound used as a source material and the third insulation layer is smaller in carbon content than the second insulation layer.

Owner:RENESAS ELECTRONICS CORP

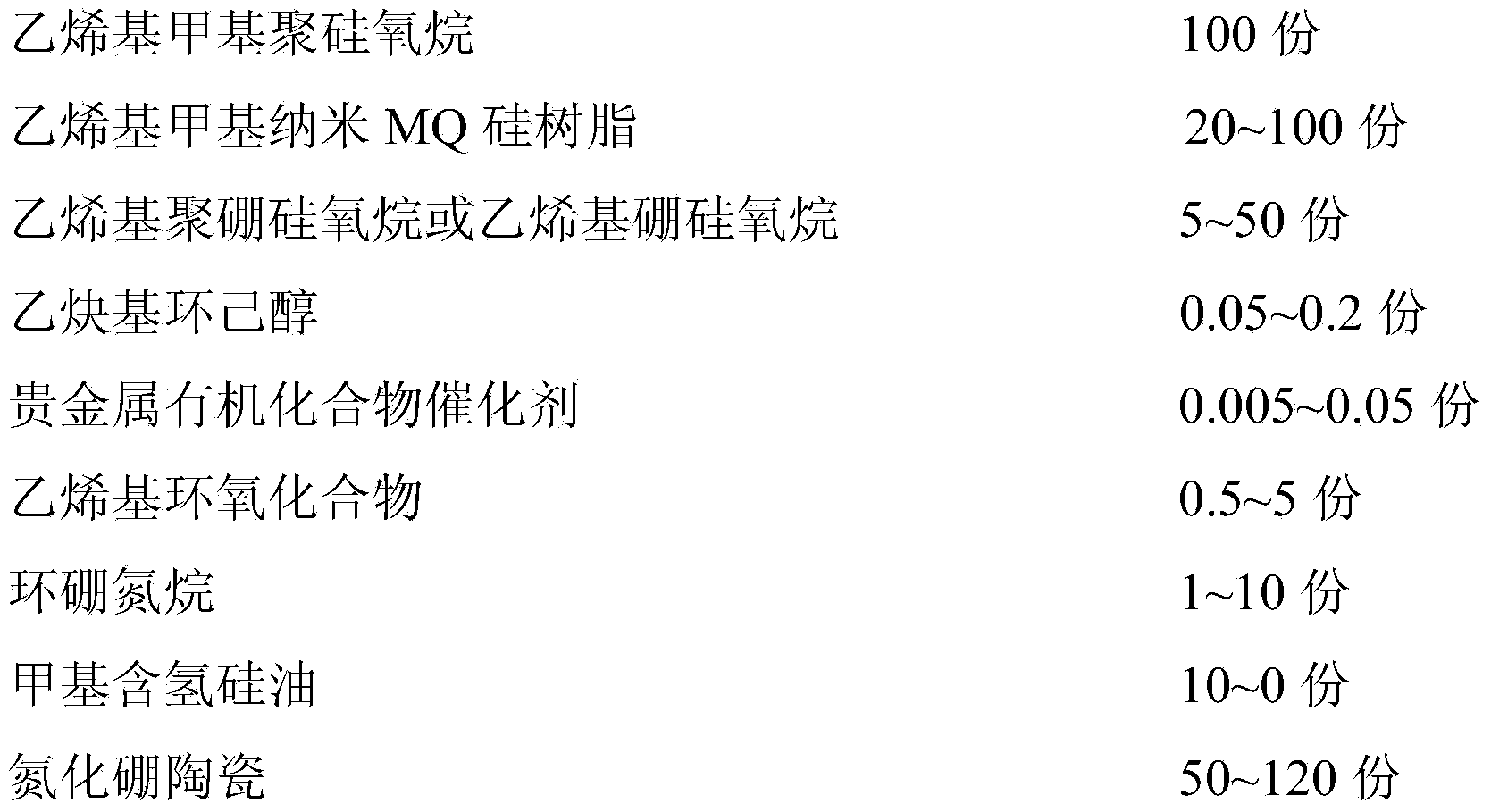

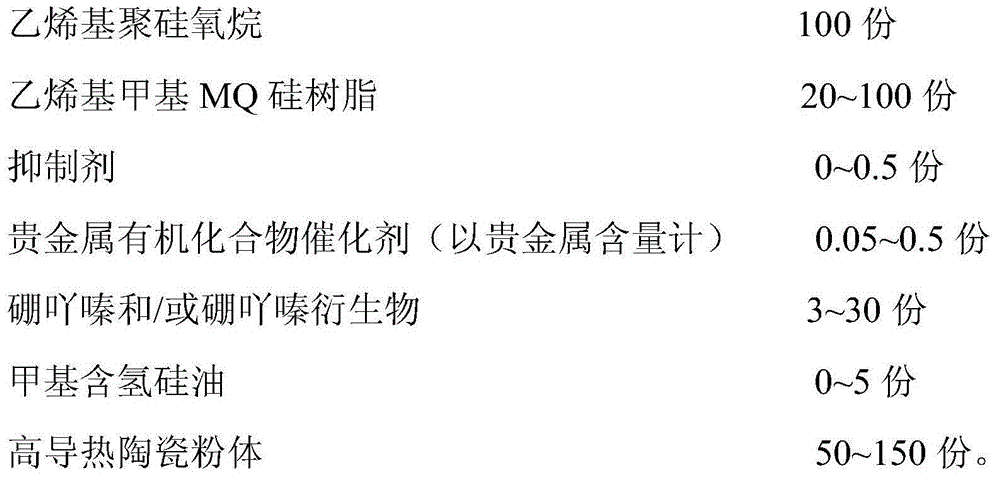

High-thermal-conductivity high-temperature-resistant polysiloxane ceramic composite material, as well as preparation method and applications thereof

ActiveCN103951983AImprove thermal conductivityIncrease elasticityHeat-exchange elementsAviationCeramic composite

The invention discloses a high-thermal-conductivity high-temperature-resistant polysiloxane ceramic composite material, as well as a preparation method and applications thereof. The composite material comprises the following components in parts by mass: 100 parts of vinyl polysiloxane, 20-100 parts of vinyl methyl MQ silicone resin, 0-0.5 part of inhibitor, 0.05-0.5 part of precious metal organic compound catalyst, 3-30 parts of borazine and / or borazine derivatives, 0-5 parts of methyl hydrogen silicone oil and 50-150 parts of high-thermal-conductivity ceramic powder. The high-thermal-conductivity high-temperature-resistant polysiloxane ceramic composite material is high in thermal conductivity coefficient, good in elasticity, waterproof, damp-proof, insulating, can absorb absorption, and has excellent high temperature ageing resistance, thus having wide application prospects in the fields of aviation, aerospace, electronics, electrics and communication and illumination and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

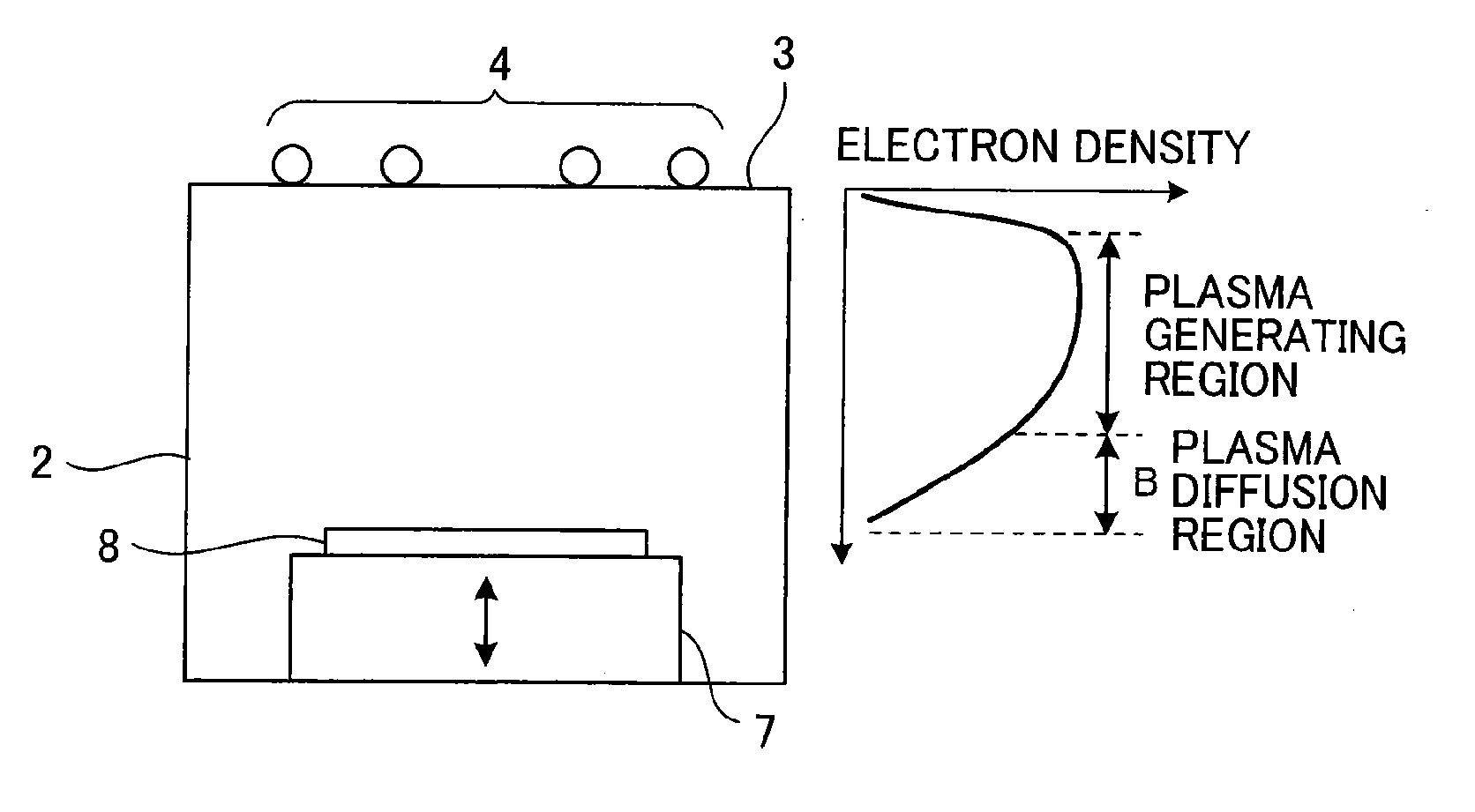

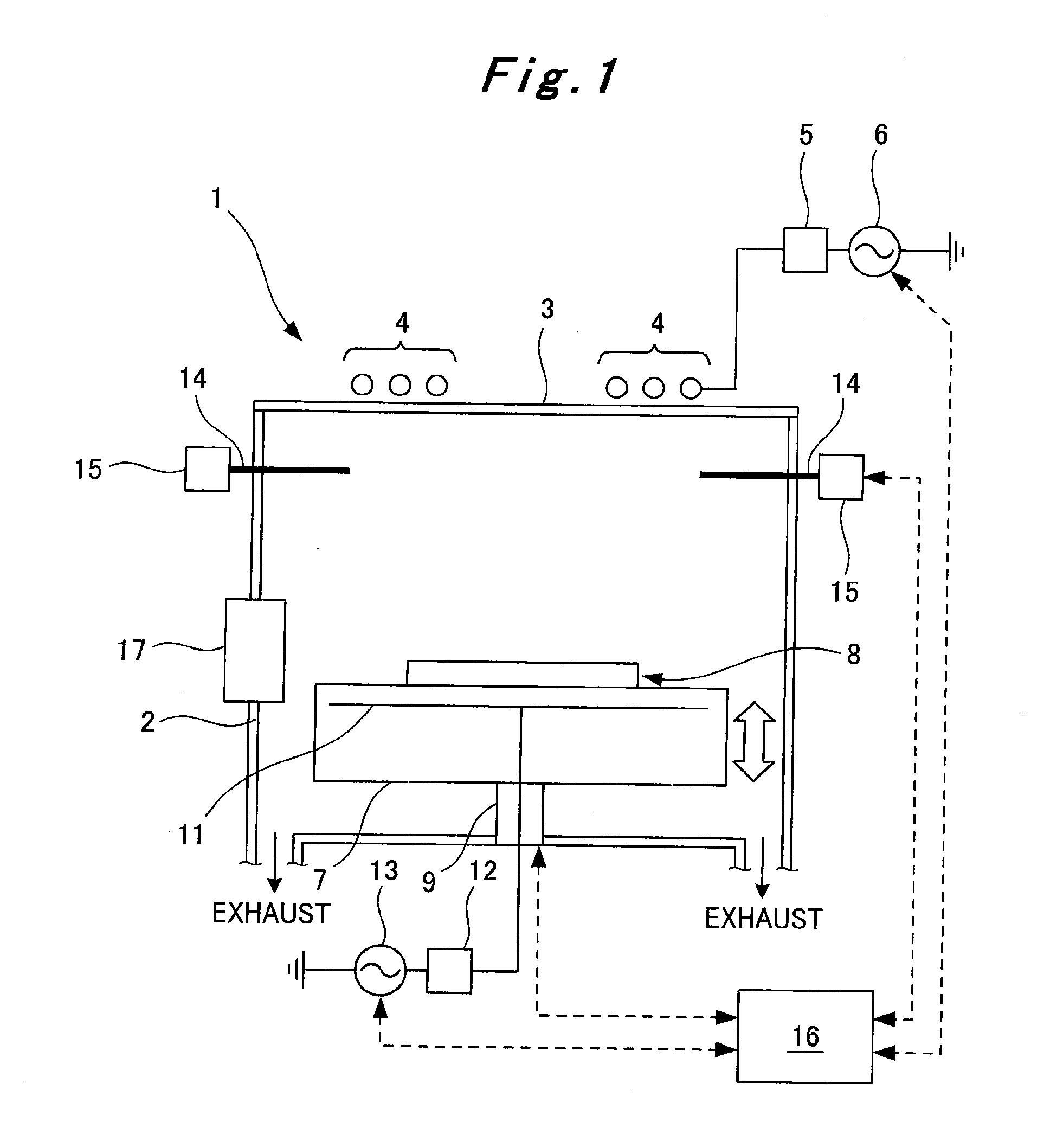

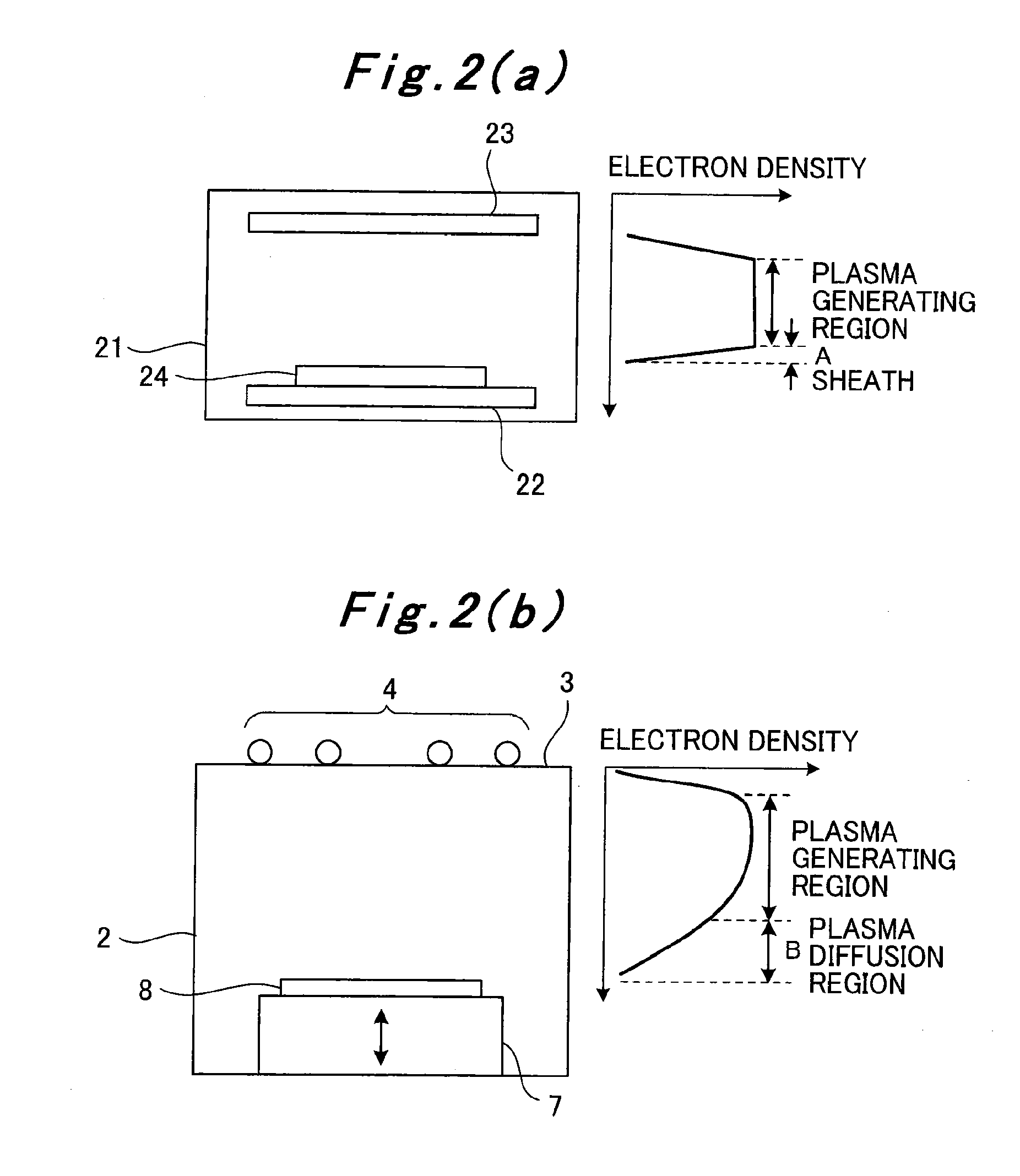

Insulating film for semiconductor device, process and apparatus for producing insulating film for semiconductor device, semiconductor device, and process for producing the semiconductor device

InactiveUS20110266660A1Reduce carbon contentHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesPlasma diffusionGas phase

An object is to provide an insulating film for a semiconductor device which has characteristics of a low permittivity, a low leakage current, and a high mechanical strength, undergoes less change in these characteristics with the elapse of time, and has an excellent water resistance, as well as to provide a process and an apparatus for producing the insulating film for a semiconductor device, a semiconductor device, and a process for producing the semiconductor device. A gas containing a raw material gas which gasified a predetermined alkylborazine compound is supplied in a chamber (2); an electromagnetic wave is introduced into the chamber (2) using with an inductive coupling type plasma generation mechanism (4, 5, 6) to convert the gas into a plasma; a substrate (8) is placed in a plasma diffusion region of the plasma; gas-phase polymerization is performed with borazine skeletal molecules, as a fundamental unit, dissociated from the alkylborazine compound by the plasma so as to form the insulating film for semiconductor devices on the substrate (8).

Owner:MITSUBISHI HEAVY IND LTD +1

Method for preparing boron nitride nanorod by using precursor conversion method

ActiveCN102120568ASimple processHigh purityNitrogen compoundsNanotechnologyOrganic solventCarbon nanotube

The invention relates to a method for preparing a boron nitride nanorod by using a precursor conversion method. The method for preparing the boron nitride nanorod comprises the following steps of: soaking a carbon nanotube in concentrated nitric acid at 60 DEG C for 10-24h, washing and drying; dissolving poly(alkylamino) borazine in an organic solvent, and soaking the dried carbon nanotube in a mixed solution; and filtering at a reduced pressure, then carrying out solid-liquid separation, placing solid in a high temperature finance and preserving the temperature for 0.5-5h at 60-200 DEG C in ammonia gas, then heating to 800-1500 DEG C in a heating speed of 60-450DEG C / min, preserving the temperature for 0.5-5h, and removing carbon element while pyrolyzing to obtain the boron nitride nanorod. The prepared boron nitride nanorod has the diameter of 50nm, has the advantages of simple process, no need of catalyst, high purity, low production cost and high efficiency and is easy to realize large-scale production. The prepared boron nitride nanorod can be applied to materials with the functions of hydrogen storage, catalysis, structure reinforcement and high-temperature resistance and has wide application prospect.

Owner:NAT UNIV OF DEFENSE TECH

Materials for electroluminescent devices

Materials containing one or more borazine rings are employed as materials for electroluminescent devices. The compounds have molecular structures represented by the following formula: in which R1-R6 are independently a metal; a whole or part of an optionally substituted borazine ring; hydrogen; halogen; hydroxyl; optionally substituted alkyl, cycloalkyl, aryl, acyl, alkoxy, acyloxy, amino, acylamino, aralkyl, cyano, carboxyl, thio, vinyl, styryl, aminocarbonyl, carbamoyl, aryloxycarbonyl, phenoxycarbonyl, or alkoxycarbonyl, as well as recognized donor and acceptor groups. The compounds have high thermal stability as well as hole and electron mobilities.

Owner:VERSITECH LTD

Boron nitride material and method of preparation thereof

ActiveCN109196139APolycrystalline material growthNitrogen compoundsBoron carbonitrideOptoelectronics

A method of preparing a boron nitride material, such as boron nitride (BN) or boron carbonitride (BCN), is provided. The method may include providing a substrate, and sublimating an amine borane complex onto the substrate to obtain the boron nitride material. The amine borane complex may include, but is not limited to, borazine, amino borane, trimethylamine borane and triethylamine borane. In addition, the temperature at which the sublimating is carried out may be varied to control composition of the boron nitride material formed. In addition, various morphologies can be obtained by using thepresent method, namely films, nanotubes and porous foam.

Owner:NANYANG TECH UNIV

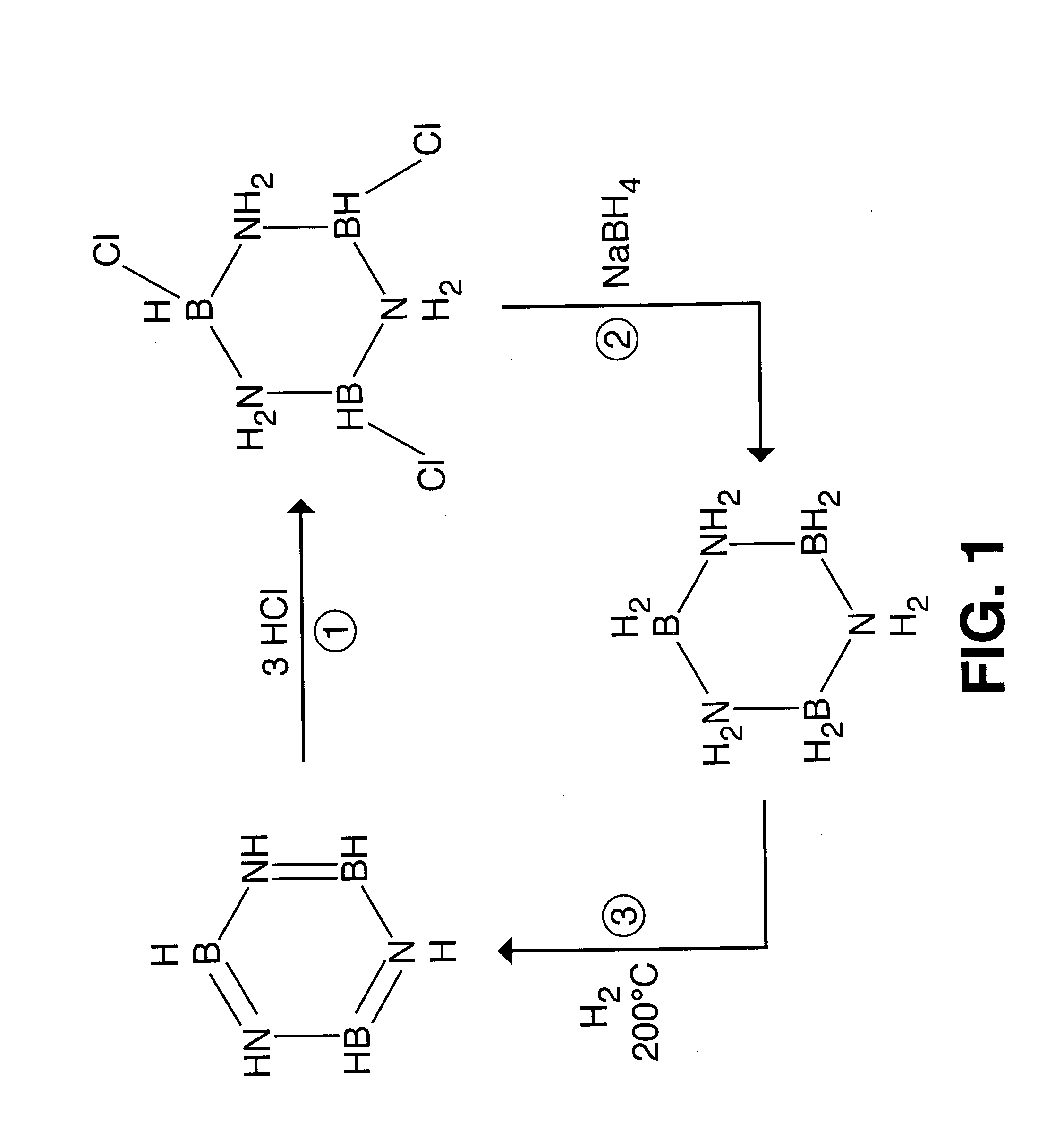

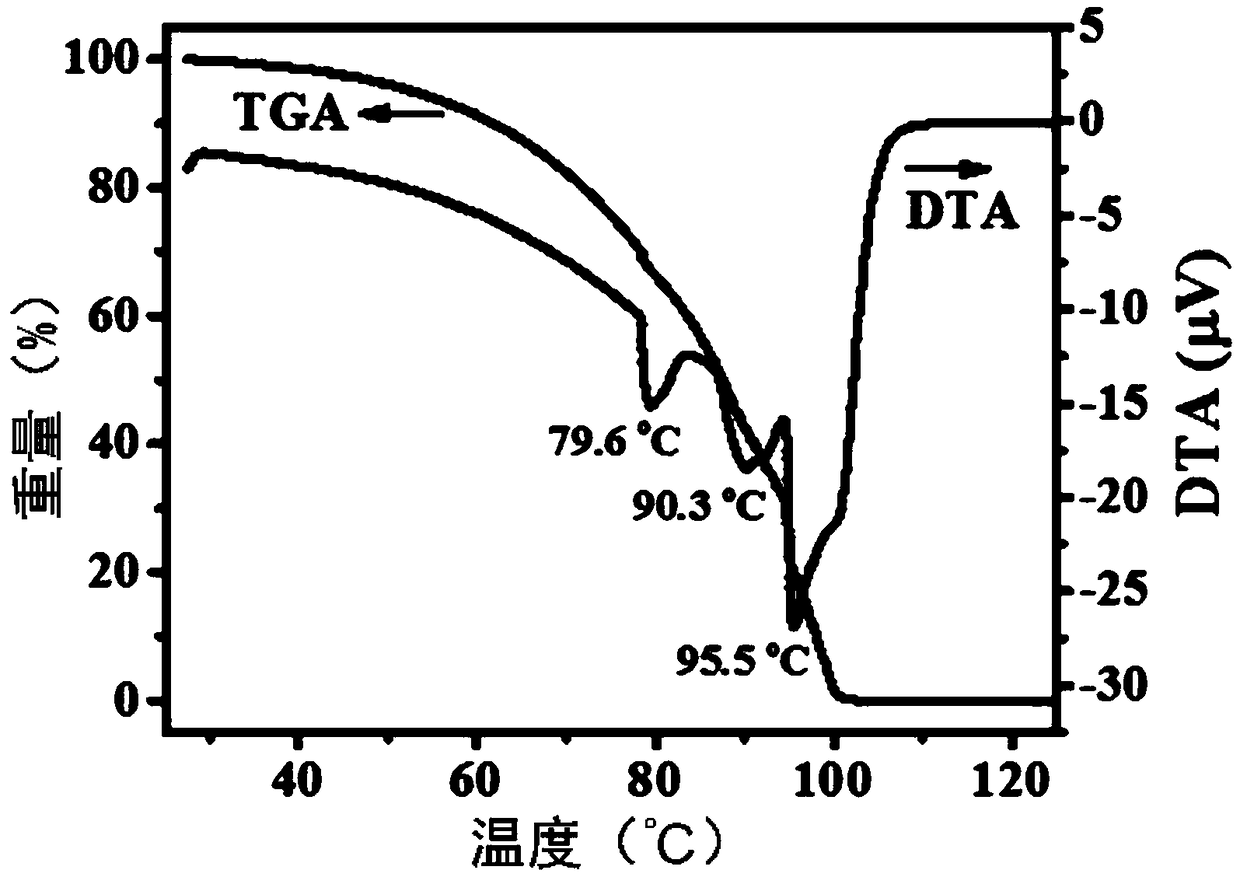

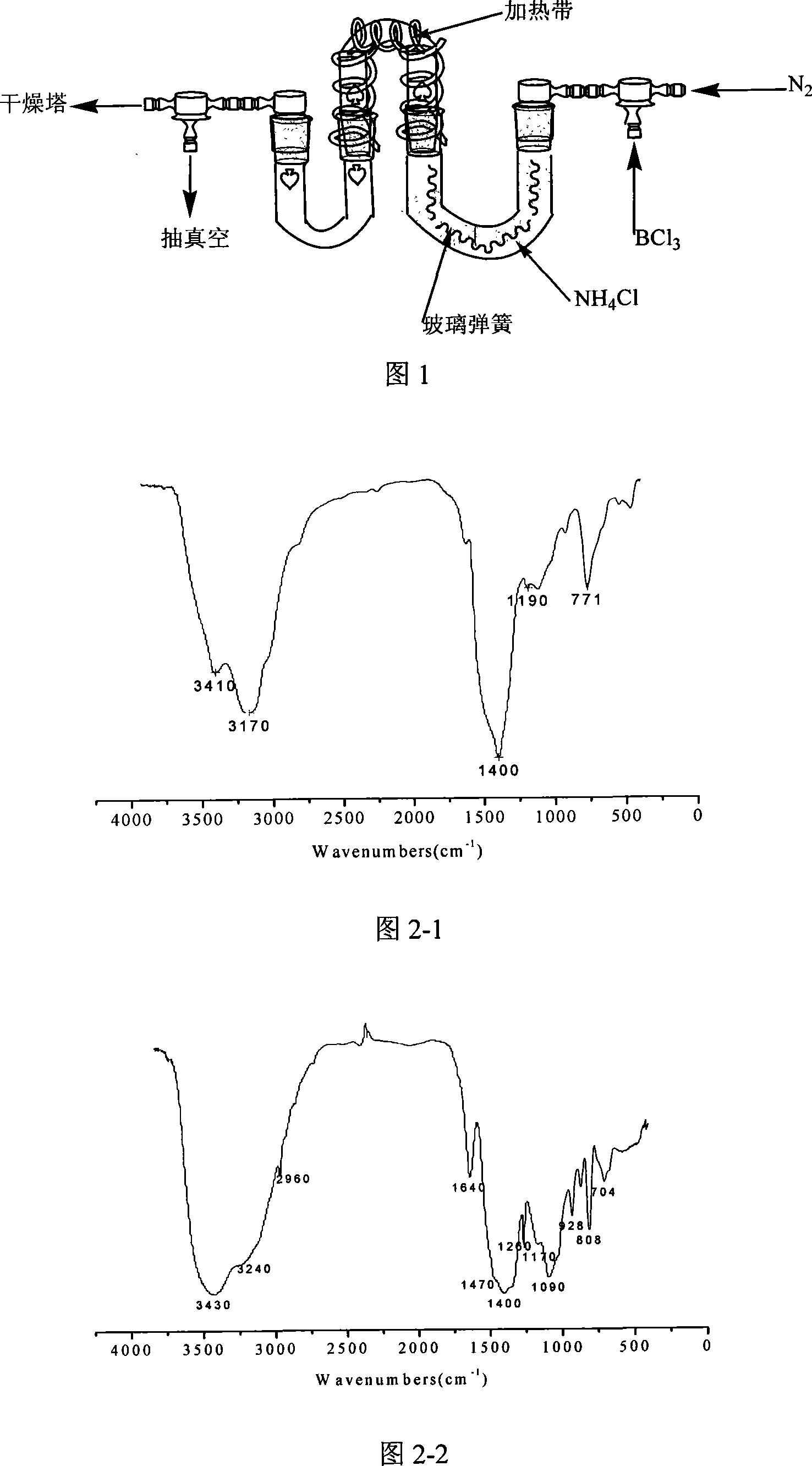

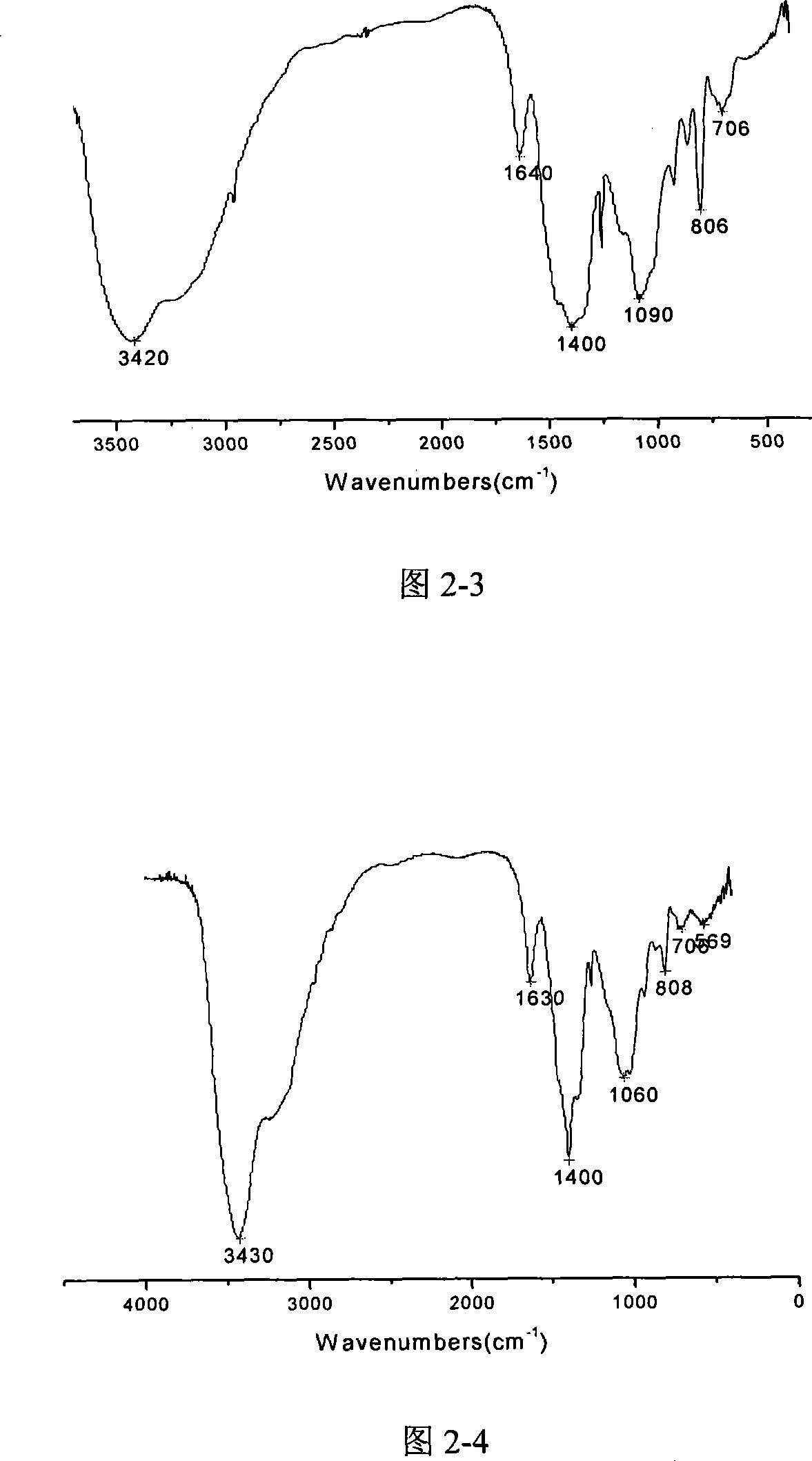

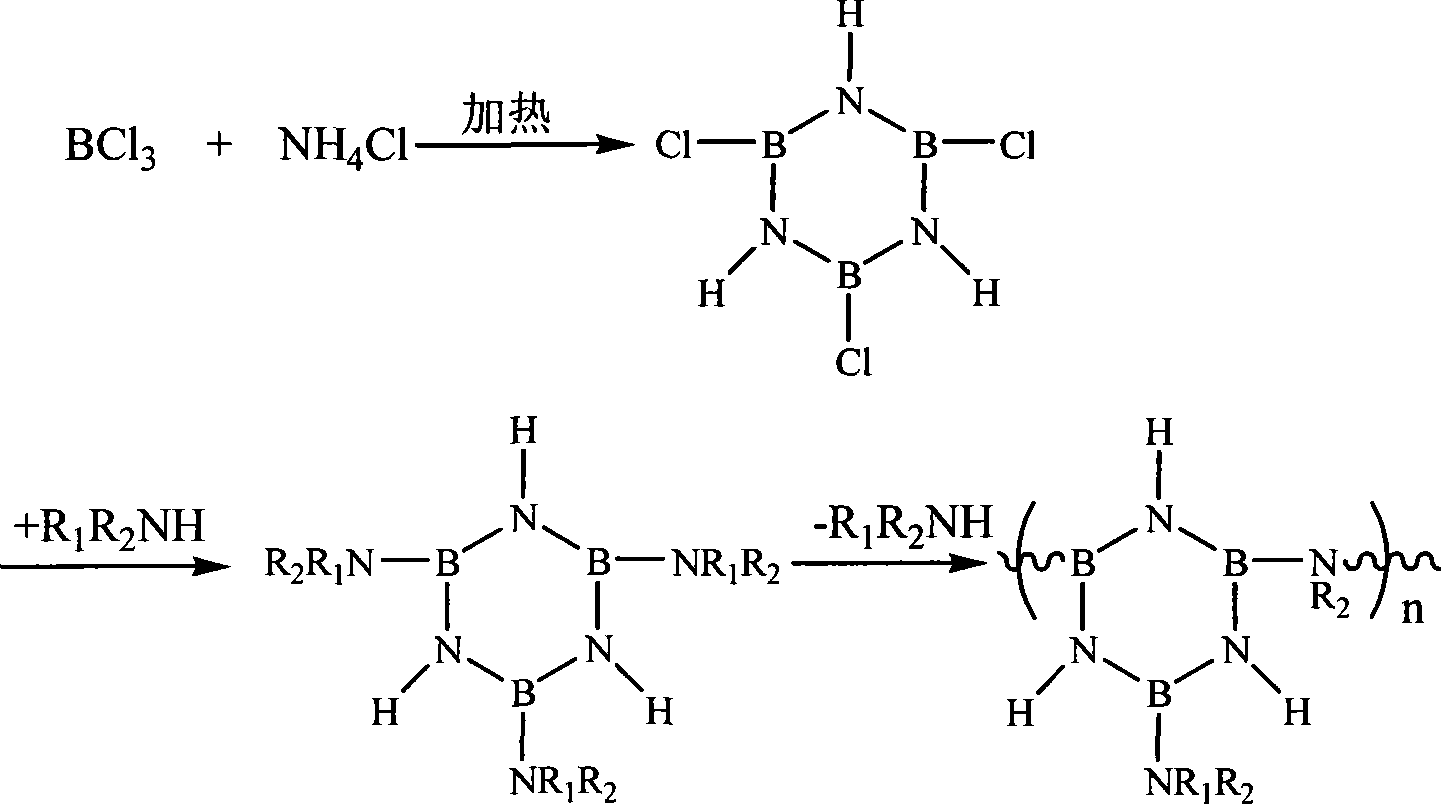

Method for producing boron-nitrogen ceramic fibre fore-runner body

The invention relates to a preparation method of a boron nitrogen ceramic fiber precursor. The method synthesizes a trichloroborazine crystal through a high-temperature reaction of boron trichloride and ammonium chloride, and the product is mixed with an aliphatic compound containing an amino or imine group. The alkylamine is reacted at low temperature, then raised to room temperature for reaction, and then heated to 130°C to 250°C for reaction to obtain a precursor polymer. The precursor has good spinnability, and the pyrolysis product contains very little carbon element, which can make the final boron nitrogen fiber have good wave permeability.

Owner:DONGHUA UNIV

Low dielectric constant insulating material and semiconductor device using the material

ActiveUS7427443B2Shorten speedIncrease capacityLayered productsSemiconductor/solid-state device detailsParasitic capacitanceInterconnection

The use of a material possessing a six-member borazine ring consisting of at least boron and nitrogen elements in the form of a low dielectric constant insulating film in a hard mask, a Cu diffusion barrier layer and an etching stopper which are necessary when low dielectric constant interlayer insulating films and Cu wiring in the multilayer interconnection of an LSI allows the parasitic capacity between the multilayer wirings to be suppressed and enables the ULSI to produce a high-speed operation.

Owner:HITACHI CHEM CO LTD

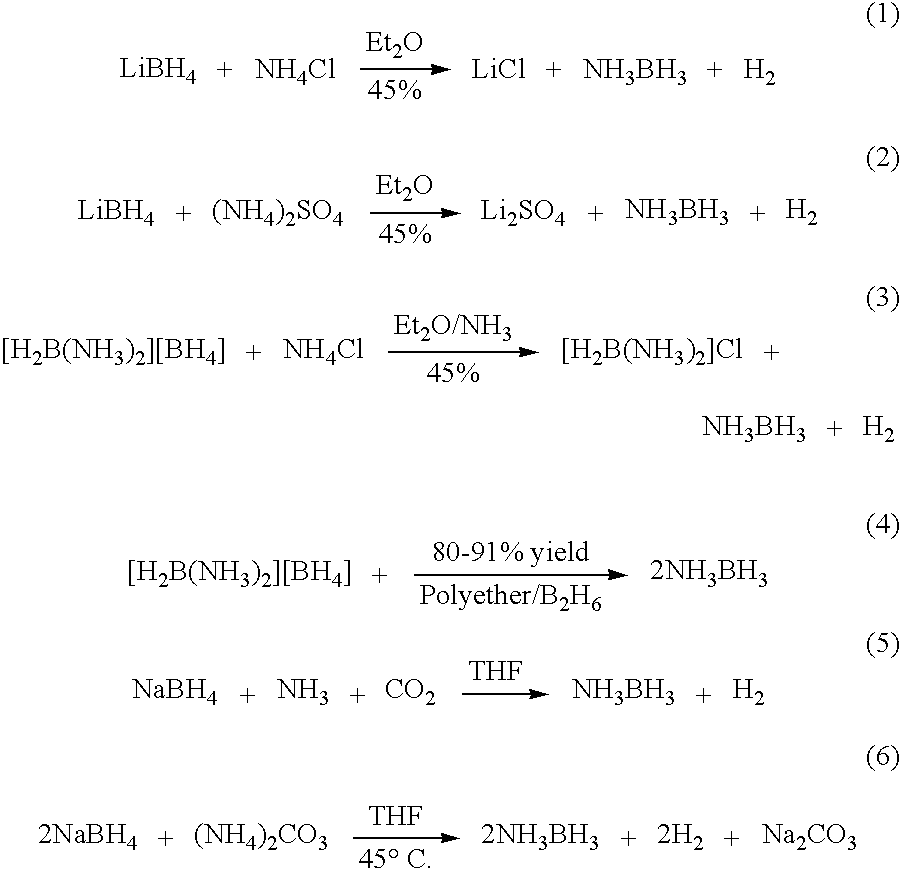

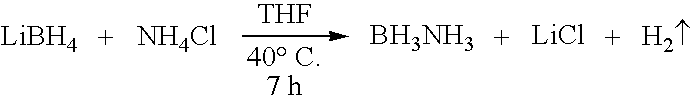

Method for making boron nitride fibers from aminoborazines

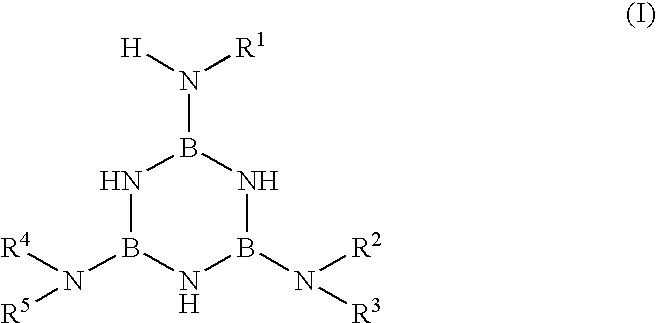

The invention concerns a method for making boron nitride fibers by drawing a polymer precursor and treating with ceramics the polymer fibers obtained by drawing. The invention is characterized in that the precursor polymer is obtained by thermal polymerization of a borazine of formula (I) wherein: R<1>, R<3>, R<4 >and R<5>, identical or different, represent an alkyl, cycloalkyl or aryl group; and R<2 >represents a hydrogen atom or an alkyl, cycloalkyl or aryl group.

Owner:EADS LAUNCH VEHICLE

Graphene substituted with boron and nitrogen, method of fabricating the same, and transistor having the same

Graphene, a method of fabricating the same, and a transistor having the graphene are provided, the graphene includes a structure of carbon (C) atoms partially substituted with boron (B) atoms and nitrogen (N) atoms. The graphene has a band gap. The graphene substituted with boron and nitrogen may be used as a channel of a field effect transistor. The graphene may be formed by performing chemical vapor deposition (CVD) method using borazine or ammonia borane as a boron nitride (B—N) precursor.

Owner:SAMSUNG ELECTRONICS CO LTD

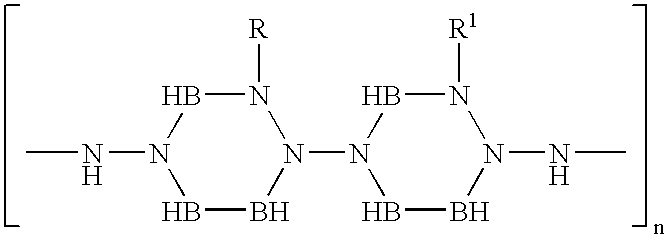

Borazine aryne resin and preparation method thereof

InactiveCN103524746AImprove heat resistanceLow dielectric constantGroup 3/13 element organic compoundsPolymer scienceResin-Based Composite

The invention discloses a borazine aryne resin and a preparation method thereof. The borazine aryne resin is structurally characterized in that the polymer molecular chain contains borazine and aryl alkynyl structures. The preparation method of the resin comprises the following steps: on the basis of taking diacetylene-benzene, boron trihalide and ammonium chloride or organic primary amine as raw materials, reacting in three steps in the presence of an inert gas so as to synthesize the borazine aryne resin. The preparation method is simple in process, convenient to operate and short in reaction time, the process condition is easy to control, and the aftertreatment process is simple; the borazine aryne resin is reddish brown viscous fluid or faint yellow solid, and can be solidified in a light and thermal polymerization mode; the borazine aryne resin has excellent thermal resistance and low dielectric property, can be used for preparing an advanced resin-based composite material, can be also used as a low dielectric material, and can be widely applied to the fields of aerospace and electronic information.

Owner:EAST CHINA UNIV OF SCI & TECH

High-temperature-resistant wave-transparent ceramic-based composite material and preparation method thereof

The invention provides a high-temperature-resistant wave-transparent ceramic-based composite material. A preparation method for preparing the temperature-resistant wave-transparent ceramic-based composite material is further provided; the preparation method for preparing the temperature-resistant wave-transparent ceramic-based composite material comprises the following steps of (1) taking a silicon nitride fiber fabric, and conducting impregnating compound removal treatment on the surfaces of the silicon nitride fiber fabric; and (2) conducting high-pressure immersion treatment and thermal treatment on the silicon nitride fiber fabric treated in the step (1) by means of a borazine precursor to obtain the high-temperature-resistant wave-transparent ceramic-based composite material. Silicon nitride fibers are used as an enhancing phase, boron nitride converted from the borazine precursor is used as a matrix, the high-temperature-resistant wave-transparent ceramic-based composite material and the preparation method thereof are provided, and the high-temperature-resistant wave-transparent ceramic-based composite material has excellent high-temperature stability, high-temperature mechanical property, high-temperature dielectricity and ablation resistance performance.

Owner:北京玻钢院复合材料有限公司

Water-based metalworking fluid incorporating polymeric boron materials

A water-based metalworking fluid is comprised of a polymeric boron species which includes at least B, N and H, together with a surfactant operable to provide an emulsion of the boron species with water. The polymeric boron species may be a polyborane or a borazine polymer and may be configured as a polyborane or borazine polymer backbone having side chains pendent thereupon. The side chains may include silicon and / or phosphorous. The silicon may be in the form of a silane or a siloxane species, including polymeric species. Disclosed are specific compositions as well as methods for using the compositions and methods for making the compositions.

Owner:MASCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com