High-heat-conductivity boroheteropolysiloxane potting adhesive and preparation method thereof

A technology of heteropolysiloxane and polyborosiloxane, which is applied in the field of high thermal conductivity boropolysiloxane encapsulant and its preparation, can solve the problem of easy generation of bubbles and pores, failure to meet packaging performance requirements, and impact on Composition adhesive sealing and high temperature aging resistance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

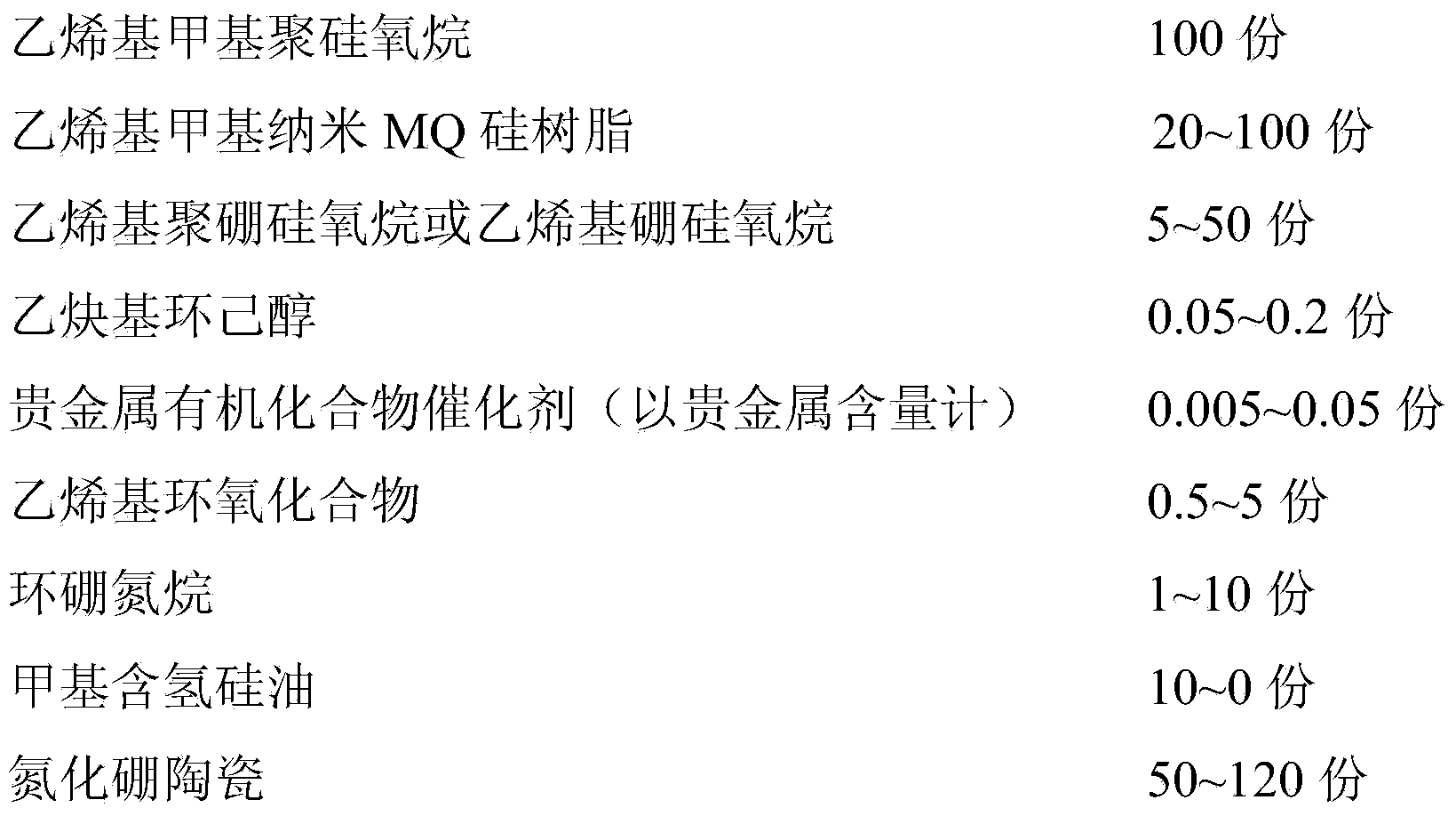

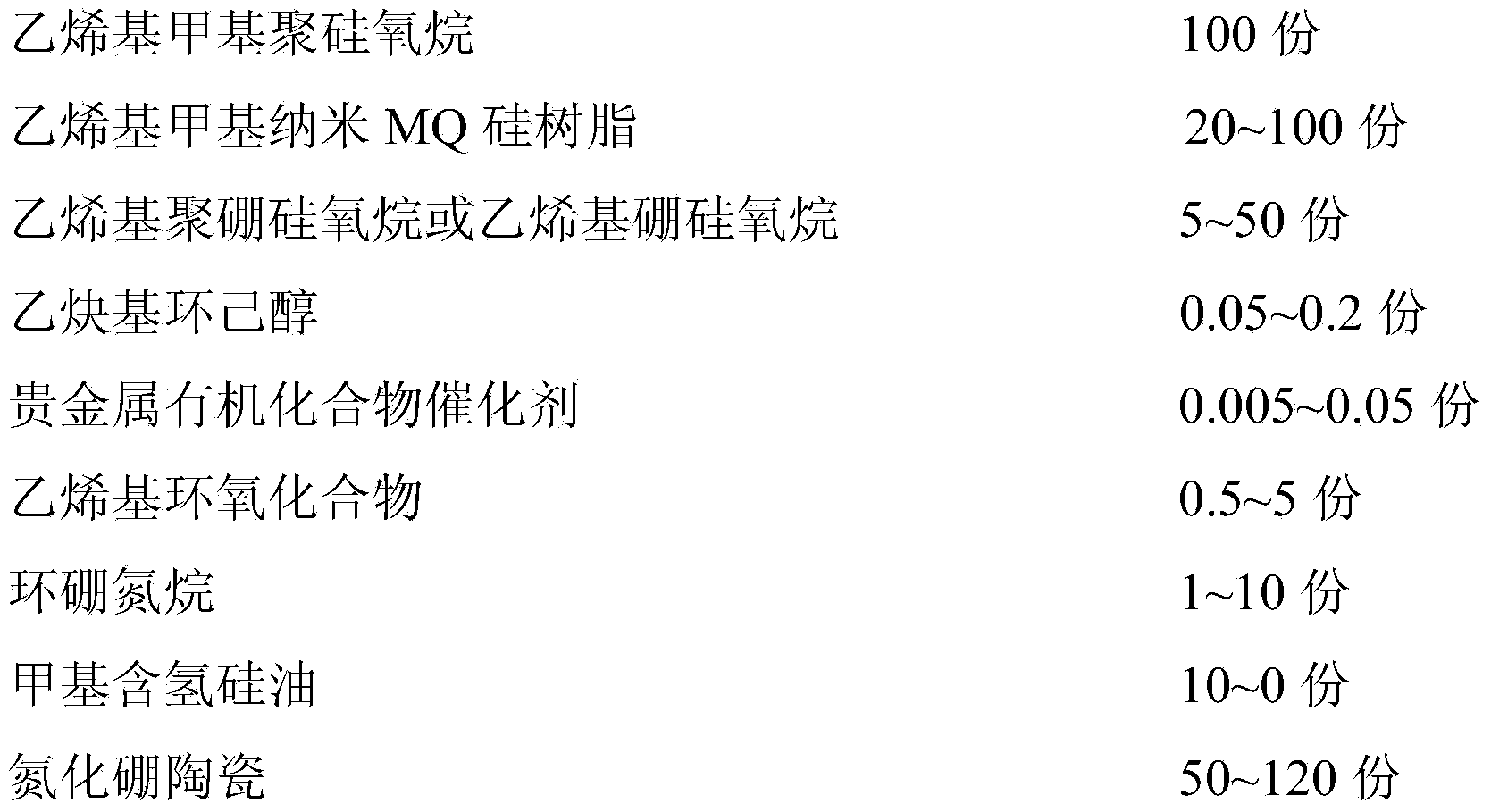

Method used

Image

Examples

example 1

[0043] Example 1: Raw material preparation

[0044] (1) Preparation of vinyl borosiloxane: add 61g of phenylboronic acid and 130g of vinyl dimethylethoxysilane in a 500ml three-necked flask equipped with a thermometer, condenser, mechanical stirrer and heating device, and stir at room temperature Make it dissolve slowly, then add 0.2 g of trifluoromethanesulfonic acid, heat to 60°C and keep for 1 hour, continue heating to 80°C, and reflux for 5 hours. Then remove the by-product ethanol by proper vacuum distillation, cool, neutralize the mixture with 2g of calcium carbonate and keep stirring at room temperature for 1 hour, filter, and obtain 140g of filtrate, which is a liquid vinyl containing phenyl group on the boron atom. Borosiloxane monomer BS1 (ie vinyl borosiloxane).

[0045] (2) Preparation of vinyl polyborosiloxane:

[0046] A. Add 61g of phenylboronic acid and 66g of methylvinyldimethoxysilane into a 250ml three-necked flask equipped with a thermometer, condenser, m...

example 2

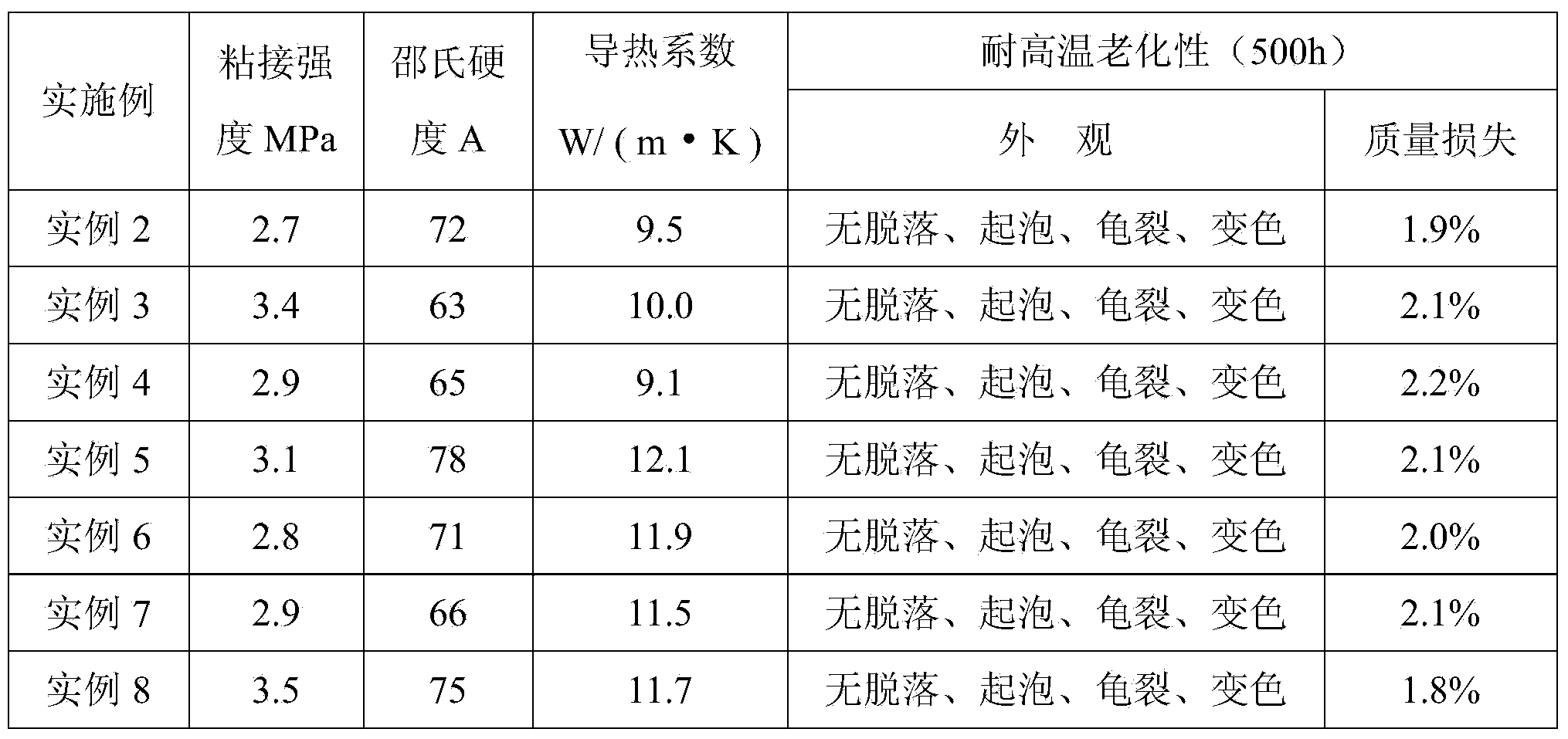

[0053] At room temperature, 100g of vinyl-terminated methyl silicone oil (also known as vinyl-terminated polydimethylsiloxane, viscosity 3000mPa·s), 100g of vinylmethyl nano-MQ silicone resin (vinyl content 2.4wt%, M / Q =0.75), 5g vinyl borosiloxane BS1, 0.05g ethynyl cyclohexanol, 0.034g tetrakis (triphenylphosphine) platinum Pt (PPh 3 ) 4 (the content of platinum is 15wt%) (the consumption of platinum is 0.15*0.034=0.0051), 0.5g allyl glycidyl ether, 10g borazine and 120g dry treated boron nitride powder (average particle diameter 10μm ) after mixing evenly, make corresponding modules according to the corresponding test methods, place them in an environment of 50°C for 2 hours, then raise the temperature to 100°C for 4 hours, and measure the composite materials (that is, high thermal conductivity boropolysilicon Oxane potting glue) Shore hardness, thermal conductivity and high temperature aging resistance and bonding strength. The test results are shown in Table 1.

[0054...

example 3

[0059] At room temperature, 100g of vinyl-terminated methyl silicone oil (vinyl-terminated polydimethylsiloxane, viscosity 50000mPa·s), 20g of vinylmethyl nano-MQ silicone resin (vinyl content 4.0wt%, M / Q=1.5 ), 50g vinyl polyborosiloxane PBS2, 0.2g ethynyl cyclohexanol, 0.2g bis(triphenylphosphine) platinum dichloride (PPh 3) 2 PtCl 2 (the content of platinum is 24.2wt%) (the consumption of platinum is 0.242*0.2=0.0484), 5g4-vinyl epoxycyclohexane, 6g borazine and 100g dry treated boron nitride powder (average particle size diameter 10μm) after mixing evenly, according to the corresponding test method to make the corresponding modules, first placed in the environment of 60 ℃ for 2 hours, then heated up to 120 ℃, heat preservation for 3 hours, after cooling, the composite materials (that is, high thermal conductivity boron Heteropolysiloxane potting glue) Shore hardness, thermal conductivity and high temperature aging resistance and bonding strength. The experimental test r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com