Patents

Literature

827results about How to "Reduced tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

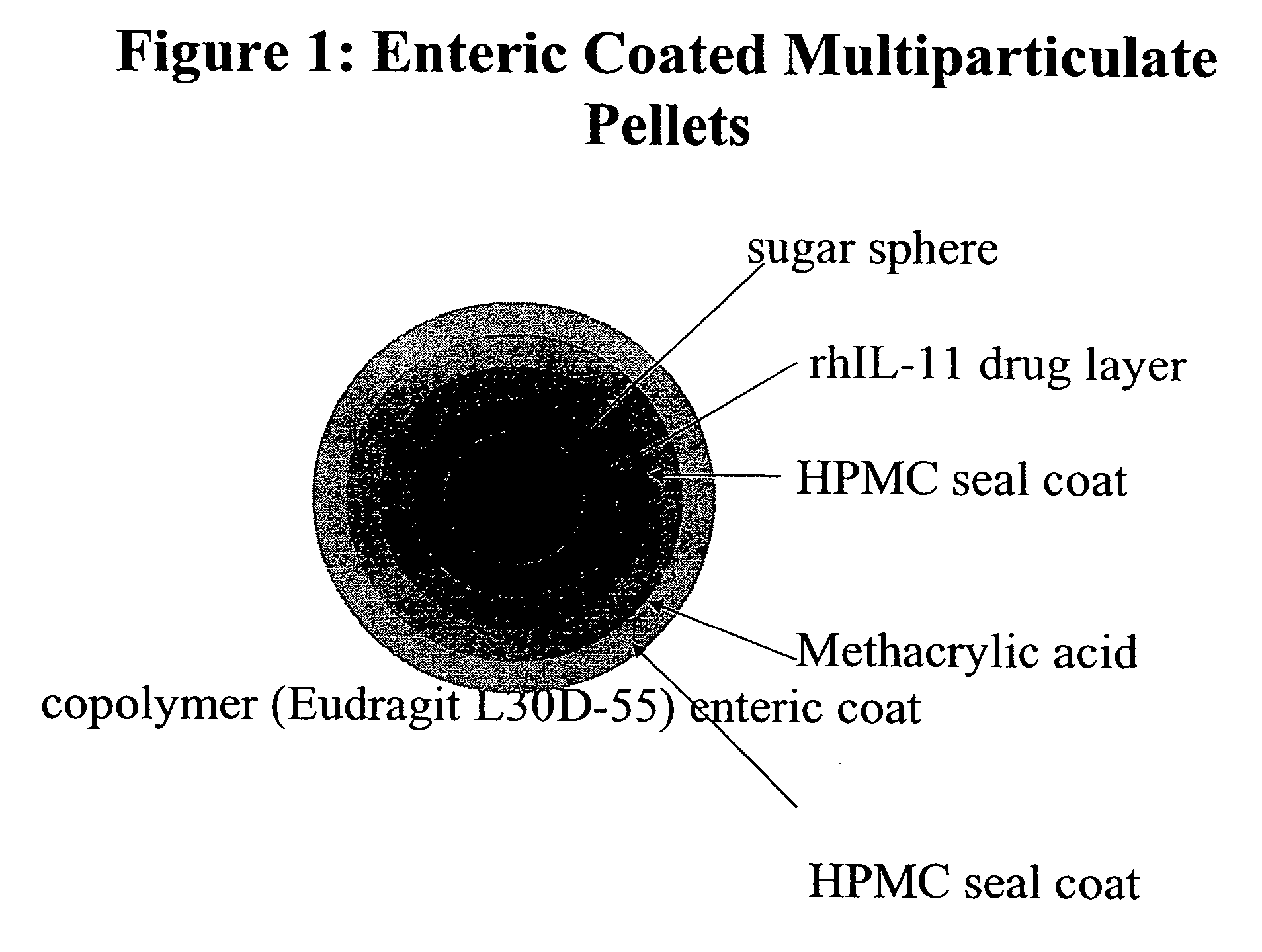

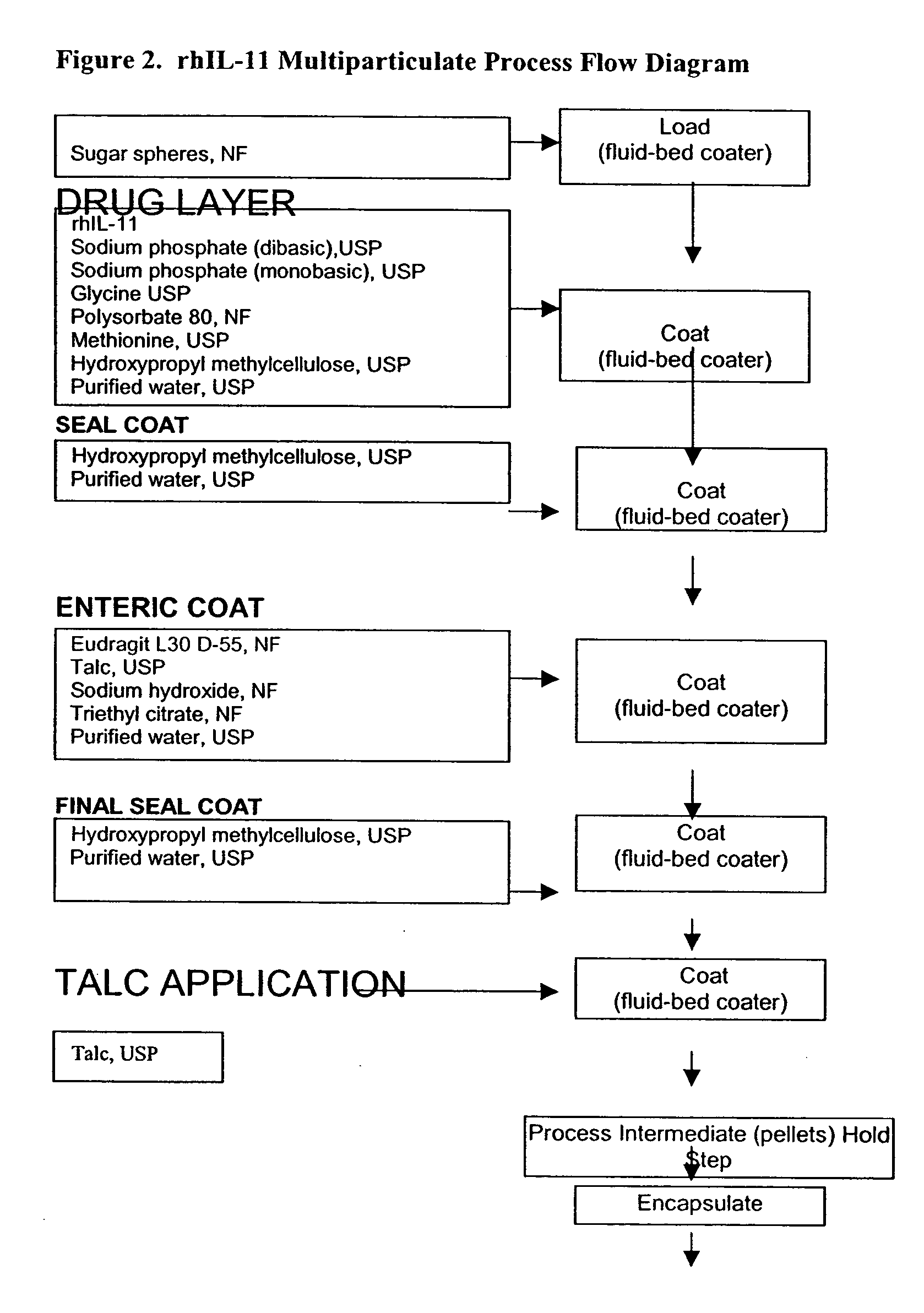

Delayed release formulations for oral administration of a polypeptide therapeutic agent and methods of using same

InactiveUS20040126358A1Increase ionic strengthReduced strengthAntipyreticAnalgesicsOral medicationWhite blood cell

The invention provides compositions containing polypeptides, including therapeutic polypeptides such as interleukin-11, that are suitable for oral administration.

Owner:WYETH LLC

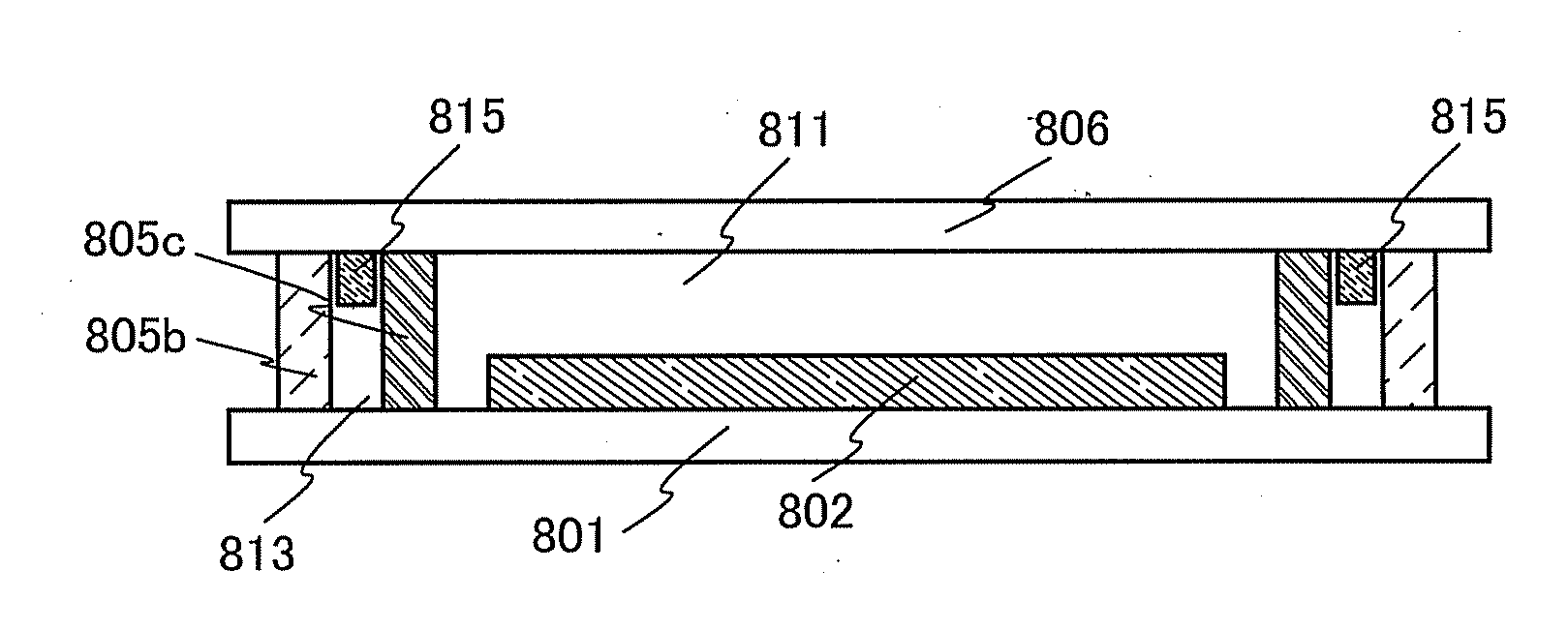

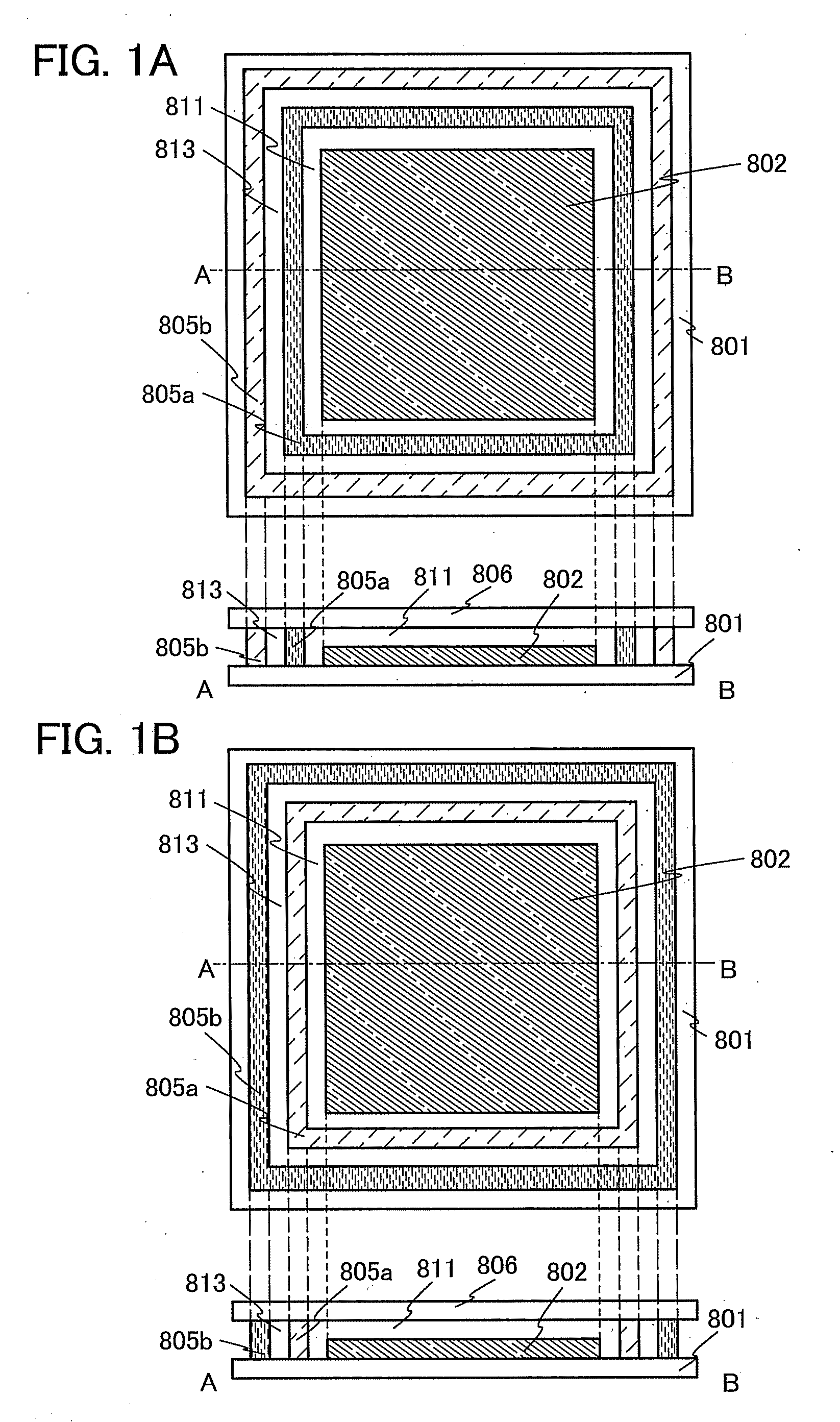

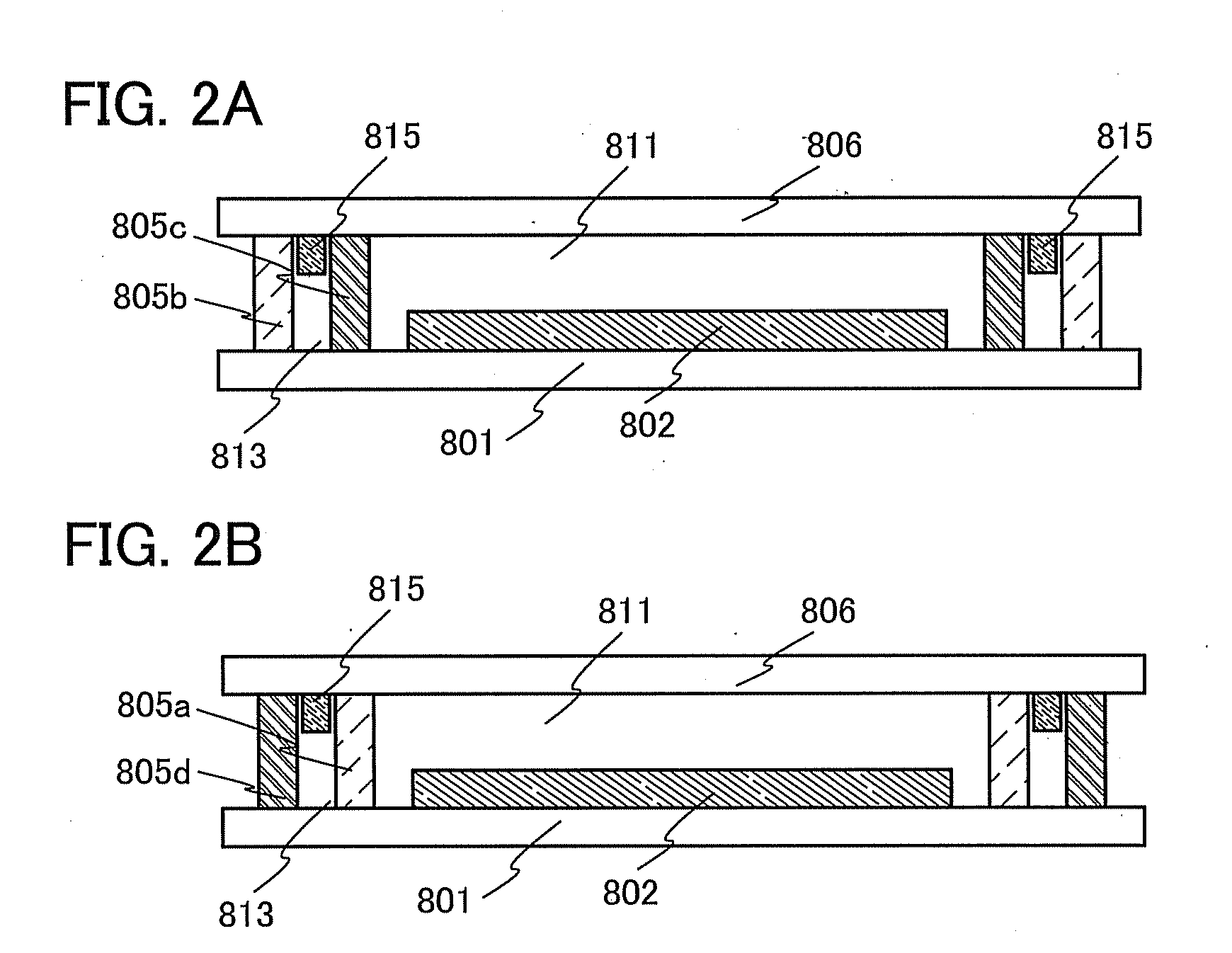

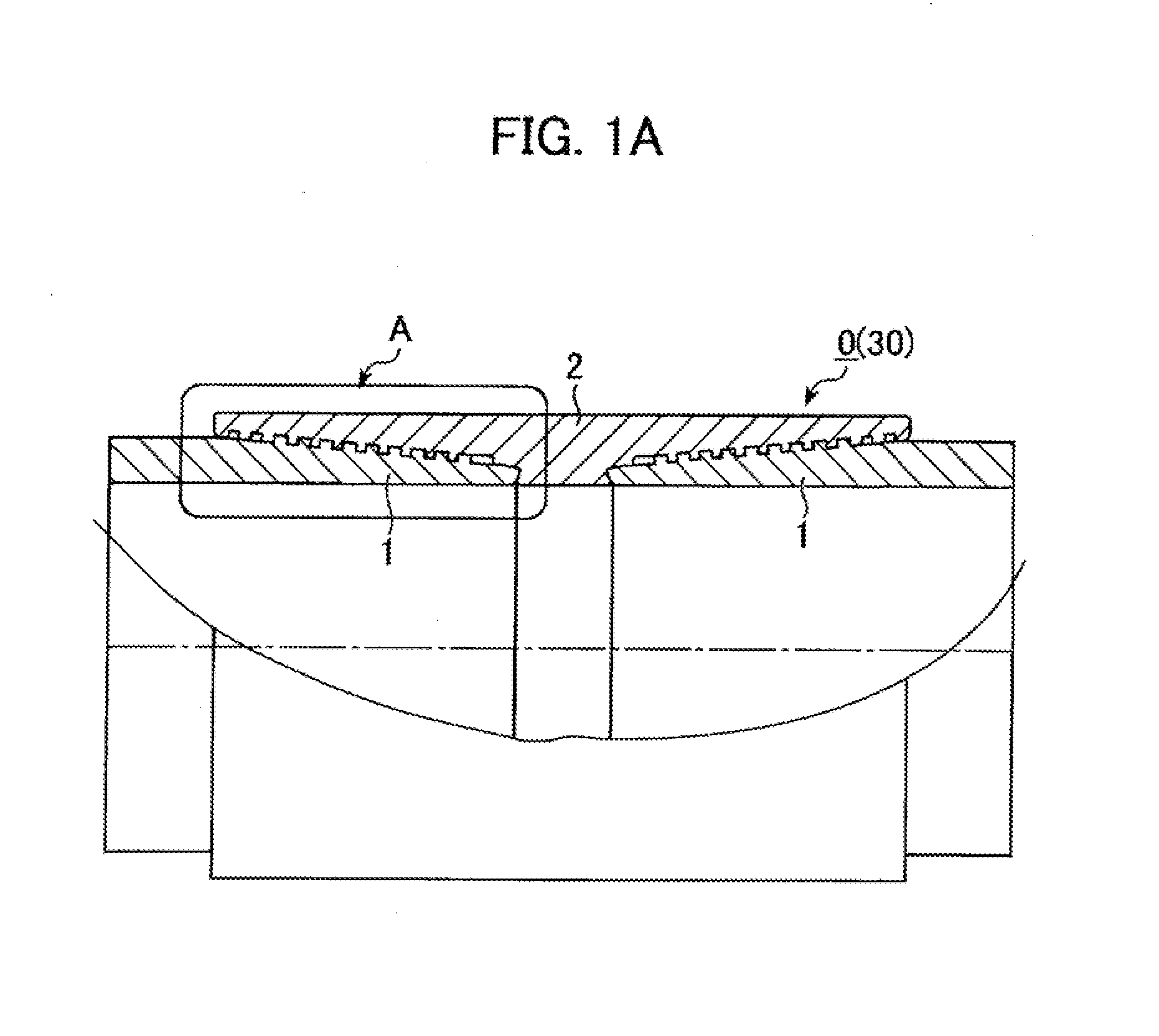

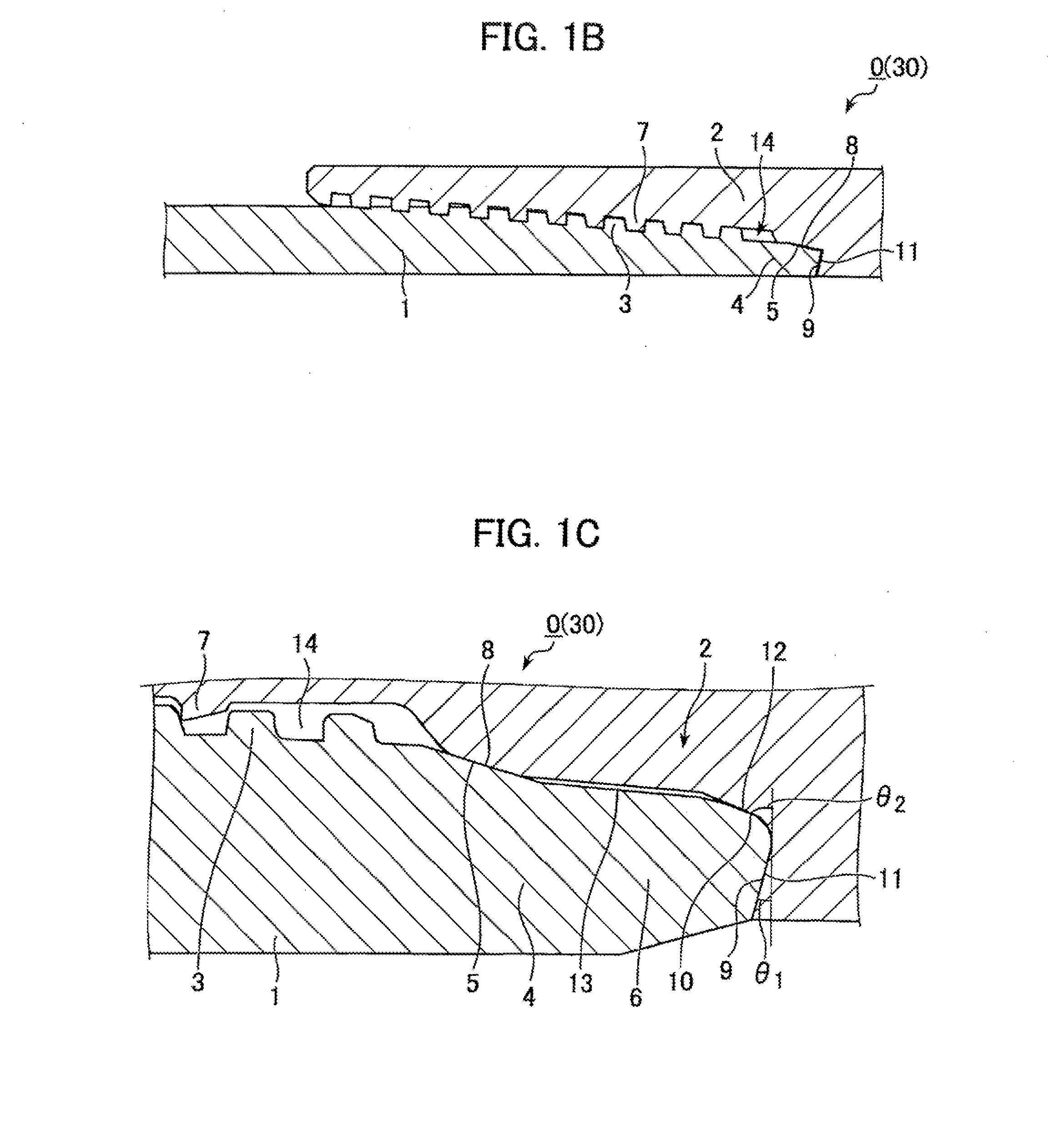

Light-Emitting Device, Electronic Device, Lighting Device, and Method for Manufacturing the Light-Emitting Device

ActiveUS20130048967A1DeteriorationReduce pressureElectroluminescent light sourcesSolid-state devicesDrying AgentsEngineering

A light-emitting device in which deterioration of an organic EL element due to impurities such as moisture or oxygen is suppressed is provided. The light-emitting device includes a first substrate and a second substrate facing each other, a light-emitting element provided over the first substrate, a first sealant provided so as to surround the light-emitting element, and a second sealant provided so as to surround the first sealant. One of the first sealant and the second sealant is a glass layer and the other is a resin layer. A dry agent is provided in a first space surrounded by the first sealant, the second sealant, the first substrate, and the second substrate, or in the resin layer. The light-emitting element is included in a second space surrounded by the first sealant, the first substrate, and the second substrate.

Owner:SEMICON ENERGY LAB CO LTD

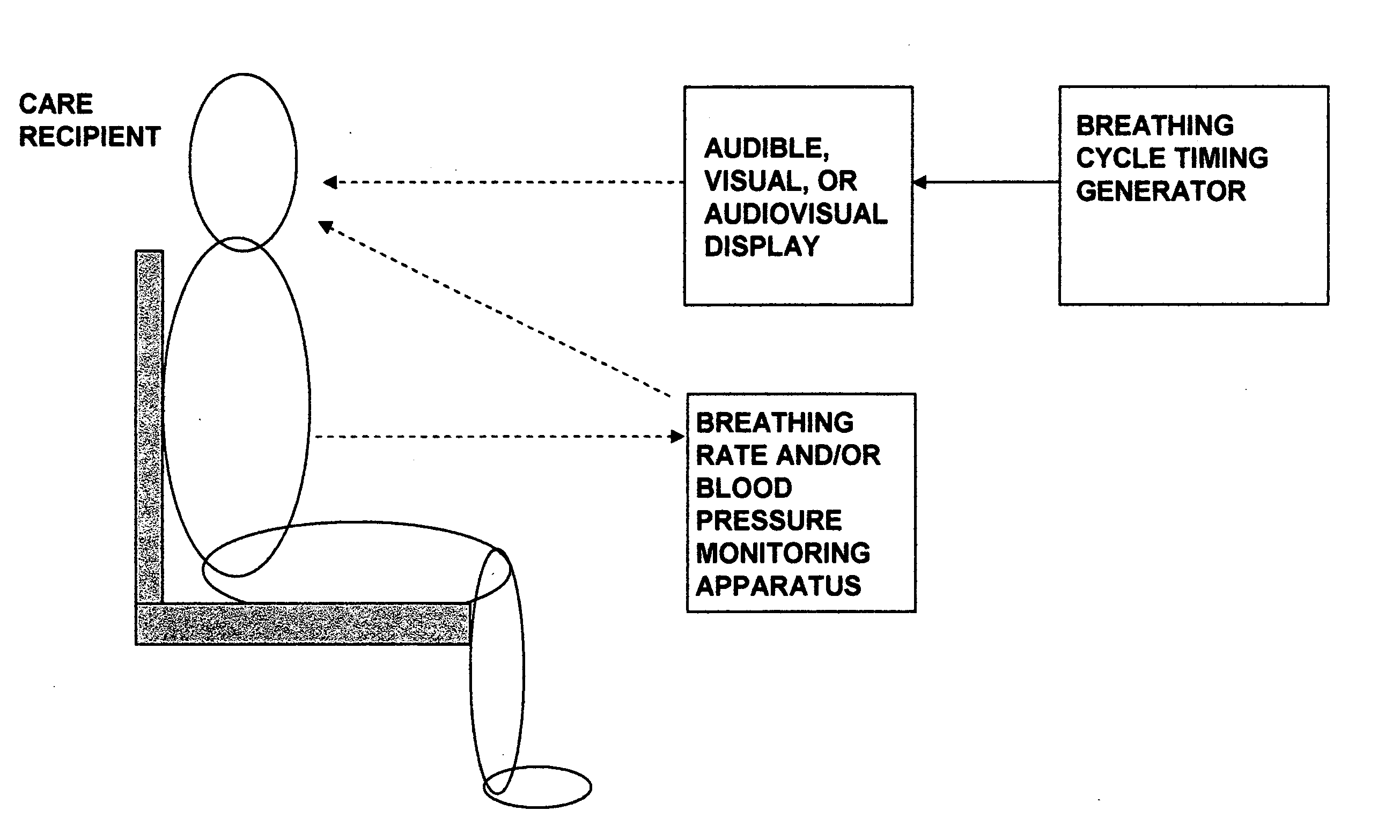

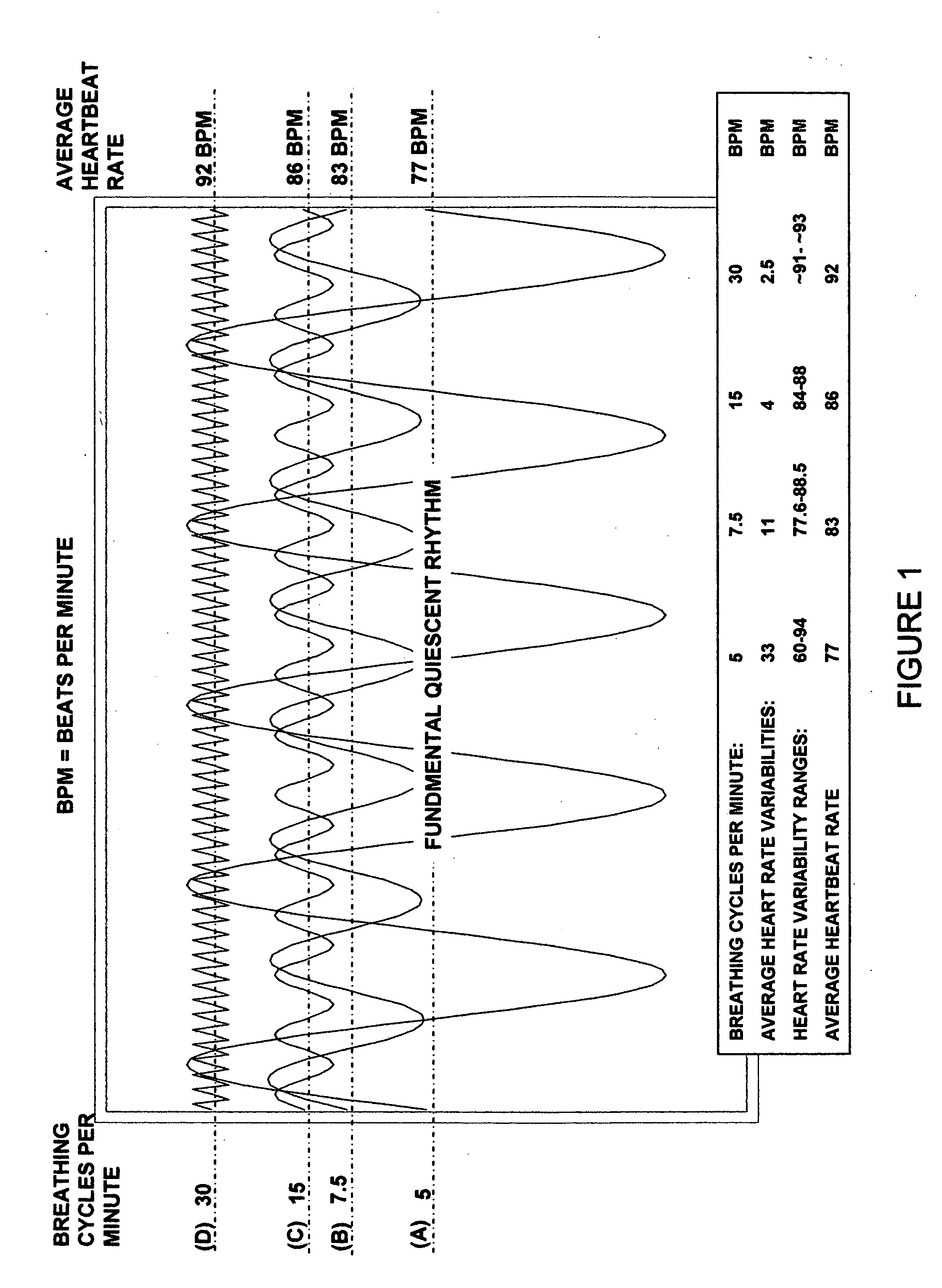

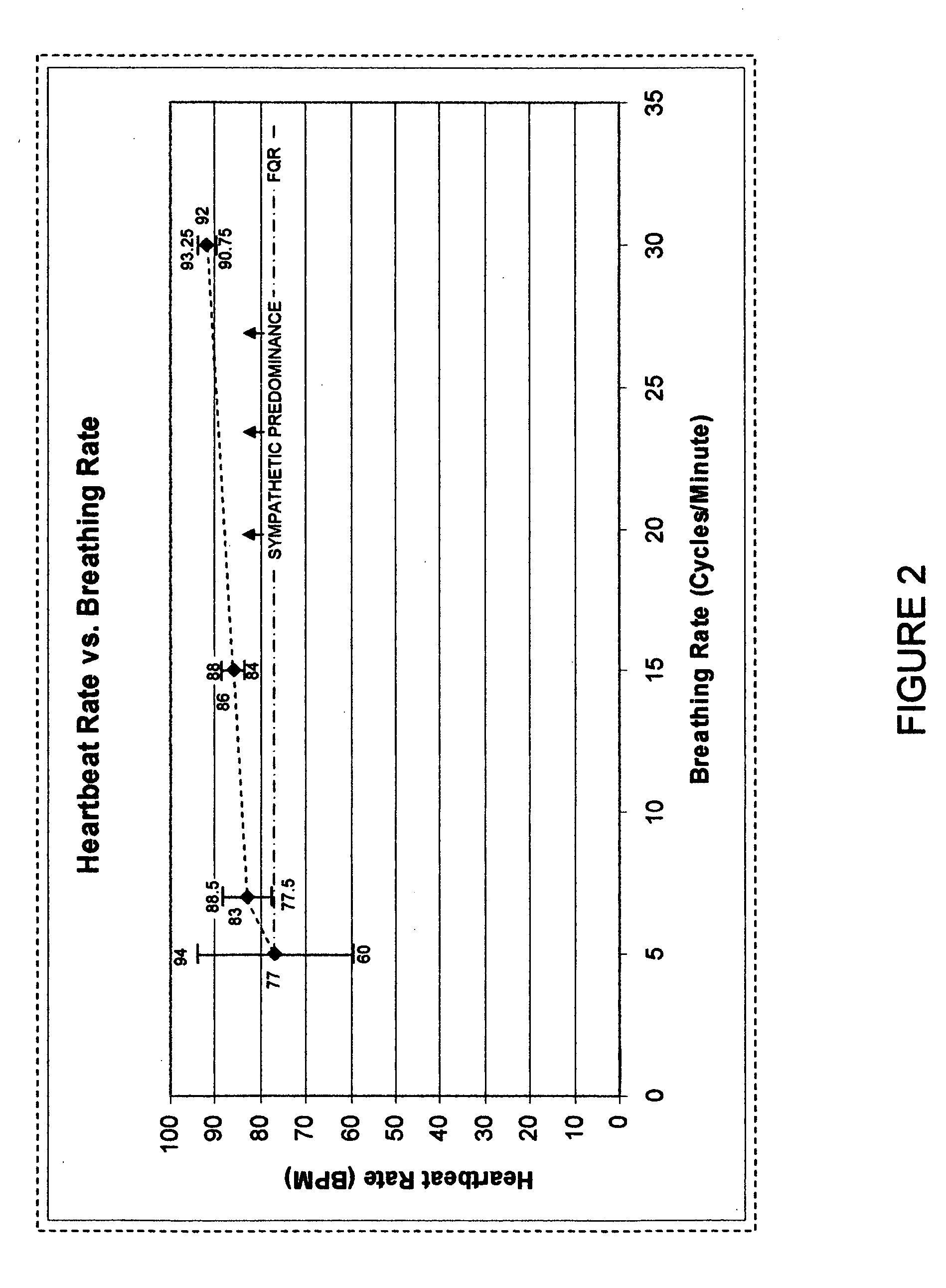

Method and system of breathing therapy for reducing sympathetic predominance with consequent positive modification of hypertension

InactiveUS20060047202A1Avoid influenceReduction in “ tenseness ”Gymnastic exercisingCatheterDiseaseNervous system

The invention specifies a method and system for leading a person suffering from “sympathetic predominance”, a specific symptom of which is “hypertension”, to breathe according to a certain pattern for the express purpose of positively altering the condition of sympathetic predominance (over activation), having the effect of bringing the autonomic nervous system into the state of balance, with consequent reductions in “tenseness”, blood pressure, muscular tightness, and emotional strain, as well as the alleviation of the myriad of subtle neuro-physiological consequences resulting from sympathetic predominance potentially including headaches, anxiety, sleep disorders, allergies, and other maladies that have yet to be attributed to this condition, thus leading to a general improvement in health, well being, and homeostasis. It accomplishes this by systematically reducing the breathing frequency with consequent increases in breathing depth, the ultimate goal being the realization and ongoing maintenance of 1 complete breathing cycle in 11.76 seconds or 5 complete breathing cycles in 58.8 seconds, the result being improved health, well being, and homeostasis.

Owner:ELLIOTT STEPHEN BENNETT

Heat curing in-situ forming high-conductivity silicon rubber composition and application thereof

The invention relates to a heat curing in-situ forming high-conductivity silicon rubber composition and application thereof. The composition is composed of the following components: (1) 60-90 parts by weight of mixture of ethylene end-blocked polyorganosiloxane in the same or different viscosities; (2) 10-35 parts by weight of silicone oil containing hydrogen; (3) 1-25 parts by weight of one or multiple R<6>cSiX4-c or partial hydrolytic condensation product thereof; (4) 100-500 parts by weight of metal base conductive filler with the average particle size of 10-150 Mum; (5) 0.01-10 parts by weight of organic metal compound or chelate which contains chloroplatinic acid or contains platinum or palladium and is used as metal base catalyst of heat curing; (6) 1-30 parts by weight of reinforcing filler or functional filler. The invention is applied to the shielding case part of RF equipment requiring electromagnetic shielding and sealed environment. The invention reduces material consumption, simplifies production technology and improves production efficiency and cost performance of product.

Owner:SHANGHAI RELAND PHOTOVOLTAIC MATERIAL

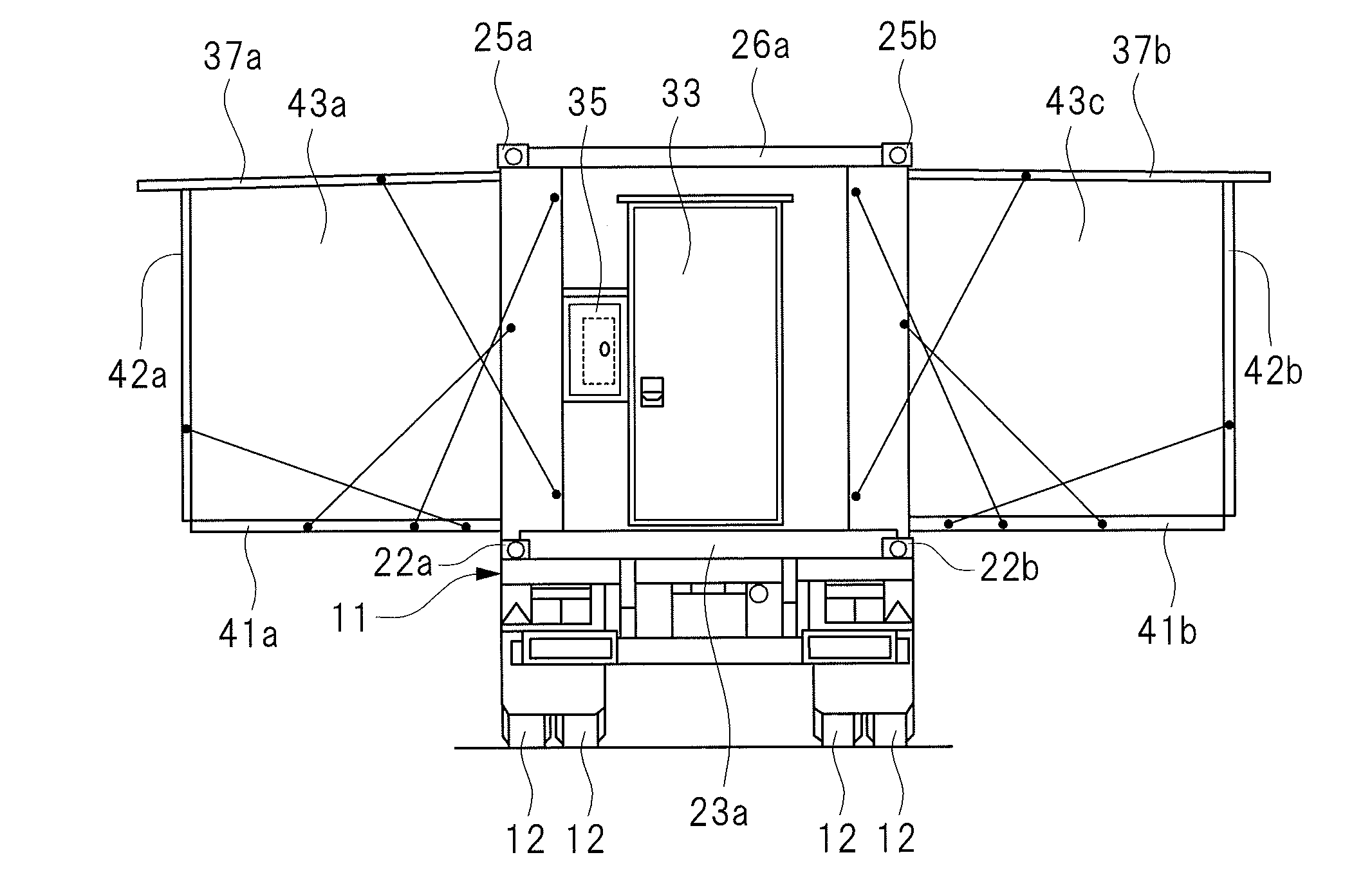

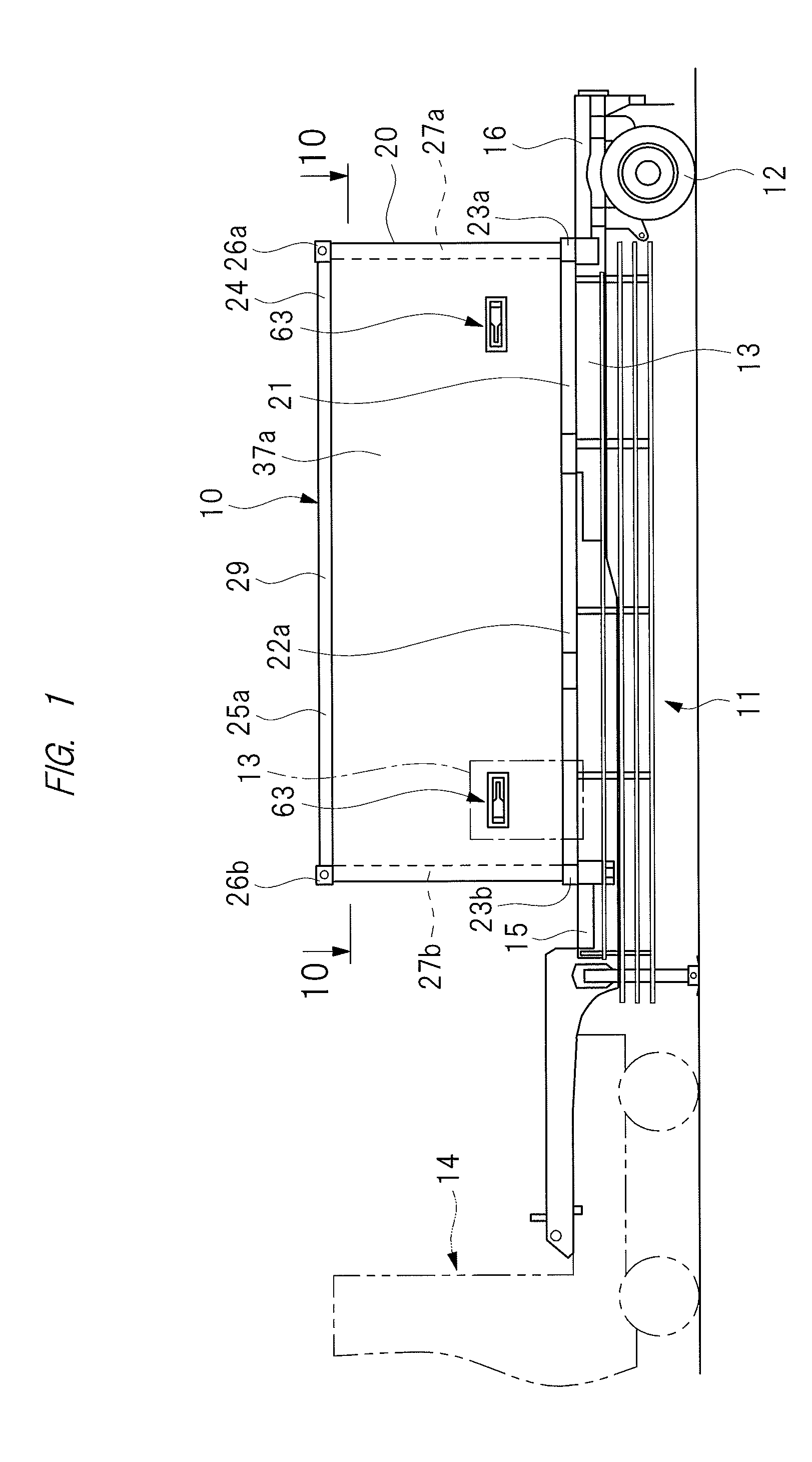

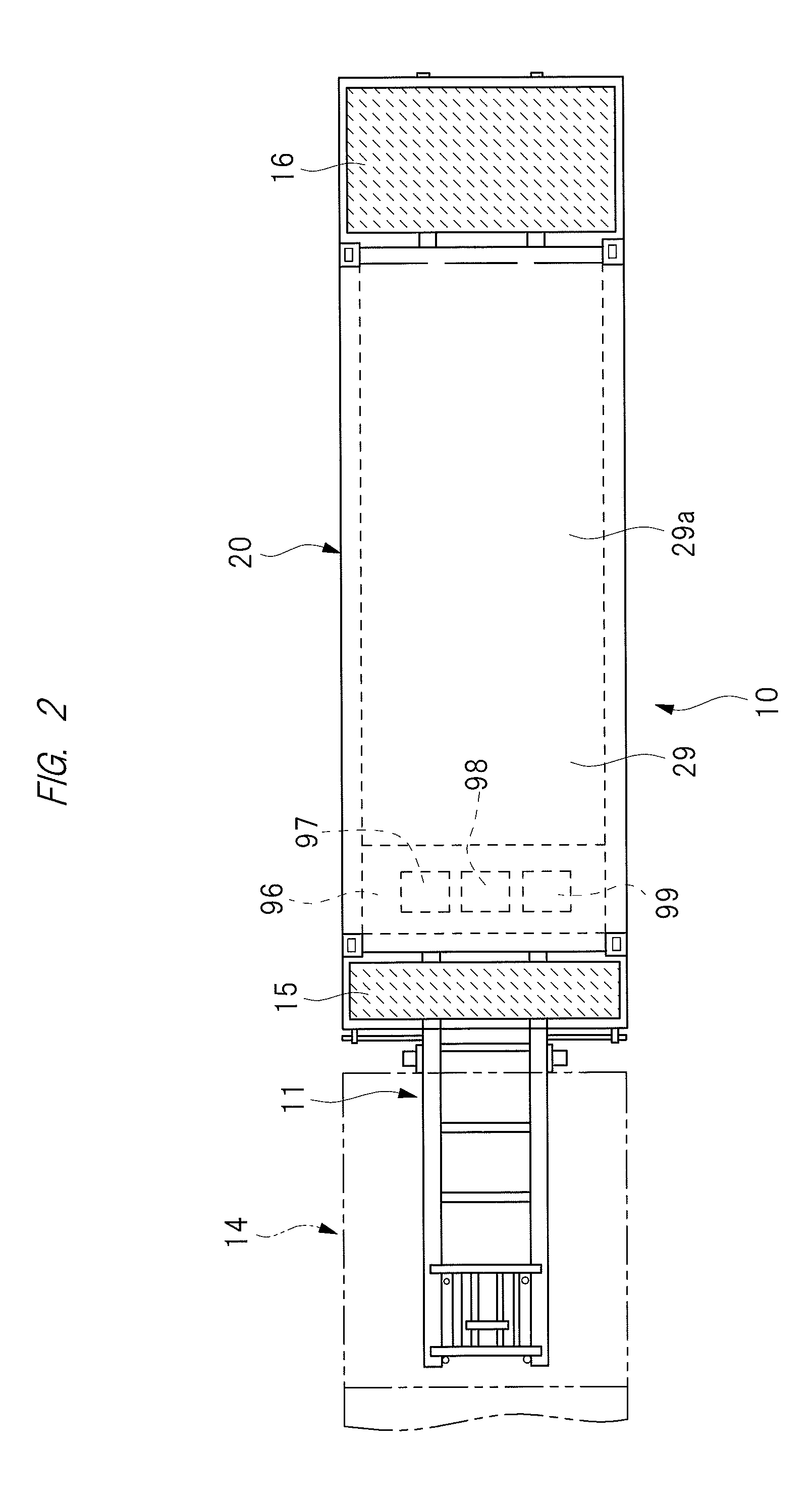

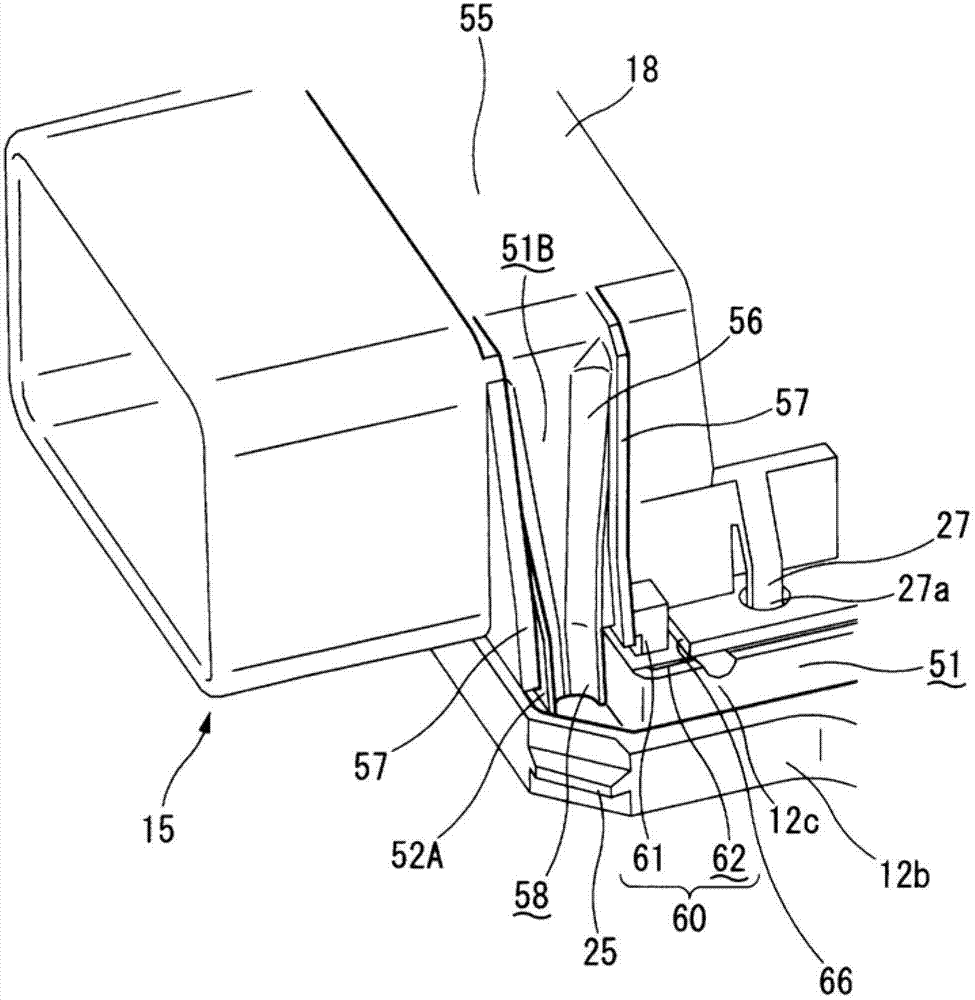

Deployment shelter

InactiveUS20140202089A1Reduced tightnessDrive stabilityTents/canopiesSpecial buildingMechanical engineering

Owner:NIPPON TREX

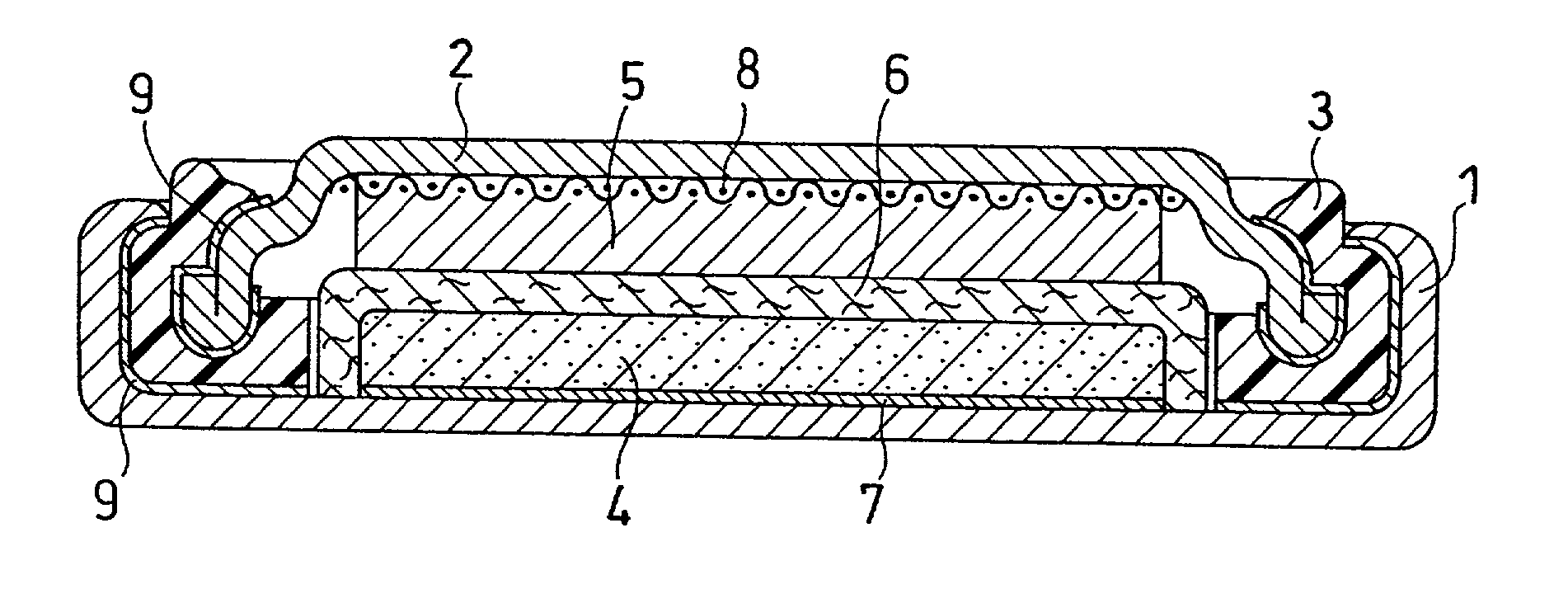

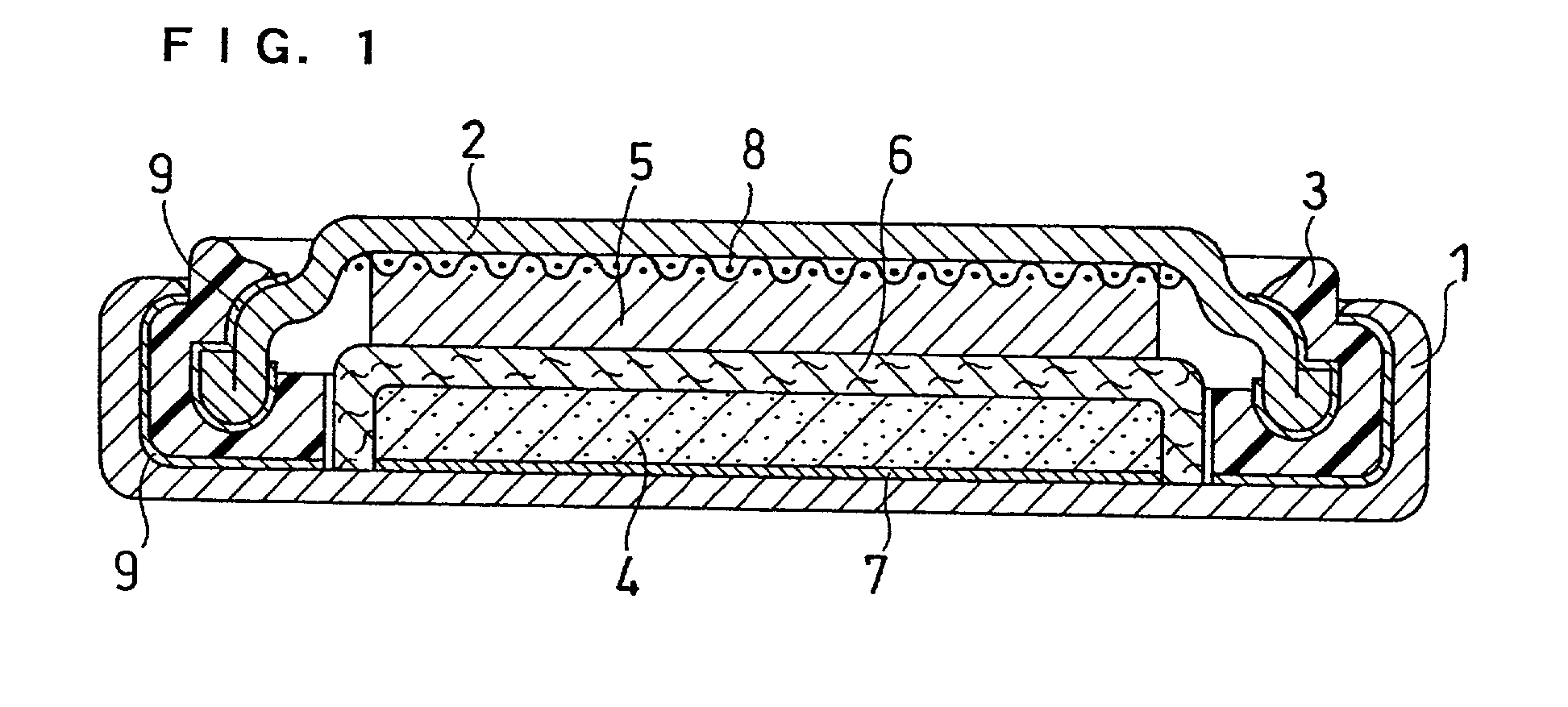

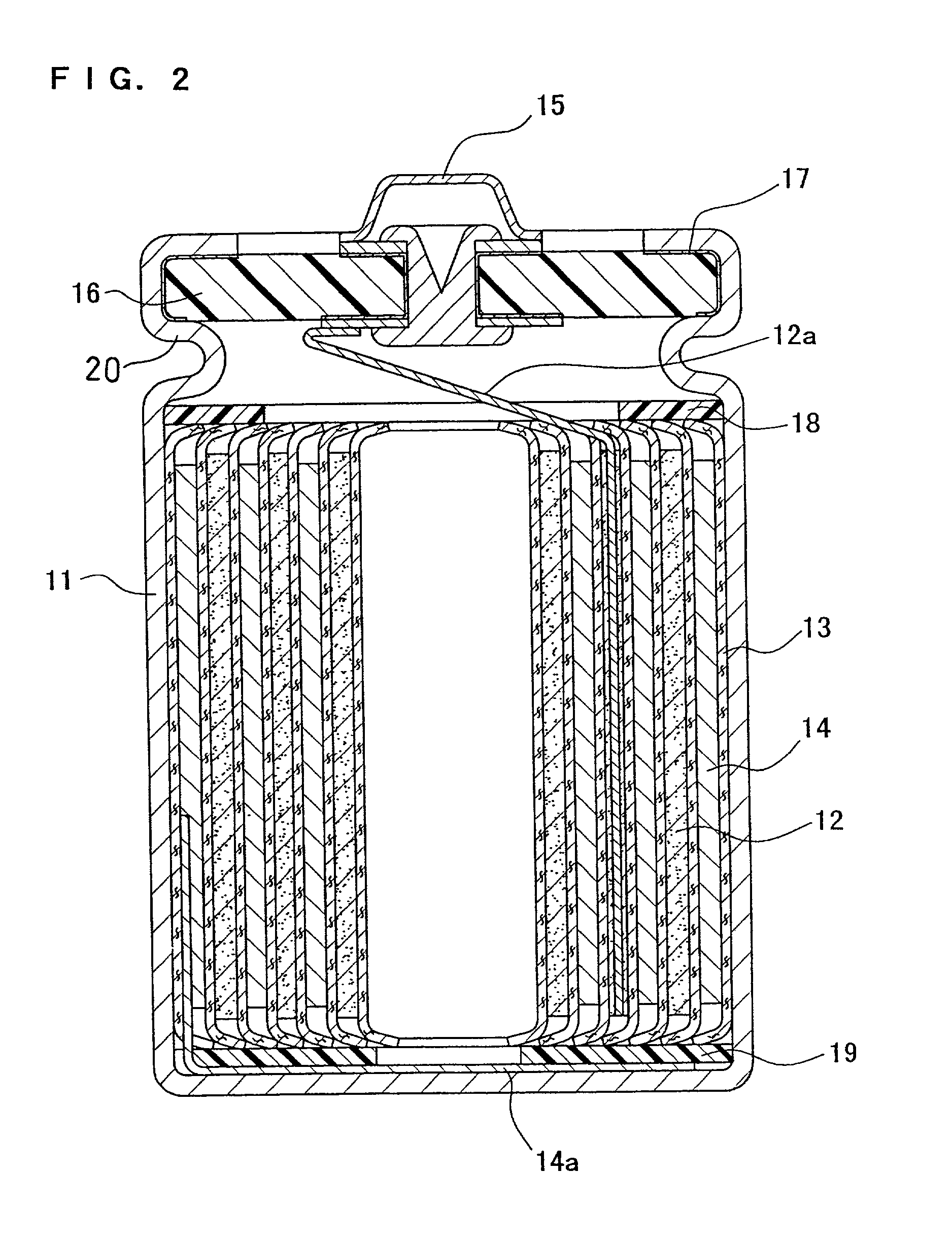

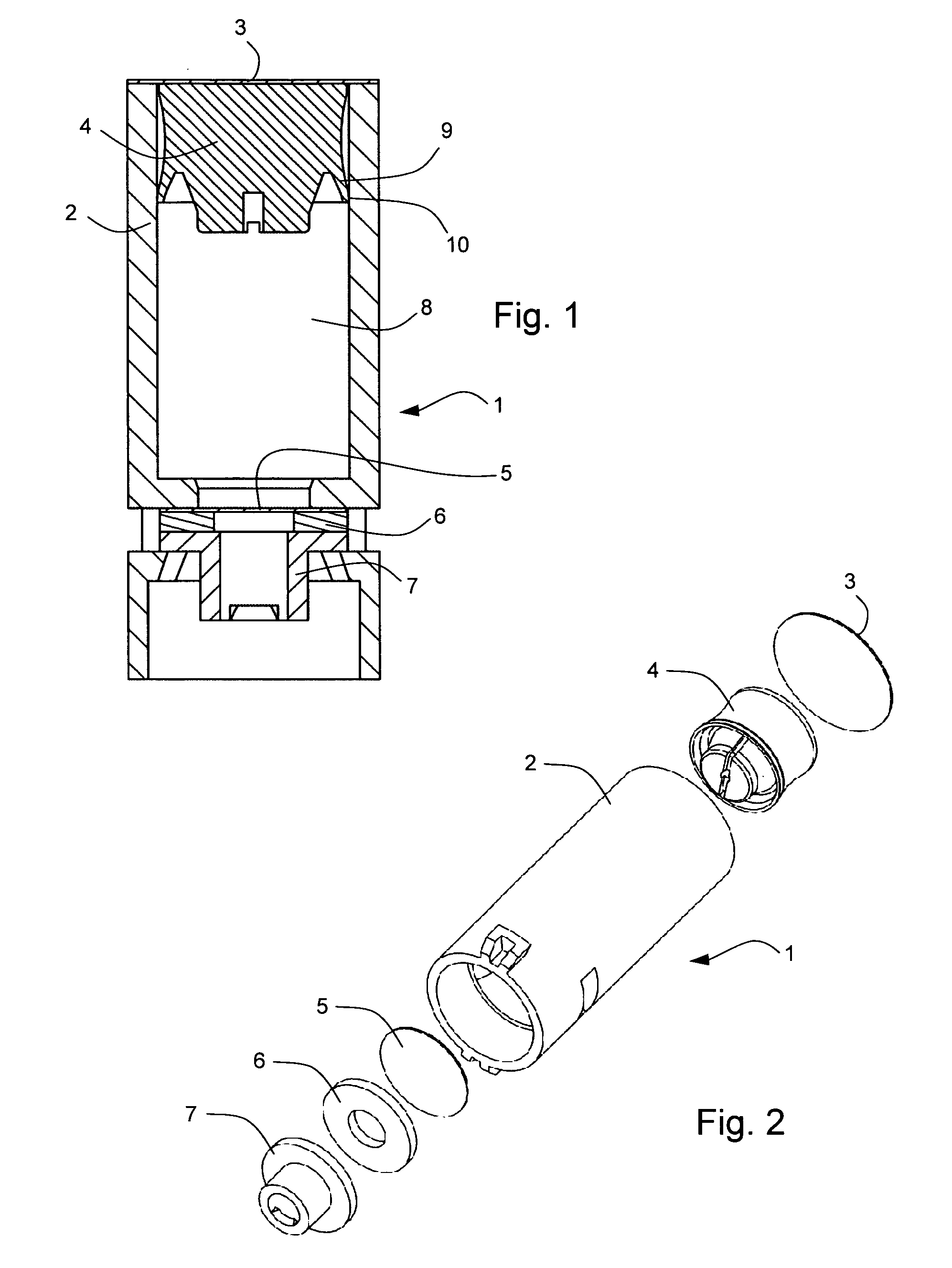

Electrochemical element

InactiveUS20020106559A1Reduce variationEasy to controlNon-aqueous electrolyte accumulatorsFinal product manufactureElastomerEngineering

An electrochemical element having a metal case for accommodating an element unit in which a positive electrode and a negative electrode are disposed to face each other with a separator between them, and an electrolyte; a sealing body for sealing an opening of the metal case; and a sealant provided between the metal case and the sealing body, wherein the sealant comprises an elastomer as a main component and an organic pigment and is colored in a color different from the metal case and sealing body. The present invention also includes an electrochemical element which further has a gasket interposed between the sealing body and the metal case, and in which the sealant is provided between the gasket and the sealing body or the metal case.

Owner:PANASONIC CORP

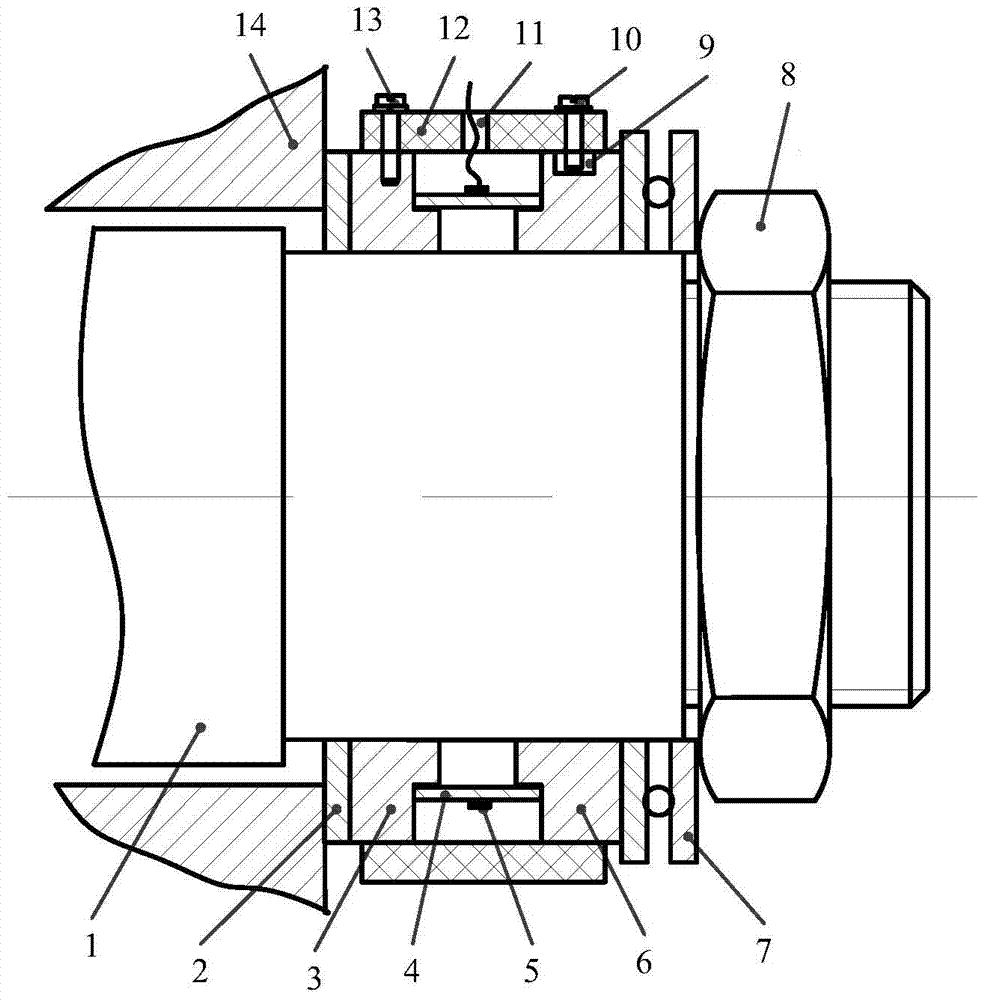

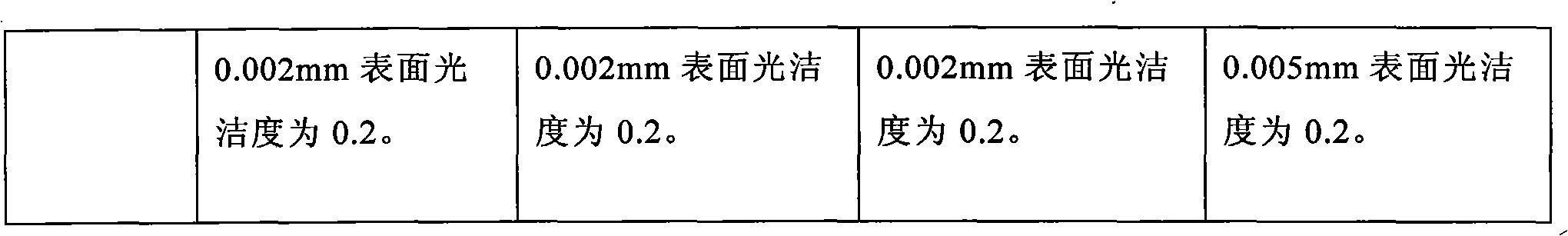

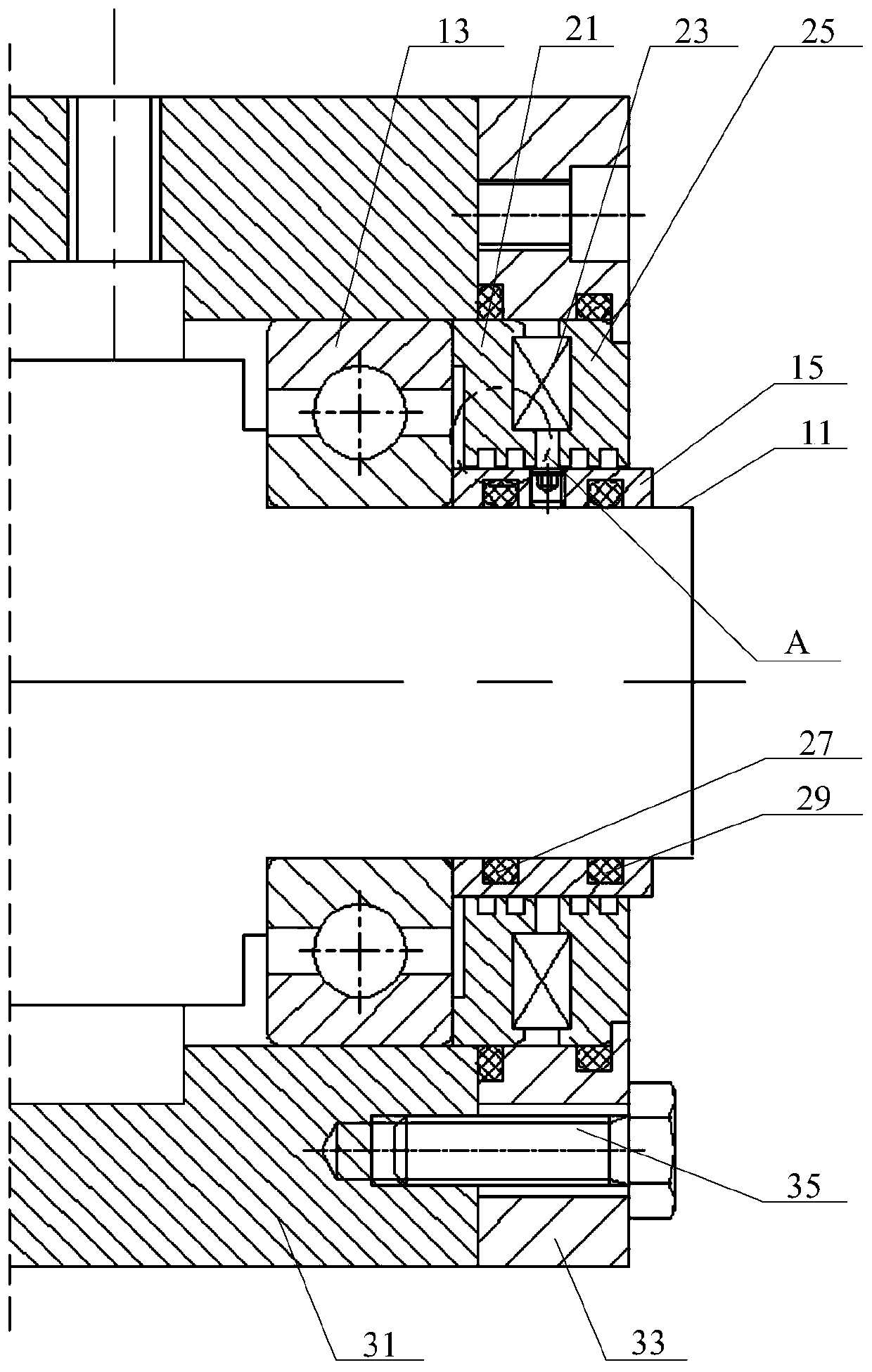

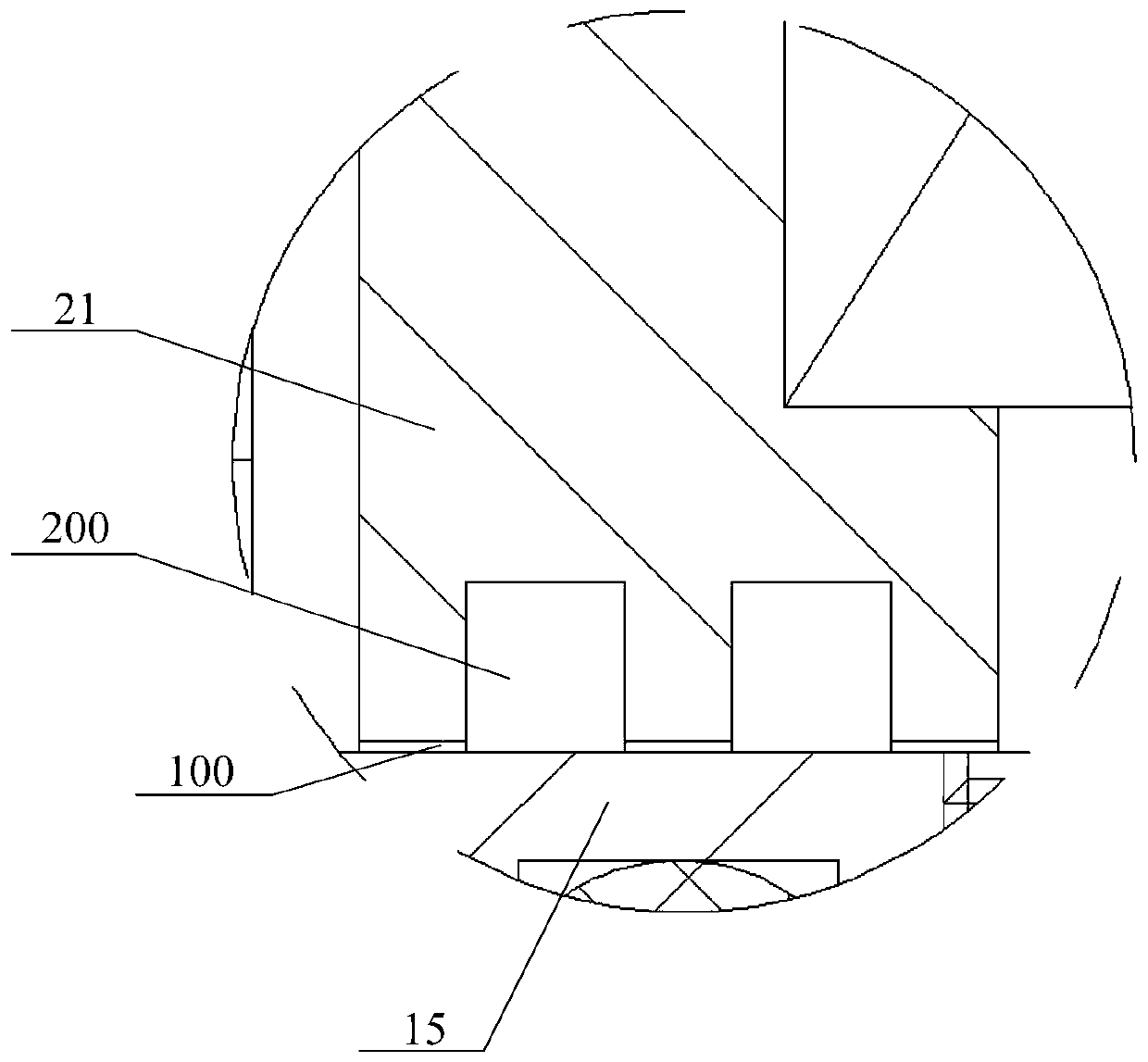

Rotation shaft combined sealing device

InactiveCN101799075AThe installation accuracy is up toEasy to installEngine sealsEngineeringMagnetic liquids

Owner:BEIJING JIAOTONG UNIV

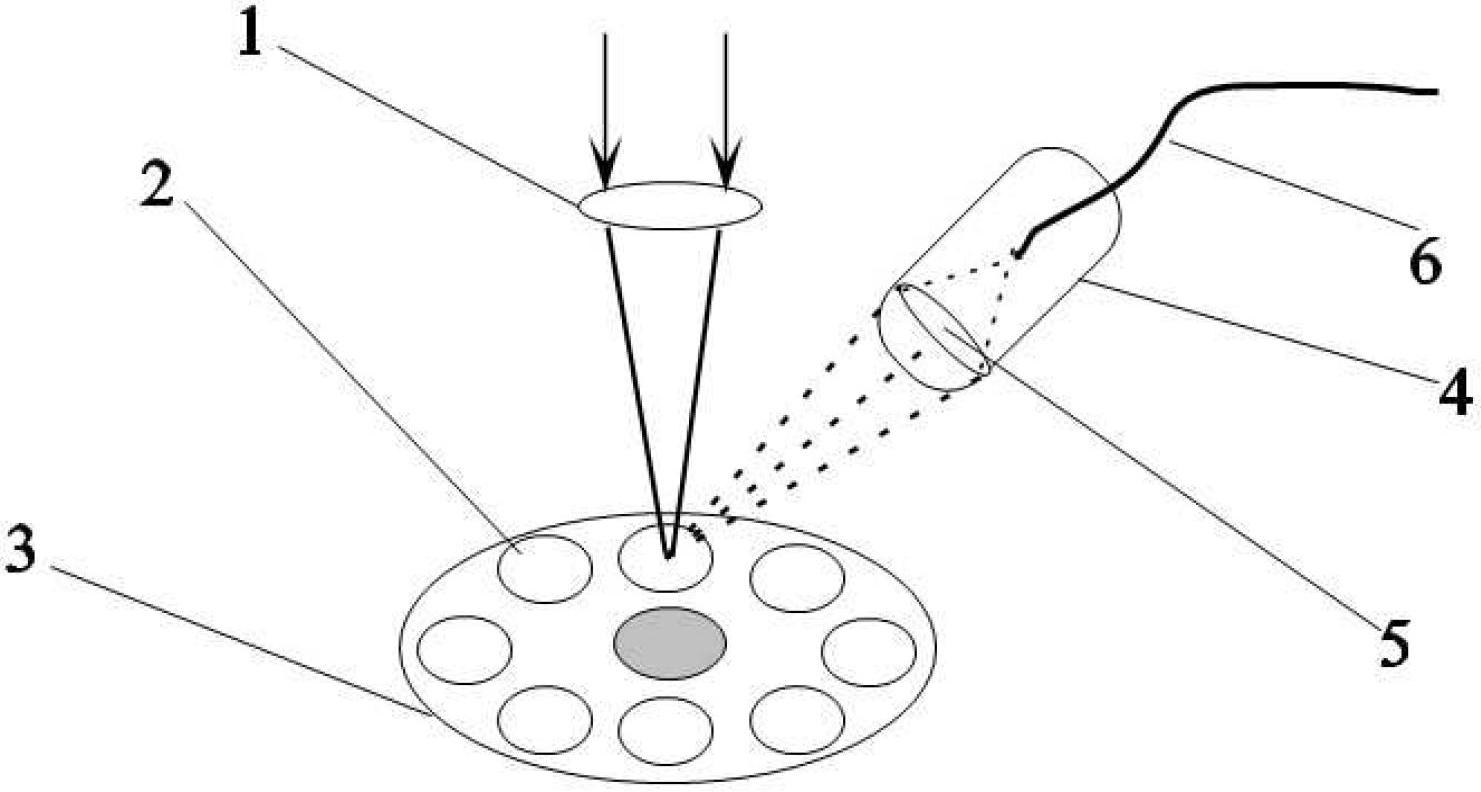

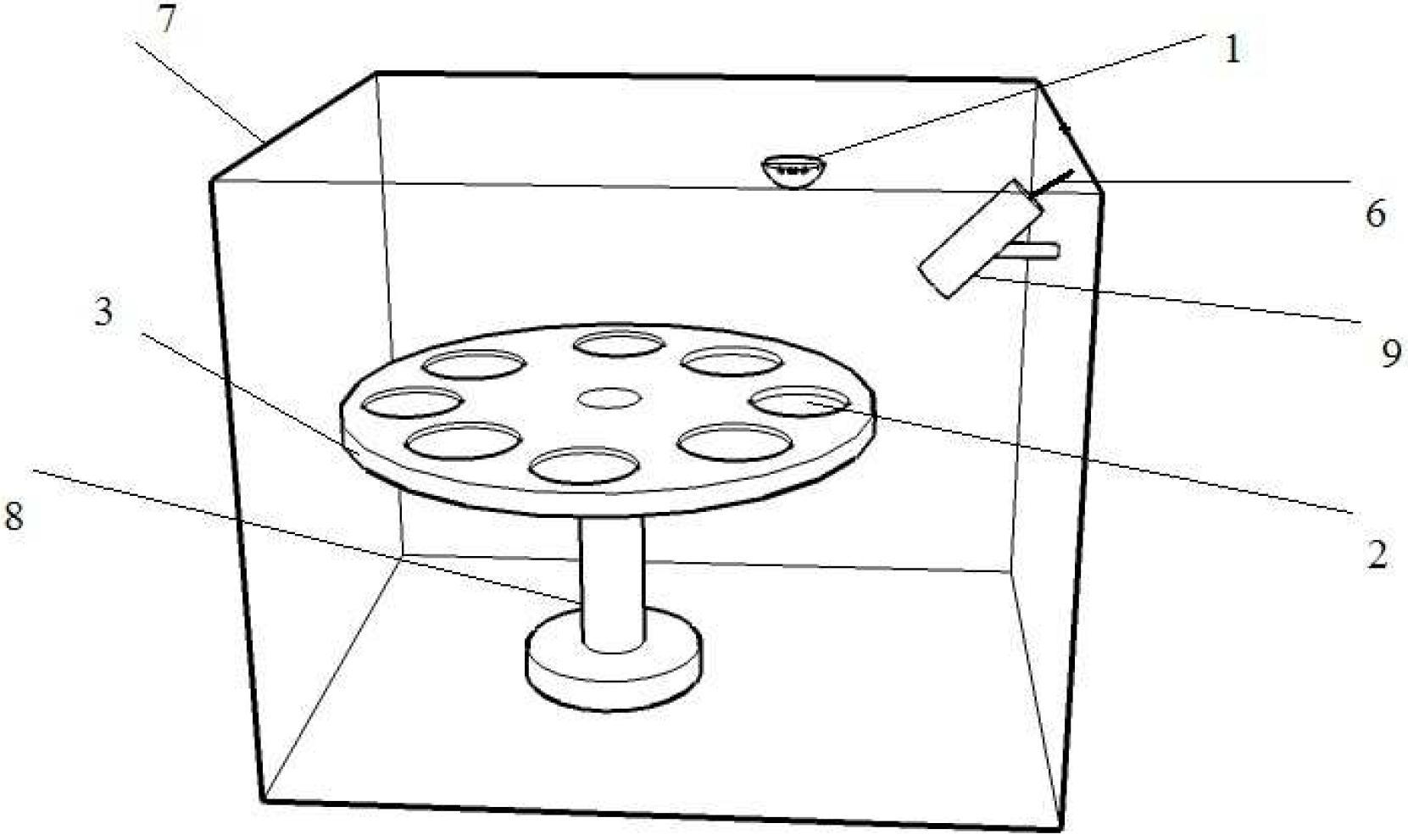

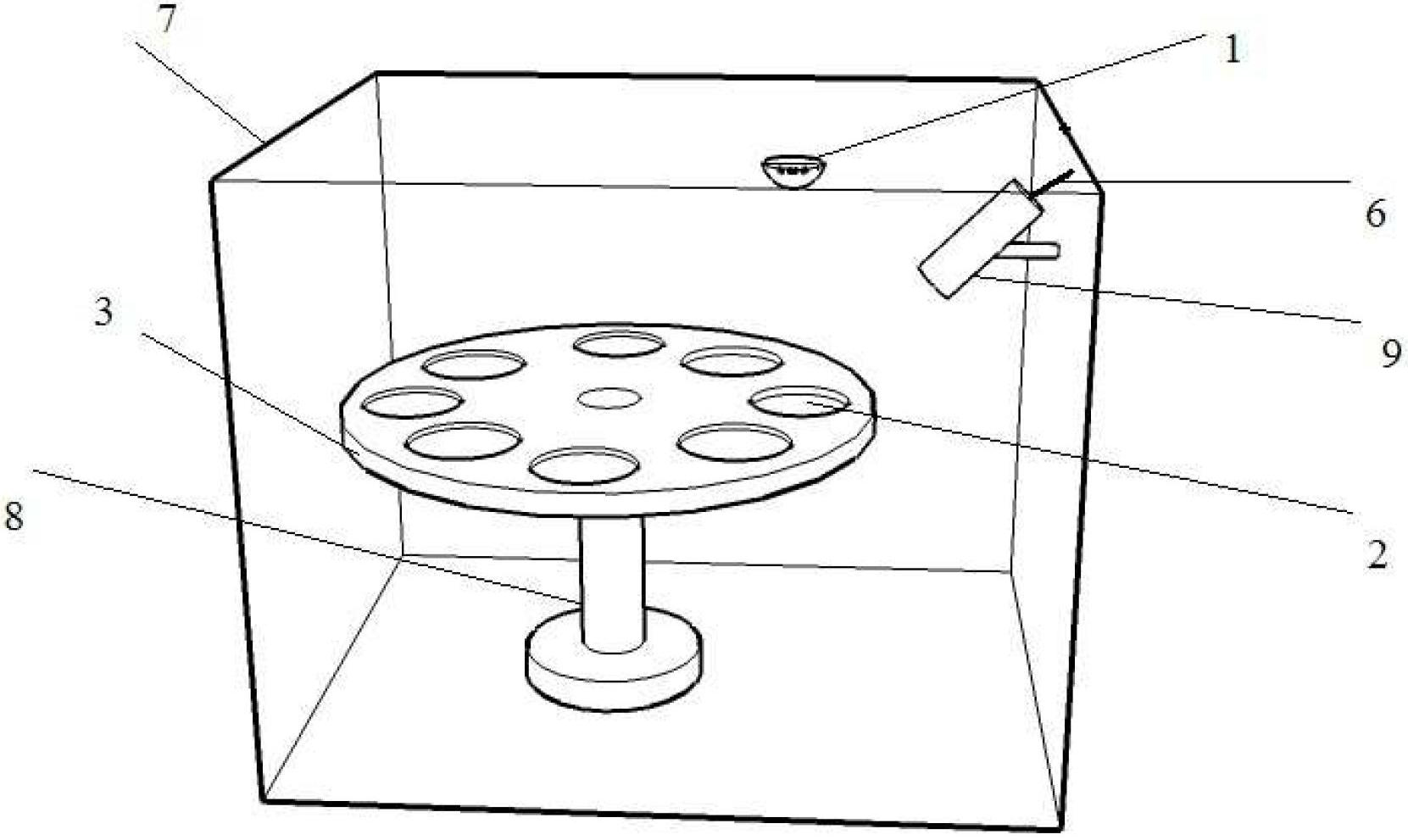

Small multifunctional sample room for LIBS (laser-induced breakdown spectroscopy)

The invention discloses a small multifunctional sample room for LIBS (laser-induced breakdown spectroscopy), whose structure mainly includes an openable closed cavity, a focusing lens arranged on a casing top of the cavity, a sample plate mounted on a rotatable lifting column table positioned at the center of the bottom of the cavity, and a signal collection device placed on the casing wall of the cavity and connected with an external detector, wherein no less than one sample cell is designed on the sample plate, is positioned in the sample plate and can rotate to the position below the focusing lens during the rotation of the sample plate; and a lens of the signal collection device points to the sample cell rotating to the position below the focusing lens. The small multifunctional sample room disclosed by the invention can be used for bearing solid particulates, powders and liquid samples simultaneously for measurement, has the characteristics of excellent focusing performance, tightness and working performance, small volume and the like, can be integrated in a laser optical spectrum analyzer or used independently, and is particularly suitable for simultaneously analyzing in-situ collected scraps, rock and slurry samples in petroleum drilling and geological exploration.

Owner:SICHUAN UNIV

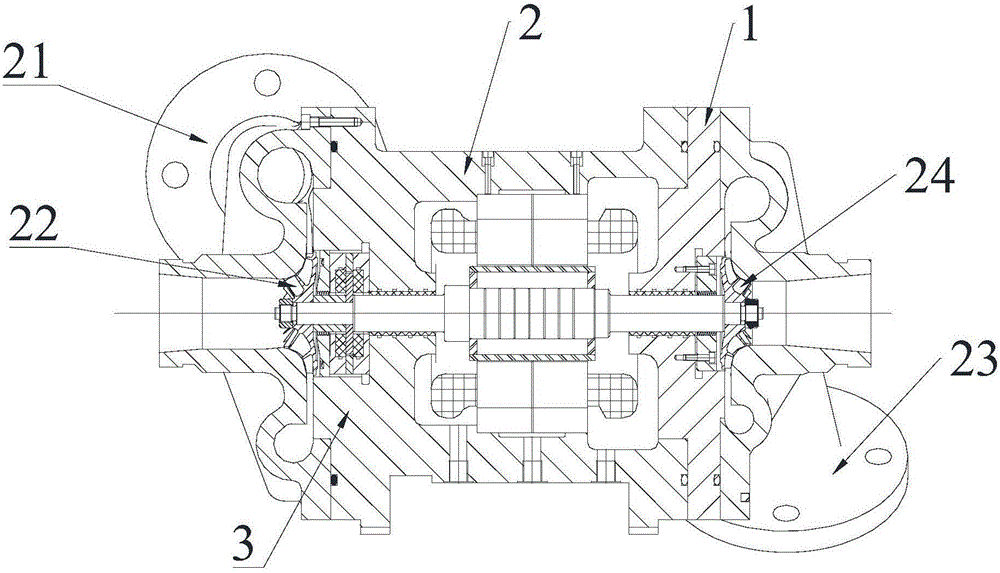

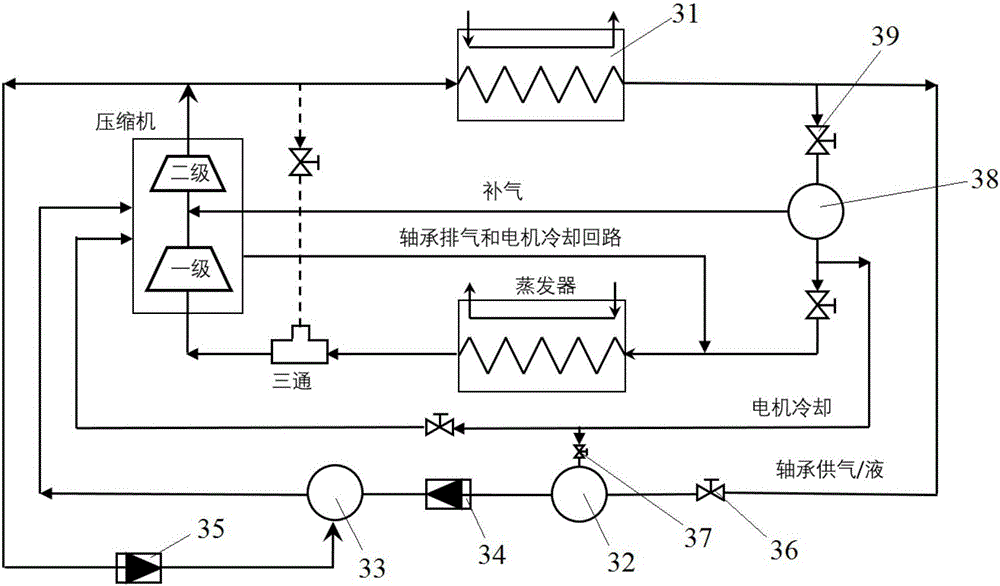

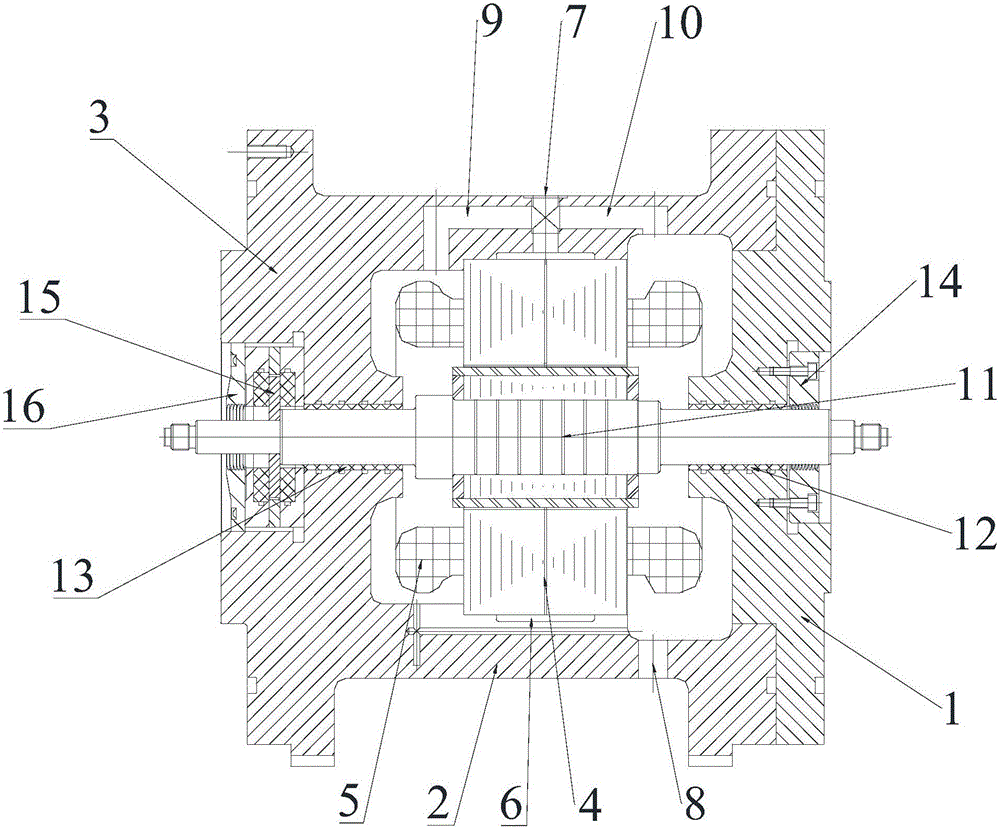

Centrifugal compressor

The invention discloses a centrifugal compressor. The centrifugal compressor comprises a motor and a first-level compressor body. The motor drives the first-level compressor body to run. A motor rotor of the motor is supported by a radial hydrostatic bearing to rotate, and the axial force of the motor rotor is balanced through an axial hydrostatic bearing. Gas and liquid double-phase low-viscosity fluid is adopted as lubrication media for the radial hydrostatic bearing and the axial hydrostatic bearing. According to the centrifugal compressor, low-velocity liquid and gas double-phase refrigerant porous material hydrostatic air bearings are adopted as the radial hydrostatic bearing and the axial hydrostatic bearing supporting the motor rotor, the radial and axial waggling of the rotor is reduced, and therefore gaps and sealing gaps between the tops of blades of impellers and volutes are allowed to be reduced by a half, and accordingly the efficiency of the centrifugal compressor can be improved by 10% or above.

Owner:ZHEJIANG FUTENG FLUID TECH CO LTD

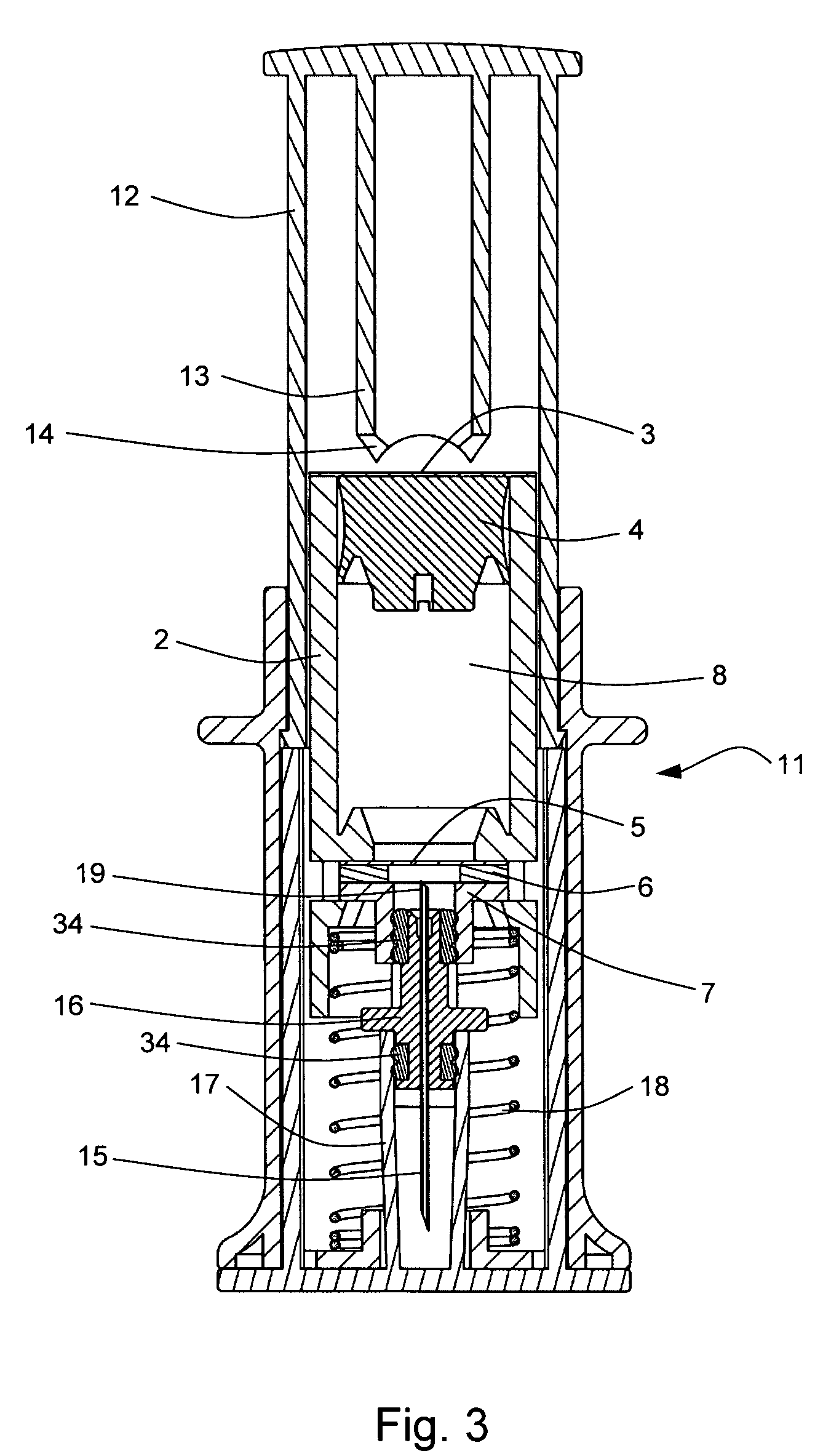

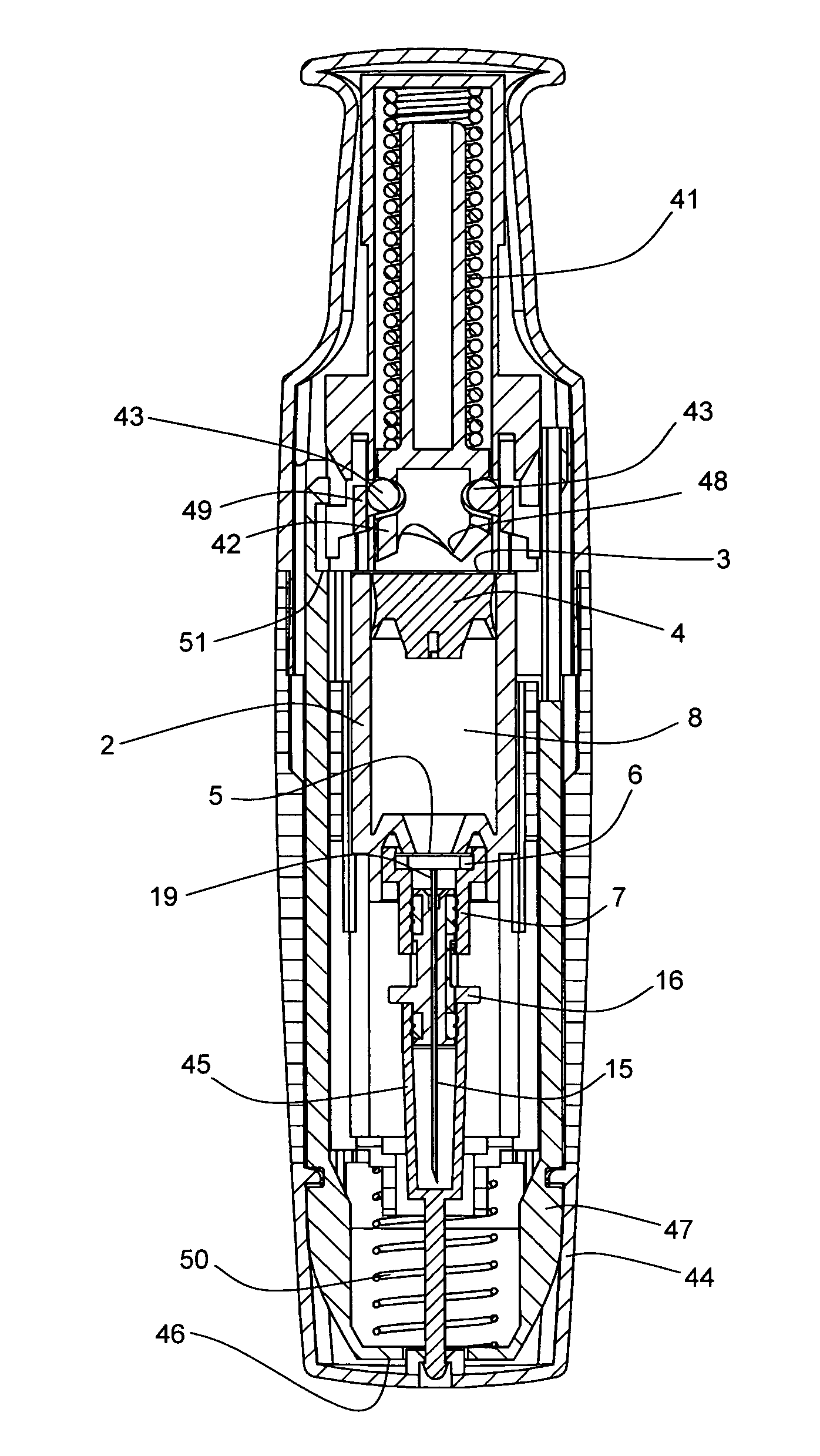

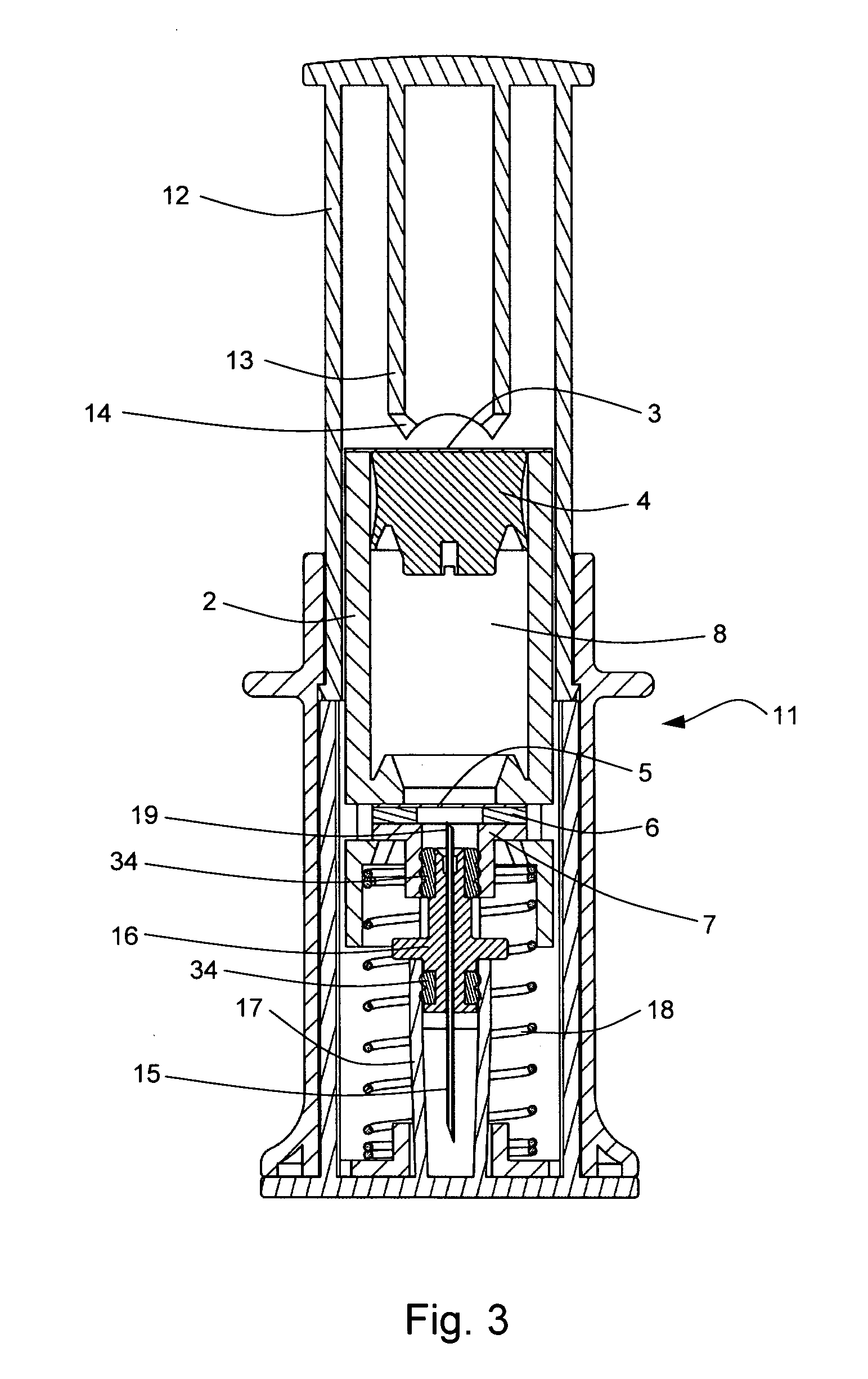

Drug container and delivery mechanism

ActiveUS8632504B2Reduced tightnessLittle strengthAmpoule syringesAutomatic syringesEngineeringMechanical engineering

Owner:OVAL MEDICAL TECH

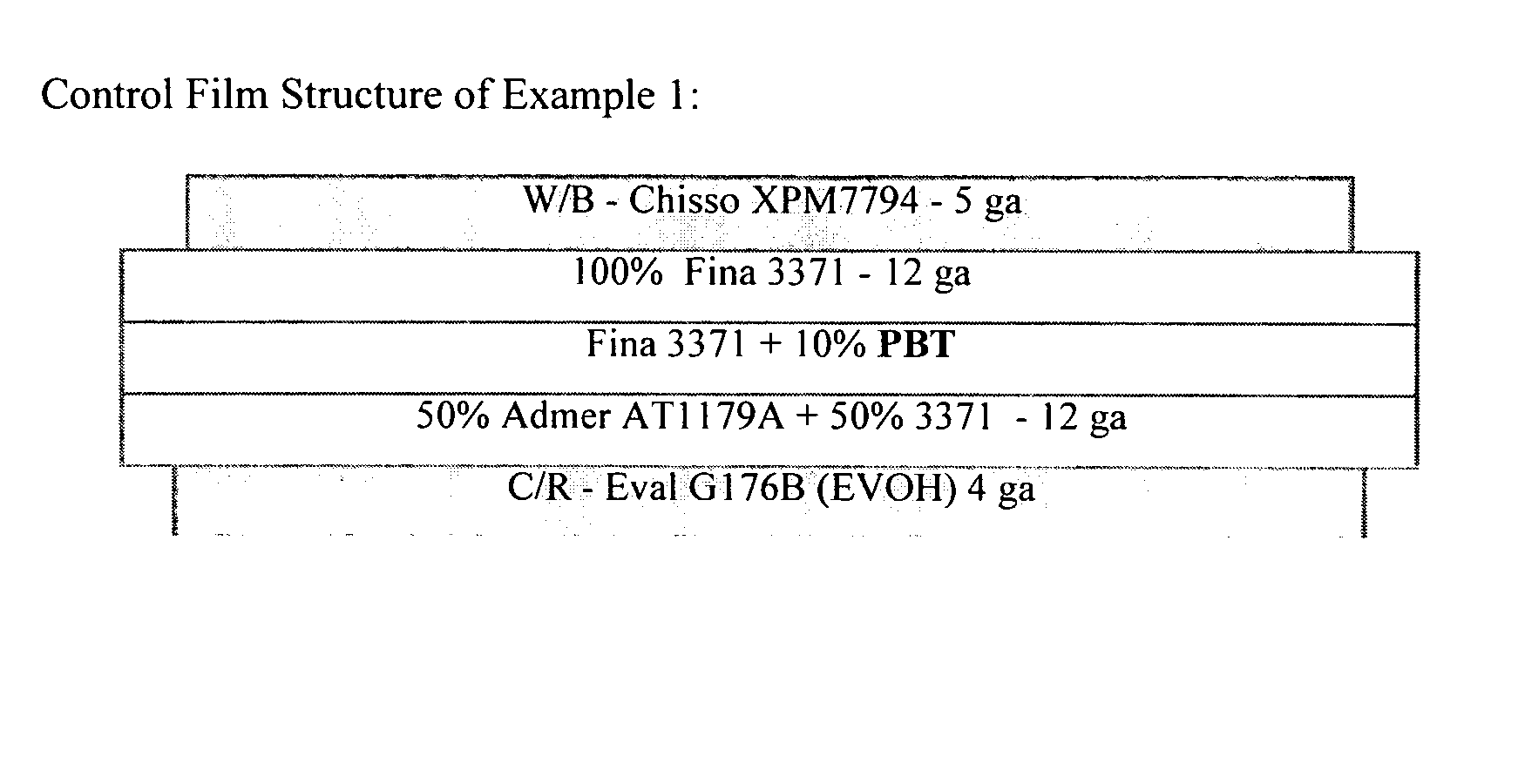

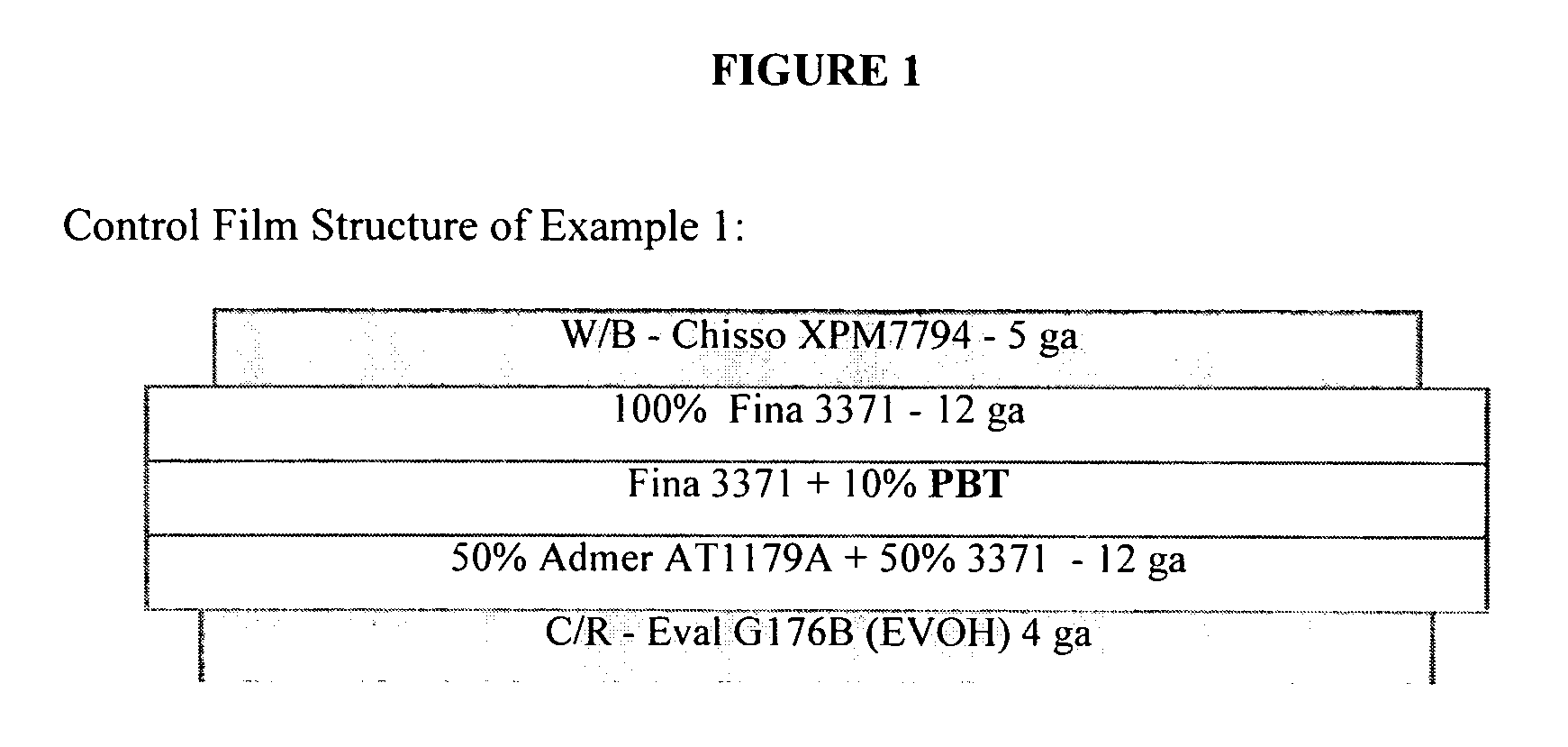

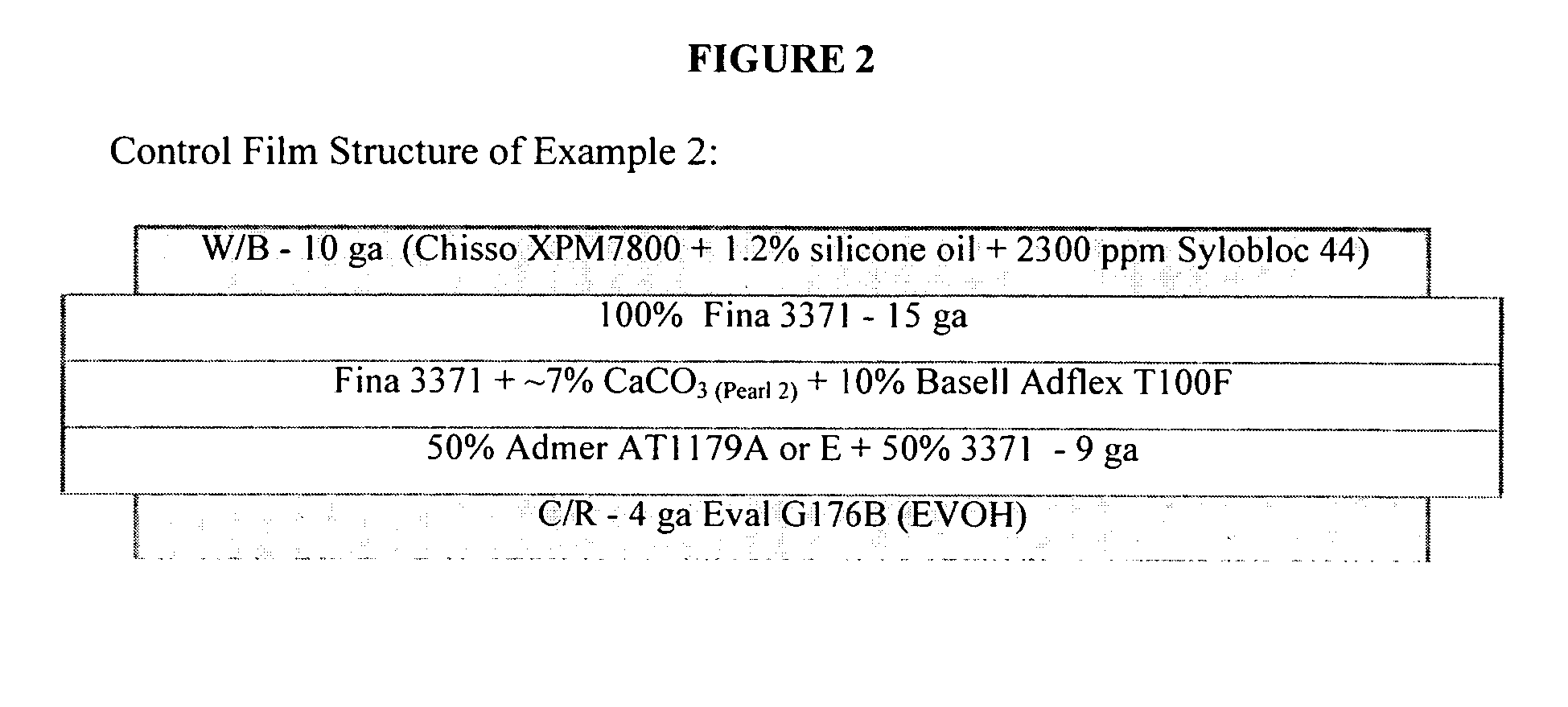

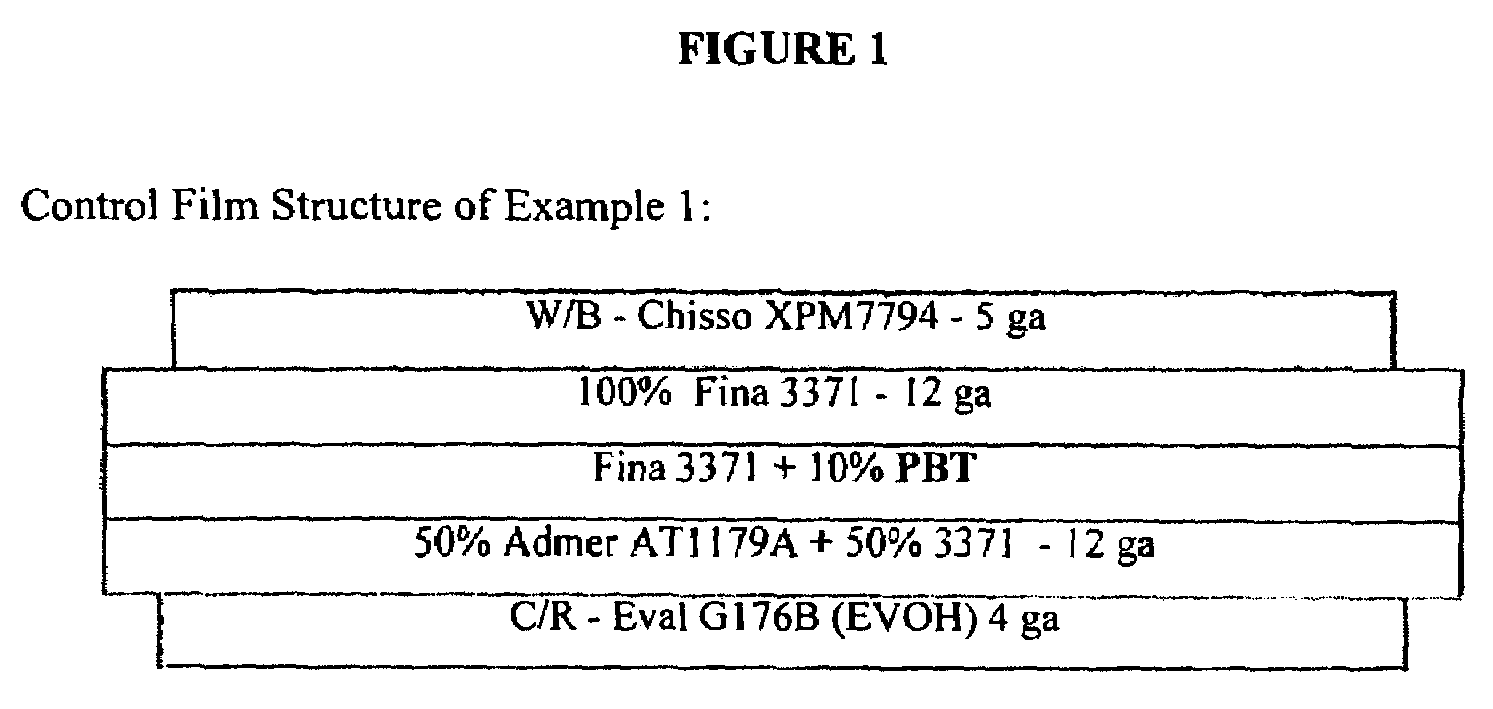

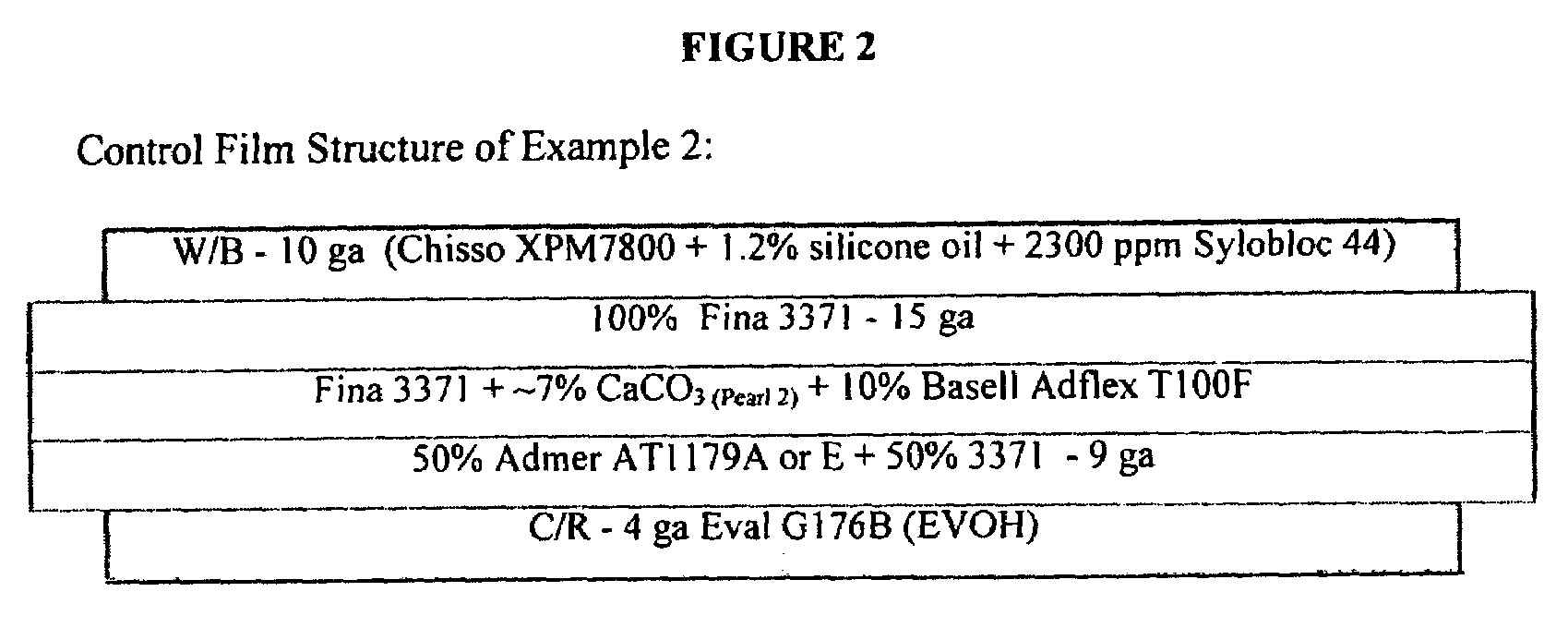

Multi-layer films having improved sealing properties

InactiveUS20050238874A1Low sealing propertyImprove seal strengthSynthetic resin layered productsLaminationEngineeringPolymer

Multi-layer films that are suitable for packaging and having improved sealing properties are disclosed. Some embodiments may also provide a lower minimum sealing temperature. A soft polymer is blended in a core layer and a tie layer comprising the soft polymer and, optionally, another polymer. A sealable layer is provided on the side of the tie layer opposite the core layer. The multi-layer films may be transparent, contain a cavitating agent, or are pigmented to form an opaque film. Also, the multi-layer film may be metallized or coated with a barrier coating.

Owner:JINDAL FILMS AMERICAS LLC

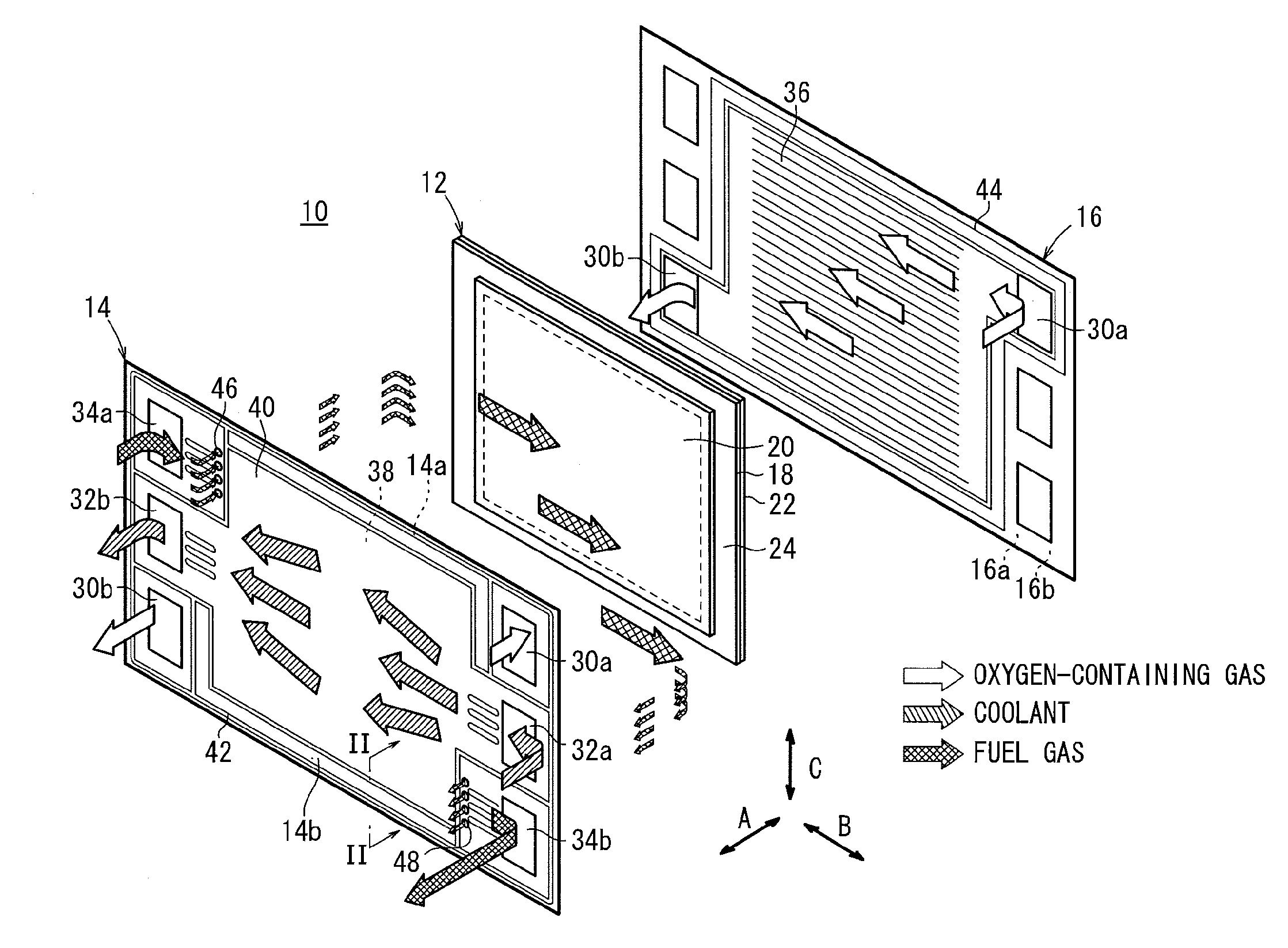

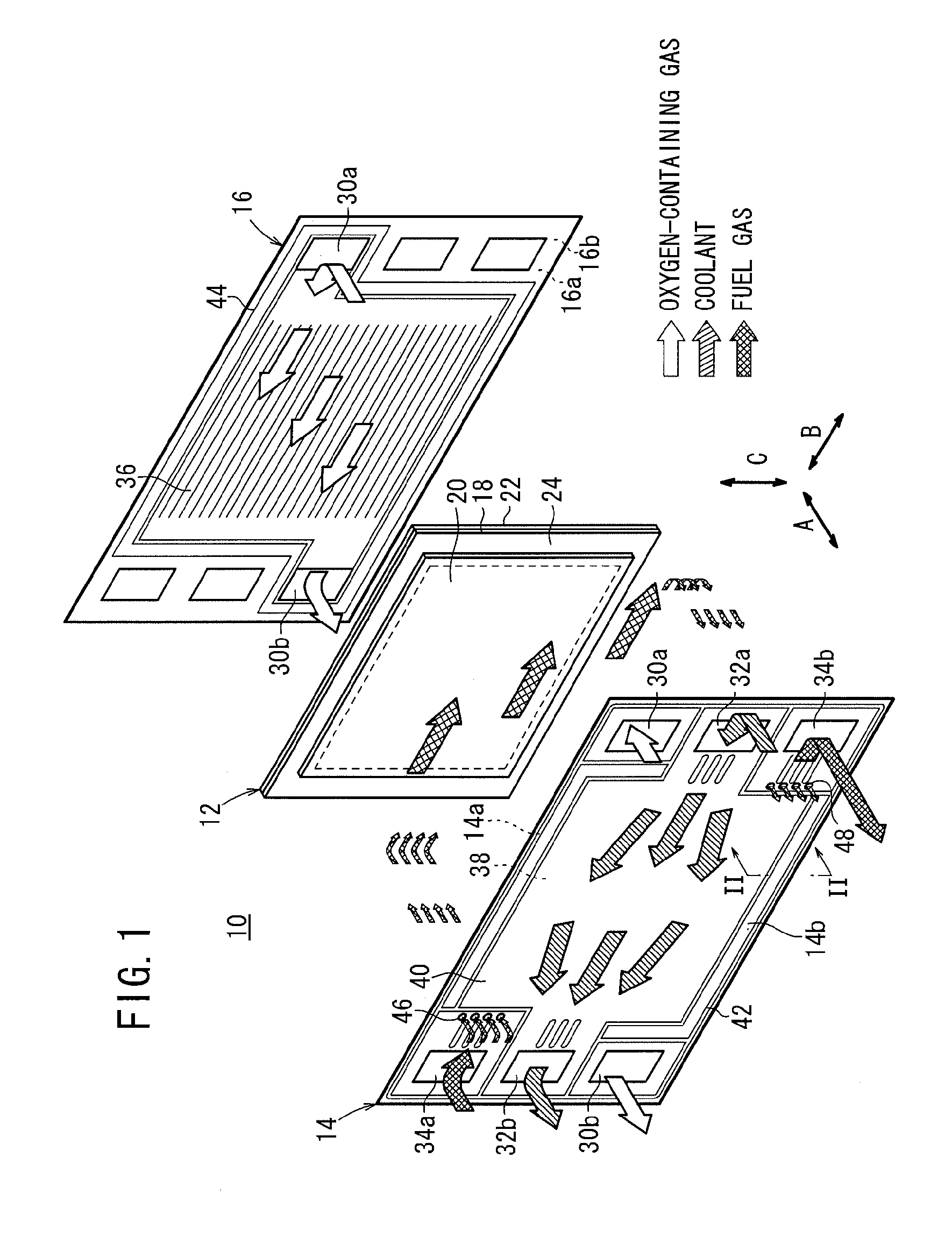

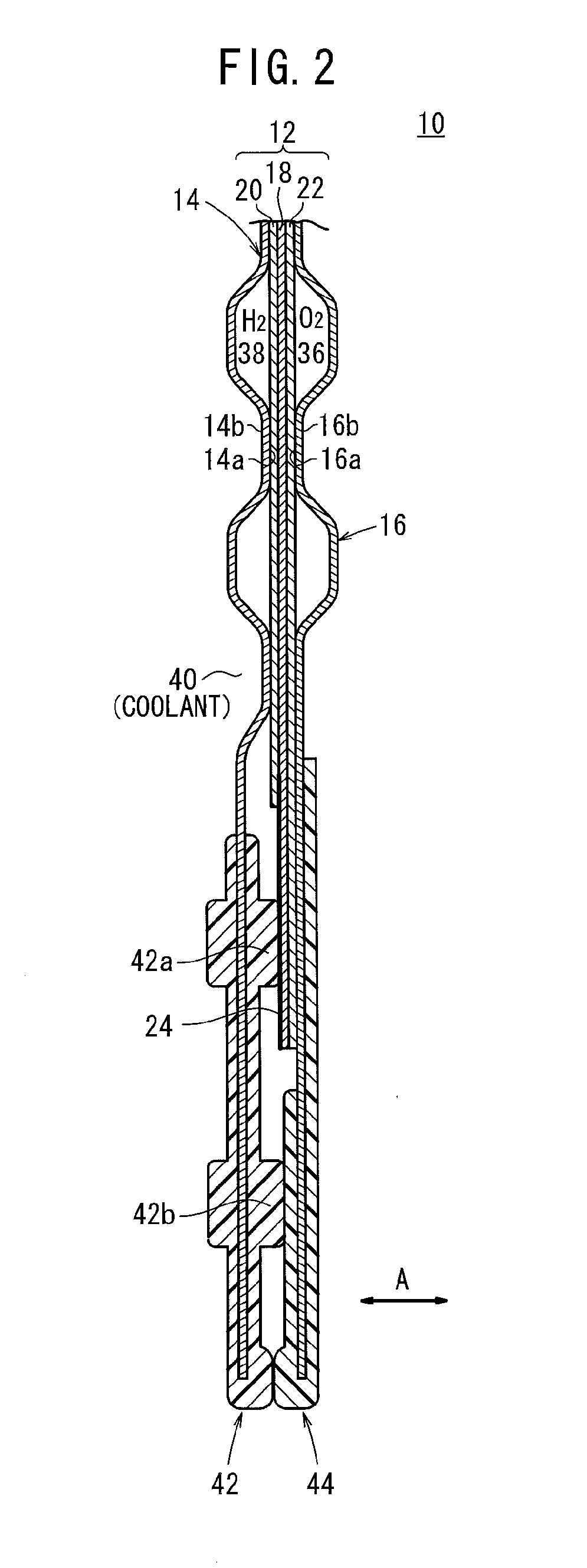

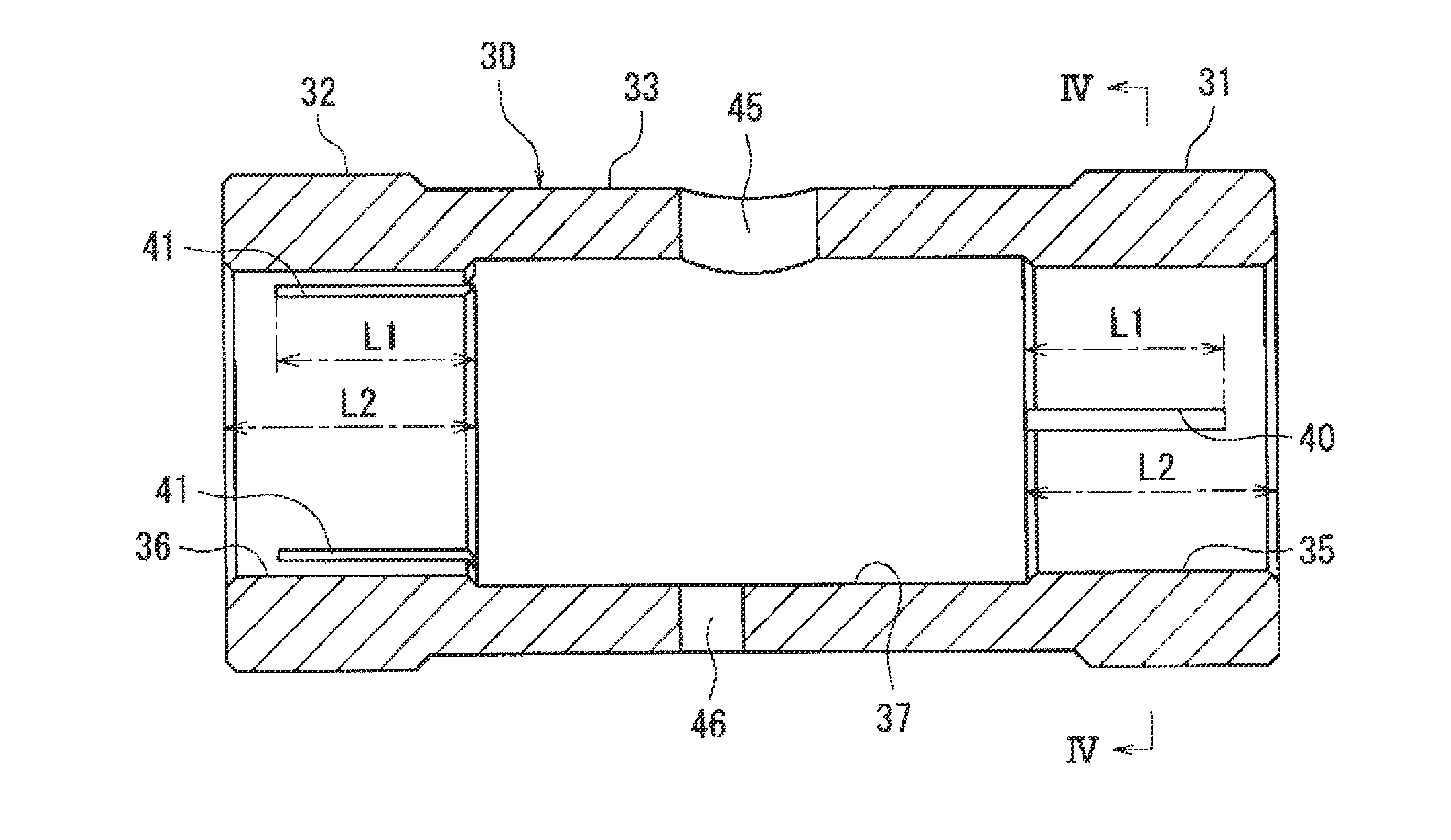

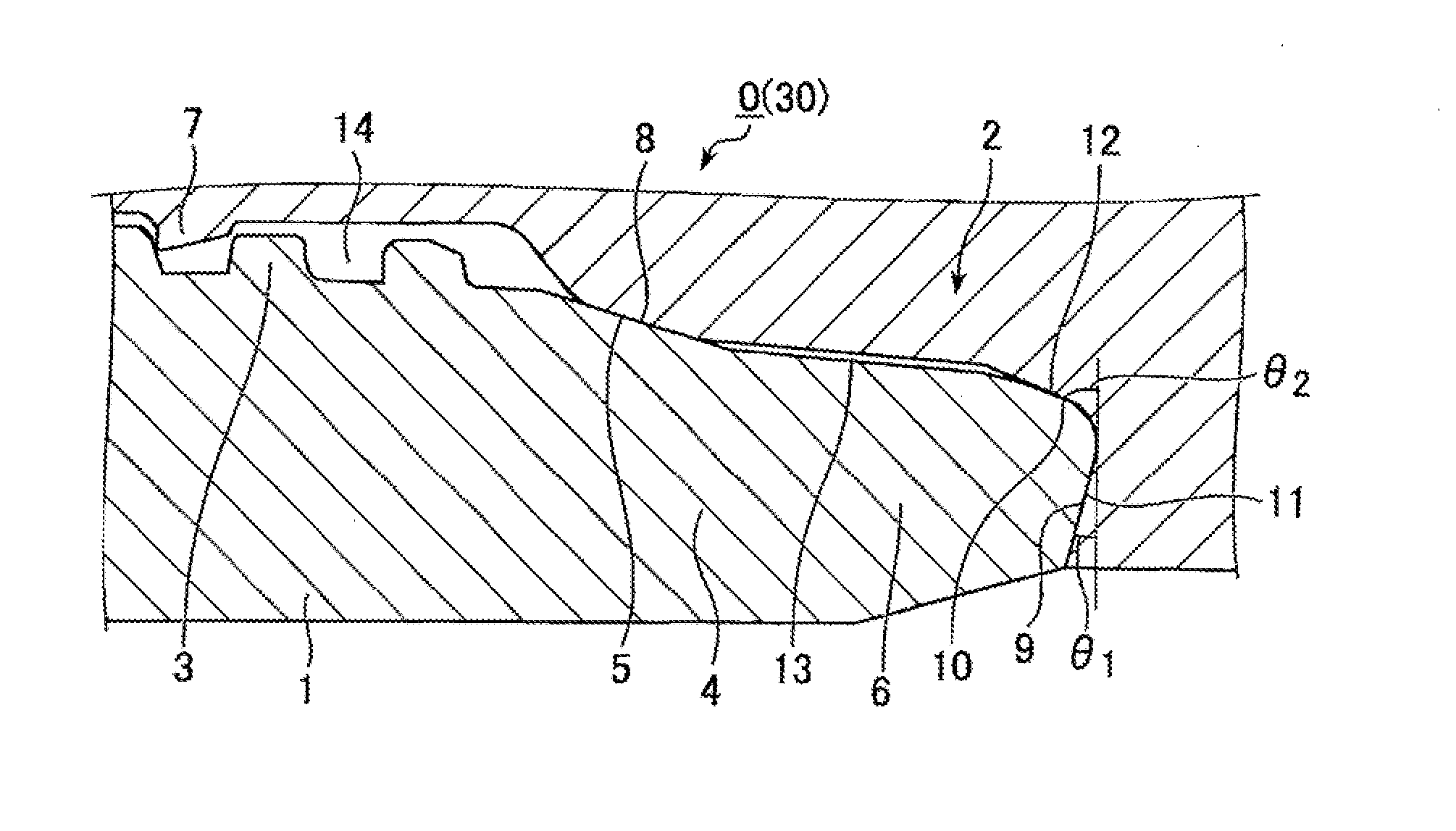

Electrolyte membrane/electrode structure and fuel cell

InactiveUS20110136038A1High strengthAvoid damageSolid electrolyte fuel cellsPolymer electrolytesFuel cells

An electrolyte membrane / electrode structure constituting a fuel cell comprises a solid polymer electrolyte membrane, an anode side electrode and a cathode side electrode sandwiching the solid polymer electrolyte membrane. The anode side electrode is provided with an electrode catalyst layer and a gas diffusion layer abutting on one side of the solid polymer electrolyte membrane and exposing the outer circumference thereof in the shape of a frame, and the cathode side electrode is provided with an electrode catalyst layer and a gas diffusion layer abutting on the other side of the solid polymer electrolyte membrane. A reinforcing sheet member is arranged on the frame-shaped surface of the solid polymer electrolyte membrane projecting from the outer circumference of the gas diffusion layer.

Owner:HONDA MOTOR CO LTD

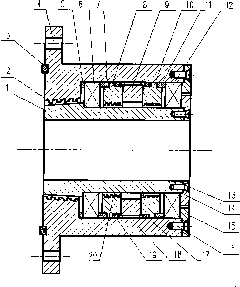

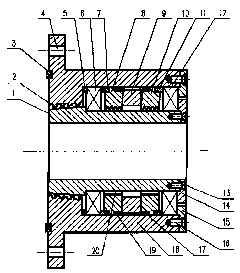

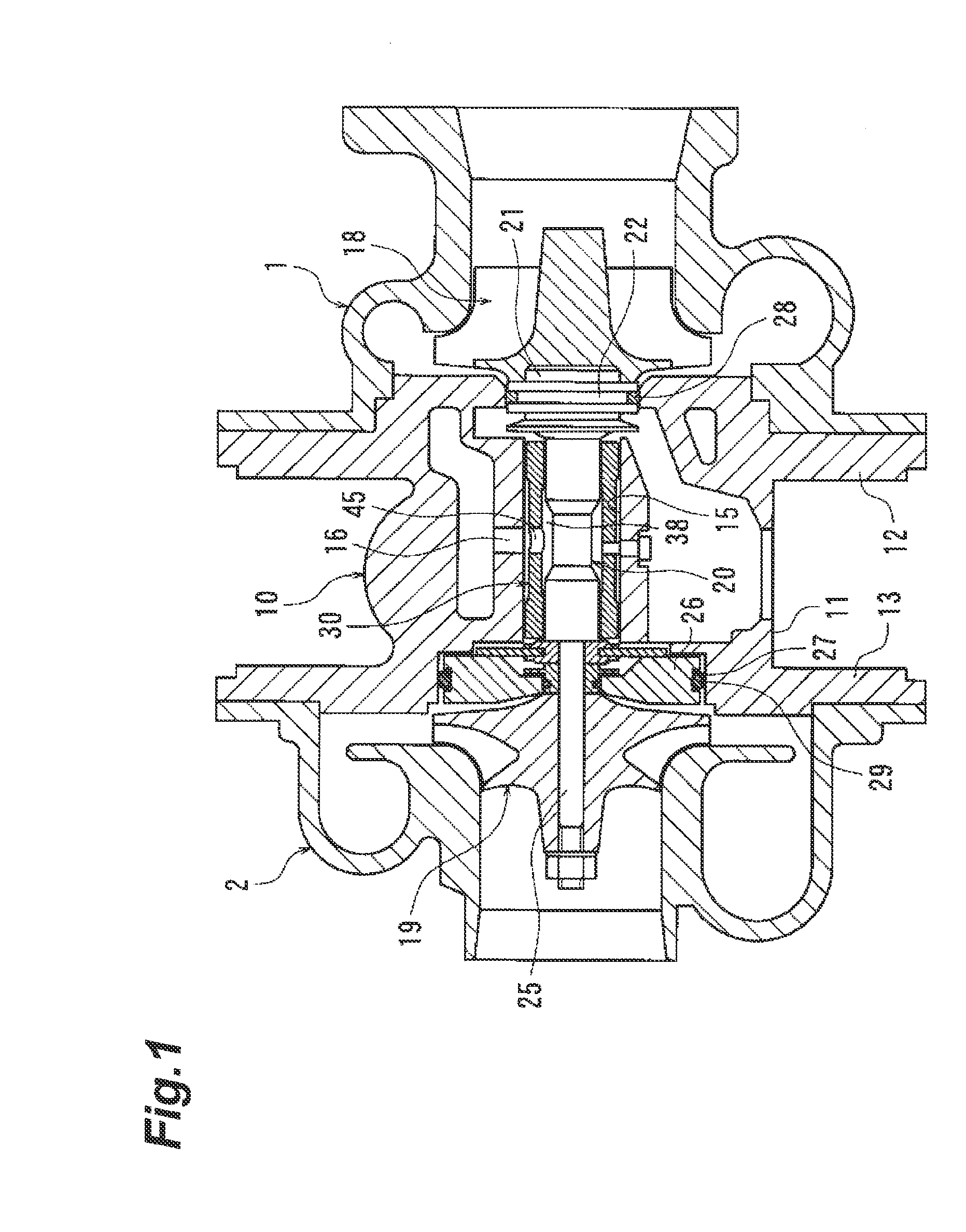

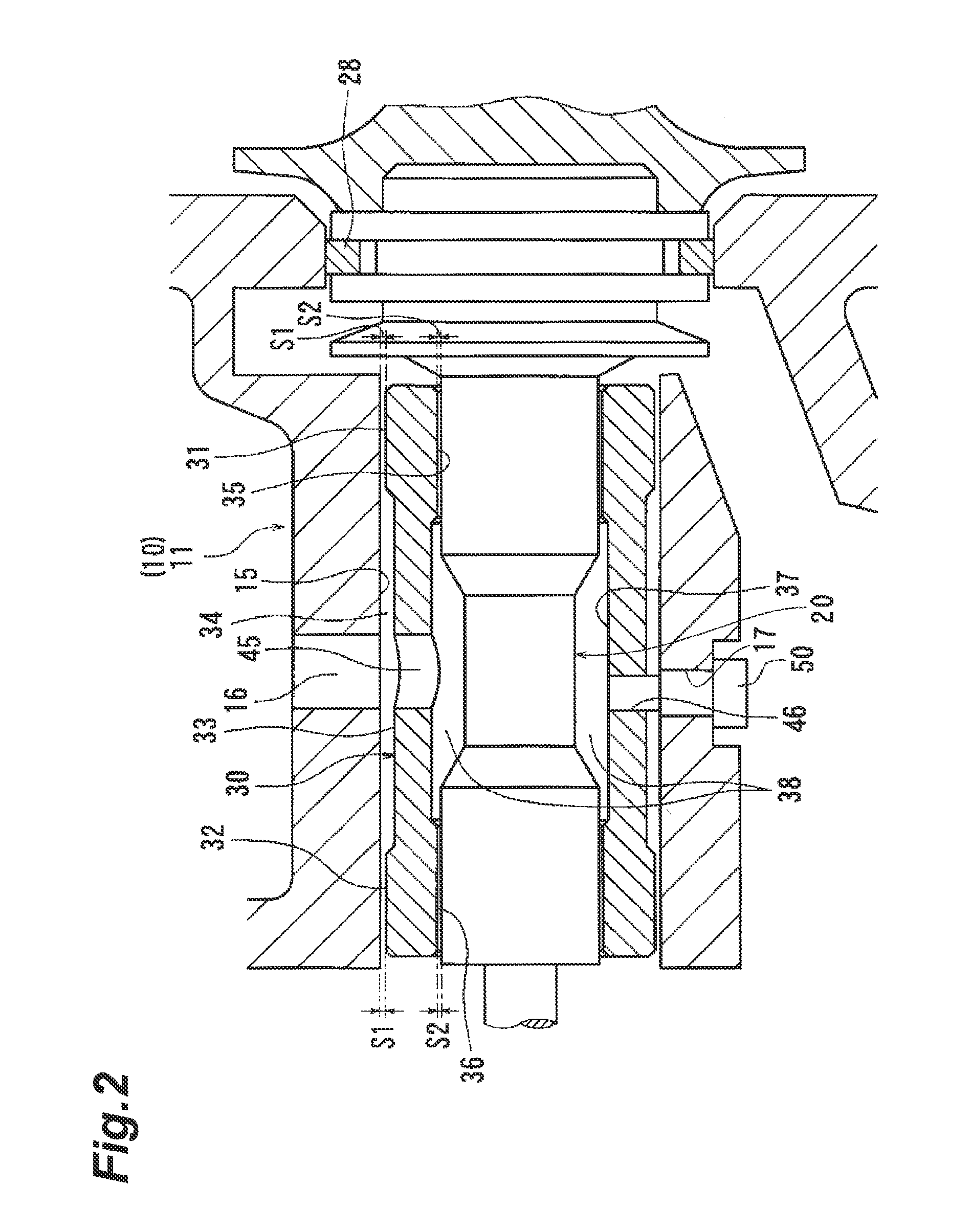

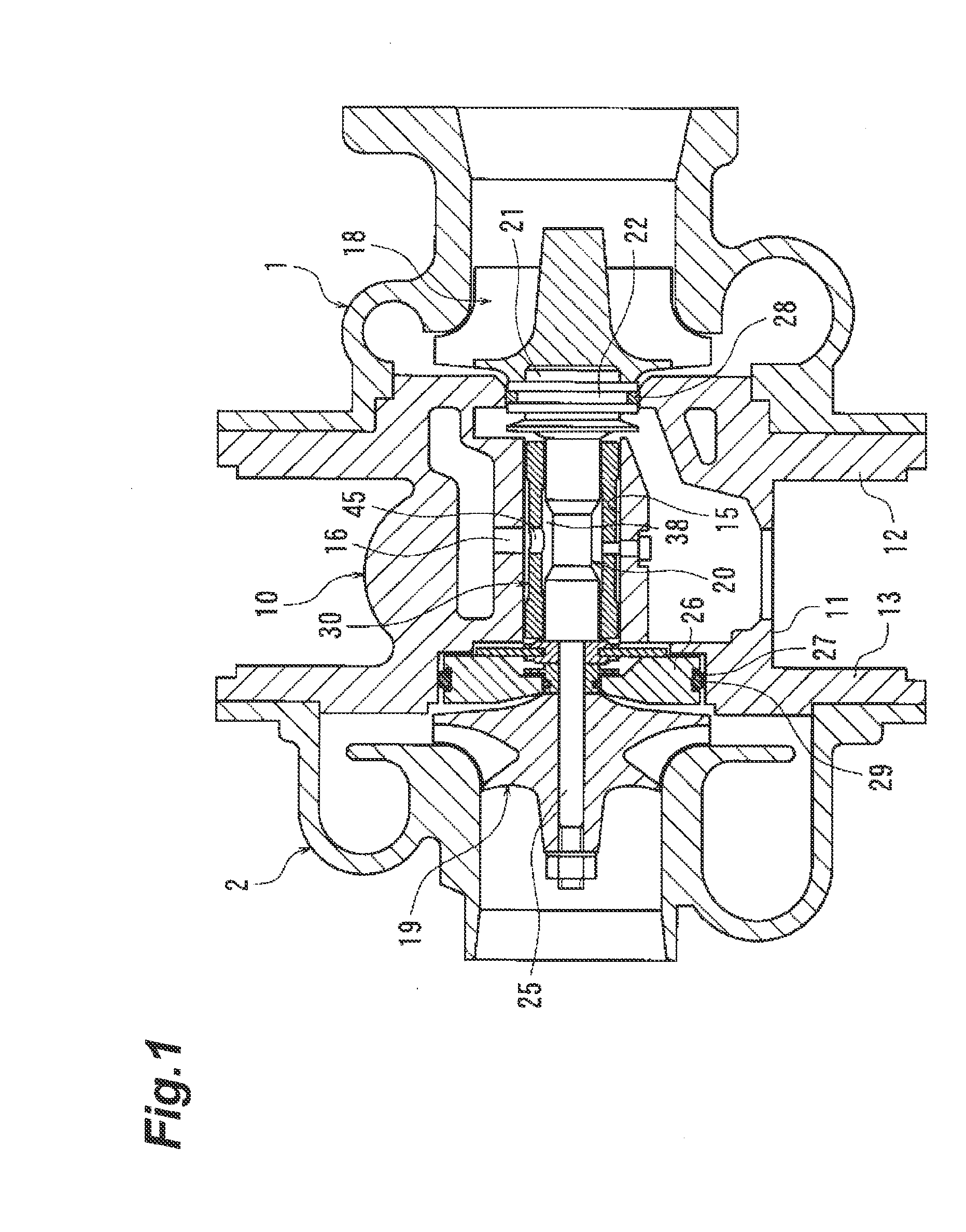

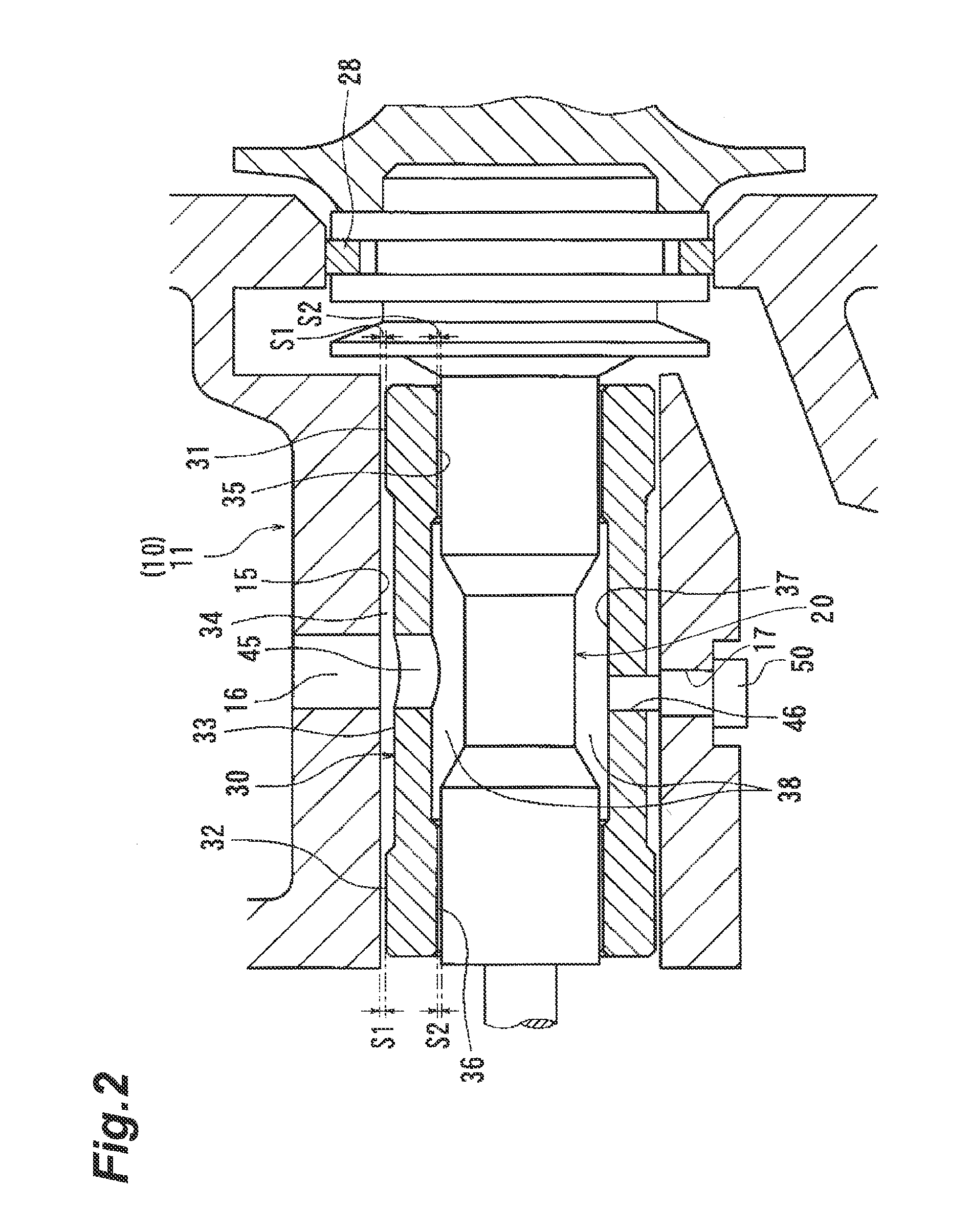

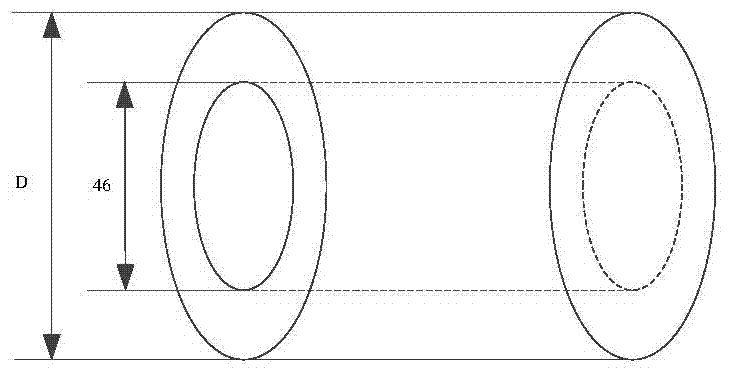

Bearing structure of turbocharger

InactiveUS8628247B2Reduce rotation speedReduce vibrationCrankshaftsBearing assemblyTurbochargerMechanical engineering

Owner:TOYOTA IND CORP

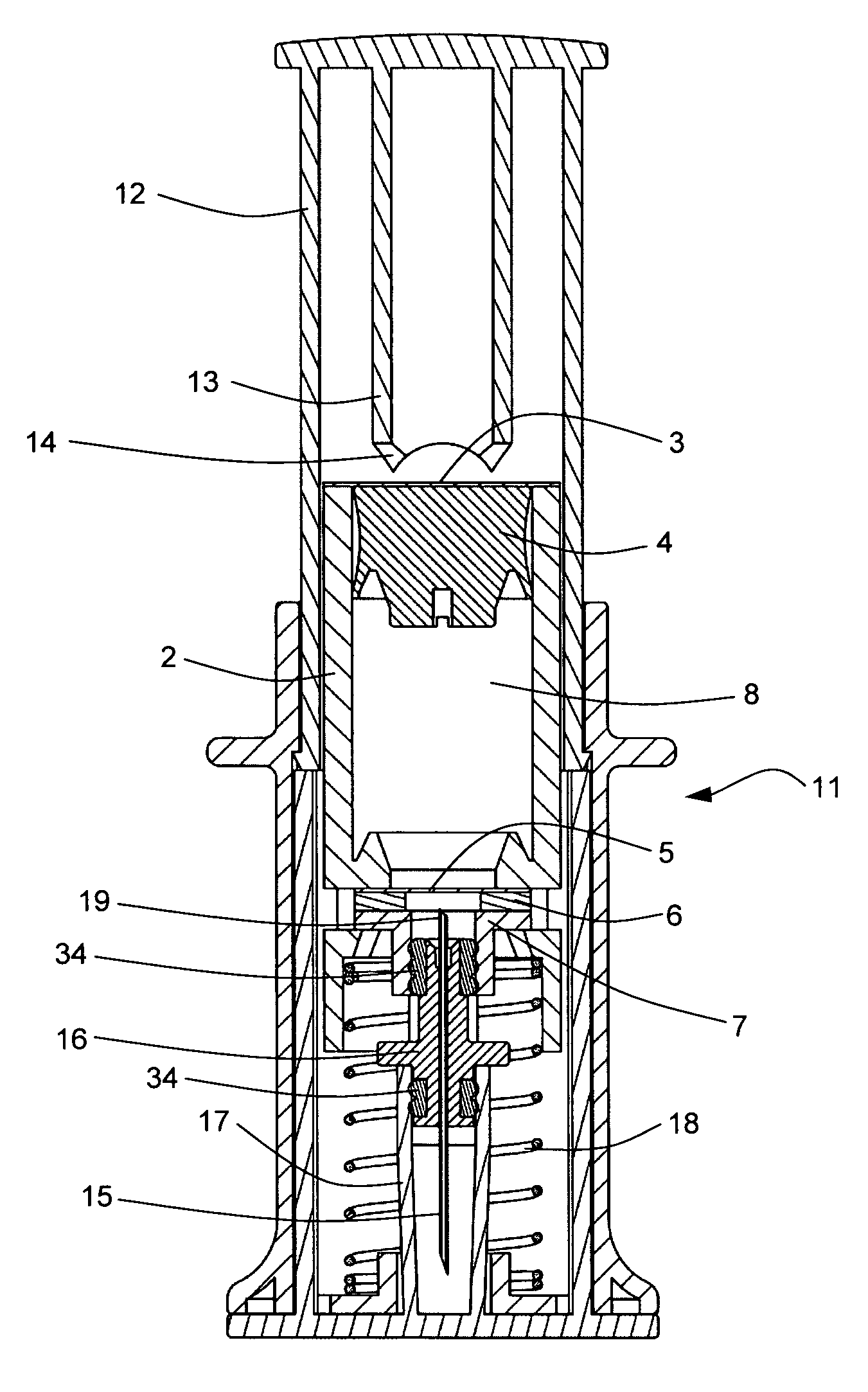

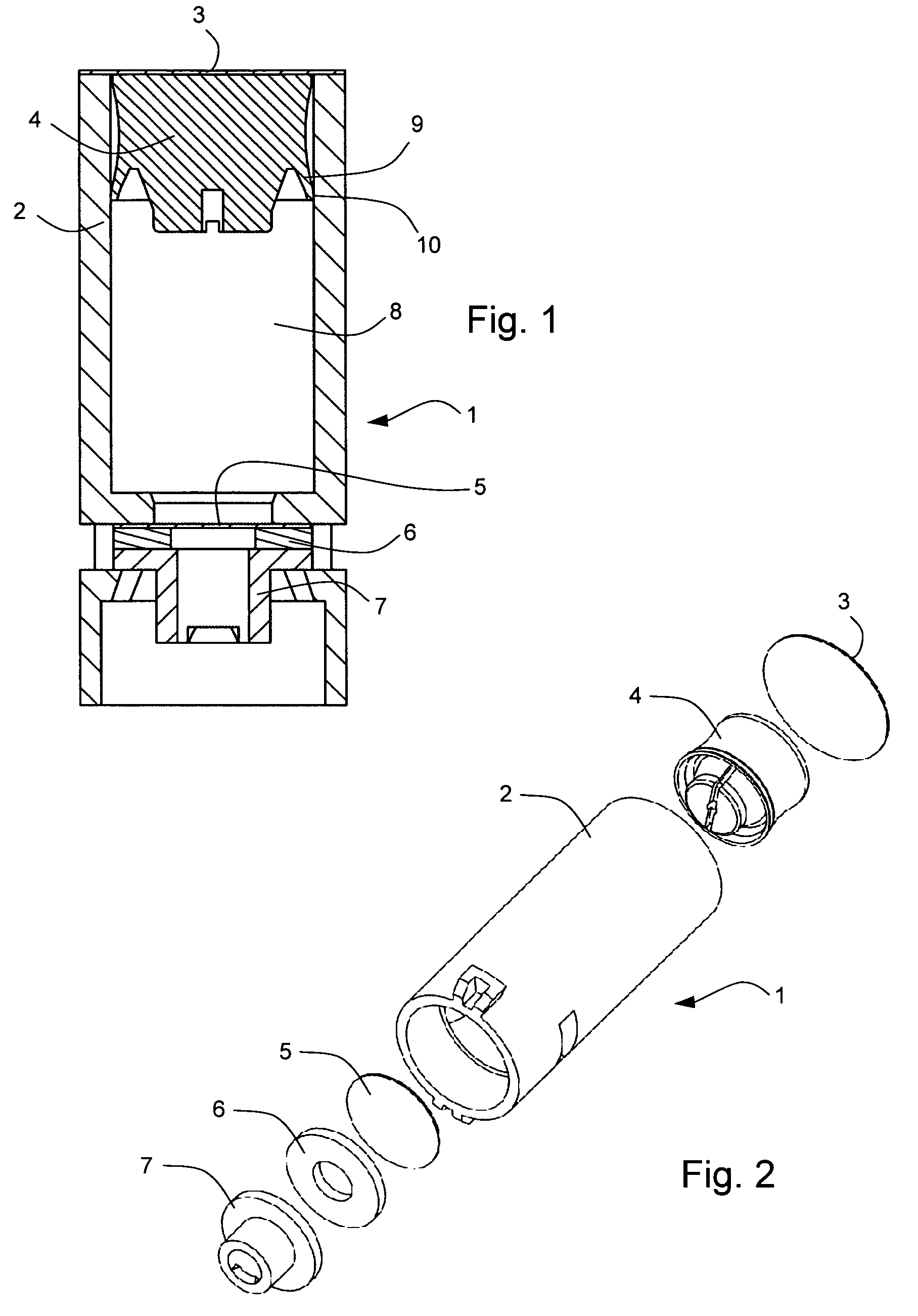

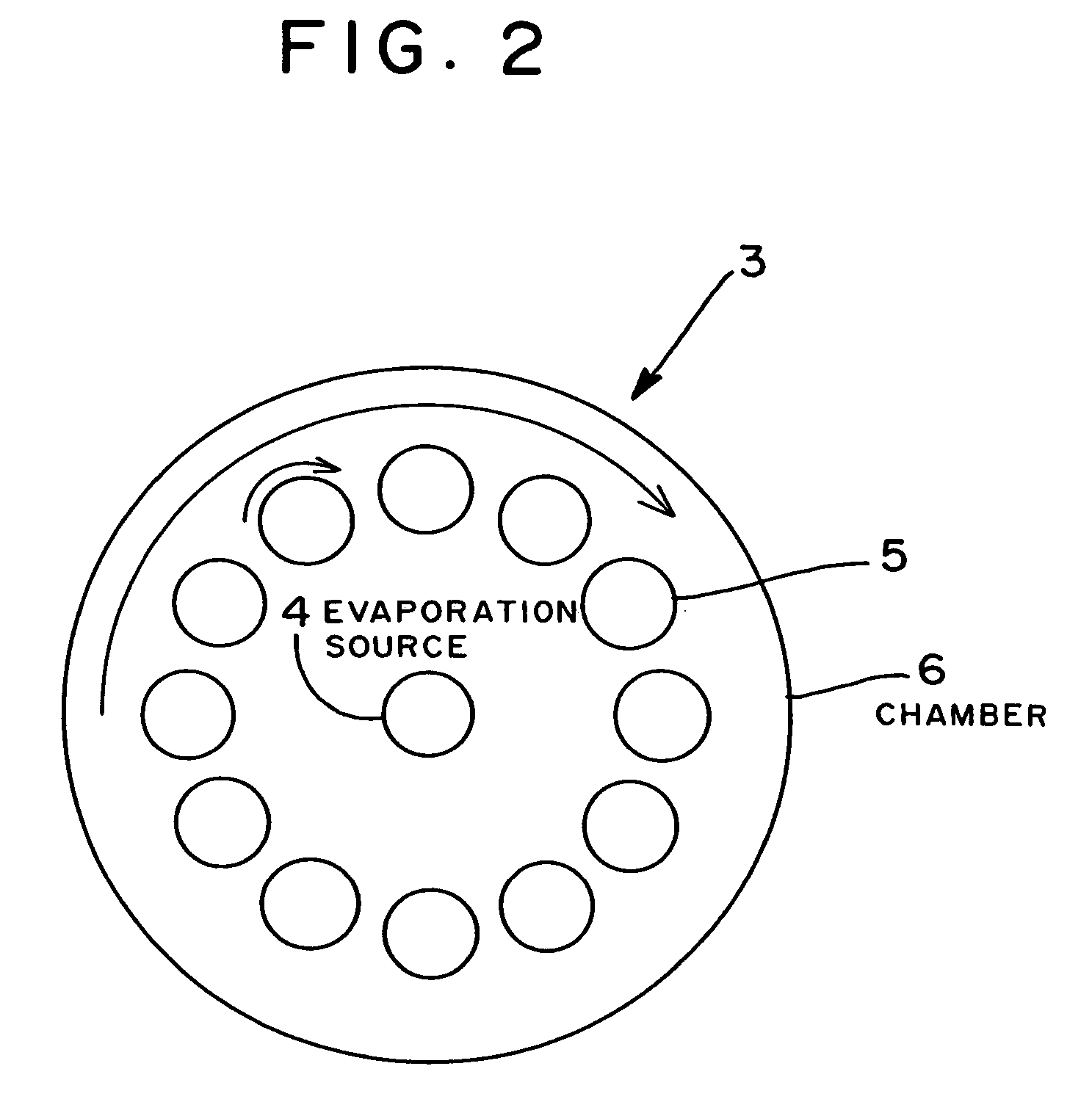

Drug container and delivery mechanism

ActiveUS20110301548A1Augments sealLess likely to ‘ stall ’Ampoule syringesAutomatic syringesBiomedical engineeringDrug Containers

A device for storing and administering drug includes a housing, a sealing element (3) and a separate low friction plunger (4) which is substantially-permeable to gas over time. The sealing element (3) is typically broken to allow delivery of the drug. The housing (2) may be filled with the drug through an opening other than the opening through which the pusher (13) enters the housing to move the plunger so as to expel the drug during administration to a patient.

Owner:OVAL MEDICAL TECH

Quick pipeline connecting method and joint using same

The invention discloses a quick pipeline connecting method and a joint using the same. The joint comprises a joint body, wherein a clamping ring, a conical base and an O-shaped sealing ring are sequentially arranged inside the joint body along the pipeline insertion direction; when the pipeline is inserted into the joint, a flange arranged on the clamping ring is deflected; and when the pipeline expands under increased pressure after the introduction of a liquid, the O-shaped sealing ring expands axially under the action of pressure, and the clamping ring is driven to move along a direction opposite to the pipeline insertion direction by pushing the conical base to clamp the pipeline. The invention also discloses a quick pipeline joint adopting the quick connecting method. The joint has the advantages of capabilities of making an elastic pipe body (such as a PEX pipe body) easier to insert and ensuring that the elastic pipe body does not loosen easily after being inserted and expanded due to increased pressure caused by the introduction of the liquid, high air tightness and connecting reliability.

Owner:LA CASA ANGELA HLDG

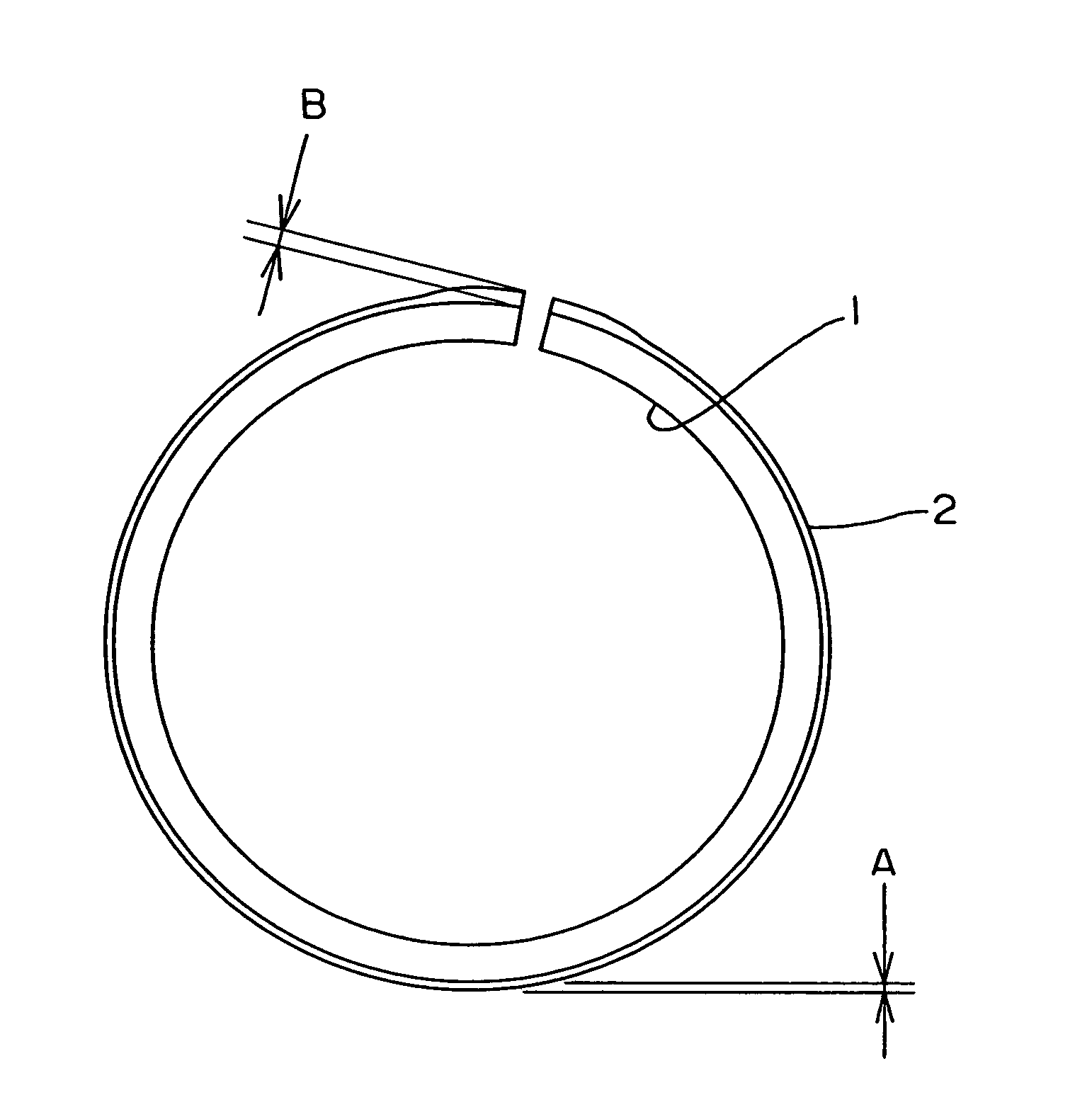

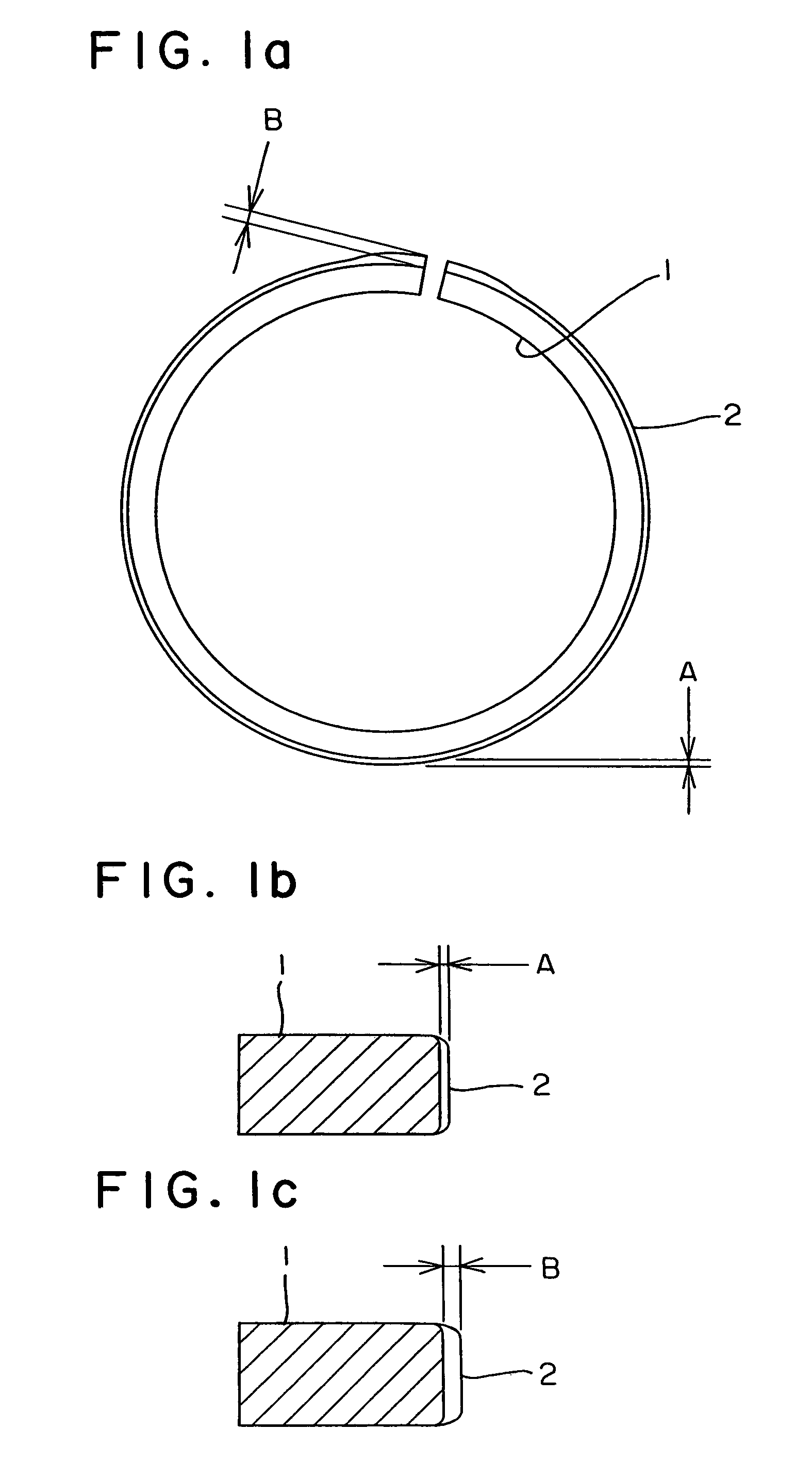

Piston ring and method of manufacturing the same

InactiveUS7052019B2Improve wear resistancePrevent peelingPiston ringsBraking action transmissionCountermeasurePiston ring

A manufacturing method of a piston ring is developed, wherein the method provides a countermeasure for wear of butt ends of the ion plating film coated piston ring and a countermeasure for breakage of the piston ring and the piston ring manufactured at a low cost. A thickness of the film (2) in the vicinity of butt ends (7) of a piston ring (1) is made greater than the thickness of the film (2) at other outer peripheral surface. Piston ring blanks (5) are rotated around their own axes toward an evaporation source (4) and a speed is lowered when the butt ends (7) face the evaporation source (4).

Owner:RIKEN CO LTD

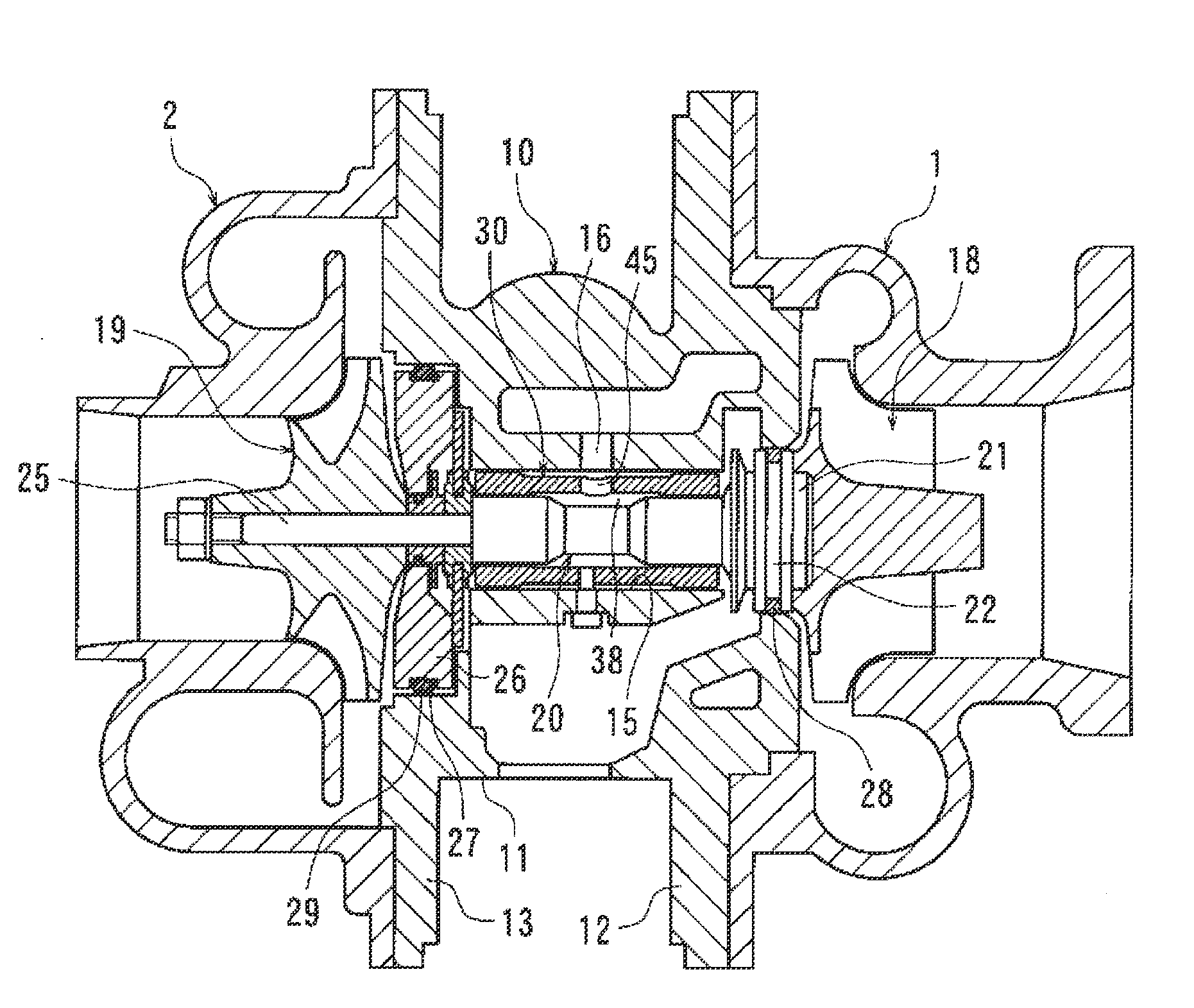

Bearing structure of turbocharger

InactiveUS20120237149A1Reduce rotation speedReduce vibrationCrankshaftsBearing assemblyTurbochargerEngineering

A turbocharger is provided with a rotor shaft, a bearing housing in which a bearing hole is formed, and a bearing member of the semi-floating type arranged in the bearing hole and supporting the rotor shaft in a rotatable state. The bearing member has a first bearing portion and a second bearing portion spaced at a predetermined interval in the axial direction of the rotor shaft, in its inner periphery. A region between the first bearing portion and the second bearing portion in the inner periphery of the bearing member, and an outer periphery of the rotor shaft constitute an oil passage for supply of lubricant oil to inside surfaces of the first and second bearing portions. Oil grooves to suppress the whirl vibration are formed in each of the inside surfaces of the first and second bearing portions. The oil grooves are closed in part.

Owner:TOYOTA IND CORP

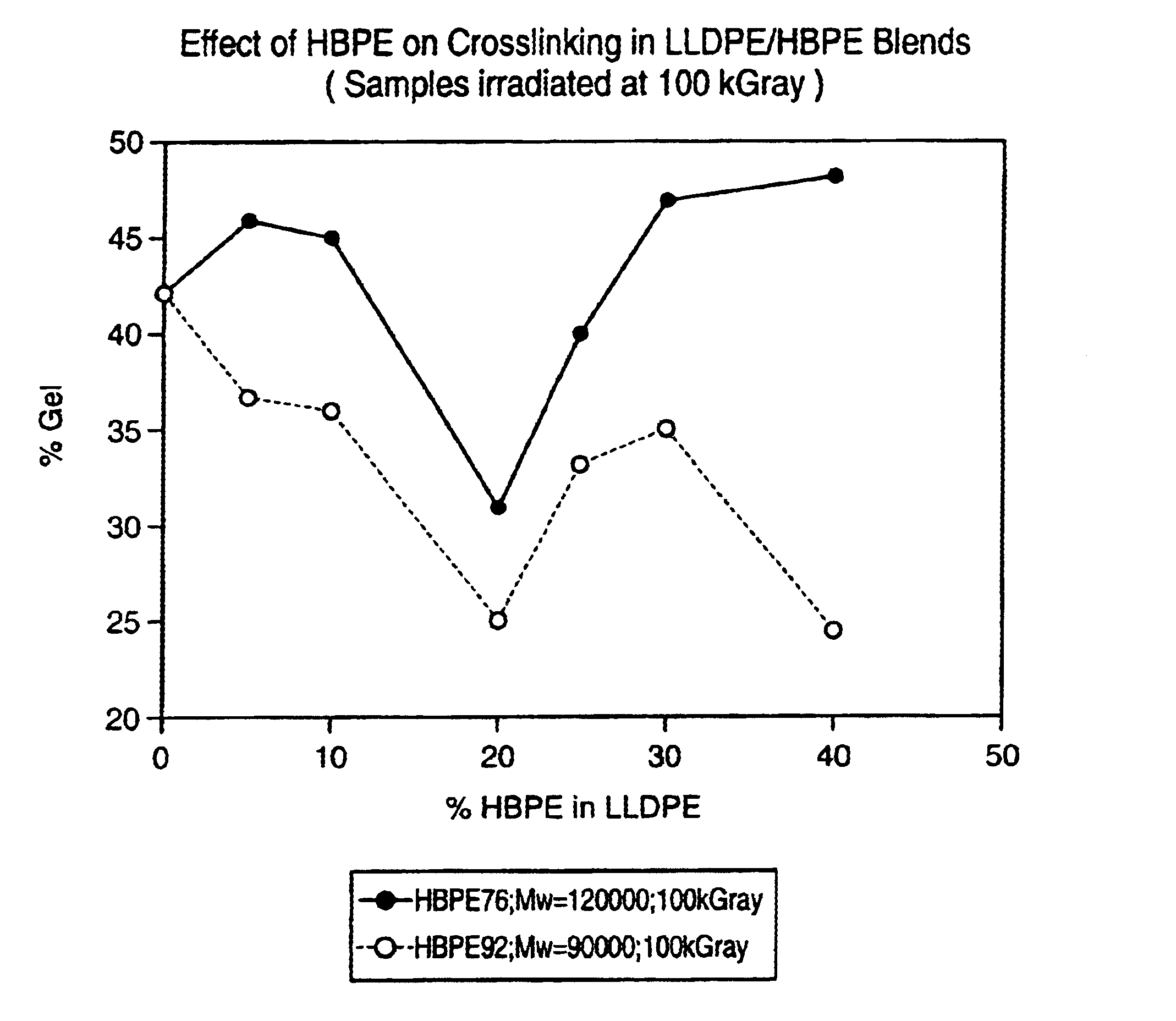

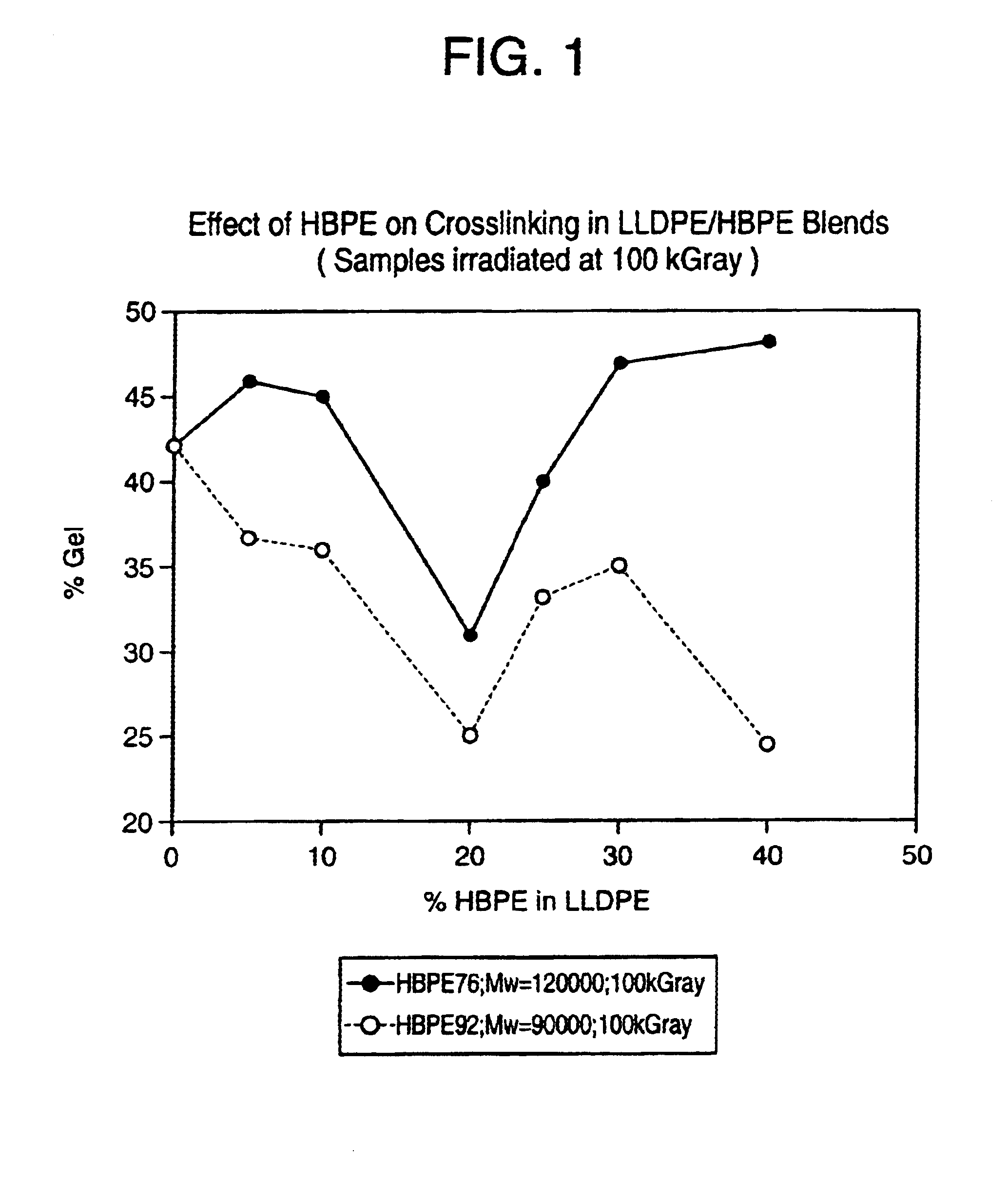

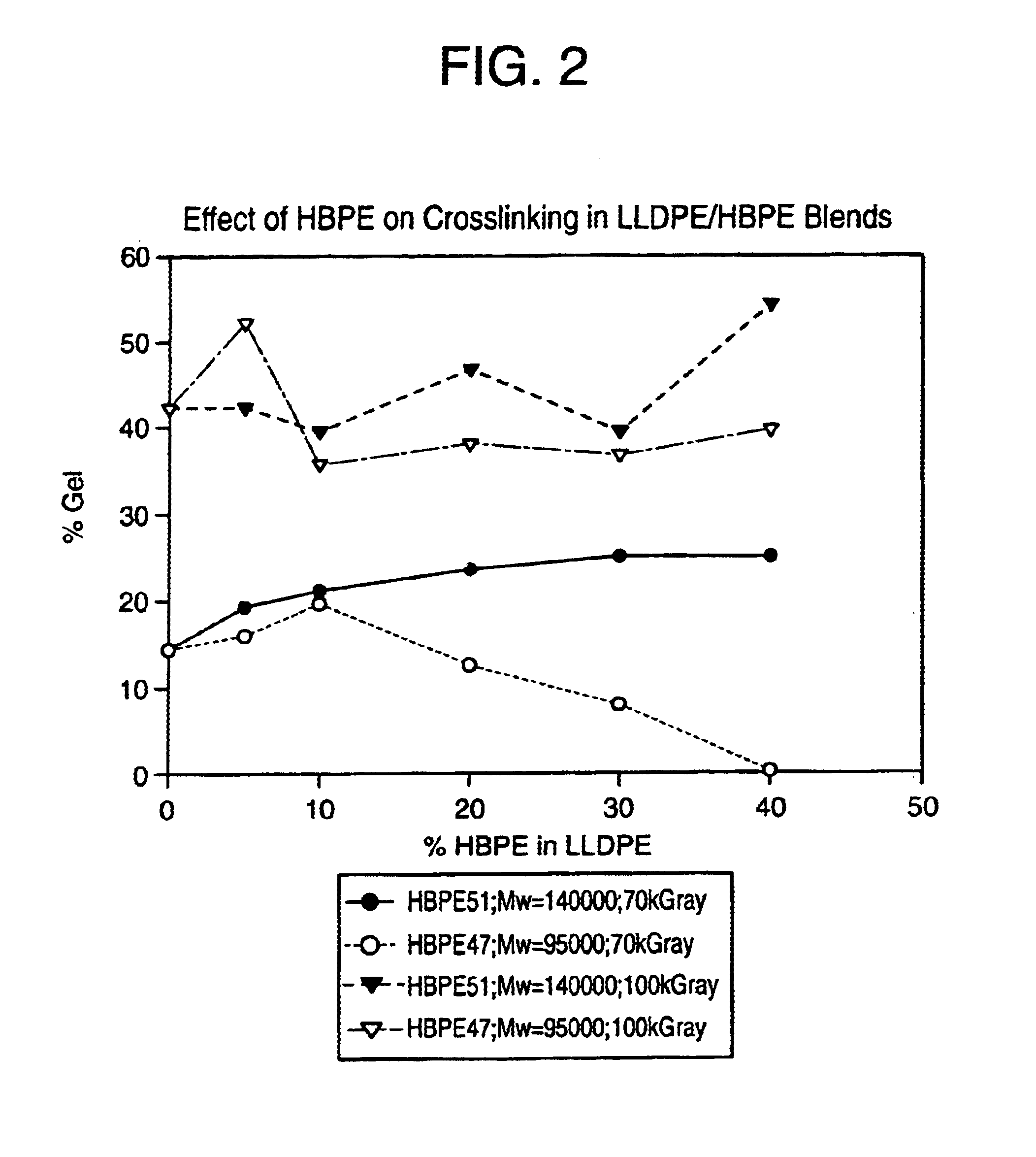

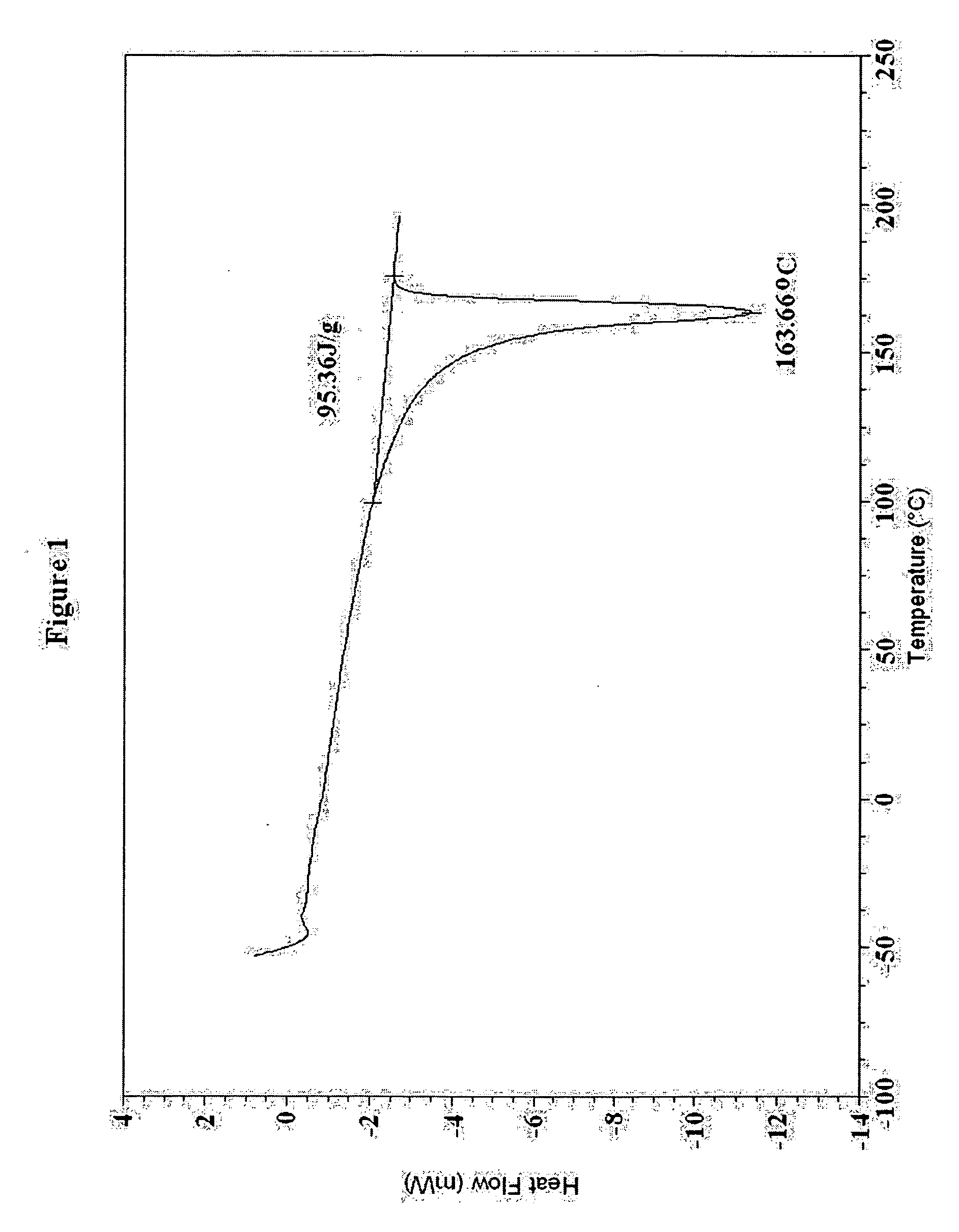

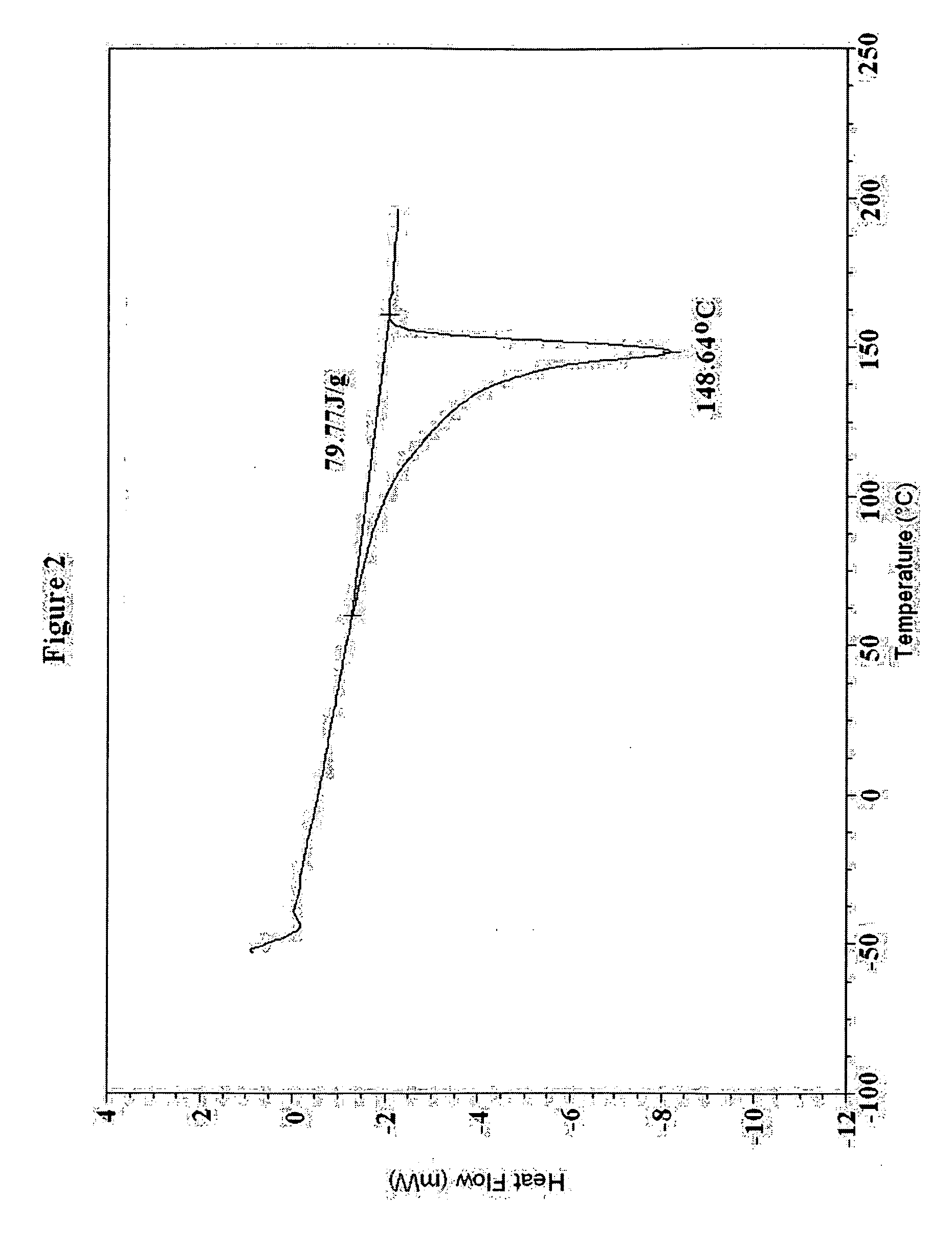

Irradiated multilayer film having seal layer containing hyperbranched polymer

InactiveUS6858275B2Diminishing heat seal performance of sealReduces heat seal performanceWrappersThin material handlingPolyolefinPolymer network

An irradiated multilayer film has a first layer and a second layer. The first layer is an outer heat seal layer containing a blend of a highly branched homogeneous polymer and a semicrystalline polymer. The highly branched homogeneous polymer has at least 40 branches per 1000 methylene groups, an Mw / Mn less than 3.0, and a density of less than 0.89 g / cc. The highly branched homogeneous polymer is present in an amount of from about 1 to 50 weight percent, based on layer weight. The semicrystalline polyolefin has a density of at least 0.90 g / cc. The semicrystalline polyolefin is present in an amount of from about 60 to 99 weight percent, based on total layer weight. The second layer contains a thermoplastic polymer in a crosslinked polymer network. A process for making a packaging article includes coextruding the first and second layers, irradiating the resulting multilayer film, and thereafter heat sealing the first layer to itself or another component of the packaging article.

Owner:CRYOVAC INC

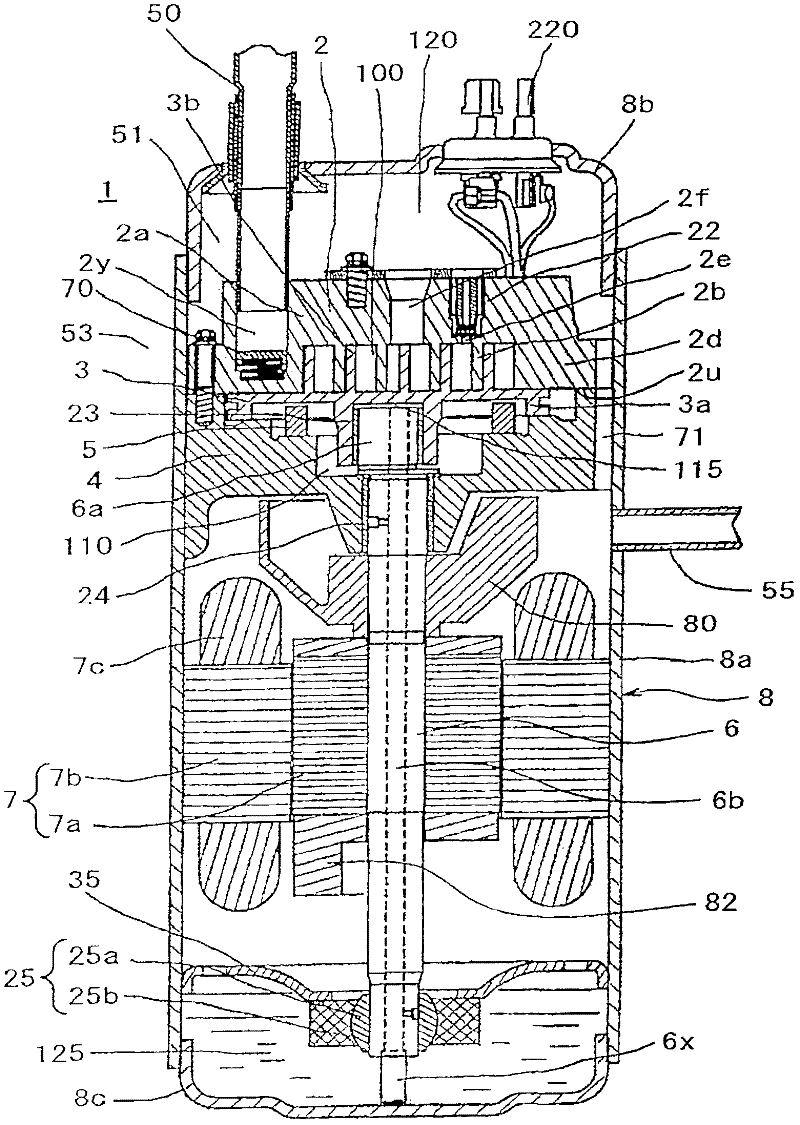

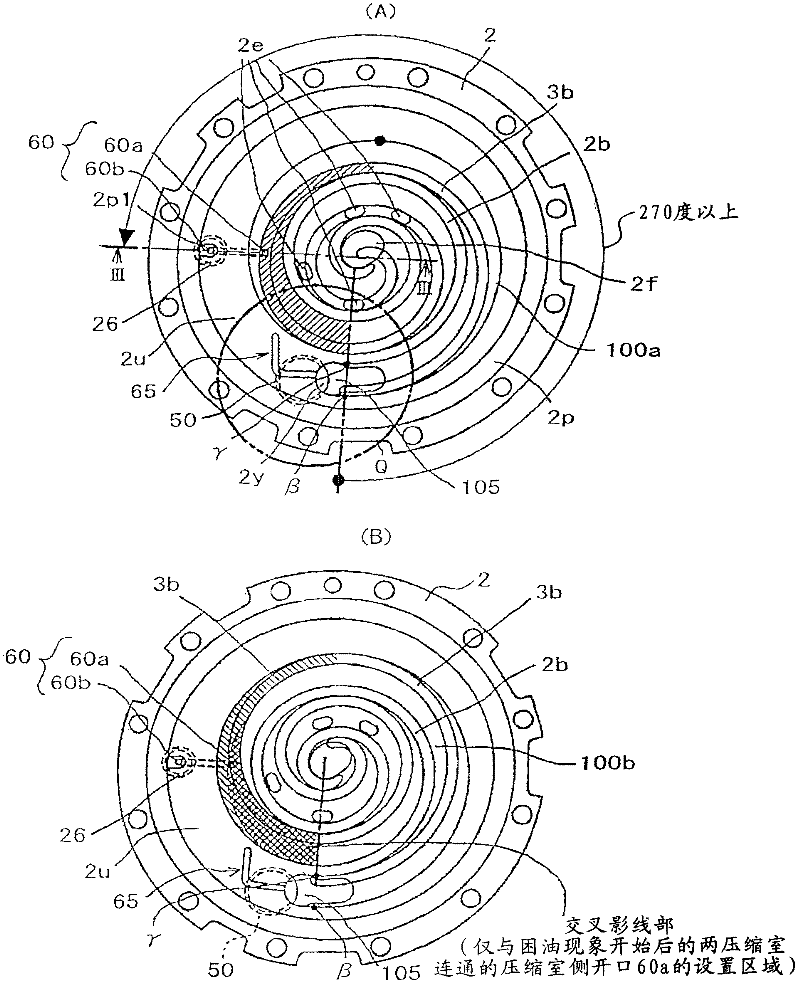

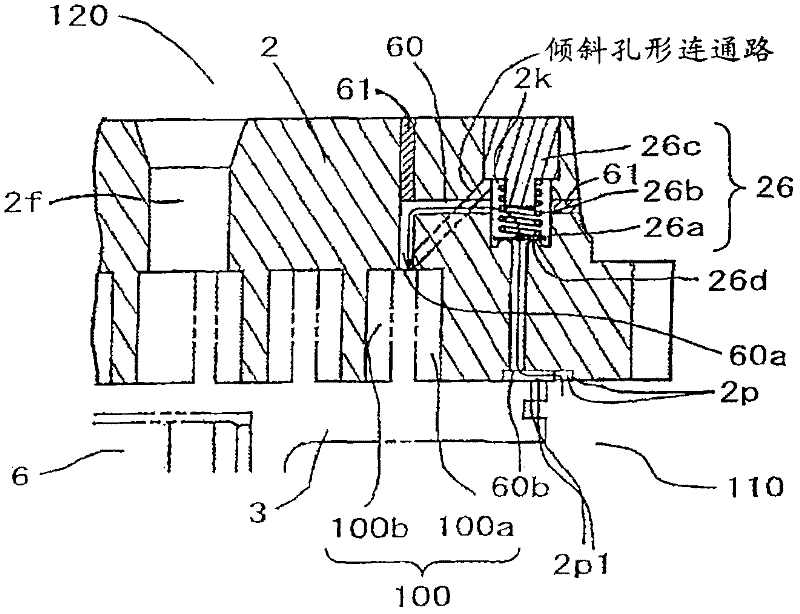

Scroll compressor

InactiveCN102454603AReduced tightnessAvoid heatingRotary piston pumpsRotary piston liquid enginesHigh energyWorking fluid

The invention provides a scroll compressor, which prevents the sealing performance at the utmost external engaged part of a fixed scroll and a revolving scroll from decreasing and inhibits the heating of a working fluid within a suction zone so as to realize the high energy efficiency. The scroll compressor, comprises a fixed scroll, a revolving scroll rotating through being engaged with the fixed scroll so as to form a compression chamber between the fixed scroll and the revolving scroll, and an oil supply way which supplies oil to a back pressure chamber used for exerting an extrusion force on the fixed scroll from the revolving scroll, and to the discharge side of the back pressure chamber to the compressor. The compressor also comprises a compression chamber communicating passage and a suction zone communicating passage. The compression chamber communicating passage comprises a back pressure valve, which is communicated only with the compression chamber after the oil blocking phenomenon and is opened or closed through the pressure difference from start to finish. Therefore, oil in the back pressure chamber flows towards the compression chamber, so that the pressure of the back pressure chamber is controlled. The suction zone communicating passage only communicates the back pressure chamber with the suction zone of the compression chamber so as to supply oil to the suction zone.

Owner:HITACHI APPLIANCES INC

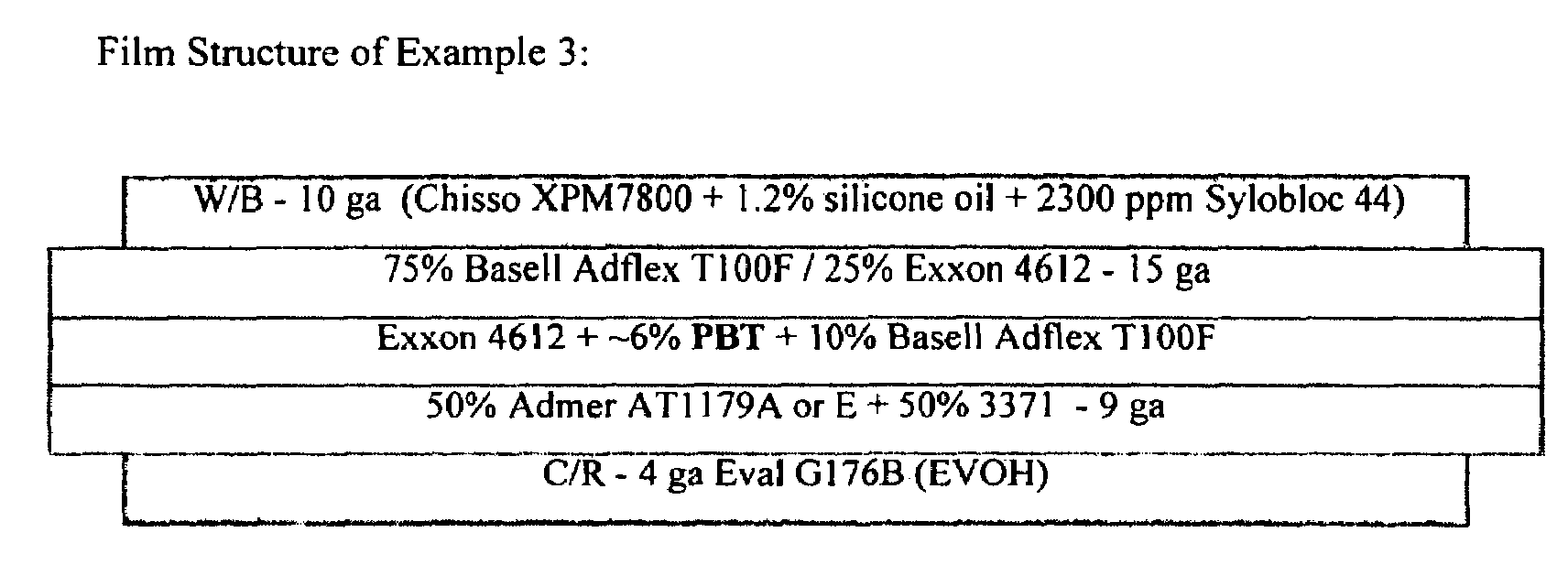

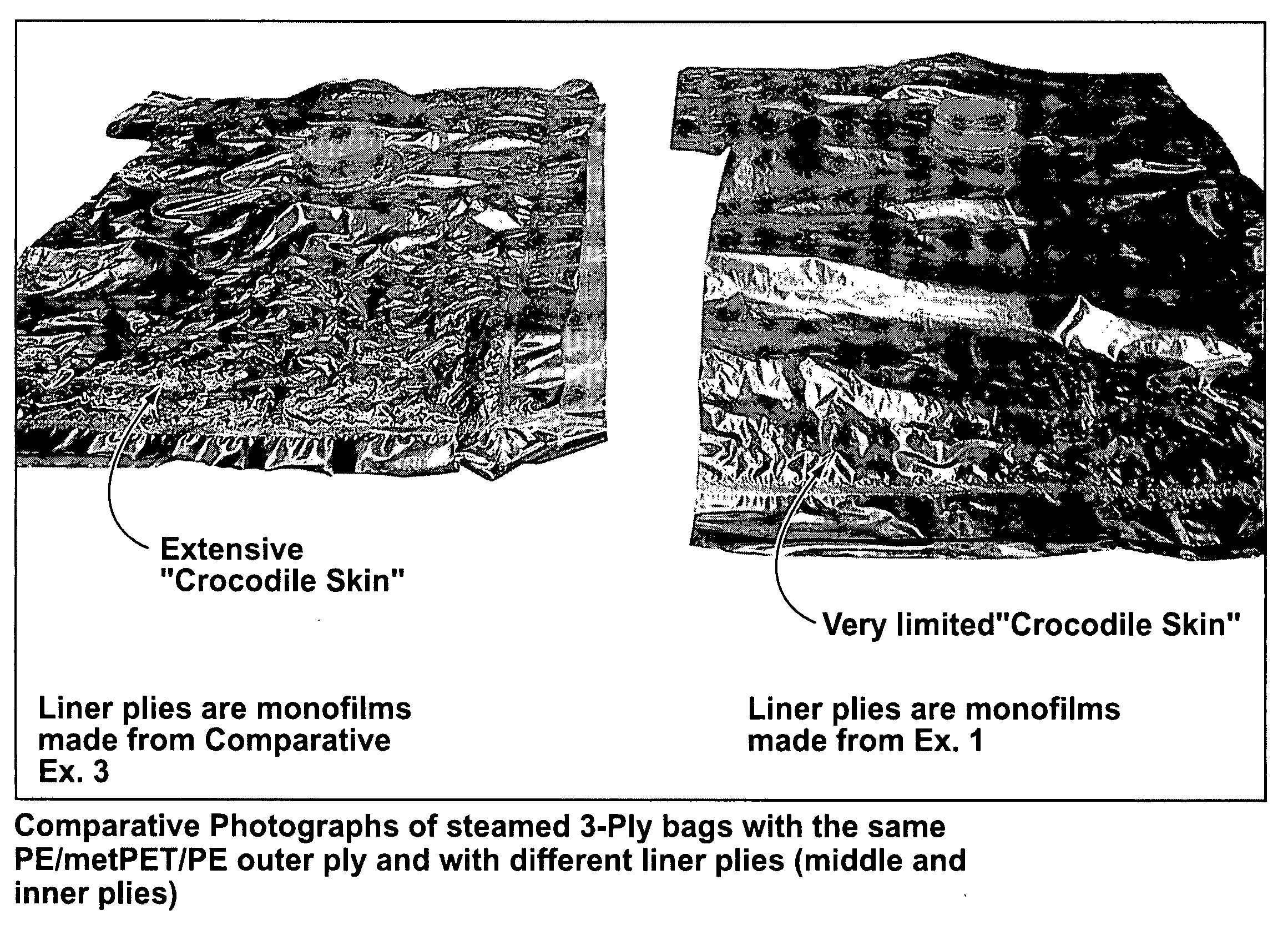

Multi-layer films having improved sealing properties

InactiveUS7537829B2Improving seal strength and impact strength and resilience and hermeticityReduced-temperature sealabilitySynthetic resin layered productsLaminationEngineeringPolymer

Multi-layer films that are suitable for packaging and having improved sealing properties are disclosed. Some embodiments may also provide a lower minimum sealing temperature. A soft polymer is blended in a core layer and a tie layer comprising the soft polymer and, optionally, another polymer. A sealable layer is provided on the side of the tie layer opposite the core layer. The multi-layer films may be transparent, contain a cavitating agent, or are pigmented to form an opaque film. Also, the multi-layer film may be metallized or coated with a barrier coating.

Owner:JINDAL FILMS AMERICAS LLC

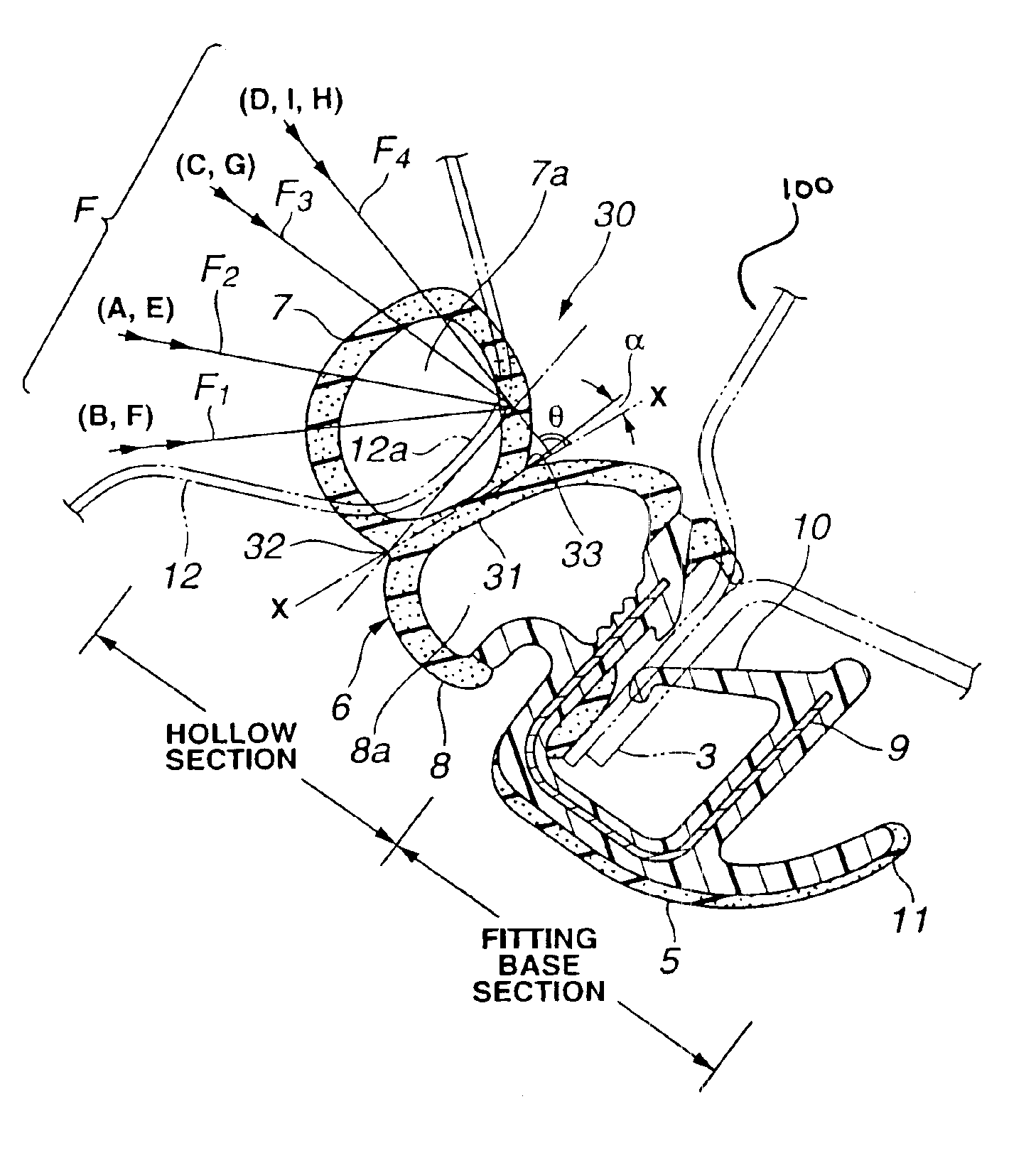

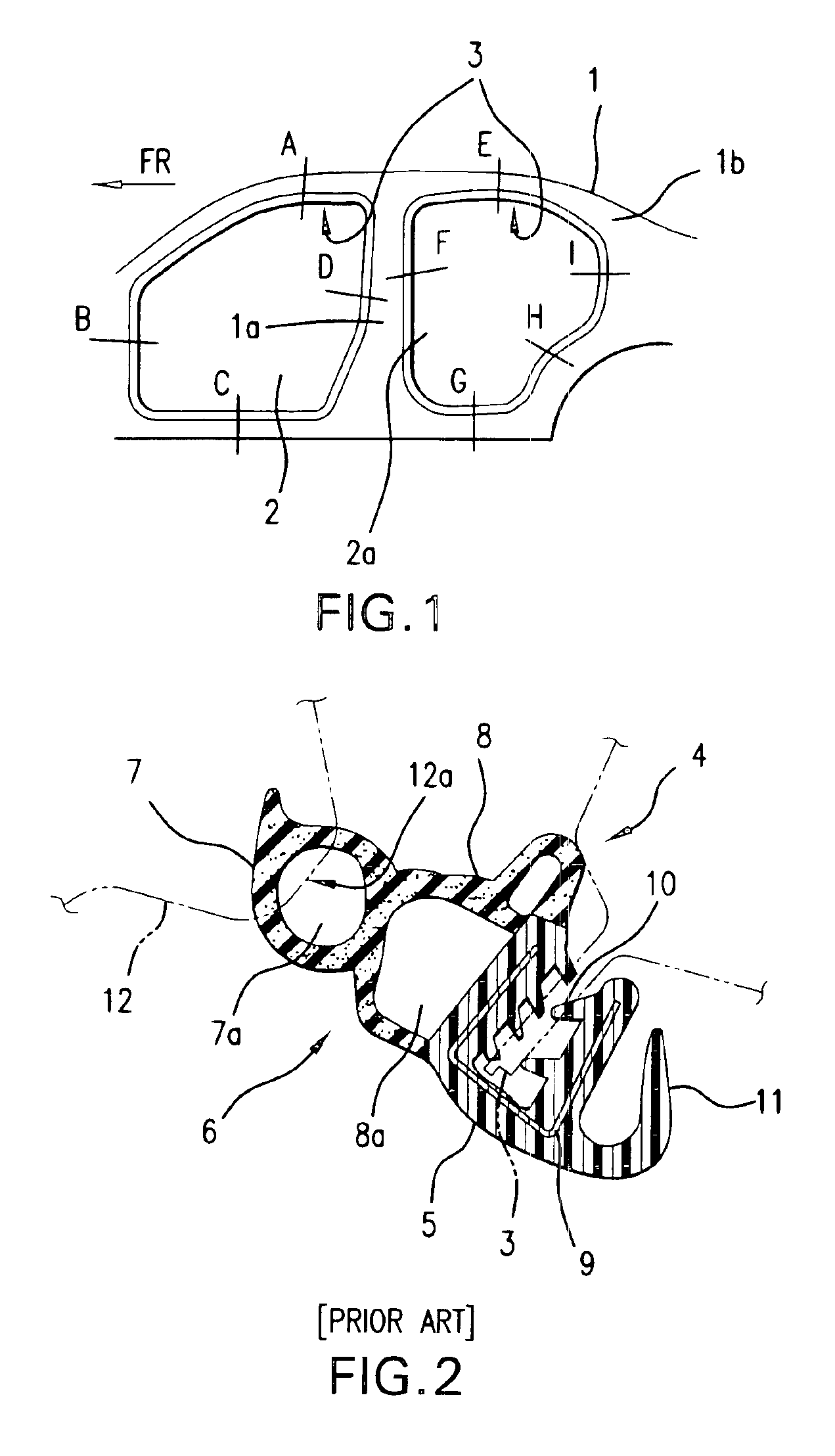

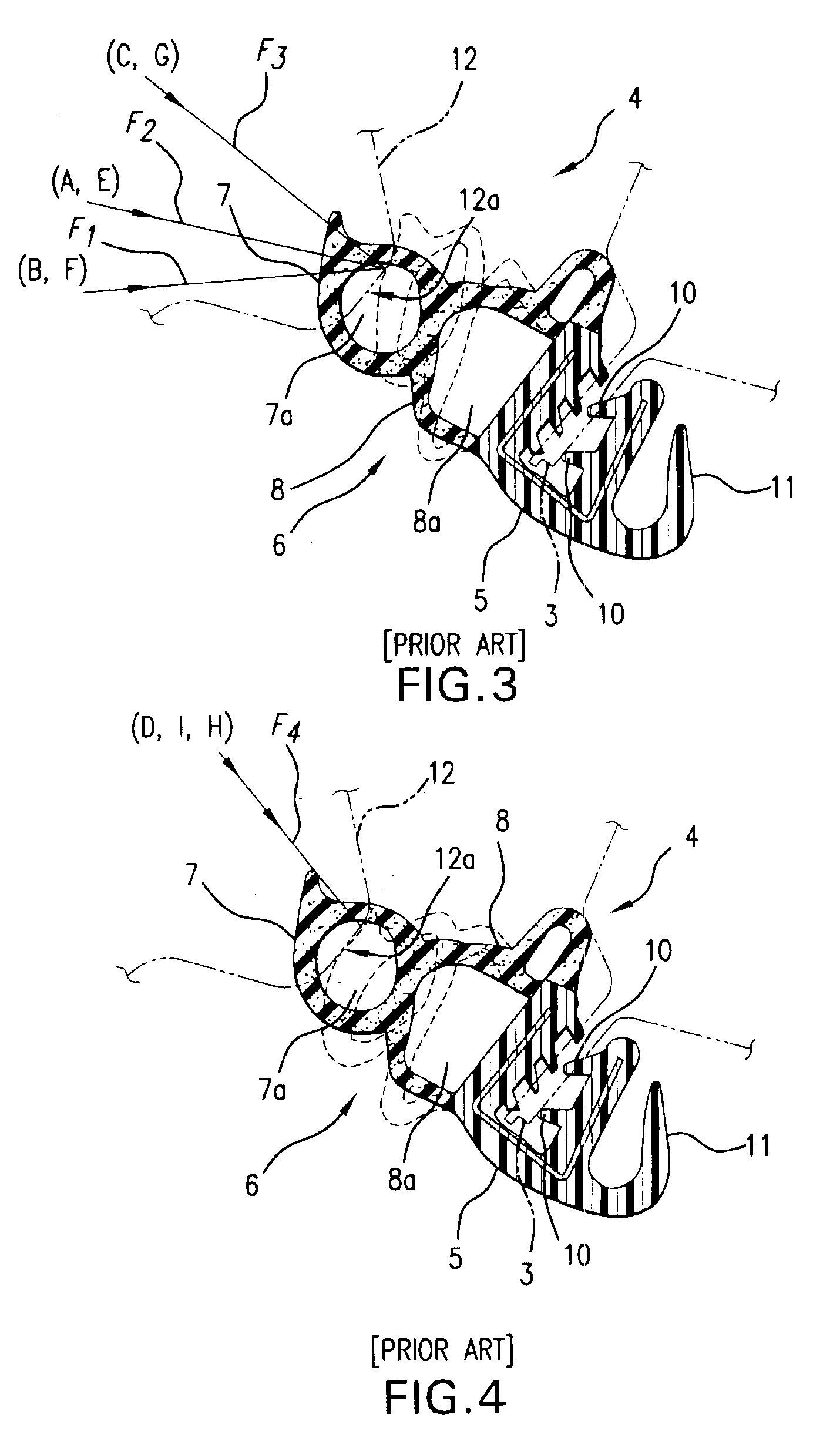

Weather strip

InactiveUS7017305B2Wind noise be preventReduced tightnessLayered productsSealing arrangementsEngineeringElectrical and Electronics engineering

Owner:KINUGAWA RUBBER IND CO LTD

Threaded joint for pipes

ActiveUS20150001841A1Promote formationReduced tightnessSleeve/socket jointsPipe supportsEngineeringBiomedical engineering

A threaded joint for pipes comprises a pin and a box, each having a threaded and unthreaded portion metal contact surface. The unthreaded metal contact portion includes a sealing surface and a shoulder surface, the shoulder surface of the pin located on the pin end surface. A non-contacting region where the pin and the box do not contact each other exists between the sealing surfaces and the shoulder surfaces of the pin and the box. One or more grooves is formed in at least one of the pin and the box shoulder surfaces and extending to the non-contacting region and to the interior of the joint. At least one of the contact surfaces has a solid lubricating coating exhibiting plastic or viscoplastic rheological behavior. A total volume V (mm3) of the grooves and coating weight W (g) of the solid lubricating coating satisfy the equation V / W≧24 (mm3 / g).

Owner:NIPPON STEEL CORP +1

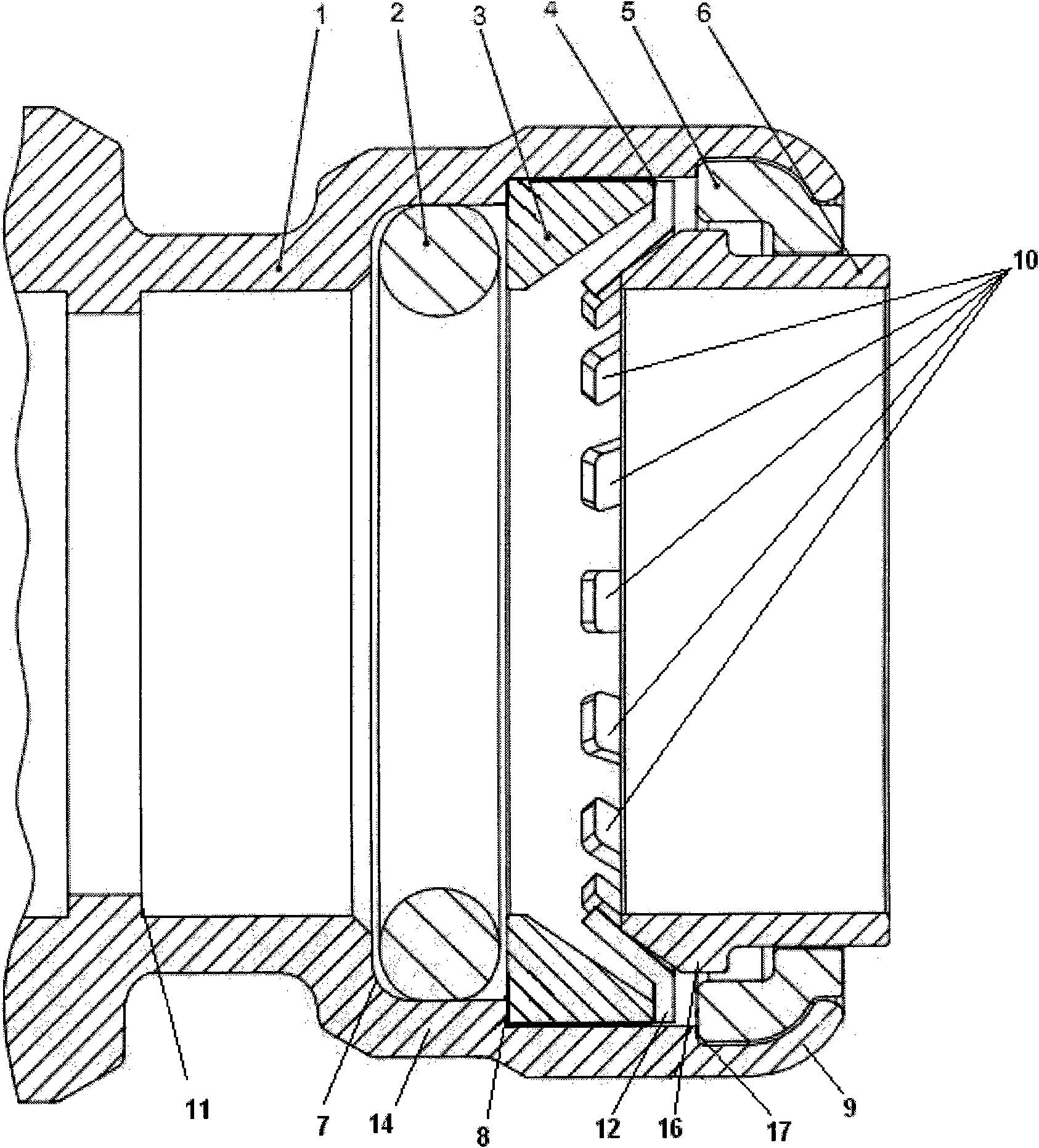

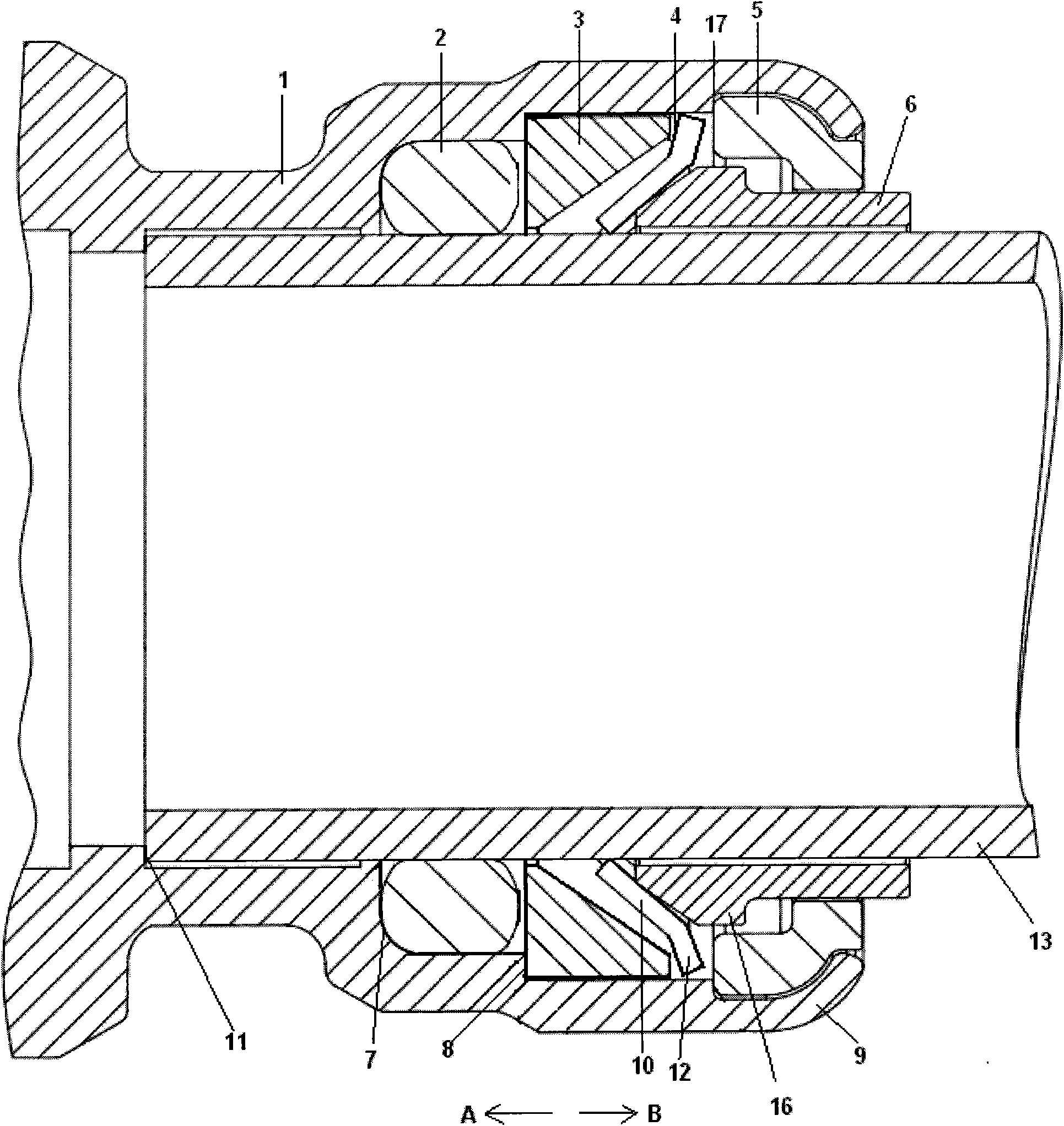

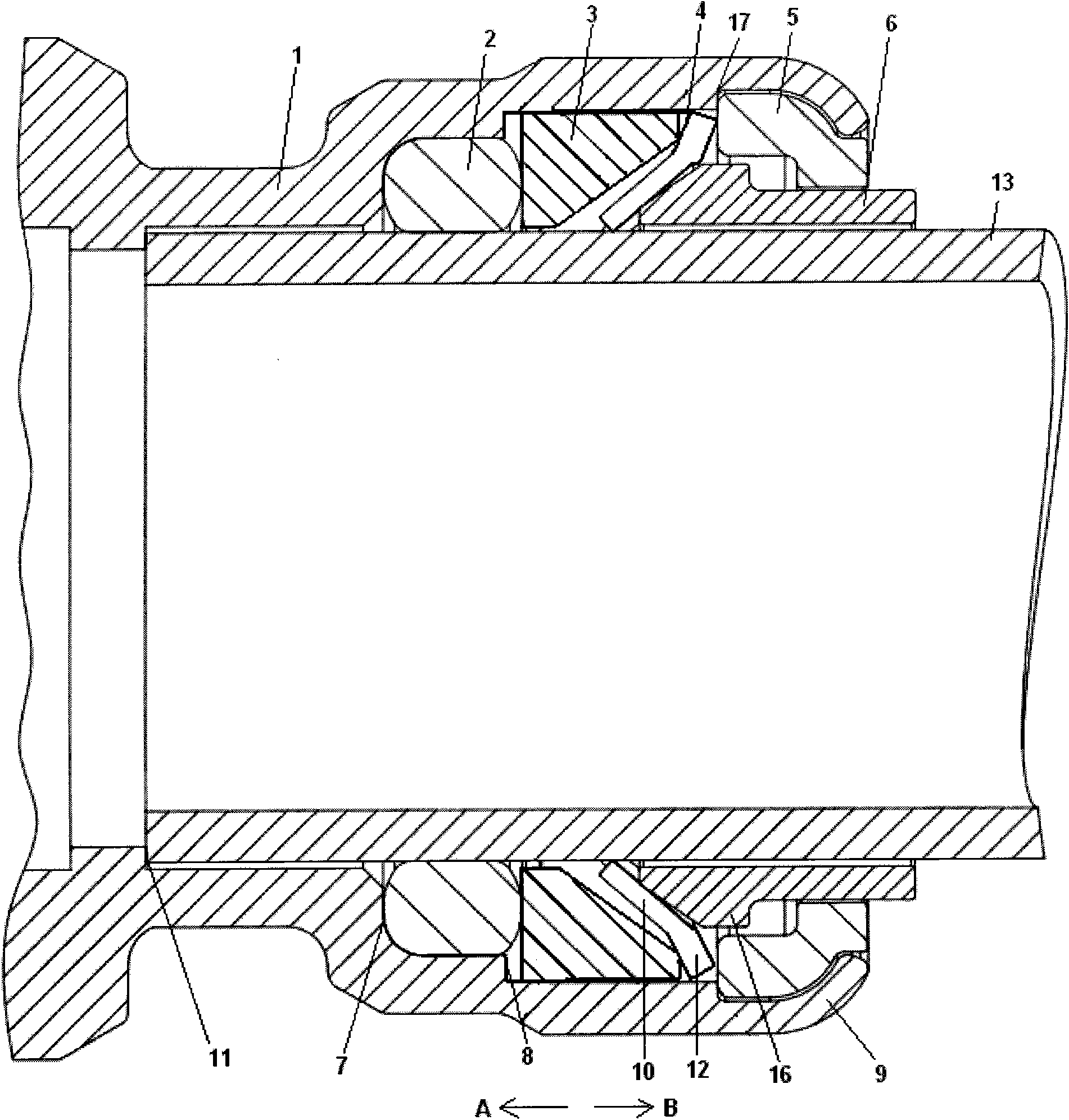

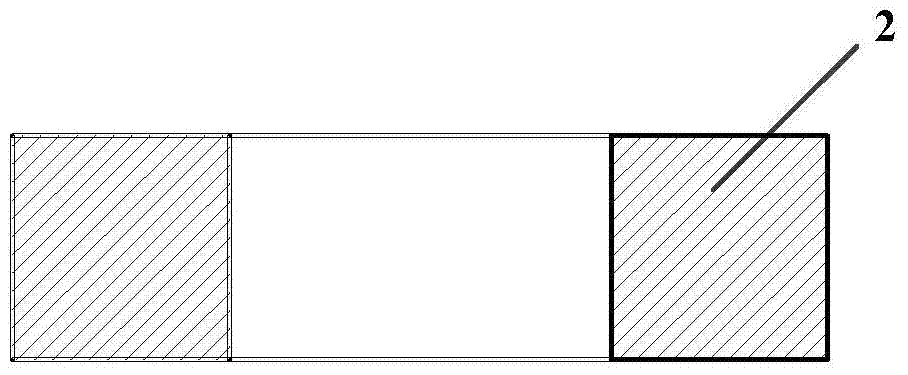

Axial pre-tightening force sensor

InactiveCN103592062AClear principleWide range of axial preloadForce measurementAxial displacementBall bearing

The invention relates to an axial pre-tightening force sensor. The axial pre-tightening force sensor comprises a regulating gasket 2, a left end cover 3, an elastic sensitive element 4, a strain gage 5, a right end cover 6, a thrust ball bearing 7, an axial hole groove 9, a right bolt 10, a fairlead 11, a package shell 12 and a left bolt 13. The regulating gasket is used for regulating the axial position of the sensor on a shaft, the left end cover and the right end cover support the elastic sensitive element through bosses, the elastic sensitive element generates axial strain because of bearing axial force, and the axial force can be measured through the resistance strain effect and a measuring circuit. The axial hole groove 9 in the right end cover 6 of the sensor is matched with the right bolt 10 to be used for preventing the elastic sensitive element from generating circumferential strain in a pre-tightening process, axial displacement of the right end cover 6 and axial strain of the elastic sensitive element 4 are allowed, and the thrust ball bearing is used for insulating circumferential twisting force generated when the pre-tightening force is exerted so that the axial twisting force can be prevented from being transmitted to the elastic sensitive element 4.

Owner:NANJING UNIV OF SCI & TECH

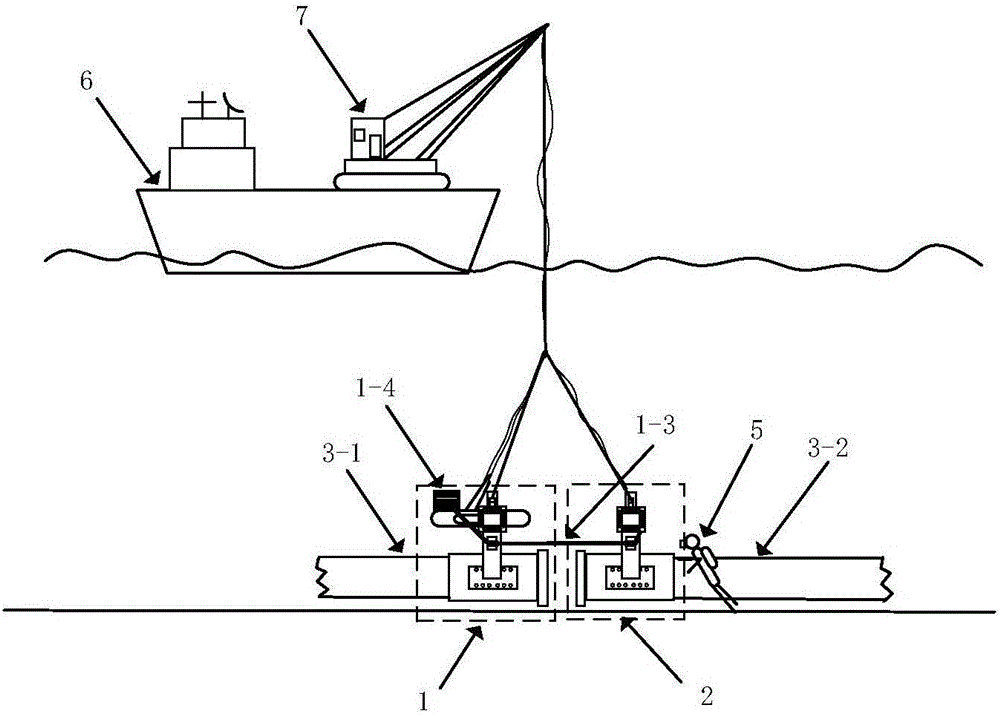

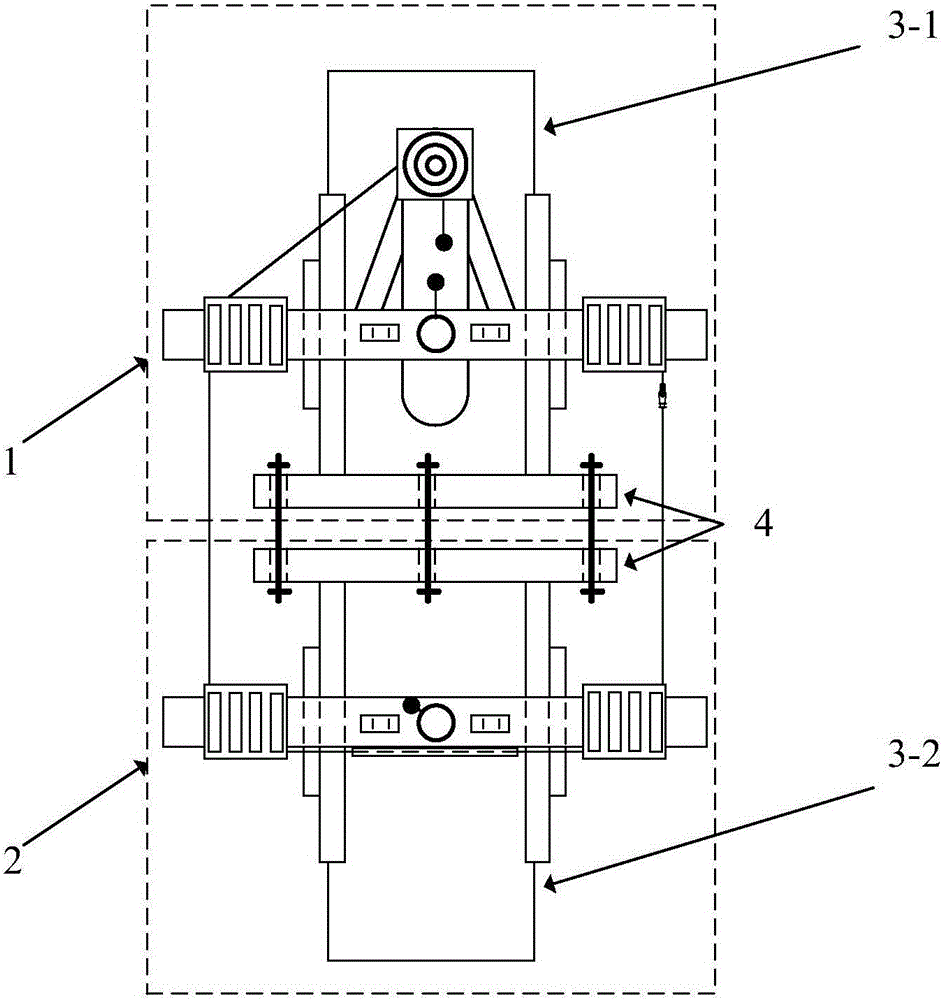

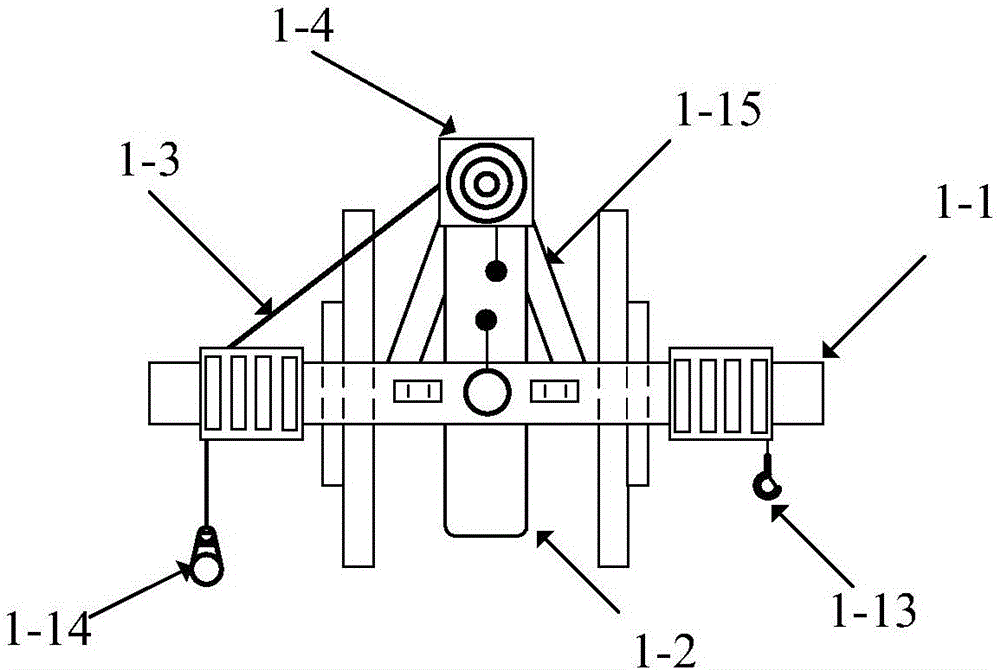

Submarine pipeline flange underwater abutting joint installation method

The invention discloses a submarine pipeline flange underwater abutting joint installation method. A main flange connecting device is installed on the abutting joint end of a submarine pipeline A, an auxiliary flange connecting device is installed on the abutting joint end of a submarine pipeline B, the submarine pipeline A to be butted and the submarine pipeline B to be butted are connected together through the main flange connecting device and the auxiliary flange connecting device, the negative influence of the marine condition on underwater flange connection can be removed, the influence of ship shake on the movement of the submarine pipeline A and the submarine pipeline B can be removed, underwater adjusting steps of a diver can be reduced, the diver can adjust the positions of the submarine pipeline A and the submarine pipeline B conveniently, the underwater operation difficulty degree of the diver can be reduced, the underwater operation time of the diver can be shortened, the case that flanges get close to each other in an aligned manner can be ensured, the force applied to a gasket of each flange is consistent, uniform deformation is generated, and the leakproofness of the flanges can be improved. The flange connection quality can be improved, the operating time of the support ship can be saved, the construction period of the whole fleet can be shortened, the working efficiency is improved, and the installation cost is saved.

Owner:CNOOC ENERGY TECH & SERVICES

Polyethylene and polypropylene blends for liquid packaging films

ActiveUS20080090062A1Good low temperature sealing propertyInsufficient thermal resistanceSynthetic resin layered productsBagsButeneCrack resistance

There is disclosed a flowable material packaging film comprising at least a resin blend of (a) from about 33 wt % to about 80 wt % of at least one ethylene-C4 to C10-α-olefin interpolymer having a melt index of from 0.4 to 1.5 g / 10 min (190° C., 2.15 kg), a density of from 0.900 to 0.916 g / cc; and (b) from about 67 wt % to about 20 wt % of at least one heterogeneous interpolymer of propylene with ethylene or ethylene and butene comprising from about 71 mol % to about 86 mol % propylene and from about 29 mol % to about 14 mol % ethylene or ethylene and butene, the interpolymer having an overall weight average molecular weight (MW) of at least about 400,000, a xylene soluble phase of not less than 30% (wt), with the xylene soluble phase having a MW of at least about 275,000 and said heterogeneous interpolymer of polypropylene has a density of from 0.875 to 0.91 g / cc; and the film has a Hot Tack Initiation Temperature in the range of from about 100° C. to about 140° C. and a Hot Tack Strength of not more than about 5 N / inch in the temperature range of about 100° C. to about 150° C., when fabricated at a thickness of about 50 microns and tested using a JB Instrument Hot Tack Tester set at a 0.5 second dwell, 0.2 second delay time, 40 psi seal bar pressure and 250 mm / second peel rate; and the film has a flex crack resistance such that it develops 5 or less pinholes per 300 cm2 in 10,000 cycles of Gelbo Flex testing as measured according to ASTM F392. The film exhibits flex crack resistance and thus is useful in the manufacture of pouches and bags made from such films. Processes for making such pouches and bags which may include aseptic conditions are also described.

Owner:LIQUI BOX

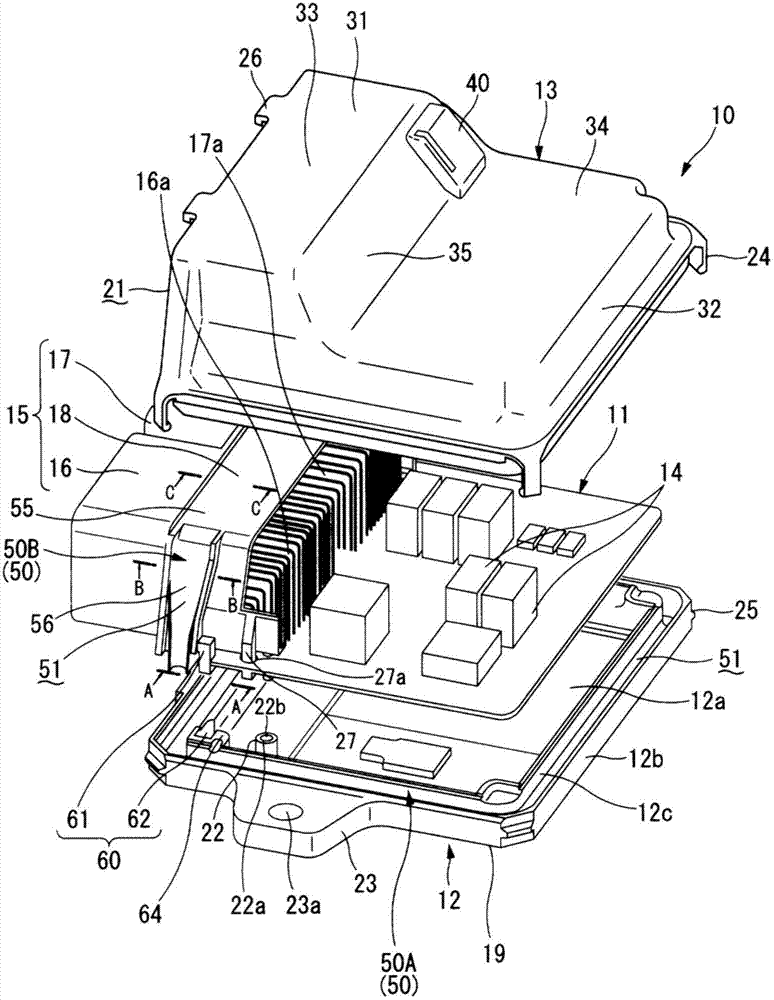

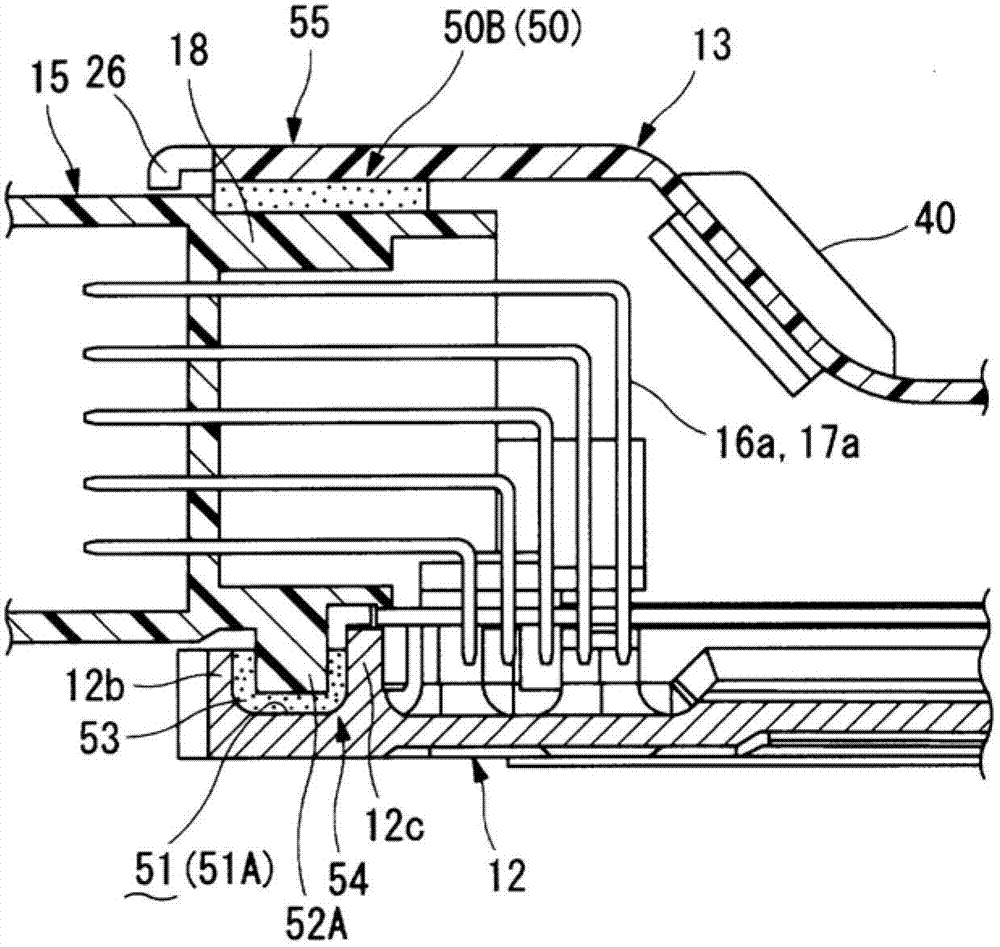

Electronic control device

ActiveCN103022837AAvoid displacementIncrease loading capacityCouplings bases/casesFixed connectionsEngineeringSealant

Provided is an electronic control device which is capable of suppressing the shift of the connector with respect to the housing and excellent in load-carrying capacity. The electronic control device has a circuit board to which, at one side thereof, a connector is fixed; a housing having a pair of connector sandwiching members that sandwich the connector, a part of the connector being exposed to an outside of the housing and a remaining part of the connector and the circuit board being housed in a watertight space of the housing, and one of the connector sandwiching members being set to be higher in rigidity than the other; a seal portion filled with a sealant; and a shift suppression unit having a protruding portion formed at one side of the higher-rigidity connector sandwiching member and the connector and a hollow portion formed at the other side. The shift suppression unit suppresses a shift of the connector with respect to the housing by fitting of the protruding portion and the hollow portion together.

Owner:HITACHI ASTEMO LTD

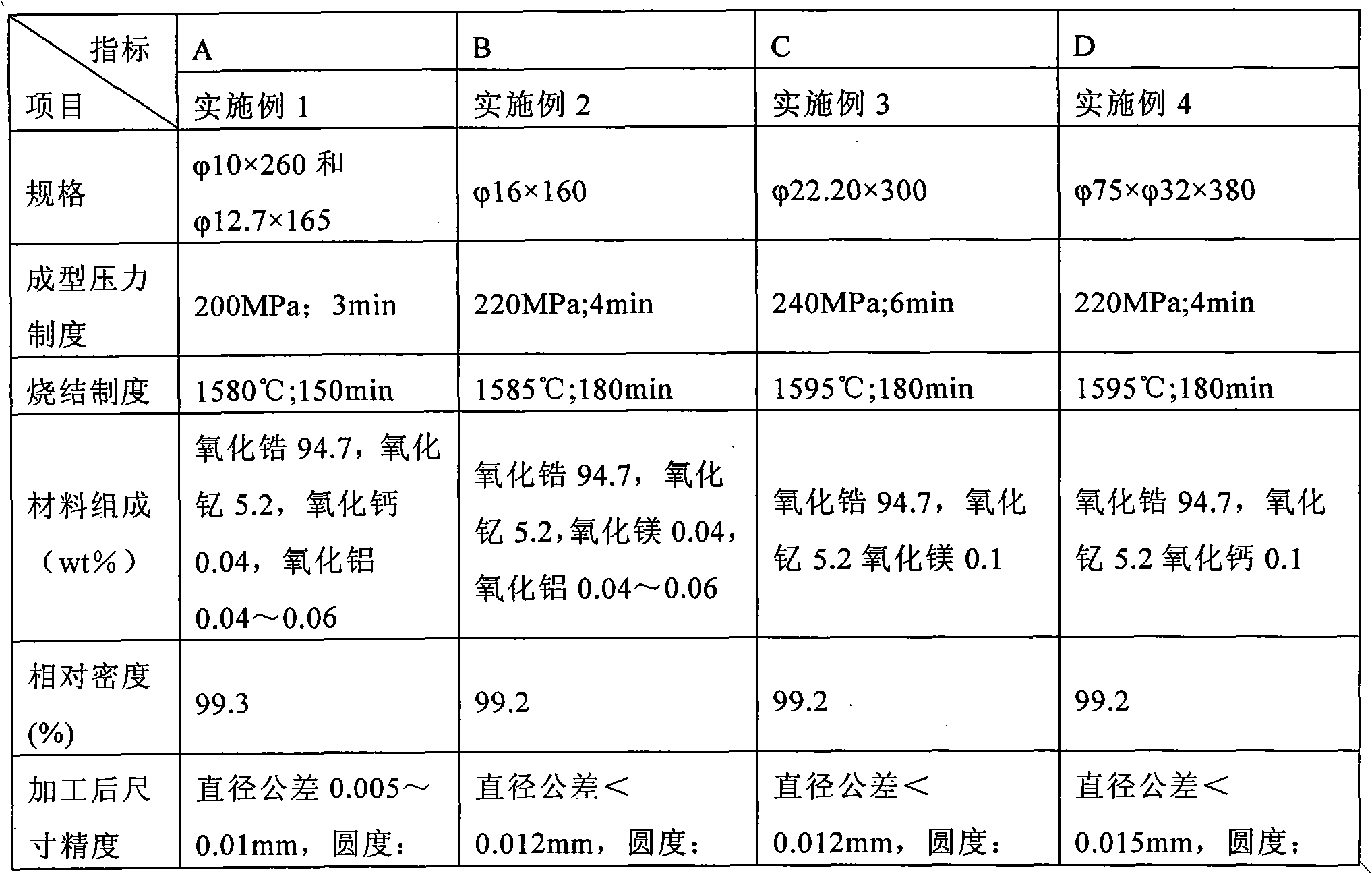

Preparation method of compact zirconia ceramic plunger

The invention relates to a preparation method of a compact zirconia ceramic plunger. The preparation method comprises the following steps: fully mixing zirconia ceramic granulated powder with a compound additive; placing the obtained mixture in a die for isostatic pressing; sintering the molded sample into a compact zirconia ceramic plunger blank; and finally grinding the blank into the ceramic plunger with precise size. Compared with the prior art, by utilizing the zirconia plunger material and the preparation method thereof provided by the invention, the compactness, the forming efficiency and the finished product ratio of the ceramic plunger are effectively improved. A high-pressure plunger pump manufactured by the compact zirconia ceramic plunger has the advantages of long service life, wear resistance, corrosion resistance, expanded application range, and shortened time for maintaining and replacing a high-pressure plunger and a sealing bush in the case of shutdown, thus saving engineering operating cost.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Sealing device and bearing box system

PendingCN110081177AImprove reliabilityGuaranteed service lifeEngine sealsBearing unit rigid supportHuman healthMagnetic line

The invention provides a sealing device and a bearing box system. The device is installed in a bearing cavity which is provided with a shaft, a bearing and a shaft sleeve, wherein the bearing and theshaft sleeve are arranged outside the shaft in a sleeving mode, the shaft sleeve abuts against the end surface of the bearing, and the shaft sleeve is made of a magnetic material; the sealing device comprises a first magnetic conductor, a permanent magnet and a second magnetic conductor; the first magnetic conductor, the permanent magnet and the second magnetic conductor are arranged outside the shaft sleeve in a sleeving mode, the first magnetic conductor abuts against the end surface, the permanent magnet is clamped between the first magnetic conductor and the second magnetic conductor, andthe permanent magnet, the first magnetic conductor, the shaft sleeve and the second magnetic conductor are matched to form a closed magnetic line; and gaps are formed between the outer wall of the shaft sleeve and the inner wall of the first magnetic conductor and between the outer wall of the shaft sleeve and the inner wall of the second magnetic conductor, and pole teeth are arranged on the inner wall of the first magnetic conductor and the inner wall of the second magnetic conductor, and the gaps and the pole teeth are all filled with magnetic fluid. The embodiment of the sealing device caneffectively ensure the sealing effect on the bearing cavity, thereby avoiding environmental pollution and harm to human health.

Owner:BEIJING UNIV OF CHEM TECH

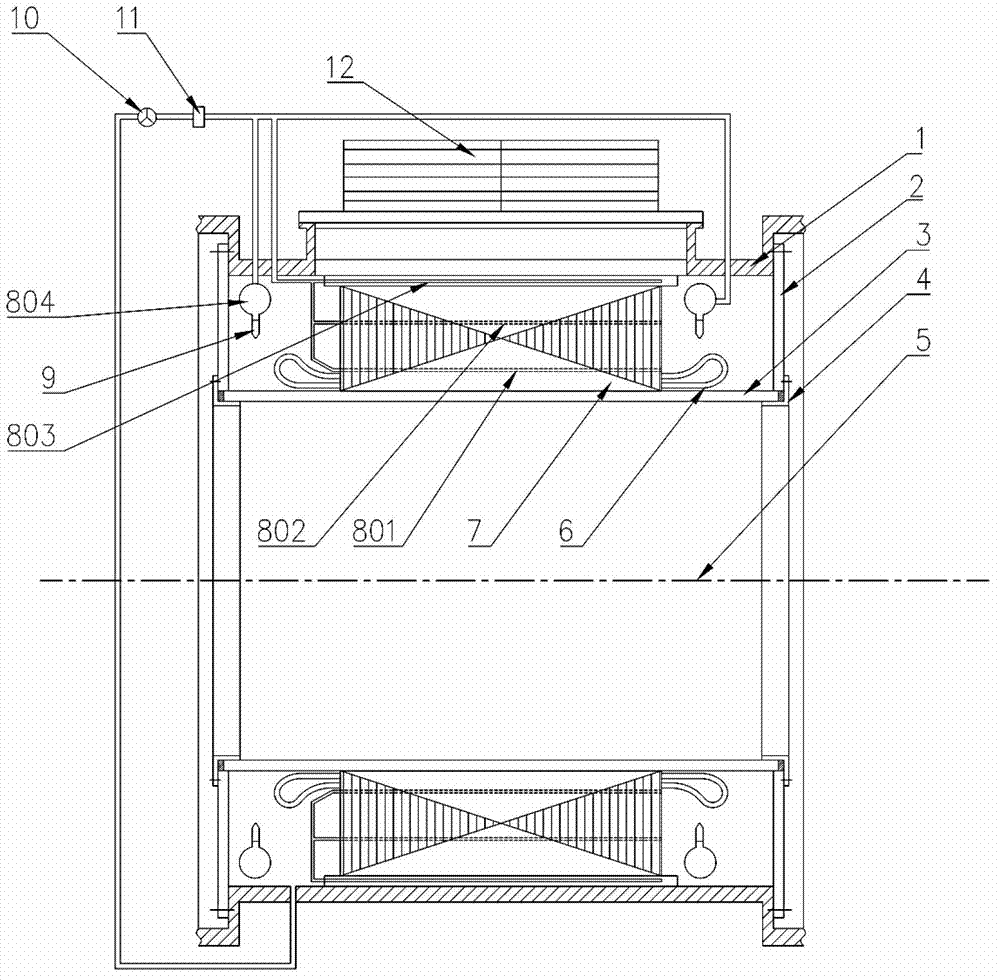

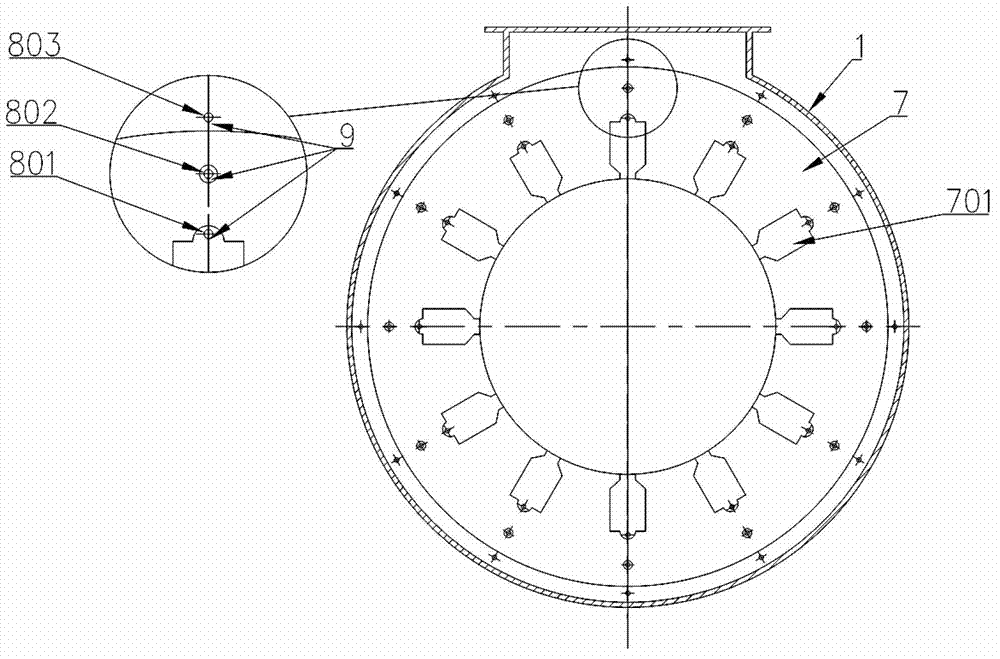

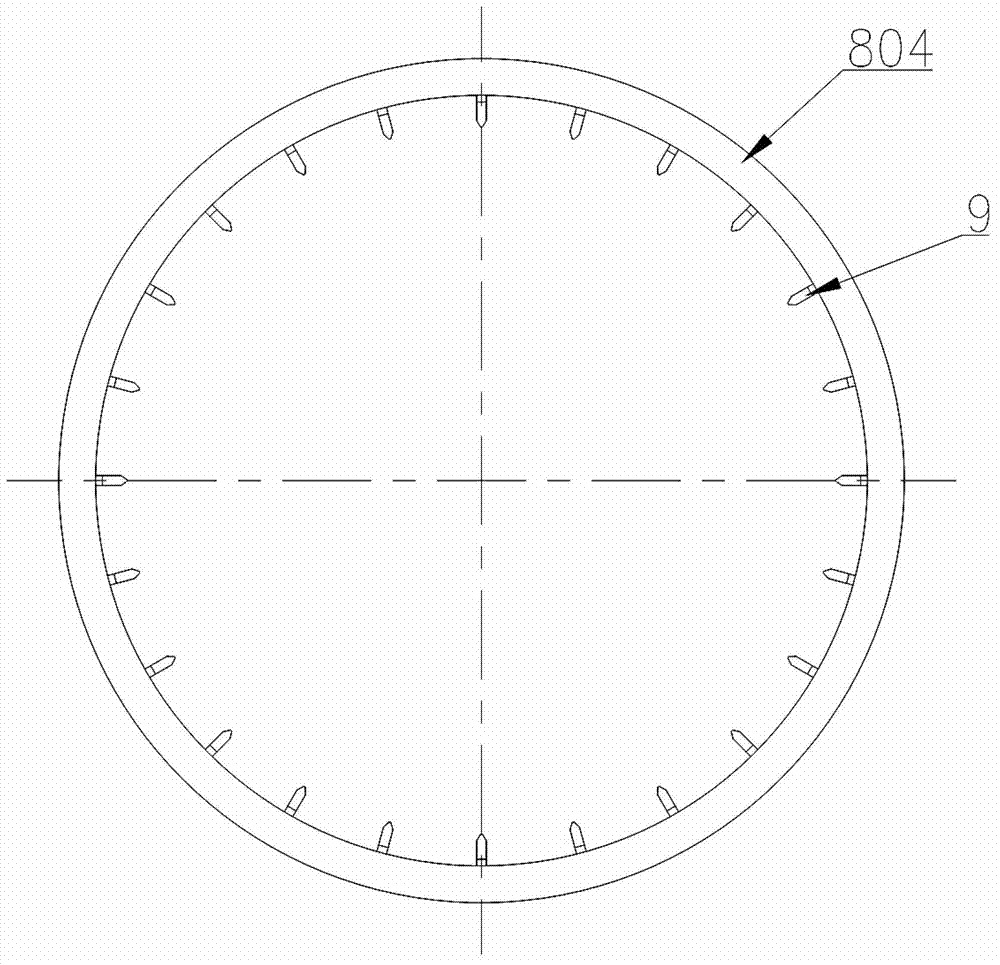

Spray type motor stator evaporative cooling system

ActiveCN102820738AReduce in quantityReduced tightnessMagnetic circuit stationary partsCooling/ventillation arrangementSpray nozzleConductor Coil

The invention discloses a spray type motor stator evaporative cooling system, wherein a stator enclosed space consists of a stator enclosure (1), a spacing sleeve (3) and an end cover (2). A spraying system comprises liquid dispensers (801, 802, 803 and 804) which are distributed at the back part of a stator core (7), in the stator core (7), in a stator slot bottom subslot and the periphery of the end part of a stator winding (6) and nozzles (9) which are arranged on the liquid dispensers (801, 802, 803 and 804). A circulating pump (10) in an outer forced circulation system pumps an evaporative cooling medium from the bottom of the stator enclosed space, and the evaporative cooling medium is filtered by a filter (11), and is delivered to the nozzles (9) through the liquid dispensers (801, 802, 803 and 804). The atomized evaporative cooling medium is directly sprayed to all the heating elements of the stator. The evaporative cooling medium which is subjected to heat exchange flows into the stator enclosed space, the vaporized evaporative cooling medium flows into a condenser (12) at the top of the stator enclosure (1), and is changed into the liquid after being condensed by the condenser (12), and the liquid flows back into the stator enclosed space.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

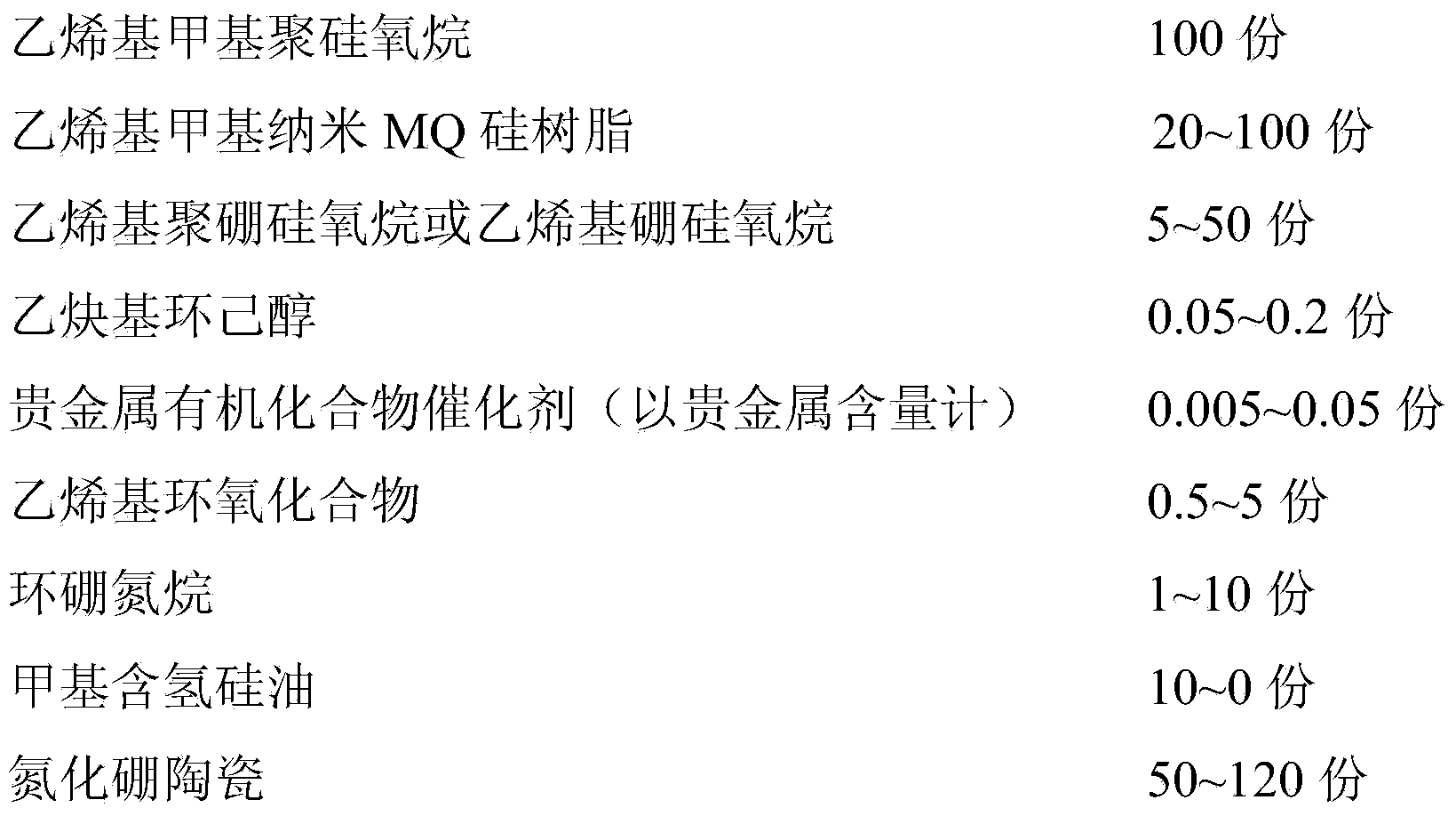

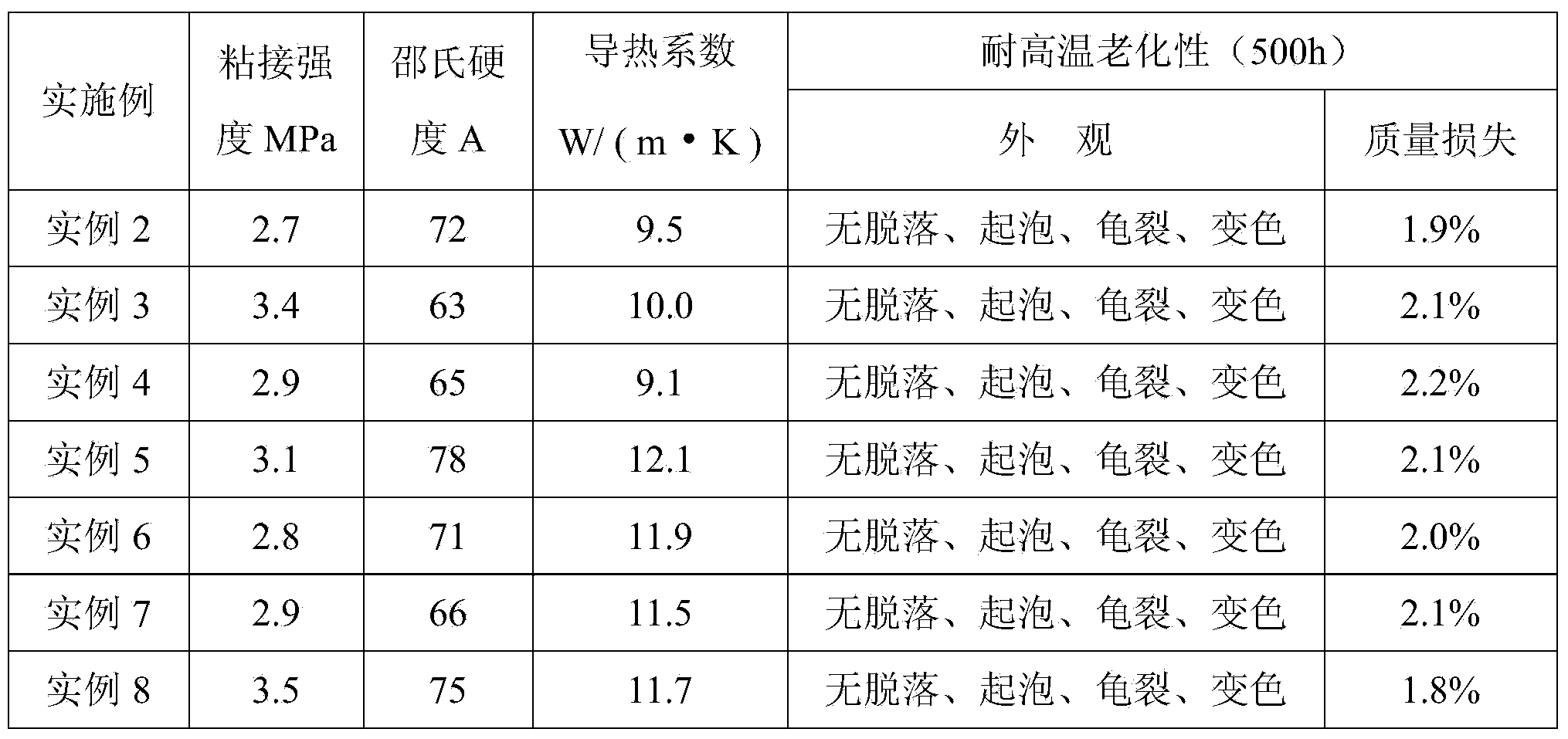

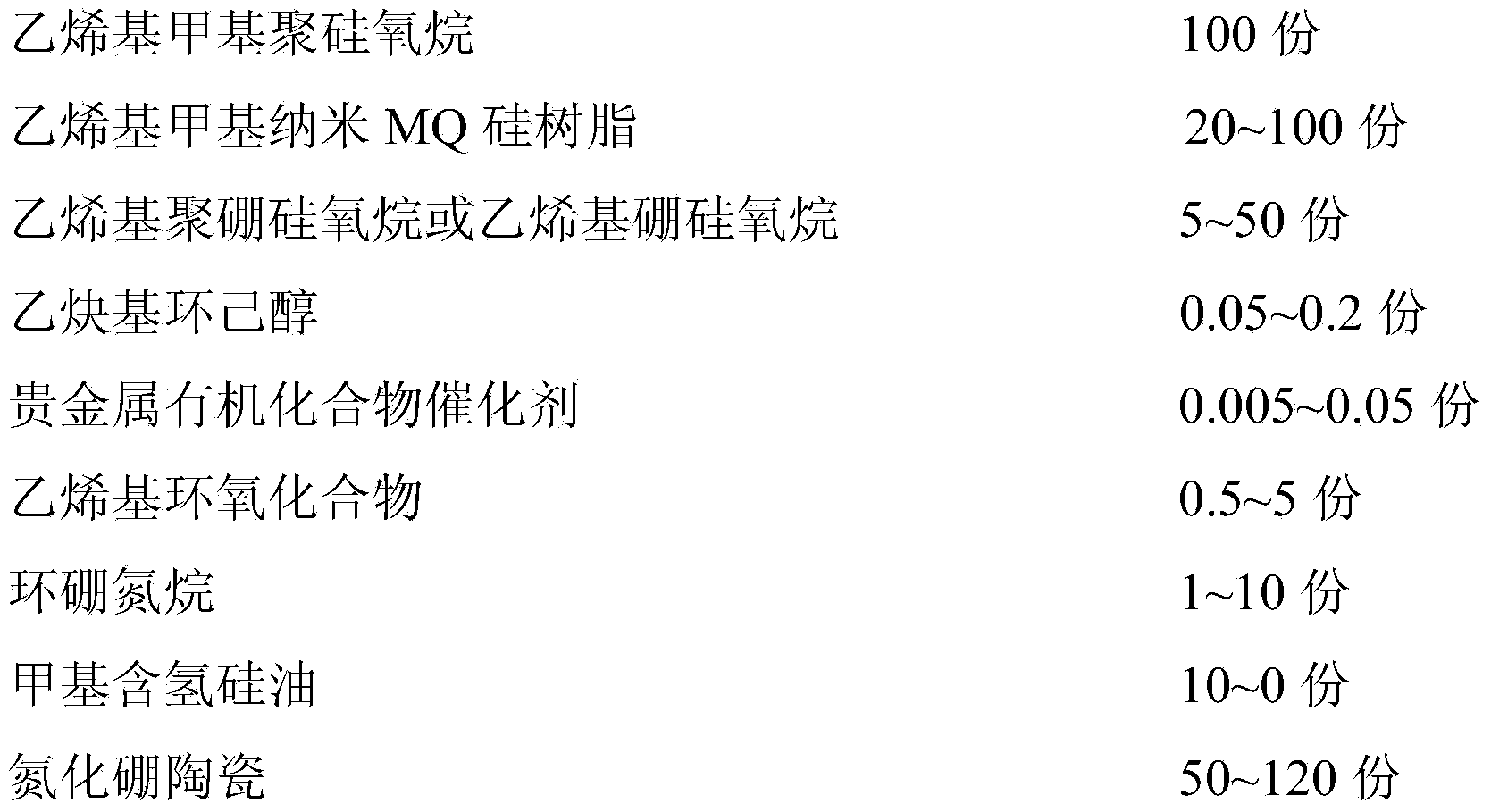

High-heat-conductivity boroheteropolysiloxane potting adhesive and preparation method thereof

ActiveCN104031603ALow shrinkageImprove shrinkageNon-macromolecular adhesive additivesModified epoxy resin adhesivesEpoxyAdhesive

The invention belongs to the field of potting materials, and discloses a high-heat-conductivity boroheteropolysiloxane potting adhesive and a preparation method thereof. The potting adhesive is composed of the following components in parts by mass: 100 parts of vinylmethyl polysiloxane, 20-100 parts of vinylmethyl nano MQ silicon resin, 5-50 parts of vinyl polyborosiloxane or vinyl borosiloxane, 0.05-0.2 part of acetylenyl cyclohexanol, 0.005-0.05 part of noble metal organic compound catalyst, 0.5-5 parts of vinyl epoxy compound, 1-10 parts of borazine, 10-0 part of methyl hydrogen-containing silicon oil and 50-120 parts of boron nitride ceramic. The high-heat-conductivity boroheteropolysiloxane potting adhesive has the advantages of high heat conductivity, favorable sealing property, high bonding force, favorable elasticity, water and moisture resistance, electric insulation, shock absorption, high temperature resistance and excellent aging resistance, and has wide application prospects in packaging of high-power electronic information components, semiconductor communication and illumination components and other components.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com