Axial pre-tightening force sensor

An axial preload, sensor technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of nonlinear output of the sensor, reduce the conversion efficiency, measurement error, etc., reduce the additional circumferential strain, and facilitate the extraction of lead wires. 、Easy to use and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

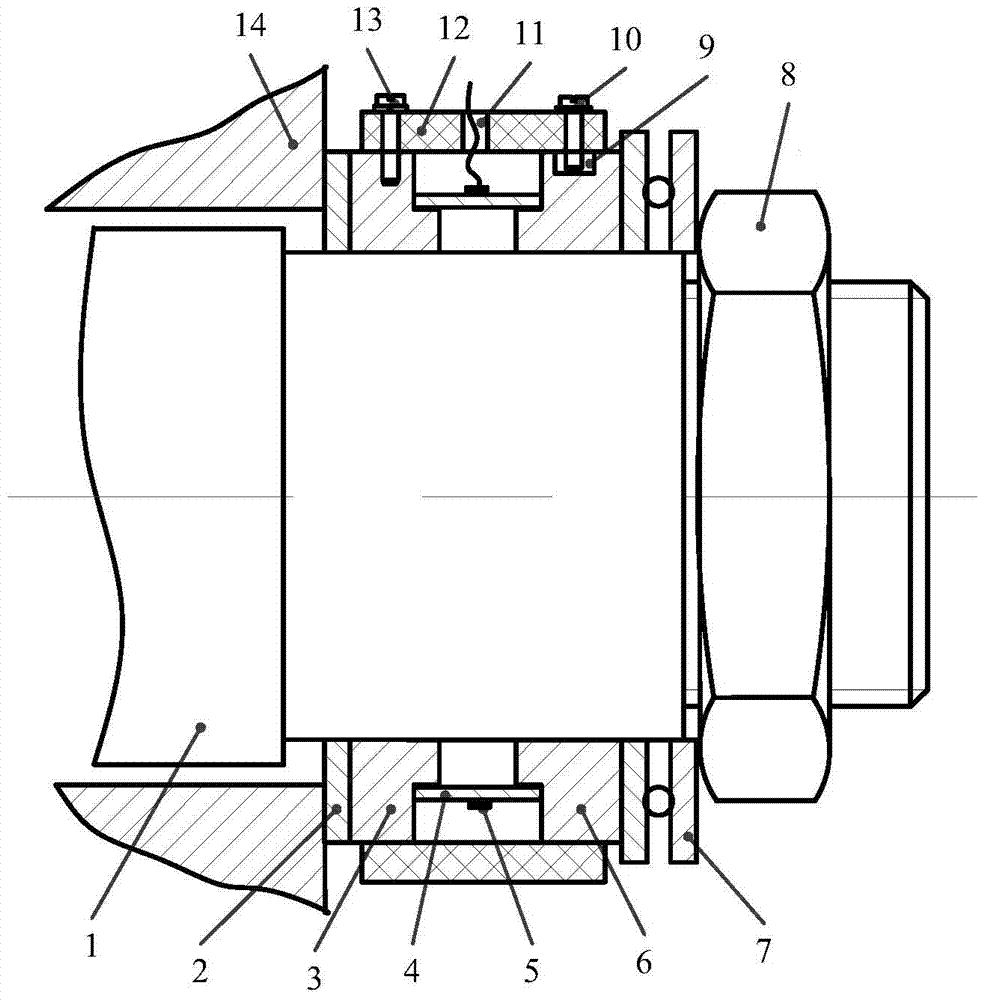

[0021] An axial preload sensor, characterized in that it includes an adjusting gasket 2, a left end cover 3 with a boss and a threaded hole, an elastic sensitive element 4, a strain gauge 5, and a The right end cover 6, the thrust ball bearing 7, the axial hole groove 9 on the right end cover, the screw 10, the lead wire hole 11 on the package shell, the package shell 12 and the screw 13.

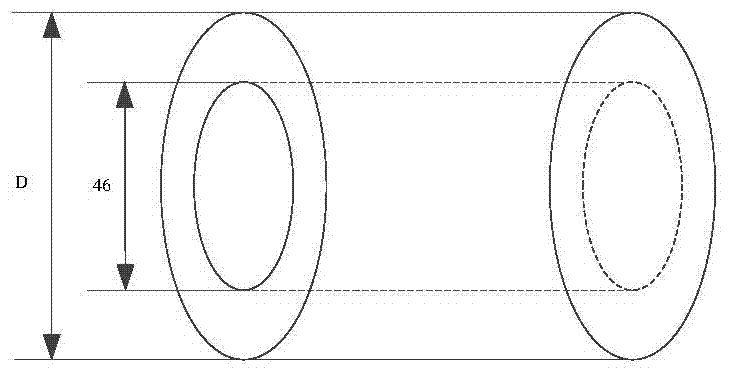

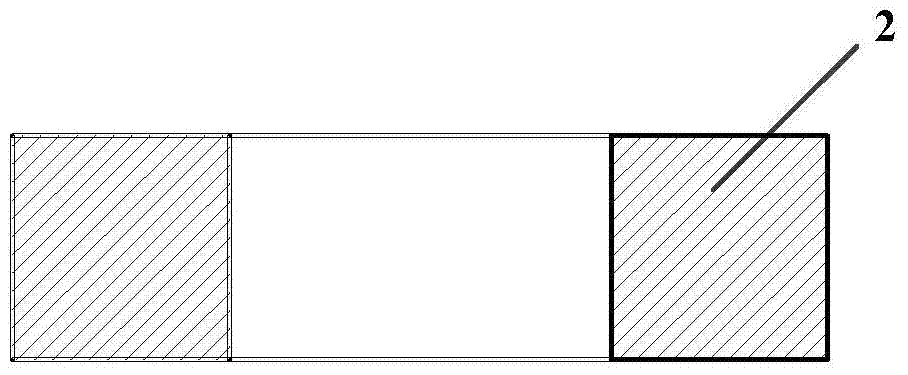

[0022] The sensor designs the inner diameter of the left end cap 3 and the right end cap 6 and the size of the boss on the end cap according to the size of the measured shaft 1. The inner diameter of the elastic sensitive element 4 is designed according to the size of the boss of the left and right end caps. The yield strength of the material determines the outer diameter of the elastic sensitive element, and the adjusting gasket 2 is designed according to the size of the measured shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com