Manufacturing method of micrometer and nanometer composite spherical metal powder of core-shell structure

A core-shell structure, composite metal technology, applied in the field of core-shell structure micro- and nano-composite metal spherical powder manufacturing, can solve the problems of inconsistent cooling history of metal particles, difficult to control temperature and cooling rate, wide particle size distribution, etc. The effect of clear principle, high sphericity and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

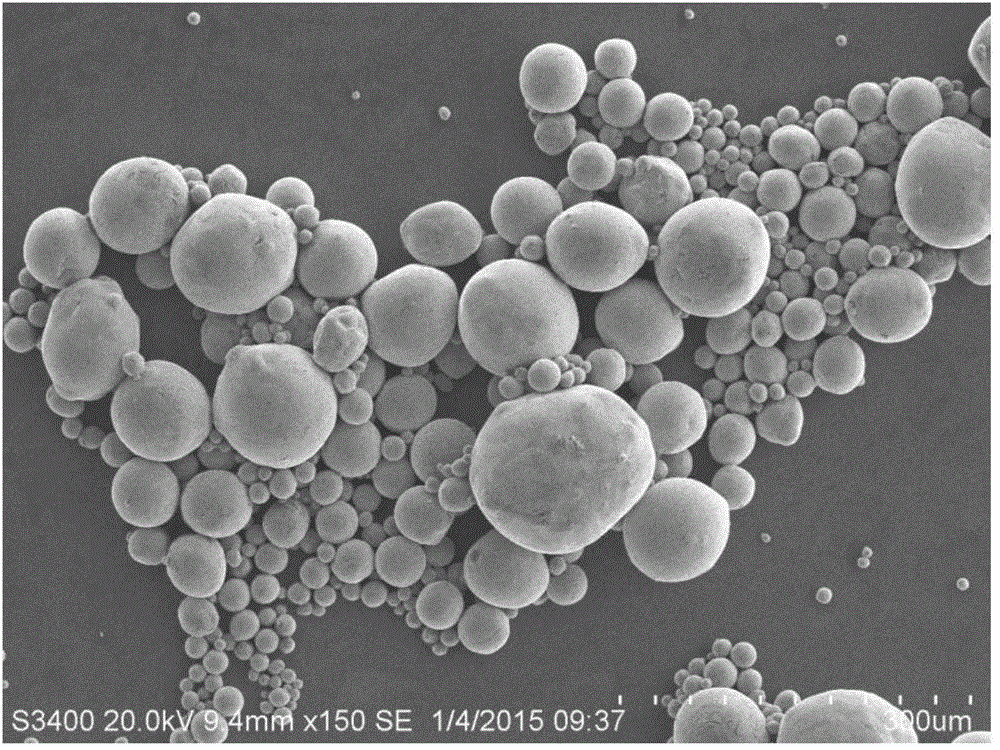

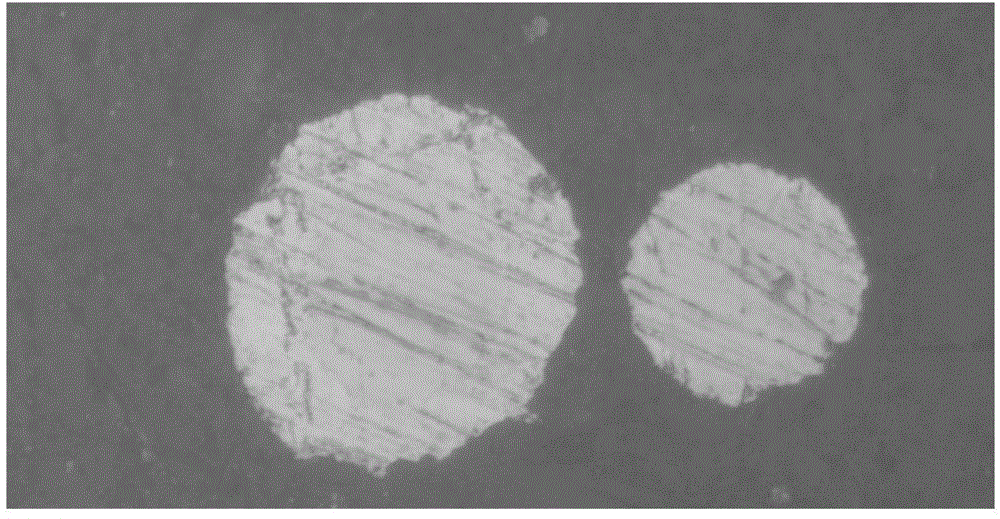

[0036] Preparation of core-shell structure iron / copper composite metal micron spherical powder. Using metal oxides as raw materials, weigh copper oxide and ferric oxide powder according to the atomic percentage of the required copper ferrite component (Cu:Fe=1:2), mix them uniformly and press them into tablets, anneal at 800°C for 6 Hours, then mechanically grind and homogenize, press into tablets, and anneal at 800°C for 3 hours to obtain uniform copper ferrite. Take 2 grams of copper ferrite flakes, mechanically crush them to a powder with a size of about 20 microns, mix the copper ferrite powder with graphite powder with a size of about 400nm in a mass ratio of 1:1, mechanically stir, and mix evenly again .

[0037] Put the above-mentioned mixed copper-ferrite iron powder / graphite powder mixed powder into an alumina crucible, put the crucible into the heating zone of the annealing furnace, and evacuate to 6×10 -3 Pa, introduce 0.01Mpa hydrogen and 0.03Mpa argon, heat to 8...

Embodiment 2

[0040] Preparation of core-shell structure iron / copper composite metal micron spherical powder.

[0041]Using metal salts as raw materials, weigh copper acetate and ferric chloride according to the required atomic percentage of copper and iron (Cu:Fe=1:1), dissolve them in deionized water, and keep stirring. During the stirring process, excessive potassium hydroxide solution was gradually added dropwise, and the mixed solution of copper acetate and ferric chloride gradually became turbid, and the reaction produced copper and iron hydroxide precipitates. The precipitate was filtered, washed with plenty of deionized water to remove other ions and impurities, and dried. Grind the dried ferric hydroxide and copper hydroxide precipitates into fine powder, and mix them evenly with 400nm graphite powder.

[0042] The above-mentioned mixed powder of ferric hydroxide, copper hydroxide and graphite was put into an alumina crucible, and the steps described in Example 1 were followed. T...

Embodiment 3

[0044] Preparation of core-shell structure iron / silver composite metal micron spherical powder.

[0045] Using silver acetate and iron nitrate as raw materials, weigh iron nitrate and silver acetate according to the atomic percentage of iron and silver (Fe:Ag=2:1), heat and stir in deionized water to prepare a mixture of silver acetate and iron nitrate solution. During the stirring process, excess potassium hydroxide solution is gradually added dropwise, and the reaction produces iron and silver precipitated powder. The precipitate was filtered, washed with plenty of deionized water to remove other ions and impurities, and dried. Grind the dried ferric hydroxide and silver oxide precipitates into fine powder, and mix them evenly with 400nm graphite powder.

[0046] Put the above-mentioned mixed powder of ferric hydroxide and silver oxide powder / graphite powder into an alumina crucible. Put the crucible into the heating zone of the annealing furnace, and evacuate to 6×10 -3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com