Quick pipeline connecting method and joint using same

A quick connection and pipeline technology, applied in the direction of mechanical equipment, couplings, etc., to avoid the reduction of sealing performance, improve reliability and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

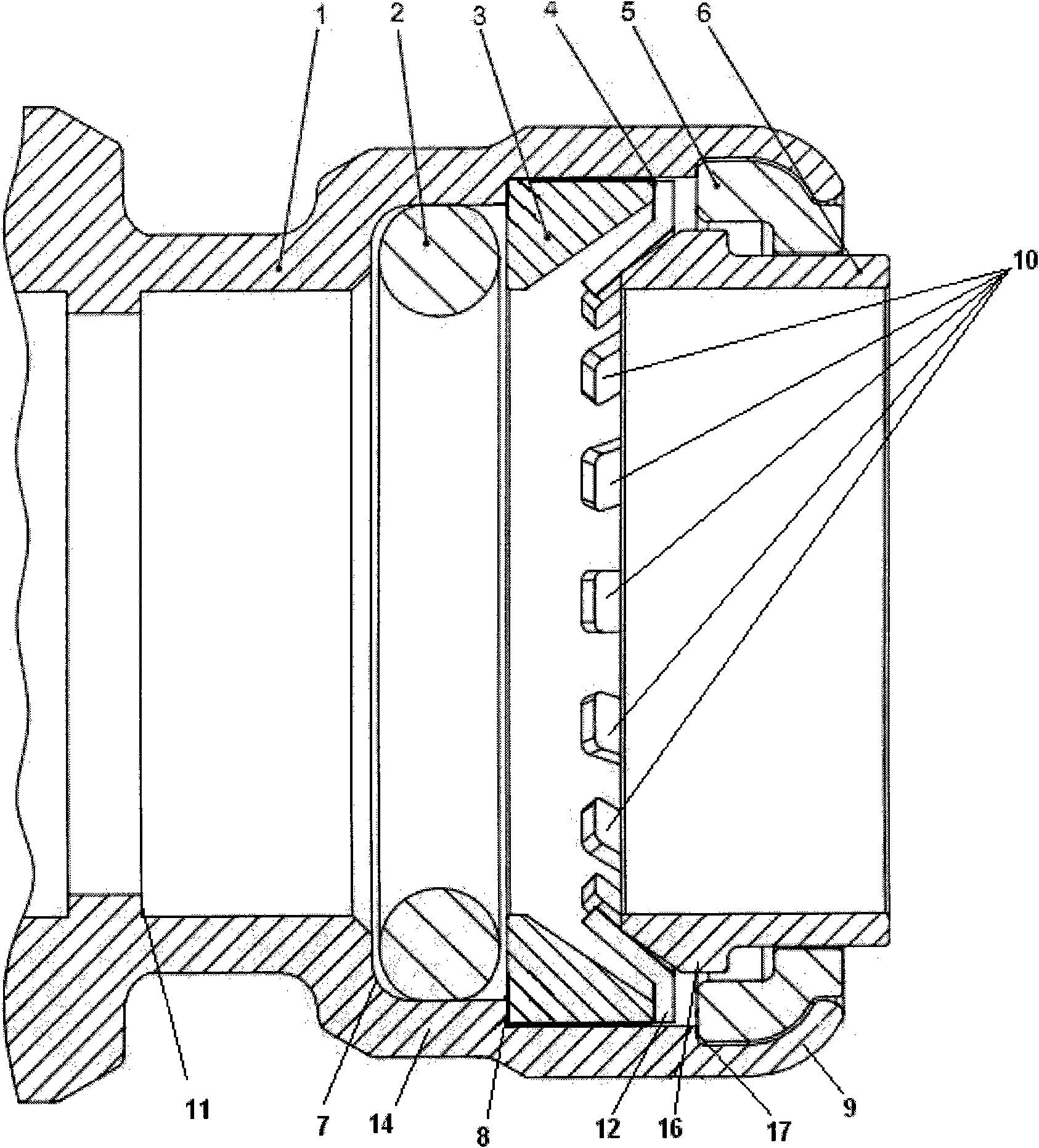

[0050] Such as figure 1 Piping quick connectors shown, including:

[0051] The joint body 1, the interior of the joint body 1 is sequentially arranged along the pipeline insertion direction (direction A):

[0052] Locking cap 5, used to prevent the inner parts from withdrawing;

[0053] The locking cap stopper part 9 is arranged on the pipe insertion end of the joint body, and is used to prevent the locking cap 5 from withdrawing;

[0054] Disassemble the ring 6 to release the locking of the pipeline;

[0055] The snap ring 4 has an annular elastic flange 12 and several latch teeth 10 arranged on the flange 12 for clamping the outer wall of the pipe 13;

[0056] The cone seat 3 is slidingly connected with the inner wall of the joint body 1, and is used to prevent the snap ring 4 from moving in the direction of pipe insertion;

[0057] The cone seat shoulder 8 is provided on the inner wall of the joint body 1, and is used to prevent the cone seat 3 from moving in the direct...

Embodiment 2

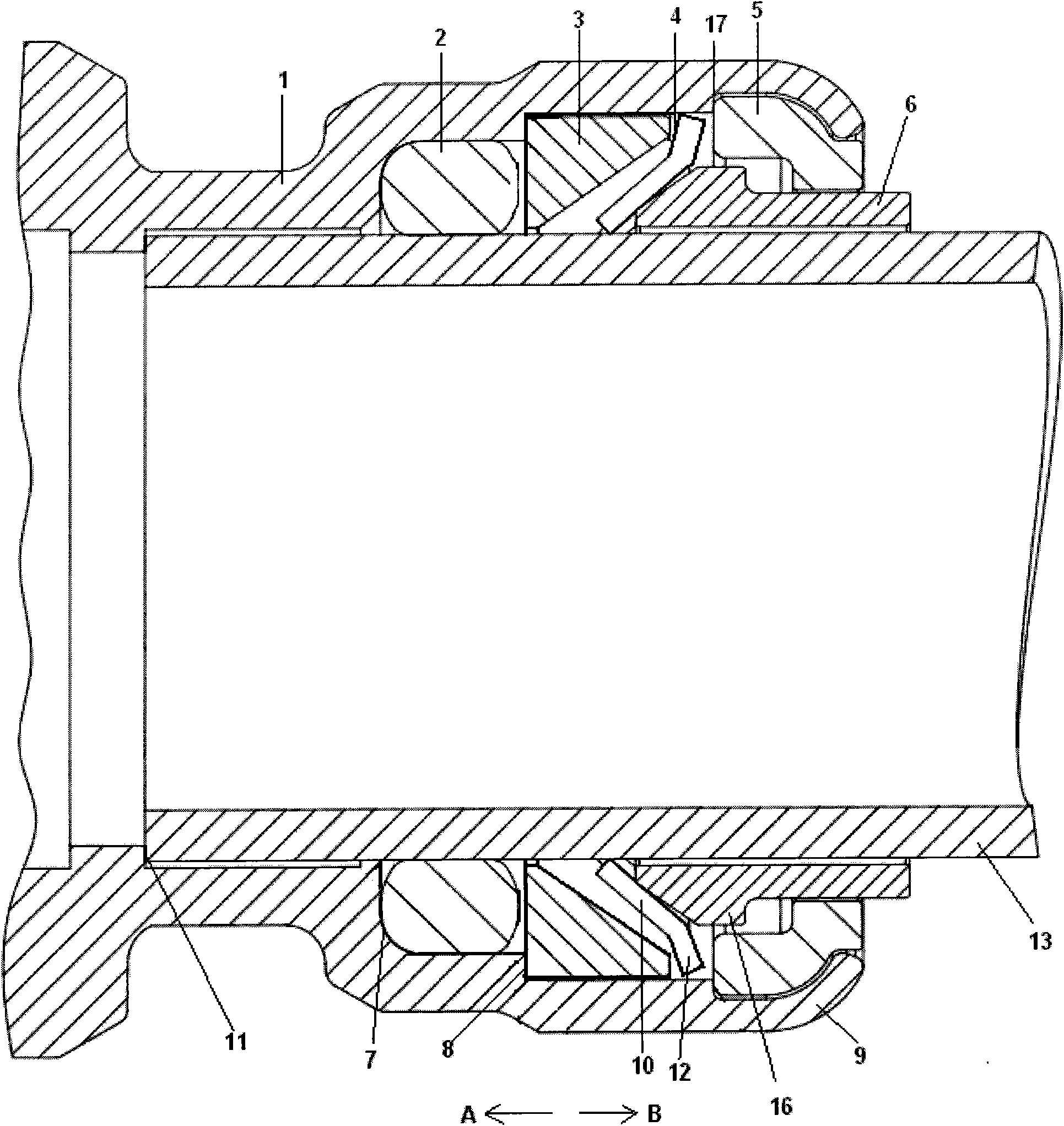

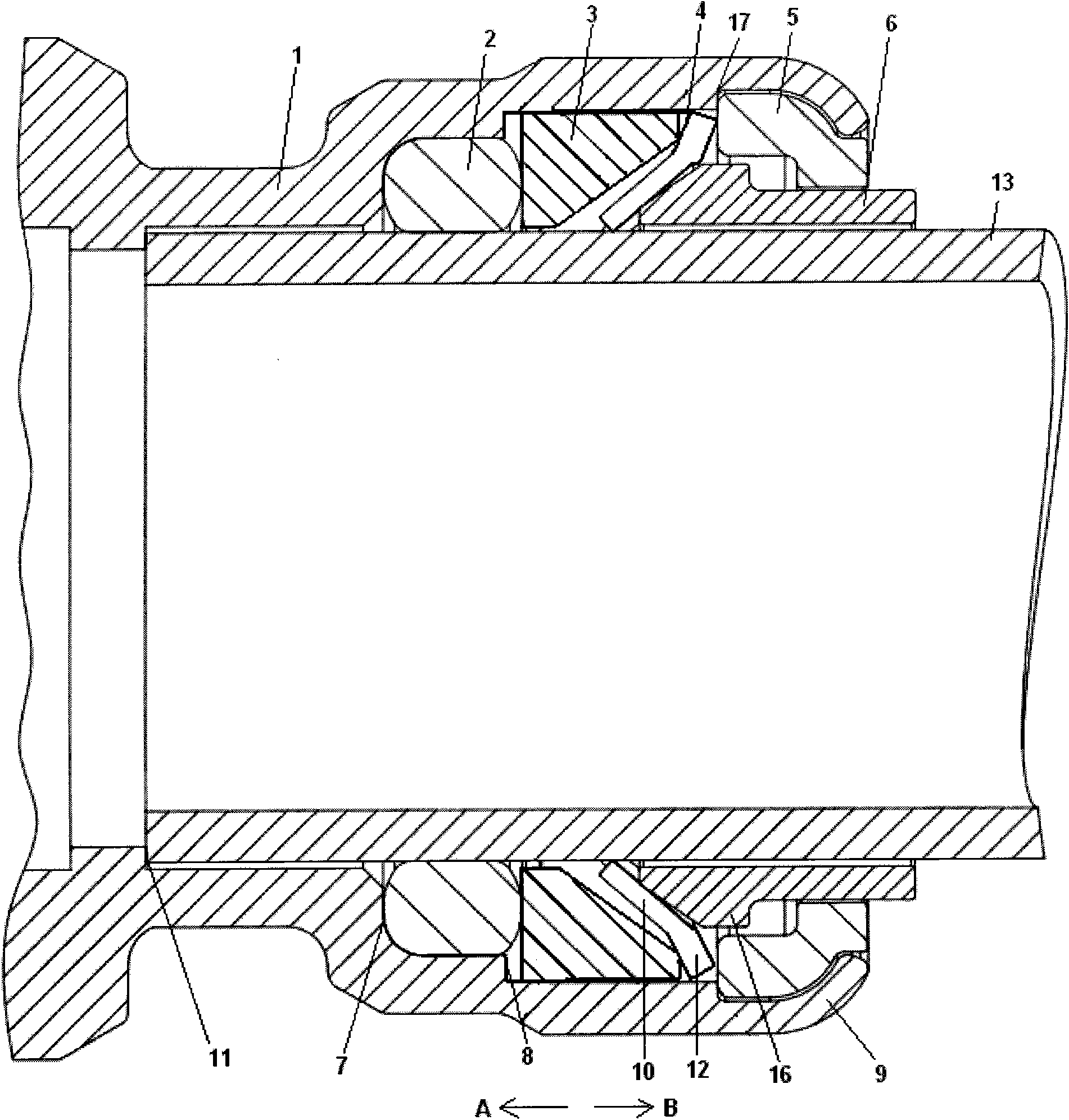

[0077] Such as Figure 4 Piping quick connectors shown, including:

[0078] The joint body 1, the interior of the joint body 1 is sequentially arranged along the pipeline insertion direction (direction A):

[0079] Locking cap 5, used to prevent the inner parts from withdrawing;

[0080] The locking cap stopper part 9 is arranged on the pipe insertion end of the joint body, and is used to prevent the locking cap from withdrawing;

[0081] Disassemble the ring 6 to release the locking of the pipeline;

[0082] The snap ring 4 has an annular elastic flange 12 and several latch teeth 10 arranged on the flange 12 for clamping the outer wall of the pipe 13;

[0083] The cone seat 3 is slidingly connected with the inner wall of the joint body 1, and is used to prevent the snap ring 4 from moving in the direction of pipe insertion;

[0084] The cone seat shoulder 8 is provided on the inner wall of the joint body 1, and is used to prevent the cone seat 3 from moving in the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com