Centrifugal compressor

A centrifugal compressor and compressor technology, applied in the direction of electromechanical devices, mechanical equipment, engine components, etc., can solve the problems of centrifugal compressor efficiency decline, etc., to achieve the effect of improving efficiency and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

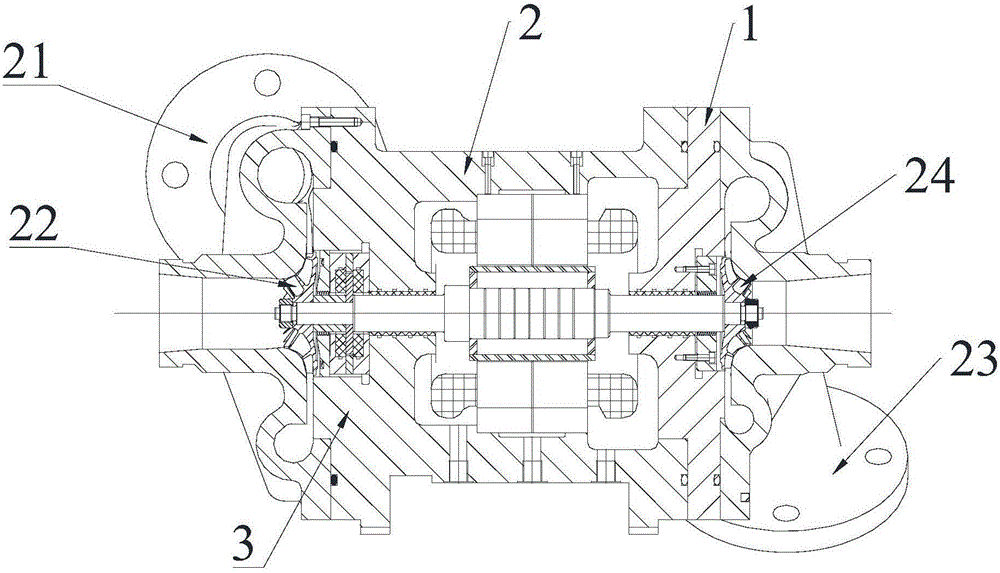

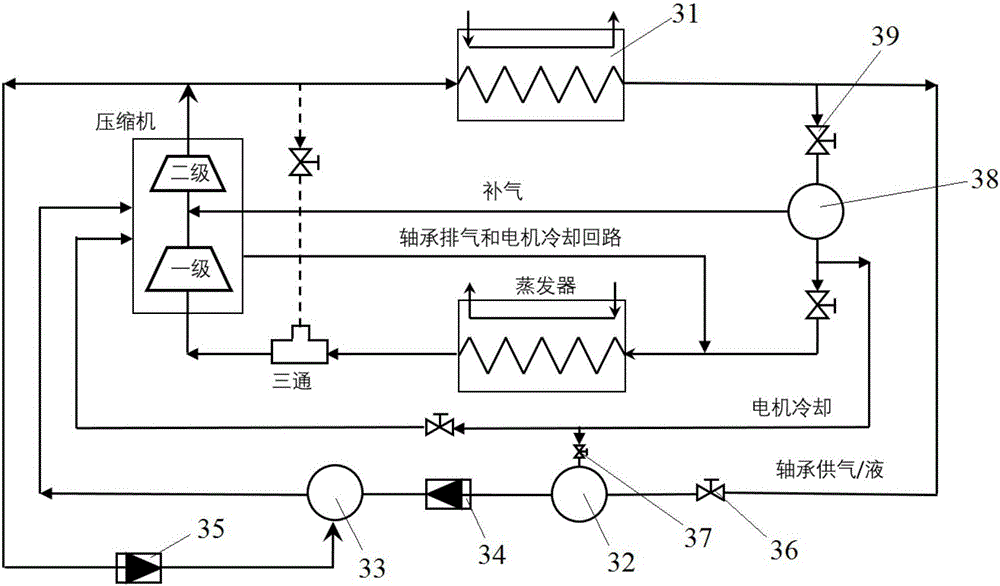

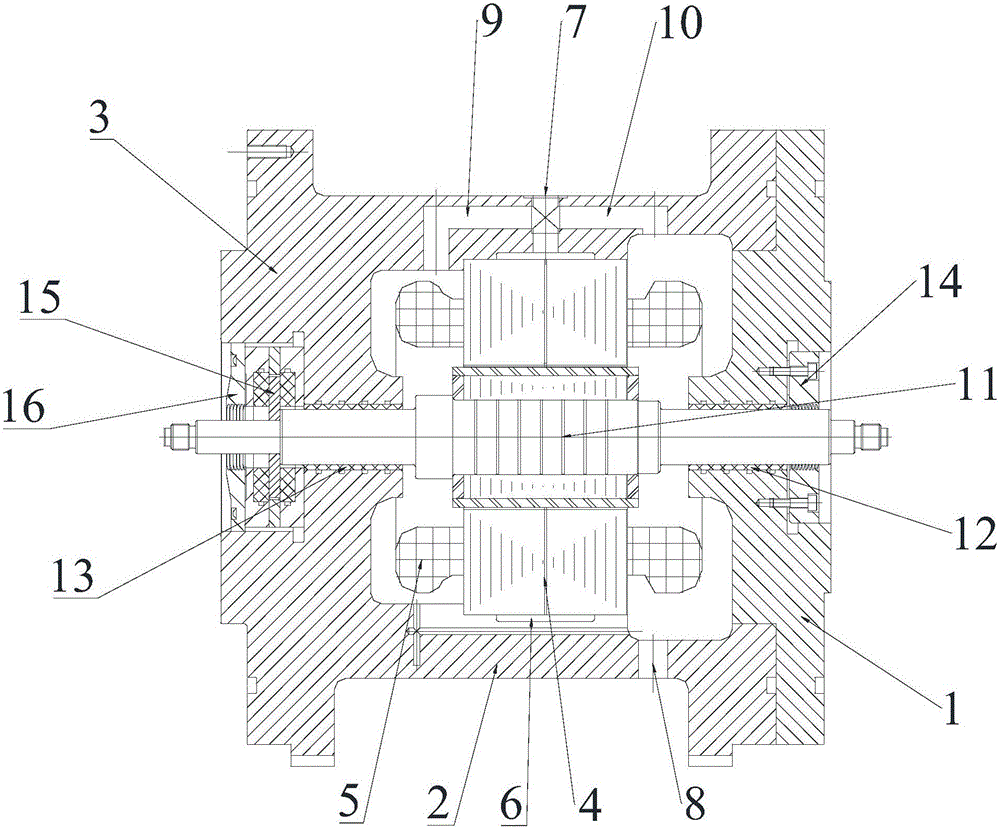

[0038] This embodiment provides a centrifugal compressor, especially a small centrifugal compressor, which includes a motor, a first-stage compressor and / or a second-stage compressor.

[0039] The motor drives the first-stage compressor and the second-stage compressor to operate. In this embodiment, the motor is a high-speed permanent magnet motor, and the high-speed permanent magnet motor uses a radial hydrostatic bearing to support the motor For the rotation of the rotor, an axial hydrostatic bearing is used to balance the axial force of the motor rotor; and the radial hydrostatic bearing and the axial hydrostatic bearing both use gas and liquid two-phase low-viscosity fluid as a lubricating medium.

[0040] In this embodiment, when it only includes a first-stage compressor, the centrifugal compressor is a single-stage compressor, and when it includes a first-stage compressor and a second-stage compressor, it is a two-stage compressor, At this time, the motor is a dual-outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com