Patents

Literature

50 results about "Plasma diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The plasma diffusion across the magnetic field is an important topic in magnetic confinement of fusion plasma. It is especially concerning how the plasma transport is reduced by the strength of the external magnetic field. The classical diffusion gives the 1/B² scaling, while the Bohm diffusion, borne out of experimental observations from the early confinement machines, was conjectured to follow the 1/B scaling. The Hsu diffusion predicts the 1/B³⸍² scaling, that is presumably the best confinement scenario in magnetized plasma.

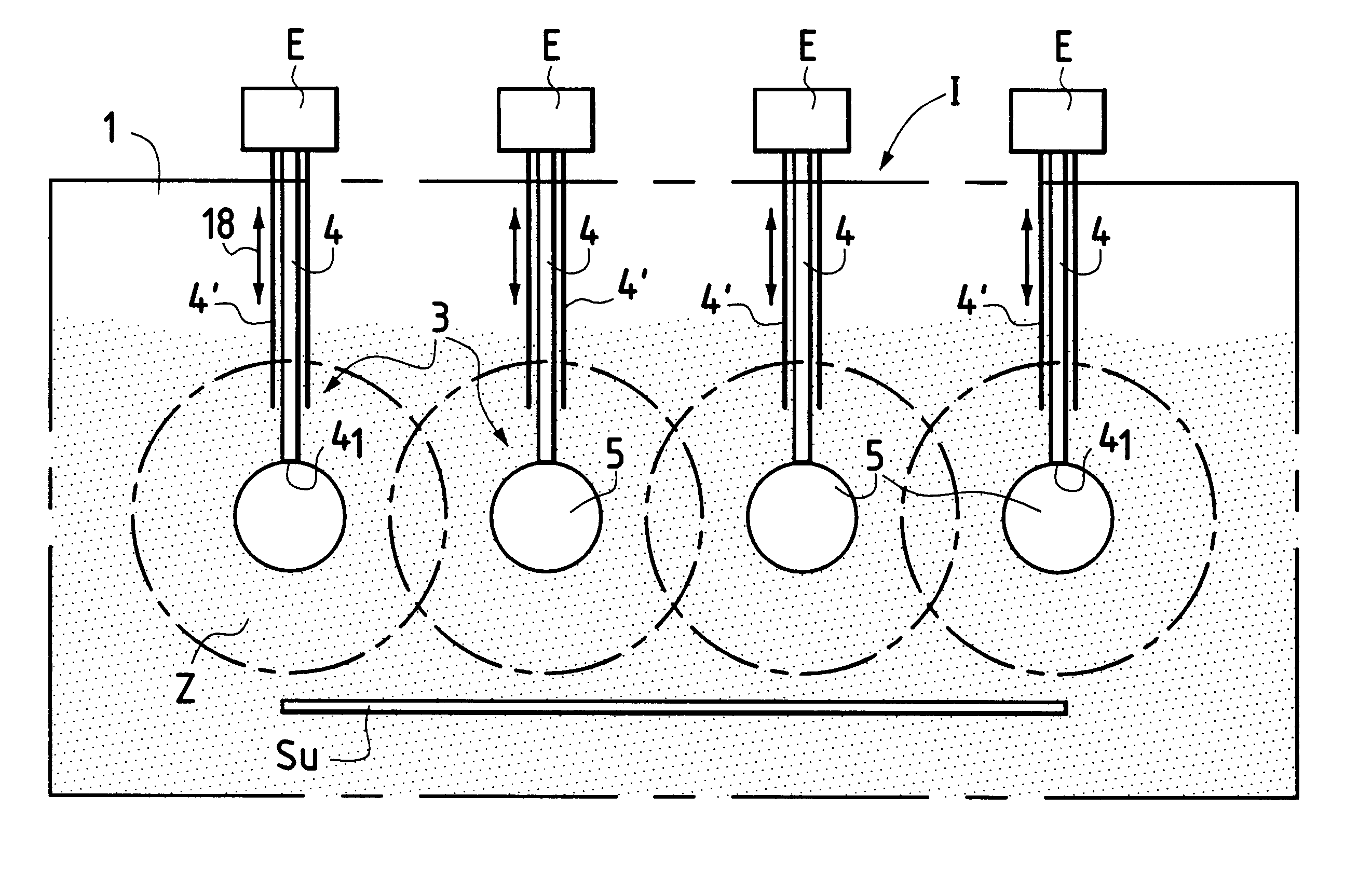

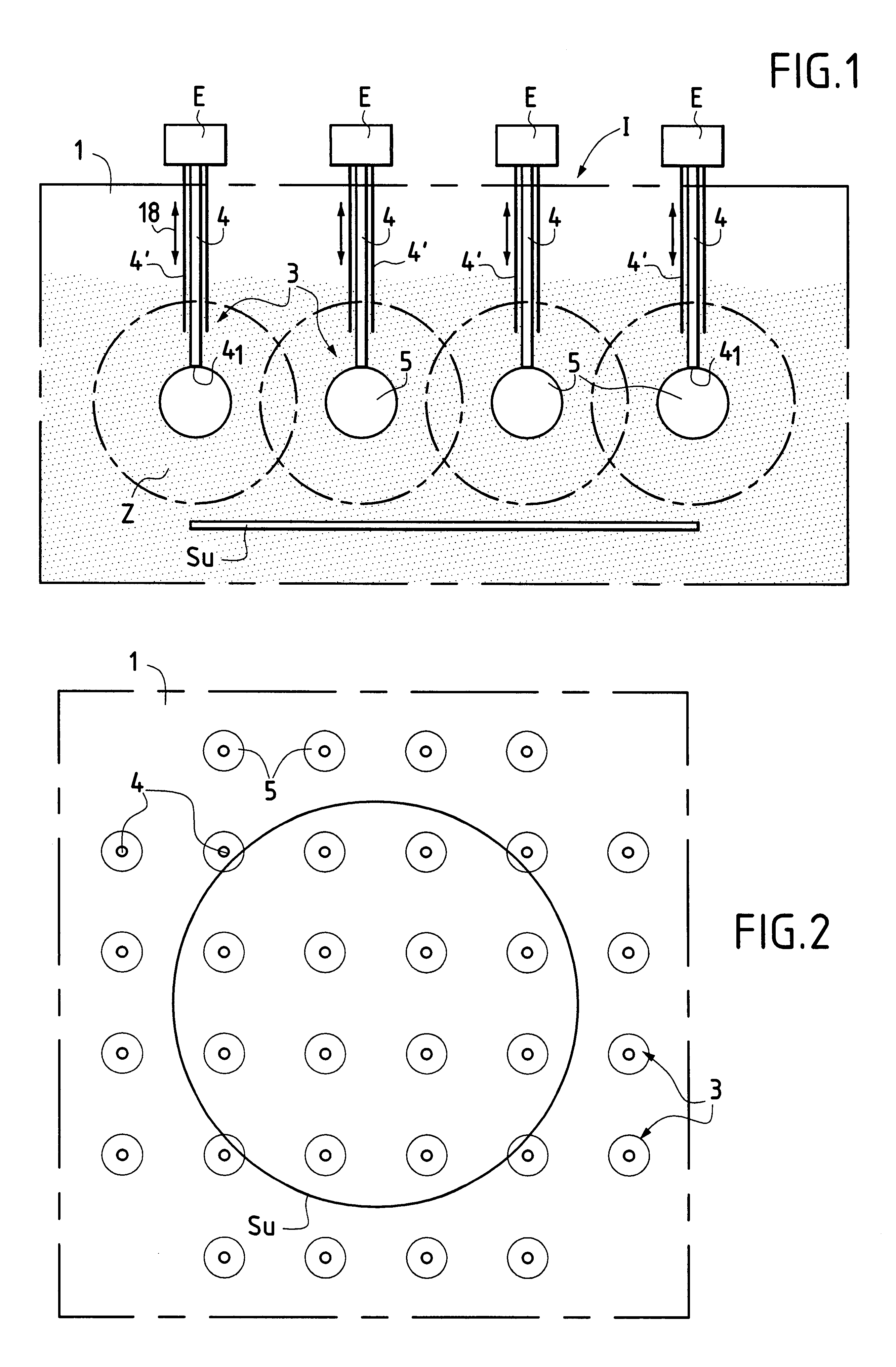

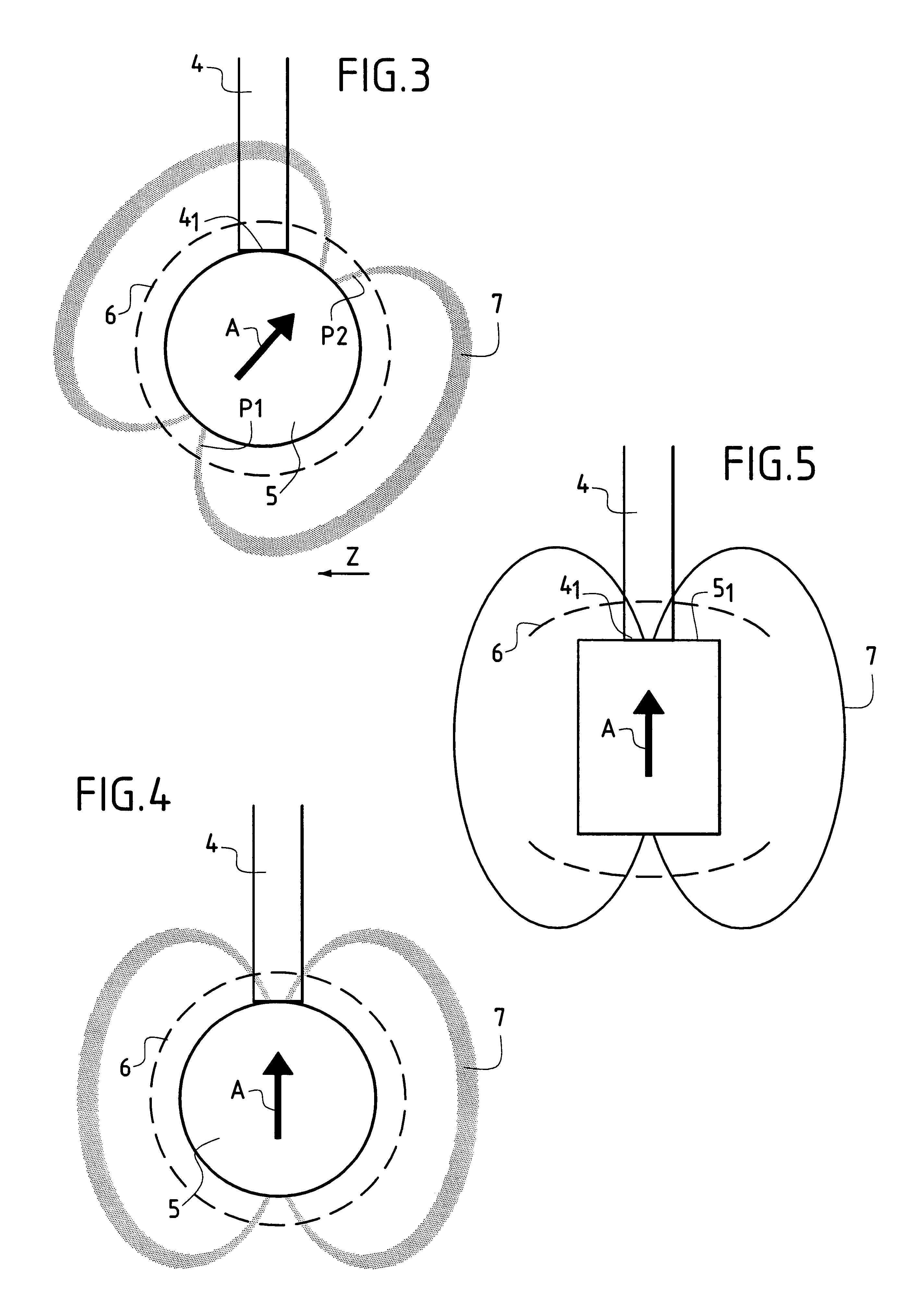

Method of producing individual plasmas in order to create a uniform plasma for a work surface, and apparatus for producing such a plasma

InactiveUS6407359B1Electric discharge tubesElectric arc lampsPlasma diffusionElectron cyclotron resonance

The invention provides apparatus having a series of individual plasma excitation devices each constituted by a wire applicator of microwave energy, having one end connected to a source for producing microwave energy and having an opposite end fitted with at least one magnetic dipole for creating at least one surface having a magnetic field that is constant and of intensity corresponding to electron cyclotron resonance, the dipole being mounted at the end of the microwave applicator in such a manner as to ensure that electrons accelerated to electron cyclotron resonance oscillate between the poles so as to create a plasma diffusion zone situated on the side of the dipole that is remote from the end of the applicator, the individual excitation devices being distributed relative to one another and in proximity with the work surface so as to create together a plasma that is uniform for the work surface.

Owner:H E F

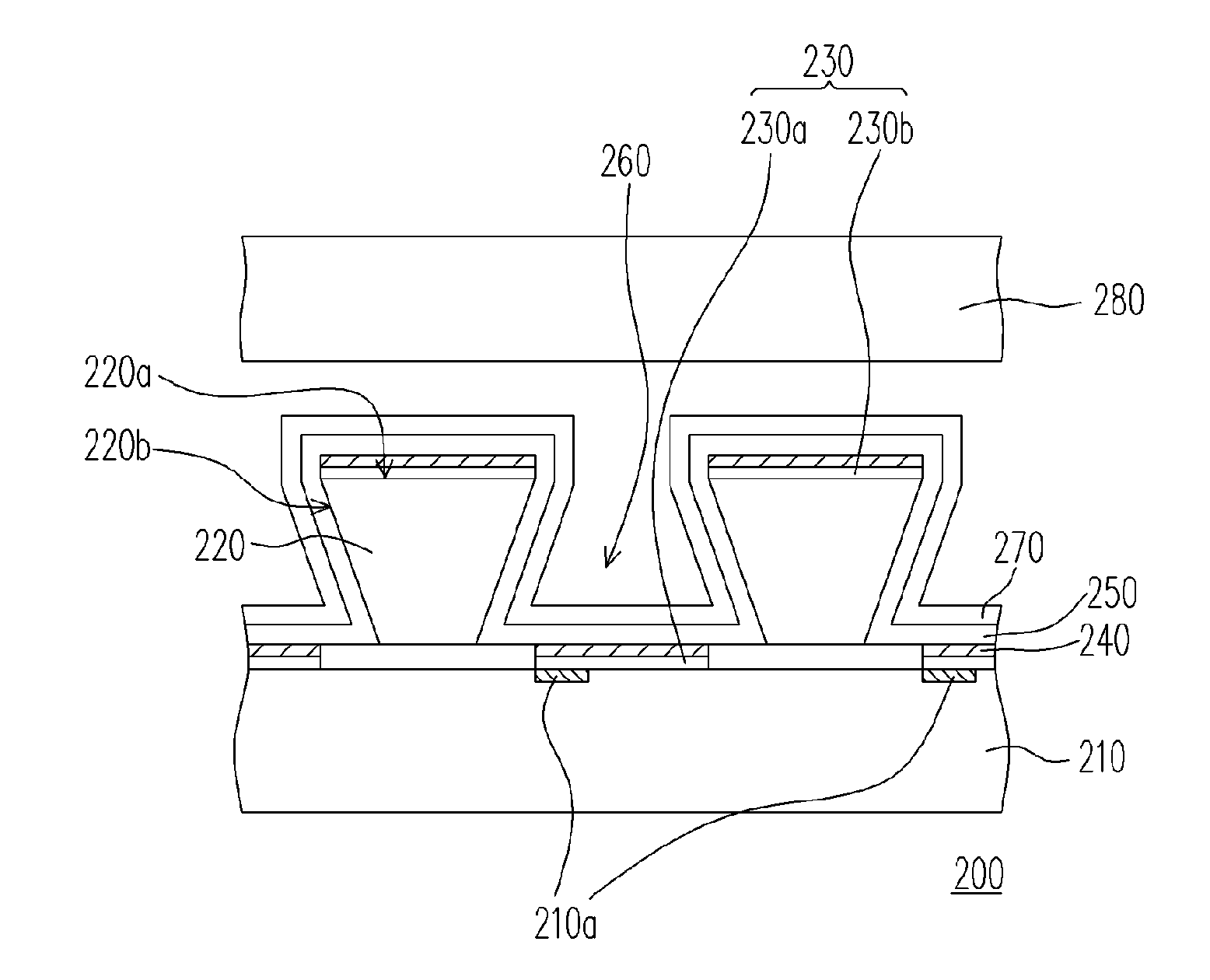

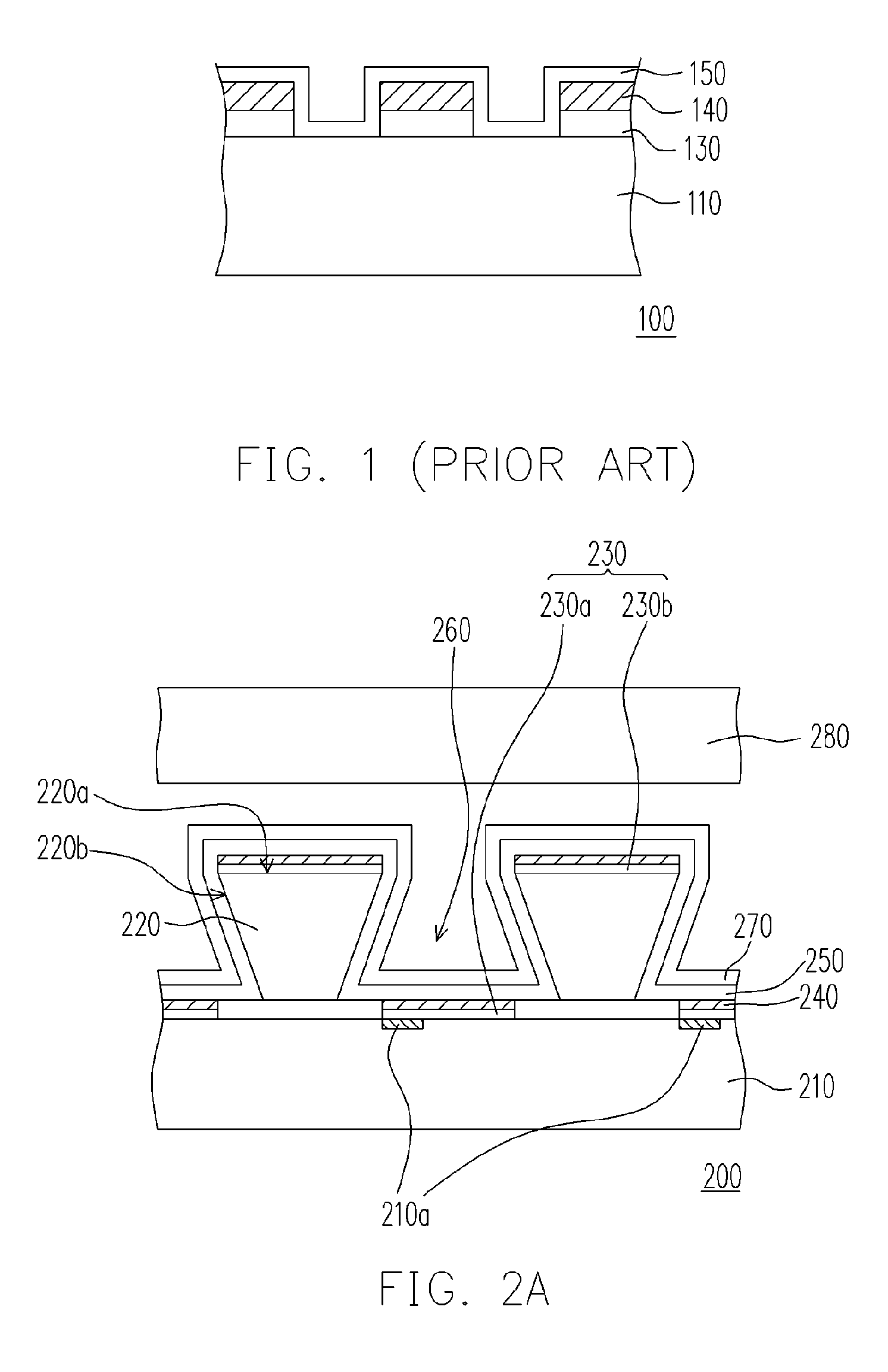

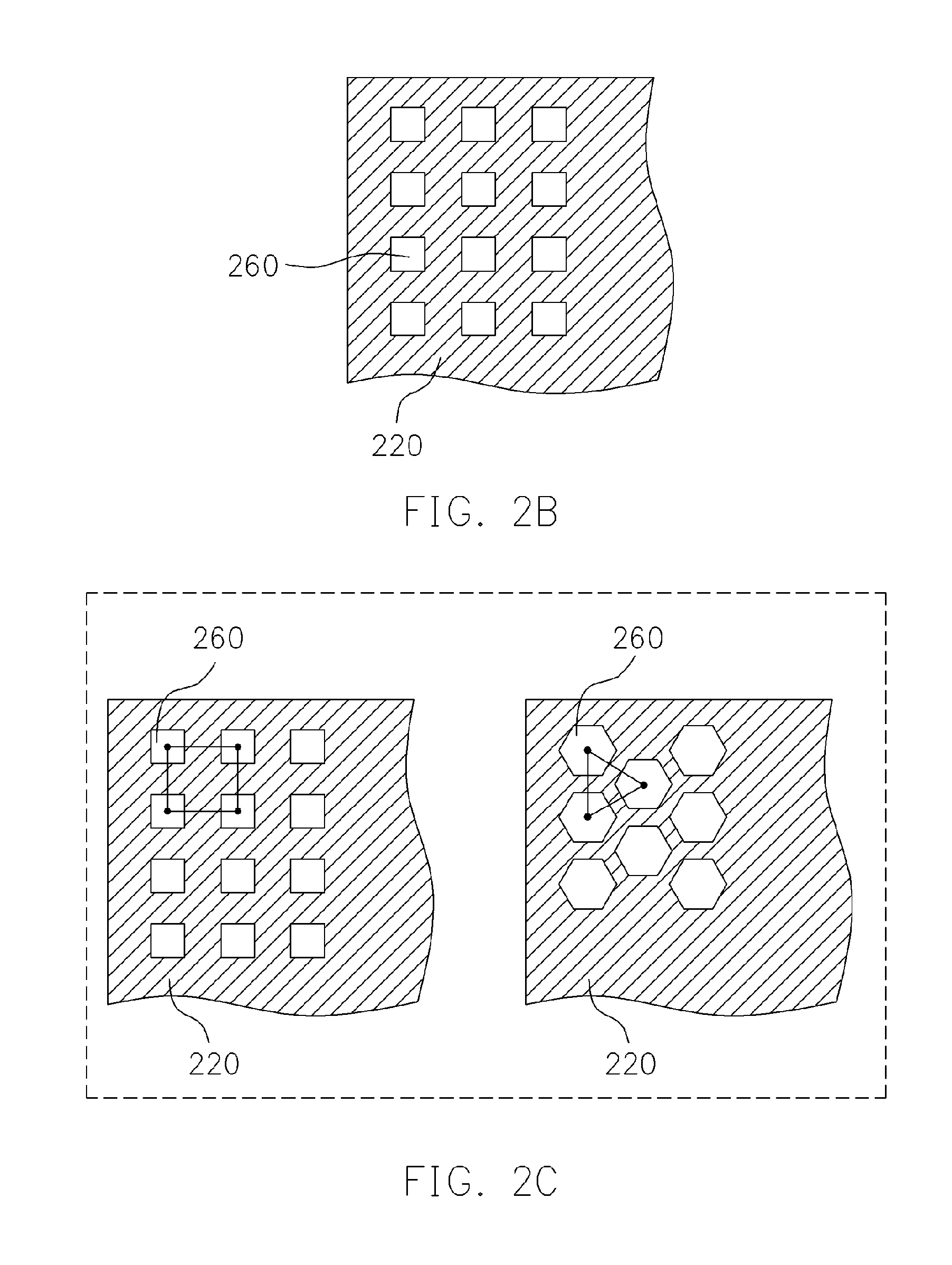

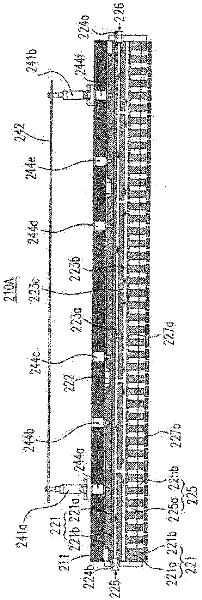

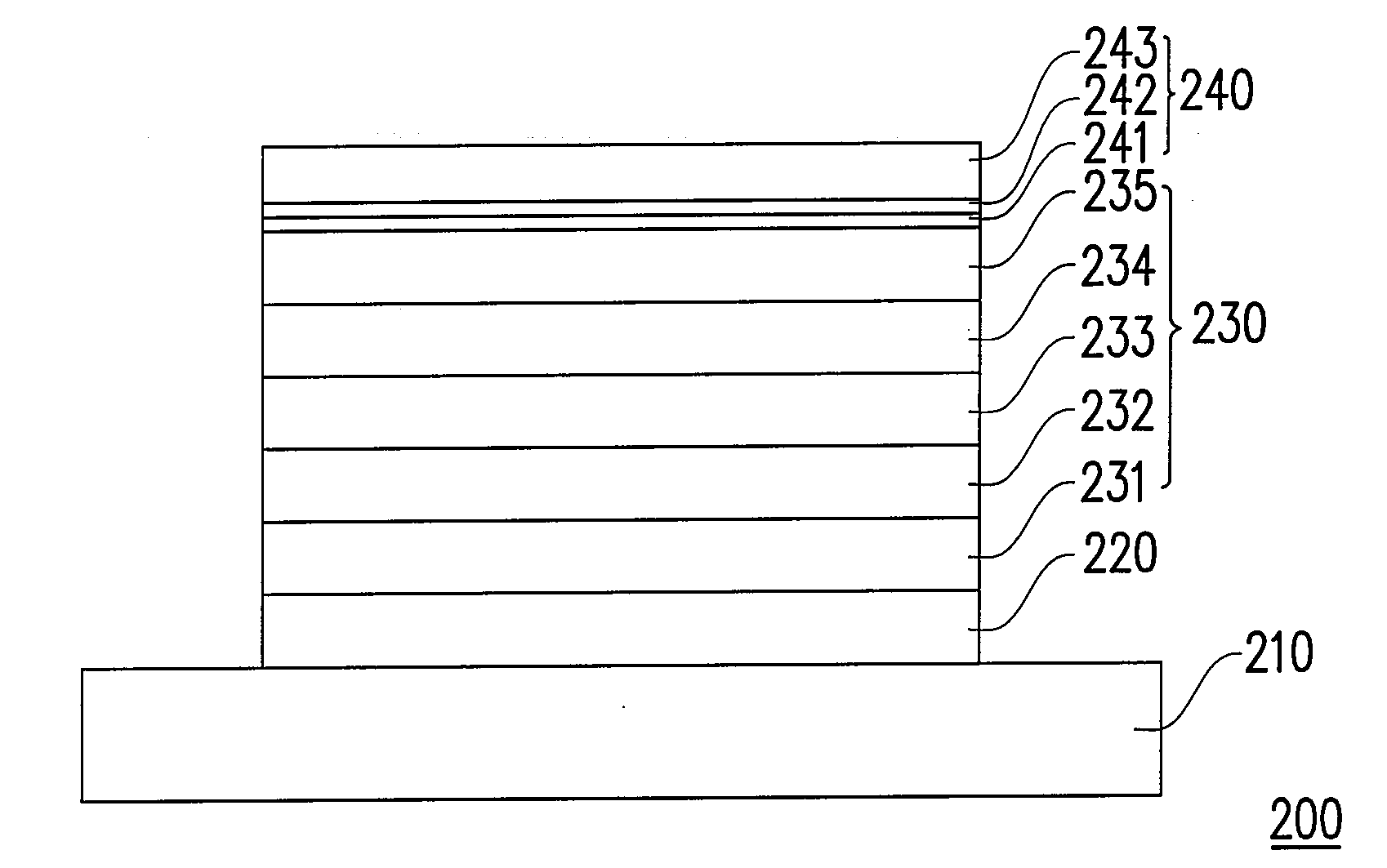

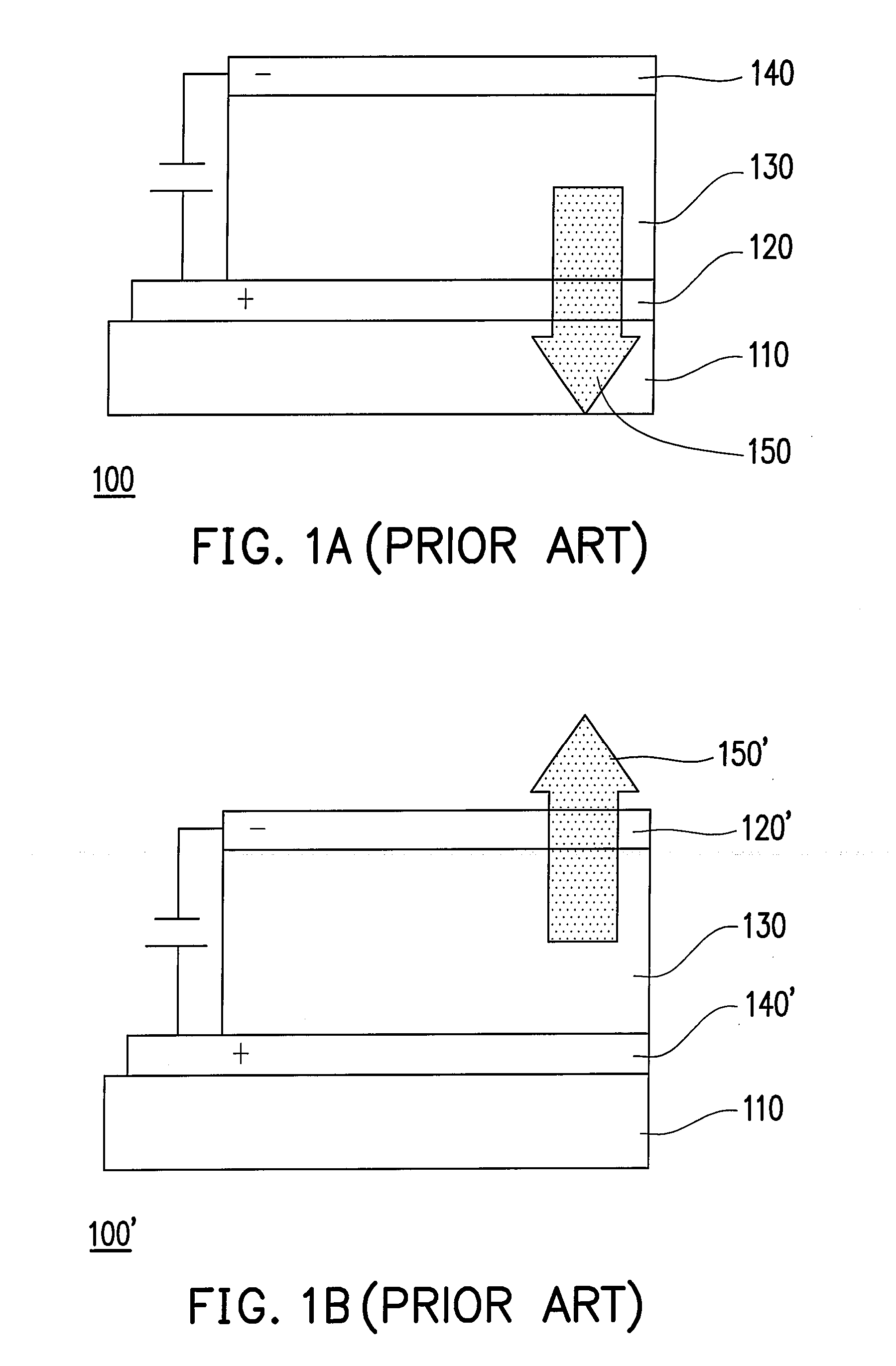

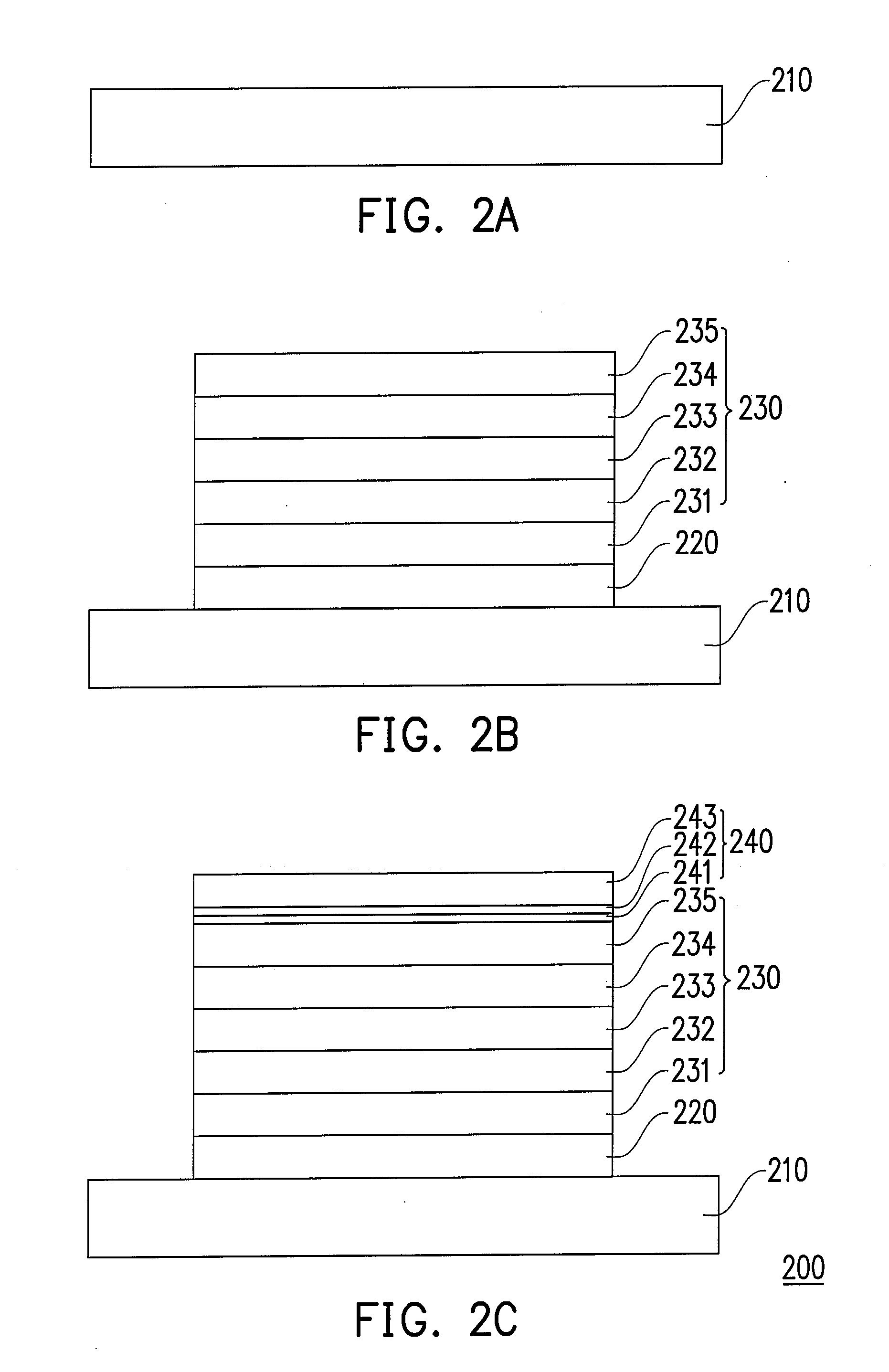

Active matrix organic electro-luminescence device array and fabricating process thereof

InactiveUS20060125385A1Simplify manufacturing stepsImprove display efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesActive matrixPlasma diffusion

An active matrix organic electro-luminescence device array comprises an active element array substrate, a patterned rib, a conductive layer, an organic luminescent layer and a common electrode layer. The active element array substrate has a plurality of active elements, and the patterned rib is disposed over the active element array substrate, wherein the patterned rib has a plurality of apertures exposing the active elements. The conductive layer is disposed over the active element array substrate and the patterned rib, wherein a portion of the conductive layer disposed over the active element array substrate and a portion of the conductive layer disposed over the patterned rib are disconnected. The organic luminescent layer is disposed over the conductive layer in the apertures. Finally, for example, the common electrode layer is formed by a plasma diffusion method to cover the organic luminescent layer and the patterned rib completely and continuously.

Owner:CHUNGHWA PICTURE TUBES LTD

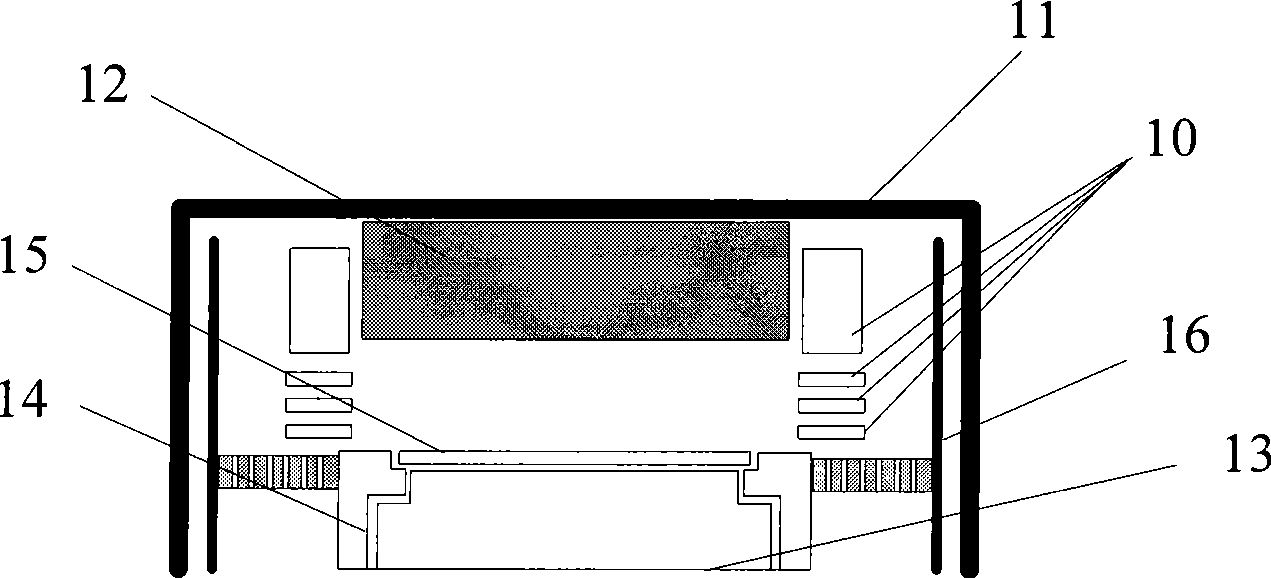

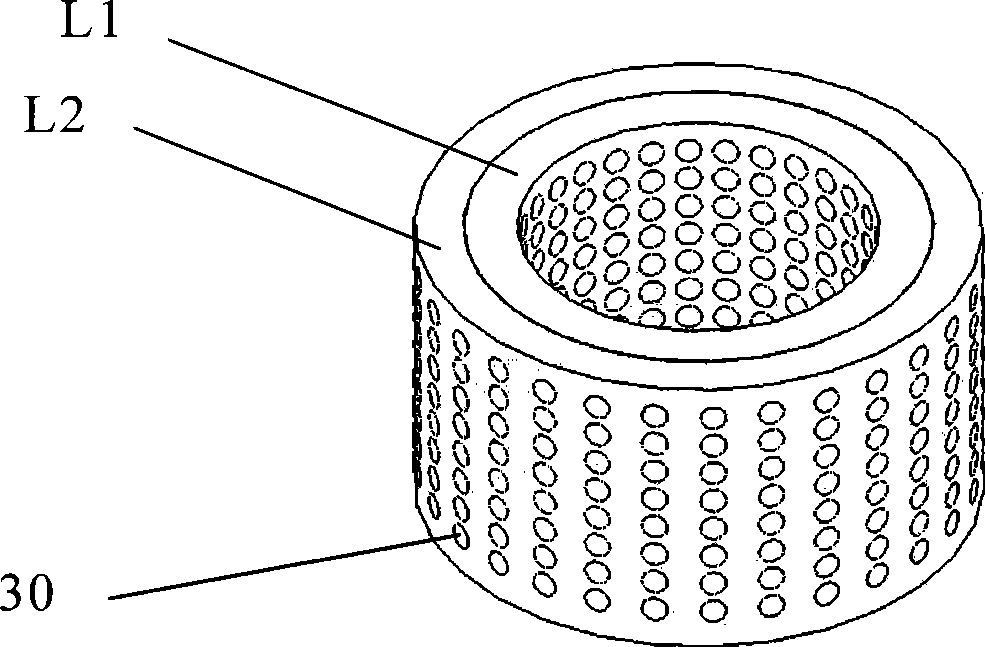

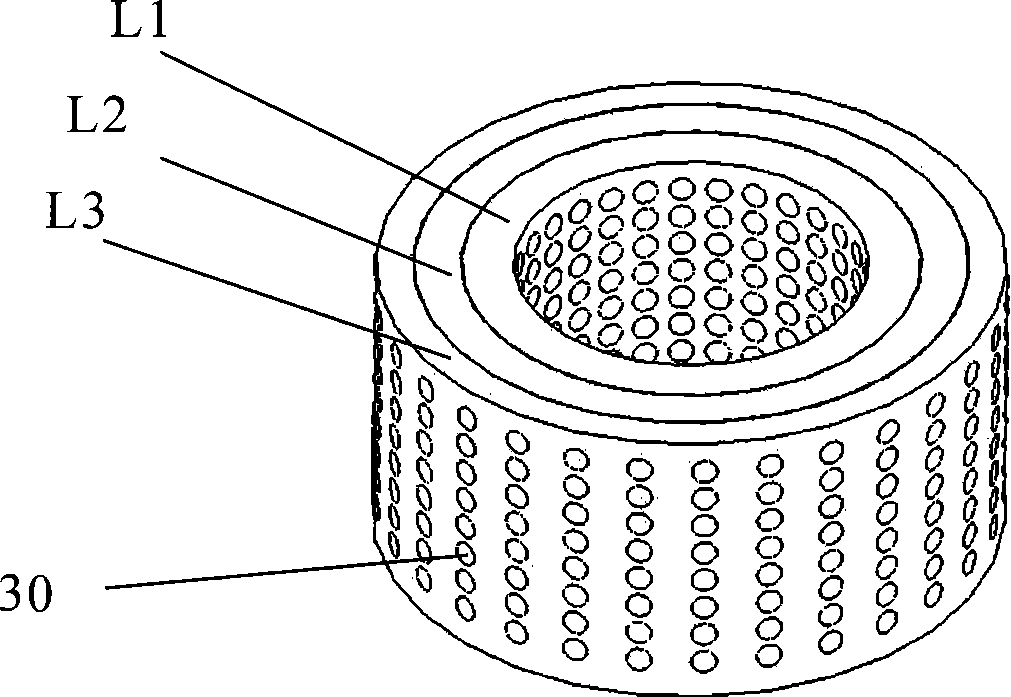

Plasma confinement apparatus and semiconductor processing equipment applying the same

ActiveCN101441983ANot easy to damageEasy to installElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma diffusionEngineering

The invention provides a plasma constraint device for limiting plasma diffusion. The constraint device comprises at least one layer of cylindrical constraint cover, wherein each layer of the constraint cover is provided with a through hole so as to form a constraint passage. The invention also provides semiconductor processing equipment applying to the plasma constraint device, which comprises a reaction cavity, an upper electrode, a lower electrode and the plasma constraint device, wherein the constraint device is positioned in the reaction cavity and encircles the reaction zone between the upper electrode and the lower electrode so as to prevent the plasma from diffusing outside the constraint device. The plasma constraint device and the semiconductor processing equipment are convenient for mounting and maintenance and uneasy to destroy. Meanwhile, the plasma constraint device and the semiconductor processing equipment can reduce and even avoid particle pollution caused by the plasma outside the reaction zone, so as to increase product yield and prolong service life of parts in the reaction cavity.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Plasma display panel with spacers diagonally opposed to the electrode sets

A plasma display panel is provided to solve the problem of crosstalk due to discharge which generates from plasma diffusion between cells adjacent to each other, preventing color spread of the vertical edge. The plasma display panel of the invention includes a barrier located at an angle to its data electrode, the barrier being formed on an upper substrate on which a sustain electrode is formed.

Owner:LG ELECTRONICS INC

Capacitor array structure and manufacturing method thereof

PendingCN108538835AImprove electrical connection stabilityReduce the probability of electric leakageSolid-state devicesSemiconductor devicesCapacitanceElectrical conductor

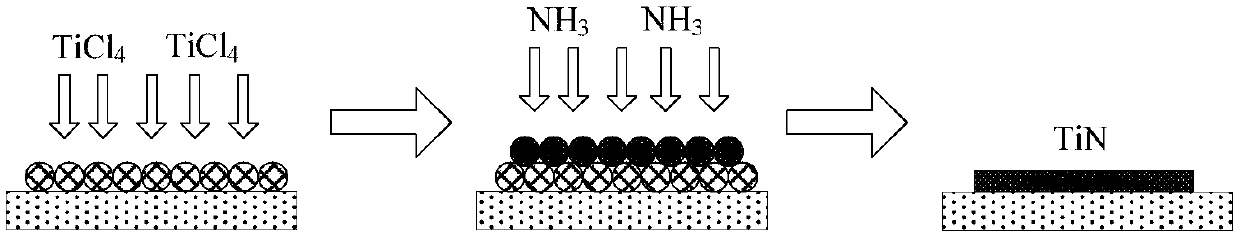

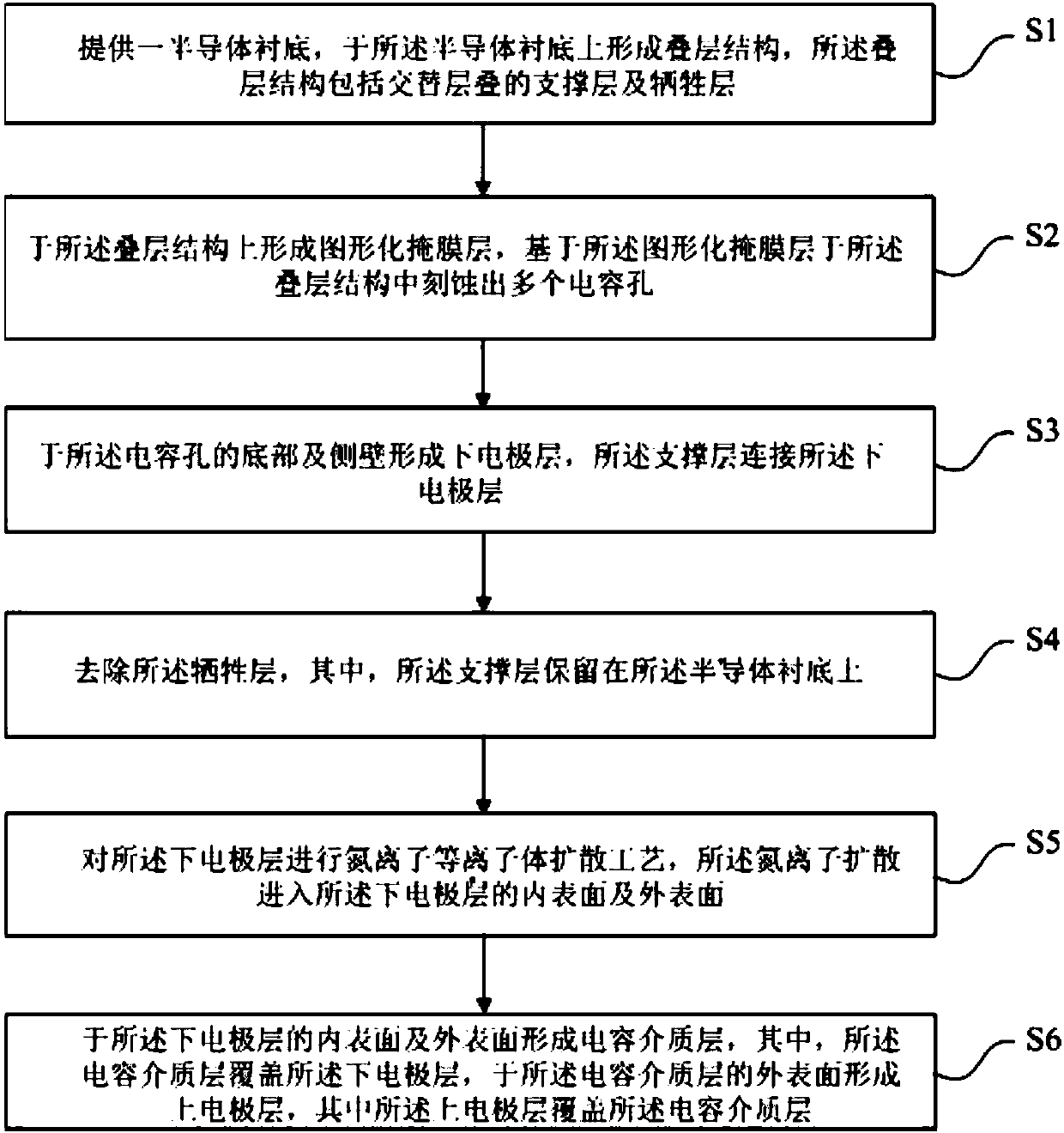

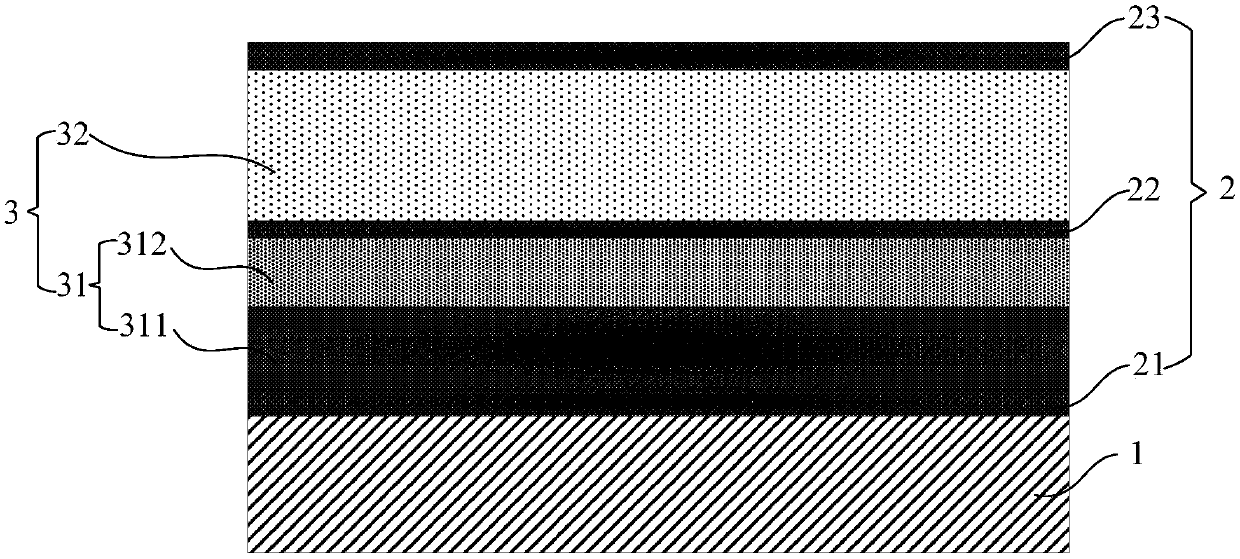

The invention provides a capacitor array structure and a manufacturing method thereof. The method comprises steps: 1) a semiconductor substrate is provided, and a laminated structure is formed on thesemiconductor substrate; 2) a patterned mask layer is formed on the laminated structure and multiple capacitor holes are etched in the laminated structure based on the patterned mask layer; 3) a lowerelectrode layer is formed on the bottom part and the side wall of the capacitor hole, and a supporting layer is connected with the lower electrode layer; 4) a sacrificial layer is removed; 5) a nitrogen ion plasma diffusion process is carried out on the lower electrode layer, and the nitrogen ions are diffused to the inner surface and the outer surface of the lower electrode layer; and 6) a capacitive dielectric layer is formed on the inner surface and the outer surface of the lower electrode layer and an upper electrode layer is formed on the outer surface of the capacitive dielectric layer.Through carrying out nitrogen ion plasma diffusion process processing on the lower electrode layer, the electrical connection stability and the charge storage capacity of the capacitor can be effectively improved, and the electricity leakage rate of the capacitor is also reduced.

Owner:CHANGXIN MEMORY TECH INC

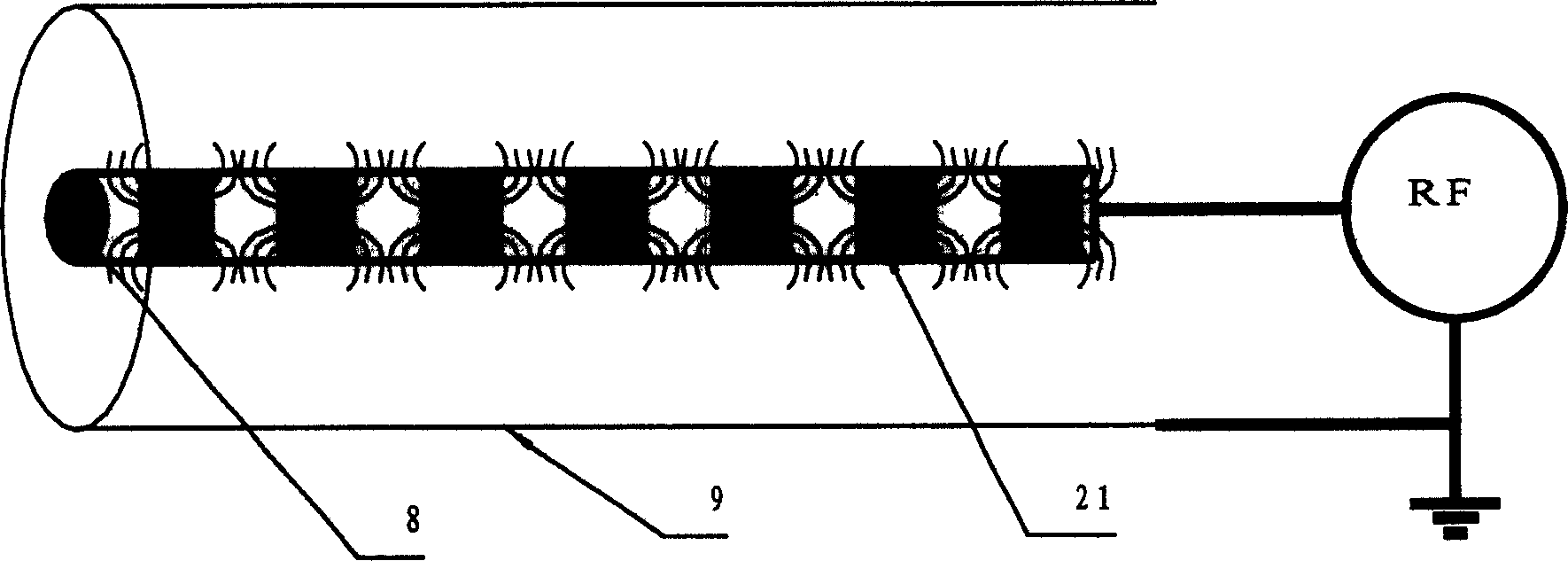

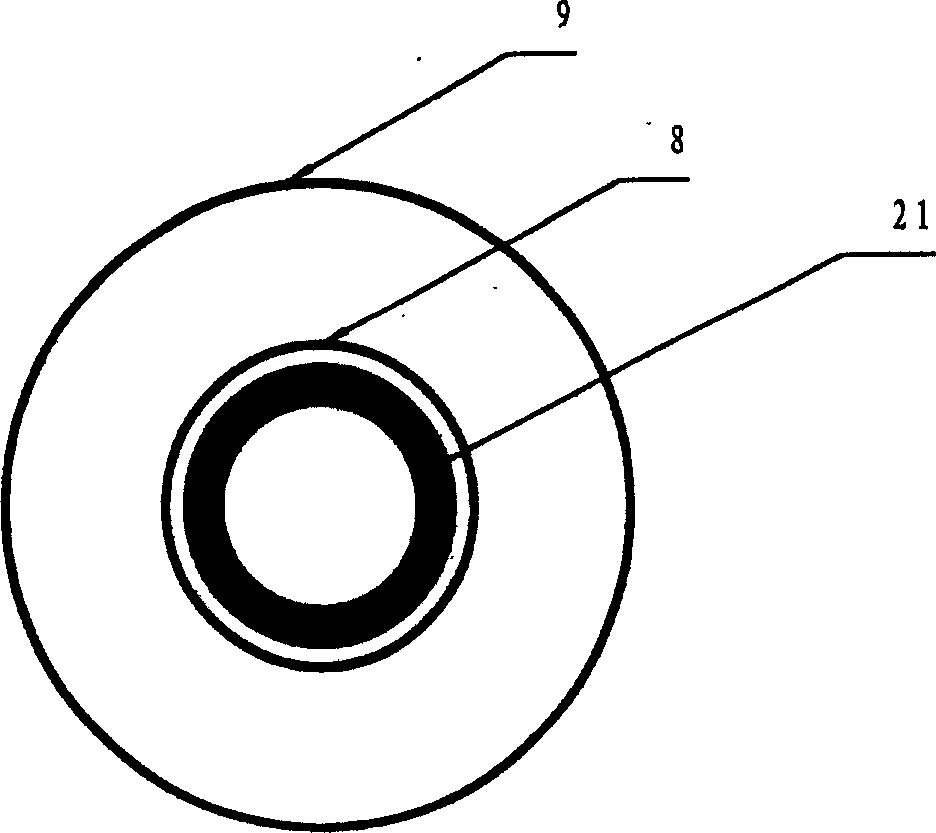

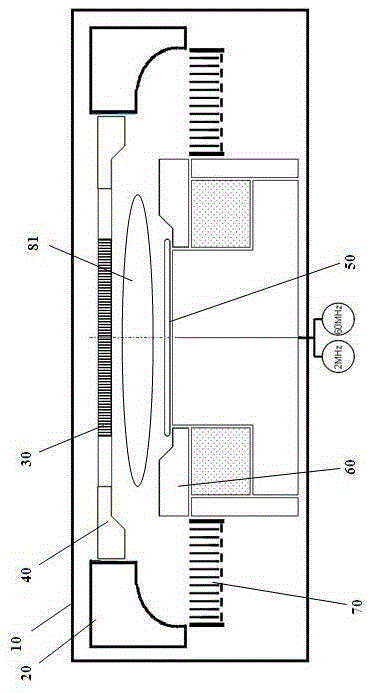

Apparatus for inner surface modification by plasma source ion implantation

InactiveCN1635177AImprove Surface Machining EfficiencyIncrease gas ionization rateVacuum evaporation coatingSputtering coatingPlasma diffusionType distribution

The invention relates to a device for inner surface modification by injecting plasma ion source, wherein: setting a tubular work-piece into a processing chamber, laying a columnar electrode and a tubular electrode allowing plasma diffusion in the tubular work-piece from inside to out side coaxially_ contacting the two electrodes with the radio frequency power supply, connecting a negative high tension supply between the tubular electrode and the tubular work-piece, also including a driving device capable of making relative rotation between tubular work-piece and tubular electrode; the tubular electrode is made up of electrode wires on the outer surface of tubular support, the electrode wires are in circumferential uniform distribution or screw-type distribution; the columnar electrode is a hollow tube with magnetic-irons in it; the tubular electrode is an interconnected hollow metal tube. the magnetic-irons are ring, and axially uniformly distributed with homopolarity opposition. The invention intensifies the sputtering of plasma to center electrode material by setting magnetic-irons in the tubular electrode, and improves the processing efficiency of tubular work-piece inner surface.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

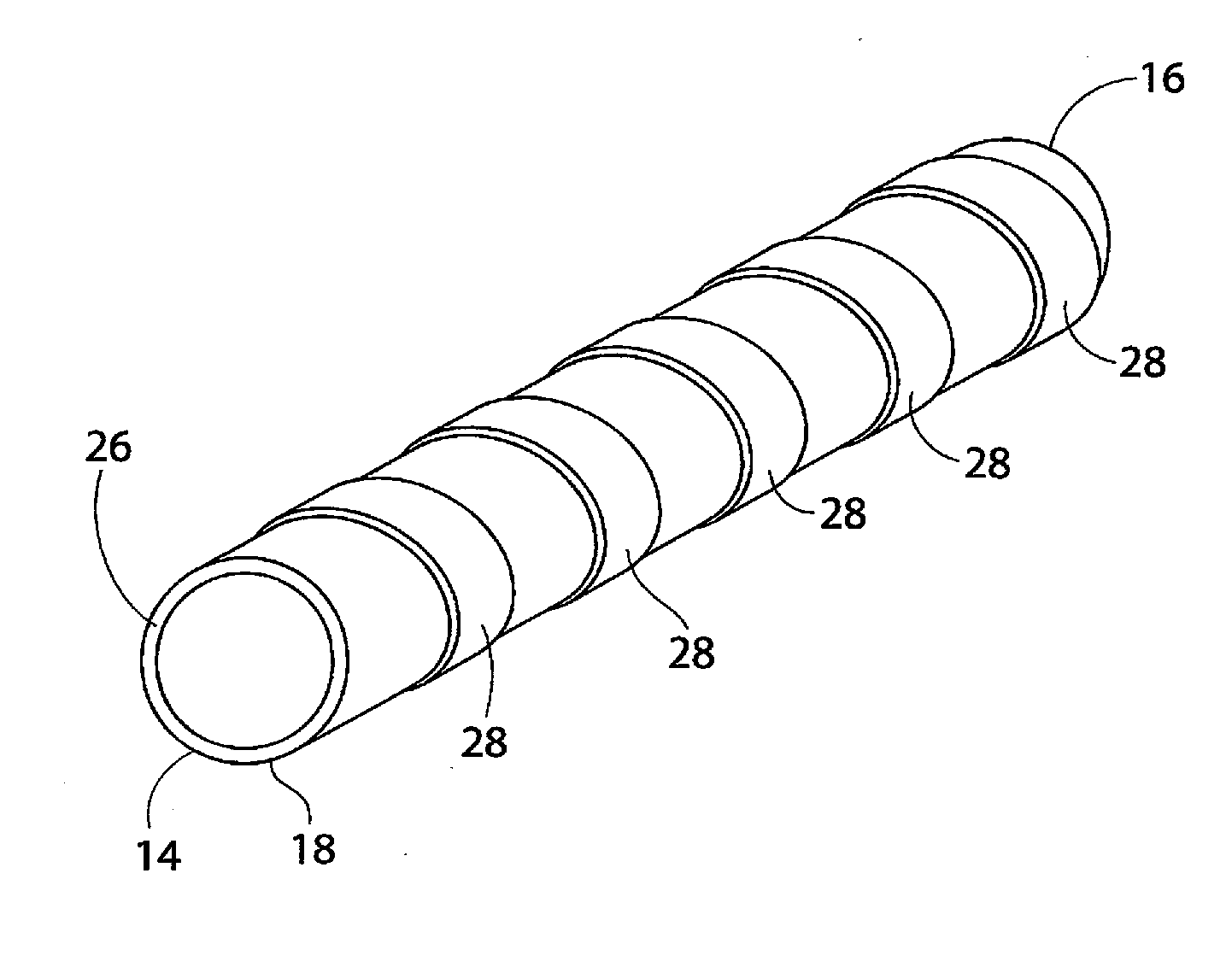

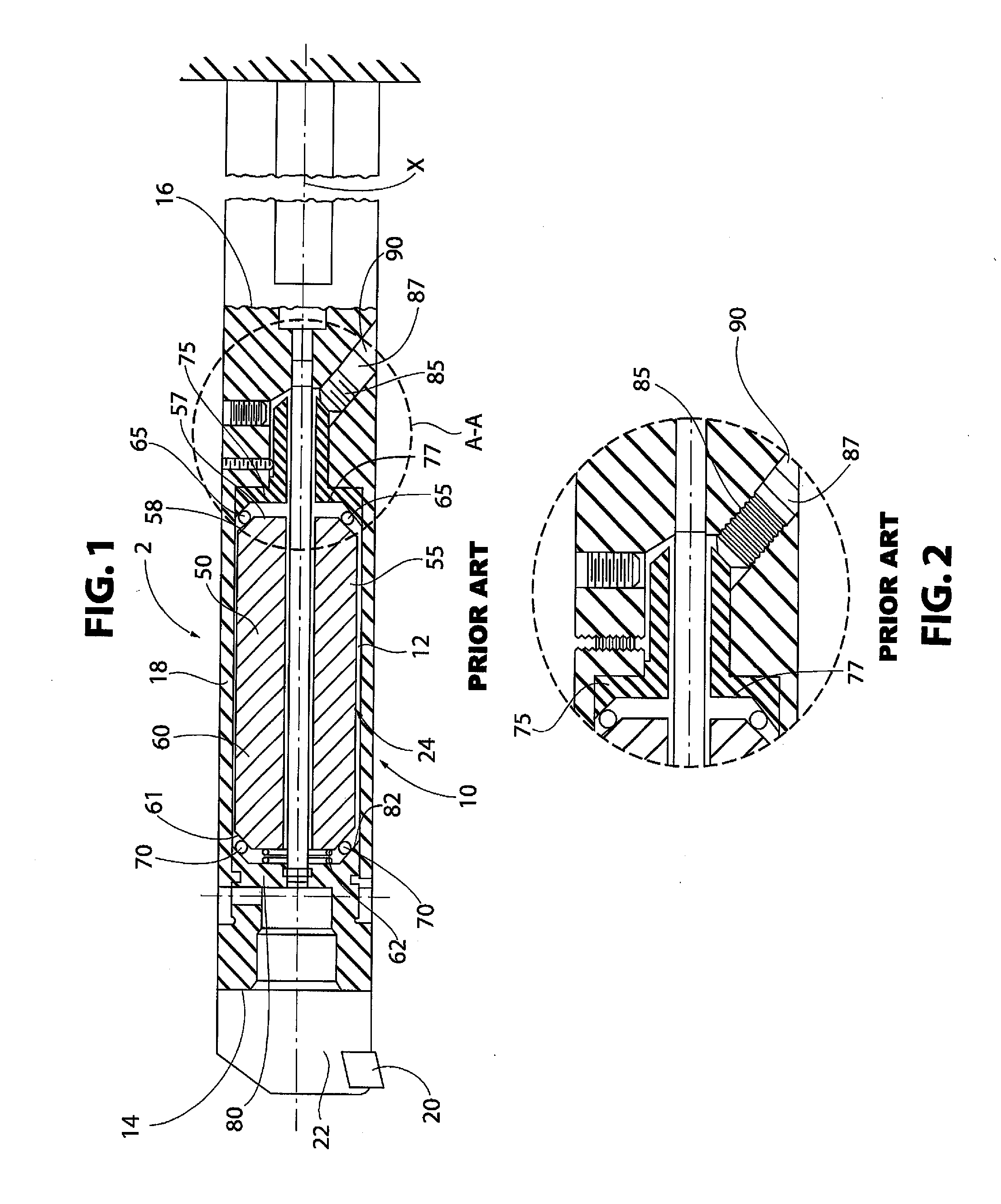

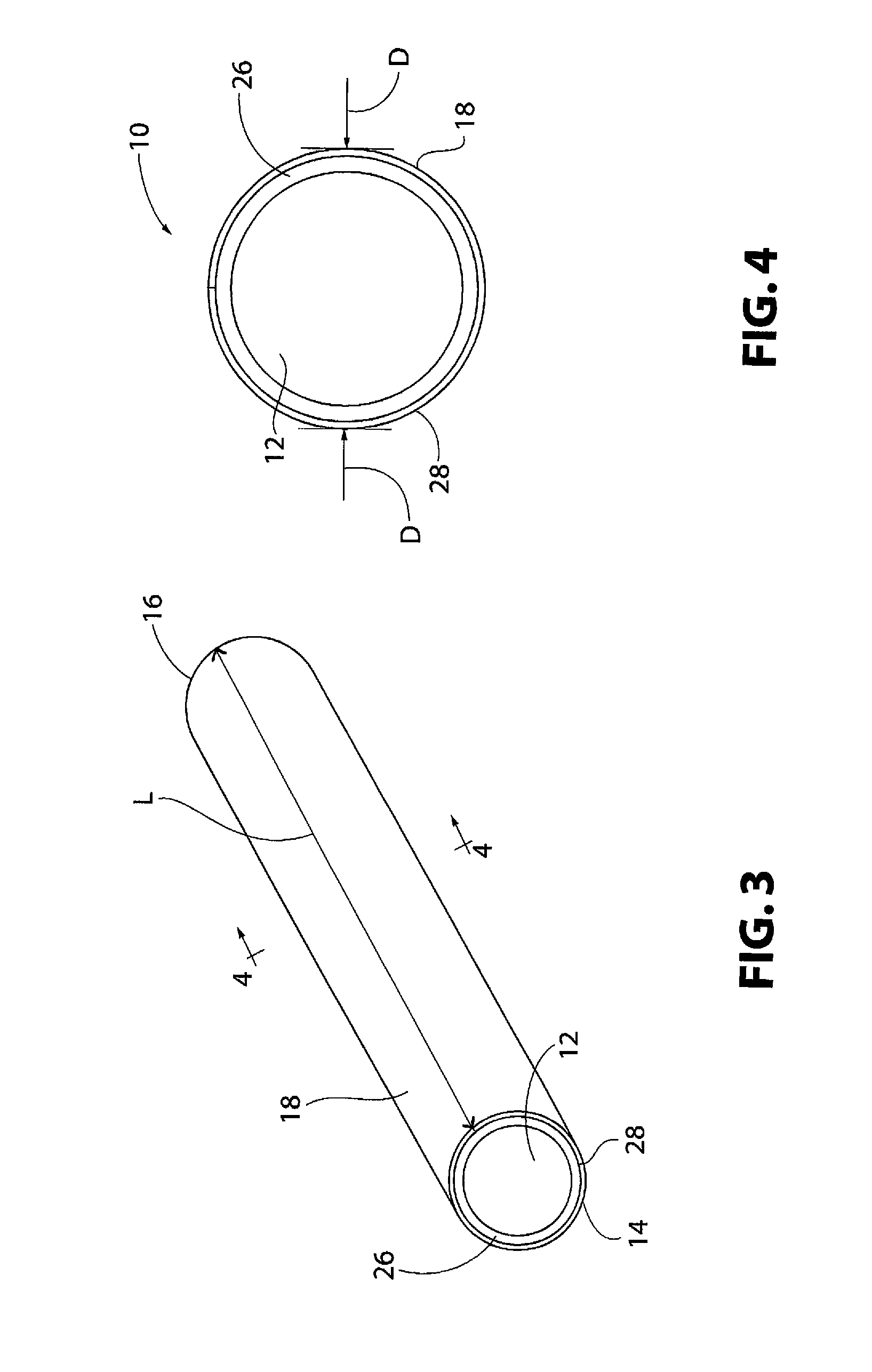

"Boring Bar with Improved Stiffness"

ActiveUS20150258612A1High dynamic stiffnessImprove dynamic stiffnessTransportation and packagingWorkpiecesDistal portionPlasma diffusion

A tunable or tuned boring bar having increased stiffness is provided. Increasing the stiffness of the bar increases the natural frequency, thereby reducing directional deformation of the bar during use. The tunable boring bar includes a distal portion configured to support a tool, a proximal portion configured for attachment to a support structure of a metalworking machine, and a body, which is at least partially tubular, extending between the proximal portion and the distal portion. The tubular portion of the body has an elongated cylindrical cavity. The body of the boring bar includes a core layer formed from a first material and a coating layer formed from a second material. The second material has a higher modulus of elasticity than the first material. In certain configurations, the coating layer is bonded to the core layer by cladding, welding, chemical adhesives, chemical vapor deposition, pulsated plasma diffusion, or combinations thereof.

Owner:KENNAMETAL INC

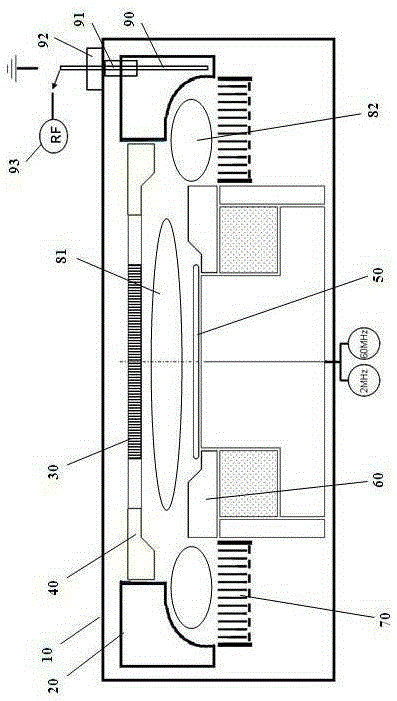

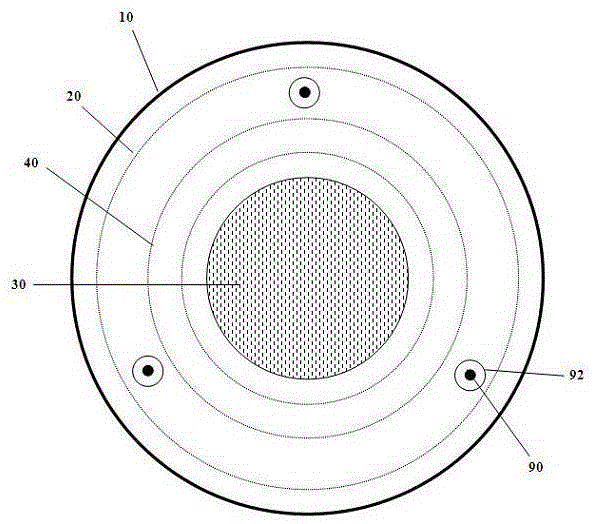

Plasma processing equipment and cleaning system and method thereof

ActiveCN106548914AAvoid the problem of etching eccentricityIt has the effect of radio frequency shieldingElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma diffusionRadio frequency

The invention relates to plasma processing equipment and a cleaning system and method thereof. A mobile ring is arranged at the inner side of a chamber wall of a reaction chamber and an electrode is arranged in the mobile ring; the electrode communicates with a radio frequency power supply through a selector switch, so that edge plasma is formed in an edge region within a plasma diffusion range limited by the mobile ring; or the electrode communicates with a ground circuit through the selector switch, so that a radio frequency electric field formed in the reaction chamber is shielded on the chamber wall of the reaction chamber. According to the plasma processing equipment, the cleaning effect on edge components of the chamber can be strengthened, or the effect of shielding a radio frequency of the chamber wall to improve eccentric etching is achieved.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

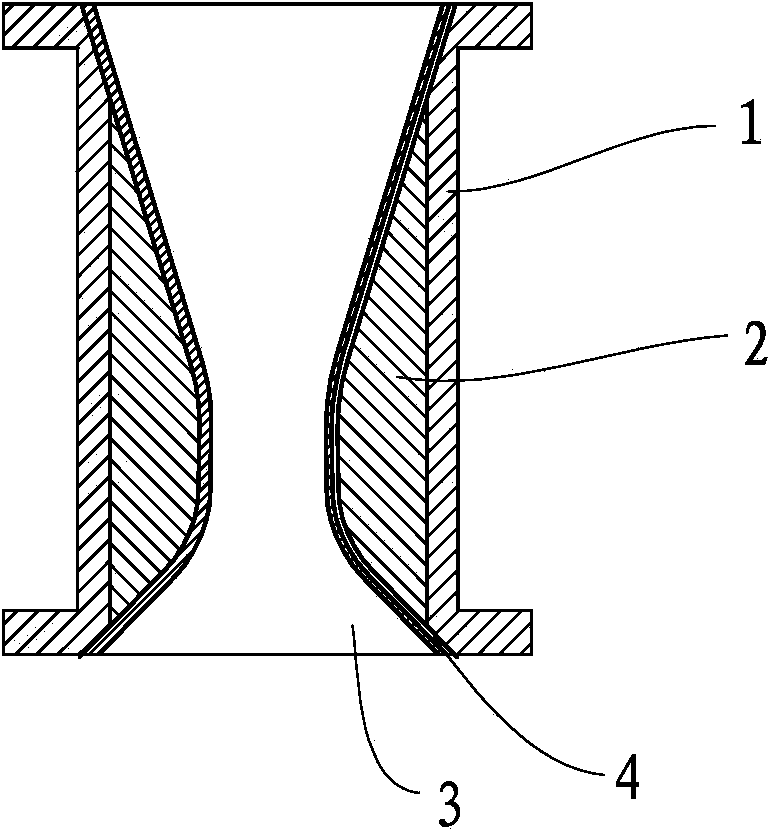

Discharge plasma diffusion welding manufacture method for Laval nozzles

ActiveCN103537789AWidely used valueSolve process problemsMetal working apparatusJet propulsion plantsPlasma diffusionMicrometer

The invention relates to a discharge plasma diffusion welding manufacture method for Laval nozzles and belongs to the welding field. The method comprises the steps of (1) blanking, (2) machine shaping, wherein the welding position roughness <= 1.6 micrometers; (3) chemical degreasing and surface oxide removing; (4) drying, which is performed in a drying box of an air blower; (5) assembly; (6) discharge plasma diffusion welding; (7) finish turning. The method has the advantages that the process problem of discharge plasma diffusion welding of or Laval nozzle components is solved, and a positive role is played in the promotion and application of the diffusion welding of the Laval nozzle components in spacecrafts; the welded rate is high, and the joint strength is identical to the strength of base materials; the member deformation is small, the size accuracy is high, and product design requirements can be met; the method is free of environmental pollution and capable of being automated easily.

Owner:SICHUAN FUTURE AEROSPACE IND LLC +1

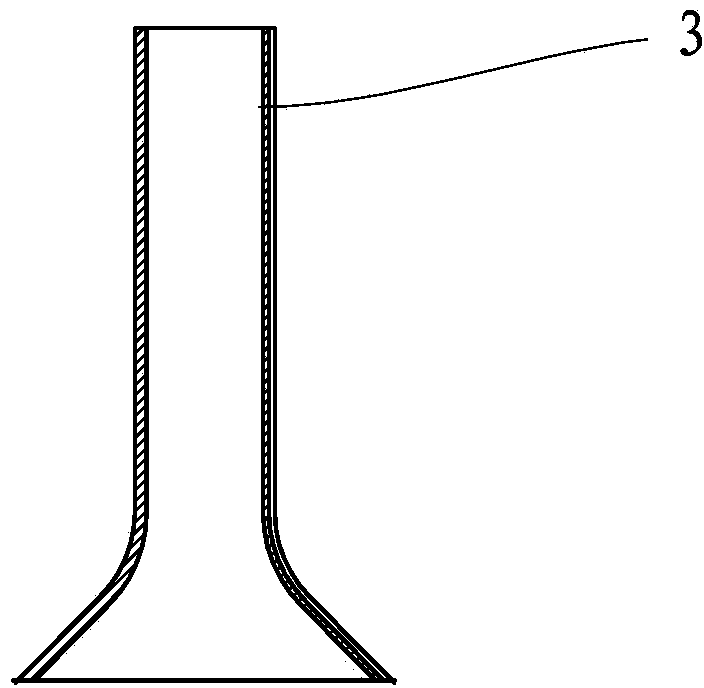

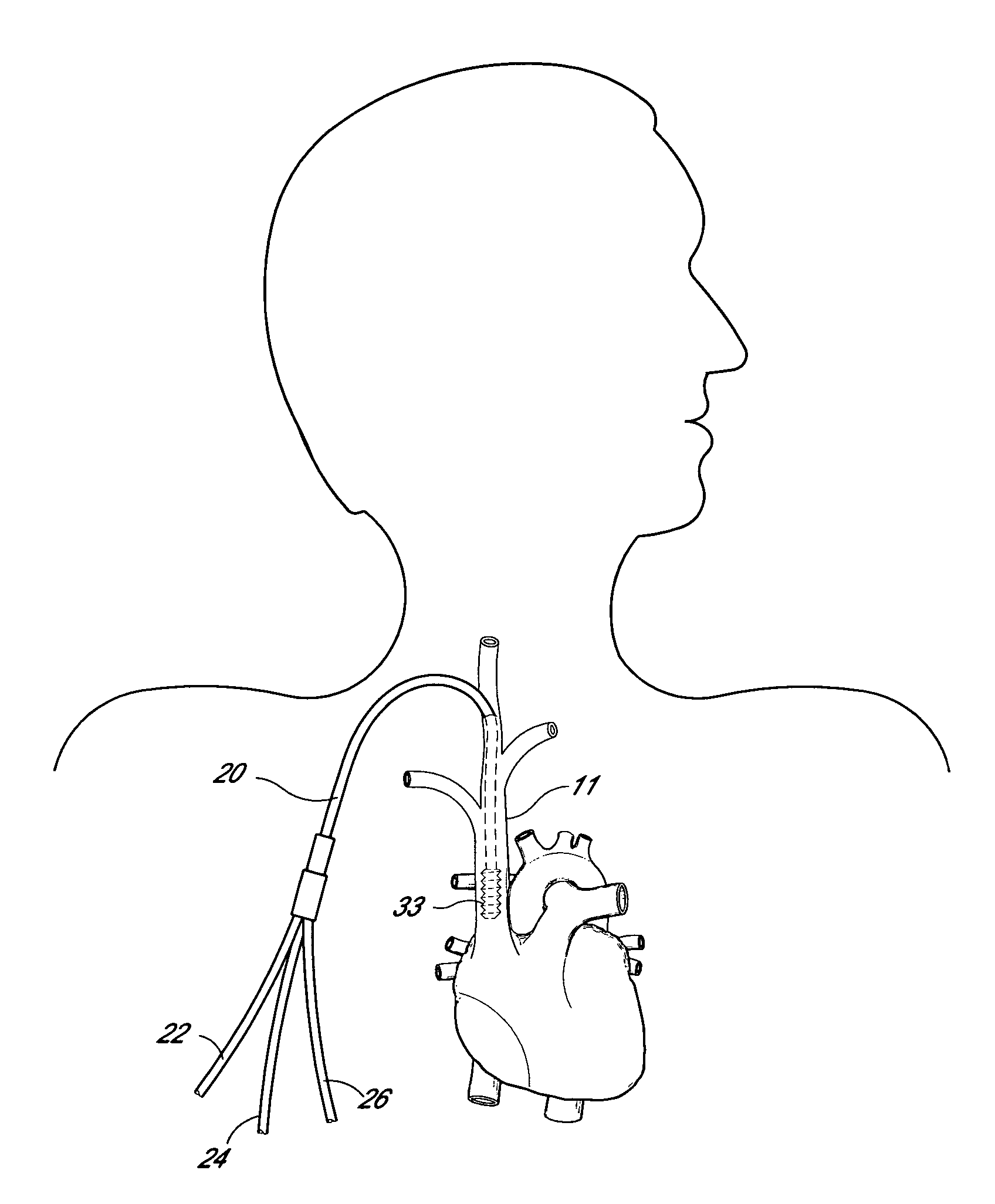

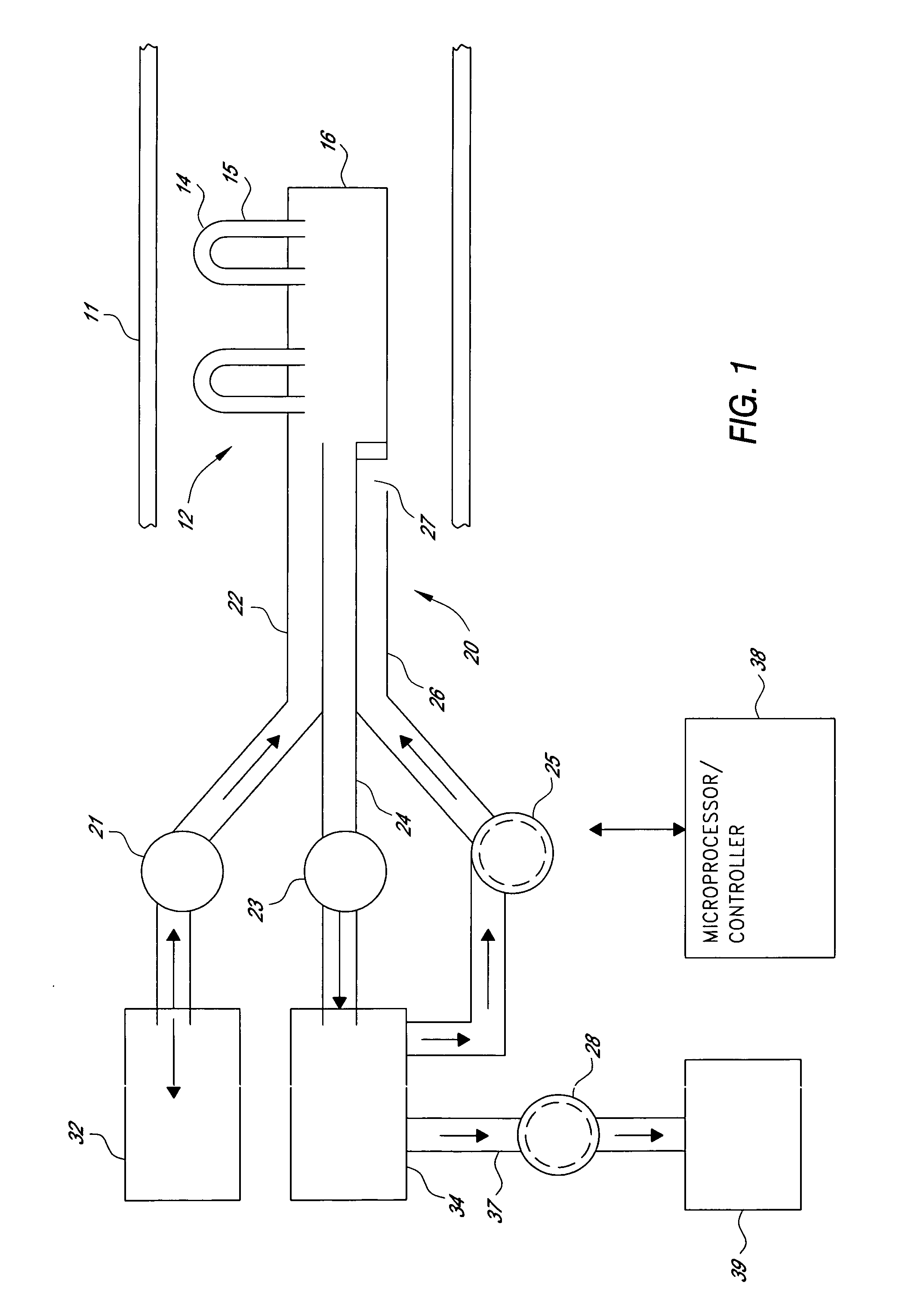

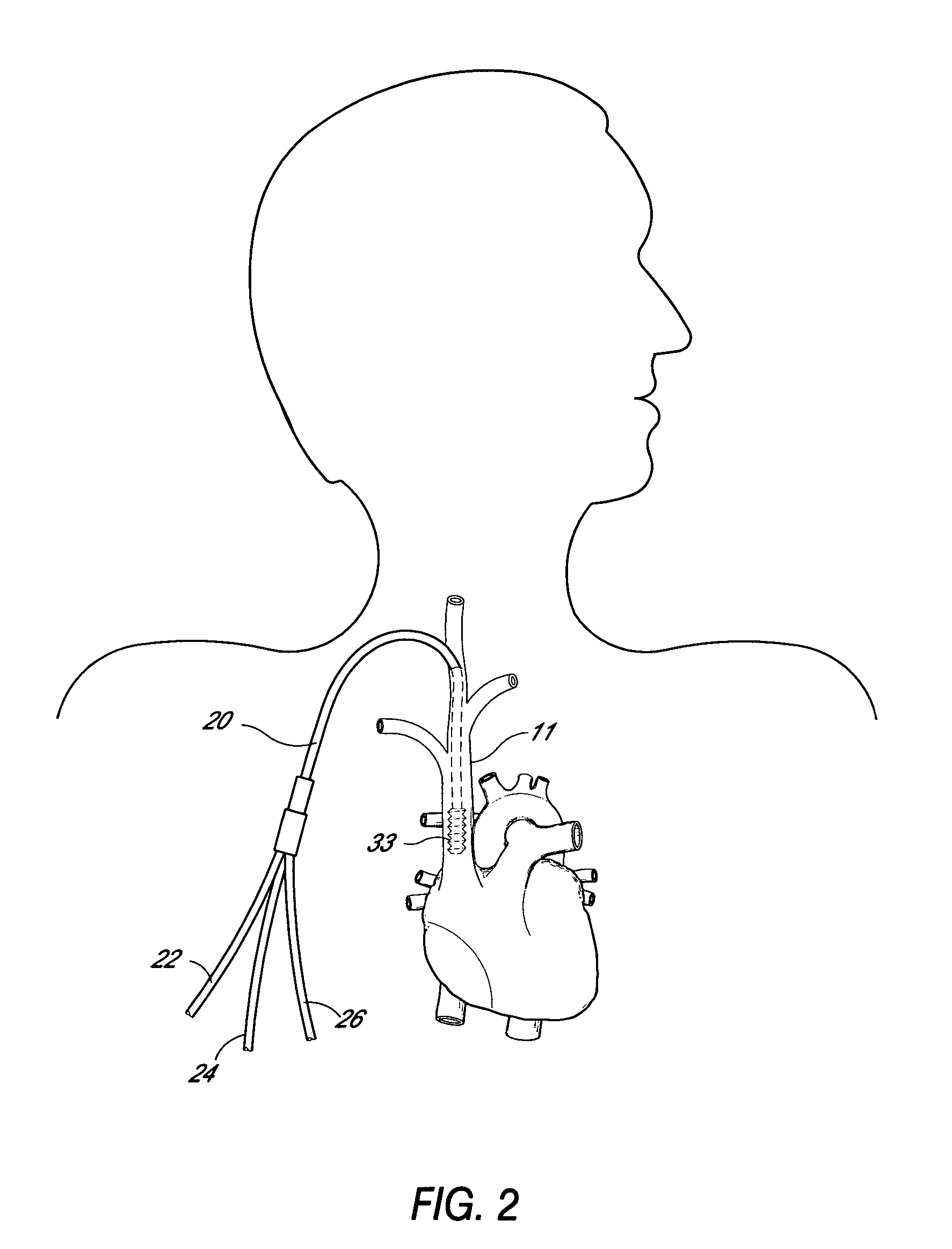

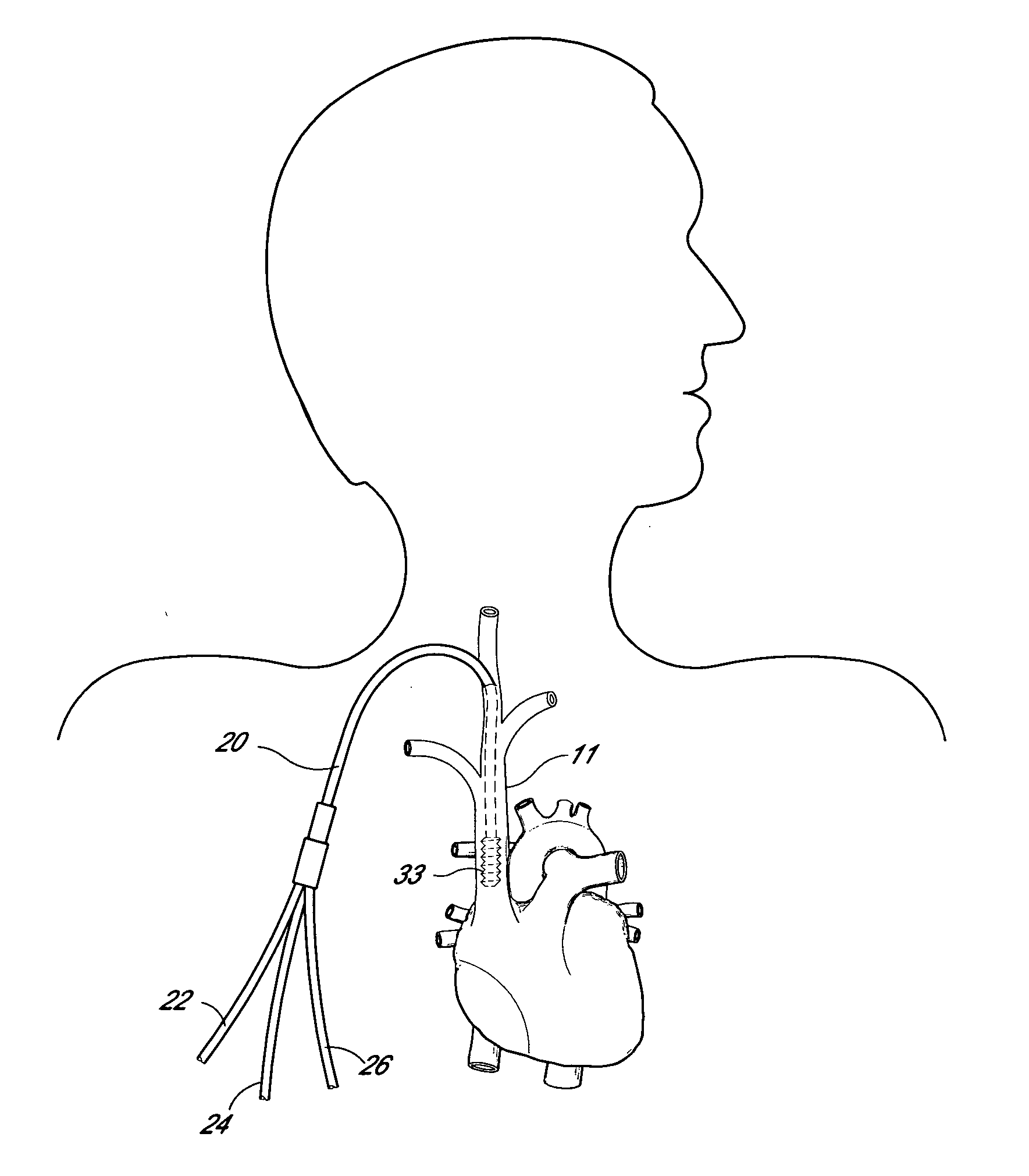

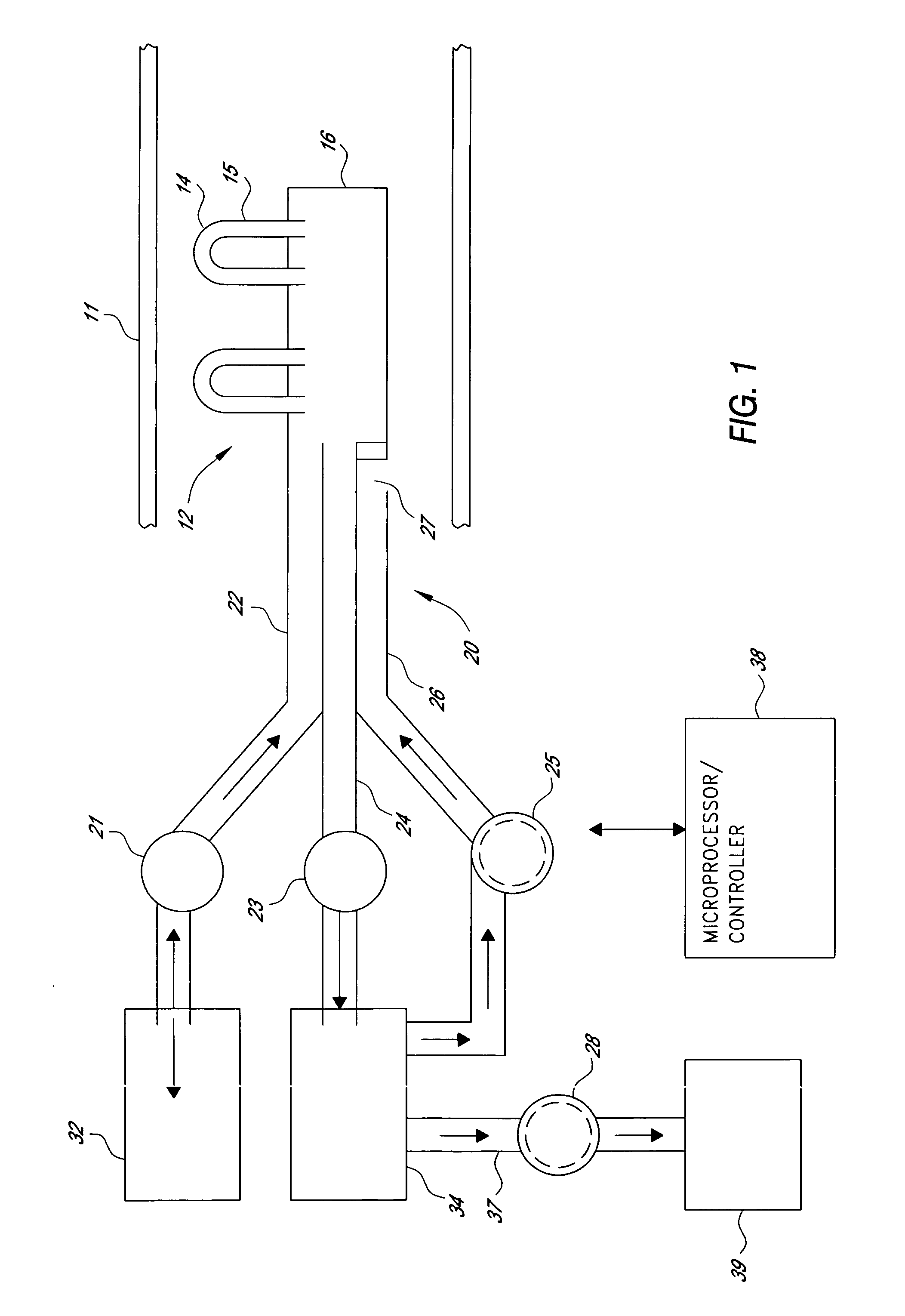

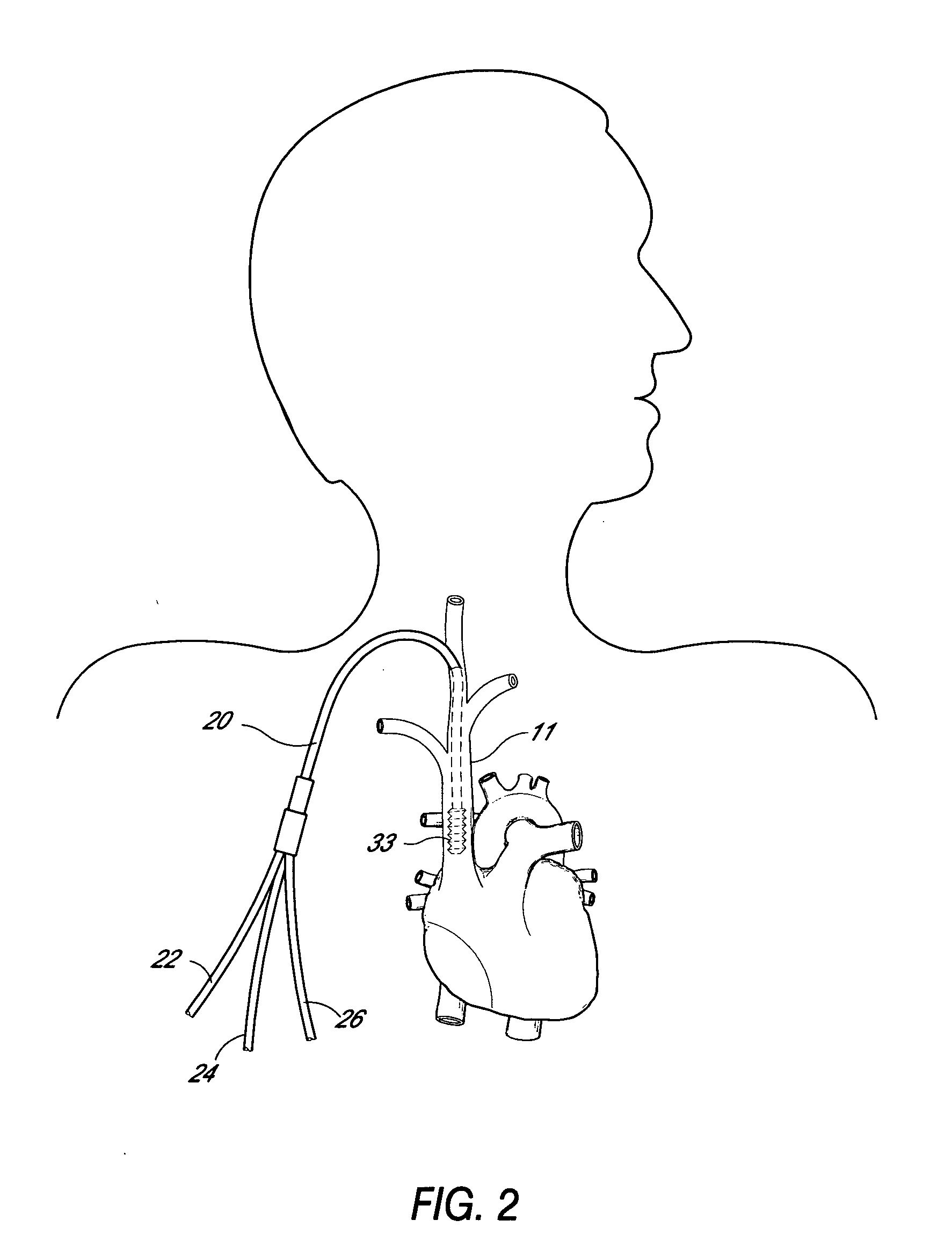

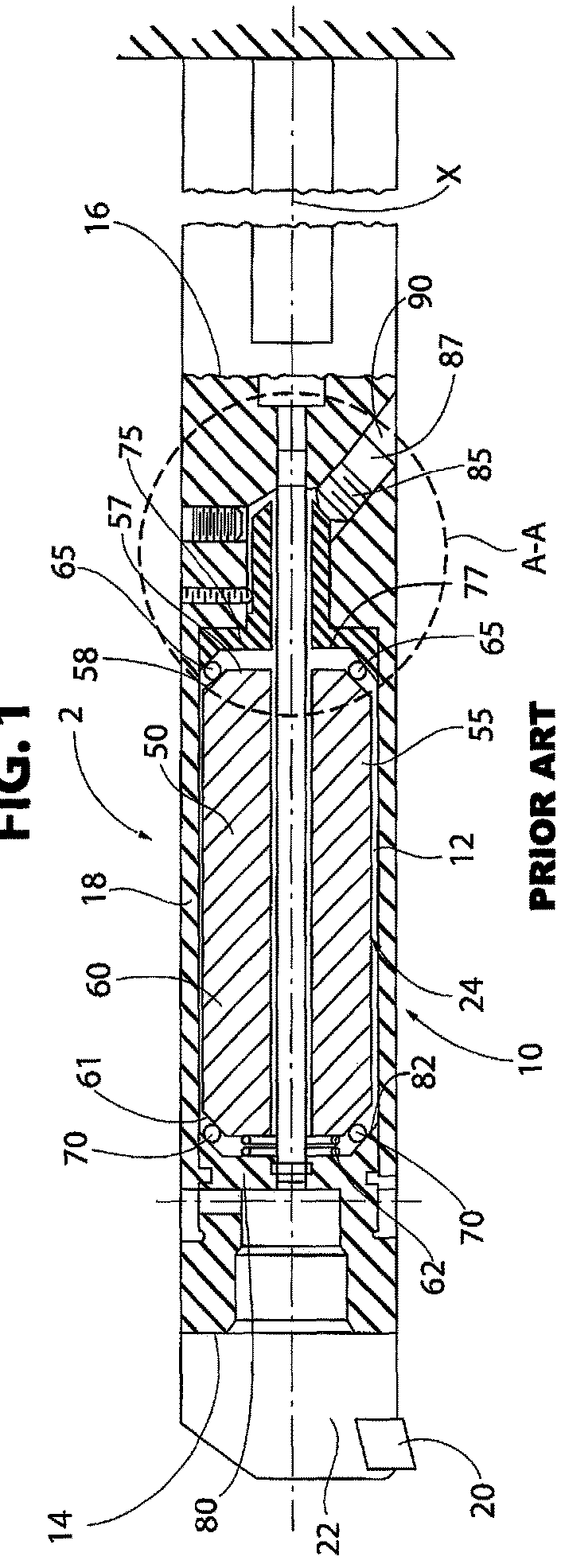

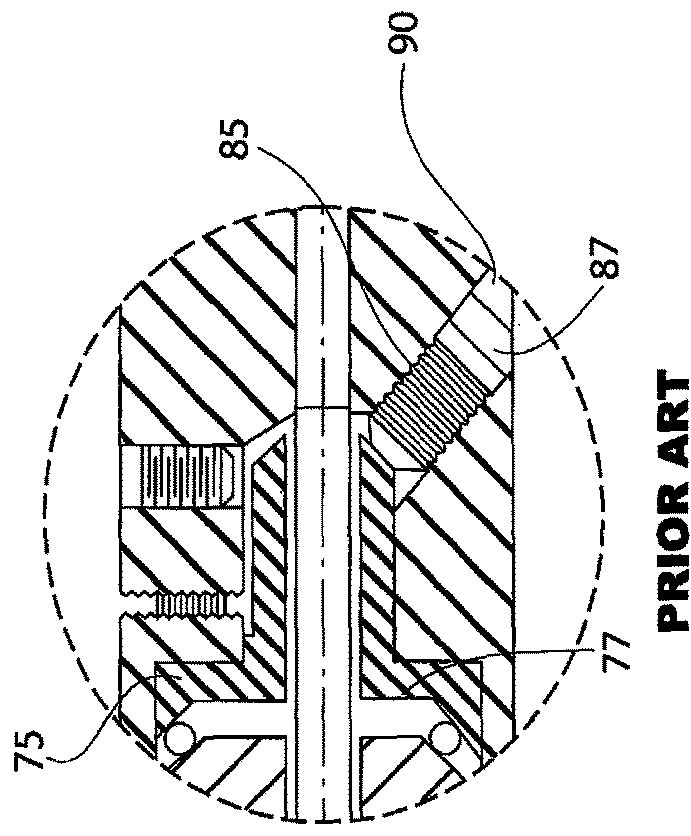

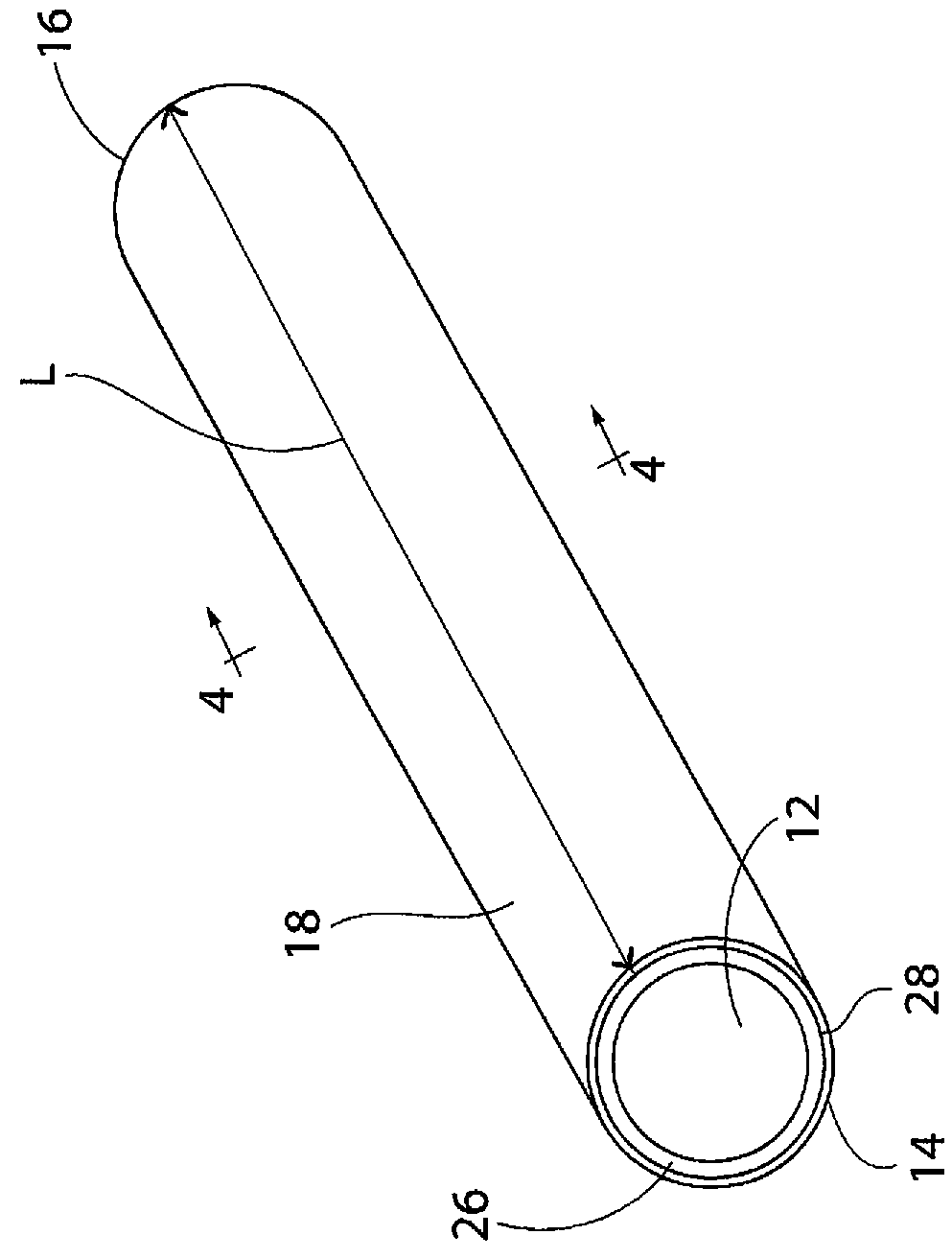

Apparatus and method for in-vivo plasmapheresis using periodic backflush containing anticoagulant

Method for in-vivo plasmapheresis utilizing a plurality of elongated hollow microporous filter fibers periodically interrupt diffusion of blood plasma from a patient, and, for a selected time, directing backflush fluid into the fibers at a pressure and interval sufficient to cleanse the fiber pores, after which plasma diffusion is resumed. The backflush fluid, preferably a normal saline solution, may contain an anticoagulant such as heparin, citrate or NO donor in suitable concentration for systemic anti-coagulation or for treating the fiber for thromboresistance.

Owner:TRANSVIVO

Hybrid PiN junction Schottky diode and manufacturing method thereof

ActiveCN110571281AImprove surge current capabilityAvoid local heatingFinal product manufactureSemiconductor/solid-state device manufacturingPower flowPlasma diffusion

The invention discloses a hybrid PiN junction Schottky diode and a manufacturing method thereof. The hybrid PiN junction Schottky diode comprises a plasma diffusion layer and a semiconductor region, wherein the semiconductor region is arranged below the surface of an epitaxial layer; the semiconductor region comprises a plurality of cells, and each cell comprises a first region and a plurality ofsecond regions; the plasma diffusion layer is arranged below the surface of the epitaxial layer; the plasma diffusion layer comprises a plurality of plasma diffusion channels; each plasma diffusion channel is communicated with the first regions in the two cells and penetrates through the second regions in the cells; and the first region, the plurality of second regions, the plasma diffusion layerand the epitaxial layer form a PN junction of the hybrid PiN junction Schottky diode. Thus, the surge current resistance of the hybrid PiN junction Schottky diode can be improved.

Owner:山东天岳电子科技有限公司

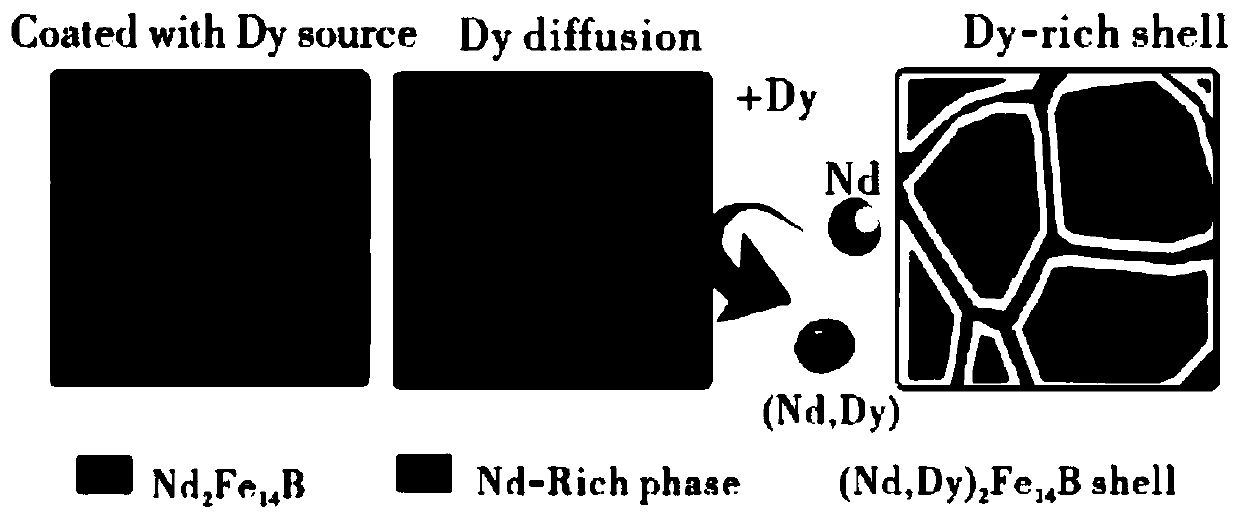

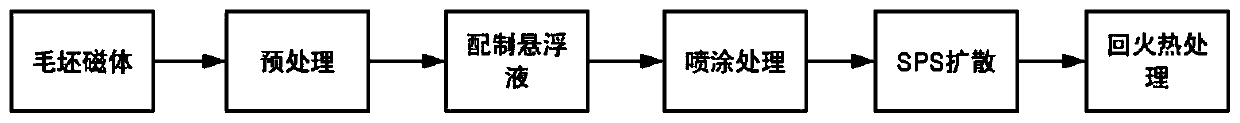

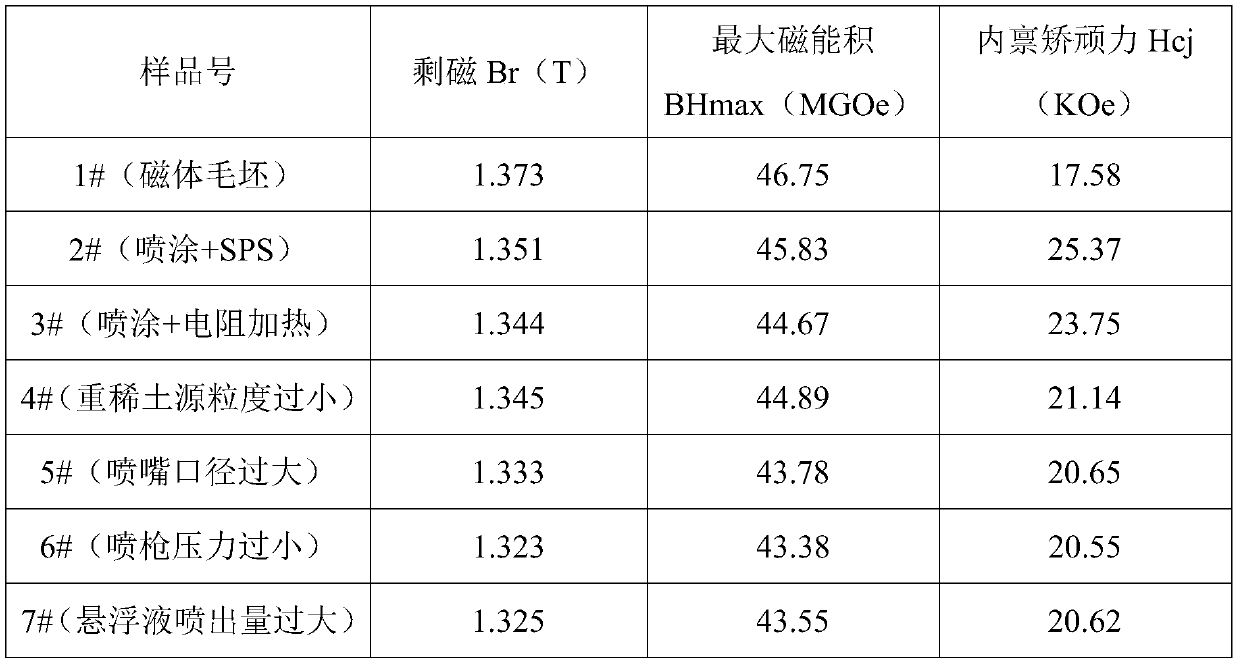

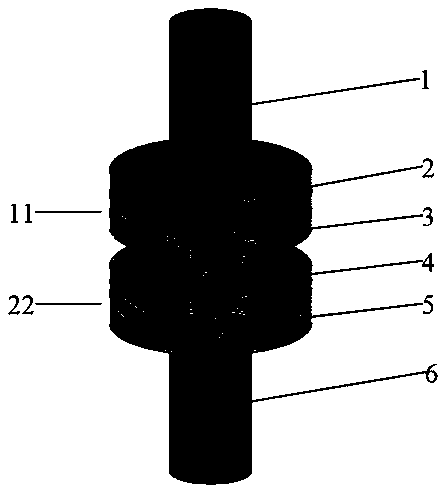

Preparation method of sintered neodymium-iron-boron magnet with high magnetic energy product and high coercivity

InactiveCN110534331AGuaranteed thickness uniformityGuaranteed thickness consistencyInductances/transformers/magnets manufactureMagnetic materialsState of artHydrogen

The invention discloses a preparation method of a sintered neodymium-iron-boron magnet with high magnetic energy product and high coercivity. The method comprises the steps that firstly, a sintered neodymium-iron-boron rough magnet is prepared through the processes of batching, melting stripping, hydrogen explosion, air milling, magnetic field molding, sintering and machining; then pretreatment steps including derusting, degreasing, pickling and cleaning are carried out on the rough magnet; the rough magnet is sprayed and coated with a prepared heavy rare earth suspension; and finally spark plasma diffusion treatment (SPS) and tempering heat treatment are carried out on the magnet sprayed with the heavy rare earth adhesion layer to acquire the sintered neodymium-iron-boron magnet. Compared with the prior art, the preparation method provided by the invention has the advantages of excellent utilization of heavy rare earth, high processing efficiency, low production cost, high magneticproperty consistency and the like, is easy to realize commercial applications, can well meet customer needs, and is suitable for preparing the low-costed sintered neodymium-iron-boron magnet with highmagnetic energy product and high coercivity.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

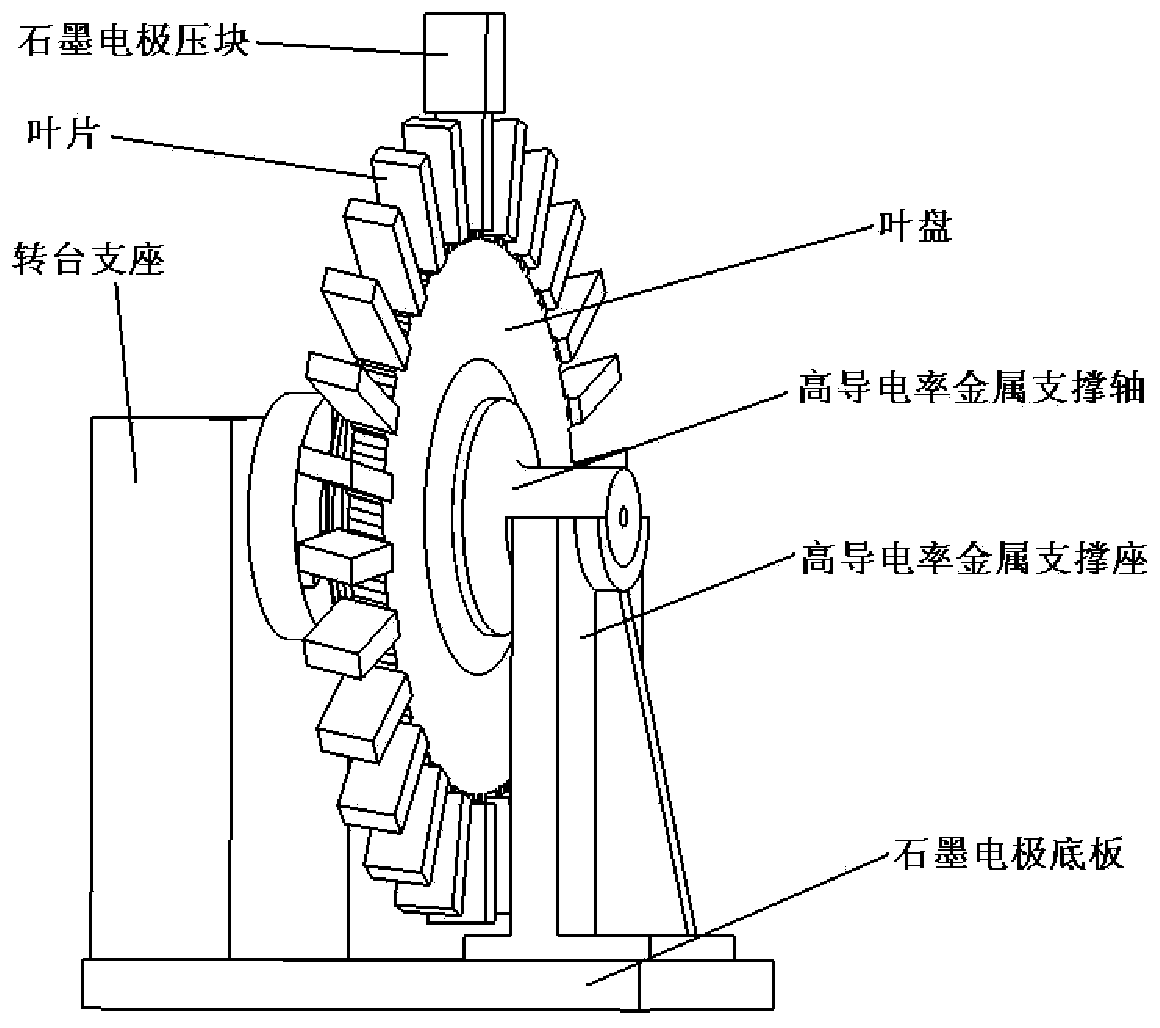

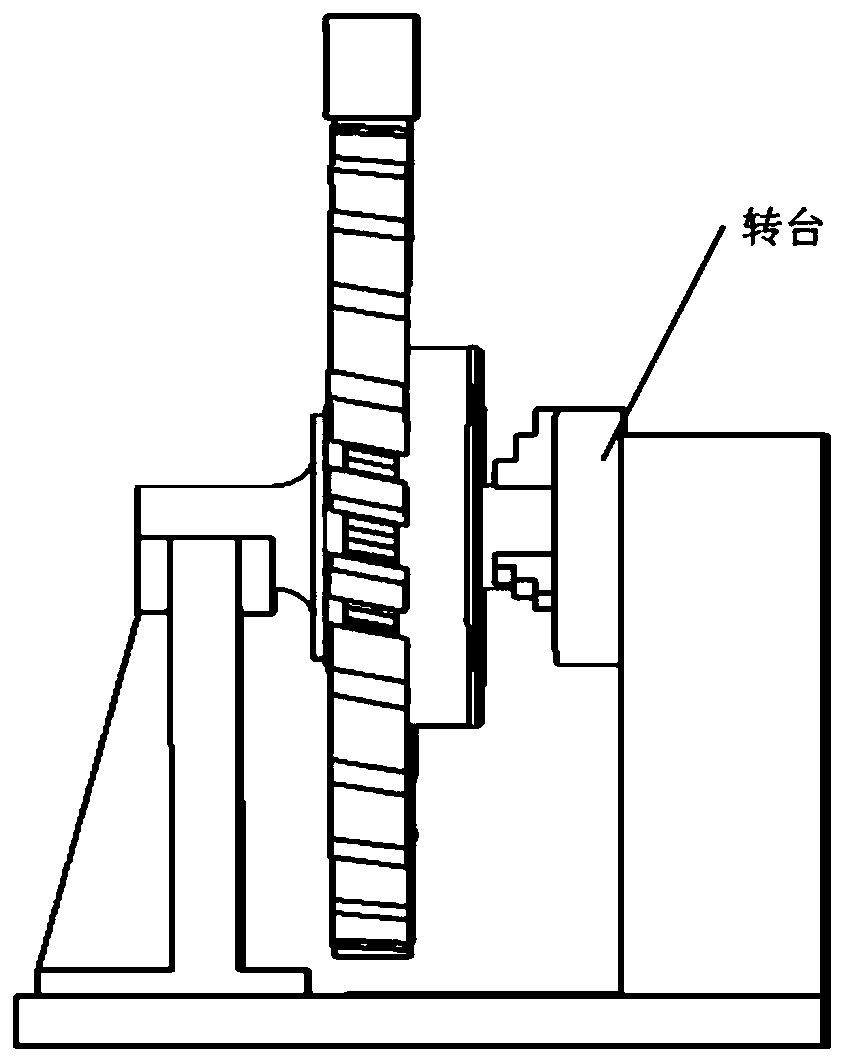

Manufacturing method for dissimilar alloy integral blade disc structure

ActiveCN110303259ASolve difficultyMeet the needs of high-performance blisksWelding apparatusPlasma diffusionAlloy

The invention relates to a manufacturing method for a dissimilar alloy integral blade disc structure. The method comprises the steps that a blade disc is rotationally and axially mounted on a high-conductivity metal support base through a high-conductivity metal support shaft, and the support base is mounted on a graphite electrode bottom plate; and after blades and the blade disc are assembled, discharge plasma diffusion welding is adopted for welding, during welding, the upper portions of the blades are pressed through a graphite electrode pressing block, direct current pulse current is connected between the graphite electrode pressing block and the graphite electrode bottom plate, discharge plasma is generated, diffusion welding of the blades and the blade disc is rapidly achieved underthe action of impact pressure, joule heat and an electric field, all the blades are welded to the blade disc, and the integral blade disc is obtained, wherein the blades and the blade disc are prepared from different alloys. Through the discharge plasma diffusion welding method, the problems of high manufacturing difficulty and high scrap rate of integral blade discs are solved, the performance and economic complementarity advantages of the dissimilar alloys are fully achieved, and the demand for the high performance integral blade disc of aeroengines is met.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

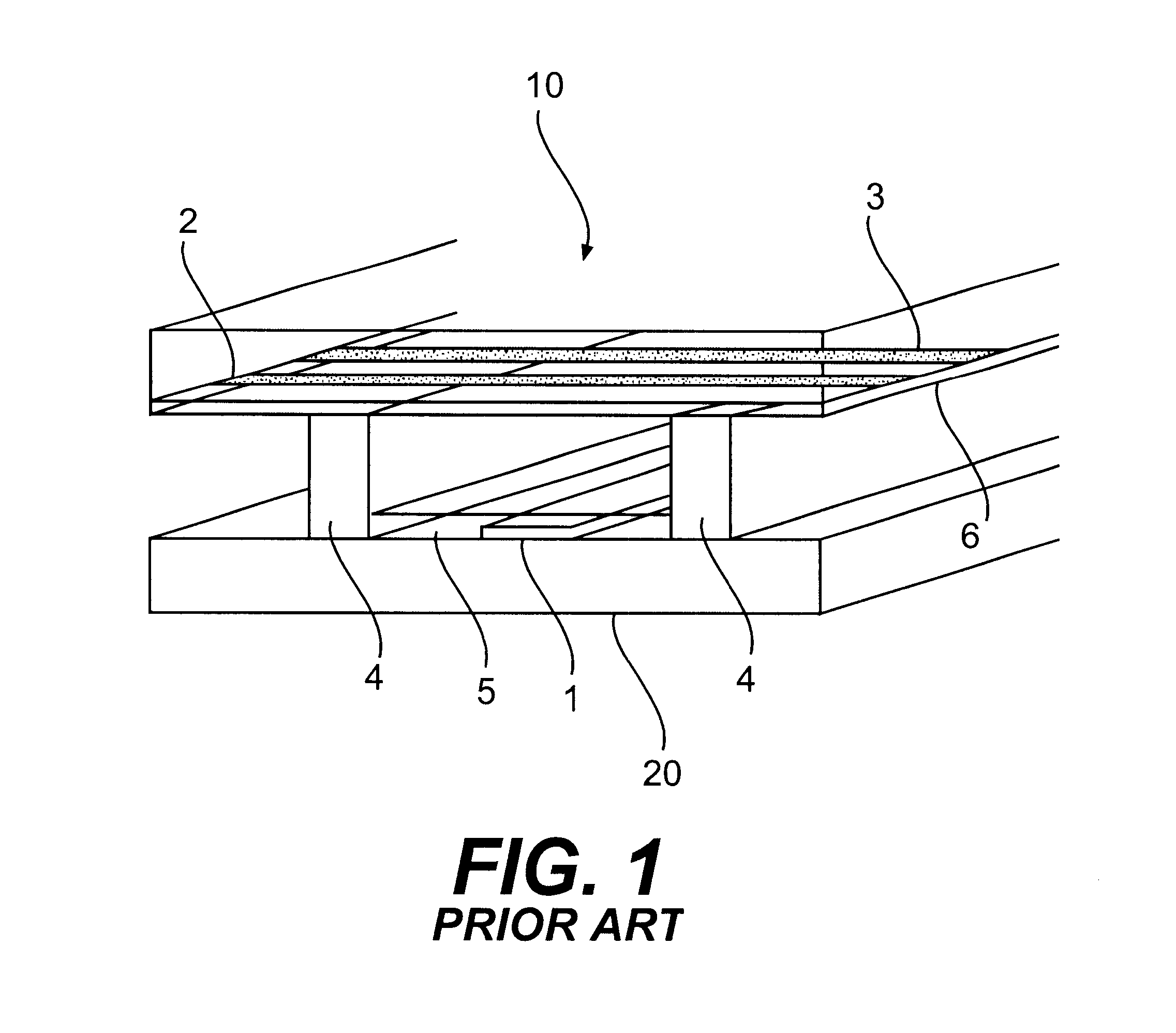

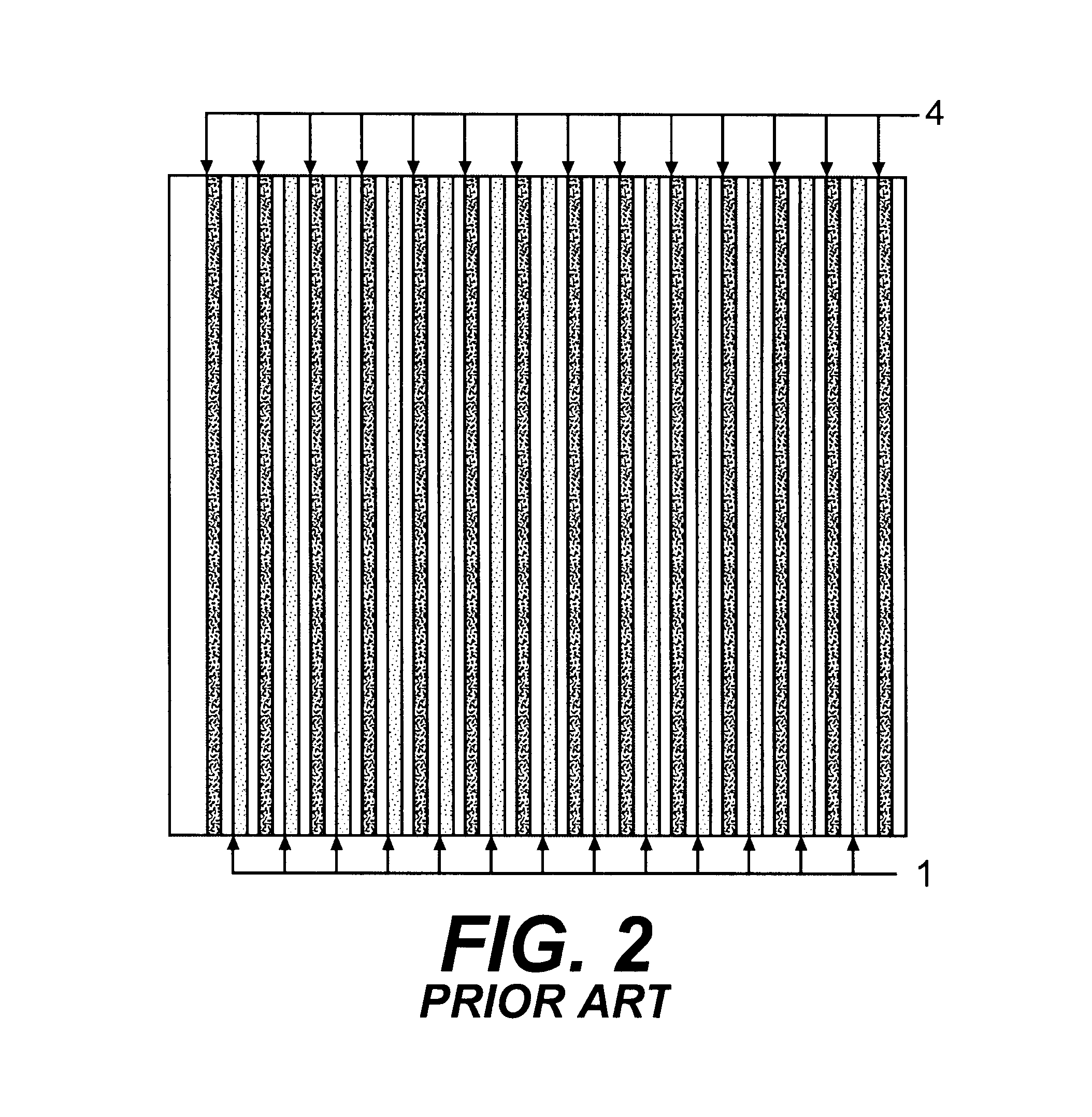

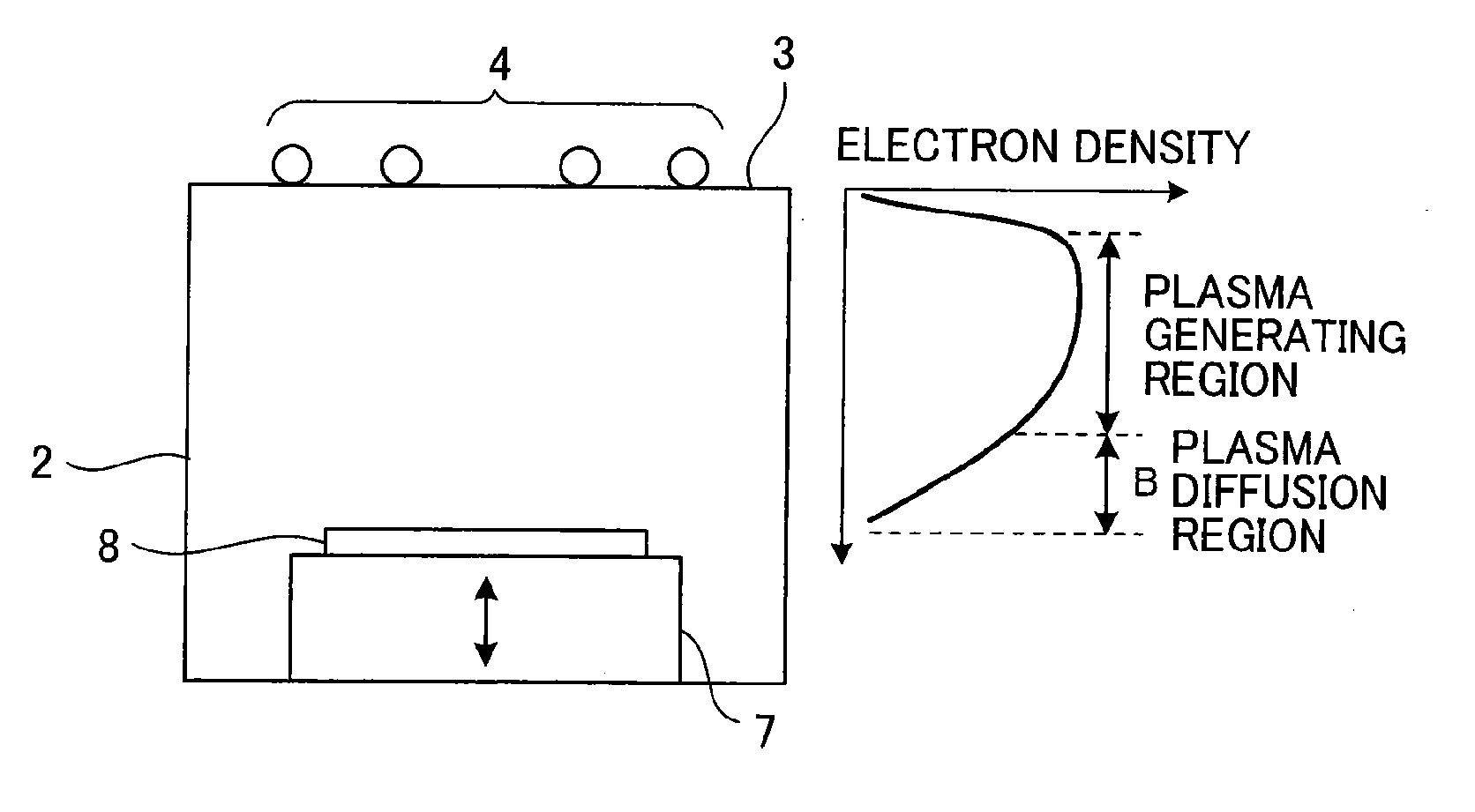

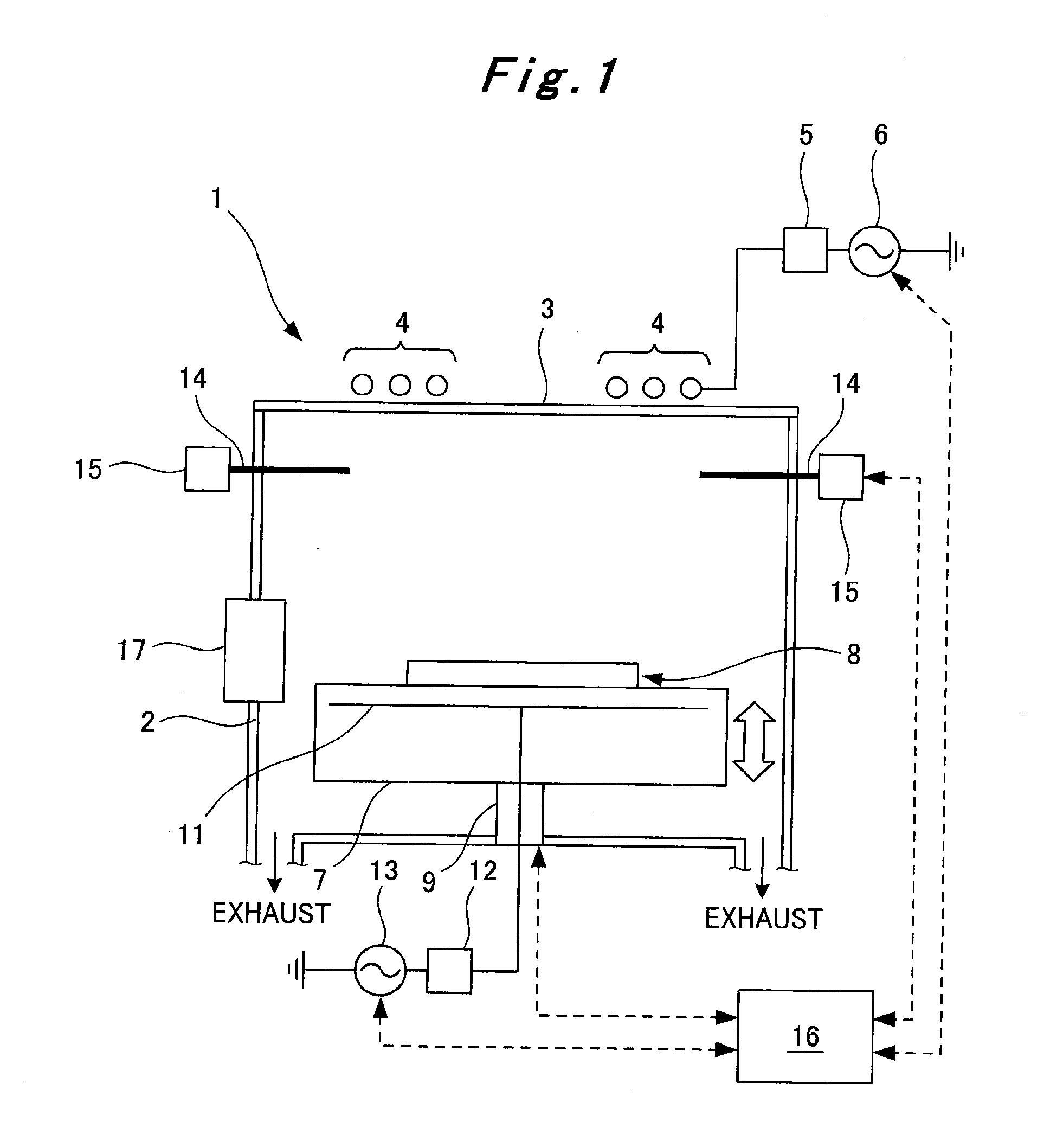

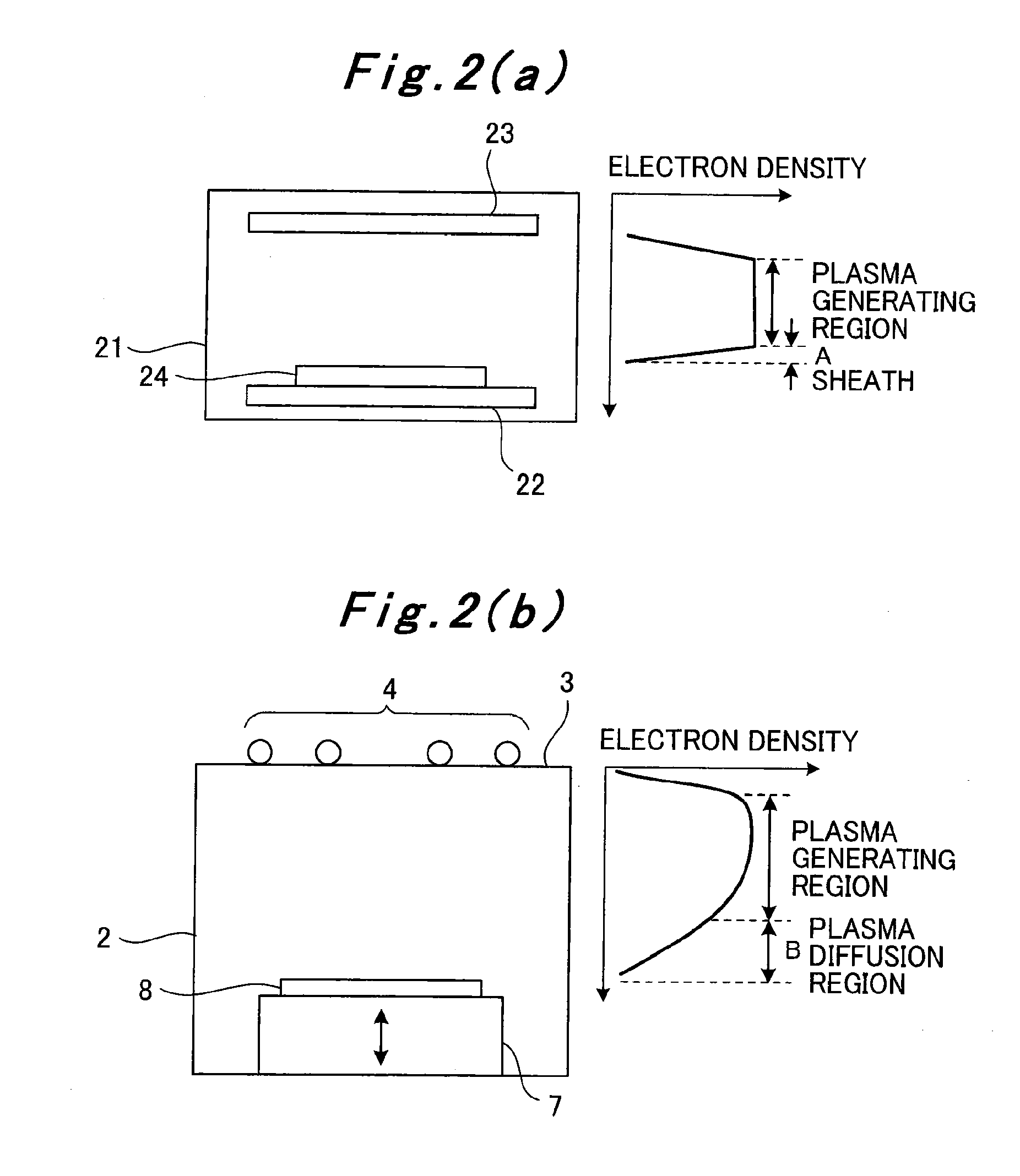

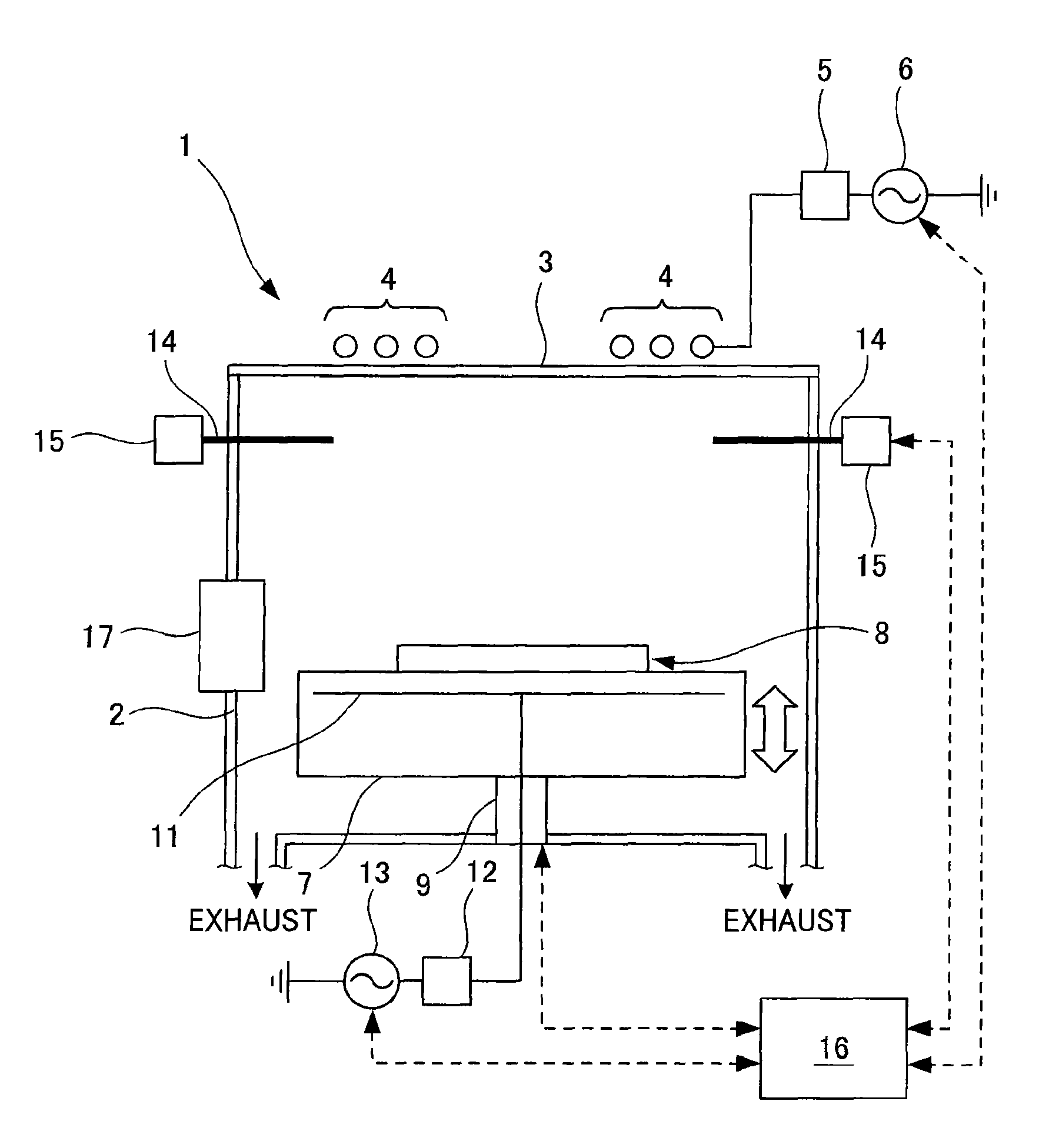

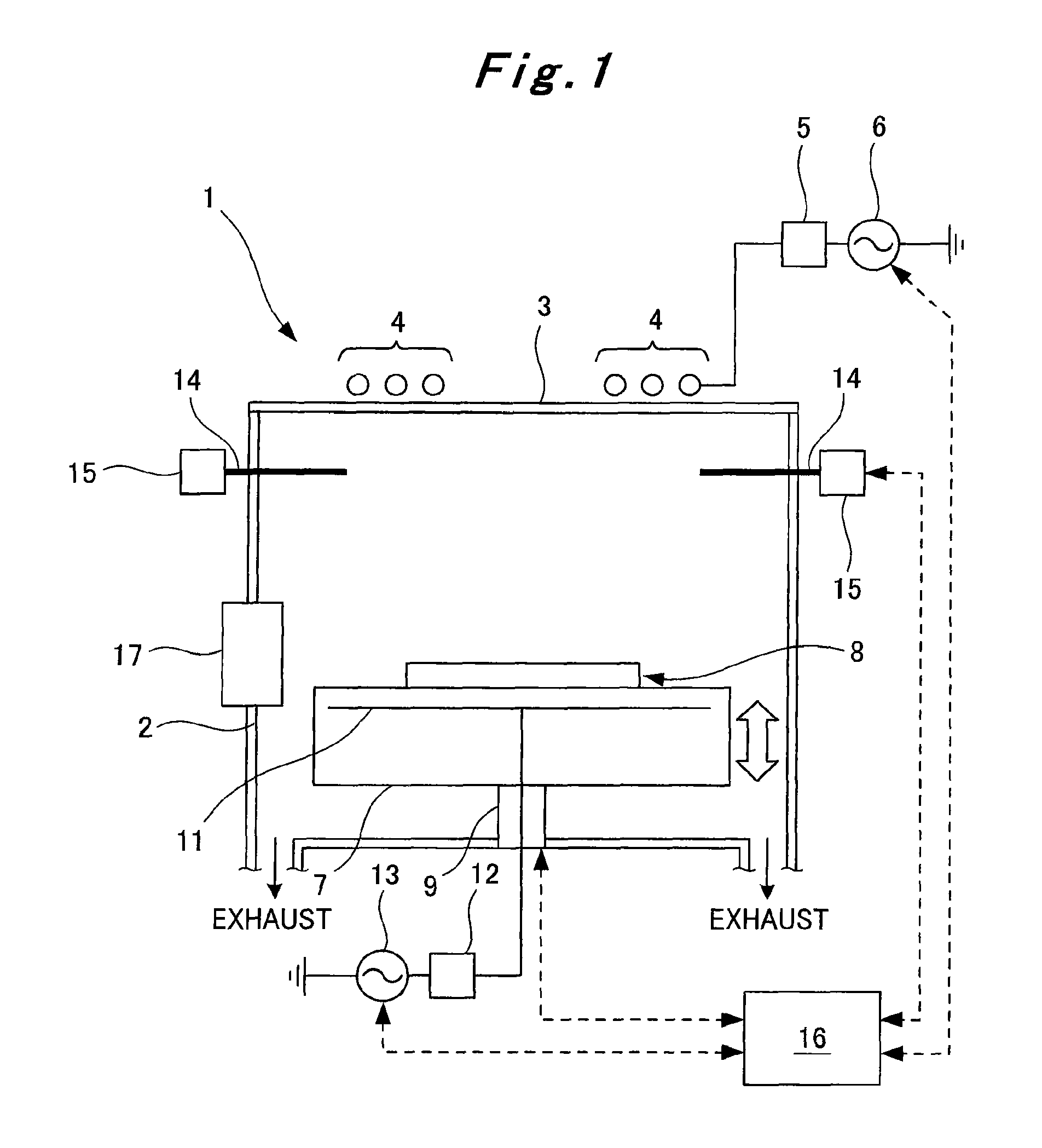

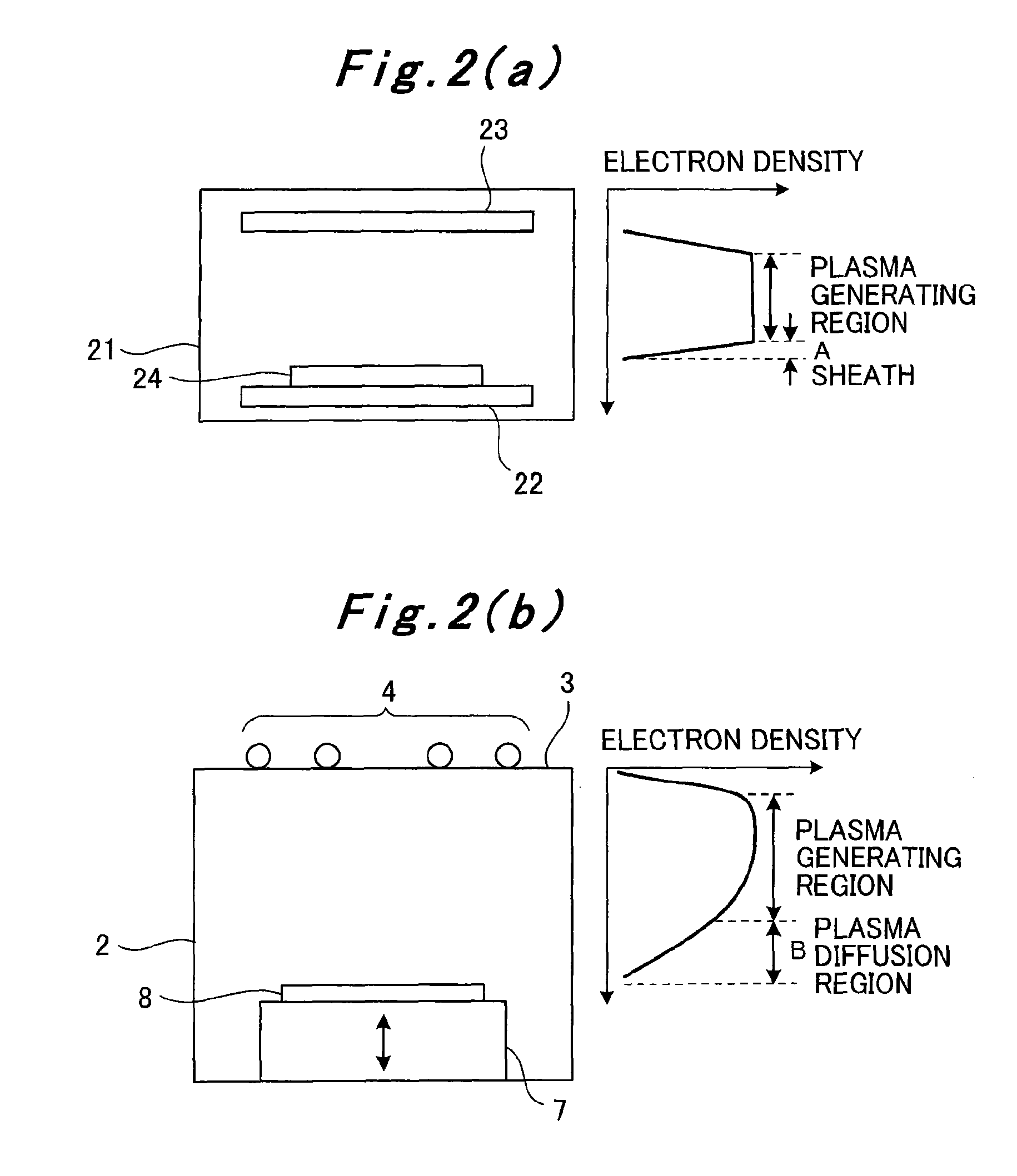

Insulating film for semiconductor device, process and apparatus for producing insulating film for semiconductor device, semiconductor device, and process for producing the semiconductor device

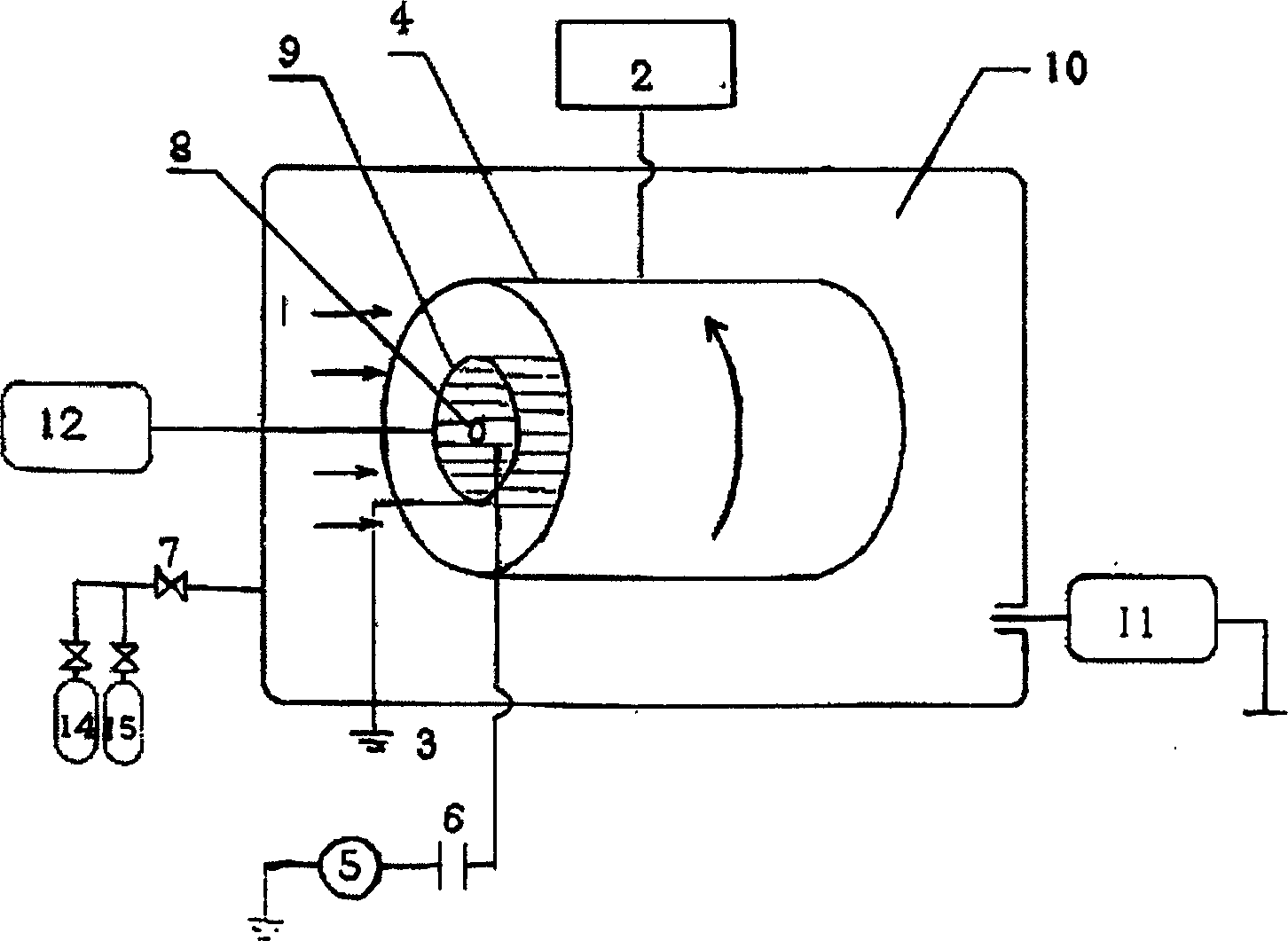

InactiveUS20110266660A1Reduce carbon contentHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesPlasma diffusionGas phase

An object is to provide an insulating film for a semiconductor device which has characteristics of a low permittivity, a low leakage current, and a high mechanical strength, undergoes less change in these characteristics with the elapse of time, and has an excellent water resistance, as well as to provide a process and an apparatus for producing the insulating film for a semiconductor device, a semiconductor device, and a process for producing the semiconductor device. A gas containing a raw material gas which gasified a predetermined alkylborazine compound is supplied in a chamber (2); an electromagnetic wave is introduced into the chamber (2) using with an inductive coupling type plasma generation mechanism (4, 5, 6) to convert the gas into a plasma; a substrate (8) is placed in a plasma diffusion region of the plasma; gas-phase polymerization is performed with borazine skeletal molecules, as a fundamental unit, dissociated from the alkylborazine compound by the plasma so as to form the insulating film for semiconductor devices on the substrate (8).

Owner:MITSUBISHI HEAVY IND LTD +1

Apparatus and method for in-vivo plasmapheresis using periodic backflush containing anticoagulant

Method for in-vivo plasmapheresis utilizing a plurality of elongated hollow microporous filter fibers periodically interrupt diffusion of blood plasma from a patient, and, for a selected time, directing backflush fluid into the fibers at a pressure and interval sufficient to cleanse the fiber pores, after which plasma diffusion is resumed. The backflush fluid, preferably a normal saline solution, may contain an anticoagulant such as heparin, citrate or NO donor in suitable concentration for systemic anti-coagulation or for treating the fiber for thromboresistance.

Owner:TRANSVIVO

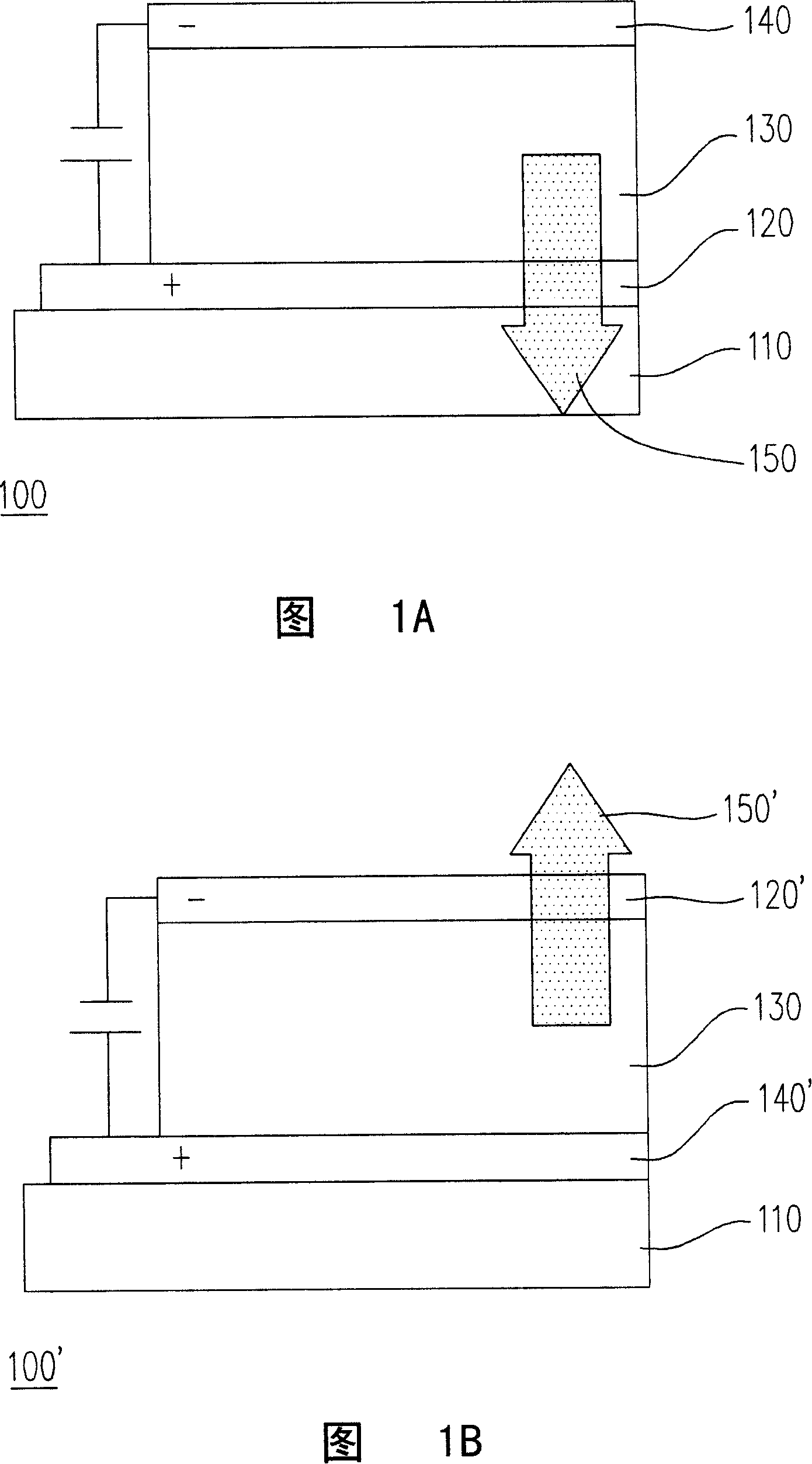

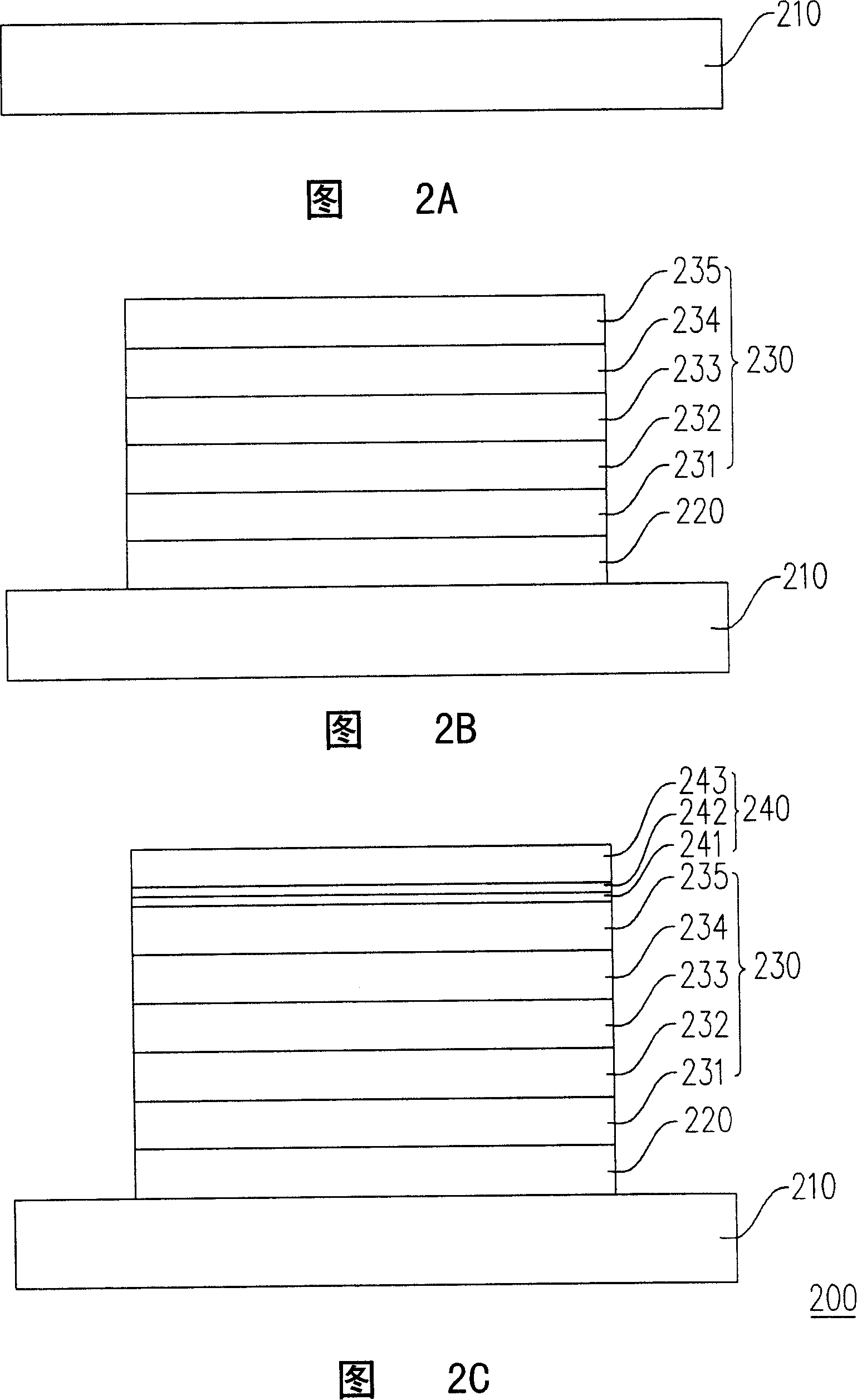

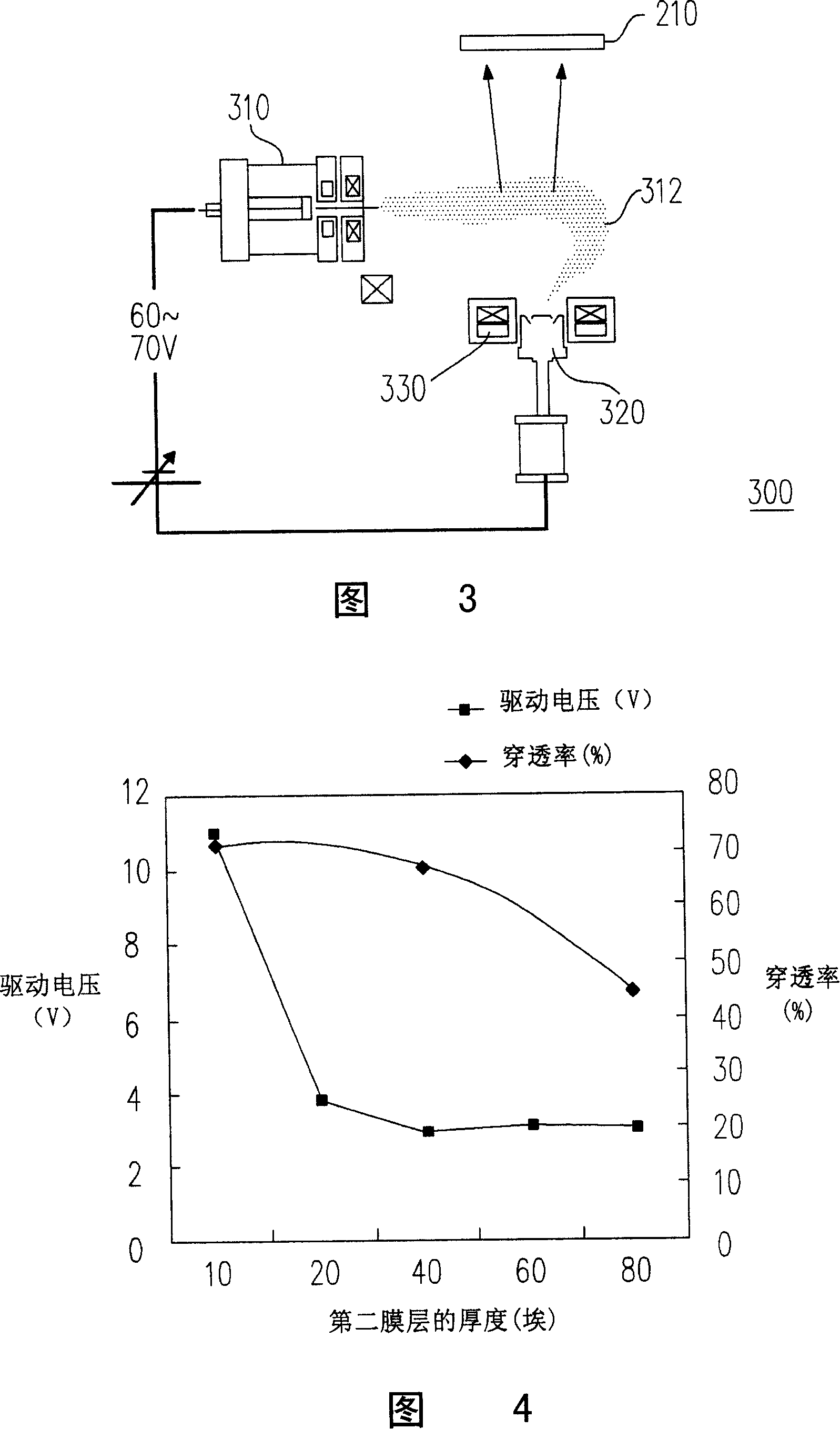

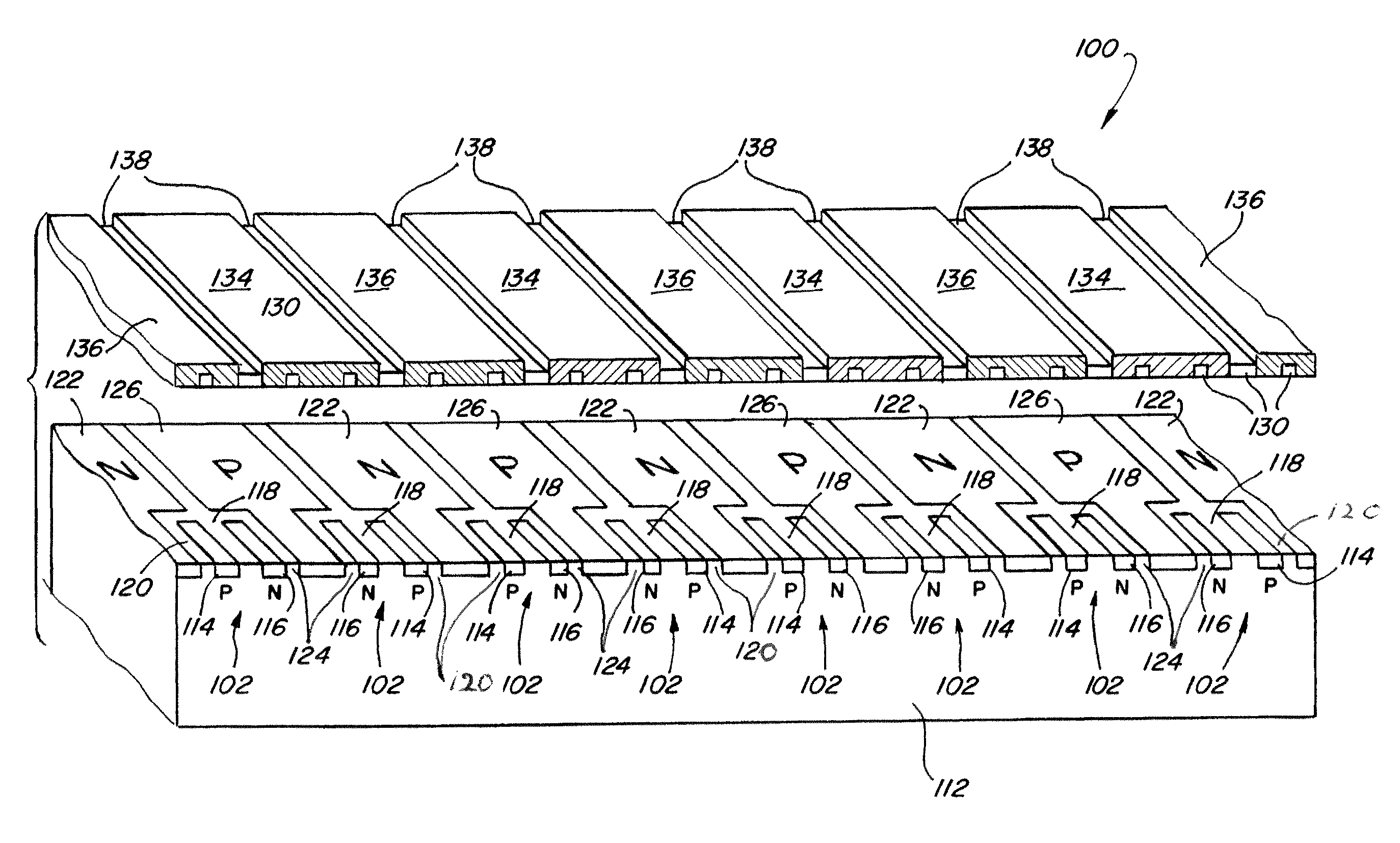

Dual-side luminescent type organic LED and its making method

InactiveCN101123302AReduce the driving voltageIncrease the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingAlkaline earth metalPlasma diffusion

The invention discloses a fabrication method of the double-sided luminescence type organic light-emitting diode, comprising the following steps. Firstly, a transparent substrate is provided; secondly, a first transparent electrode and an organic luminescent layer are formed on the transparent substrate in order; and then a second transparent electrode is formed on the organic luminescent layer. The procedure of forming the second transparent electrode comprises that a first film layer is formed on the organic luminescent layer, and the first film layer is made of an alkali metal compound or an alkaline earth metal compound; a second film layer is formed on the first film layer, and the second film layer is made of a metal material with the thickness of 20 angstrom to 50 angstrom; Finally, a plasma diffusion deposition process or an ionic thermal evaporation process for forming a third film layer on the second film layer is carried out, and the third film layer is made of a transparent conductive material.

Owner:CHUNGHWA PICTURE TUBES LTD

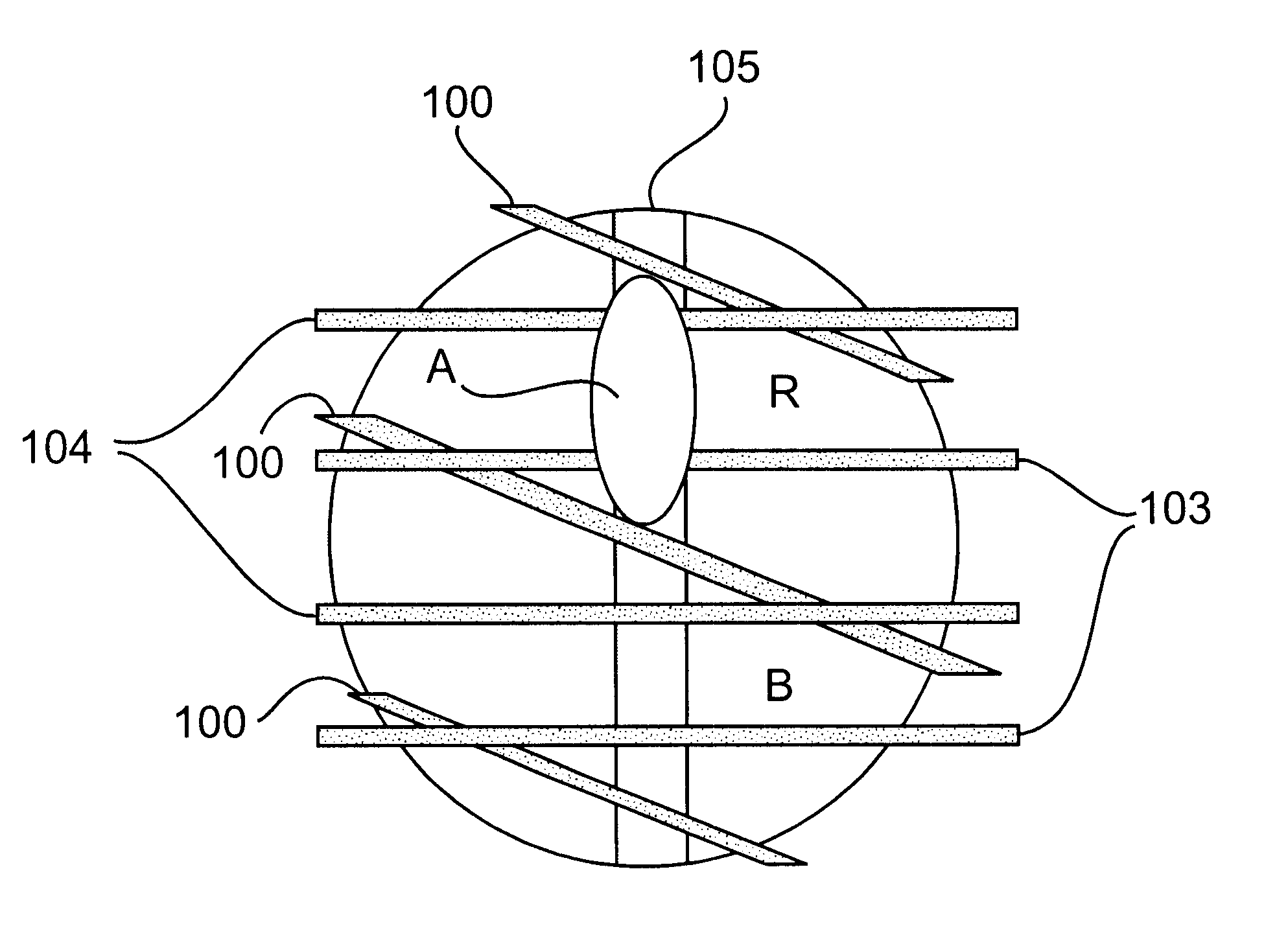

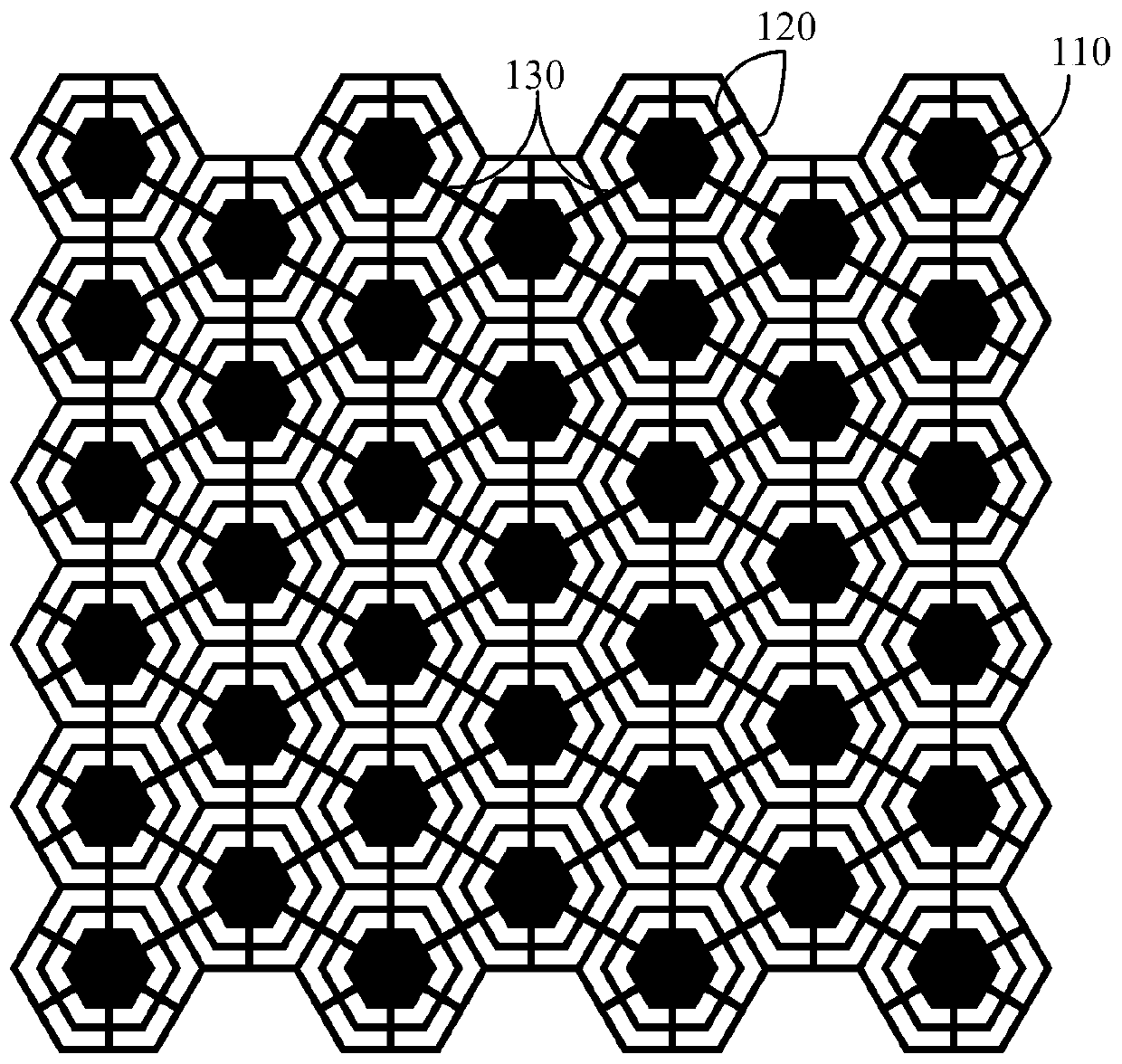

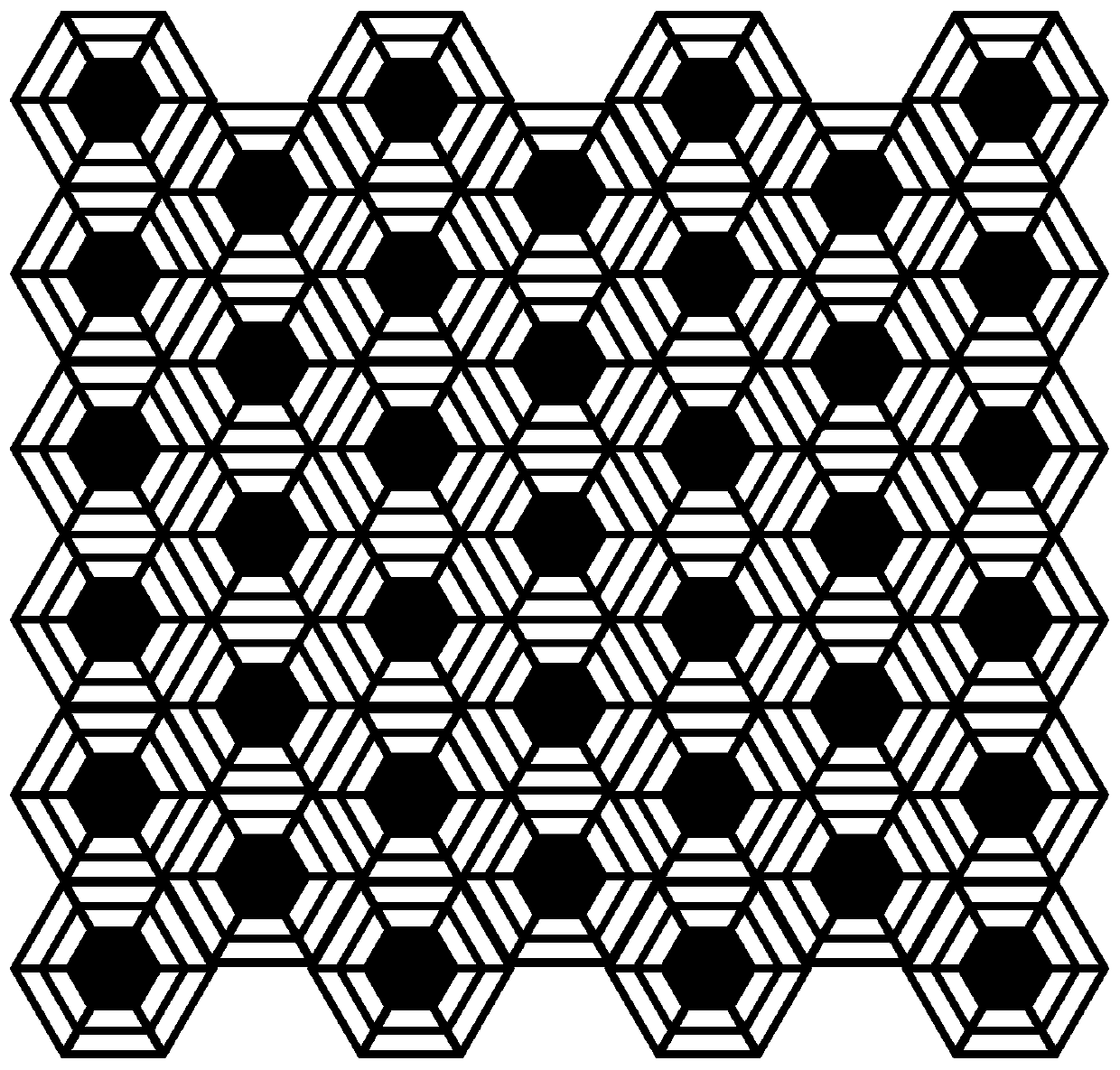

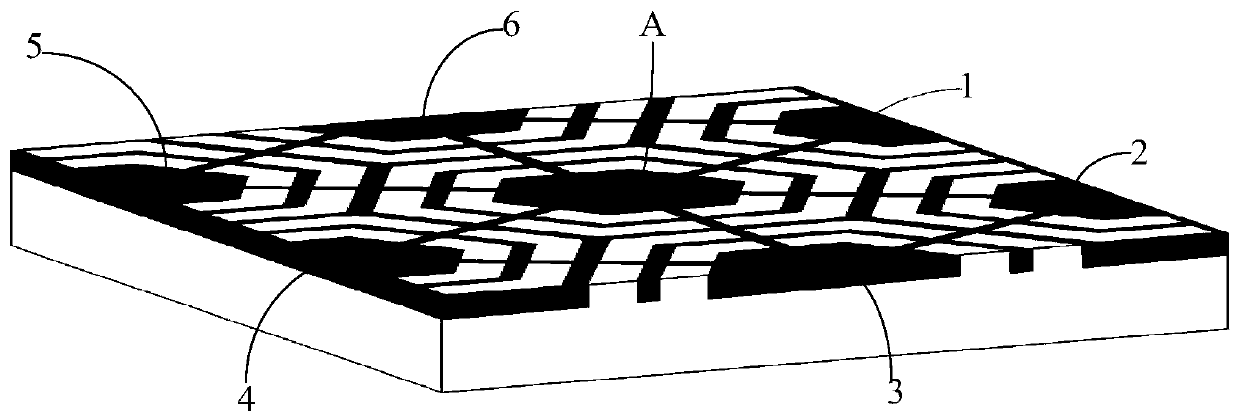

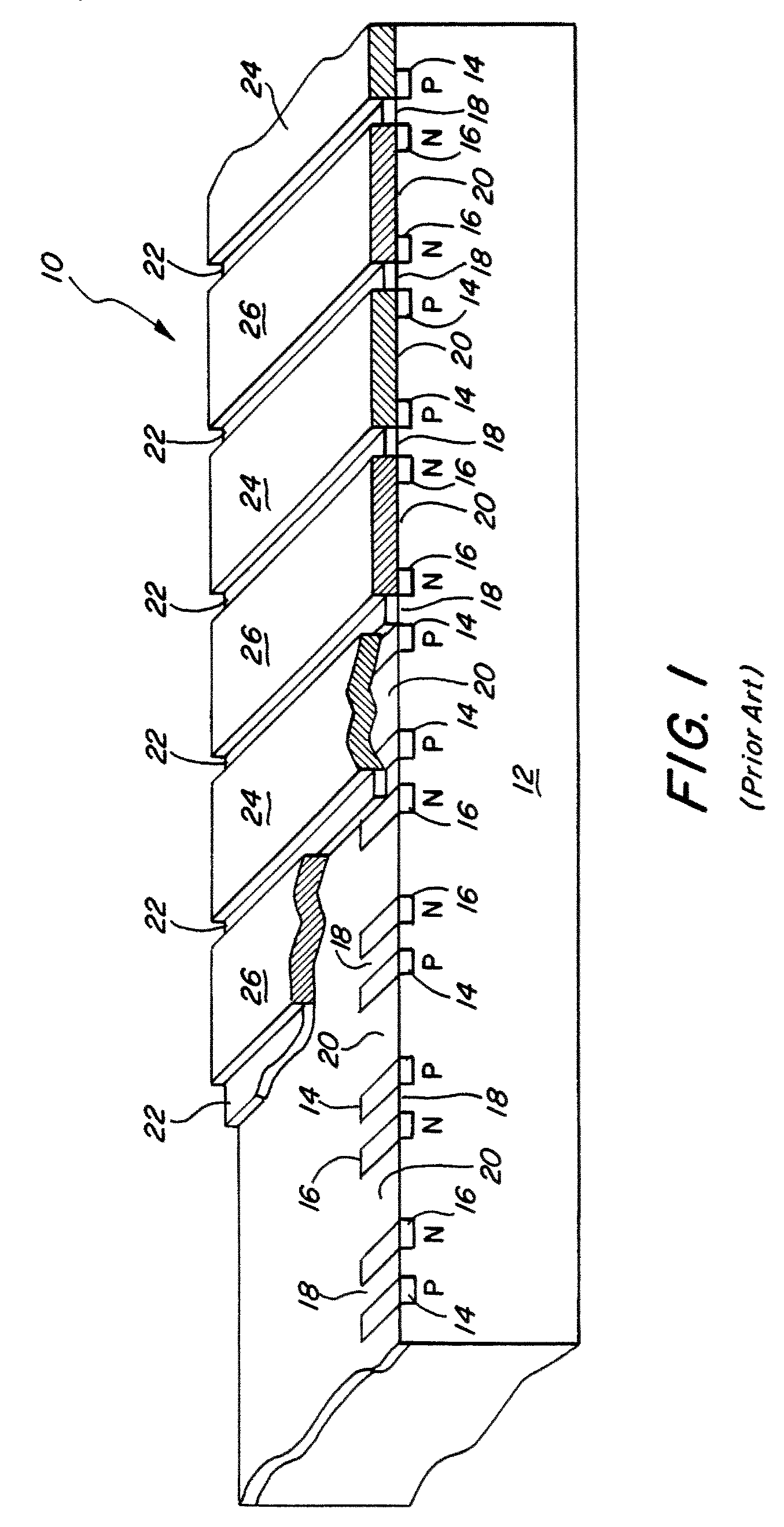

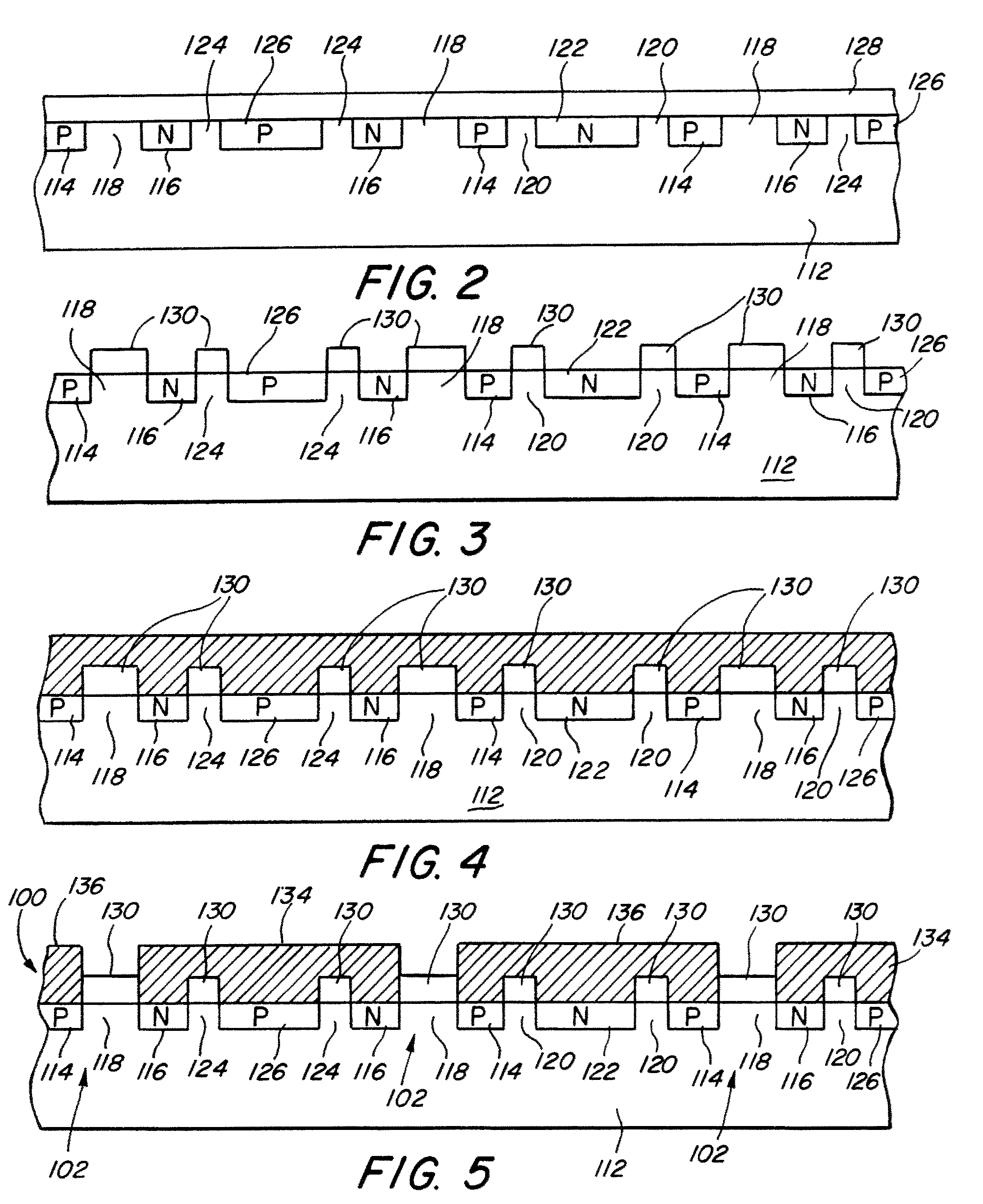

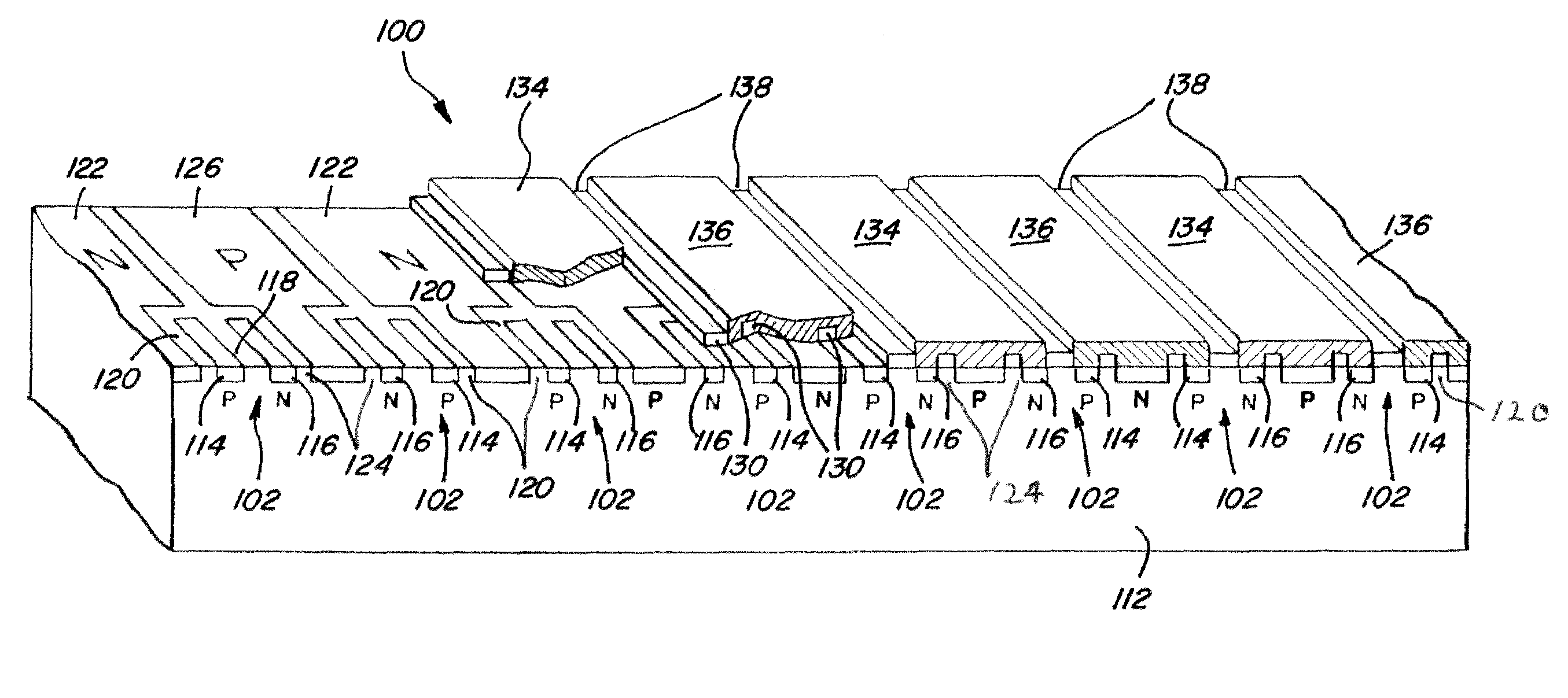

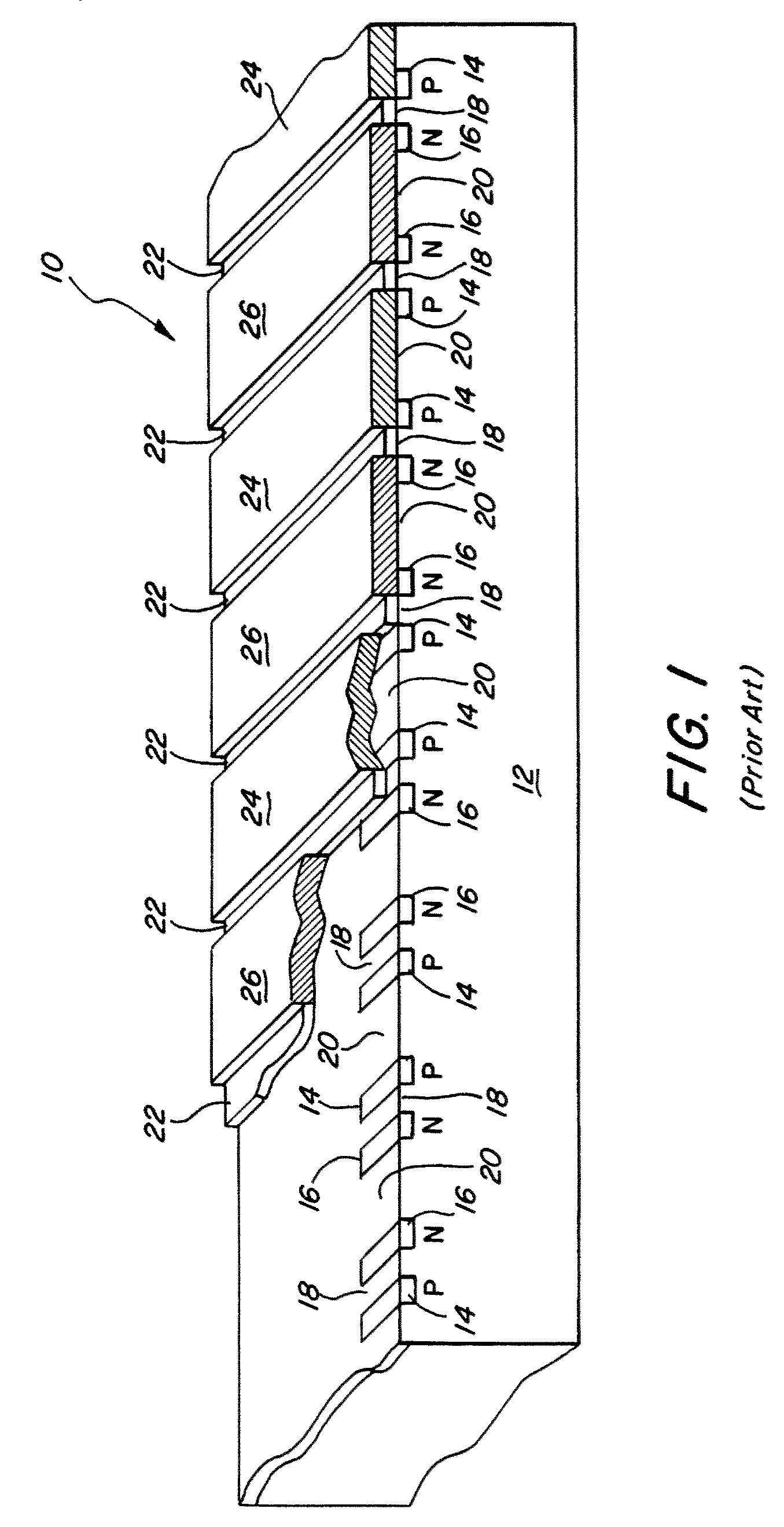

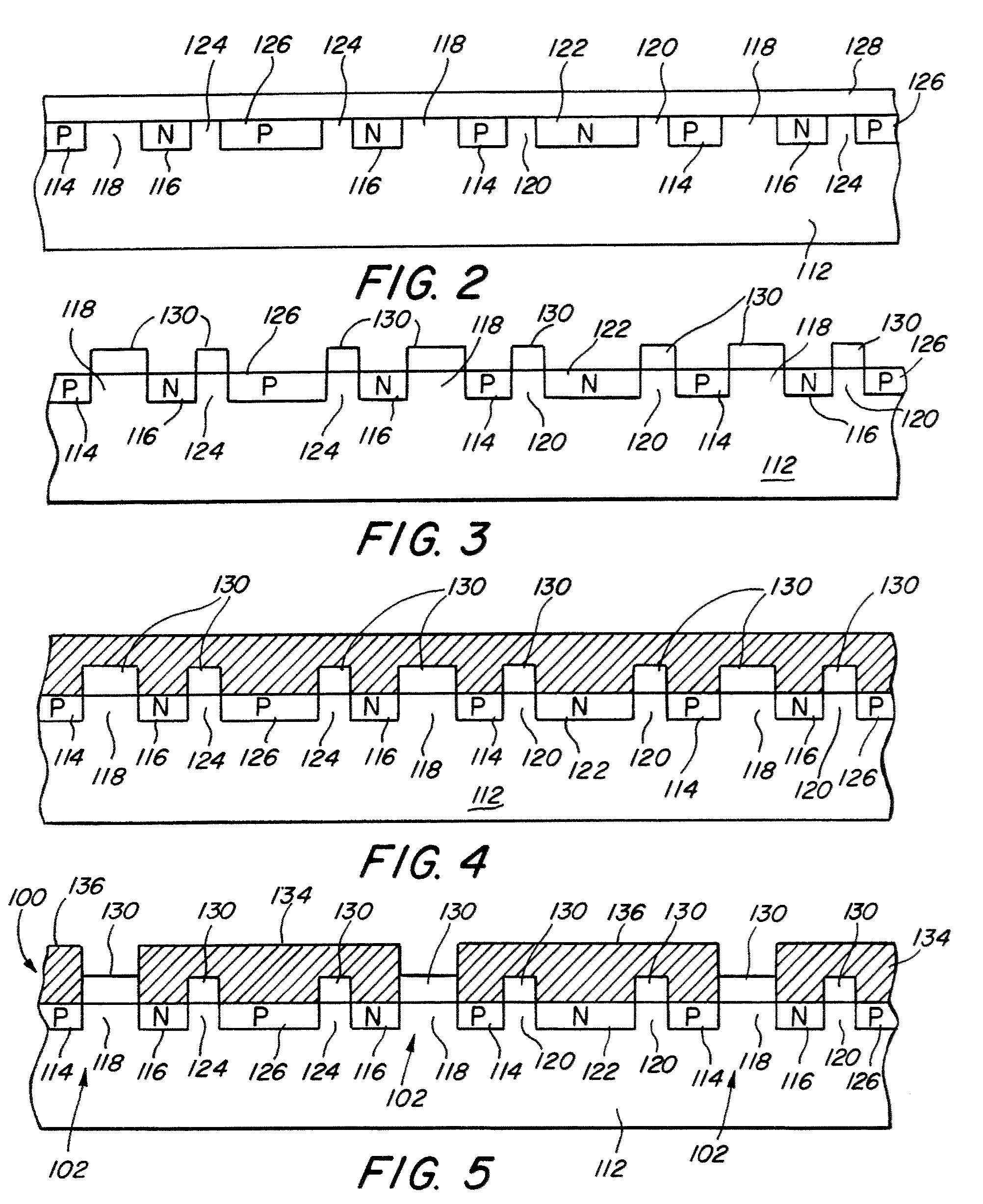

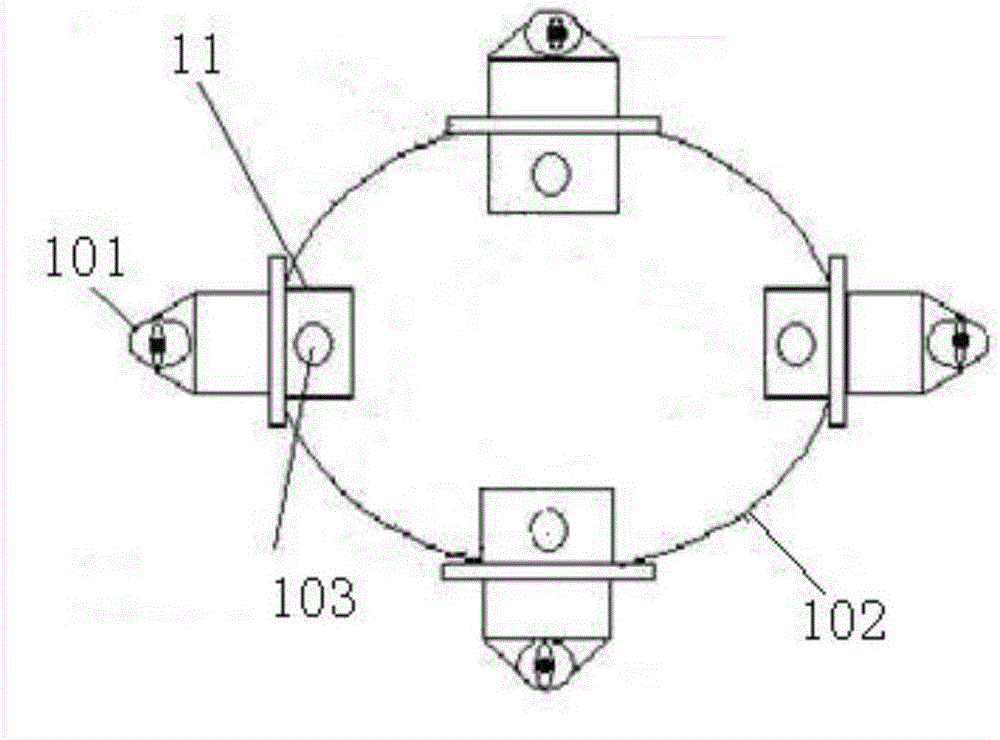

Monolithic semiconductor microwave switch array

ActiveUS7777286B2Minimizes, orReduce harmful effectsSolid-state devicesSemiconductor/solid-state device manufacturingMicrowavePlasma diffusion

A microwave switch array includes a plurality of microwave slotlines, each of which is controlled by a semiconductor switch including a first PIN junction formed by a primary P-type electrode and a primary N-type electrode separated by the slotline. The switches inject a plasma into the slotline in response to a potential applied across the first PIN junction. Each of the switches includes a second PIN junction between the primary P-type electrode and a secondary N-type electrode, and a third PIN junction between the primary N-type electrode and a secondary P-type electrode. Metal contacts connect the primary P-type electrode and the secondary N-type electrode across second PIN junction, and the primary N-type electrode and the secondary P-type electrode across the third PIN junction. The secondary electrodes extract plasma that diffuses away from the first PIN junction, thereby minimizing the performance degrading effects of plasma diffusion.

Owner:SIERRA NEVADA CORP

Insulating film for semiconductor device, process and apparatus for producing insulating film for semiconductor device, semiconductor device, and process for producing the semiconductor device

InactiveUS8288294B2Reduce carbon contentHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesPlasma diffusionGas phase

An object is to provide an insulating film for a semiconductor device which has characteristics of a low permittivity, a low leakage current, and a high mechanical strength, undergoes less change in these characteristics with the elapse of time, and has an excellent water resistance, as well as to provide a process and an apparatus for producing the insulating film for a semiconductor device, a semiconductor device, and a process for producing the semiconductor device. A gas containing a raw material gas which gasified a predetermined alkylborazine compound is supplied in a chamber (2); an electromagnetic wave is introduced into the chamber (2) using with an inductive coupling type plasma generation mechanism (4, 5, 6) to convert the gas into a plasma; a substrate (8) is placed in a plasma diffusion region of the plasma; gas-phase polymerization is performed with borazine skeletal molecules, as a fundamental unit, dissociated from the alkylborazine compound by the plasma so as to form the insulating film for semiconductor devices on the substrate (8).

Owner:MITSUBISHI HEAVY IND LTD +1

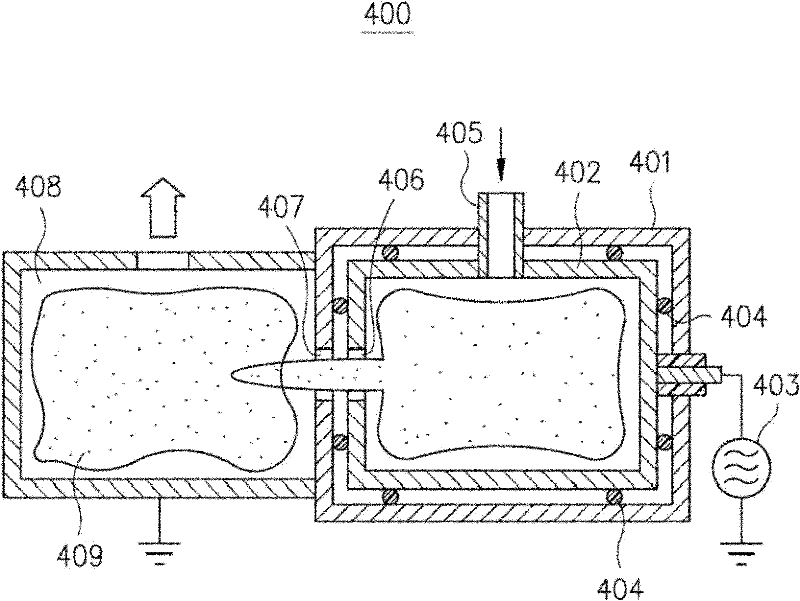

Plasma processing apparatus

ActiveCN102477547AImprove uniformityIncrease dissociationElectric discharge tubesChemical vapor deposition coatingHigh densityPlasma diffusion

A plasma processing apparatus is disclosed, which includes: a cathode module comprising a plurality of first channels which generate plasma; an anode having a chamber which contains the cathode and having at least one plasma outlet corresponding to the first channels; an electrode connected to a high-frequency electrical power and the cathode; and a plurality of second channels penetrating through the anode; wherein each first channel and each second channel are disposed alternately. A first gas is introduced into the first channels ionized under high frequency electrical power. In the first channels, the free electrons collided brings high density of plasma. The generated plasma is expelled through the plasma outlet to form a plasma diffusion region. A second gas is introduced into the plasma diffusion region through the second channels to take part in the reaction of plasma.

Owner:IND TECH RES INST

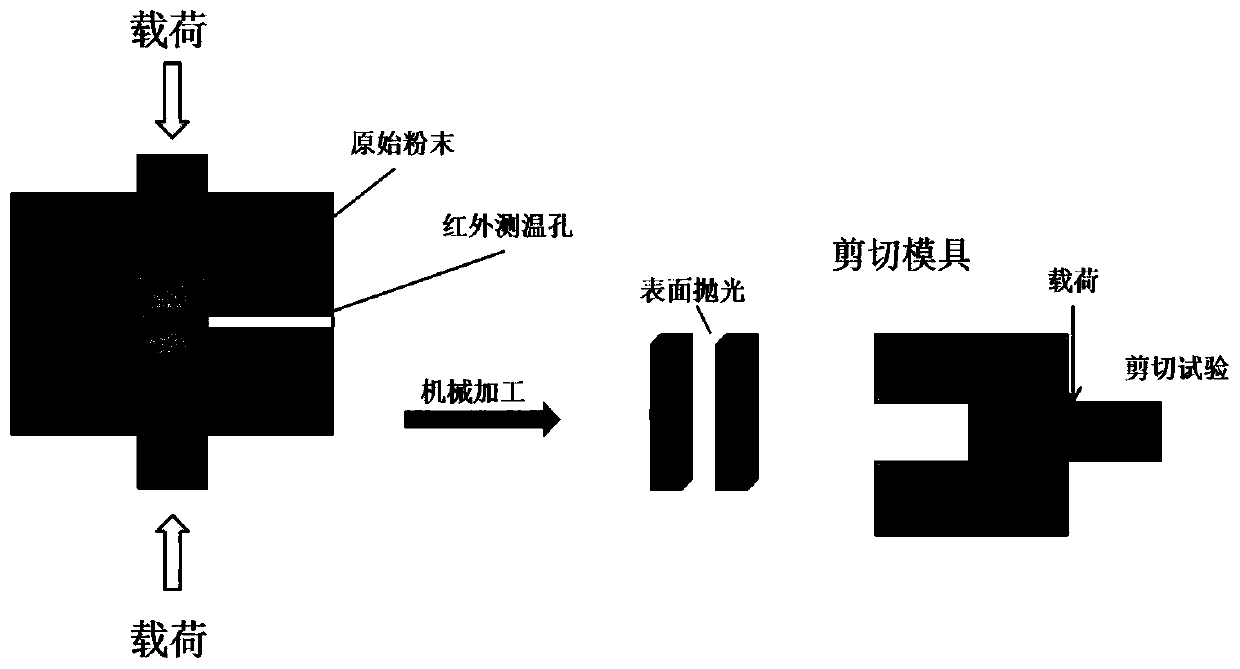

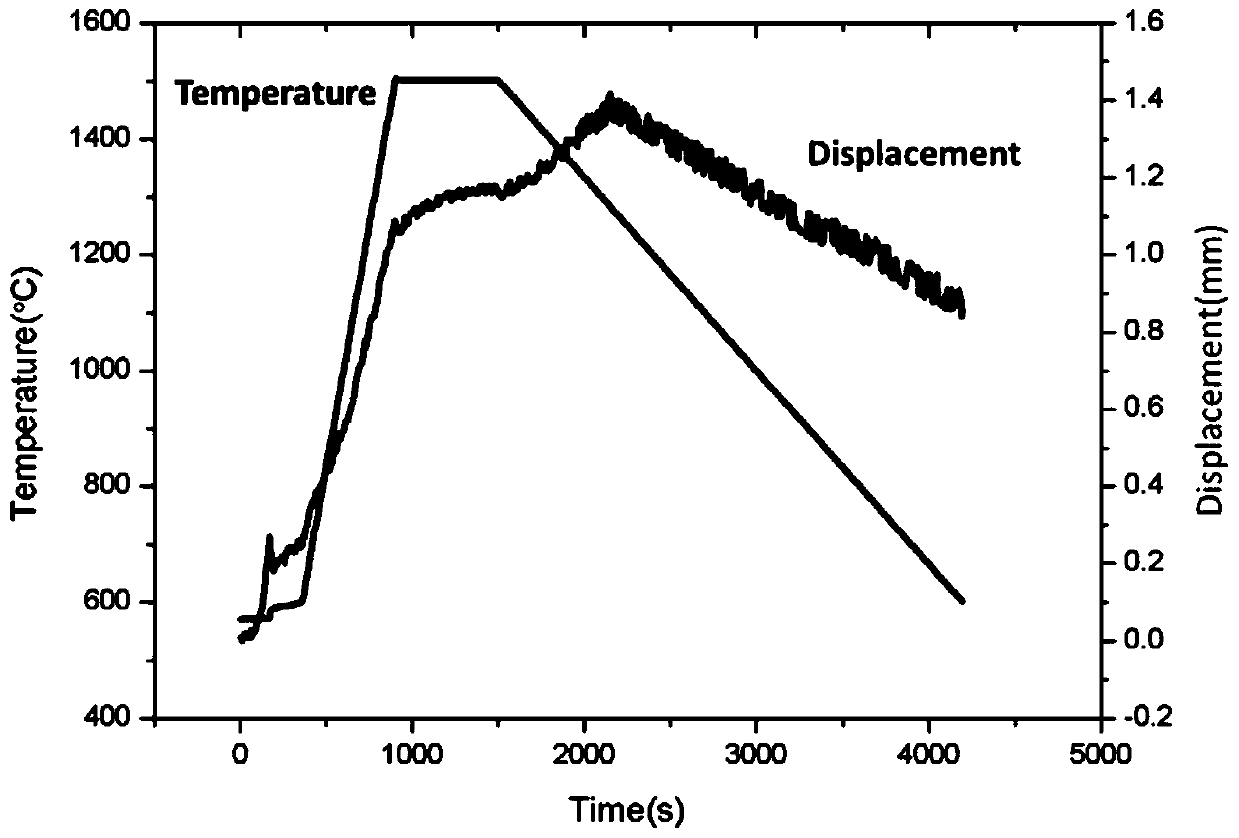

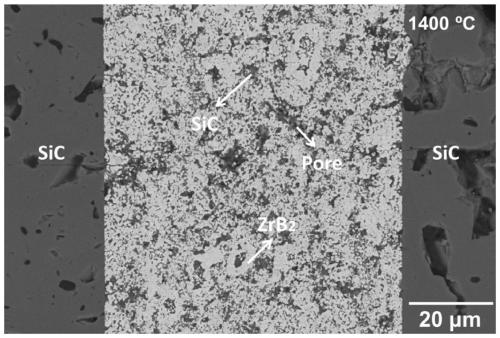

Discharge plasma diffusion bonding method for silicon carbide ceramic

The invention discloses a discharge plasma diffusion bonding method for silicon carbide ceramic. Materials of a bonding layer mainly consist of ZrB2 and SiC two phases. The preparation of a multiphaseceramic bonding layer and the diffusion bonding of SiC ceramic joints are completed at the same time. The bonding layer is formed by an in-situ reaction of ZrH2, B4C and Si powder at high temperature. The proportion of the raw materials is as follows, by mass percent: 20-25% of the B4C and 10-15% of the Si, with the balance being the ZrH2. The bonding layer is composed of composite ceramic composed of ZrB2 and SiC and has thermophysical properties and mechanical properties similar to those of SiC ceramic, thereby realizing good interface bonding, avoiding the formation of joint cracks and improving the joint strength.

Owner:HEFEI UNIV OF TECH

Double side emitting organic light emitting diode and method of fabricating the same

InactiveUS20080018242A1Reduce the driving voltageImprove transfer rateDischarge tube luminescnet screensElectroluminescent light sourcesFlexible organic light-emitting diodeAlkaline earth metal

A method of fabricating a double side emitting organic light emitting diode (OLED) including the following steps is provided. First, a transparent substrate is provided. Then, a first transparent electrode and an organic light emitting layer are sequentially formed on the transparent substrate. Next, a second transparent electrode is formed on the organic light emitting layer. The method of forming the second transparent electrode includes the following steps. A first film composed of alkali metal compound or alkaline-earth metal compound is formed on the organic light emitting layer; a second film composed of metal material is formed on the first film and has a thickness between 20 angstroms and 50 angstroms; a third film composed of transparent conductive material is formed on the second film by using a plasma diffusion deposition process or an ionic thermal evaporation process.

Owner:CHUNGHWA PICTURE TUBES LTD

Monolithic semiconductor microwave switch array

ActiveUS20090121804A1Deleterious effectMinimizes, orSolid-state devicesSemiconductor/solid-state device manufacturingPlasma diffusionEngineering

A microwave switch array includes a plurality of microwave slotlines, each of which is controlled by a semiconductor switch including a first PIN junction formed by a primary P-type electrode and a primary N-type electrode separated by the slotline. The switches inject a plasma into the slotline in response to a potential applied across the first PIN junction. Each of the switches includes a second PIN junction between the primary P-type electrode and a secondary N-type electrode, and a third PIN junction between the primary N-type electrode and a secondary P-type electrode. Metal contacts connect the primary P-type electrode and the secondary N-type electrode across second PIN junction, and the primary N-type electrode and the secondary P-type electrode across the third PIN junction. The secondary electrodes extract plasma that diffuses away from the first PIN junction, thereby minimizing the performance degrading effects of plasma diffusion.

Owner:SIERRA NEVADA CORP

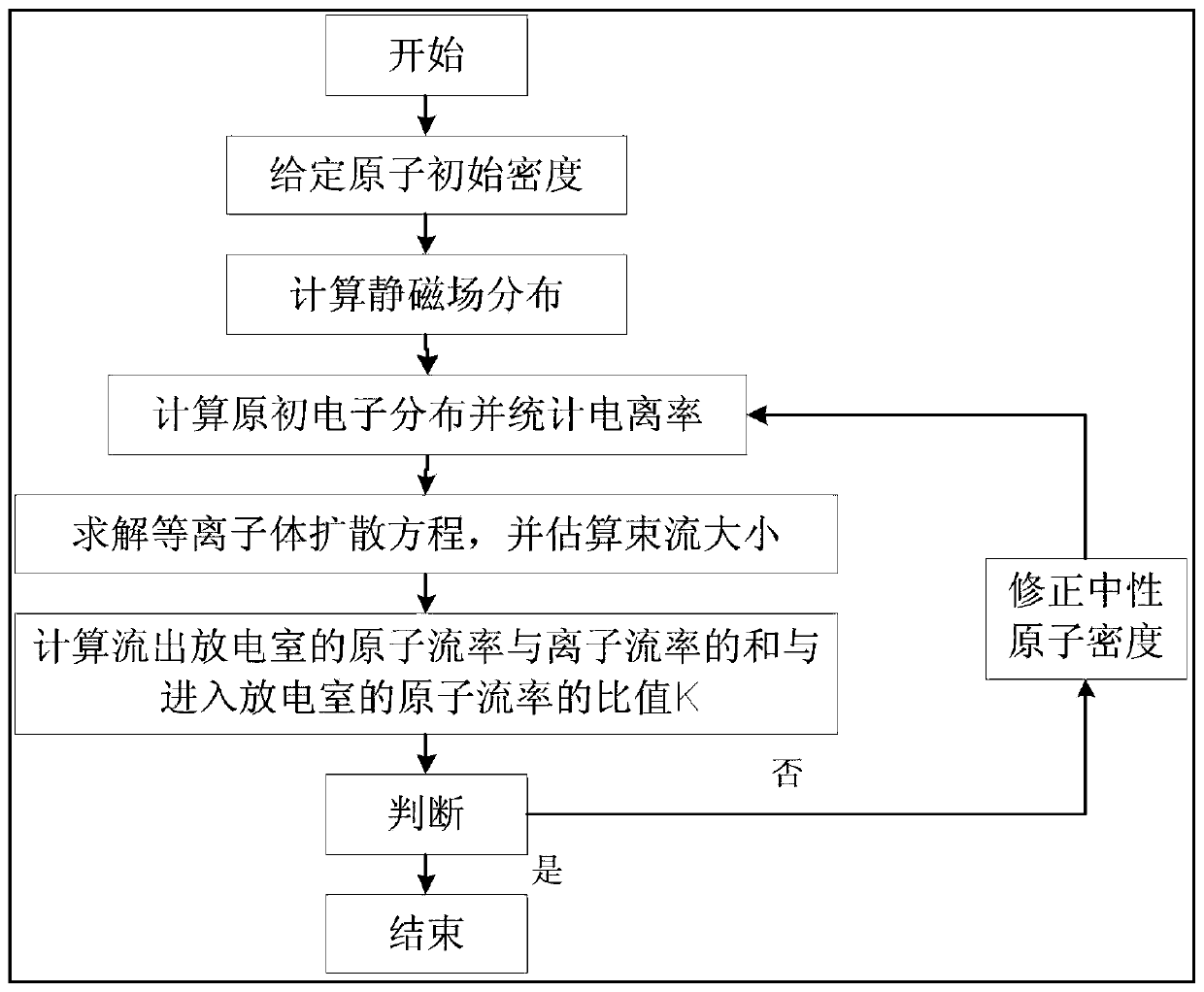

Method for simulating discharge process of discharge chamber of Kaufman ion thruster

ActiveCN111044822AImprove computing efficiencyCalculation speedElectrical testingPlasma diffusionParticle physics

The invention relates to a method for simulating a discharge process of a discharge chamber of a Kaufmann ion thruster, mainly aims at the discharge chamber of the Kaufmann ion thruster and designs aset of efficient method for simulating the discharge process of the Kaufmann ion thruster from the characteristics of different particles in the discharge chamber. The method mainly comprises the following steps of: calculating initial density of atoms; calculating static magnetic field distribution; calculating primary electron distribution and counting an ionization rate; solving a plasma diffusion equation and estimating the size of a beam current; calculating a ratio k of the sum of an atomic flow rate and an ion flow rate flowing out of the discharge chamber to an atomic flow rate entering the discharge chamber; judging whether convergence occurs or not; if so, acquiring a convergence solution of the discharging process; and if not, correcting the neutral atom density, and then recalculating from the step 3. After simulation calculation by adopting the method, the discharge process of the Kaufman ion thruster can be effectively simulated, and the calculation precision is high compared with a test result.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

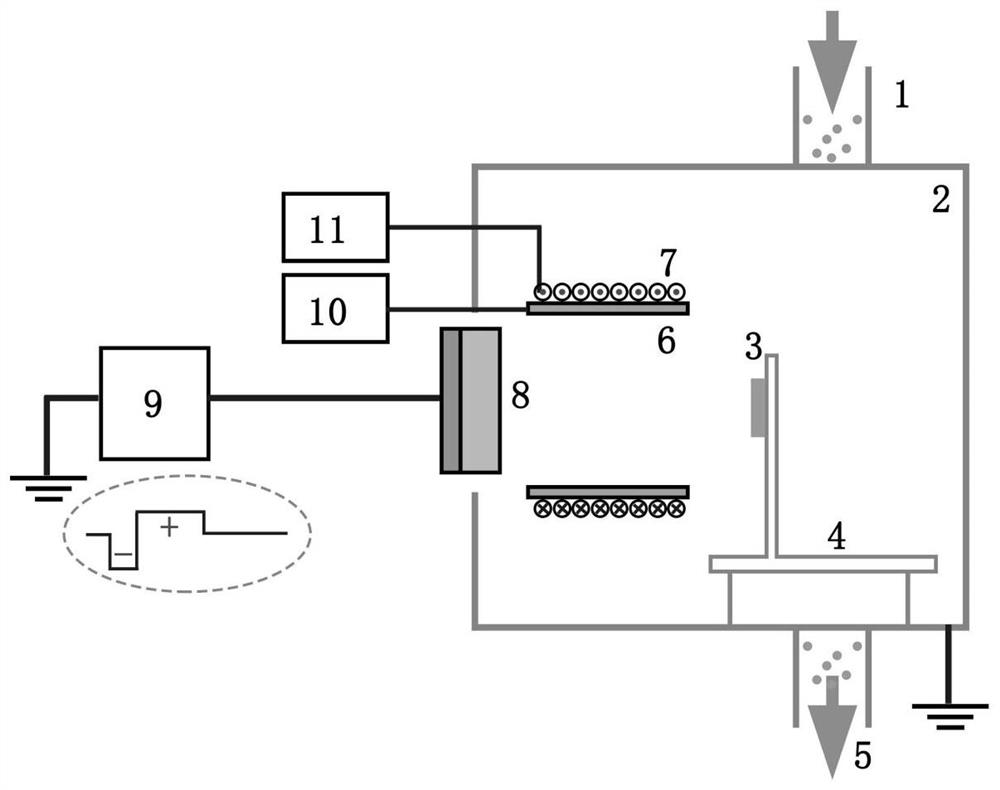

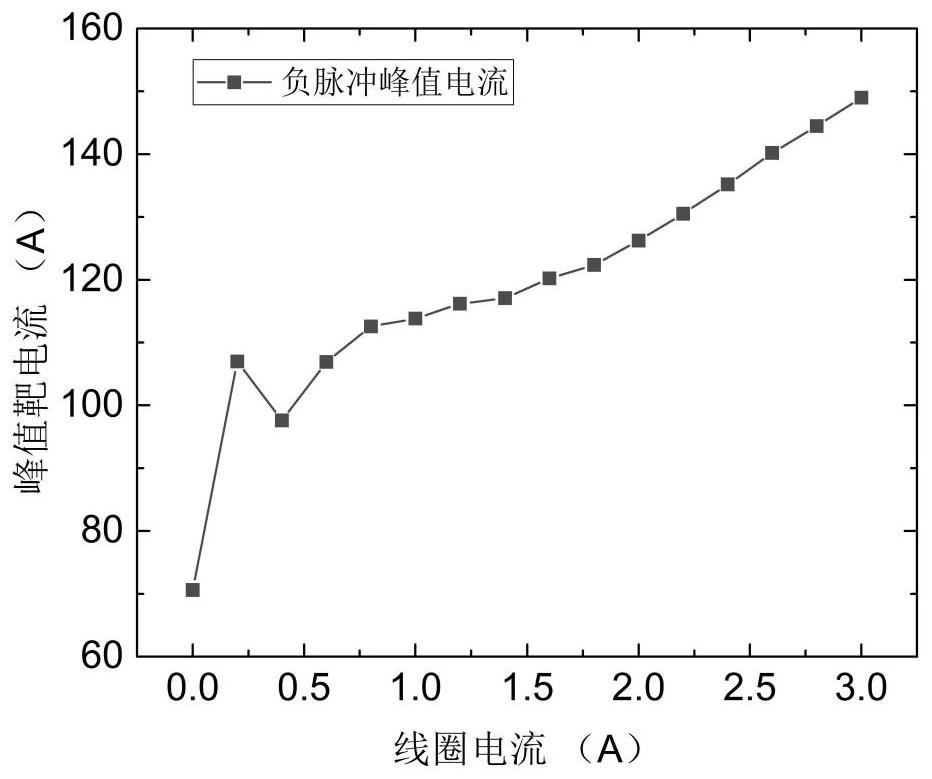

Electromagnetic field coupled bipolar pulse magnetron sputtering system and method for increasing flow and energy

PendingCN114032519AIncrease the ionization ratioHigh trafficVacuum evaporation coatingSputtering coatingSputteringElectromagnetic field coupling

An electromagnetic field coupled bipolar pulse magnetron sputtering system and a method for increasing flow and energy. The system comprises a bipolar pulse magnetron sputtering power supply and a sputtering target, and at least comprises one of an auxiliary anode and an external magnetic field unit, where a pulse output terminal of the bipolar pulse magnetron sputtering power supply is connected to the sputtering target; when the auxiliary anode is included, the auxiliary anode is arranged in front of the sputtering target; when the auxiliary anode comprises the external magnetic field unit, the external magnetic field unit can be configured on the inner side or the outer side of the auxiliary anode; ions generated by negative pulses are driven to fly away from the area nearby the surface of the sputtering target in a bipolar pulse magnetic control discharge mode; the diffusion of deposited ions is optimized by utilizing an electric field generated by the auxiliary anode; and the transmission of electrons is optimized through external magnetic field configuration, the fluidity of plasma diffusion is enhanced, and then the flow of deposited ions is increased. The system is economical and practical, the magnetron sputtering discharge deposition rate can be increased, and the performance of the thin film is improved.

Owner:BEIHANG UNIV

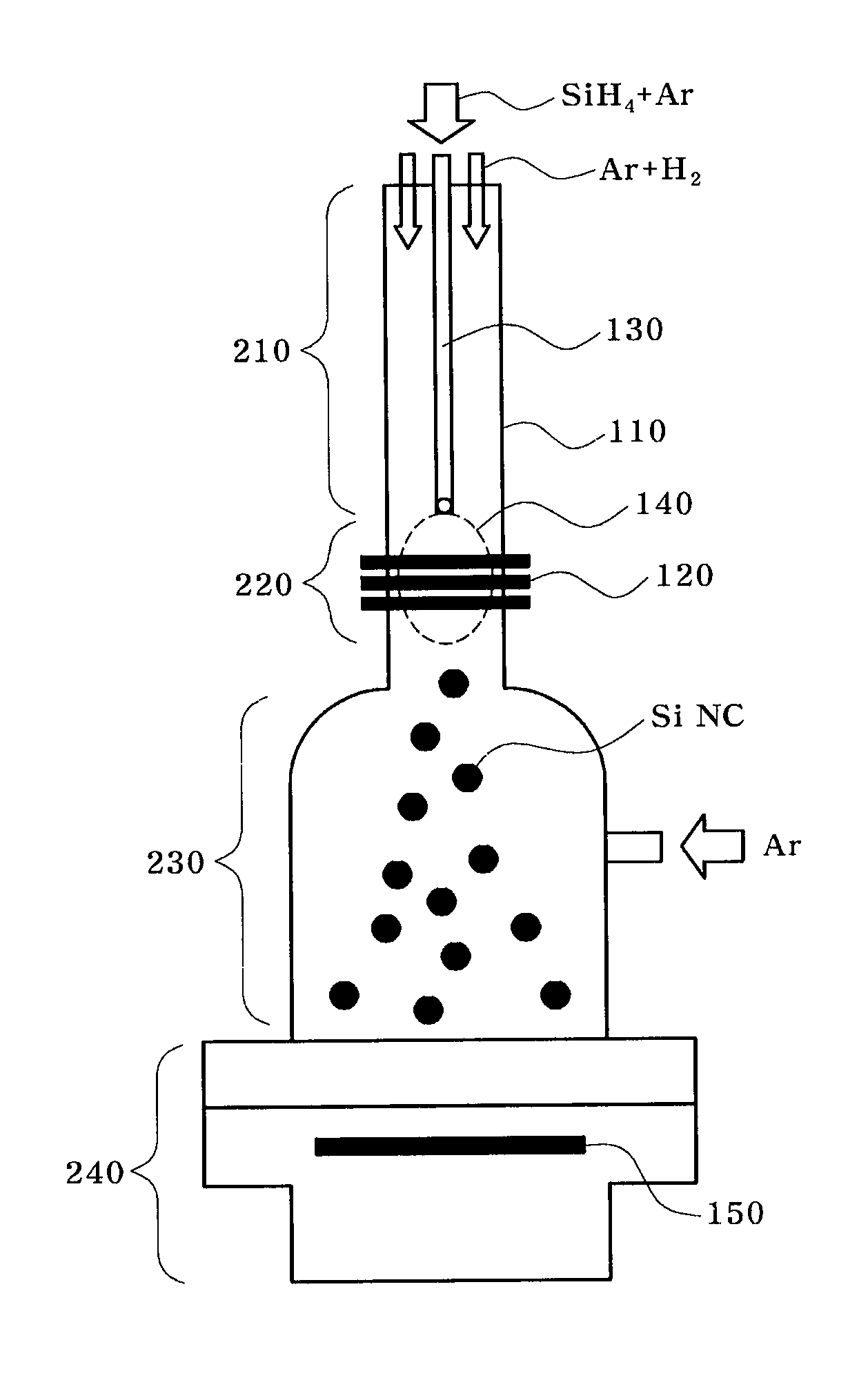

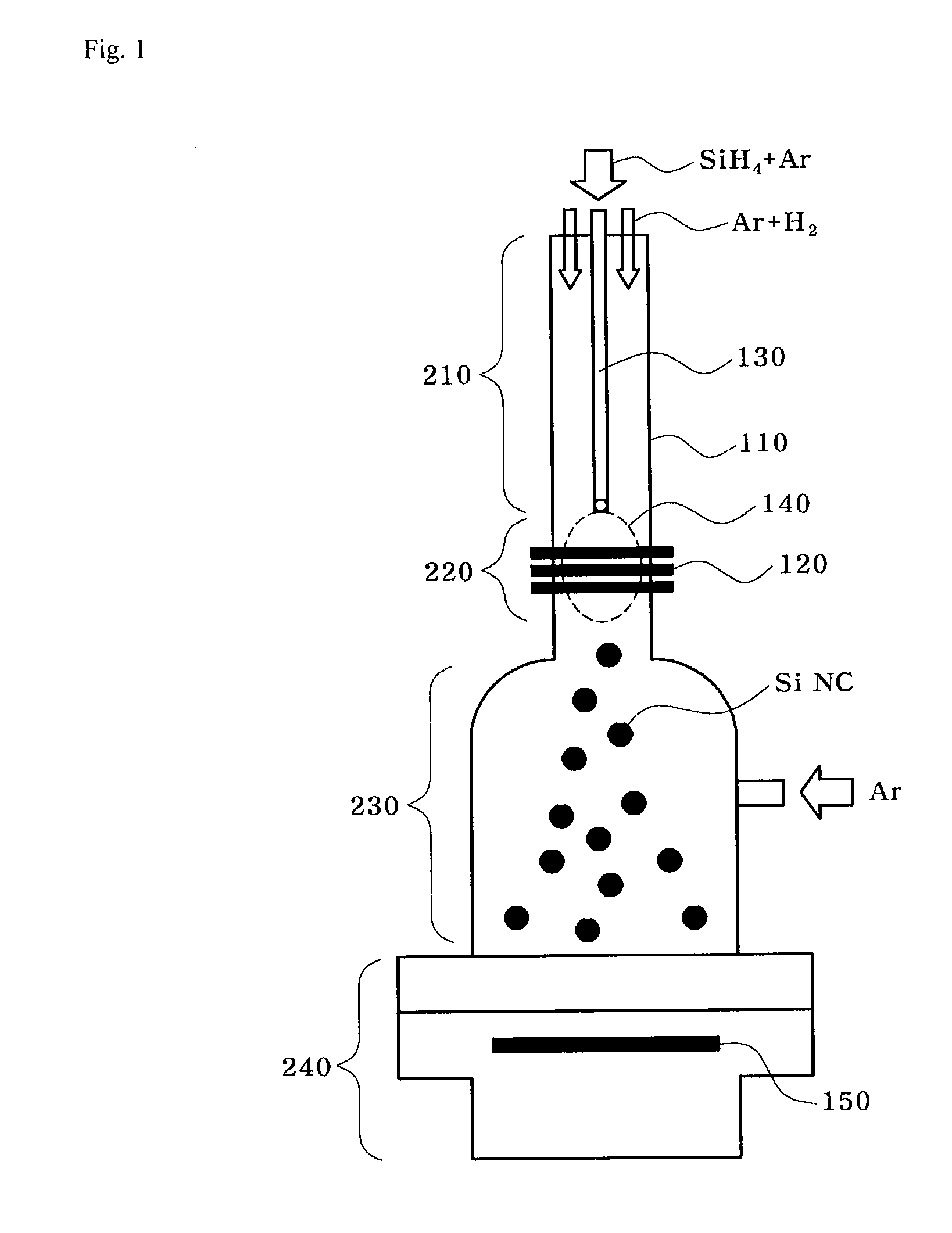

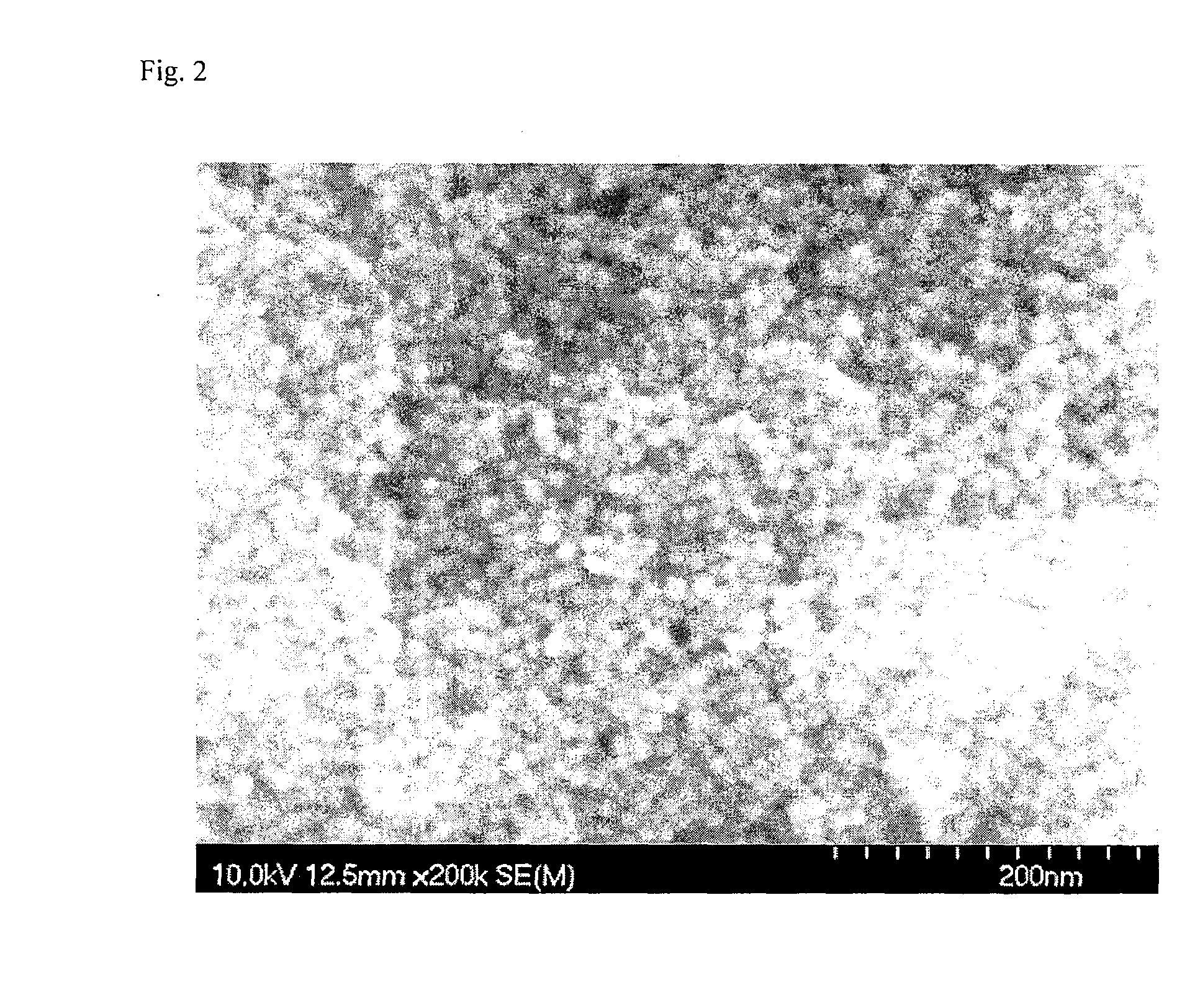

Apparatus for producing silicon nanocrystals using inductively coupled plasma

ActiveUS8377205B2Improving particle size characteristic and qualityMinimize diffusionMaterial nanotechnologyNanostructure manufactureSurface reactionPlasma diffusion

The present disclosure relates to an apparatus for producing silicon nanocrystals, which can minimize plasma diffusion by finely adjusting a plasma region created by an ICP coil. The apparatus includes a reactor having an ICP coil wound around an outer wall thereof and a tube inserted into the reactor, wherein a primary gas for forming silicon nanocrystals and a secondary gas for surface reaction of the silicon nanocrystals are separately supplied to the reactor through an inner side and an outer side of the tube, respectively.

Owner:EL INC

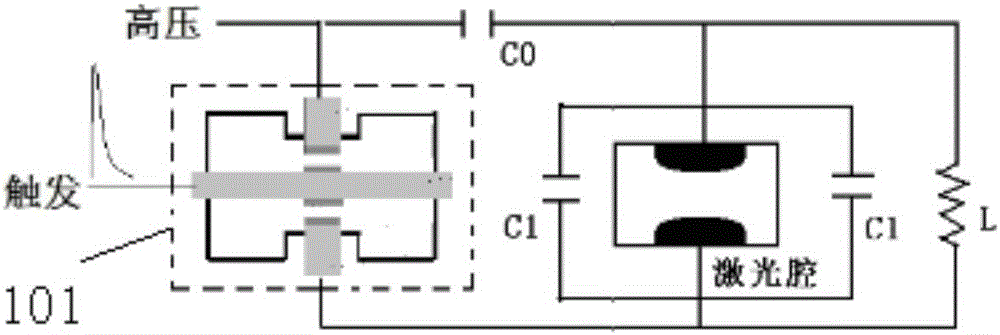

High-voltage high-current single-pulse discharge switch and high-energy excimer laser

InactiveCN106129783AIncrease working voltageGood insulationExcitation process/apparatusHigh energyPlasma diffusion

The invention discloses a high-voltage high-current single-pulse discharge switch and a high-energy excimer laser. The switch is of a closed structure and is filled with high-pressure gas with constant air pressure; the switch comprises a shell, a first electrode, a second electrode, a rotating electrode and a rotating shaft, wherein the rotating shaft penetrates through the shell; the rotating electrode is disposed on the rotating shaft; the first electrode and the second electrode are located on two sides of the rotating electrode and respectively stretch out of the shell; a first discharge gap is disposed between the rotating electrode and the first electrode; a second discharge gap is disposed between the rotating electrode and the second electrode; two sides of the first discharge gap and the second discharge gap are discharge plasma diffusion buffer areas; the shell is equipped with a gas port; and the gas port is used for gas to come in and go out. The switch has the characteristics of high working voltage, fast discharge, high conducting power and the like, the switch combines four discharge cavities, and a laser device capable of outputting high-energy laser is obtained.

Owner:HAINAN NORMAL UNIVERSITY

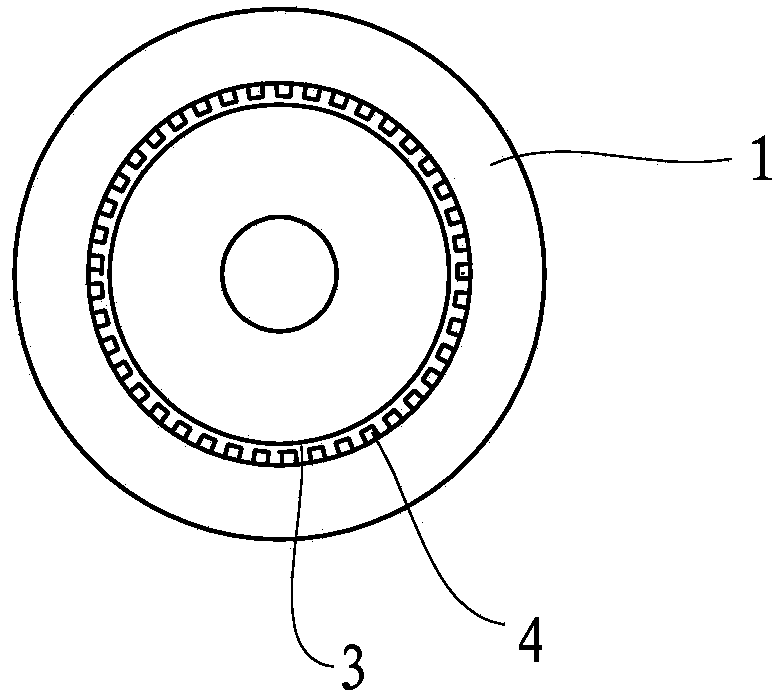

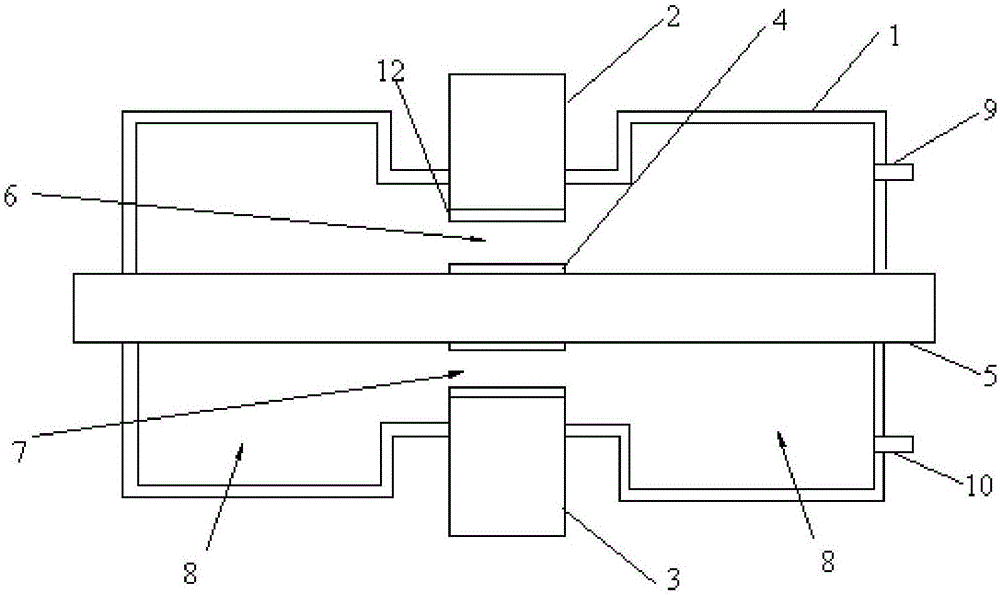

Novel longitudinal magnetic contact system with embedded magnetism gathering ring and reverse contact cup

ActiveCN110120320AImprove breaking capacityWeaken longitudinal magnetic fieldHigh-tension/heavy-dress switchesAir-break switchesPlasma diffusionEngineering

The invention designs a novel longitudinal magnetic contact system with an embedded magnetism gathering ring and a reverse contact cup. The novel longitudinal magnetic contact system is composed of aconducting rod, an external contact cup, a contact piece, the embedded magnetism gathering ring and the embedded reverse contact cup. The embedded magnetism gathering ring is coaxially and tightly connected with the external static contact cup and the contact piece; a spiral groove opposite to the external contact cup in direction is formed in the cup wall of the embedded reverse contact cup, andthe embedded reverse contact cup is coaxially and tightly connected with the external moving contact cup and the contact piece. According to the novel longitudinal magnetic contact system, through theintroduction of the magnetism gathering ring and the reverse contact cup and the optimization design of the contact structure, on the basis of improving the longitudinal magnetic field of the contactgap current at the peak moment, the residual longitudinal magnetic field in the center of the contact is effectively weakened, the influence of the residual magnetism on residual plasma diffusion isreduced, and the recovery of the dielectric strength of the contact gap after arc and the improvement of the breaking capacity of the contact are facilitated. In addition, the newly designed contact system is simple in structure, easy to assemble, high in mechanical strength and beneficial to popularization and application in actual production.

Owner:SICHUAN UNIV

Boring bar with improved stiffness

ActiveUS10040127B2High dynamic stiffnessIncrease stiffnessWorkpiecesBoring barsMetalworkingPlasma diffusion

A tunable or tuned boring bar having increased stiffness is provided. Increasing the stiffness of the bar increases the natural frequency, thereby reducing directional deformation of the bar during use. The tunable boring bar includes a distal portion configured to support a tool, a proximal portion configured for attachment to a support structure of a metalworking machine, and a body, which is at least partially tubular, extending between the proximal portion and the distal portion. The tubular portion of the body has an elongated cylindrical cavity. The body of the boring bar includes a core layer formed from a first material and a coating layer formed from a second material. The second material has a higher modulus of elasticity than the first material. In certain configurations, the coating layer is bonded to the core layer by cladding, welding, chemical adhesives, chemical vapor deposition, pulsated plasma diffusion, or combinations thereof.

Owner:KENNAMETAL INC

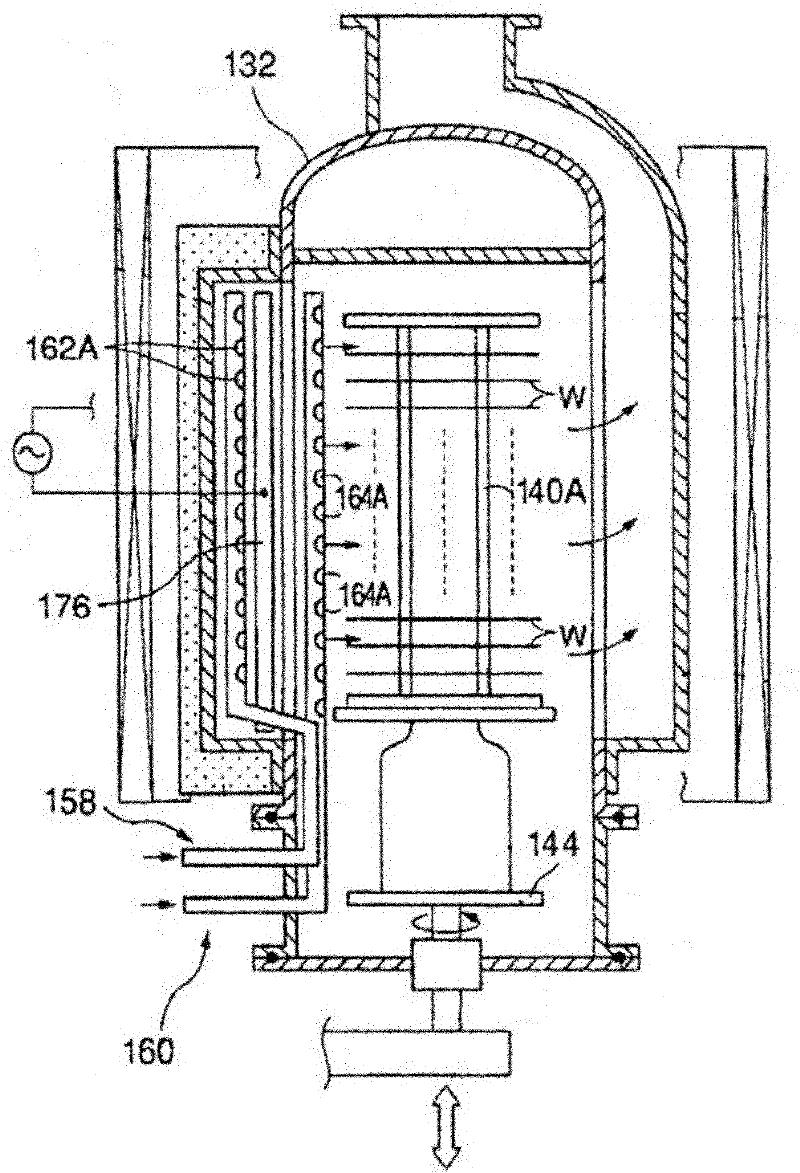

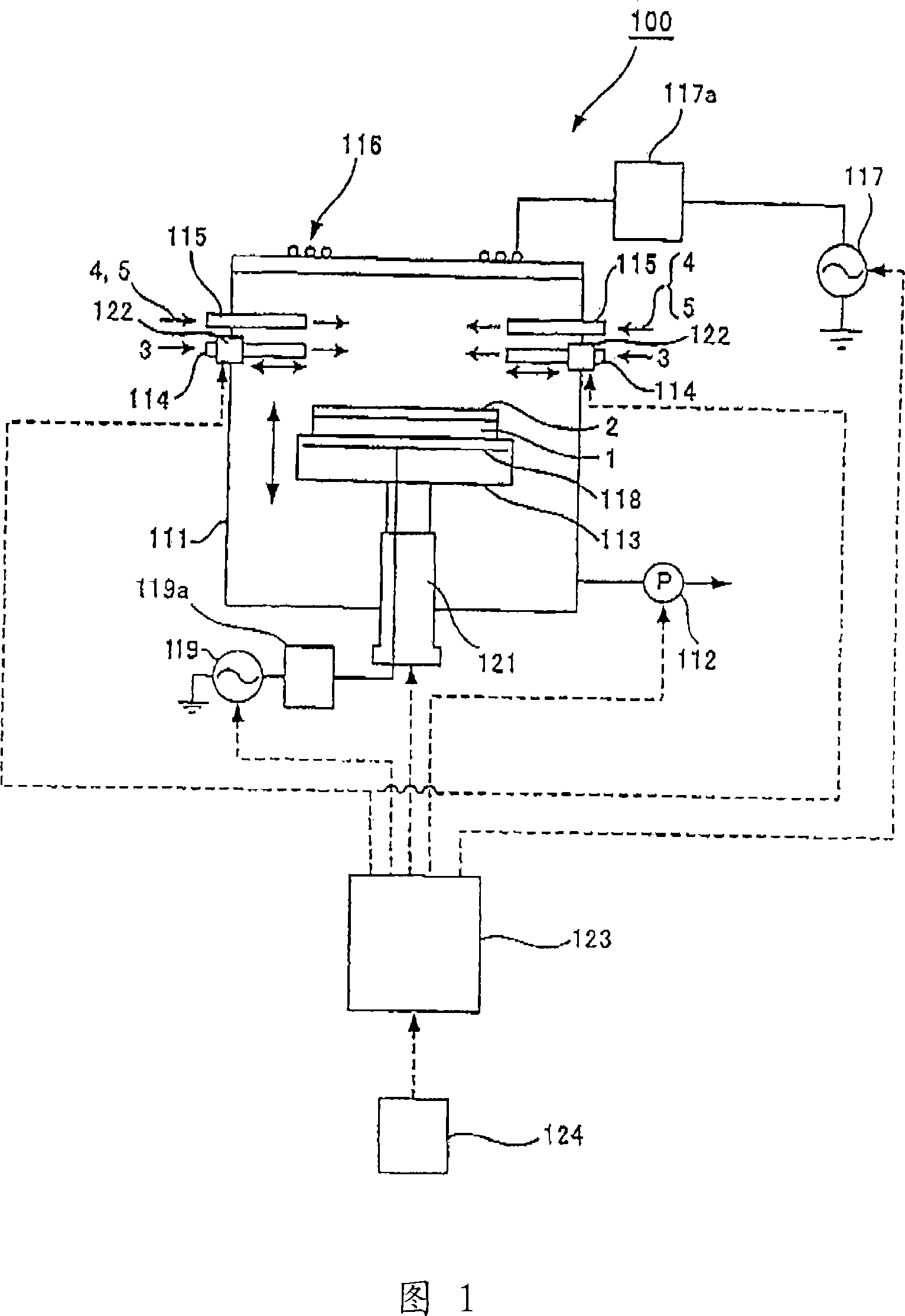

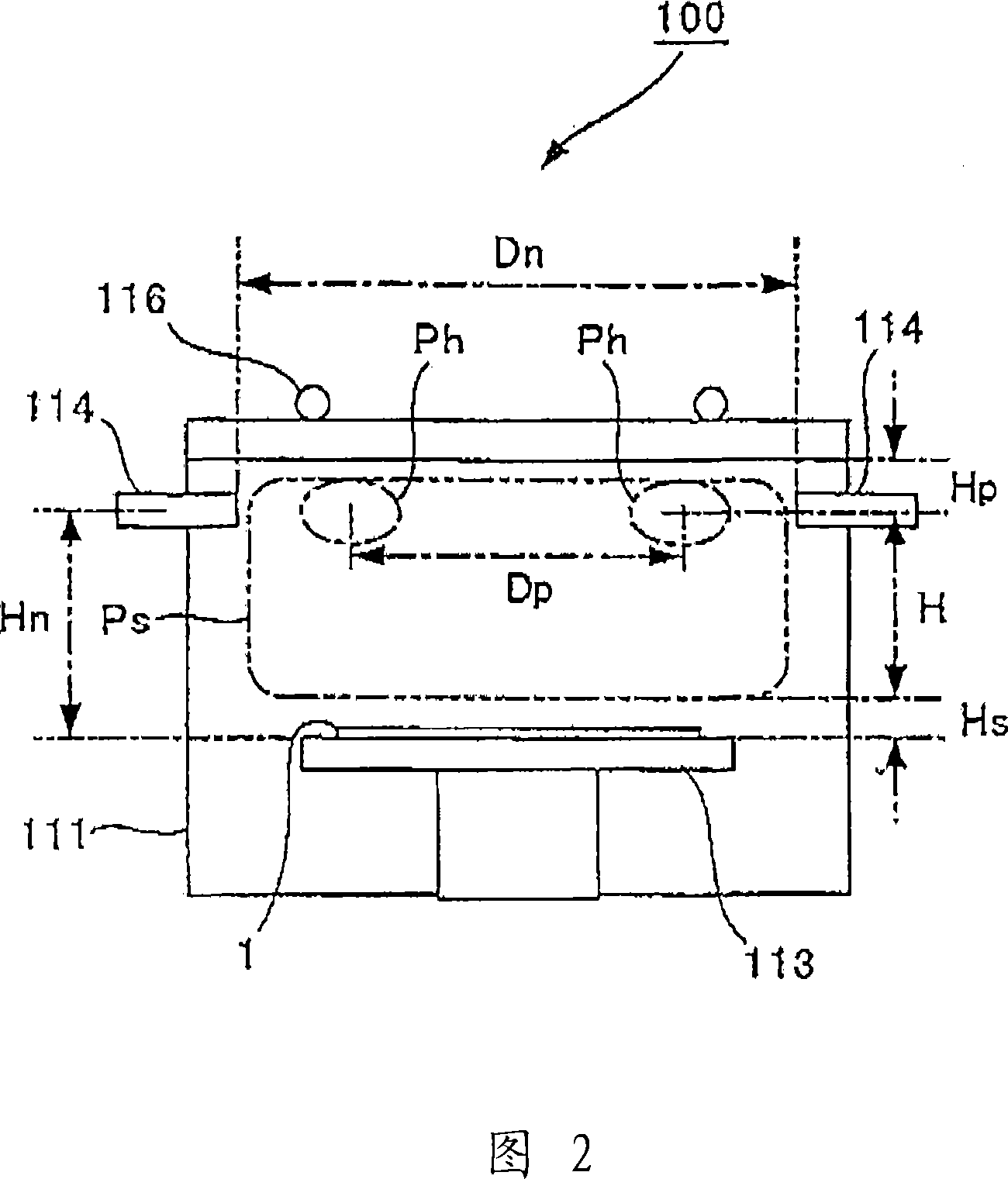

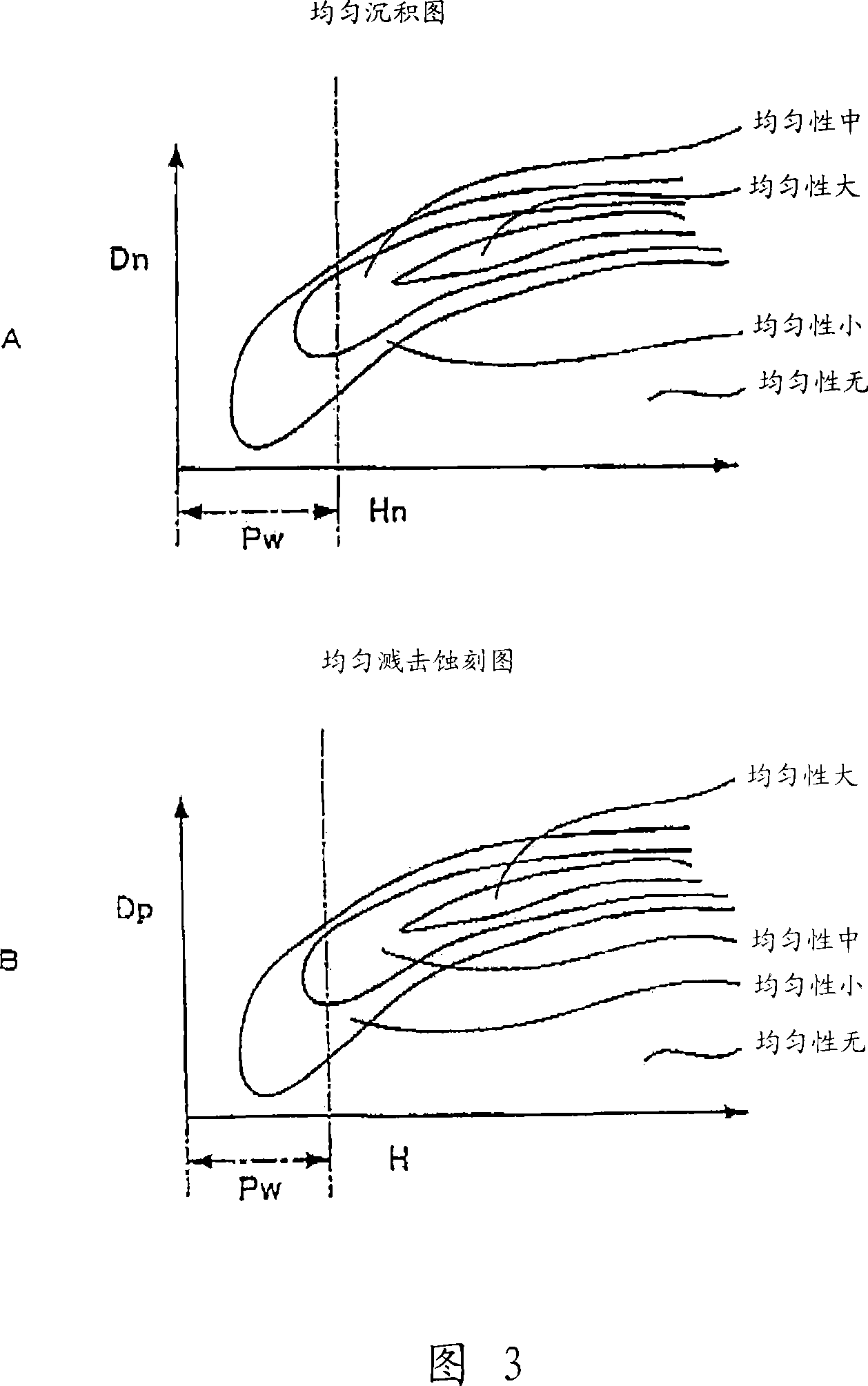

Plasma processing apparatus

InactiveCN101006564AEase of visualizationSemiconductor/solid-state device testing/measurementElectric discharge tubesInternal pressureEtching

When a size of a substrate (1) is instructed, a plasma processing apparatus reads a map, which shows a range where uniform sputter etching can be performed based on a relationship between a diameter size (Dp) of a high density plasma region and a height (H) between a center of the high density plasma region and a lower section in a plasma diffusion region. Based on an inner pressure and a frequency of an electromagnetic wave from an antenna (116), a height (Hp) between the center of the high density plasma region and an internal upper plane of a vacuum chamber (111) and the value (Dp) are obtained. Based on the inner pressure and a self-bias potential of the substrate (1), a height (Hs) between a lower section in the plasma diffusion region and an upper plane of a supporting table (113) are obtained, and based on the values of (Dp), (Hp) and (Hs), the value (H) showing the range where the uniform sputter etching can be performed is obtained from the map, and a lifting apparatus (121) is controlled so as to be at the value (H).

Owner:MITSUBISHI HEAVY IND LTD

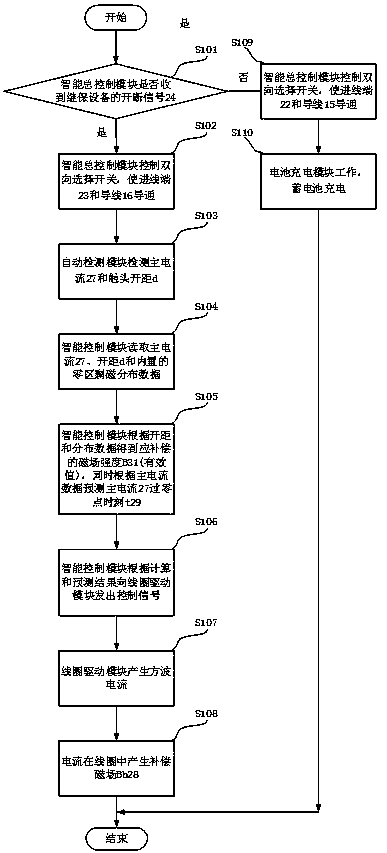

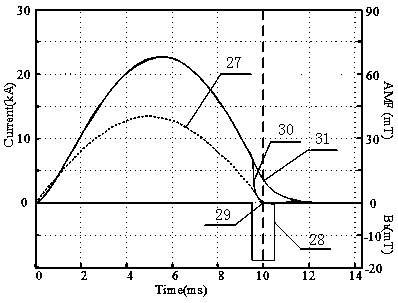

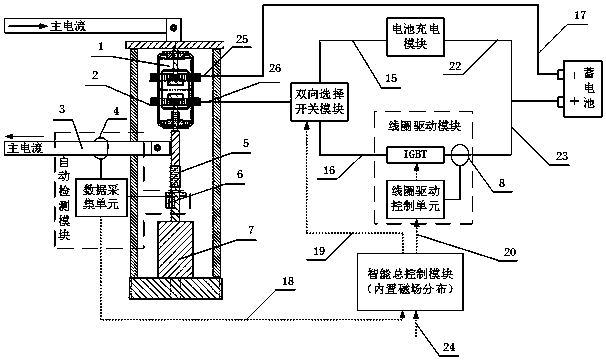

Residual magnetism automatic compensation device for axial magnetic vacuum arc-extinguishing chamber arc region

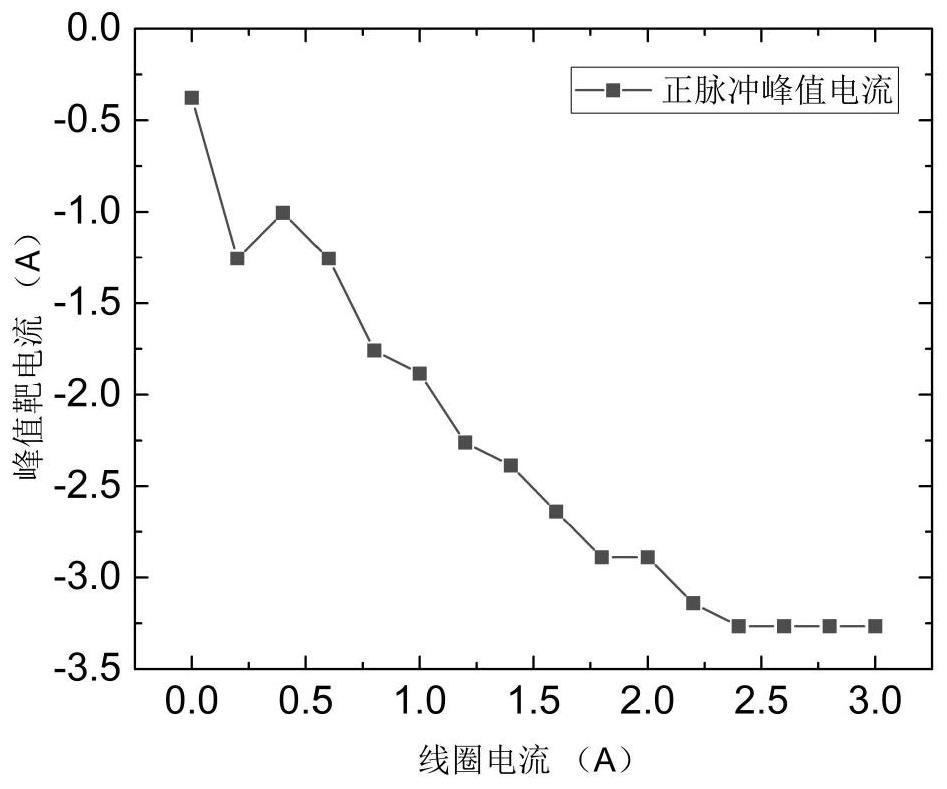

ActiveCN109545617AEasy to integrateReduce spreadHigh-tension/heavy-dress switchesAir-break switchesHelmholtz coilBattery charge

The invention discloses a residual magnetism automatic compensation device for an axial magnetic vacuum arc-extinguishing chamber arc region. The residual magnetism automatic compensation device comprises an automatic detection module, an intelligent master control module, a bidirectional switch module, a coil drive module, a battery charging module, a Helmholtz coil and a battery. The residual magnetism automatic compensation device monitors a current zero point and a switch opening distance in real time by automatic detection technology, realizes the accurate compensation of the residual magnetism of the zero region by using reverse pulse magnetic field control in combination with the residual magnetism distribution of the zero region of the vacuum arc-extinguishing chamber, and obtainszero residual magnetism in the vicinity of the zero region of a vacuum switch, thereby further reducing the constraint on the residual plasma diffusion caused by the residual magnetism in the zero region and improving the switching capacity of the vacuum switch.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com