Preparation method of sintered neodymium-iron-boron magnet with high magnetic energy product and high coercivity

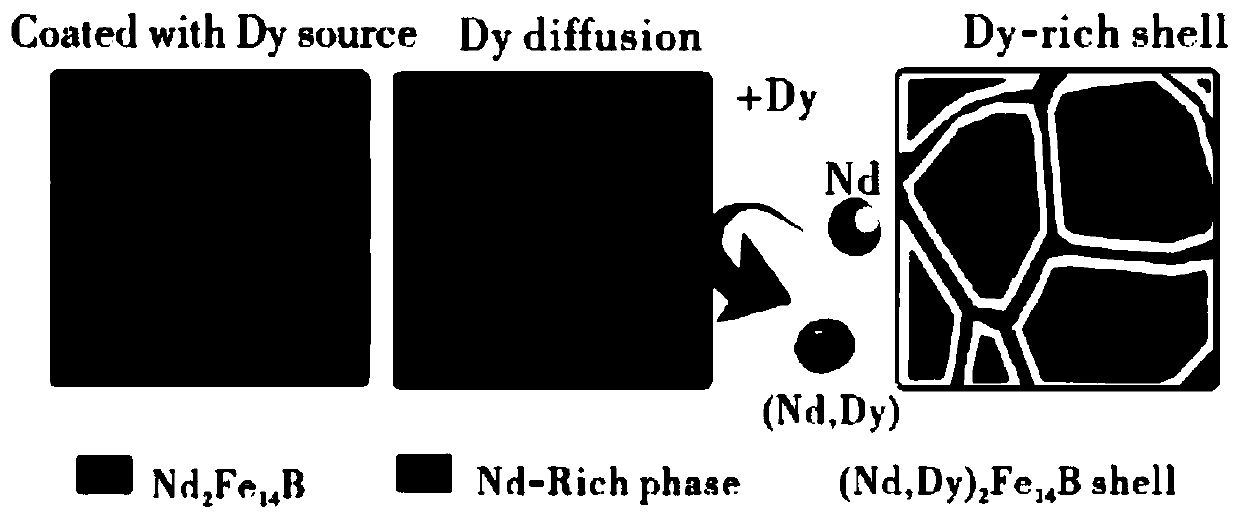

A technology with high coercive force and high magnetic energy product, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc. It can solve the problems of poor consistency of magnetic properties of magnets, unfavorable production efficiency, and low utilization of heavy rare earth elements. , to achieve the effect of high consistency of magnetic properties of products, solution to poor product consistency, and easy commercial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

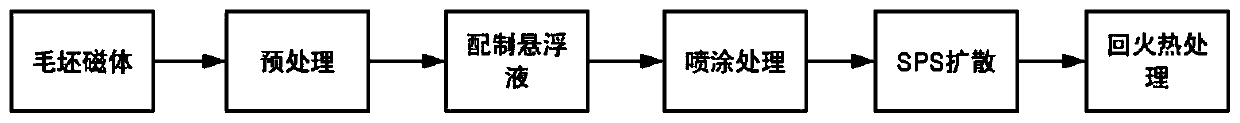

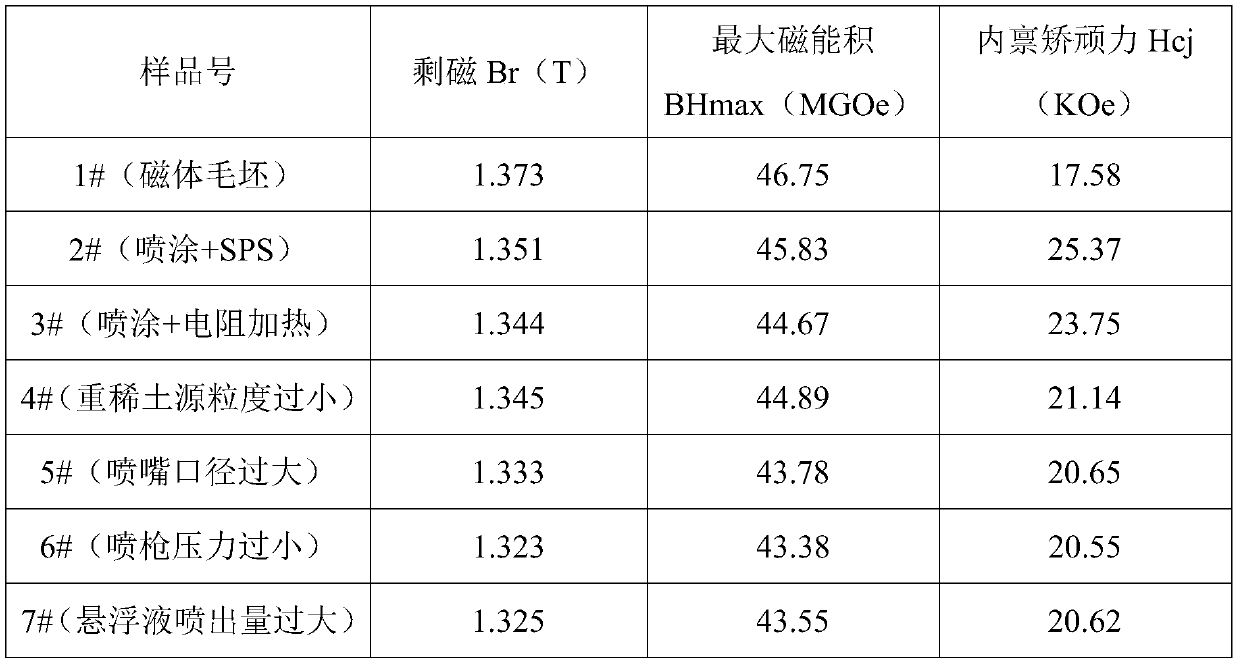

[0052] A method for preparing a high energy product, high coercive force sintered NdFeB magnet, the process is as follows:

[0053] A. Preparation of sintered NdFeB blank magnets: Through batching - smelting and stripping - hydrogen explosion - jet milling - magnetic field forming - sintering - machining and other processes, a blank magnet with a size of 8mm in the minimum thickness direction is prepared, marked as 1# .

[0054] B. Pretreatment of the sintered NdFeB blank: use sandpaper to polish the six sides of the blank magnet in turn to remove the surface oxide layer. Then use deionized water to ultrasonically clean the rough magnet to remove surface oil, and the cleaning time is 1 min. Then pickle the blank magnet in nitric alcohol solution to better absorb the heavy rare earth particles, the concentration of nitric acid in the nitric alcohol solution is 3wt.%, and the pickling time is 1min. Finally, the magnet after pickling is cleaned in absolute ethanol to remove the...

Embodiment 2

[0072] A method for preparing a high energy product, high coercive force sintered NdFeB magnet, the process is as follows:

[0073] A. Preparation of sintered NdFeB blank magnets: Through batching - smelting and stripping - hydrogen explosion - jet milling - magnetic field forming - sintering - machining and other processes, a blank magnet with a minimum thickness direction of 7.5 mm is prepared, marked as 1 #.

[0074] B. Pretreatment of the sintered NdFeB blank: use sandpaper to polish the six sides of the blank magnet in turn to remove the surface oxide layer. Then use deionized water to ultrasonically clean the rough magnet to remove surface oil, and the cleaning time is 1 min. Then pickle the rough magnet in nitric alcohol solution, in order to better absorb the heavy rare earth particles, the concentration of nitric acid in the nitric alcohol solution is 3.5wt.%, and the pickling time is 1.5min. Finally, wash the magnet after pickling in absolute ethanol to remove the ...

Embodiment 3

[0084] A method for preparing a high energy product, high coercive force sintered NdFeB magnet, the process is as follows:

[0085] A. Preparation of sintered NdFeB blank magnets: Through batching - smelting and stripping - hydrogen explosion - jet milling - magnetic field forming - sintering - machining and other processes, a blank magnet with a size of 7mm in the minimum thickness direction is prepared, marked as 1# .

[0086] B. Pretreatment of the sintered NdFeB blank: use sandpaper to polish the six sides of the blank magnet in turn to remove the surface oxide layer. Then use deionized water to ultrasonically clean the rough magnet to remove surface oil, and the cleaning time is 2 minutes. Then pickle the rough magnet in nitric alcohol solution to better absorb the heavy rare earth particles, the concentration of nitric acid in the nitric alcohol solution is 4wt.%, and the pickling time is 1.5min. Finally, wash the magnet after pickling in absolute ethanol to remove the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com