Steel belt wheel-type continuous casting machine for continuous casting of lead belts

A technology of continuous casting machine and steel strip, applied in the field of continuous casting equipment for non-ferrous alloys, can solve the problems of occupying cooling system installation space, cooling water flow or spray path, inability to set steel strip support structure, reducing cooling capacity, etc. The possibility of random deformation is small, the amount of deformation is small, and the cooling effect is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

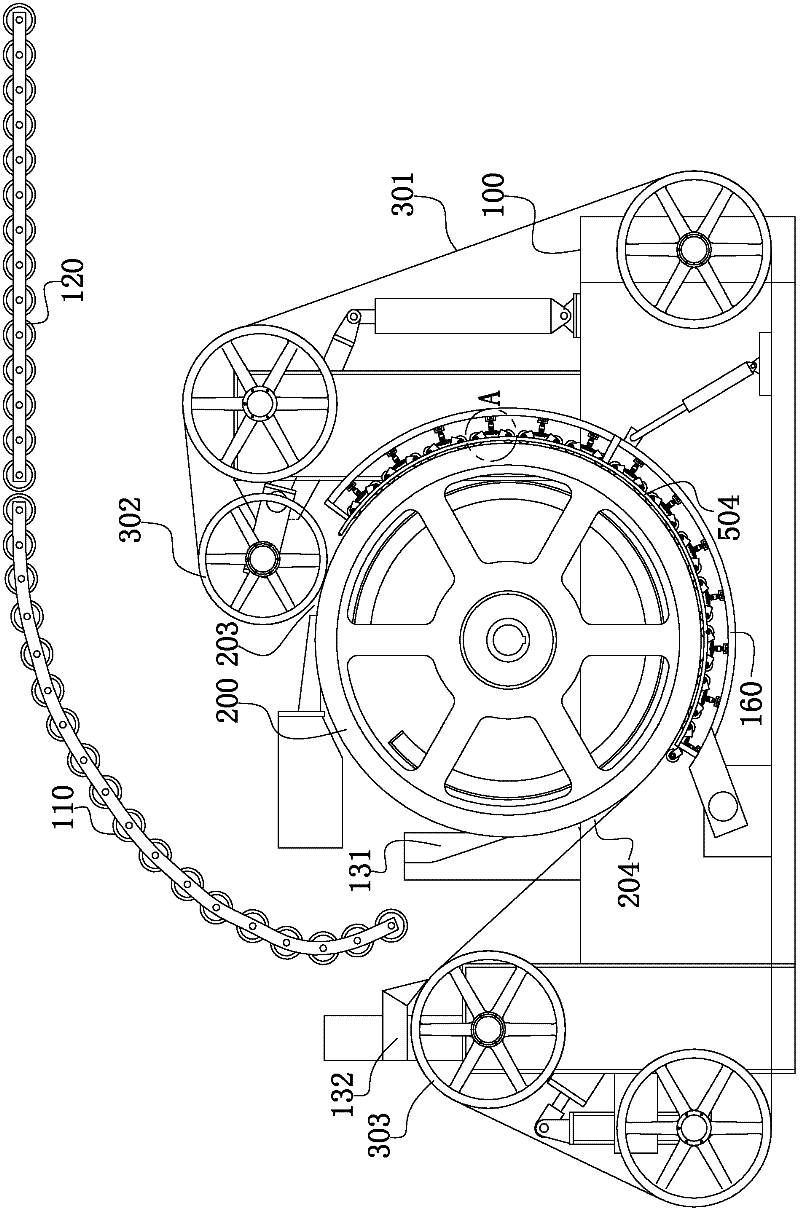

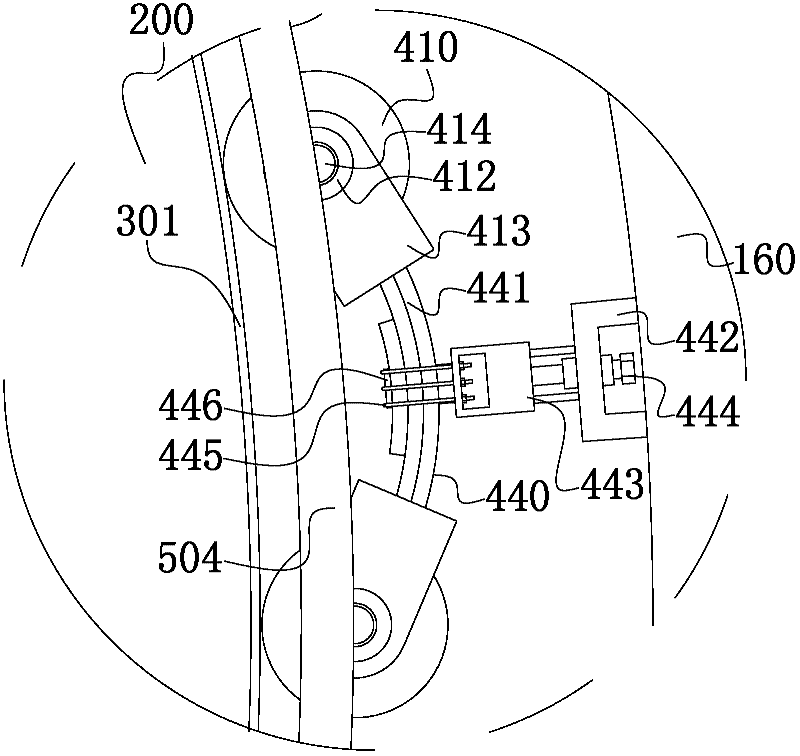

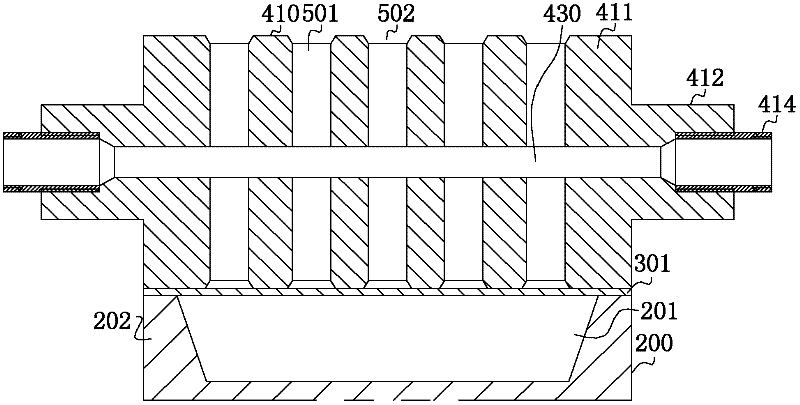

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The steel belt wheel continuous casting machine shown can produce lead belts with a width of 360mm and a thickness of 40mm, including the frame 100, the crystallization wheel 200, the steel belt wheel train, the endless steel belt 301, and the cooling system for the steel belt 301 , Cooling water supply system.

[0034] The outer diameter of the crystallization wheel 200 is 1800mm, and the outer cylindrical surface of the crystallization wheel 200 is provided with a concave crystallization cavity 201, the steel belt 301 is tightened by the steel belt wheel system and bypasses the crystallization wheel 200, and the crystallization is closed by the steel belt 301 Part of the crystallization cavity 201 of the wheel 200 constitutes a cavity extending along the circumference of the crystallization wheel 200 , and the corresponding central angle of the cavity is 215°.

[0035] One end of the cavity is the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com