Patents

Literature

140results about How to "Guaranteed thickness uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

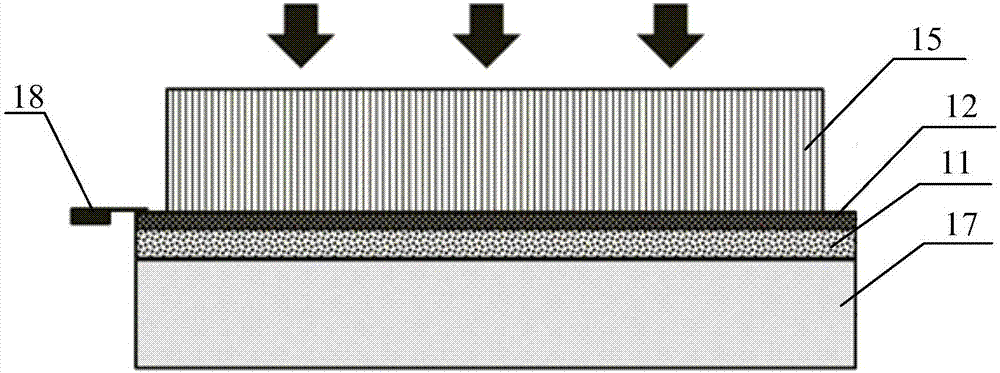

Sheet material thickness online detection and adjustment system based on laser ultrasonic

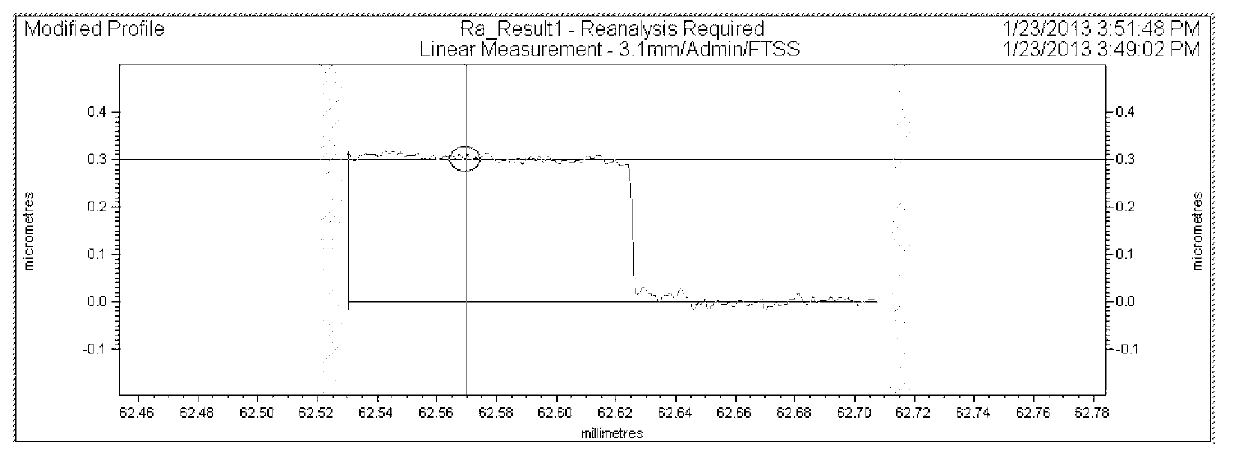

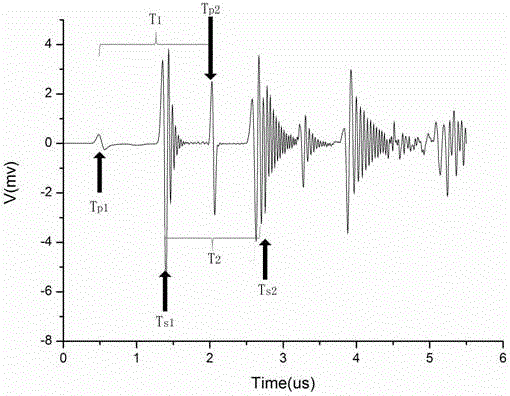

ActiveCN104707871ARealize non-contact measurementMeasuring Thickness UniformityRoll mill control devicesMeasuring devicesProcess systemsBipolar signal

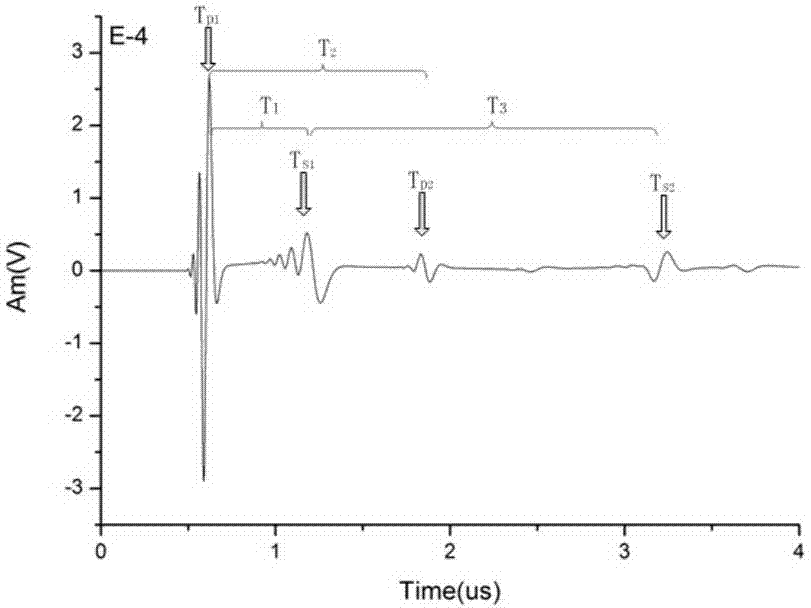

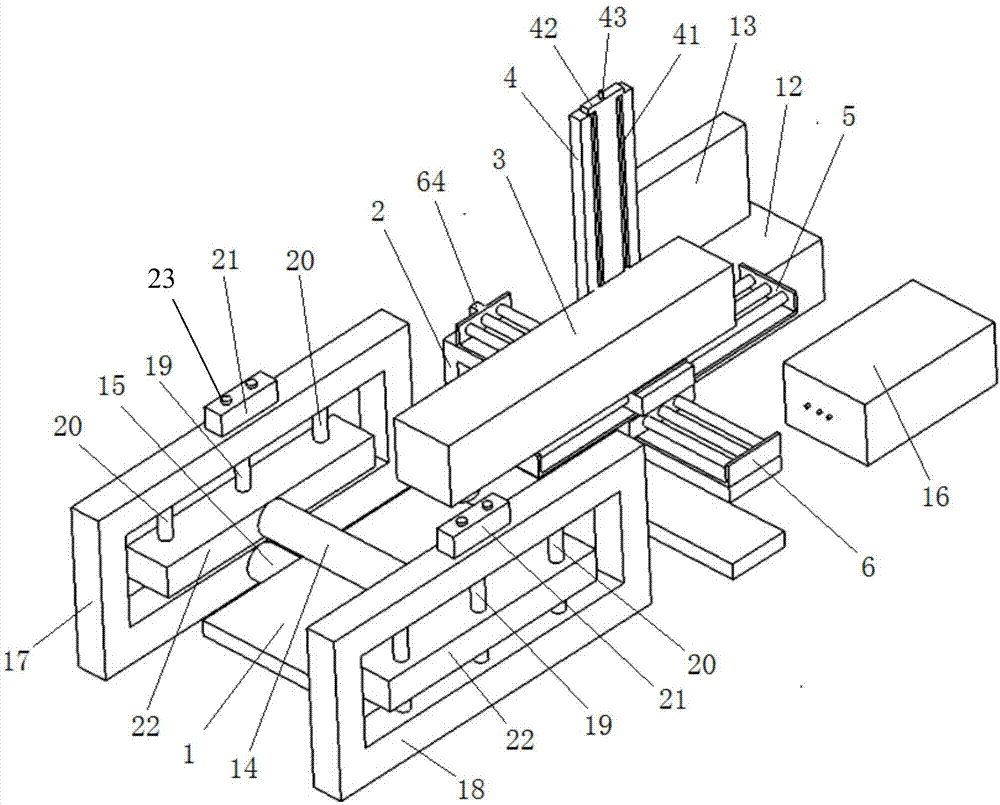

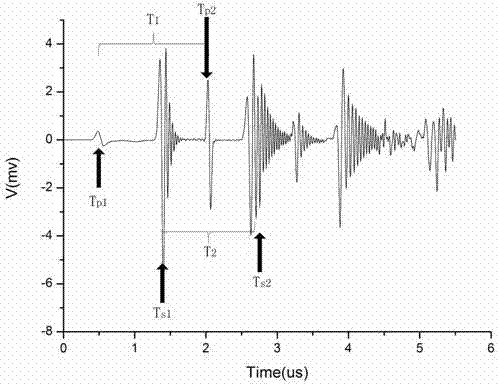

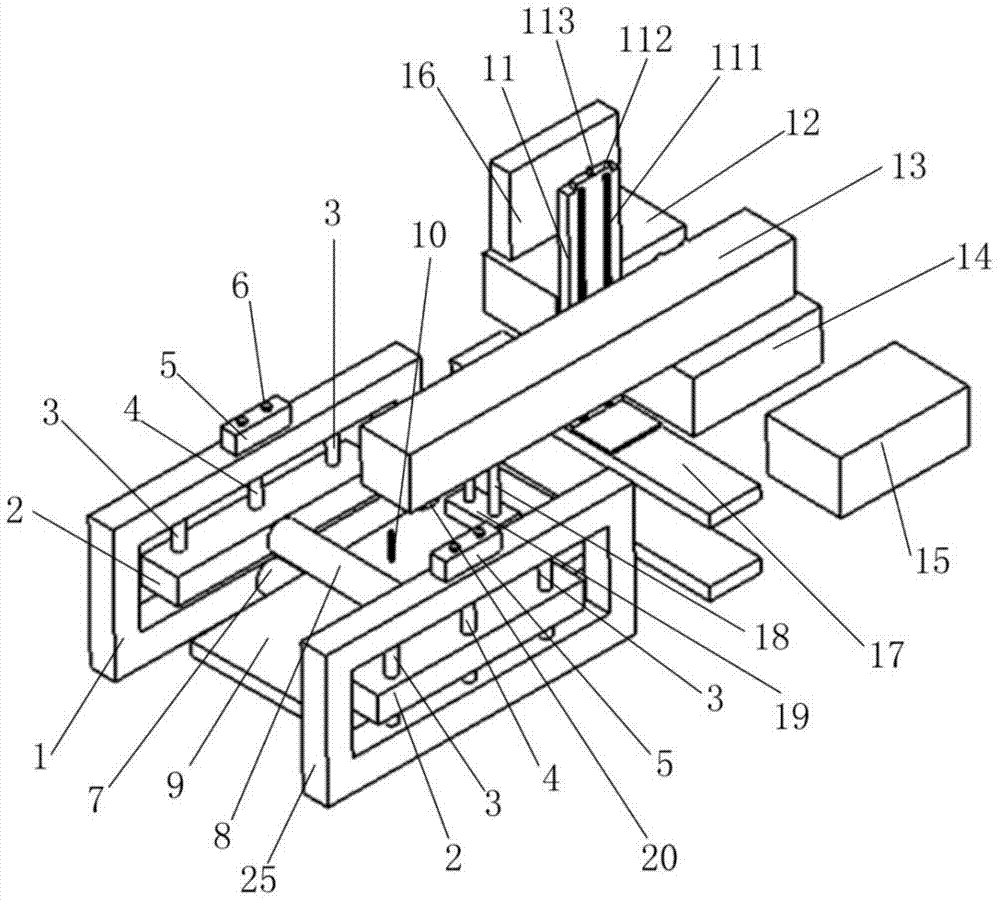

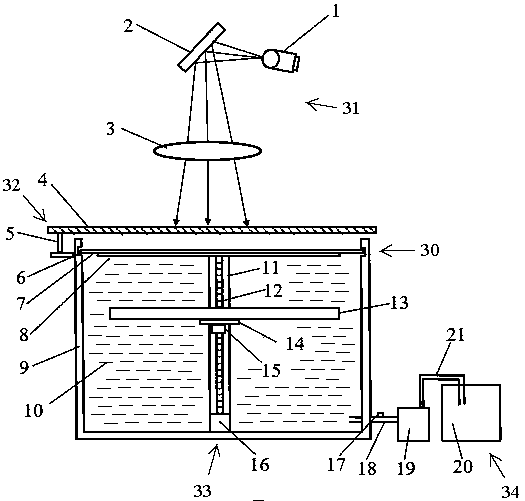

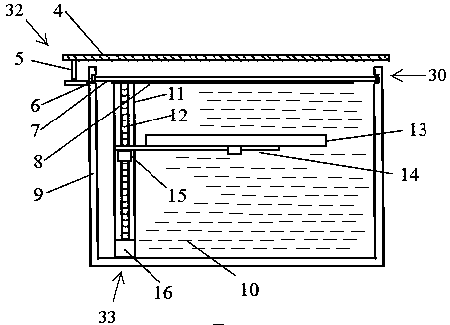

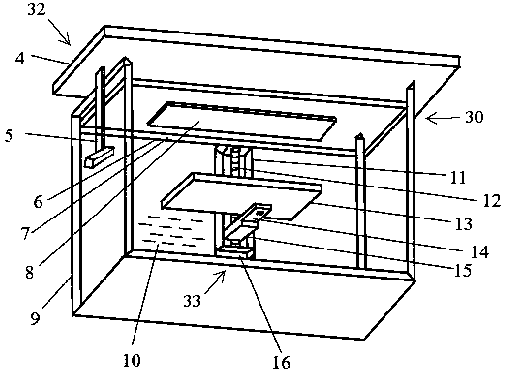

A sheet material thickness online detection and adjustment system based on laser ultrasonic comprises a sheet material rolling mechanism and a sheet material thickness online detection mechanism. The sheet material rolling mechanism comprises an upper roller, a lower roller, an upper-lower roller interval adjust mechanism and a PLC control system, the sheet material thickness online detection mechanism comprises an optics system assembly, a high temperature testing meter, a data collection system assembly and a data process system assembly, the data process system assembly transforms bipolar signals which are aliased in peak values and complex in background noise into unipolar signals which are clear in peak values and low in background noise, so that the time that longitudinal wave and transverse wave reach the center of the bottom surface of the sheet material for the first two times is obtained, and thereby the sheet material thickness value is calculated, the measured sheet material thickness value is compared with a preset sheet material thickness value in the PLC control system, the PLC control system transmits forward rotating / backward rotation movement commands to a servo motor, so that the interval between the upper roller and the lower roller is adjusted, and the sheet material thickness value is made to be consistent with the preset sheet material thickness value.

Owner:ZHEJIANG UNIV

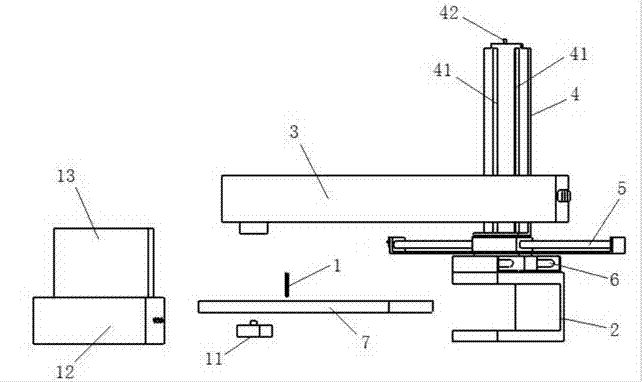

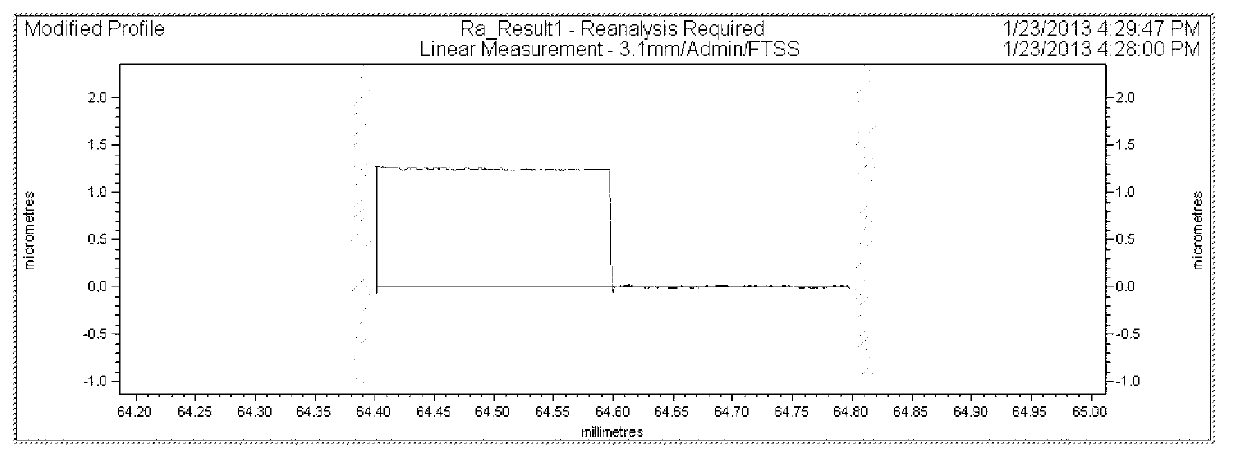

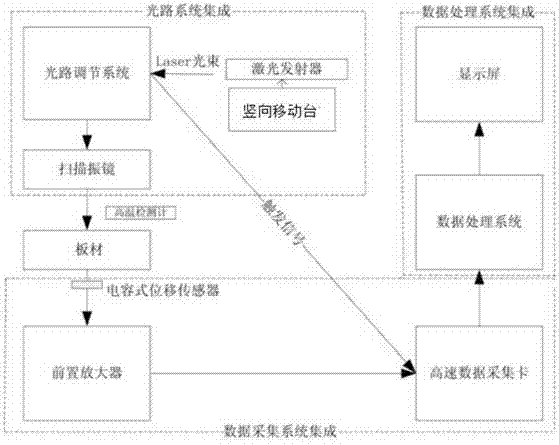

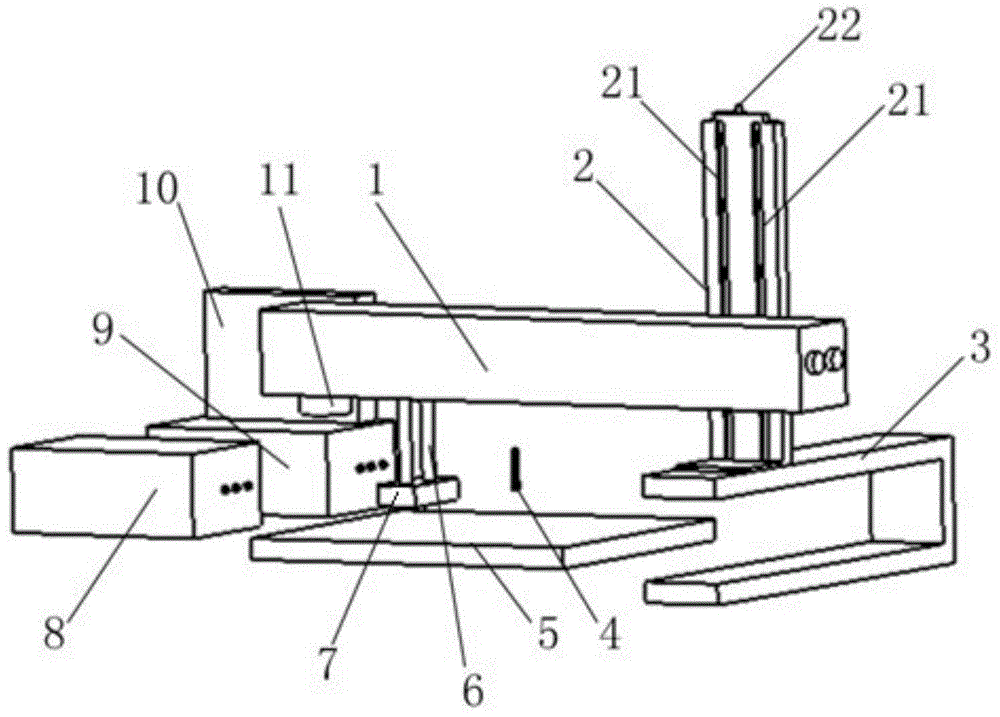

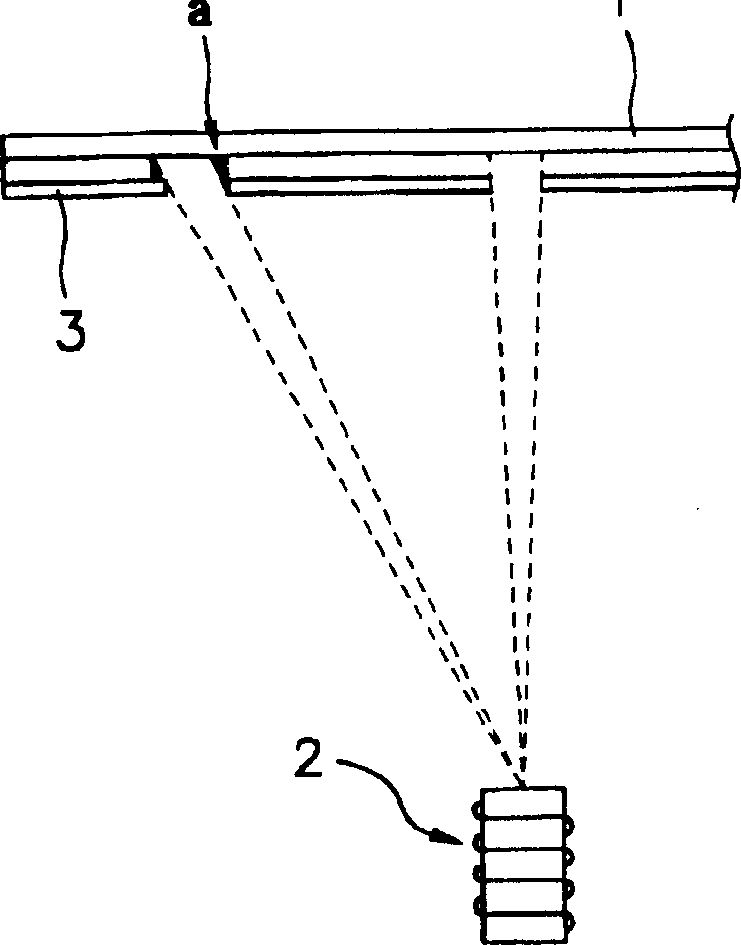

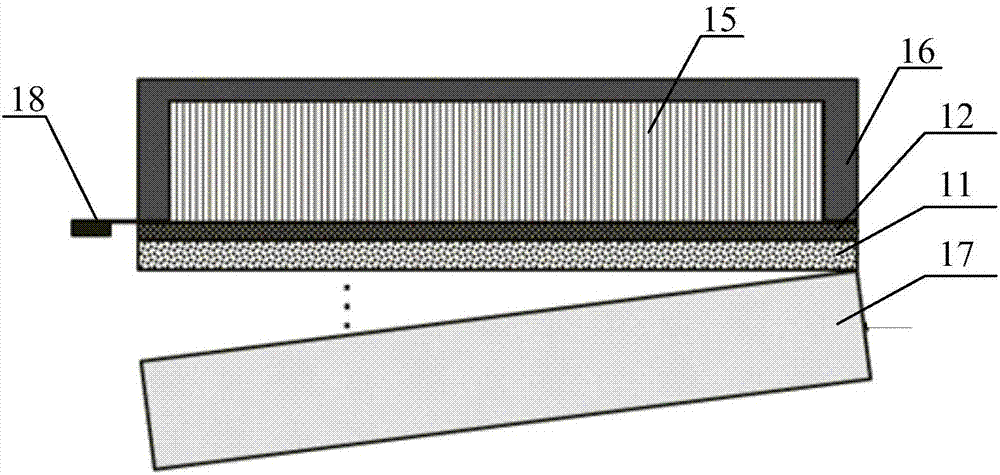

Sheet thickness online measurement system based on laser ultrasound

ActiveCN104729435AHigh movement accuracyRealize real-time online non-destructive testingUsing subsonic/sonic/ultrasonic vibration meansUsing optical meansLaser transmitterSonification

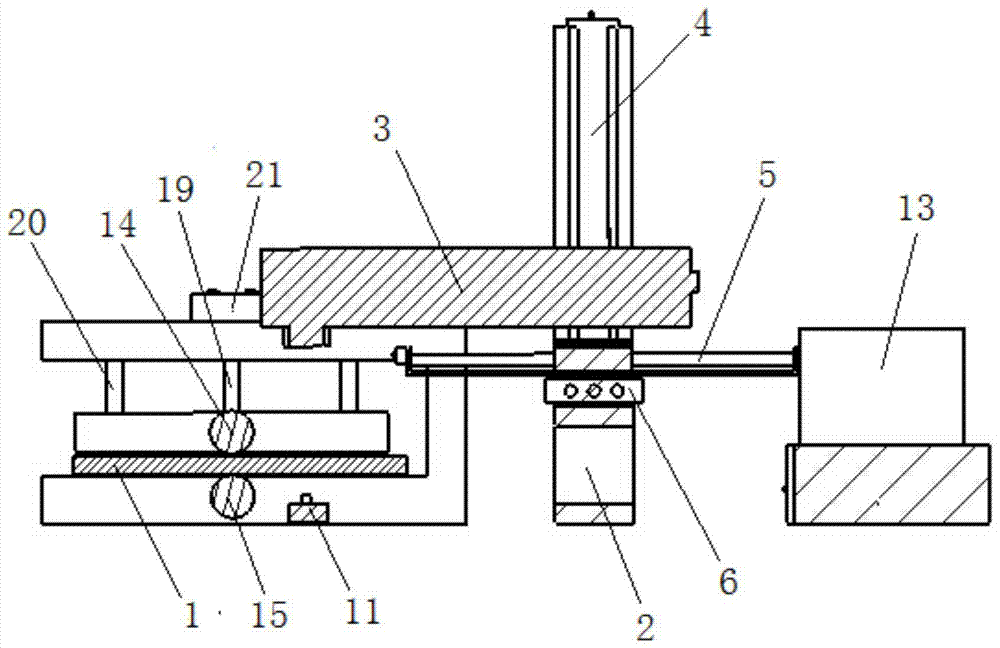

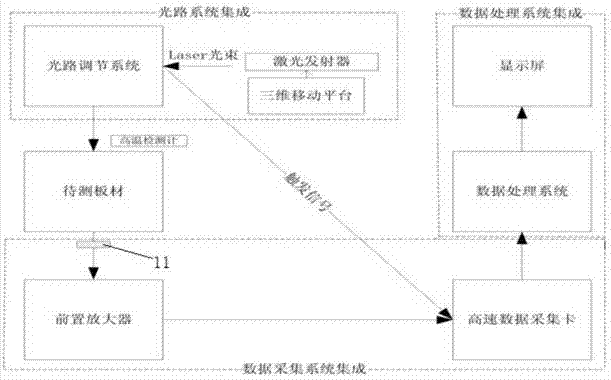

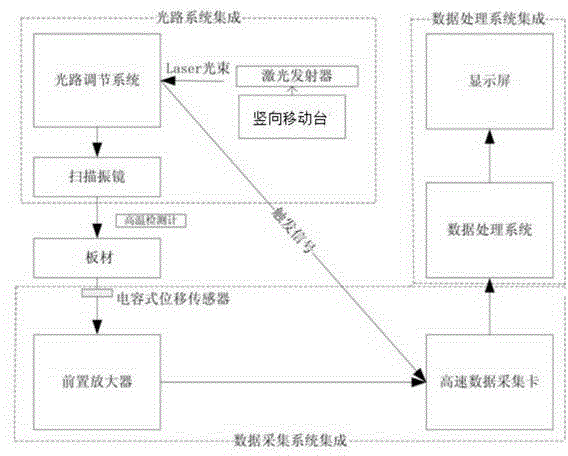

A sheet thickness online measurement system based on laser ultrasound comprises a light path system integration, a high-temperature detection meter, a data acquisition system integration and a data processing system integration, wherein the light path system integration comprises a U-shaped grounding frame, a three-dimensional mobile platform and a control cabinet integrating with a laser transmitter and a light path regulating system; the data acquisition system integration comprises a capacitive displacement sensor, a pre-amplifier and a high-speed data acquisition card, the capacitive displacement sensor is arranged at the first distance position below the alignment position of the bottom surface of a sheet, the data processing system integration converts bipolar signals having aliasing peak values and complex background noise into unipolar signals having clear peak values and low background noise, and therefore the time when longitudinal waves and transverse waves reach the alignment position of the bottom surface of the sheet first two times is accurately obtained, and the thickness of the sheet is calculated. The sheet thickness online measurement system has the advantages that the sheet thickness online measurement system is suitable for online measuring the thickness of the sheet under extreme environments such as high temperature, strong corrosion and high radiation, thickness measurement is accurate, and errors are small.

Owner:ZHEJIANG UNIV

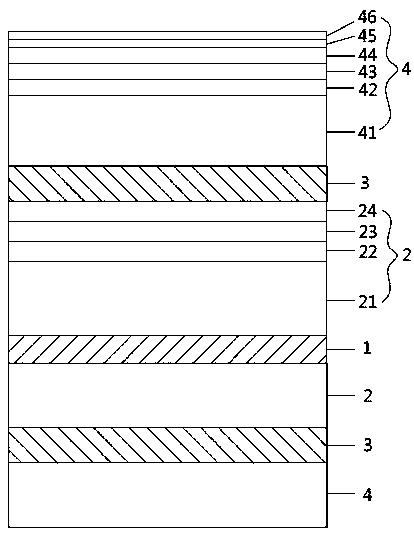

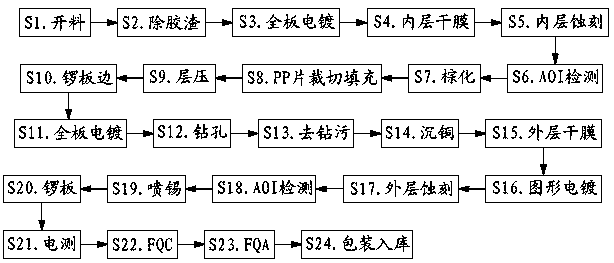

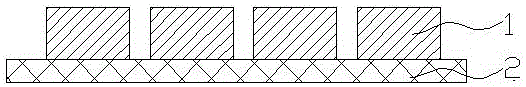

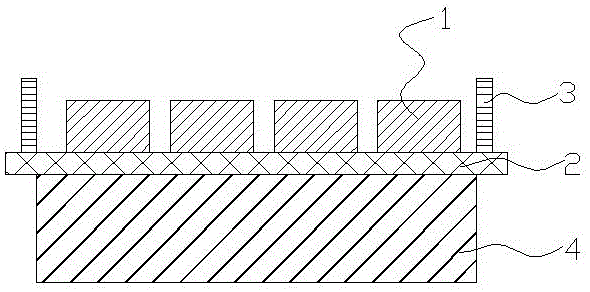

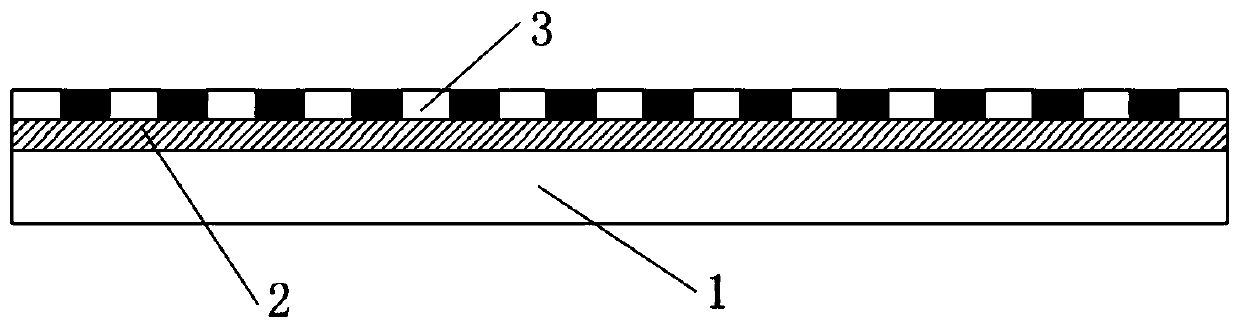

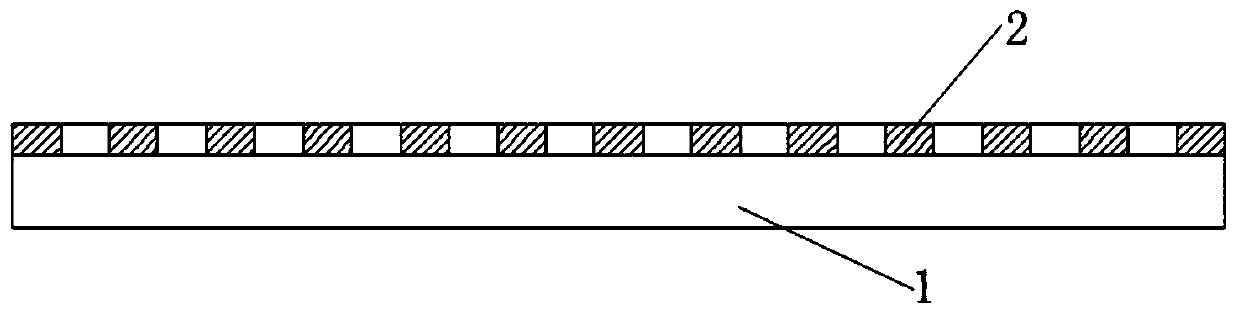

Super-thick copper PCB with inner and outer layers of 6OZ, and manufacturing method thereof

PendingCN108718480AGuaranteed thickness uniformityMeet thick requirementsPrinted circuit aspectsPrinted circuit manufactureCut and fillCopper

The invention discloses a super-thick copper PCB with inner and outer layers of 6OZ, and a manufacturing method thereof. The PCB is composed of a core board, inner-layer copper plated on the upper andlower surfaces of the core board, a PP sheet pressed on the inner-layer copper, and outer-layer copper plated on the PP sheet. The manufacturing method comprises the steps of cutting, removing smear,plating the full board, drying the film on the inner layer, etching the inner layer, AOI detection, browning, cutting and filling the PP sheet, laminating, milling the edge of the board, plating thefull board for the second time, drilling a hole, removing drill smear, drying the film on the outer layer, plating a pattern, etching the outer layer, secondary AOI detection, coating solder, millingthe board and electrical logging. According to the super-thick copper PCB provided by the invention, the inner-layer copper, the PP sheet and the outer-layer copper are sequentially arranged on the upper and lower surfaces of the core board that is 0.1mm thick to form a laminated structure, so that the overall thickness of the board is controlled to be 1.4-1.6mm, and the thickness uniformity of the PCB is ensured.

Owner:江门荣信电路板有限公司

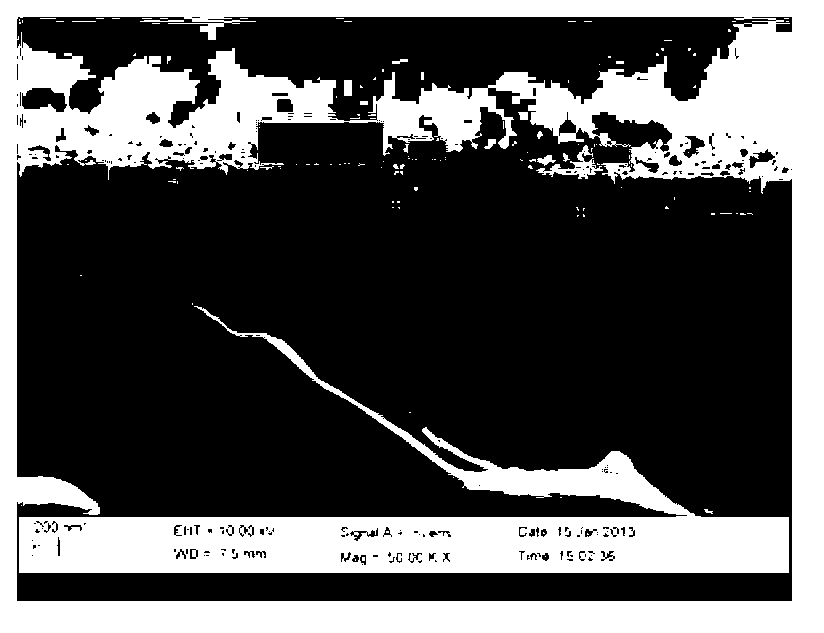

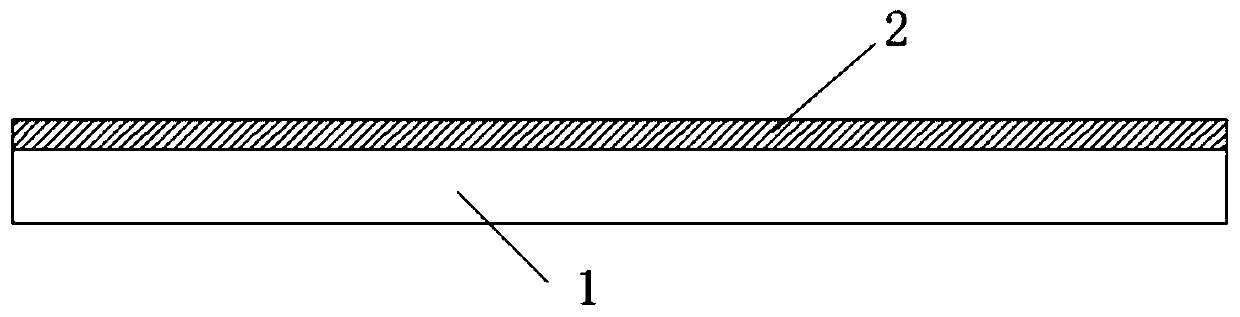

Metal film preparation method

InactiveCN103132039AFlat surfaceExcellent surface roughness Ra valueVacuum evaporation coatingSputtering coatingDiffractometerMetal substrate

The invention discloses a metal film preparation method. The method comprises the following steps: 1, coating an adhesive in a selected area on the surface of a metal substrate; 2, allowing the adhesive to stand for drying to form an adhesive layer, and coating a metal film on the surface of the metal substrate and the adhesive layer; and 3, infiltrating the metal substrate in an organic solvent after the coating completion to soften the adhesive layer, and carrying out ultrasonic treatment of the metal substrate in the organic solvent to remove the adhesive layer to obtain a metal film having a stepped structure. The adhesive is coated to protect the partial surface of the substrate, and steps are formed on the surface of the film through the adhesive removal mode, so the completeness and edge clearness of the stepped structure of the metal film are guaranteed. The metal film prepared in the invention is suitable for contourgraphs and scanning probe microscopes to measure the heights of the steps of the metal film and standardize the thickness of the film, and is also used for the metering calibration of non-contact direct thickness testers (such as X-ray diffractometers and X-ray fluorescence thickness testers).

Owner:GUANGDONG INST OF METROLOGY

Online sheet thickness detecting and adjusting system based on laser ultrasonic

ActiveCN104772348AAccurate calculationEasy to installRoll mill control devicesMeasuring devicesOptical pathData processing

An online sheet thickness detecting and adjusting system based on laser ultrasonic comprises a sheet rolling mechanism and an online sheet thickness detecting mechanism; the sheet rolling mechanism comprises an upper roller, a lower roller, an adjusting mechanism for the distance between the upper roller and the lower roller and a PLC controlling system; the online sheet thickness detecting mechanism comprises an optical path system assembly, a high temperature detecting meter, a data collecting system assembly and a data processing system assembly. The data processing system assembly can convert bipolar signals with aliasing peak values and complex background noise into unipolar signals with clear peak values and small background noise, time for the longitudinal wave and the horizontal wave to reach an O point on the upper surface of a sheet at the first two times can be obtained accurately, the sheet thickness value can be calculated out, the measured sheet thickness value is compared with a preset sheet thickness value in the PLC controlling system, the PLC controlling system can send forward rotation / reversed rotation moving instructions to a servo motor, the distance between the upper roller and the lower roller can be adjusted, and the sheet thickness value can be identical with the preset sheet value.

Owner:ZHEJIANG UNIV

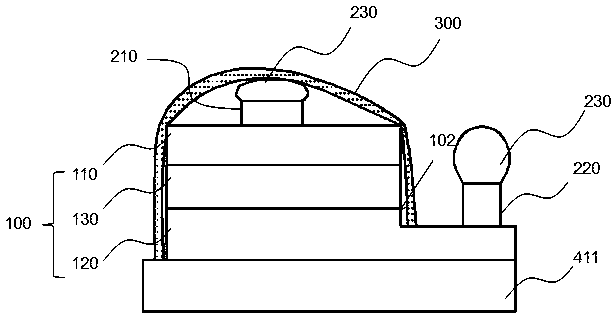

Single-sided light emission light emitting element and production method thereof

ActiveCN106025040AIncrease profitImprove consistencySemiconductor devicesPolymer light emitting diodesLight emission

The invention provides a single-sided light emission light emitting element and a production method thereof, and relates to the field of semiconductor device packaging. Two electrodes are arranged at the bottom of a light emitting diode. The single-sided light emission light emitting element is characterized in that a fluorescent powder glue layer is arranged on the front of the light emitting diode, and reflective glue layers are arranged on four sides of the light emitting diode. The preparation method is characterized in that a single single-sided light emitting diode without cutting marks on four sides without cutting is acquired, and the fluorescent powder glue layer of the light emission side of the light emitting diode can be designed through repeated filling. According to the invention, the preparation process does not need expensive and high-precision cutting equipment, so that an enterprise can have more abundant capital to expand production; since cutting is prevented, the utilization ratio of fluorescent powder glue is improved; and production period is shortened.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

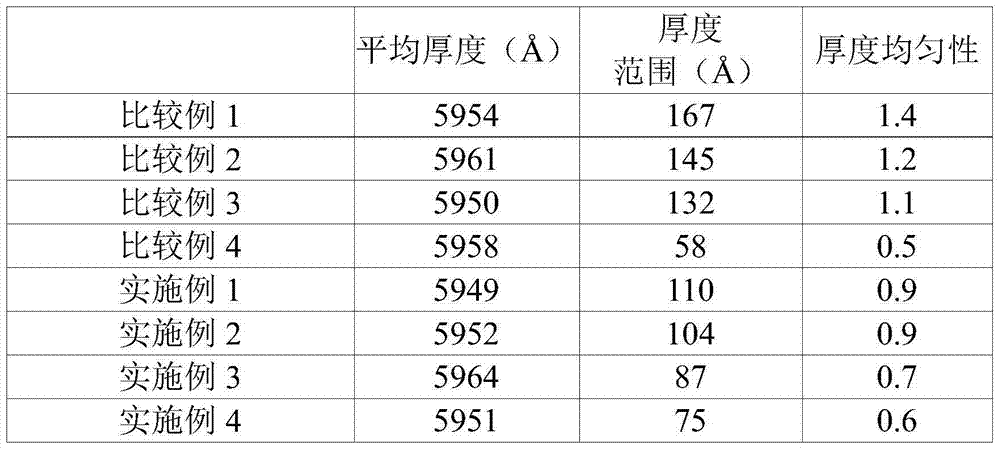

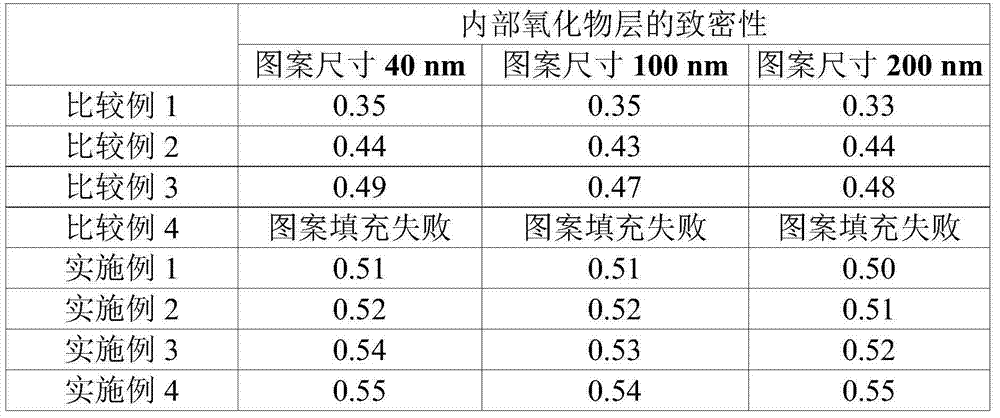

Composition for a silica based layer, and silica based layer

InactiveCN104513613AImprove compactnessGuaranteed thickness uniformityPretreated surfacesCoatingsSolventSilicon dioxide

Owner:SAMSUNG SDI CO LTD

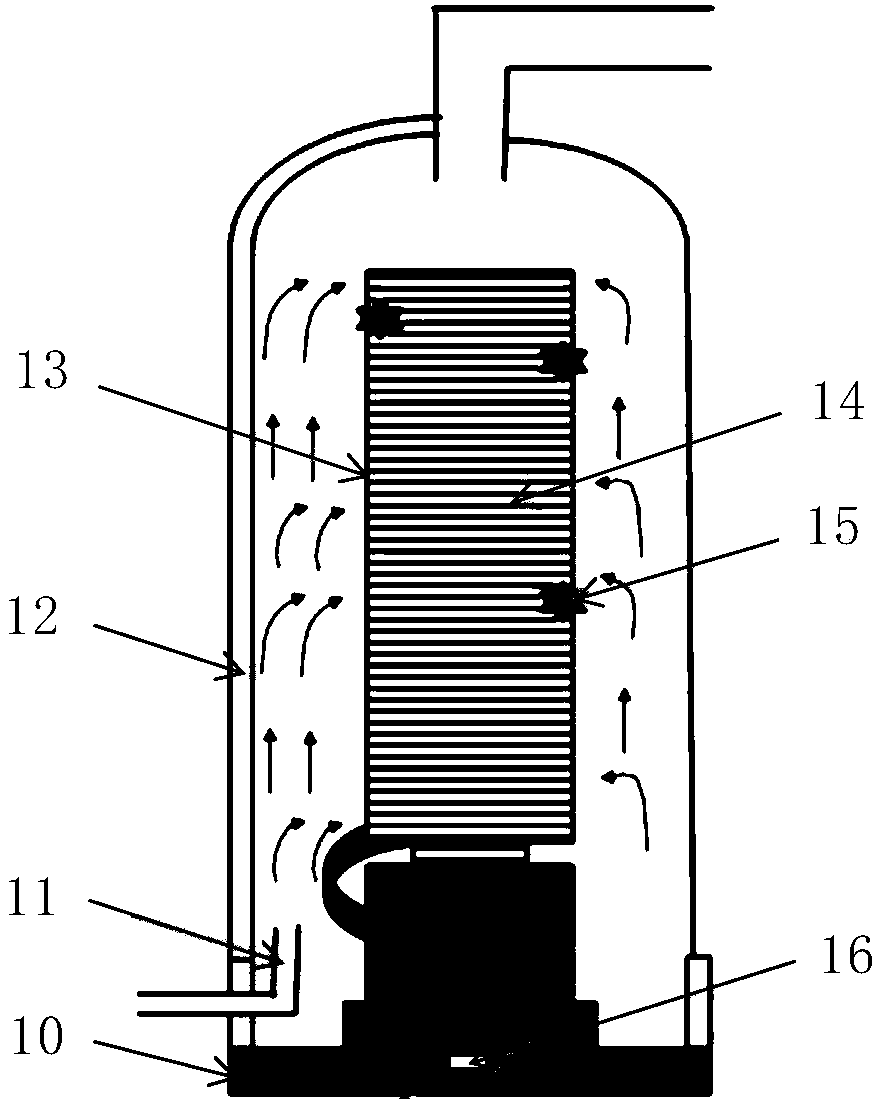

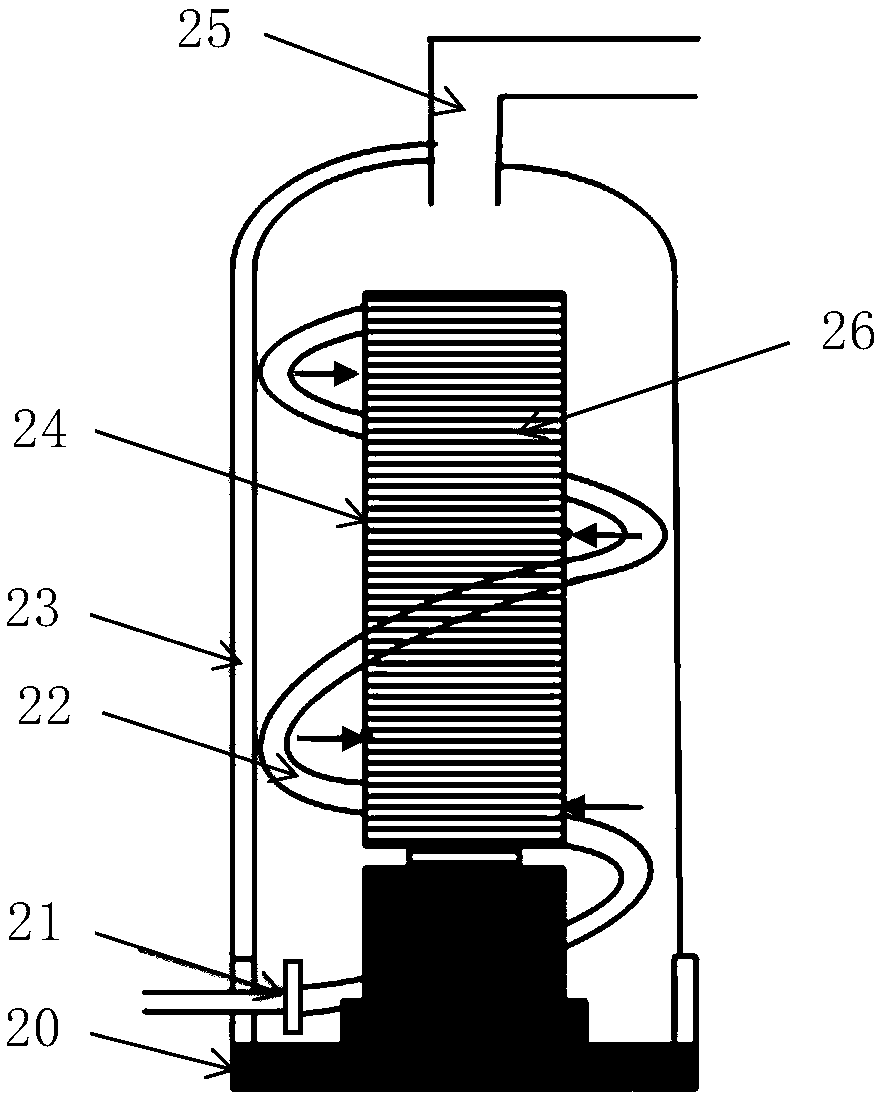

Sealing booster-type slurry pool device for overhead light source 3D printer

ActiveCN107627601AImprove adaptabilityGuaranteed dark storageManufacturing enclosures3D object support structuresSurface layerSlurry

The invention relates to a sealing booster-type slurry pool device for an overhead light source 3D printer. The sealing booster-type slurry pool device comprises a main slurry pool, a light source mechanism, a transparent sealing mechanism, a lifting mechanism, a sample platform and a booster filling mechanism, wherein the main slurry pool is filled with liquid slurry for light solidification, thelight source mechanism is installed above the device, the transparent sealing mechanism is installed on the top of the main slurry pool, the lifting mechanism is installed in the main slurry pool, the sample platform is installed on the lifting mechanism, and the booster filling mechanism is connected with the main slurry pool. According to the sealing booster-type slurry pool device, the heightcontrol over slurry in the slurry pool can be guaranteed, the coating step of the surface layer of the slurry after light solidification is omitted, the printing time is shortened, the defects of level fluctuation and uniformity in coating of a traditional scraper type spreading structure are overcome, the influence of the slurry flowability on a slurry filling process is reduced, the working efficiency is improved, and the printed layer thickness accuracy is increased.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

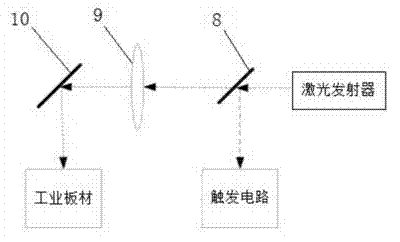

Online plate thickness measuring system based on laser ultrasonics

ActiveCN104792285ARealize non-contact measurementAccurate calculationUsing subsonic/sonic/ultrasonic vibration meansUsing optical meansLaser transmitterSonification

An online plate thickness measuring system based on laser ultrasonics comprises a light path system integration module, a high-temperature detector, a data collection system integration module and a data processing system integration module. The light path system integration module comprises a U-shaped grounding frame, a vertical moving platform and a control cabinet, a laser transmitter, a light path adjusting system and a scanning galvanometer are integrated in the control cabinet, the data collection system integration module comprises a capacitive displacement sensor, a preposed amplifier and a high-speed data collection card, the capacitive displacement sensor is arranged at a first distance position above the upper surface of a plate, and the data processing system integration module converts bipolar signals with aliasing peak value and complex background noise into unipolar signals with clear peak value and low background noise so as to accurately acquire time when longitudinal wave and transverse wave reach an O point on the upper surface of the plate in two previous times to calculate thickness of the plate. The online plate thickness measuring system has the advantages that the system utilizes a laser ultrasonics principle to measure thickness and is suitable for online measuring of thickness of the plate in extreme environment with high temperature, high corrosion and high radiation, accurate in thickness measuring and few in thickness measuring error.

Owner:ZHEJIANG UNIV

Low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention and preparation method of low-temperature 3PE dry film hot melt adhesive

InactiveCN110028915AMeet construction needsSolve the needs of joint anticorrosion constructionNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to a low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention. The low-temperature 3PE dry film hot melt adhesive is prepared by kneading a rubber elastomer, bonding resin, tackifying resin, a plasticizer, an antioxidant and a filler and conducting extruding, wherein the rubber elastomer is two or more of a styrene-isoprene-styrene block copolymer, a styrene-ethylene-butene-styrene block copolymer, butyl rubber and ethylene propylene diene monomer; the bonding resin is one or two of an ethylene-vinyl acetate maleic anhydride grafted modified material and an ethylene-acrylate-maleic anhydride terpolymer; the tackifying resin is one or more of terpene resin, C5 petroleum resin and rosin glyceride; and the plasticizer is polyisobutene or naphthenic oil. The low-temperature dry film hot melt adhesive disclosed by the invention is used for pipeline joint coating and corrosion prevention, meets the construction requirements in an extremely cold environment, and meets the pipeline joint coating and corrosion prevention construction requirements in cold regions; and the adhesive has the advantages of excellent adhesion and sealing property, good low-temperature flexibility, higher peel strength and stable performance.

Owner:江苏达胜热缩防护用品有限公司

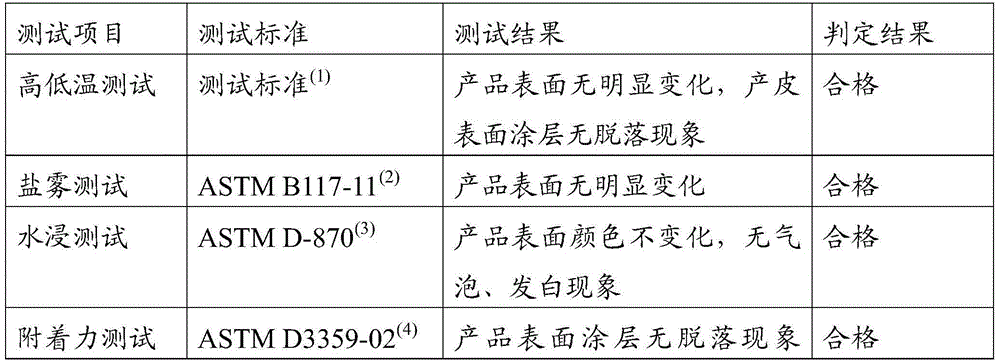

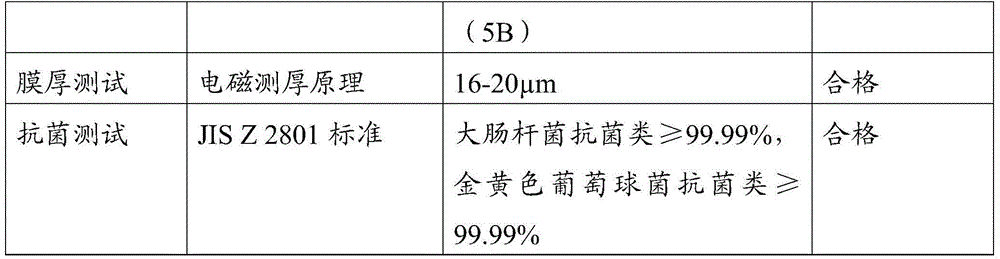

Anti-fingerprint coating and spraying method thereof

InactiveCN104893542AGuaranteed adhesionGuaranteed thickness uniformityLiquid surface applicatorsAntifouling/underwater paintsUltravioletChemistry

The invention provides an anti-fingerprint coating and a spraying method thereof. The anti-fingerprint coating comprises the following components in parts by weight: 60-70 parts of a polyurethane ultraviolet (UV)-curable coating material, 30-40 parts of a diluent and 3-10 parts of an UV-curable fluorine-containing acrylic acid compound, wherein the diluent is a mixture of butyl acetate, acetic ether and butanone. The method for spraying the anti-fingerprint coating to a product comprises the steps of completely wiping the product by virtue of machine wiping water, drying, spraying a bottom varnish, drying, spraying the anti-fingerprint coating, and carrying out UV irradiation. The anti-fingerprint coating has strong anti-fingerprint capacity and antifouling capacity and is convenient to clean, the operation of the spraying process is convenient, the time is short, and the production efficiency is improved.

Owner:SHENZHEN CENCOM TECH

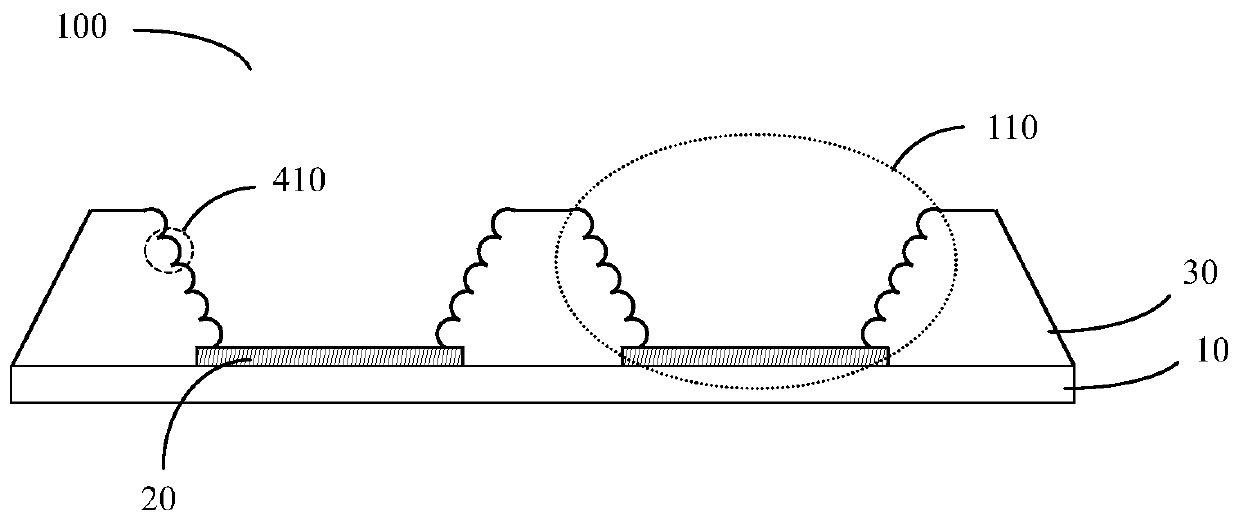

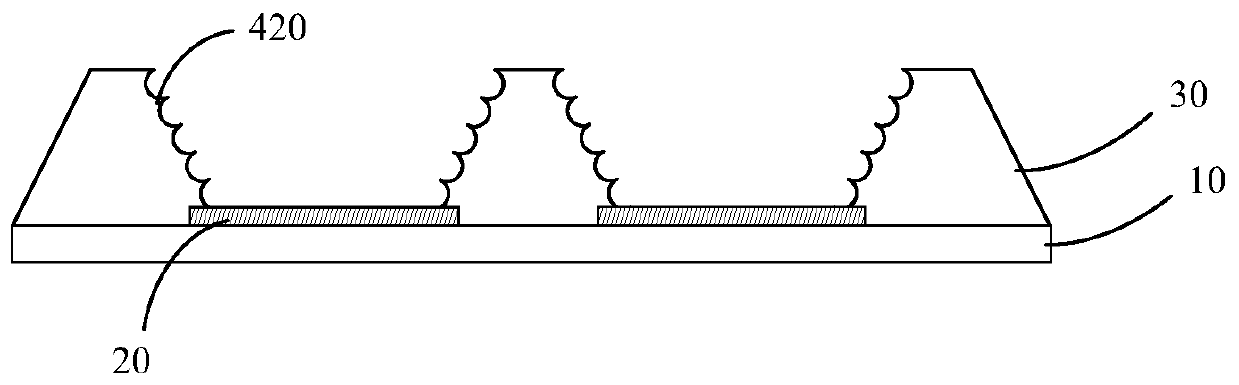

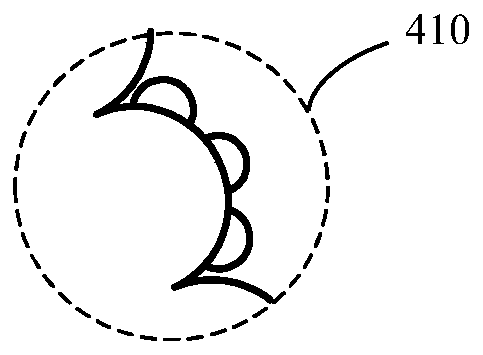

Display substrate, preparation method of display substrate and display panel

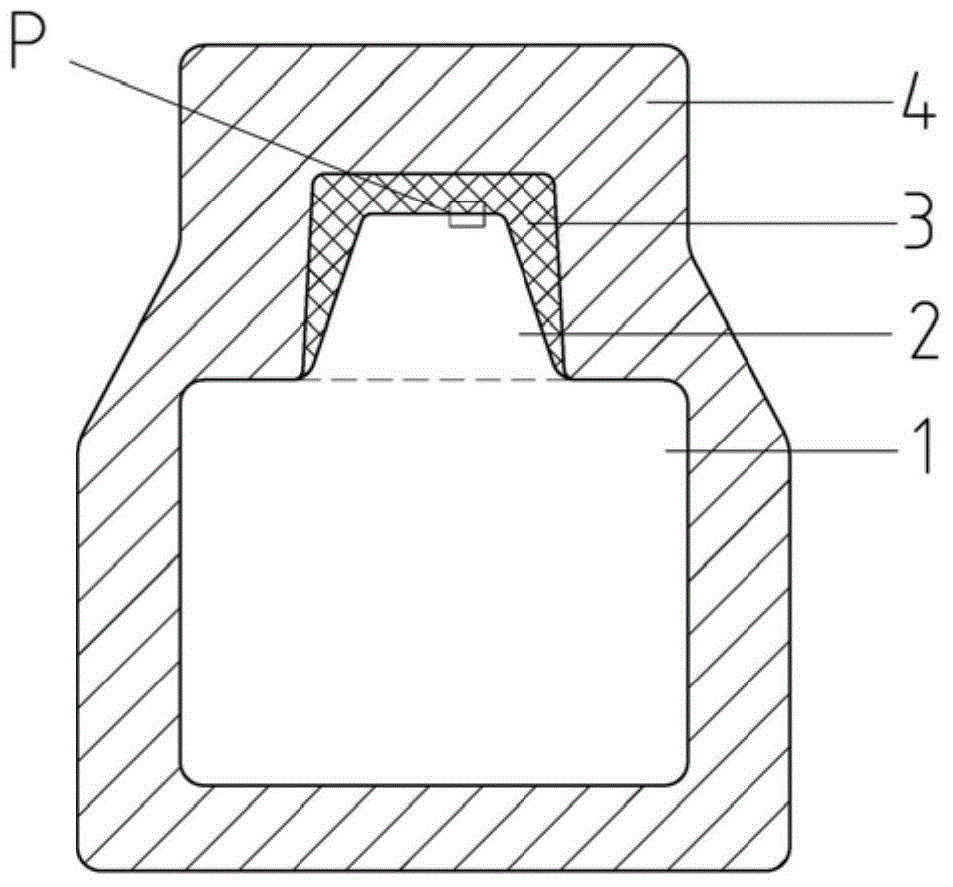

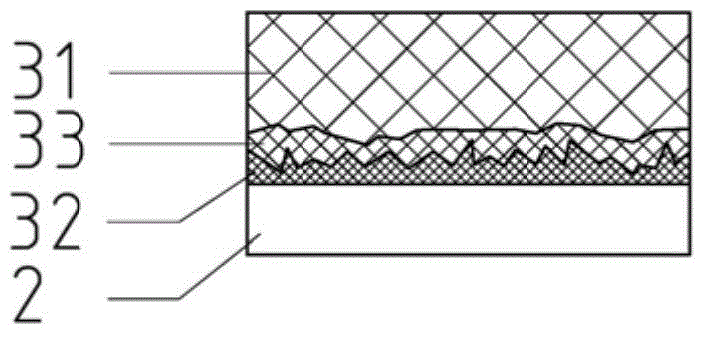

ActiveCN110224007AGuaranteed thickness uniformityReduce climbing volumeSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsMicrostructure

The invention provides a display substrate, a preparation method of the display substrate and a display panel. The display substrate comprises a substrate, a first electrode and a pixel defining layer, wherein the first electrode is arranged on the substrate; the pixel defining layer is arranged on the substrate and the first electrode; and the pixel defining layer defines a plurality of sub-pixelareas on the substrate, and the side wall of each sub-pixel area is provided with a microstructure surface. After ink-jet printing is carried out in the sub-pixel areas, ink drops can be prevented from climbing upwards along the edges by the microstructure surface in the process of drying and film forming of the ink drops, so that the uniformity of the film-forming thickness is ensured, and thenthe light-emitting uniformity of the display panel is further improved.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

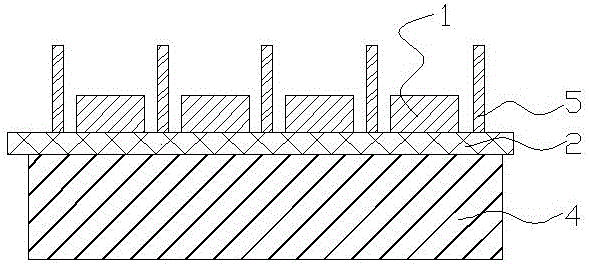

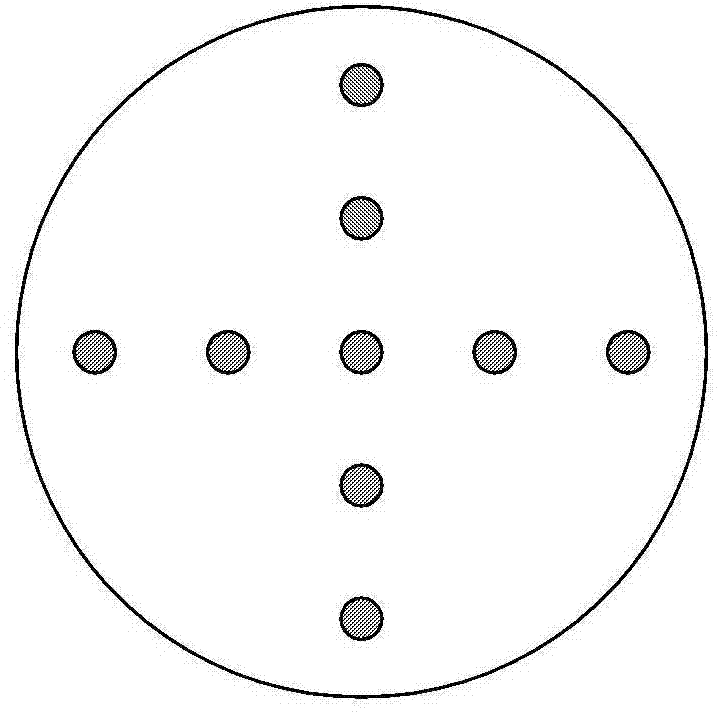

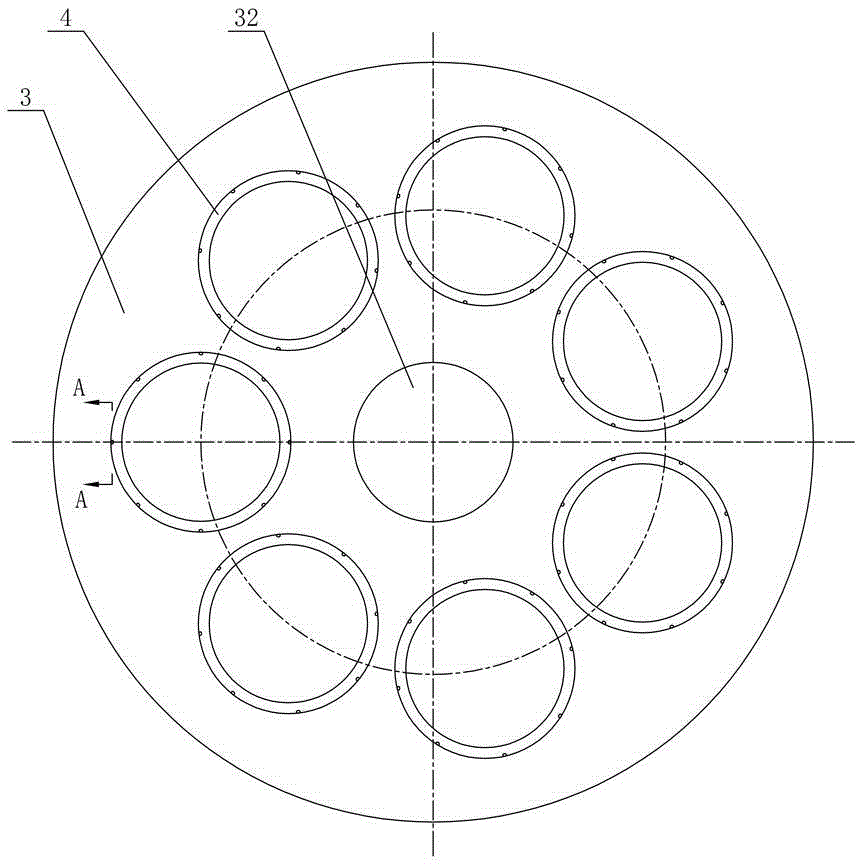

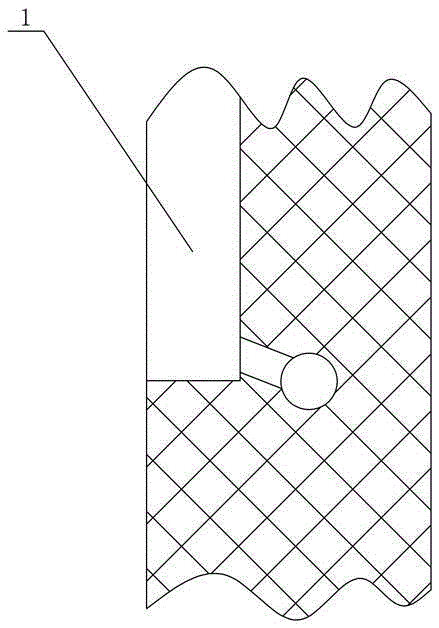

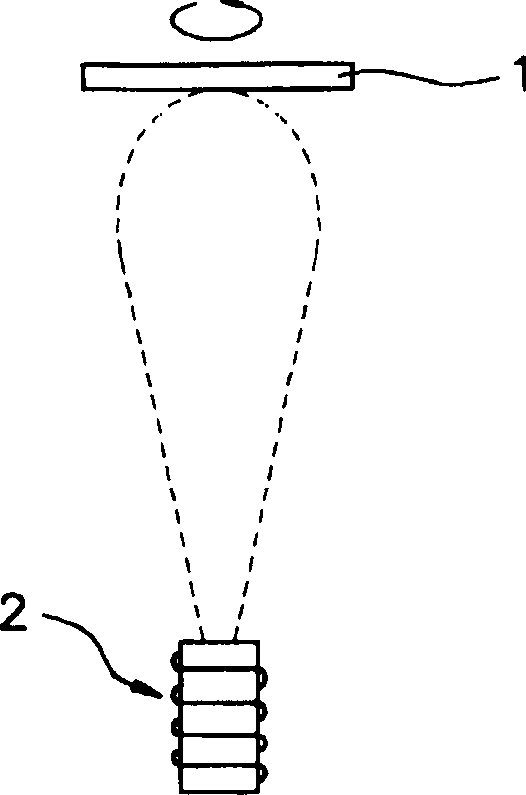

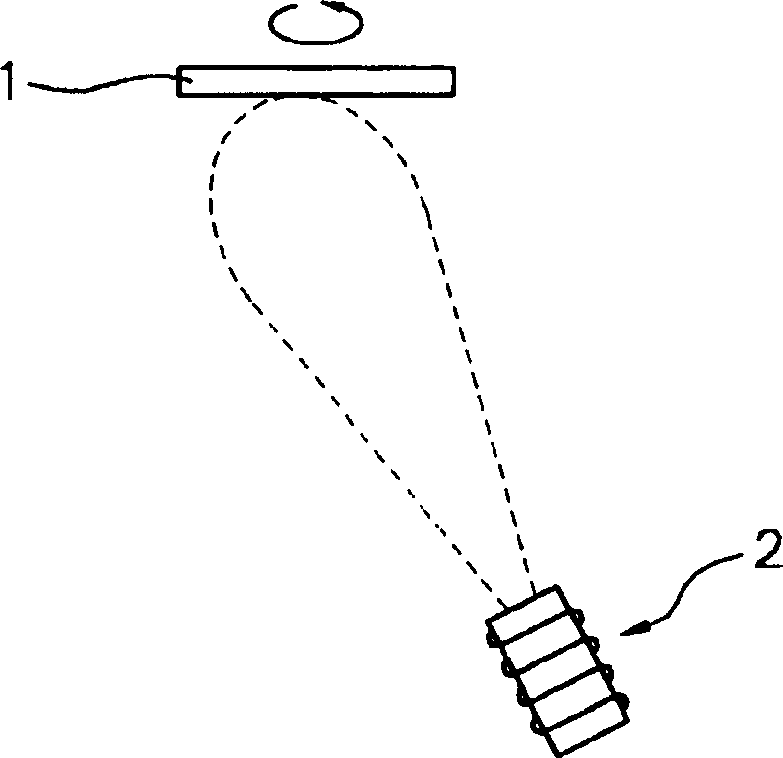

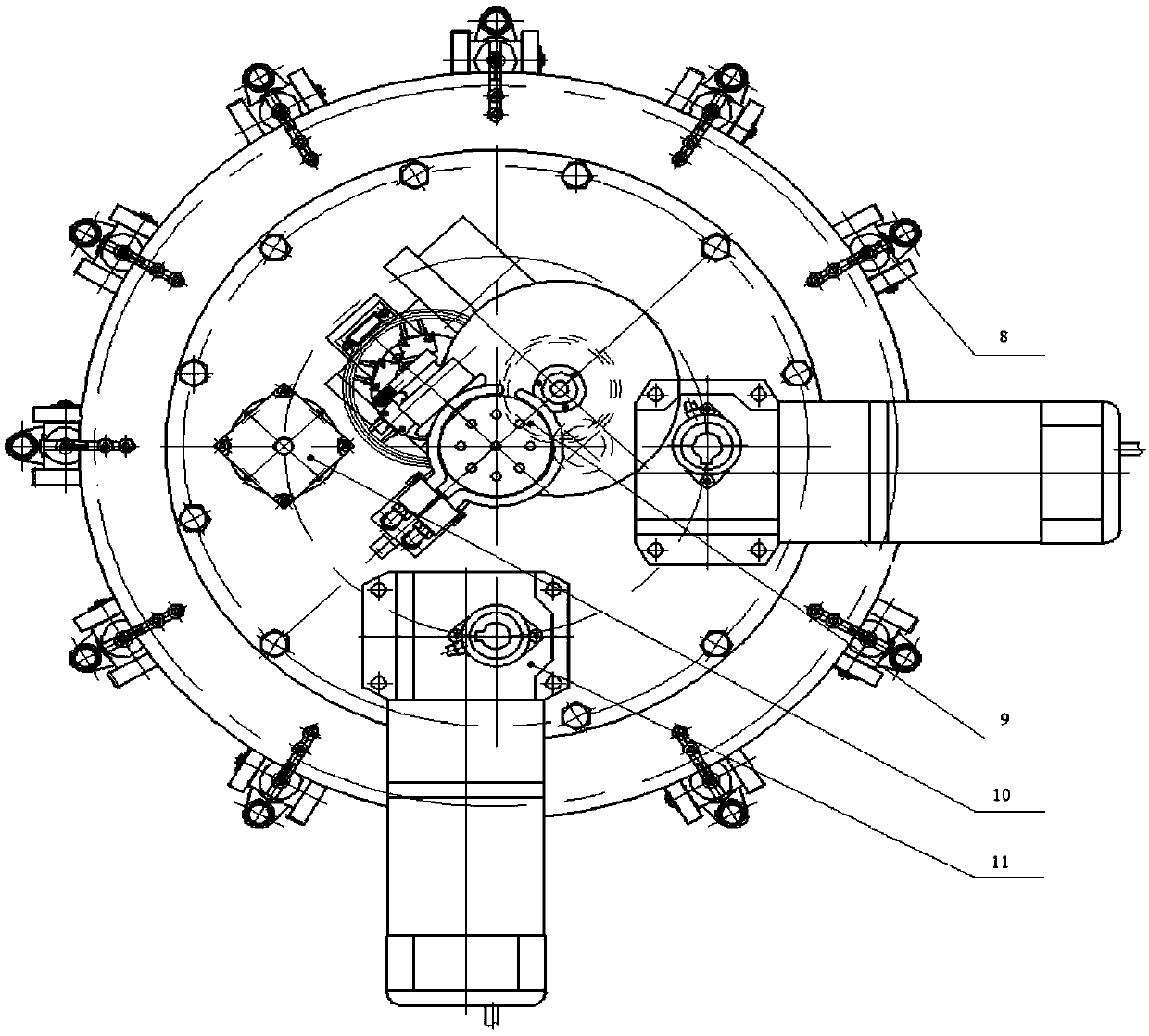

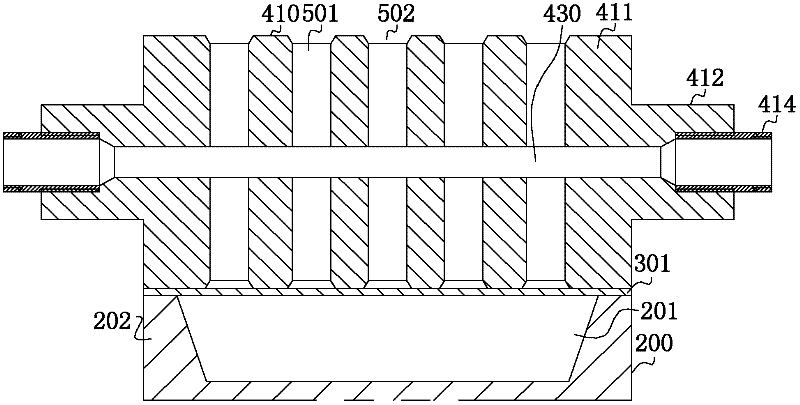

Planetary rotary device for epitaxial growth of silicon carbide

ActiveCN105386121AImprove stabilityImprove continuityPolycrystalline material growthFrom chemically reactive gasesMechanical engineeringSilicon carbide

The invention discloses a planetary rotary device for epitaxial growth of silicon carbide. The device comprises a base, a central rotary shaft and a planetary disc, wherein the central rotary shaft is arranged on the base; the planetary disc is mounted on the central rotary shaft and can rotate along the central rotary shaft; a plurality of workpiece support plates are distributed at the periphery of the planetary disc; air inlet orifices for communicating with the peripheries of the workpiece support plates and driving the workpiece support plates to rotate after ventilation are formed on the base, the central rotary shaft and the planetary disc. The device has the advantages of being simple in structure, low in cost and easy to mould, and the rotary stability and continuity can be greatly improved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

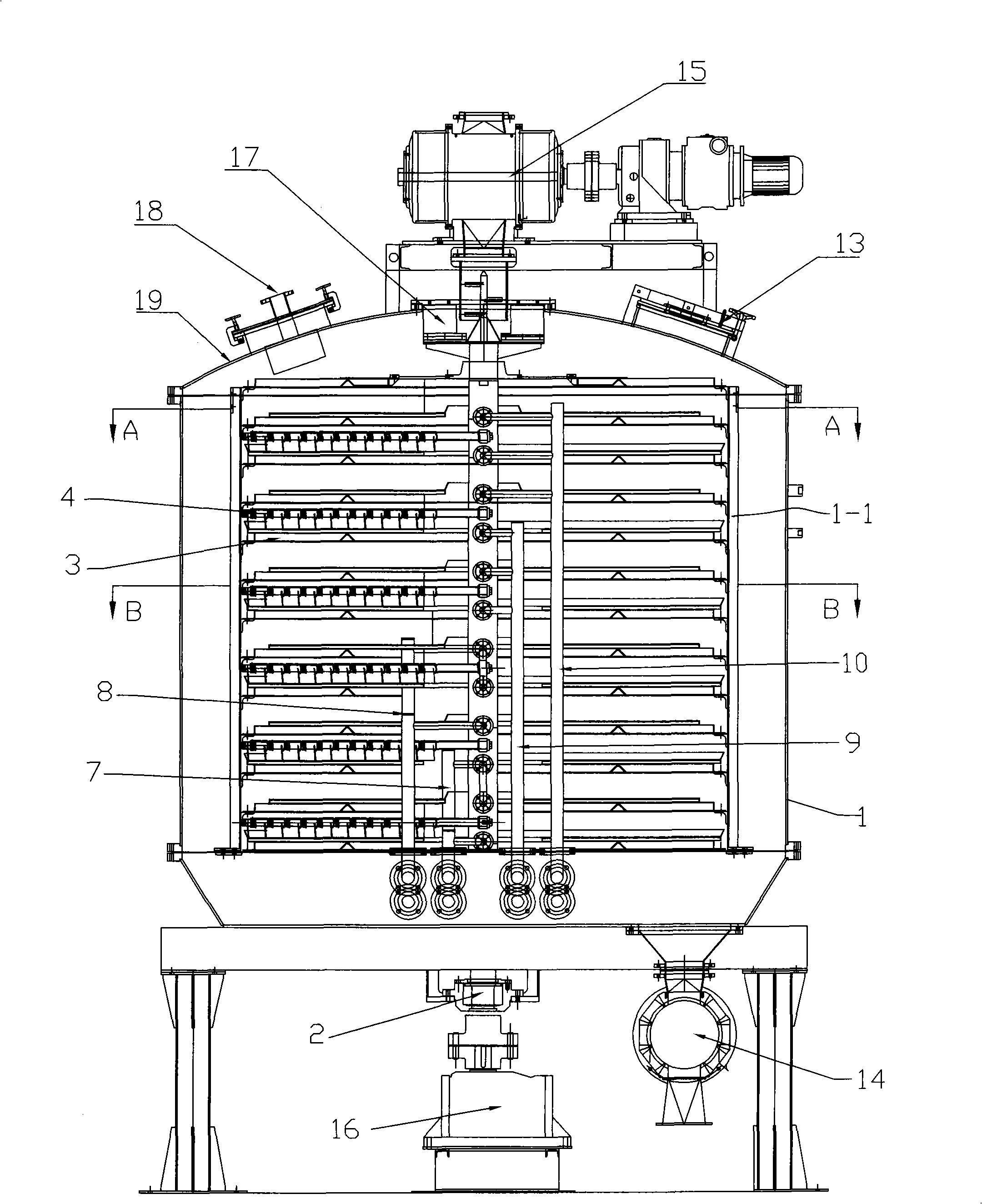

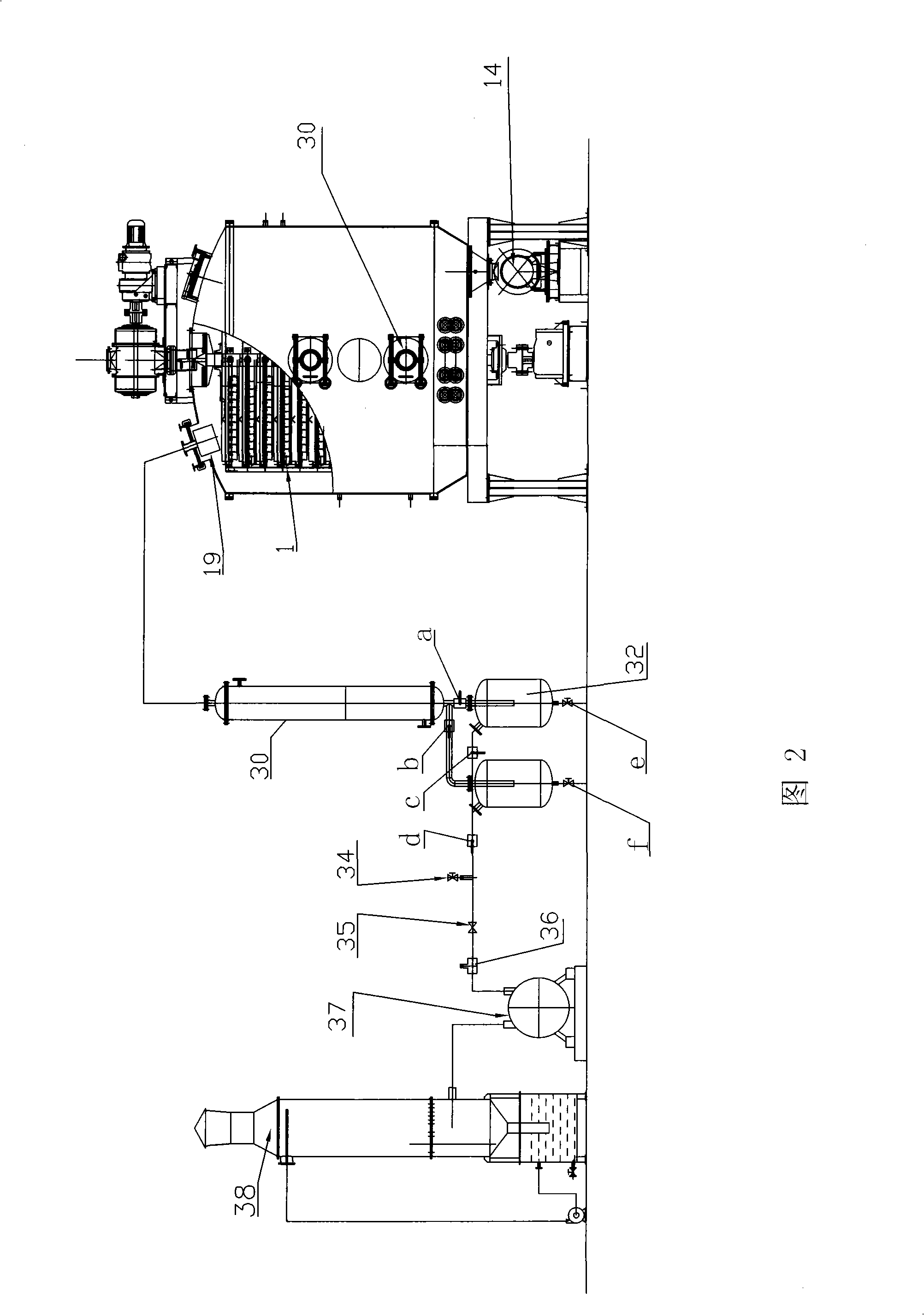

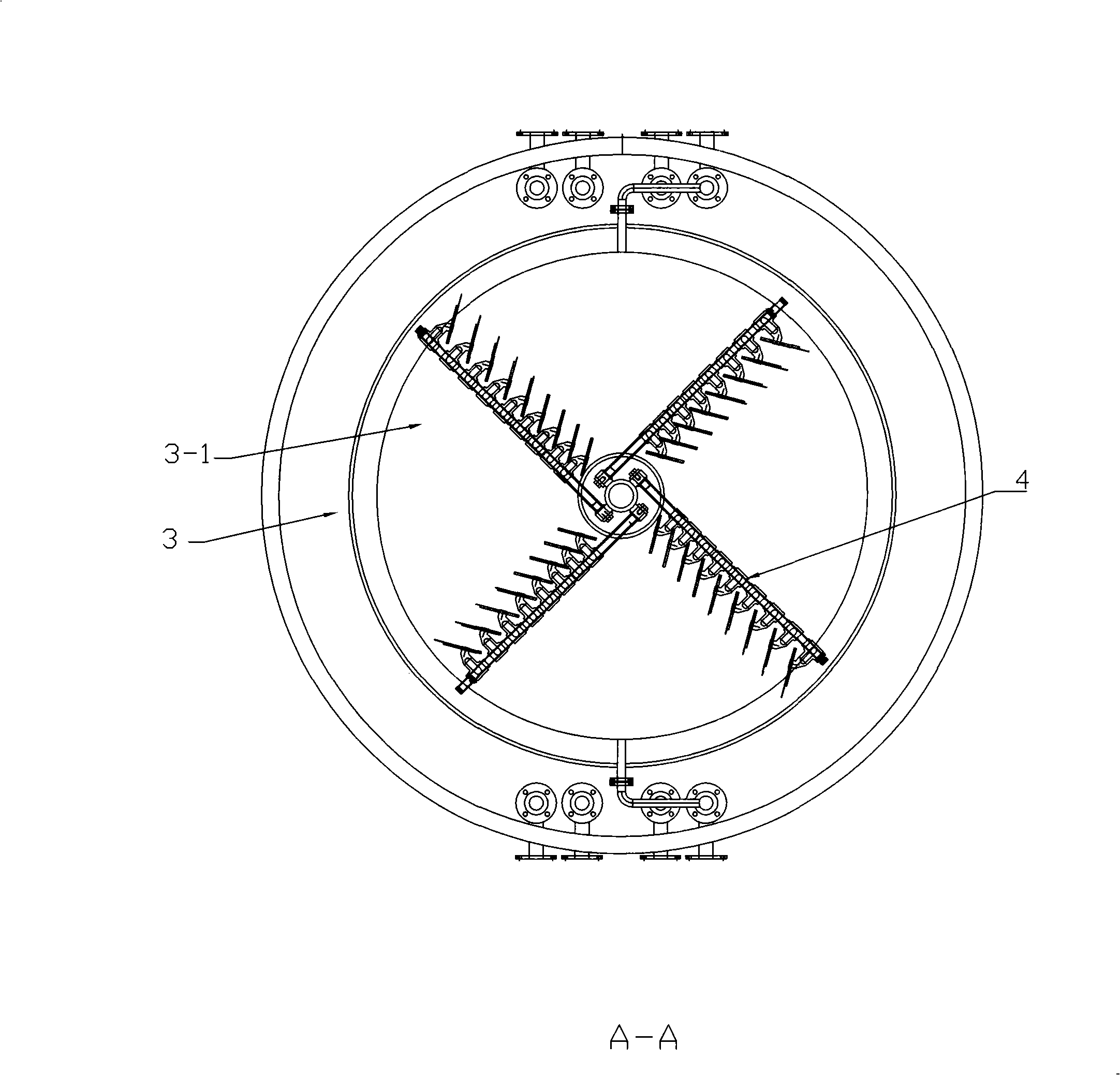

Hot plate type continuous vacuum drying system

InactiveCN101408371AGuarantee the quality of finished productsReduce the feeding and discharging speedDrying using combination processesDrying solid materials with heatHeat conductingEngineering

The invention relates to a hot-plate type continuous vacuum drying system, comprising a main machine and a cylinder of the main machine; a main shaft is arranged inside the cylinder of the main machine; a bed bracket is arranged on the inner wall of the cylinder; a plurality of layers of plate-style jacket heating devices are arranged on the bed bracket; the main shaft passes through central apertures of each plate-style jacket heating device and is arranged between the top and the bottom of the cylinder; the upper end faces of the plate-style jacket heating devices are material-bearing faces; the main shaft is provided with a plurality of branch arms and material turning plates are arranged on the lower end faces of the branch arms; and the plate-style jacket heating device is a plate jacket casing inside which a heat conducting pipeline is arranged; the plurality of layers of plate-style jacket heating devices can be at least divided into a high-temperature layer group, an intermediate-temperature layer group, a low-temperature layer group and a cooling layer group from top to bottom. The hot-plate constant vacuum drying system adopts the combined heating system adopting both drying and cooling so as to reduce the processes and largely enhance the manufacturing efficiency and the productivity; and simultaneously the drying system can realize the constant vacuum feeding and discharging, solvent recycling and disposal of harmful gas.

Owner:查晓峰

Gas pipe for vacuum coating and vacuum coating device applying gas pipe

InactiveCN103510045AGuaranteed thickness uniformityEvenly distributedVacuum evaporation coatingSputtering coatingEngineeringVacuum coating

A windpipe used in a vacuum coating device includes an outer pipe and an inner pipe positioned in the outer pipe. The inner pipe defines a plurality of first outlets arranged in a line in the peripheral wall of the inner pipe along the axial direction. The outer pipe defines a plurality of second outlets arranged in a line in the peripheral wall of the outer pipe along the axial direction.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Mass and efficient integral manufacturing method of terahertz hollow core rectangular waveguide

ActiveCN110350288AQuality improvementGuaranteed surface roughnessWaveguide type devicesAlloyGold layer

The invention relates to a mass and efficient integral manufacturing method of a terahertz hollow core rectangular waveguide, and belongs to the field of precise manufacturing of a waveguide micro device. The mass and efficient integral manufacturing method comprises the following steps of 1, fabricating a sacrifice core die comprising low-melting point alloy; 2, electroplating gold on an upper surface of the sacrifice core die to obtain an electroplating gold layer; 3, taking a single-side gold plating body of the sacrifice core die from a substrate; 4, electroplating a second layer of gold on a surface of the single-side gold plating body of the sacrifice core die; 5, electroforming copper on a surface of the electroplating gold layer to obtain an electroforming copper layer; 6, performing precise polishing on a surface of the electroforming copper layer to obtain a required size; and 7, removing the low-melting point alloy to obtain the terahertz hollow core rectangular waveguide. By the processing method, high-accuracy mass production of the sacrifice core die can be achieved, the sacrifice core die is efficiently and conveniently removed by a heating method, so that the mass and efficient manufacturing of the terahertz hollow core rectangular waveguide can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Evaporation source for deposition process and insulation fixing plate, and heating wire winding plate and method for fixing heating wire

InactiveCN1795537AIncrease usageGuaranteed thickness uniformitySemiconductor/solid-state device manufacturingShadow effectDeposition process

Disclosed is a linear evaporation source used for forming a thin film for an organic semiconductor device, the linear evaporation source comprising a crucible having a receiving space formed therein, for accommodating an evaporation material and an opening section formed at one side of the crucible in a length direction, wherein the opening section becomes narrow as it travels from both ends to a center portion thereof. If the thin film is formed using the linear evaporation source, a low material use rate of the vacuum evaporation source for the formation of the thin film is improved, thickness uniformity of the deposited thin film throughout the whole area is secured, and shadow effect due to the shadow mask is improved.

Owner:伊诺维克斯股份有限公司

Lithium transfer type lithium supplementing method for lithium battery

PendingCN111682163AImprove securityEasy to operateElectrochemical processing of electrodesElectrode carriers/collectorsLithium metalPhysical chemistry

The invention relates to a lithium transfer type lithium supplementing method for a lithium battery. The lithium supplementing method takes a base film-substrate-lithium metal composite structure as alithium transfer layer, enables the lithium metal side of the lithium transfer layer to be opposite to a lithium supplementing process surface of an electrode layer, removes the base film layer after1-100kg of pressure rolling, and forms a lithium supplementing electrode finished product with a substrate-lithium-electrode structure. Lithium is supplemented through the lithium transfer layer, theprocess safety is improved, meanwhile, nanoscale regulation of the lithium supplementing thickness is achieved, a uniform and continuous lithium supplementing layer is obtained, and a more excellentlithium supplementing effect is obtained; winding equipment is used for lithium transfer operation, the method is suitable for large-scale production, the technology is suitable for existing equipment, and special equipment does not need to be developed; as the substrate layer is made of the material with high ionic conductivity, the performance of the battery is not influenced.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

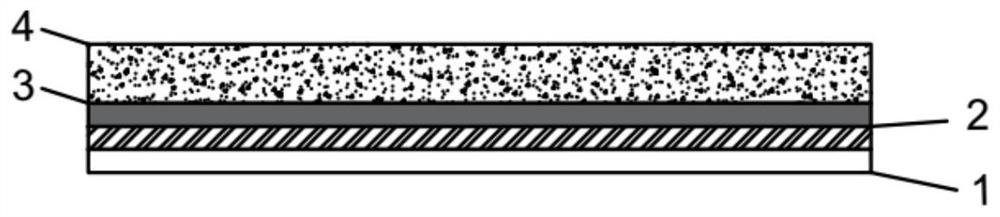

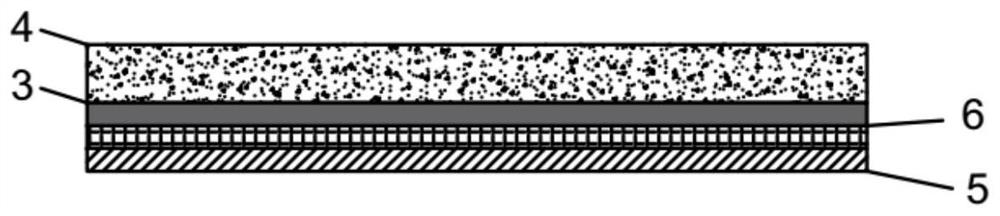

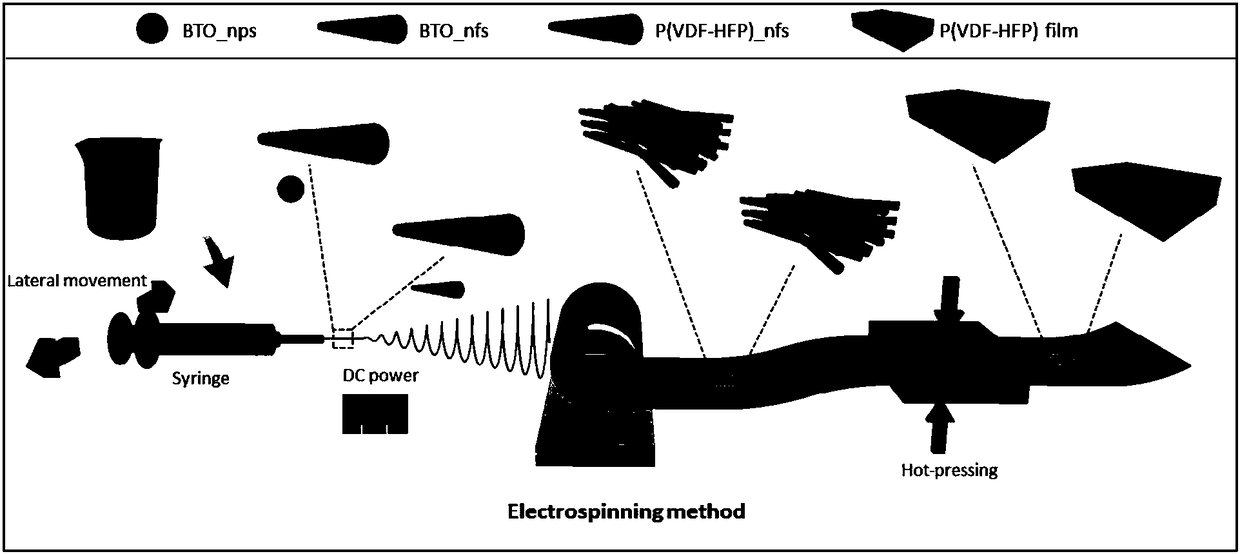

Polymer nanometer composite material and preparation method thereof

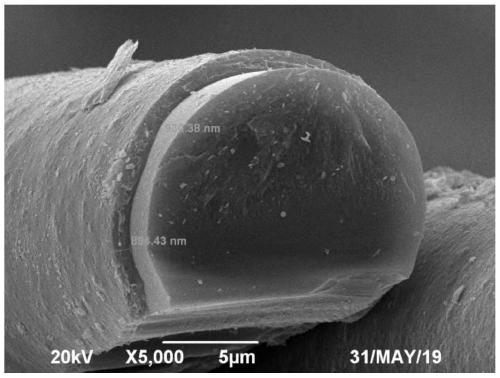

InactiveCN108866819AGuaranteed thickness uniformityImprove thickness uniformityFixed capacitor dielectricFilament/thread formingElectrospinningNonwoven fabric

The invention discloses a polymer nanometer composite material and a preparation method thereof. The method comprises following steps: (1) a composite nonwoven fabric of a nanofiller and a polymer matrix is prepared by an electrospinning method; the composite fiber constituting the composite nonwoven fabric has the polymer matrix as a main fiber skeleton, and the nano filler is dispersed in the main fiber; (2) the polymer nanometer composite material can be obtained by hot pressing the composite nonwoven fabric. Compared with the general film forming process, the method of the invention is notonly simpler and more efficient, but also has better uniformity and homogeneity of the prepared composite material. The composite material of the invention can realize the uniform dispersion of the particles of the filler material in the composite material, the surface is smooth, the interior is dense and has no pores, the thickness is uniform and fine controllable in a wide range. At the same time, it has excellent dielectric properties and high performance stability, and is expected to be widely used in dielectric materials.

Owner:TSINGHUA UNIV

Preparation method and equipment of SiC fiber prepreg tape with attached interface layer

ActiveCN111058187AImprove toughnessAvoid wire breakageTextile treatment containersFibre treatmentSic fiberFiber bundle

The invention provides a preparation method of a SiC fiber prepreg tape with an attached interface layer. The preparation method comprises the following steps of introducing a continuous silicon carbide fiber bundle onto a tension pulley after being unwound through a godet roller and a guide wheel, sending the continuous silicon carbide fiber bundle straightly into a desizing device to expand thecontinuous silicon carbide fiber bundle; introducing the continuous silicon carbide fiber bundle onto a gluing device, so that glue fully infiltrates the continuous silicon carbide fiber, after that,introducing the continuous silicon carbide fiber bundle to a silk spreading device, and fully spreading and sizing the continuous silicon carbide fiber bundle by a drawing-in roller in the silk spreading device; and enabling the fully spread and sized continuous silicon carbide fiber bundle to enter a winding roller to obtain the flat and uniform prepreg tape. The prepreg tape prepared by the invention not only can greatly improve the toughness of the silicon carbide fiber, but also a deposited interface layer is uniform, meanwhile, the overlapped parts of two adjacent fiber bundles in the prepreg tape are few, the fiber bundle is good in flatness and thin in thickness, in addition, the preparation equipment can control parameters in real time, and full automation and complete controllability can be realized.

Owner:CENT SOUTH UNIV

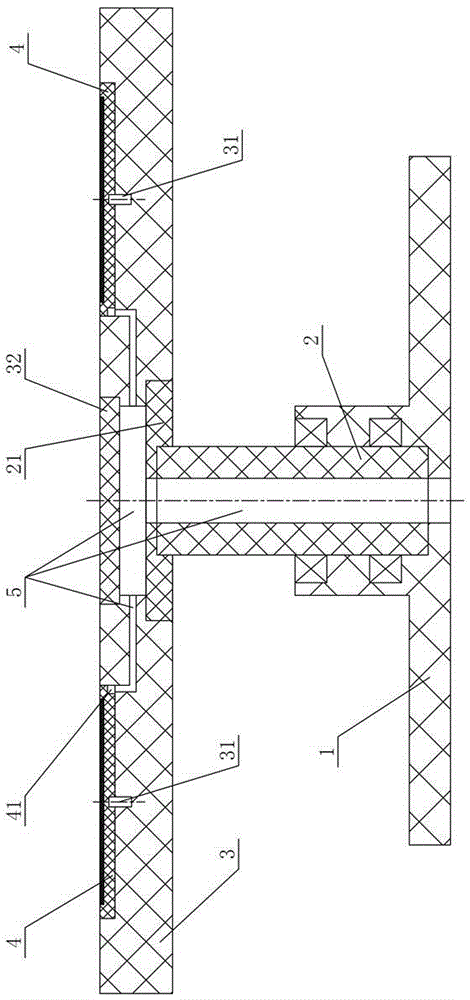

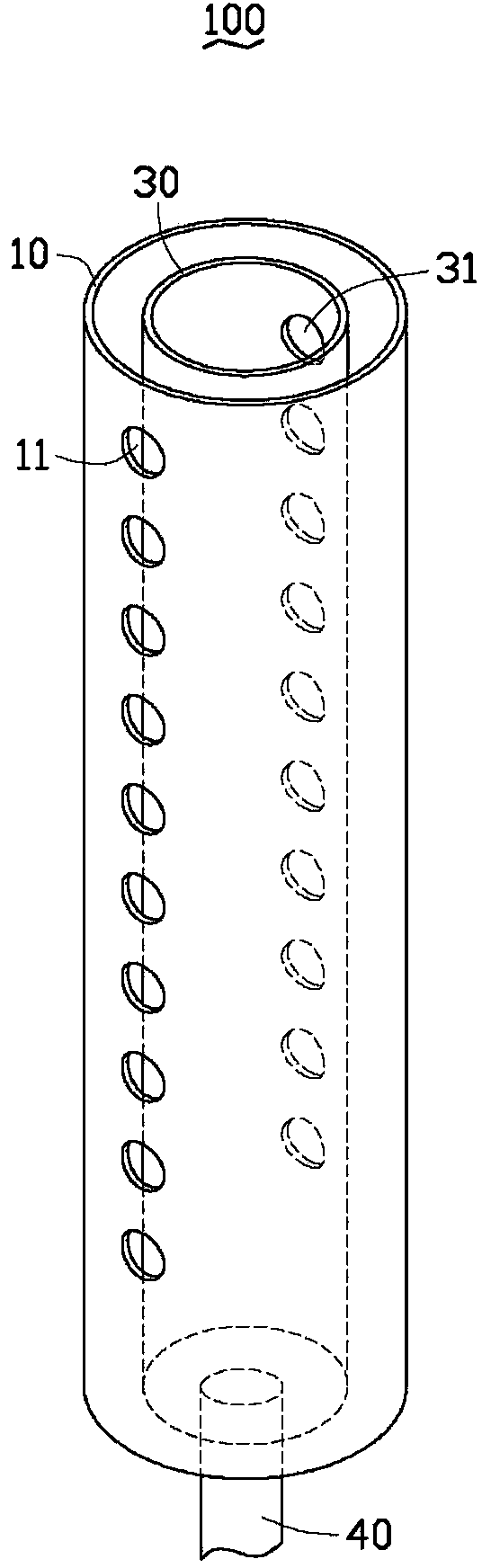

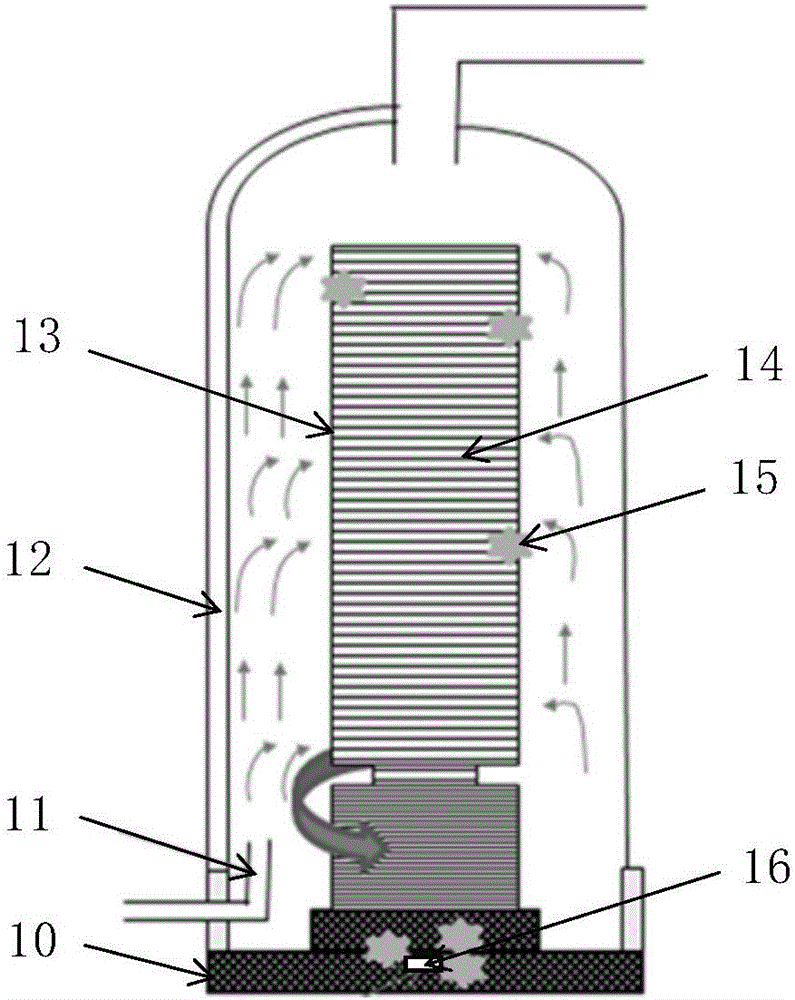

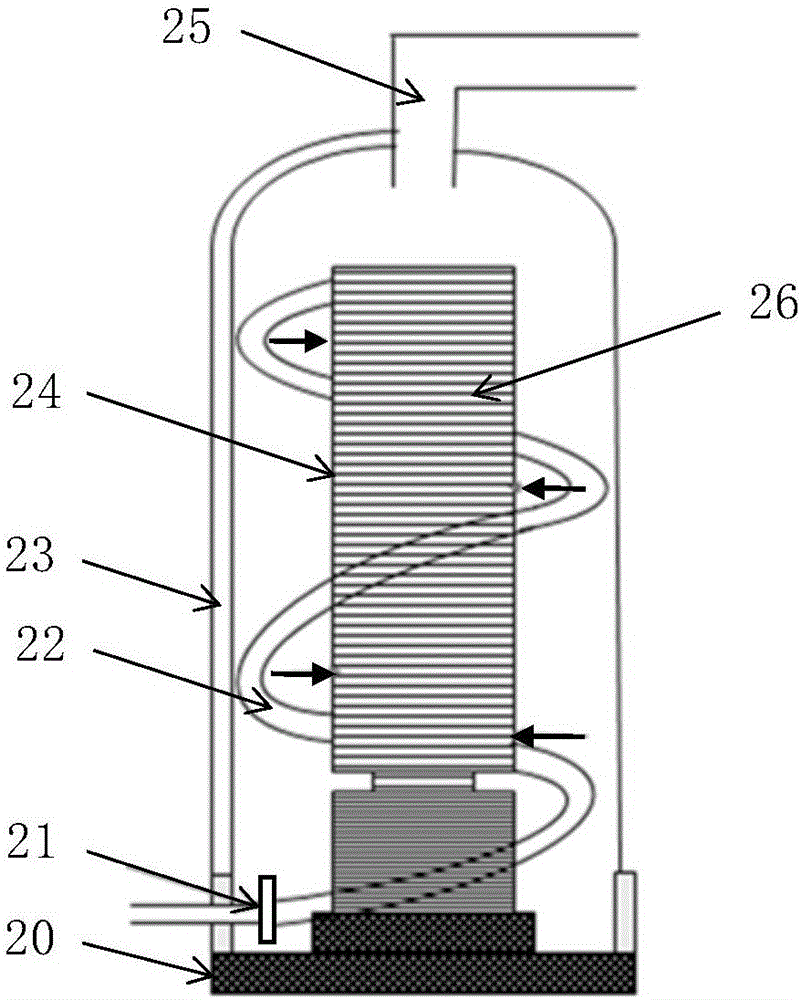

Air inlet device of furnace tube

ActiveCN106191990AReduce pollutionGuaranteed thickness uniformityFrom chemically reactive gasesEngineeringPollution

The invention discloses an air inlet device of a furnace tube. The air inlet device of the furnace tube comprises an air inlet, an air inlet pipe and a plurality of nozzles, wherein the air inlet is formed in the lower end of a side wall of a process chamber of the furnace tube, and communicated with an external reaction gas pipeline; the air inlet pipe is arranged in the process chamber, one end of the air inlet pipe is connected with the air inlet, the other end of the air inlet pipe is closed, and the air inlet pipe is arranged around a wafer boat in the process chamber from the bottom up; the plurality of nozzles are uniformly arranged in the length direction of the air inlet pipe and face towards the wafer boat; during the process, a reactive gas is introduced into the air inlet pipe through the air inlet, and the nozzles jet the reactive gas to the wafer boat, so that each layer of silicon wafer in the wafer boat is in uniform contact with the reactive gas, and furthermore, the wafer boat is kept in the stationary state to avoid particle pollution caused by rotation of the wafer boat while the thickness uniformity of a product is ensured.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

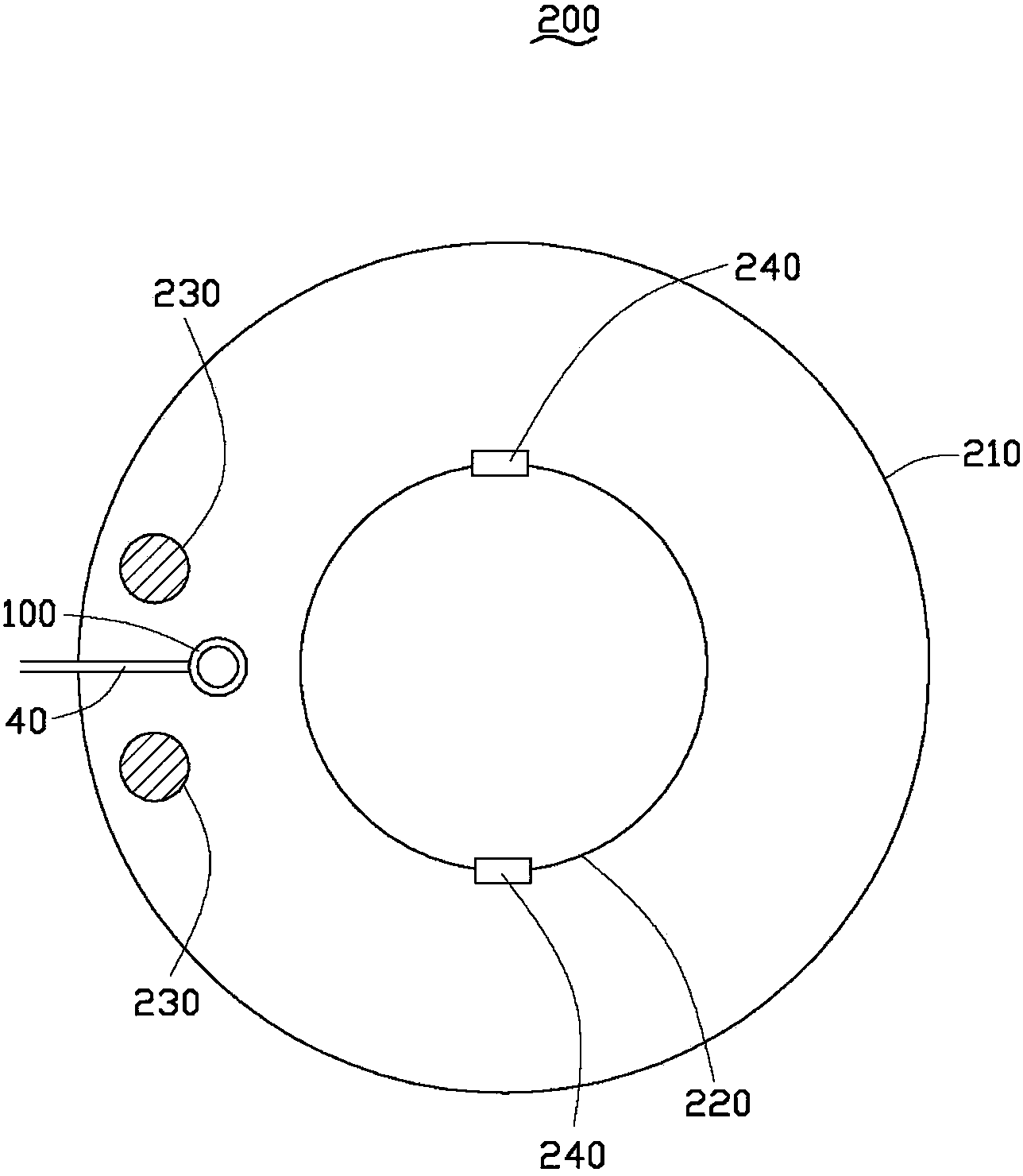

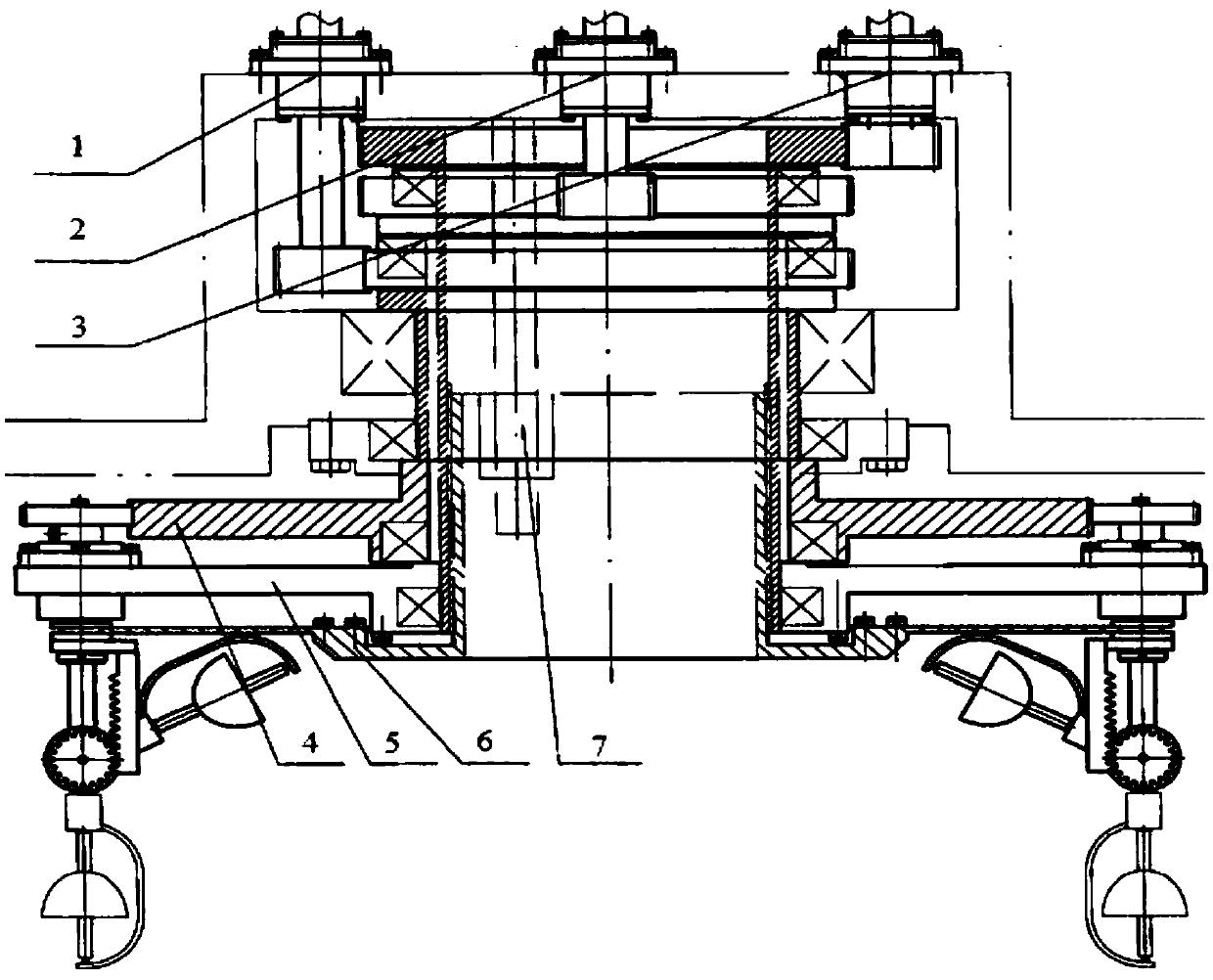

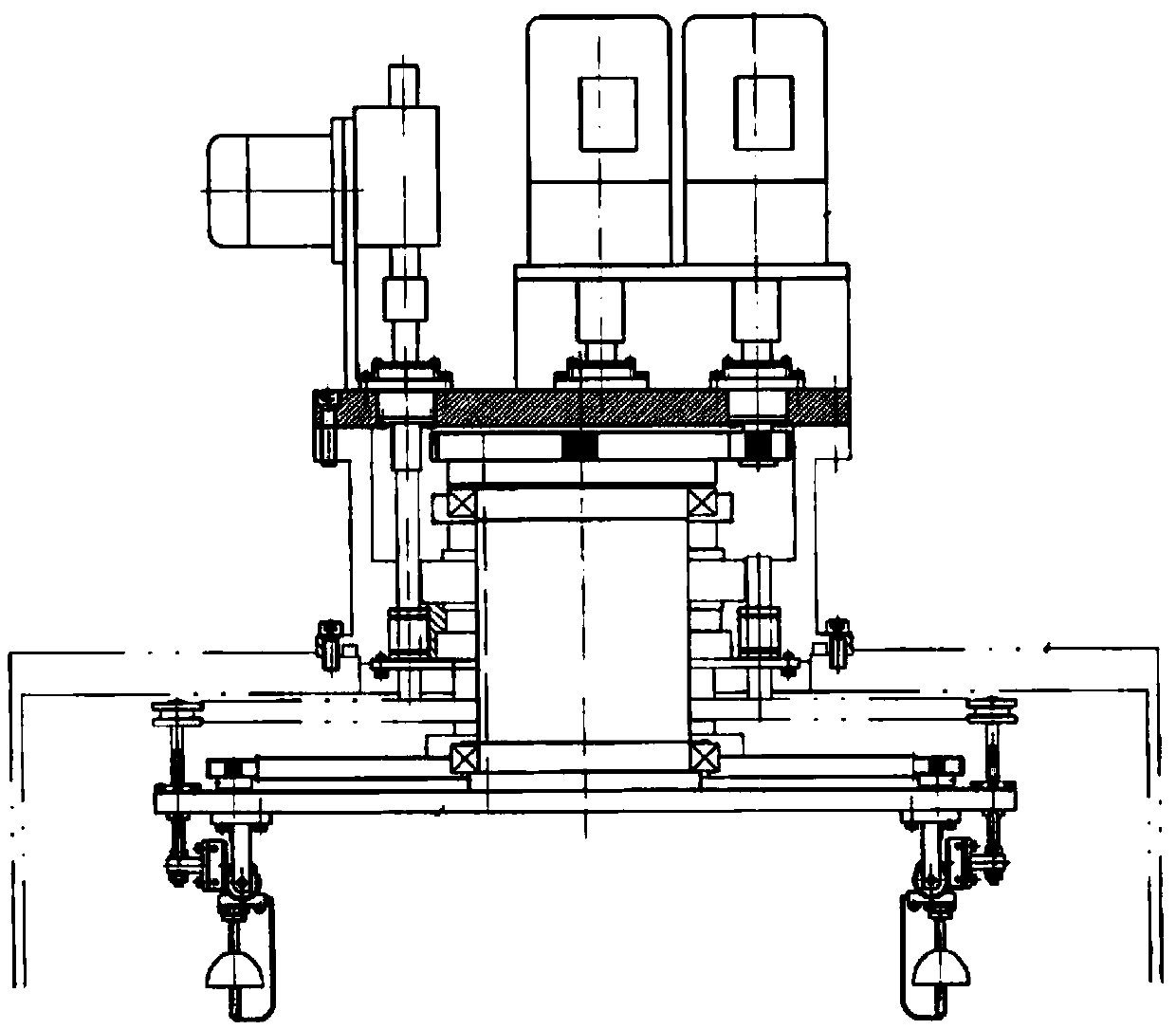

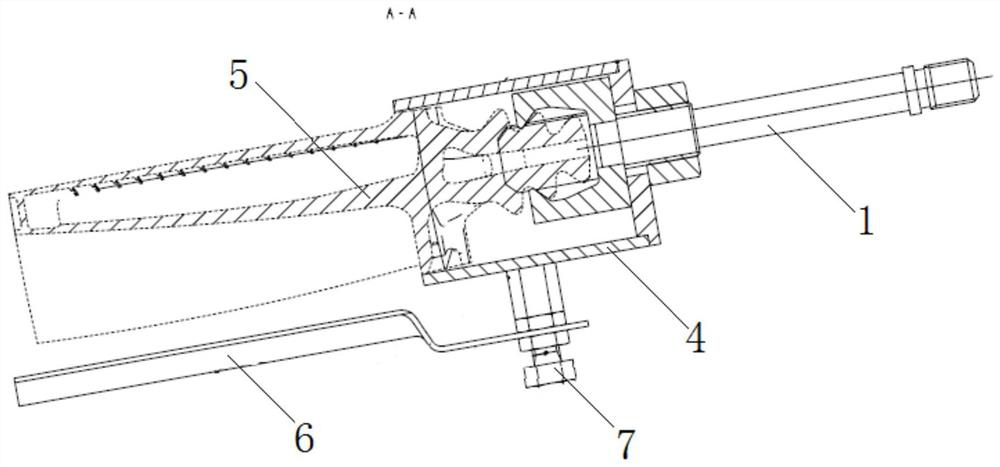

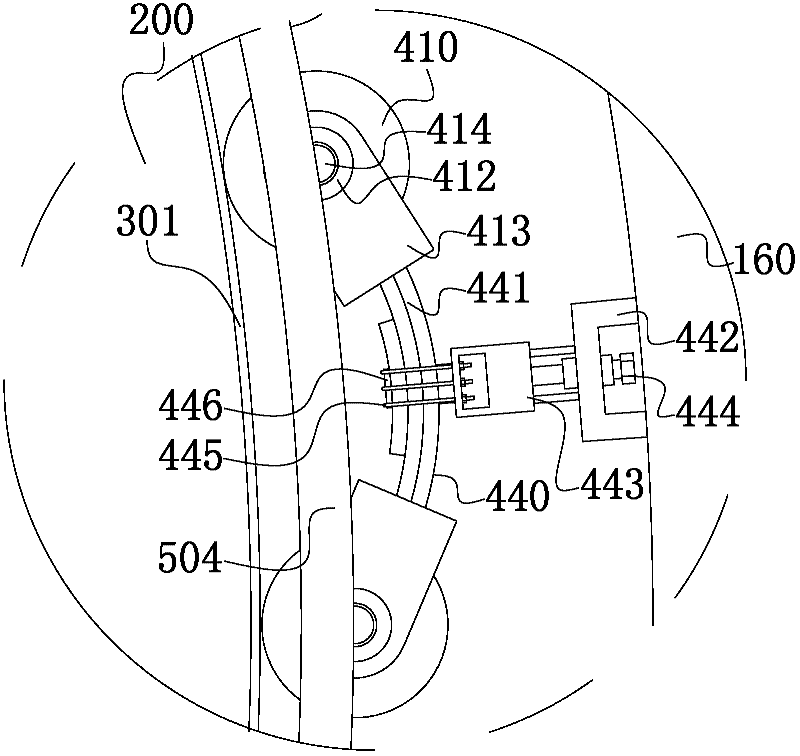

Space motion device for hemispherical resonance gyro coating

InactiveCN109628904ARealize multidimensional motionPrecise thickness controlVacuum evaporation coatingSputtering coatingElevation angleResonance

The invention discloses a space motion device for hemispherical resonance gyro coating. The space motion device for hemispherical resonance gyro coating comprises a revolution motor, a rotation motor,and a swing motor; the revolution motor is connected with a revolution plate through revolution shafting to achieve revolution motion; the rotation motor is connected with a fixture through rotationshafting, and full angle rotation of the rotation motor is realized through an elastic wire rope; and the swing motor converts rotation into up-and-down movement through swing shafting, and the swingmotor drives a rack to actuate a gear through a shift fork to achieve swing of a work piece. According to the space motion device for hemispherical resonance gyro coating, space motion can be realizedin the hemispherical resonance gyro coating process; whole surface one-time film formation is realized; three types of motion of revolution, rotation, and swing are integrated in one; the revolutionspeed, the rotation speed, and the rotation direction are independently adjusted; the speed of upward swing , the speed of downward swing , an elevation angle of swing, and up and down dwell time canbe optionally set according to requirements; and coating uniformity is improved, the problem of the low qualified rate of hemispherical resonance gyro coating is solved, and production efficiency is improved.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

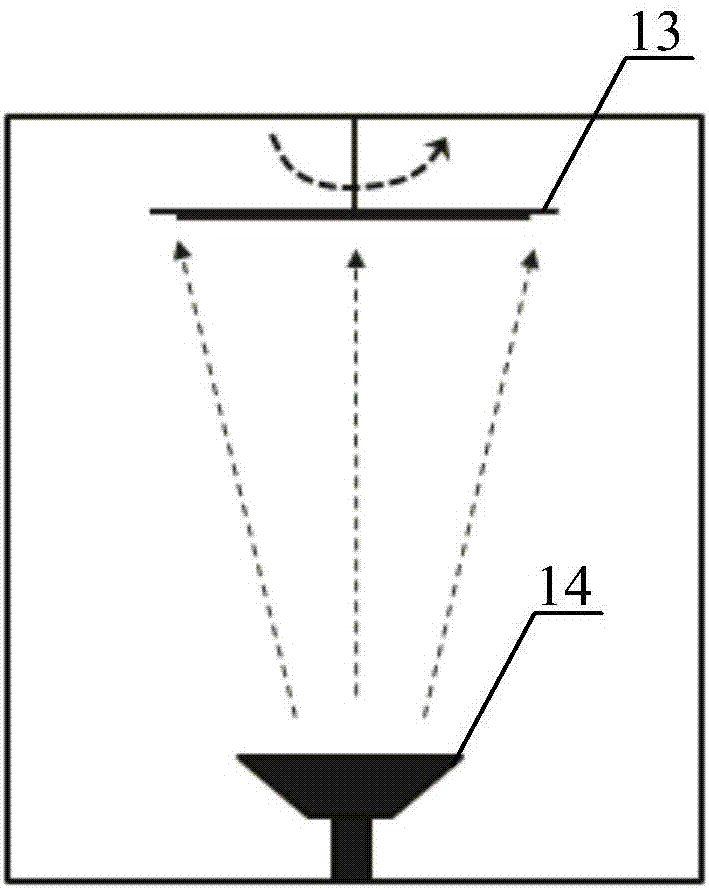

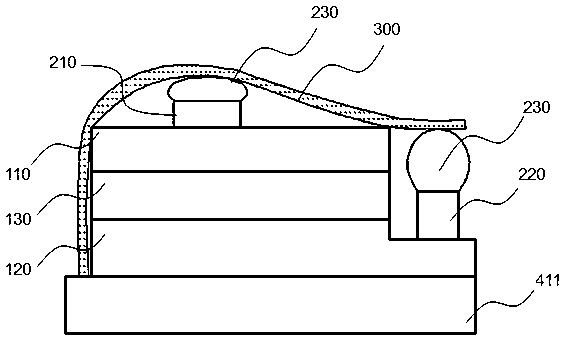

Direct growth method of flexible X-ray sensor scintillator layer

InactiveCN108010928AImprove reliabilityStable performanceX/gamma/cosmic radiation measurmentRadiation controlled devicesPhysicsPixel array

The invention provides a direct growth method of a flexible X-ray sensor scintillator layer. The growth method at least comprises the steps that firstly a flexible substrate layer of which the surfacehas preparation of a pixel array layer is provided; then the flexible substrate layer of which the surface has preparation of the pixel array layer is fixed on the plane support or the curved supportof the top part of a cavity, and a CsI scintillator layer is deposited on the surface of the pixel array layer by heating the CsI source of the bottom part of the cavity, wherein the CsI scintillatorlayer includes a CsI broken crystal layer and a CsI columnar crystal layer; and finally a sealed damp-proof layer is formed on the surface and the sidewall of the CsI scintillator layer. With application of the direct growth method, the CsI scintillator layer can be directly grown on the flexible substrate layer and the CsI layer can remain intact without crack when the sensor is bent, and the CsI can maintain performance without degradation even under the condition of multiple times of large-angle bending so as to have great reliability.

Owner:SHANGHAI IRAY TECH

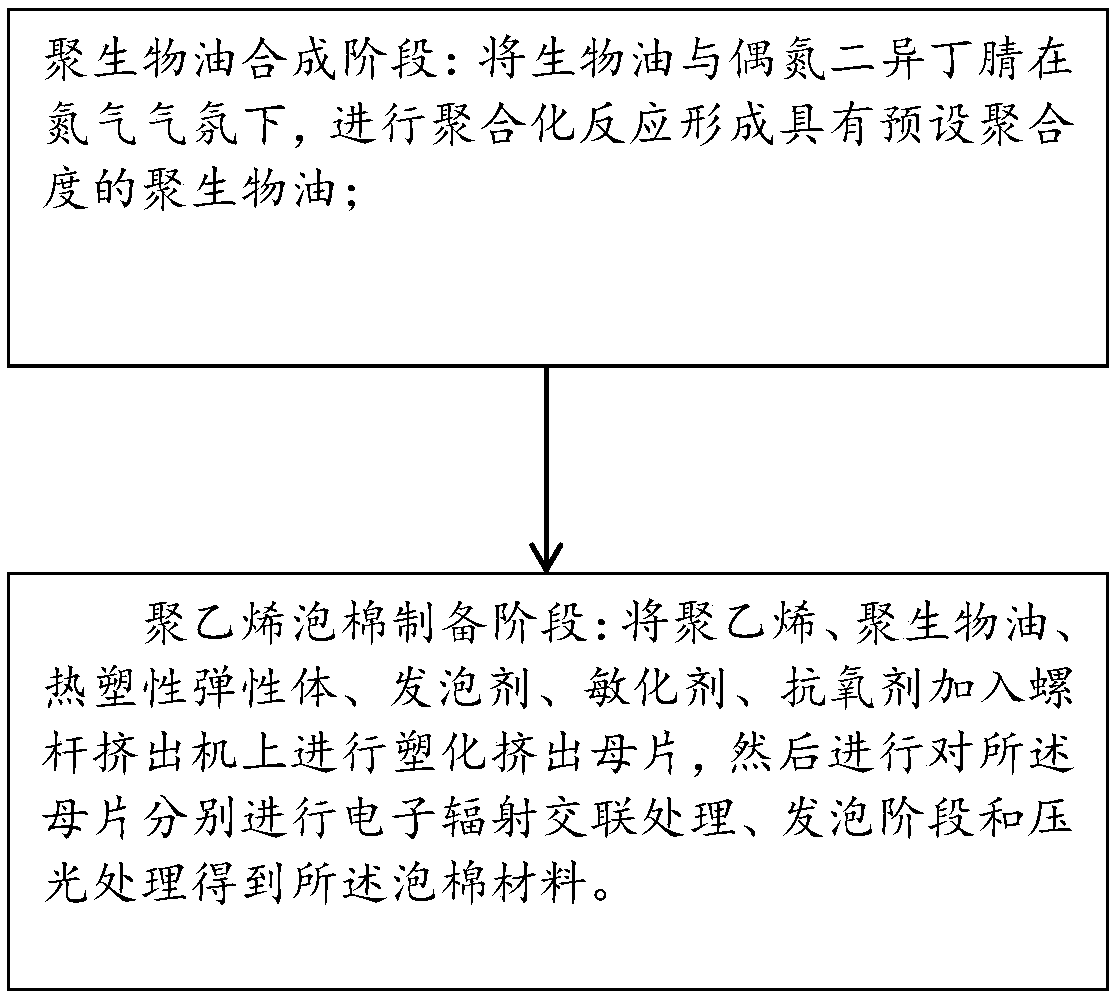

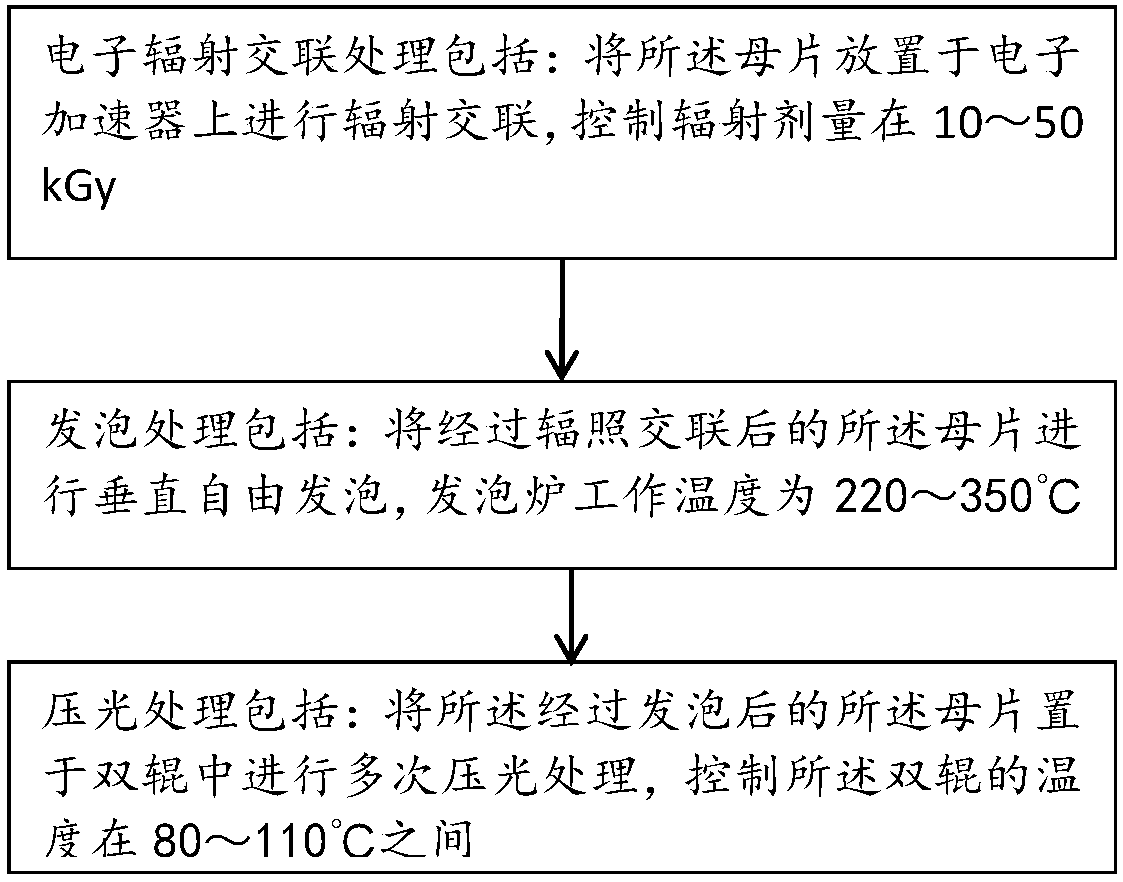

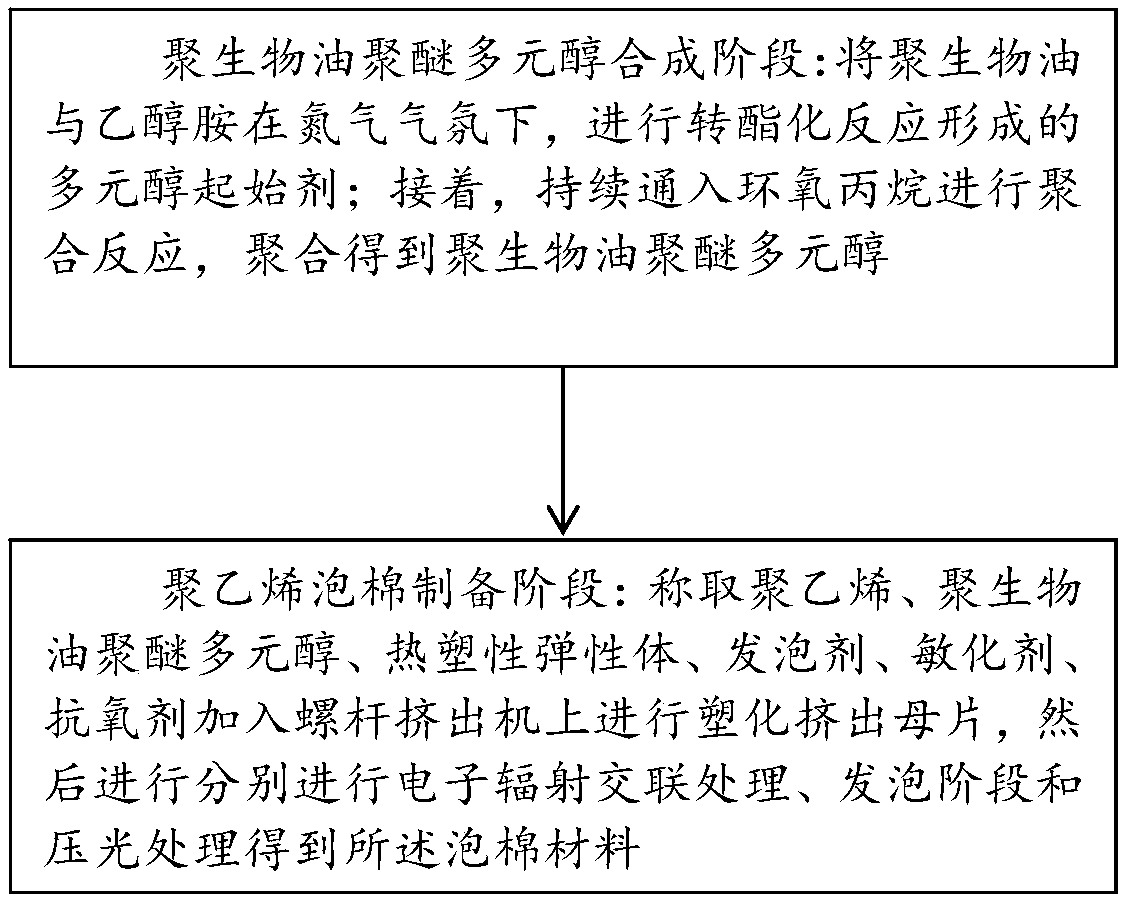

Crosslinking polyethylene foam cotton material and preparation method thereof

Owner:ZHEJIANG WANLI NEW MATERIALS TECH CO LTD

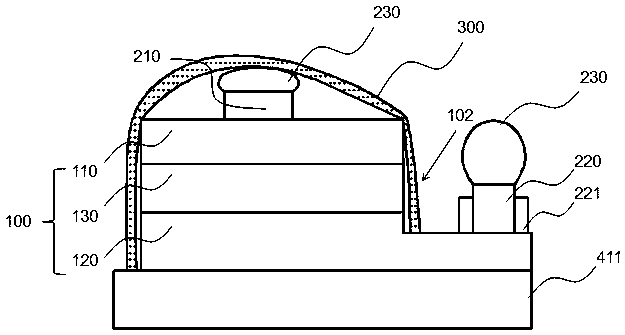

Light emitting diode

ActiveCN108630793AImprove high temperature resistanceBig turning pointSemiconductor devicesPeak valueLength wave

The invention discloses a light emitting diode, comprising a semiconductor layer sequence having an active layer between a first conductivity type layer and a second conductivity type layer for generating first light of a first peak wavelength, the first conductivity type layer being located on one side of the positive direction of the semiconductor layer sequence, and the second conductivity typelayer being partially exposed; and a wavelength conversion layer arranged in the positive direction and side wall of the semiconductor layer sequence, the wavelength conversion layer absorbing the first light emitted from the semiconductor layer sequence and emitting second light of a second peak wavelength different from the first peak wavelength; wherein a second electrode and the wavelength conversion layer are on the same side of the light emitting diode, and the distance from the second electrode to the side wall of the semiconductor layer sequence is not less than 50 microns, which solves the problem that the side wall of the semiconductor sequence leaks the first light, and improves the uniformity of light emission of the light emitting diode.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

Air intake device for furnace tube

ActiveCN106191990BReduce pollutionGuaranteed thickness uniformityFrom chemically reactive gasesChemical vapor deposition coatingReactive gasEngineering

The invention discloses an air inlet device of a furnace tube. The air inlet device of the furnace tube comprises an air inlet, an air inlet pipe and a plurality of nozzles, wherein the air inlet is formed in the lower end of a side wall of a process chamber of the furnace tube, and communicated with an external reaction gas pipeline; the air inlet pipe is arranged in the process chamber, one end of the air inlet pipe is connected with the air inlet, the other end of the air inlet pipe is closed, and the air inlet pipe is arranged around a wafer boat in the process chamber from the bottom up; the plurality of nozzles are uniformly arranged in the length direction of the air inlet pipe and face towards the wafer boat; during the process, a reactive gas is introduced into the air inlet pipe through the air inlet, and the nozzles jet the reactive gas to the wafer boat, so that each layer of silicon wafer in the wafer boat is in uniform contact with the reactive gas, and furthermore, the wafer boat is kept in the stationary state to avoid particle pollution caused by rotation of the wafer boat while the thickness uniformity of a product is ensured.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Feeder head coating structure and treatment method of aluminum alloy low-pressure cast

ActiveCN104148612AInhibit sheddingWon't fall offFoundry mouldsFoundry coresThermal insulationUltimate tensile strength

The invention relates to a feeder head coating structure and treatment method of an aluminum alloy low-pressure cast. The feeder head coating structure comprises a mold and a feeder head formed by a cavity in the mold. The feeder head is communicated with a mold cavity forming a cast body, and a sintered feeder head coating is arranged between the mold and the feeder head. The thicknesses, from the bottom of the feeder head to an opening, of the feeder head coating are gradually decreased to form a gradient. The feeder head coating with the gradient is adopted for making the coating at the bottom of the feeder head be thick, the thicknesses from the bottom of the feeder head to the opening are gradually decreased, in this way, the thermal insulation effect is excellent, molten metal at the bottom of the feeder head is prevented from solidifying firstly in the process of feeding, it can be effectively guaranteed that sufficient feeding is performed on the cast through the feeder head, the feeder head coating has certain surface strength and smoothness after sintering, the adhesion property of the coating on the mold is good, the combination between coatings is good, the possibility that in the casting process, the high-temperature molten aluminum erodes the coating is lowered, and the feeder head coating is effectively prevented from falling off in the process of cast stripping.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

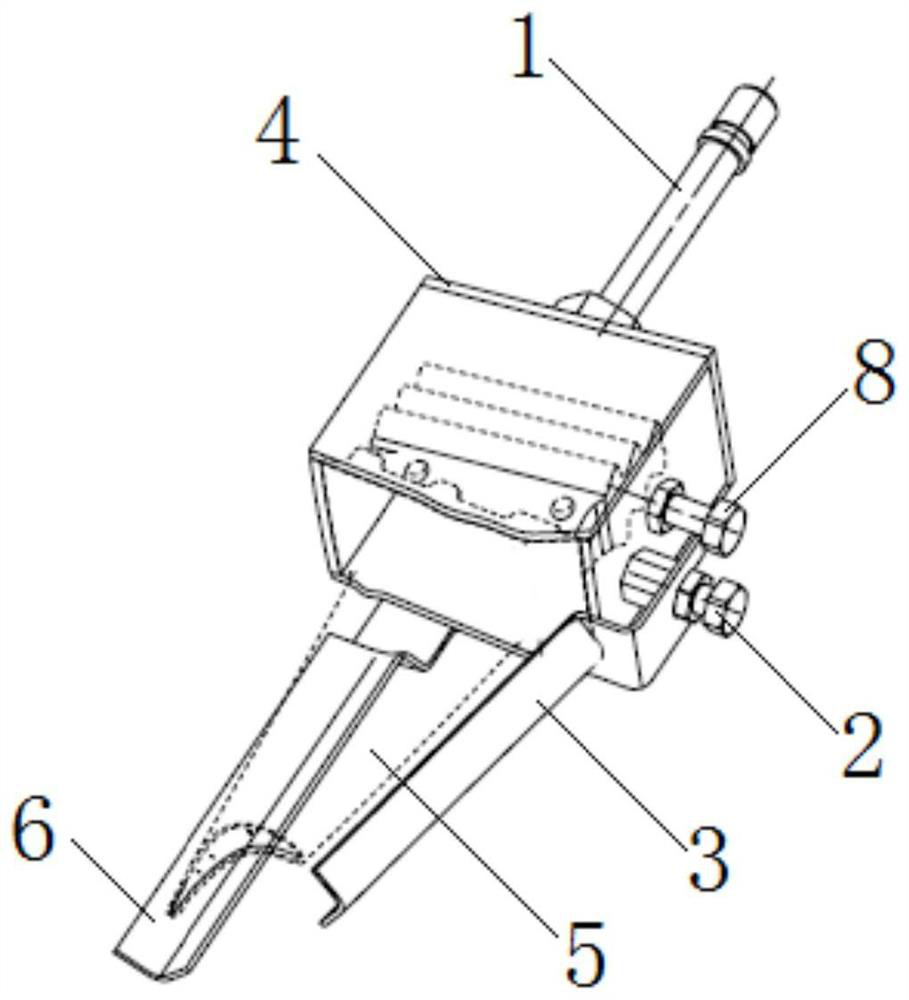

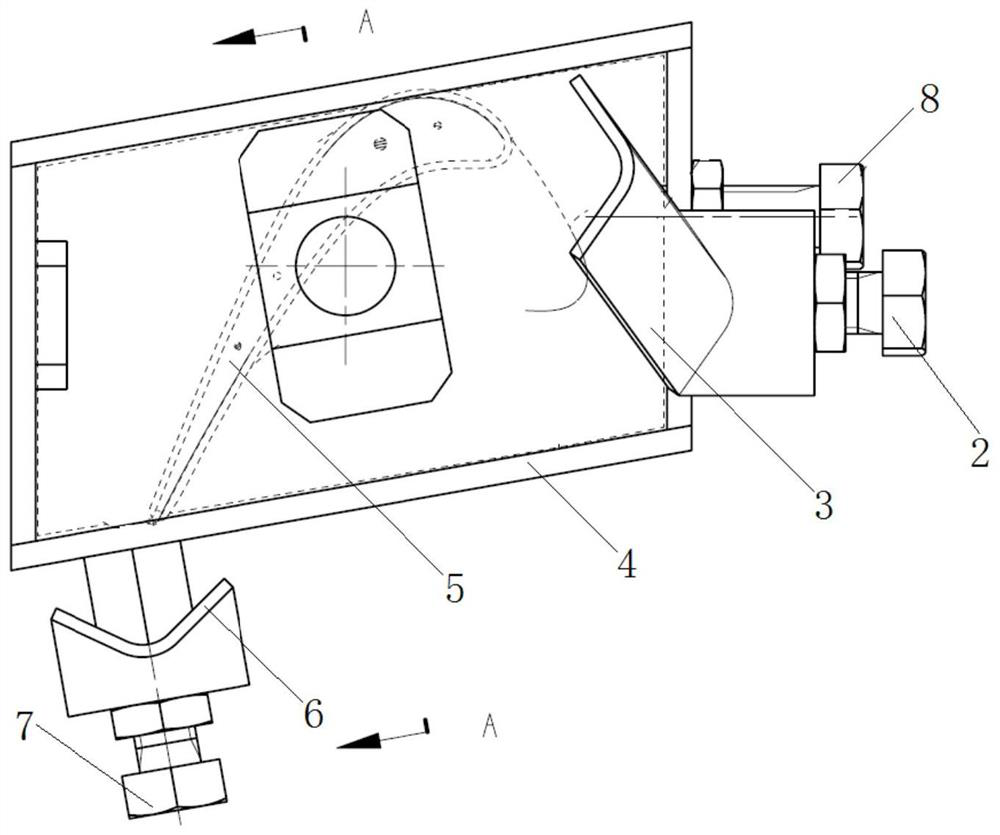

Turbine blade thermal barrier coating finishing protection device and method

ActiveCN113001339AAvoid overglazing problemsGuarantee organizationEdge grinding machinesVacuum evaporation coatingSpoilerTurbine blade

The invention discloses a turbine blade thermal barrier coating finishing protection device and a method. The turbine blade thermal barrier coating finishing protection device comprises a pull rod, an air inlet edge spoiler, a protection box and an exhaust edge spoiler; the protection box is of an open structure, a through hole is formed in the open bottom face of the protection box, a clamping groove is formed in one end of the pull rod and used for fixing a tenon of a blade to be finished, and the other end of the pull rod penetrates through the through hole in the bottom face of the protection box to fix the tenon of the blade to be finished into the protection box; the air inlet edge spoiler is arranged on one side wall of the protection box and used for protecting an air inlet edge of the blade to be finished; and the exhaust edge spoiler is arranged on one side wall of the protection box and used for protecting the exhaust edge of the blade to be finished. Firstly, wax seal is adopted to block an air film hole, a top cover hole and a tail crack of a turbine blade, and then the air inlet edge spoiler, the exhaust edge spoiler and the protection box are arranged to carry out finishing protection on the air inlet edge, the exhaust edge and the tenon.

Owner:AECC AVIATION POWER CO LTD +1

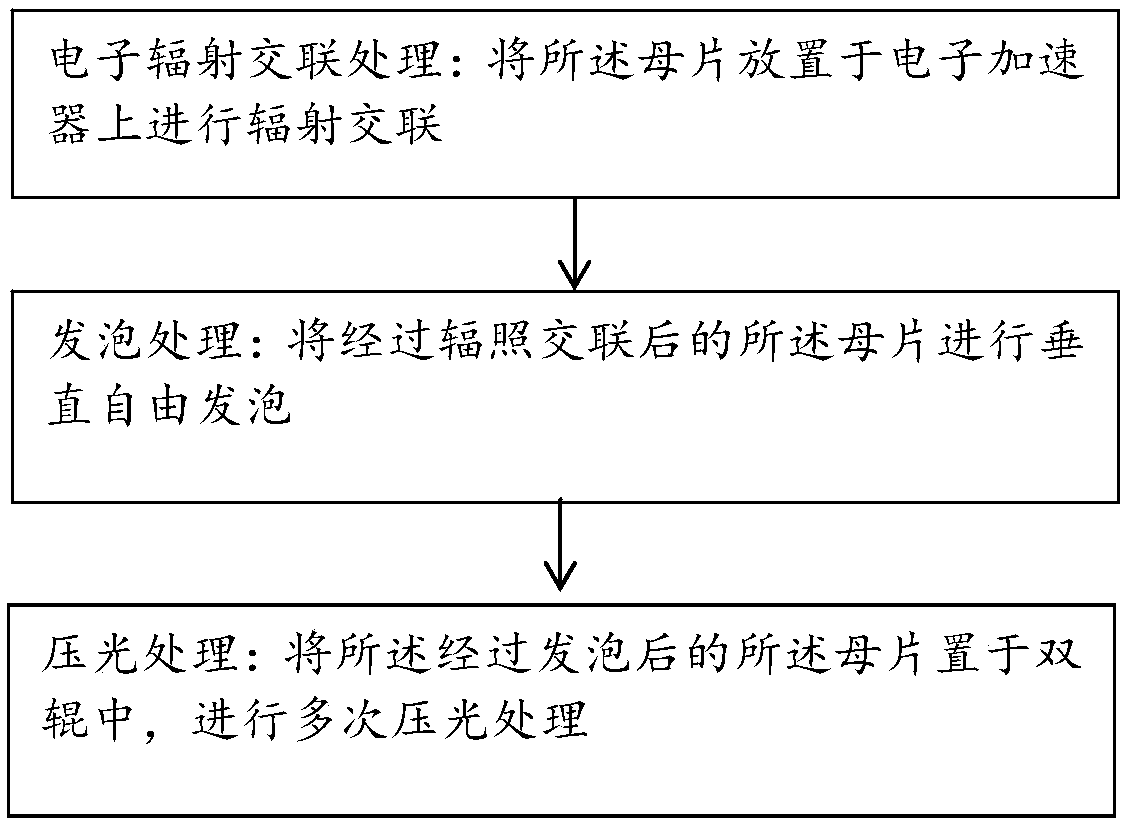

Crosslinked polyethylene foamed material and preparation method thereof

ActiveCN107759883AHighlight green environmental protectionOutstanding benefitsApparent densityPolyol

The embodiment of the invention provides a crosslinked polyethylene foamed material which is prepared from the following components in parts by weight: 65-90 parts of polyethylene, 5-30 parts of polymerized bio-oil polyether polyol, 5-30 parts of a thermoplastic elastomer, 0.5-7 parts of a foaming agent, 0.5-4 parts of a sensitizer and 0.5-5 parts of an antioxidant. The crosslinked polyethylene foamed material has good properties such as longitudinal tensile strength greater than 3.5MPa, a longitudinal elongation rate greater than 200%, transverse tensile strength greater than 1.5MPa, a transverse elongation rate greater than 350%, a 25% compression ratio less than 80KPa, and the like, and meanwhile the apparent density of the foamed material is 0.2-0.5g / cm<3>. The crosslinked polyethylenefoamed material can be used as a sealing buffer or adhesive substrate of a window and a touch screen of an electronic product.

Owner:ZHEJIANG WANLI NEW MATERIALS TECH CO LTD

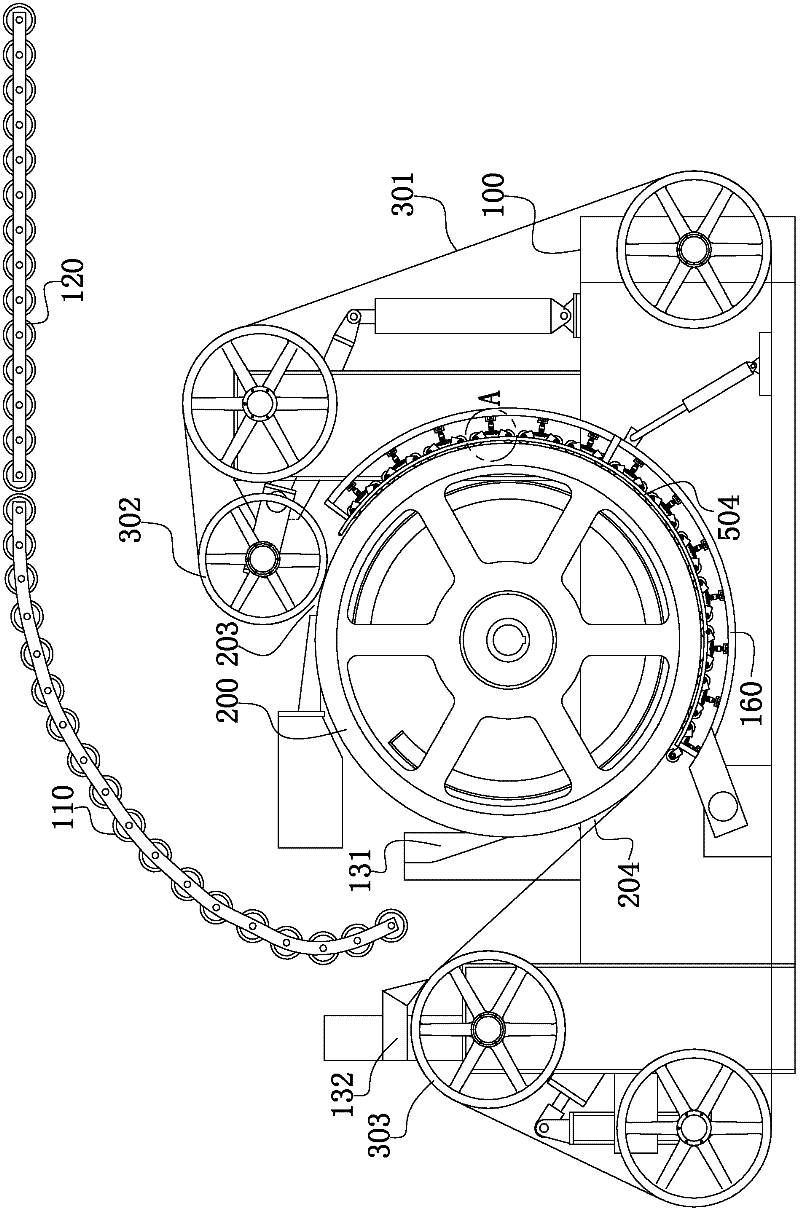

Steel belt wheel-type continuous casting machine for continuous casting of lead belts

The invention relates to a continuous casting equipment of non-ferrous alloy, providing a steel belt wheel-type continuous casting machine for continuous casting of lead belts. A steel belt supporting structure is arranged on the radial outer side of the cavity section corresponding to the crystalizing wheel. The steel belt supporting structure comprises at least one set of supporting bodies, the steel belt being positioned between the supporting body and the crystallizing wheel. One side of the crystallizing wheel corresponding to the steel belt tightly clings to the crystallizing wheel rim on both sides of the crystallizing cavity, while the other side tightly clings to the supporting body; a supporting structure external cooling device and a supporting structure internal cooling device are arranged; the cooling system of the steel belt comprises a steel belt spray cooling device and a contact-type cooling device formed by steel belt supporting structure. By arranging the steel belt supporting structure, the deformation of the steel belt is avoided, and enough cooling capacity is provided, which is applicable to the continuous casting of lead belts of large height and width.

Owner:德阳宏广科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com