Gas pipe for vacuum coating and vacuum coating device applying gas pipe

A vacuum coating and gas pipe technology, which is applied in the field of vacuum coating gas pipes and vacuum coating devices, can solve the problems of color difference of coated products, uniform distribution of difficult gases, time-consuming and other problems, and achieve the effect of ensuring thickness uniformity and color difference uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

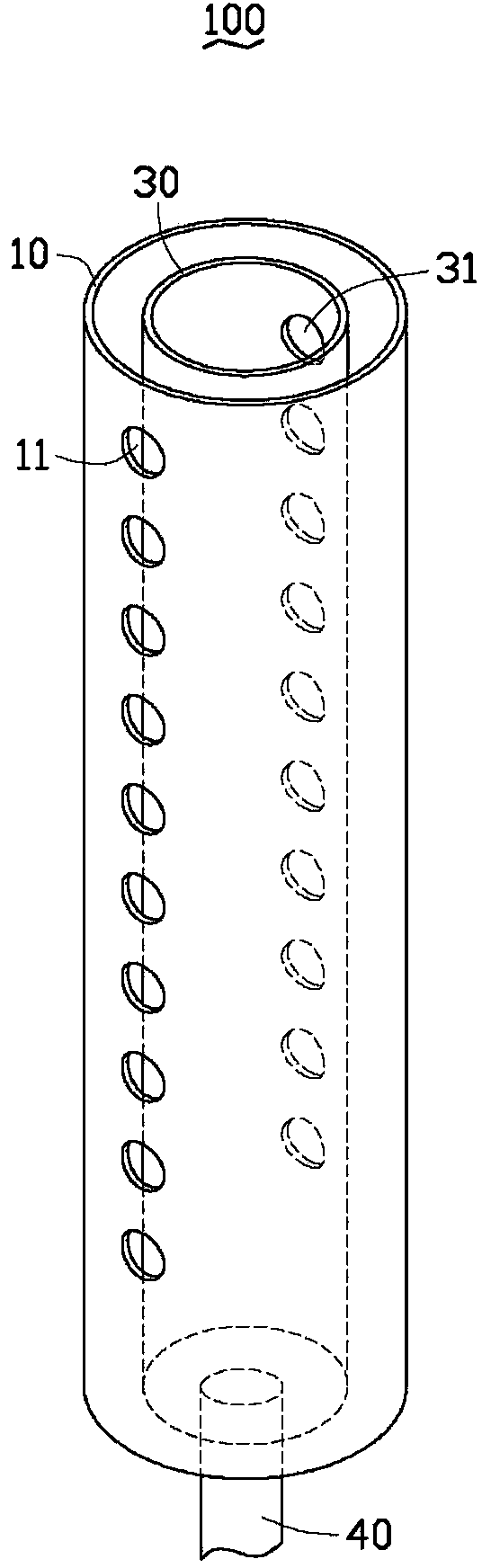

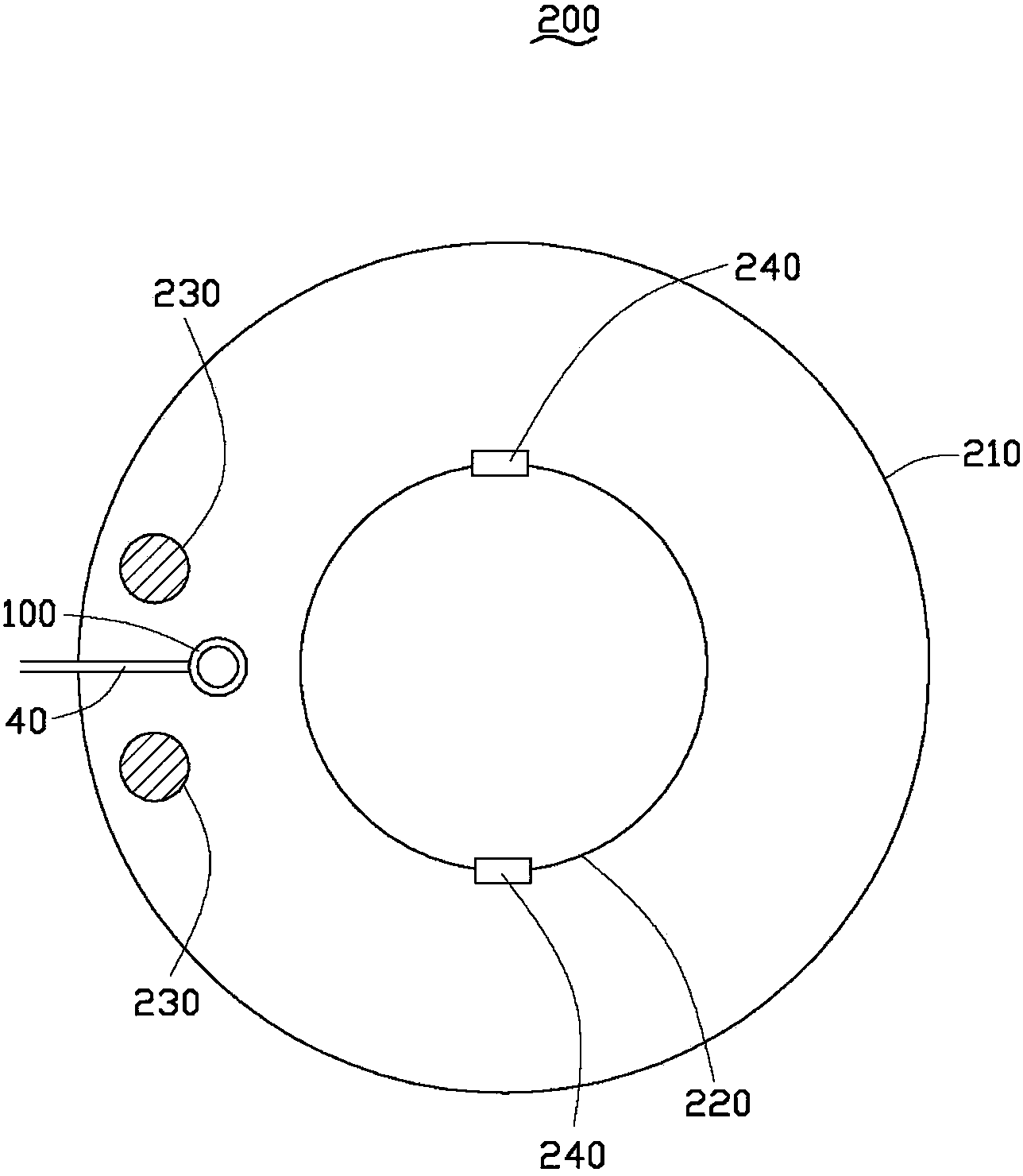

[0013] see figure 1 , the air pipe 100 for vacuum coating in a preferred embodiment of the present invention includes an outer air pipe 10 and an inner air pipe 30 disposed inside the outer air pipe 10 . The inner diameter of the outer air tube 10 is at least twice the inner diameter of the inner air tube 30 .

[0014] The inner air pipe 30 defines a row of first air holes 31 along the axial direction of the pipe wall. The outer air pipe 10 defines a row of second air holes 11 along the axial direction of the pipe wall.

[0015] The preferred relative positions of the second air holes 11 of the row and the first air holes 31 of the row make the distance between the line connecting the center points of the second air holes 11 of the row and the line connecting the center points of the first air holes 31 of the row maximum, That is, the row of second air holes 11 and the row of first air holes 31 are located on the tangent plane along the diameter direction of the outer air tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com