Crosslinked polyethylene foamed material and preparation method thereof

A technology of cross-linked polyethylene and polyethylene, which is applied in the field of polymer materials, can solve the problems of poor mutual solubility, achieve high tensile strength, highlight environmental protection, economic benefits, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

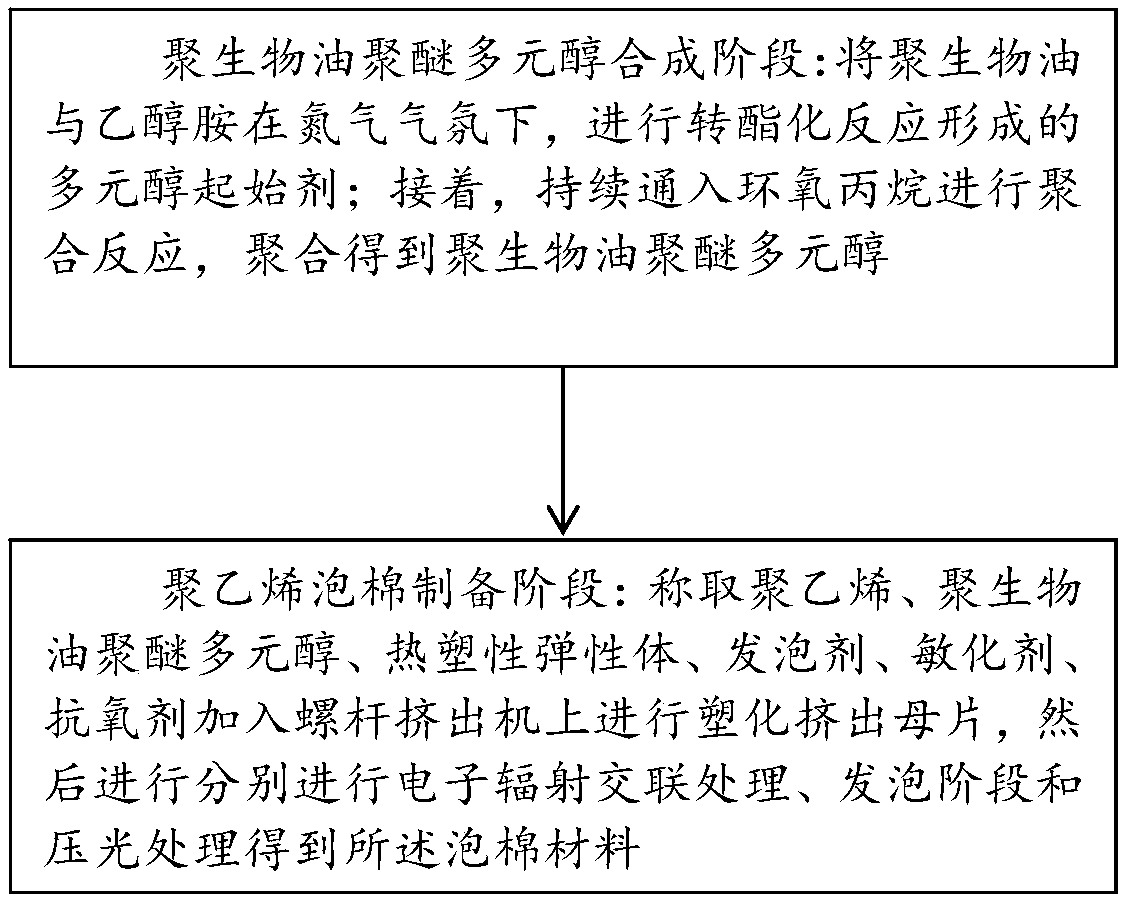

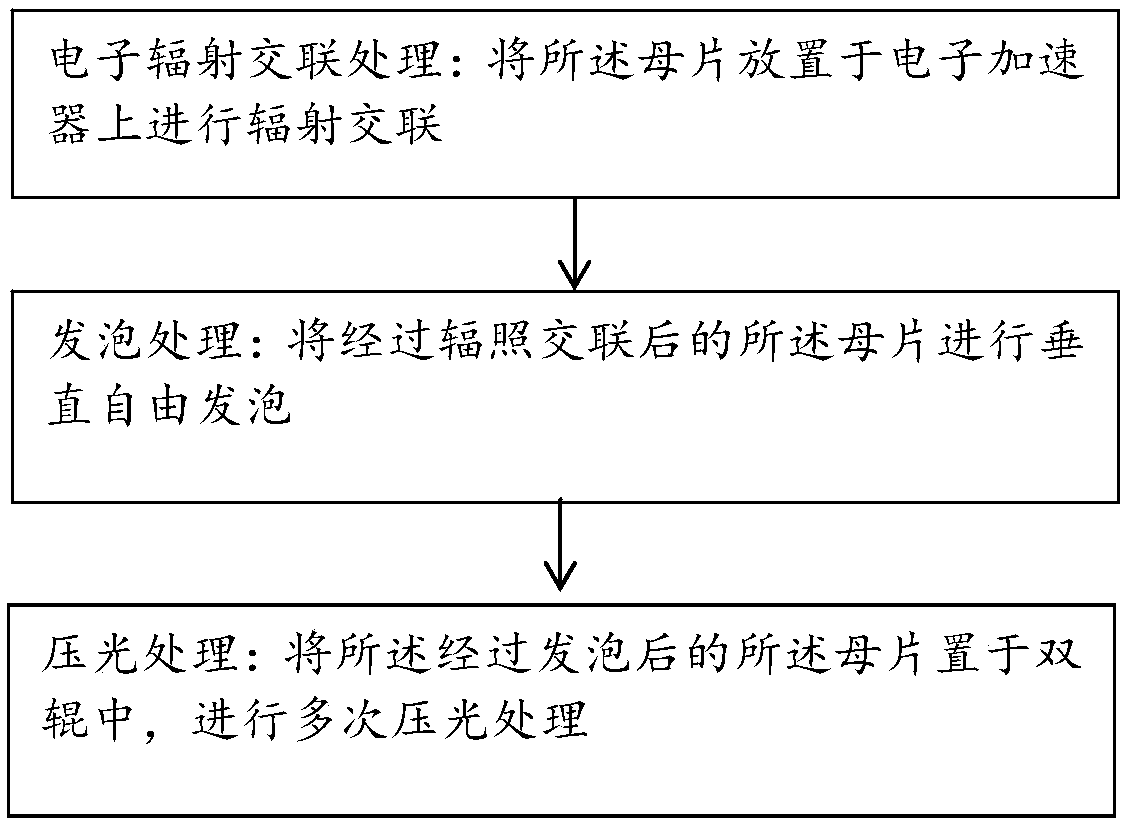

[0035] Such as figure 1 Shown, the preparation method of this cross-linked polyethylene foam material may further comprise the steps:

[0036] The present application also provides a preparation method of the above-mentioned cross-linked polyethylene foam material, the preparation method comprising the following steps:

[0037] (1) Polybio-oil polyether polyol synthesis stage: 80-95 parts by weight of poly-bio-oil and 5-20 parts by weight of ethanolamine are formed by transesterification at 150-250°C for 4-12 hours under nitrogen atmosphere Polyol initiator; then, continuously feed propylene oxide at 80-160°C for polymerization reaction, and obtain polybio-oil polyether polyol after polymerization for 4-24 hours;

[0038] (2) Polyethylene foam preparation stage: Weigh 65-90 parts by weight of polyethylene, 5-30 parts by weight of polybio-oil polyether polyol, 5-30 parts by weight of thermoplastic elastomer, and 0.5-7 parts by weight of foam agent, 0.5 to 4 parts by weight se...

Embodiment 1

[0045] Step 1 Synthesis of polypeanut oil polyether polyol

[0046] 100 parts by weight of peanut oil and 0.5 parts by weight of azobisisobutyronitrile were placed in the reactor, stirred and mixed evenly, and then the air in the reactor was replaced by nitrogen gas. In a nitrogen atmosphere, the reactor was heated to 310°C, and the peanut oil and azobisisobutyronitrile were polymerized for 8 hours to obtain polypeanut oil;

[0047] Next, 90 parts by weight of polypeanut oil and 10 parts by weight of diethanolamine were placed in the reactor for stirring and mixing, and then the air in the reactor was replaced by nitrogen gas. Heating to about 180°C in a nitrogen atmosphere for transesterification reaction for about 8 hours, forming a polyol initiator; finally, continuously feeding propylene oxide at 135-140°C for polymerization reaction, maintaining the pressure of the reaction system at about 0.8MPa , Polymerized for 12h to obtain polypeanut oil polyether polyol.

[0048] ...

Embodiment 2

[0061] Step 1 Synthesis of Poly-Rapeseed Polyether Polyols

[0062] 100 parts by weight of rapeseed oil and 0.8 parts by weight of azobisisobutyronitrile were placed in the reactor, stirred and mixed evenly, and then the air in the reactor was replaced by nitrogen gas. In a nitrogen atmosphere, the reactor was heated to 320°C, and rapeseed oil and azobisisobutyronitrile were polymerized for 18 hours to obtain polyester rapeseed oil;

[0063] Next, 95 parts by weight of rapeseed oil and 5 parts by weight of diethanolamine were placed in the reactor for stirring and mixing, and then the air in the reactor was replaced by nitrogen gas. After heating to about 160°C in a nitrogen atmosphere for transesterification reaction for about 12 hours, a polyol initiator is formed; finally, propylene oxide is continuously introduced at about 130°C for polymerization reaction, and the pressure of the reaction system is maintained at about 0.7MPa. Polymerized for 10 hours to obtain poly-rapee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com