Air intake device for furnace tube

A technology of air intake device and furnace tube, which is applied in the direction of gaseous chemical plating, chemically reactive gas, crystal growth, etc., can solve the problems of product 14 pollution in the process chamber, particle problems, and affect product quality and production efficiency, and achieve guaranteed Thickness uniformity, effect of reducing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

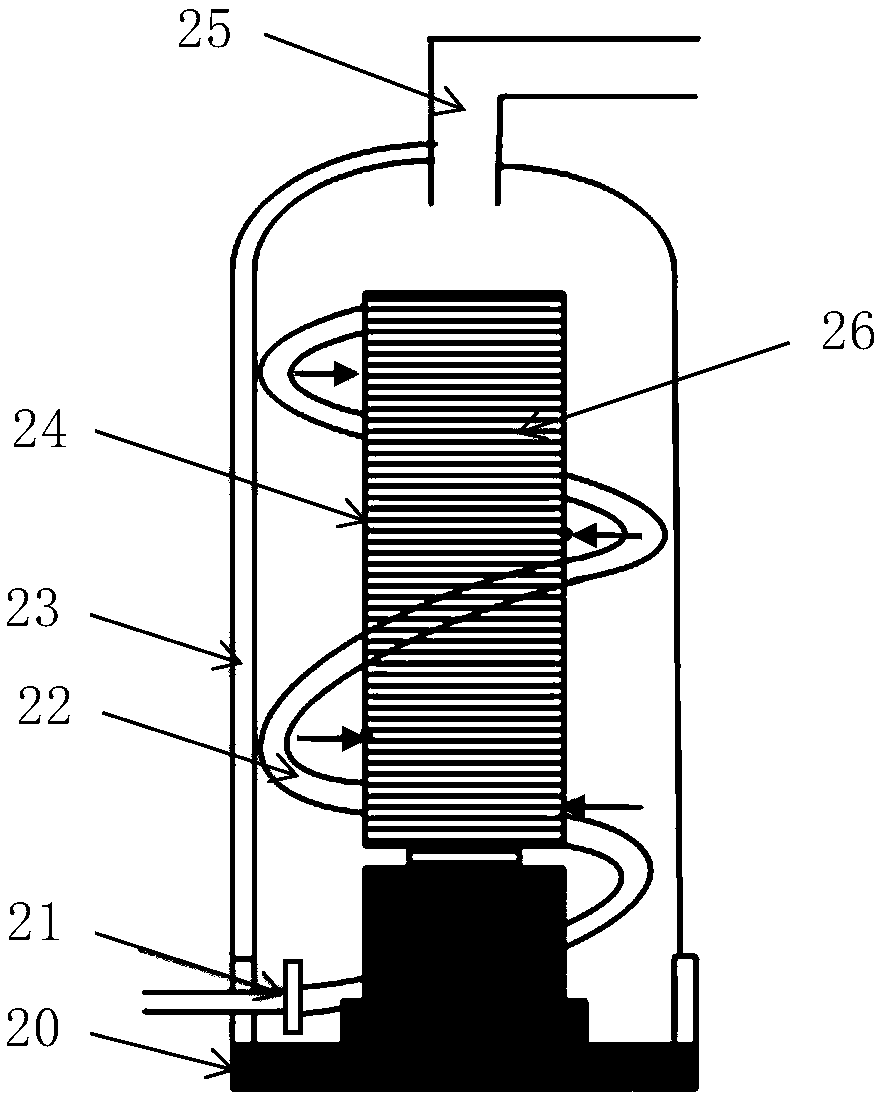

[0025] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] It should be noted that, in the following specific embodiments, when describing the embodiments of the present invention in detail, in order to clearly show the structure of the present invention for the convenience of description, the structures in the drawings are not drawn according to the general scale, and are drawn Partial magnification, deformation and simplification are included, therefore, it should be avoided to be interpreted as a limitation of the present invention.

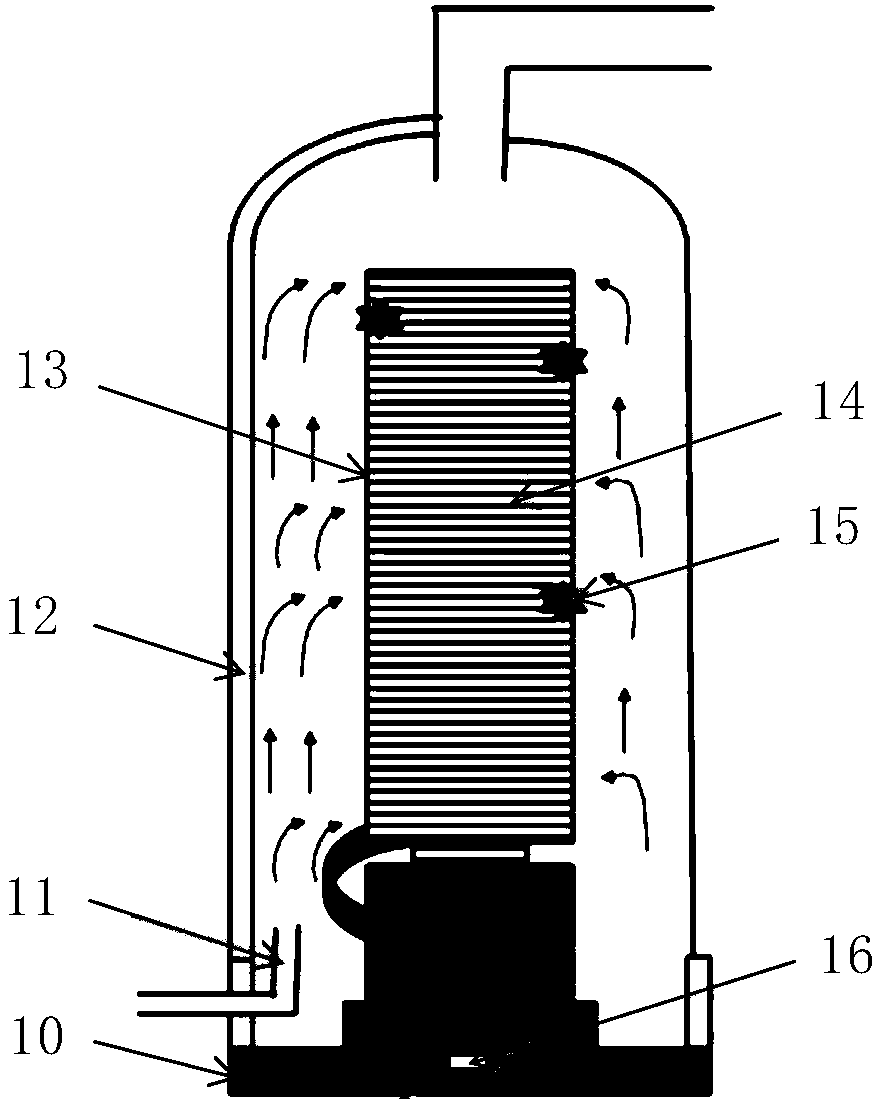

[0027] In the following specific embodiments of the present invention, please refer to figure 2 , figure 2 It is a structural schematic diagram of a gas inlet device of a furnace tube according to a preferred embodiment of the present invention. Such as figure 2 As shown, the air intake device of a furnace tube of the present invention is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com