Direct growth method of flexible X-ray sensor scintillator layer

A technology of scintillator layer and growth method, applied in radiation measurement, X/γ/cosmic radiation measurement, instruments, etc., can solve the problems of low image resolution and quantum conversion efficiency, achieve stable performance and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

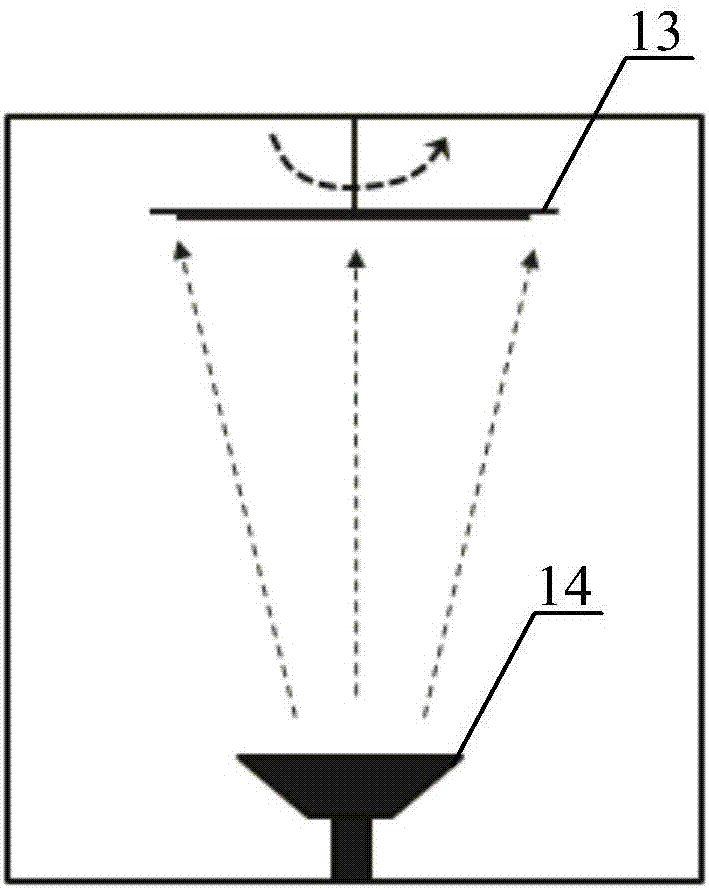

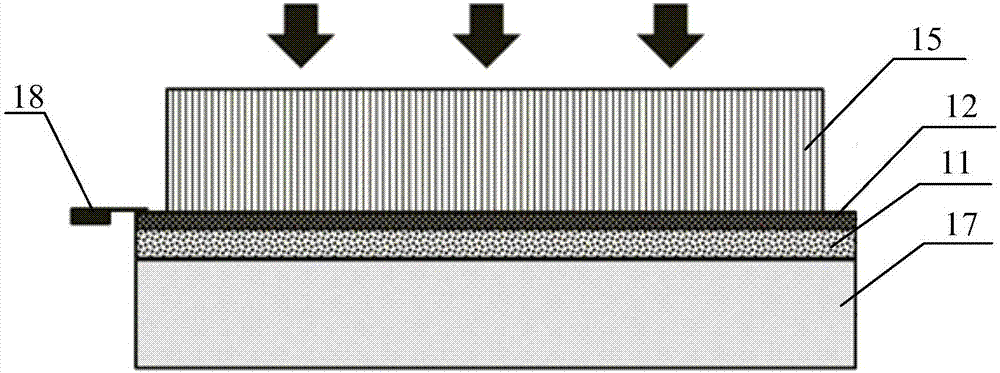

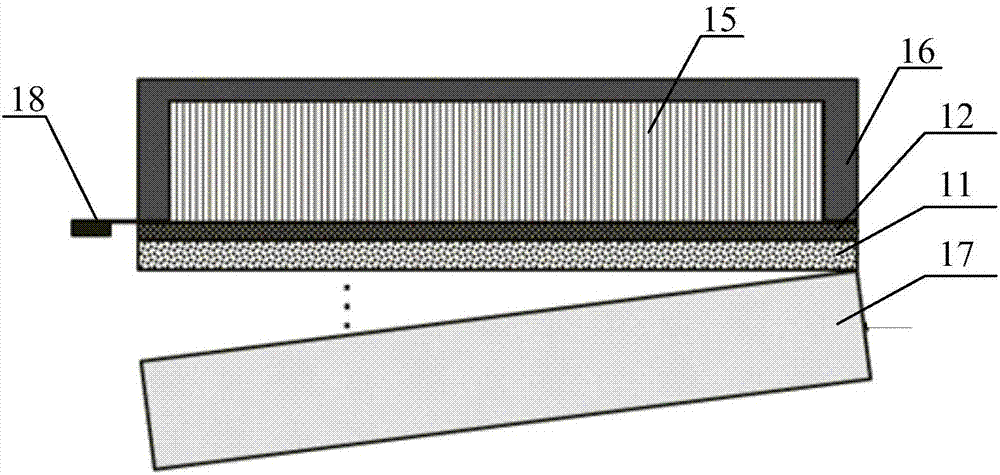

[0059] Such as Figure 1 ~ Figure 4 As shown, this embodiment provides a method for directly growing the scintillator layer of a flexible X-ray sensor. This method is a planar growth and packaging process, and is mainly applied to planar detectors and small-angle curved surface detectors. The growth method at least includes the following steps:

[0060] First, step 1-1) is performed to provide the flexible base layer 11 with the pixel array layer 12 prepared on the surface.

[0061] As an example, first provide a glass substrate 17, then coat the flexible substrate layer 11 on the surface of the glass substrate 17, and then grow the pixel array layer 12 on the surface of the flexible substrate layer 11, that is, from bottom to top These are the glass substrate 17 , the flexible substrate layer 11 , and the pixel array layer 12 in sequence.

[0062] It should be noted that the glass substrate 17 is mainly for the convenience of the planar growth process. The thickness of the ...

Embodiment 2

[0078] Such as Figure 8 ~ Figure 10 As shown, this embodiment provides a method for directly growing the scintillator layer of a flexible X-ray sensor. This method is a curved surface growth and packaging process, and is mainly applied to a curved surface detector with a large angle of curvature. The growth method at least includes the following steps:

[0079] First, step 2-1) is performed to provide the flexible base layer 21 with the pixel array layer 22 prepared on the surface.

[0080] As an example, first provide a glass substrate, then coat the flexible substrate layer 21 on the surface of the glass substrate, and then grow the pixel array layer 22 on the surface of the flexible substrate layer 21, that is, from bottom to top in order A glass substrate, a flexible substrate layer 21, and a pixel array layer 22.

[0081] The thickness of the glass substrate is 500-1000 μm. After the pixel array layer 22 is prepared and formed, the glass substrate needs to be separated f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com