Sheet material thickness online detection and adjustment system based on laser ultrasonic

A technology of laser ultrasound and adjustment system, applied in the field of sheet metal processing and manufacturing, can solve the problems of large error, high cost, and unoptimistic equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

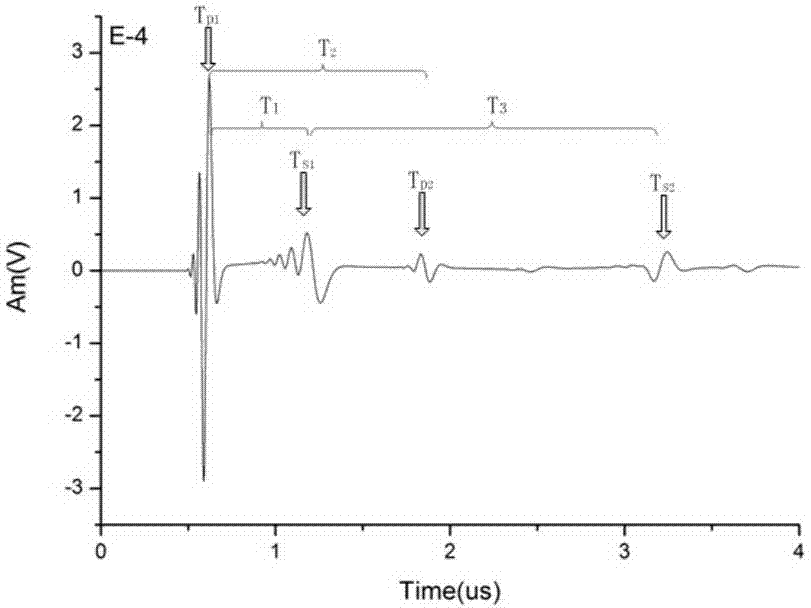

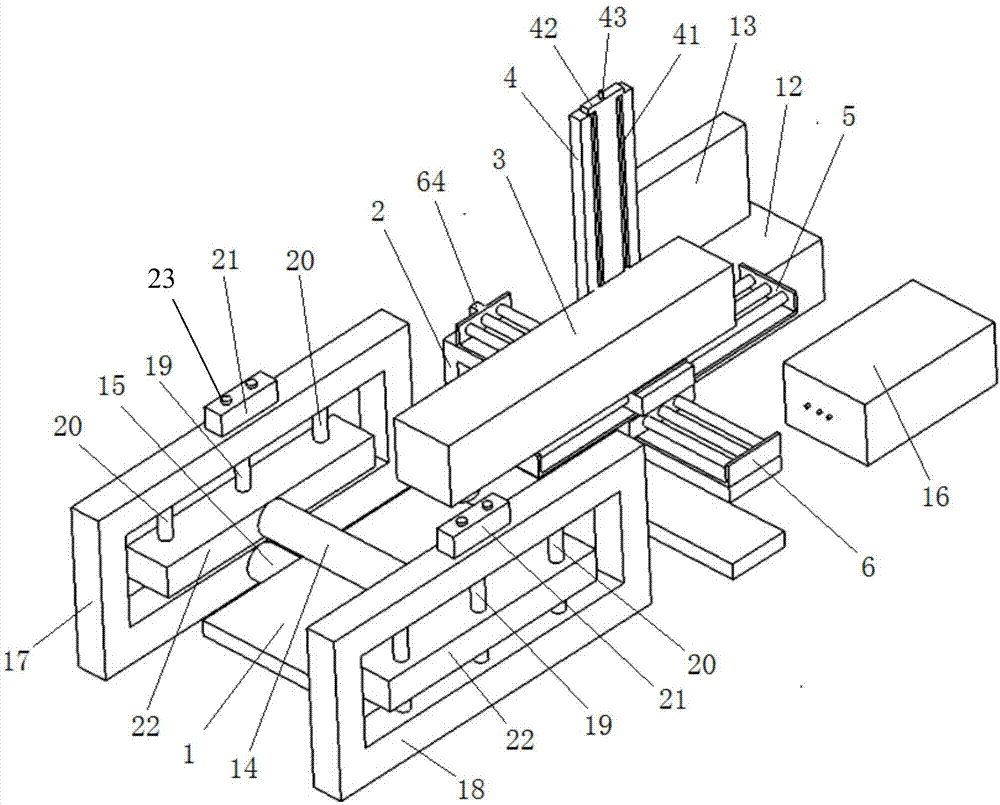

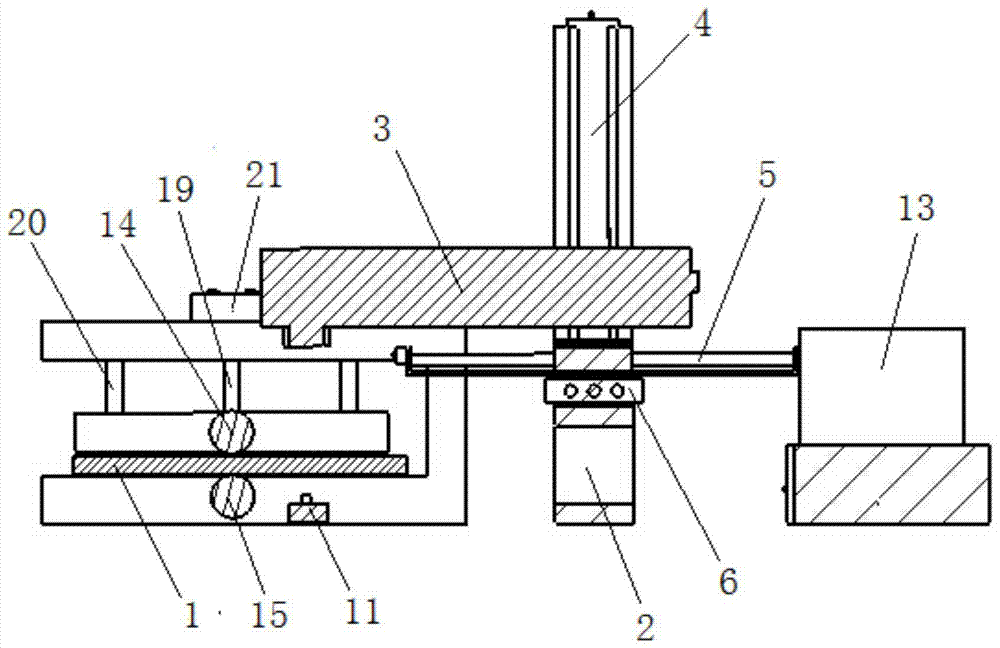

[0035] refer to Figure 1-8 : An online detection and adjustment system for sheet thickness based on laser ultrasound, including a sheet rolling mechanism and an online sheet thickness detection mechanism. The sheet rolling mechanism includes an upper roller 14, a lower roller 15, an upper and lower roller spacing adjustment mechanism, and PLC control system 16, the plate thickness online detection mechanism includes optical path system integration, high temperature detector, data acquisition system integration, and data processing system integration;

[0036] The upper and lower roller spacing adjustment mechanism includes a left bracket 17 and a right bracket 18, and the left bracket 17 and the right bracket 18 are respectively vertically provided with a fourth screw mandrel 19, and the fourth screw mandrel 19 on the left side is rotatably arranged by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sampling frequency | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com