Method and device for measuring discrete state granule graininess distribution

A particle size distribution and discrete state technology, applied in the direction of measuring devices, particle size analysis, particle suspension analysis, etc., can solve the problems that the measurement process cannot be realized, the particle size relationship is not noticed, and the sound path of ultrasonic propagation is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar structures, methods and similar changes of the present invention should be included in the protection scope of the present invention.

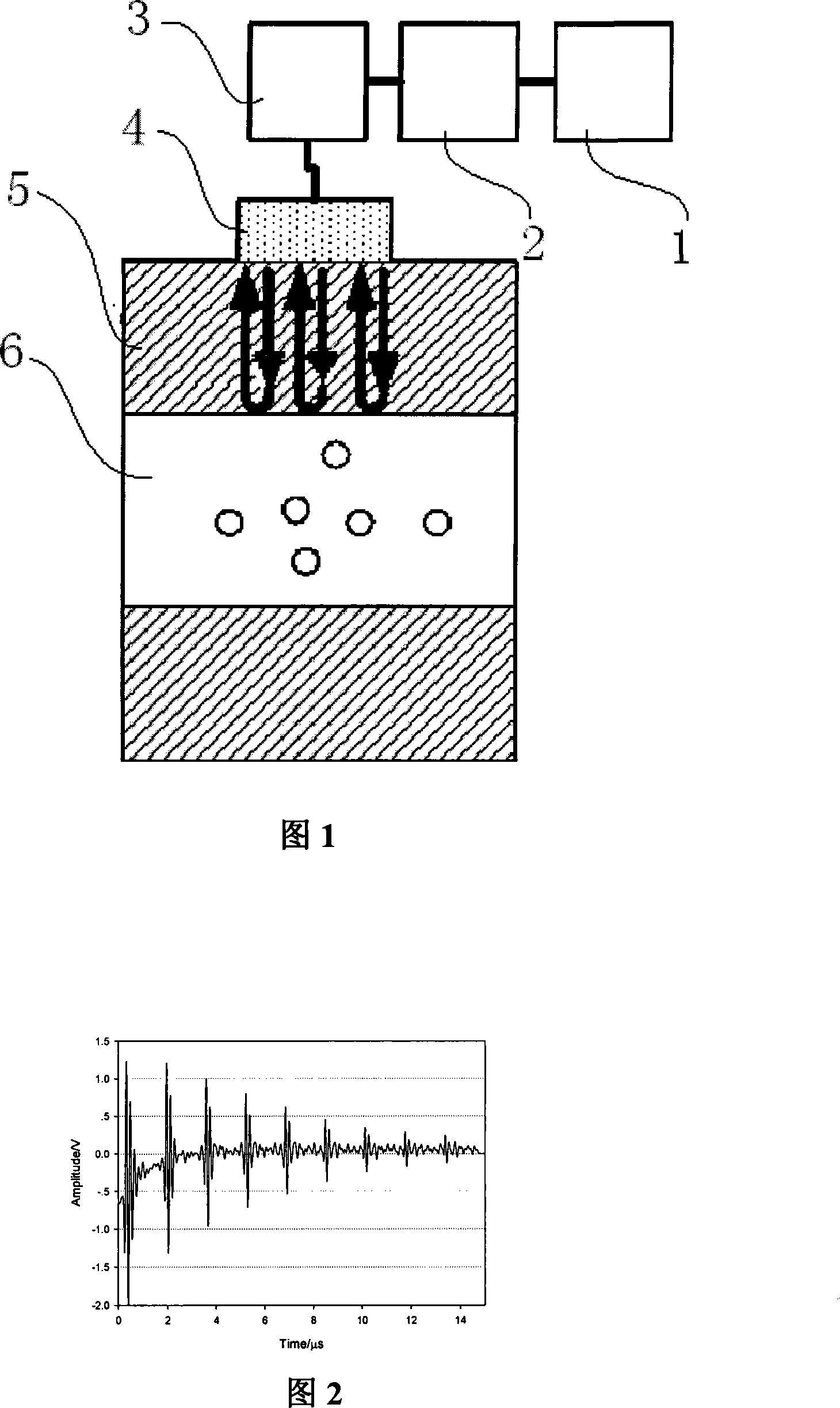

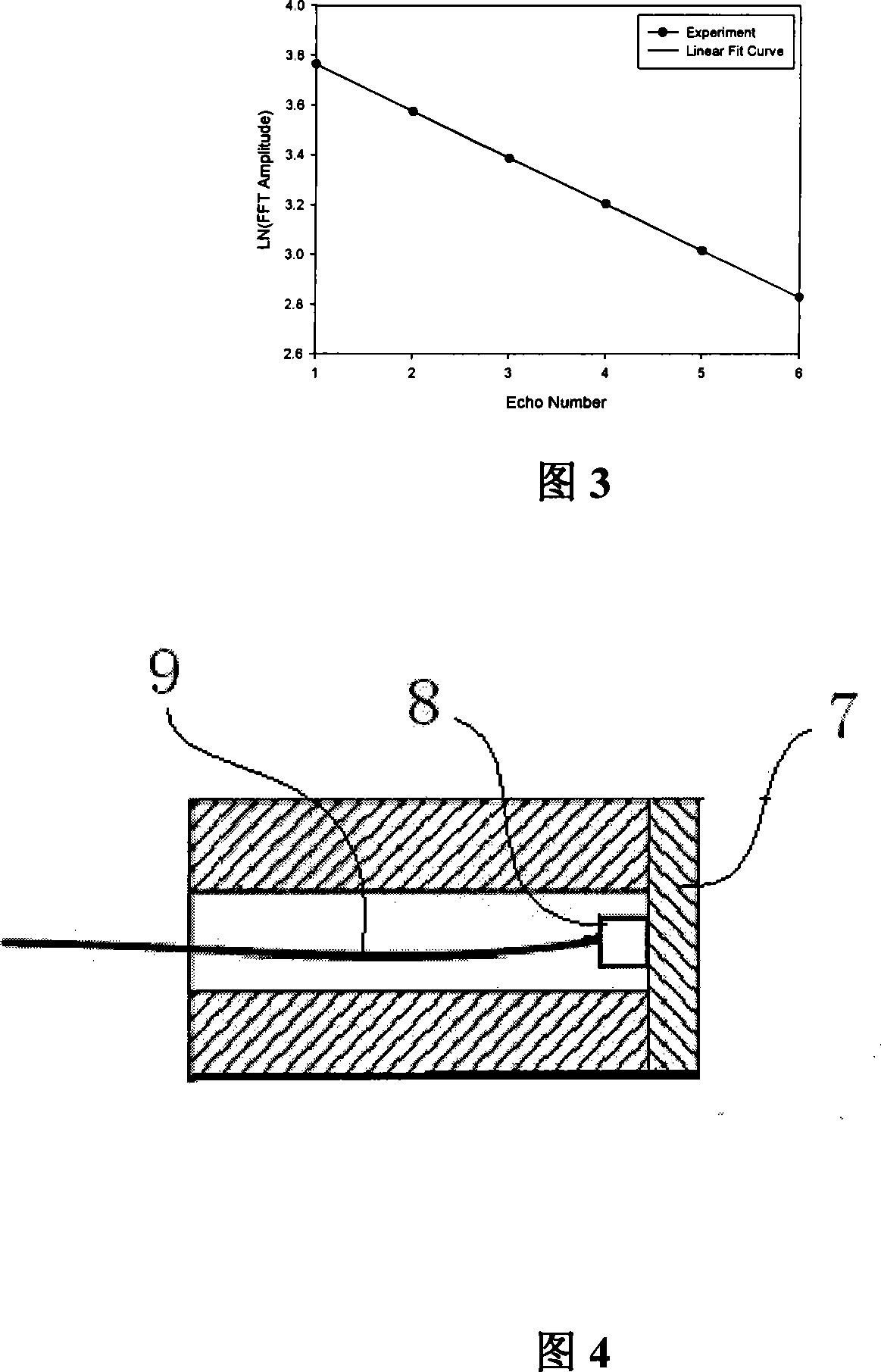

[0039] The theoretical model and inversion technology calculation of the embodiment of the present invention: as shown in Figure 1, the transducer 4 transmits the ultrasonic wave and reflects it multiple times in the plate 5, and it is respectively in the sample to be tested (referring to the continuous medium composed of particles and liquid) mixture) and the calibration substance, the reflection coefficient has the following relationship:

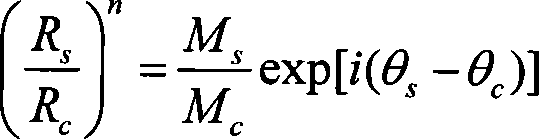

[0040] ( R s R c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com