Mass and efficient integral manufacturing method of terahertz hollow core rectangular waveguide

A rectangular waveguide and manufacturing method technology, which is applied in the field of precision manufacturing of waveguide micro-devices, can solve problems such as unusable processing methods, and achieve the effects of high production efficiency, good quality, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The waveguide to be prepared is as Figure 9 As shown, the following preparation process is used:

[0042] Step 1: Prepare a sacrificial mandrel composed of a low melting point alloy by photolithography;

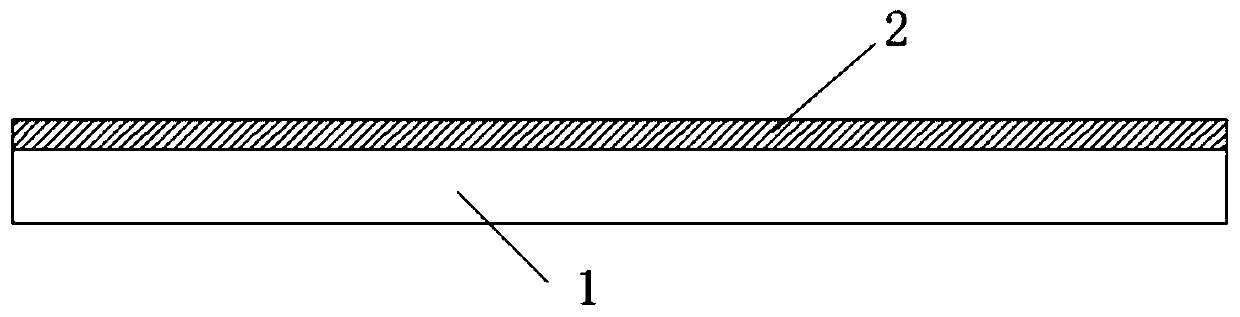

[0043] Step 1.1: coating a layer of photoresist 2 with a thickness of H1 on the substrate 1;

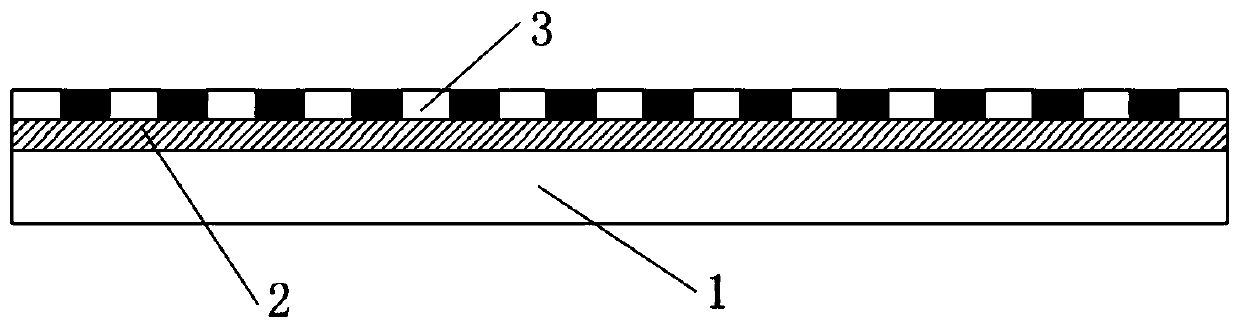

[0044] Step 1.2: Place the substrate 1 coated with photoresist in step 1.1 on the stage of the photolithography machine, and use the mask plate 3 to expose;

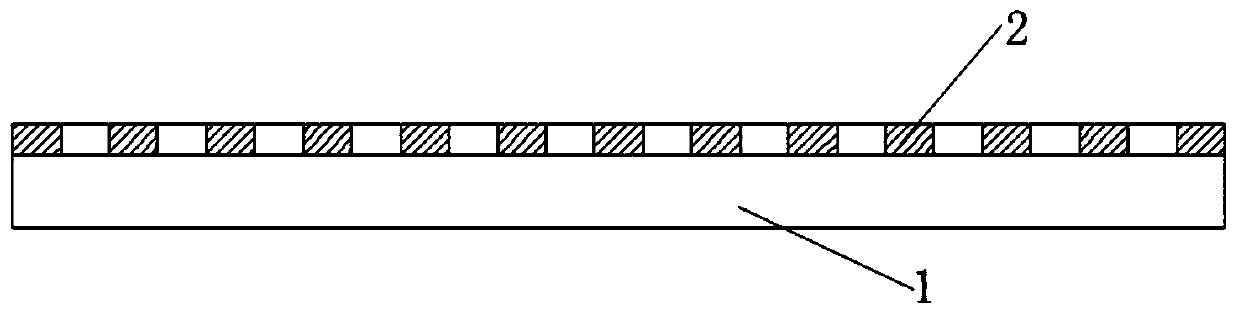

[0045] Step 1.3: put the exposed substrate 1 in step 1.2 into a developing solution for development, wash and dry after the development;

[0046] Step 1.4: Place the substrate 1 developed in step 1.3 on a heating plate, and set the temperature to a temperature higher than the melting point of the low melting point alloy, and evenly fill the molten low melting point alloy into the concave formed in step 1.3 in the slot;

[0047] Step 1.5: Precisely polish the surface of the low-melting-point alloy 4 after cooling an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com