Patents

Literature

218results about How to "Guaranteed surface roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning fluid for removing surface particles of semiconductor material and cleaning method therefor

InactiveCN101096617AReduce surface tensionIncrease surface tensionNon-ionic surface-active compoundsOrganic detergent compounding agentsSemiconductor materialsOzone layer

The invention discloses a cleaning fluid to remove surface particle of the semiconductor material and cleaning method, which comprises the following parts: 22 %-40% organic base, 3%-15% surface activator and 45%-75% pure water. The cleaning method comprises the following steps: (1)cleaning through the cleaning fluid; (2)using deionized water ultrasound; (3)using deionized water ultrasound; (4)spraying; (5)drying. The invention improves the uniform corrosiveness of the cleaning fluid to ensure the consistency, which protects environment due to adopting the material without damaging the ozone layer.

Owner:天津晶岭电子材料科技有限公司

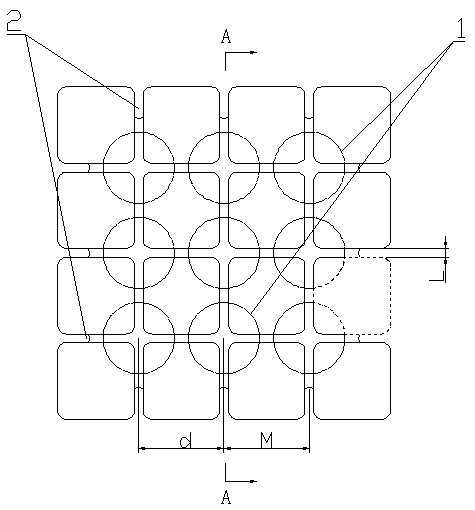

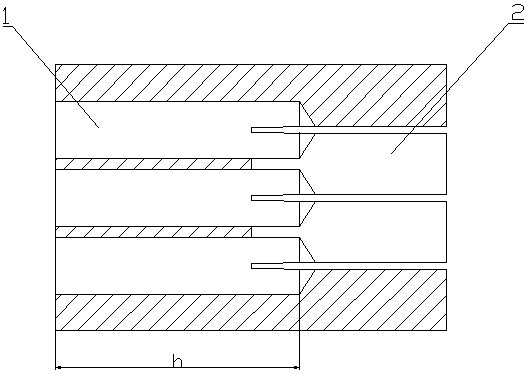

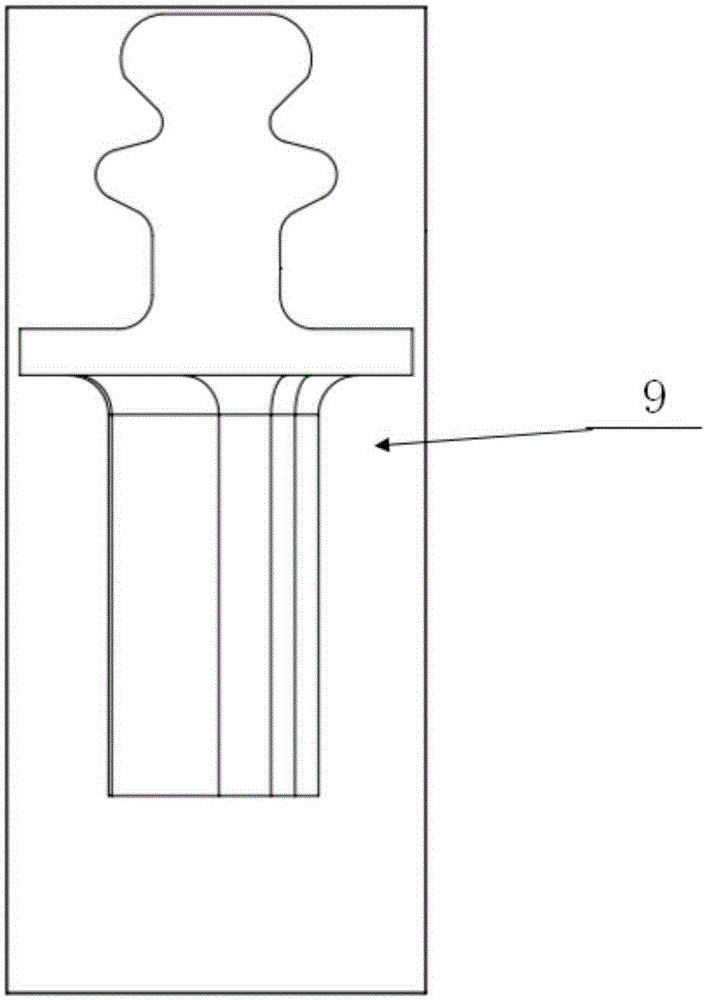

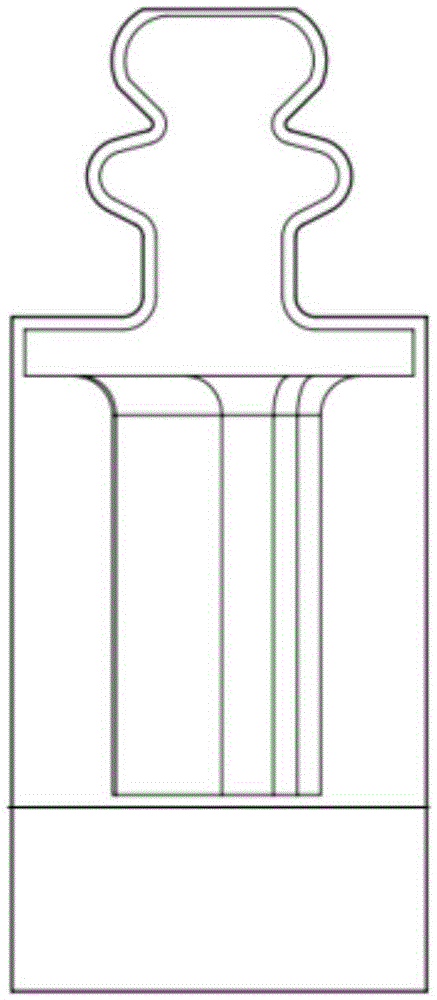

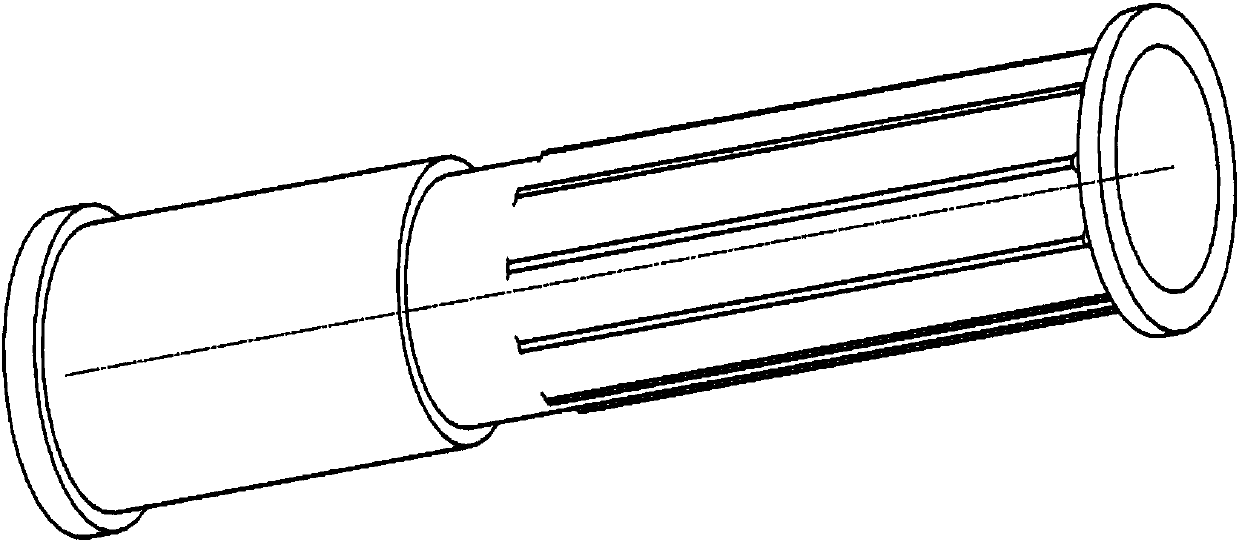

Manufacturing process of high-precision extrusion die for DeNOx catalyst

ActiveCN102039519AGuaranteed surface roughnessGuaranteed shape and position accuracySurface roughnessMachining process

The invention discloses a manufacturing process of a high-precision extrusion die for a DeNOx catalyst. The manufacturing process comprises the following steps: discharging, thermal refining, grinding, rough machining, grinding, boring holes, semi-fine grinding, thermal treatment, groove linear cutting, benching, fine grinding and protective treatment. In the process, by means of the methods such as reasonable control of machining amount, reasonable selection of equipment parameters and the like in the steps, the surface roughness, the dimensional precision and the form and position accuracy of holes (grooves) of machined parts of the extrusion die with multiple deep holes (grooves) for the catalyst are effectively ensured, wherein, the machining precision reaches 0.01mm, and the surface roughness reaches over Ra0.8; the machining process is stable and reliable; the qualification rate of the die product reaches over 99%; and the difficulty in manufacturing the complicated die with the multiple deep holes (grooves) is overcome. Compared with the prior art, the manufacturing process disclosed by the invention has the advantages of effectively avoiding scrap caused by size and location out-of-tolerance, greatly lowering production cost, improving machining efficiency and shortening production cycle.

Owner:CHONGQING YUANDA CATALYST MFG

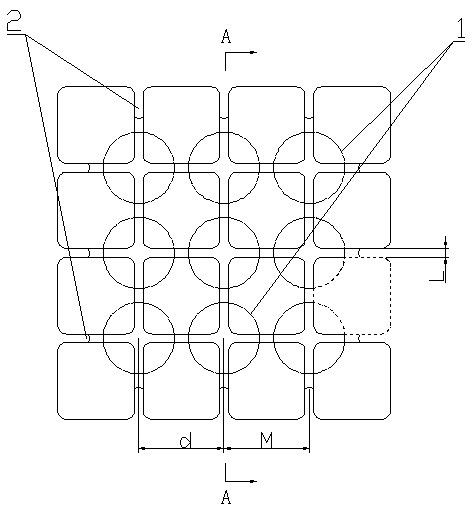

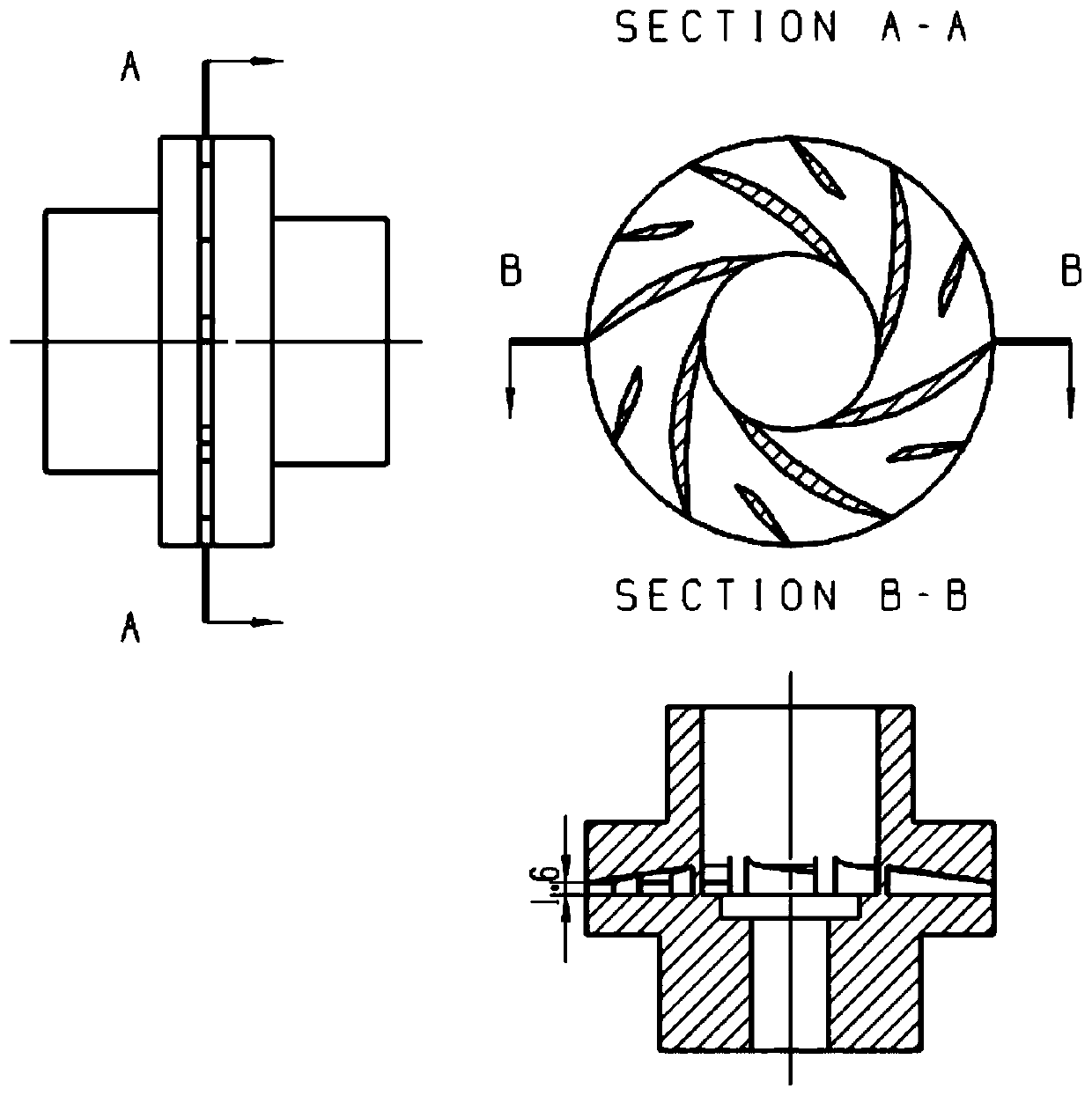

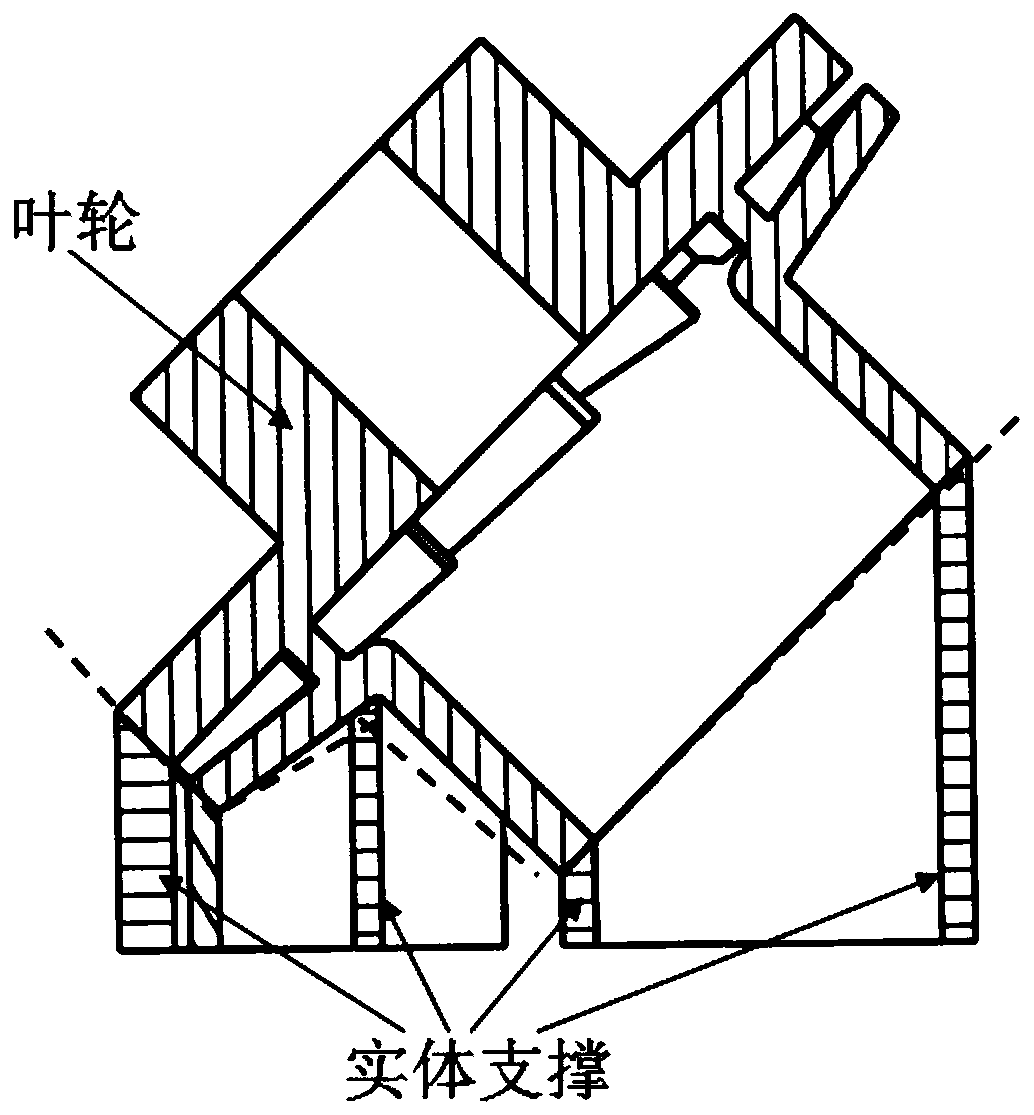

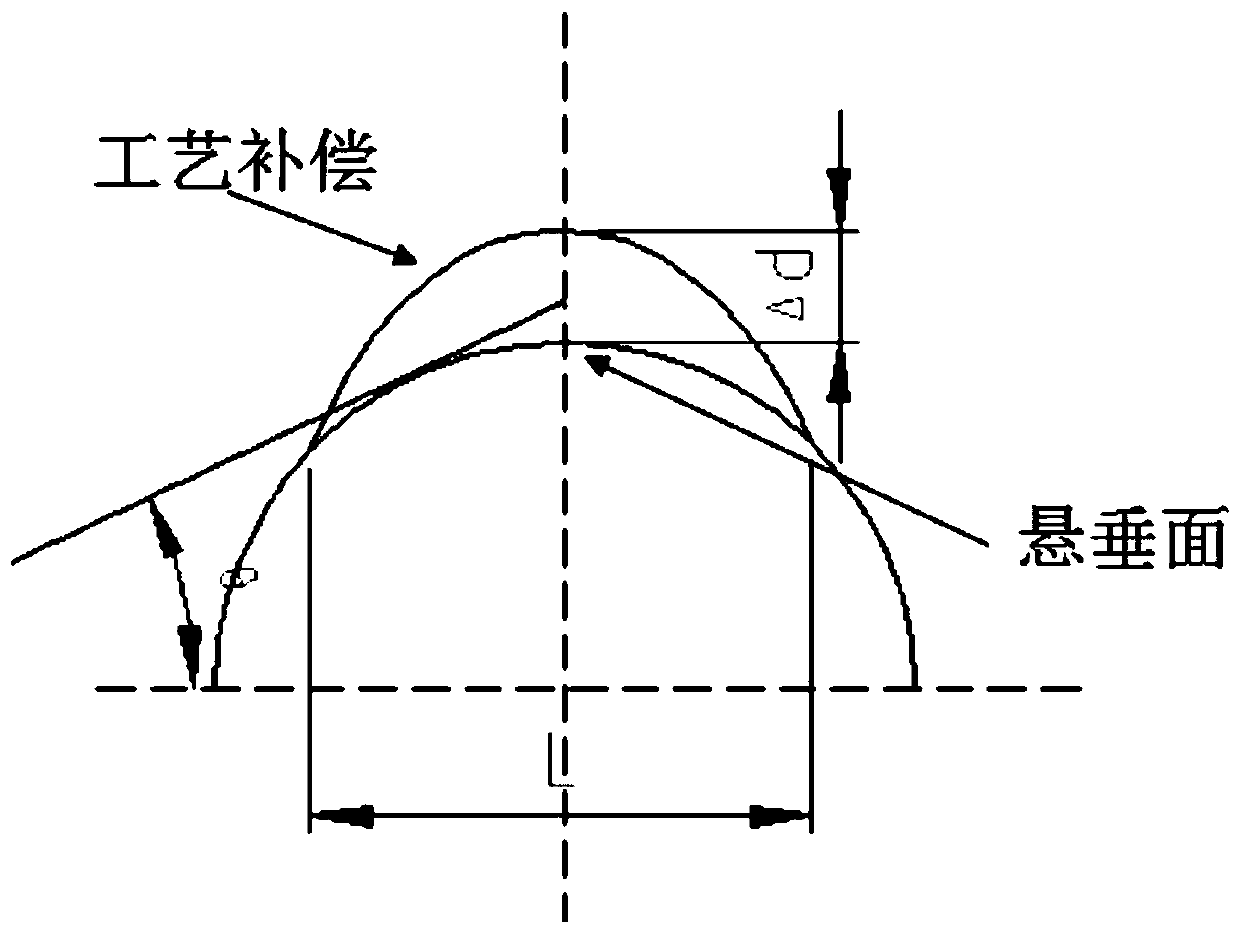

Selective laser melting forming method for small-gap closed aluminum alloy impeller

ActiveCN110153425AGuaranteed dimensional accuracyGuaranteed shape accuracyAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingImpeller

The invention relates to a selective laser melting forming method for a small-gap closed aluminum alloy impeller, and belongs to the technical field of metal additive manufacturing. The small gap refers to that an outlet gap between a front cover plate and a rear cover plate in the impeller is not more than 3 mm. Process pre-compensation is adopted, and a columnar support convenient to remove is additionally arranged, so that the size precision, the shape precision and the surface roughness of an inner runner are ensured, wherein the precision can reach + / -0.1 mm, the surface roughness of theinner runner subjected to surface finishing can reach Ra of 1.6 microns, so that overall additive manufacturing of the small-gap closed aluminum alloy impeller becomes possible.

Owner:XIAN SPACE ENGINE CO LTD

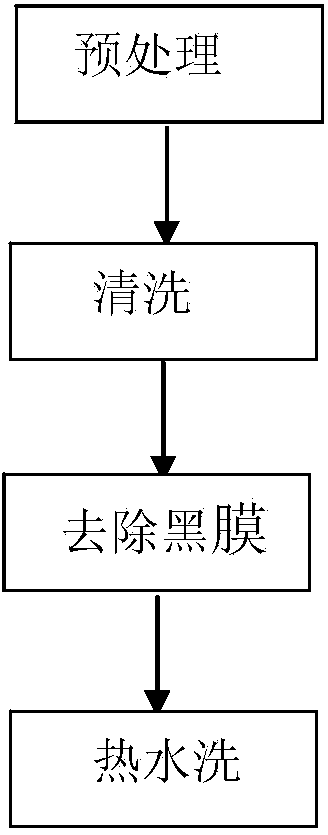

Cleaning liquor and treatment method for removing residual magnesium alloys in die

The invention provides cleaning liquor for removing residual magnesium alloys in a die. The cleaning liquor comprises the following components in percentage by weight: 60-240g of hydrochloric acid, 1-10g of ammonium citrate, 0.5-2g of EDTA (Ethylene Diamine Tetraacetic Acid), 5-55g of a corrosion inhibitor and 750-950g of water. Meanwhile, the invention provides a treatment method for cleaning the residual magnesium alloys by using the cleaning liquor according to the following four steps: pretreatment, cleaning, removing black films and washing by hot water. The cleaning liquor and treatment method have the benefits that damages cannot caused to the die and no influence is made on dimensional precision of the die, and configuration and operating method are simple and feasible, so that the surface roughness Ra1.0-1.5 of the die is effectively guaranteed. Referring to standards of GB8923-1988 Rusting Grade on Surface of Steel Products and Derusting Grade before Coating, according to the method, the surface rusting condition of the die is improved from grade D to grade A, and the grade Sa 3 of compressed-air blast cleaning is realized, so that one grade is raised relative to that of existing die cleaning liquor in the existing market.

Owner:TIANJIN DONGYI MAGNESIUM PROD +1

Machining method for aero-engine high-temperature alloy counterweight blade

The invention discloses a machining method for an aero-engine high-temperature alloy counterweight blade. The machining method includes the following steps that (1) a blade root mortise is cut in a wire cutting mode, specifically, most of the margin of a mortise part of a counterweight blade blank is removed through a wire cutting method; (2) the blade root and the blade form are milled, specifically, the blade root of the blank with the mortise margin removed in a wire cutting mode is upwards vertically clamped on a two-rotary-table five-shaft linkage machining center, then the end surface, the inner arc radial surface, the back arc radial surface, the steam inlet lateral surface and the steam outlet lateral surface of the blade root are machined through a face mill cutter in a rough and fine mode, a profile modeling milling cutter is used for machining a mortise in the steam inlet side and a mortise in the steam outlet side, and finally the adaptation surface of the blade root and the blade form and a blade form surface are machined in a rough, semi-fine and fine mode; and (3) the blade crown is cut in a wire cutting mode. According to the machining method for the aero-engine high-temperature alloy counterweight blade, the clamping frequency, the tool number and the varieties of tools are reduced. Meanwhile, the machining procedure is reasonably planned, reliability of machining is guaranteed, the machining accuracy is guaranteed, the machining efficiency is improved, and the production cost is reduced.

Owner:JIANGSU JITRI HUST INTELLIGENT EQUIP TECH CO LTD

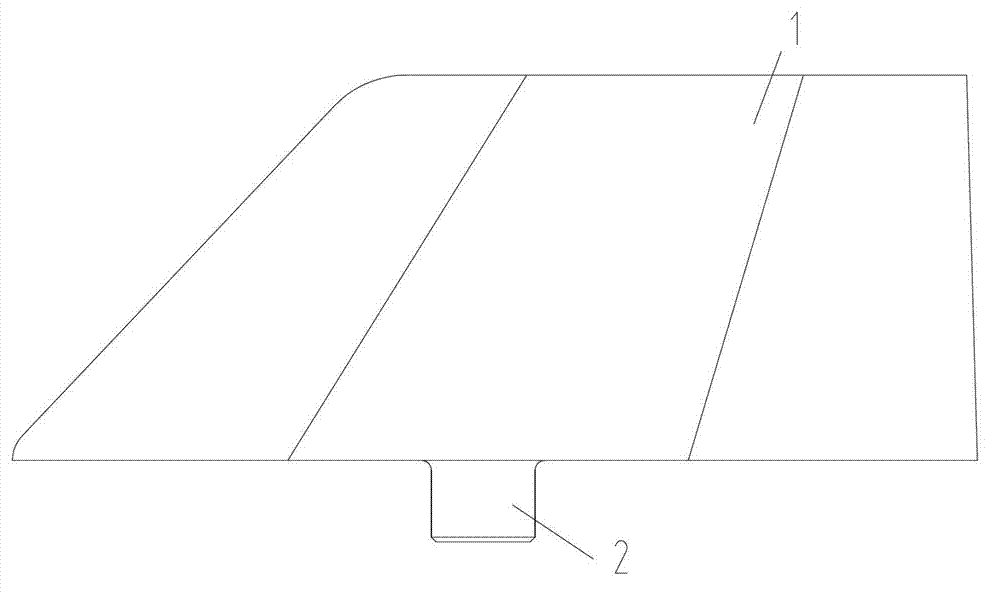

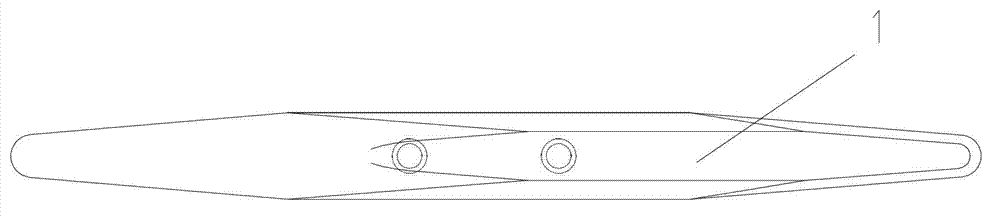

Processing method of nonmetal special-shaped rudder sheet and clamp for processing

InactiveCN102873383AGuaranteed dimensional accuracyGuaranteed surface roughnessMilling equipment detailsPositioning apparatusAbnormal shapedRudder

The invention discloses a processing method of a nonmetal special-shaped rudder sheet and a clamp for processing. The processing method comprises the following steps: 1) designing a nonmetal rudder sheet flat blank according to a product maximum profile dimension; 2) vertically clamping the nonmetal rudder sheet flat blank, symmetrically grinding the two reference surfaces of the nonmetal rudder sheet flat blank; 3) performing rough milling of the profile of the nonmetal rudder sheet flat blank, processing a process chuck for subsequent clamping at a position of a rudderpost; 4) vertically clamping the process chuck, aligning the central planes of the two reference surfaces, performing semi-finish milling of the reference surfaces of the nonmetal rudder sheet flat blank, then performing finish milling one surface to obtain the designed dimension so as to form the rudder sheet; 5) vertically clamping the rudder sheet, performing semi-finish milling of the process chuck to obtain a rudderpost shape; 6) performing finish milling of the rudderpost to obtain the designed dimension so as to finish the processing of the nonmetal special-shaped rudder sheet. With the processing method of the nonmetal special-shaped rudder sheet and the clamp for processing, the processing precision and the form and location tolerance of the nonmetal special-shaped rudder sheet can be effectively ensured.

Owner:湖北三江航天江北机械工程有限公司

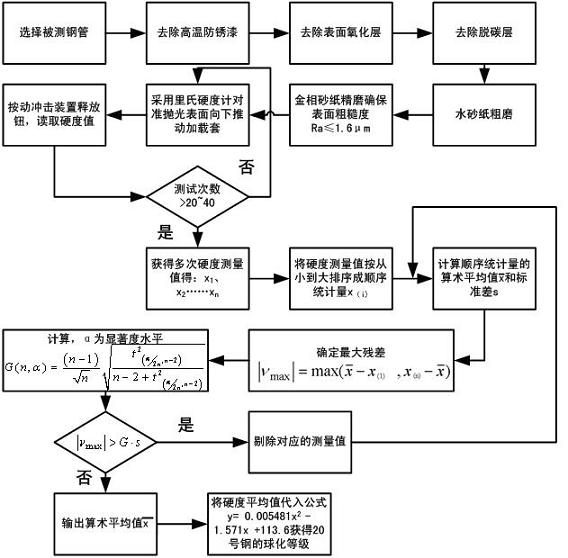

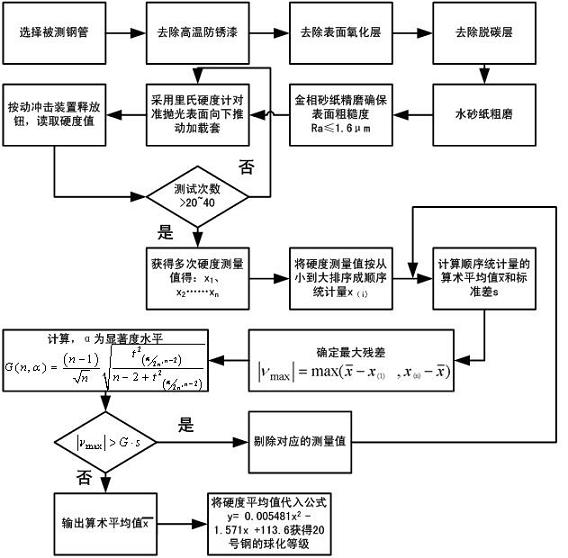

On-site test method for pearlite spheroidization grade of No.20 steel

InactiveCN102183430AAvoid damageLower level requirementsInvestigating material hardnessTest efficiencySurface roughness

The invention discloses an on-site test method for pearlite spheroidization grade of No.20 steel, which solves the problems of damage on work parts, complex test process, higher demand on knowledge level and experience of operators and the like in a conventional metallographical method. The on-site test method provided by the invention comprises the following steps of: mechanically clearing a surface of an objective steel piece, then, mechanically grinding and polishing the surface of the objective steel piece while spraying water, orderly testing the hardness of a same part for 20-40 times by a Leeb hardness tester when the surface roughness Ra is controlled to be not more than 1.6 mum, respectively reading a Brinell hardness number of the same part, and performing data processing on the Brinell hardness numbers obtained after many tests to obtain the pearlite spheroidization grade of the No.20 steel piece, wherein the whole data processing procedure is finished by a computer program. The on-site test method for the pearlite spheroidization grade of the No.20 steel is less in damage to work pieces, simple in test process, simple in used devices, low in demand on the knowledge level and experience of the operators, high in test efficiency and degree of automation, higher in accuracy, excellent in repeatability and the like.

Owner:YANGZHOU UNIV

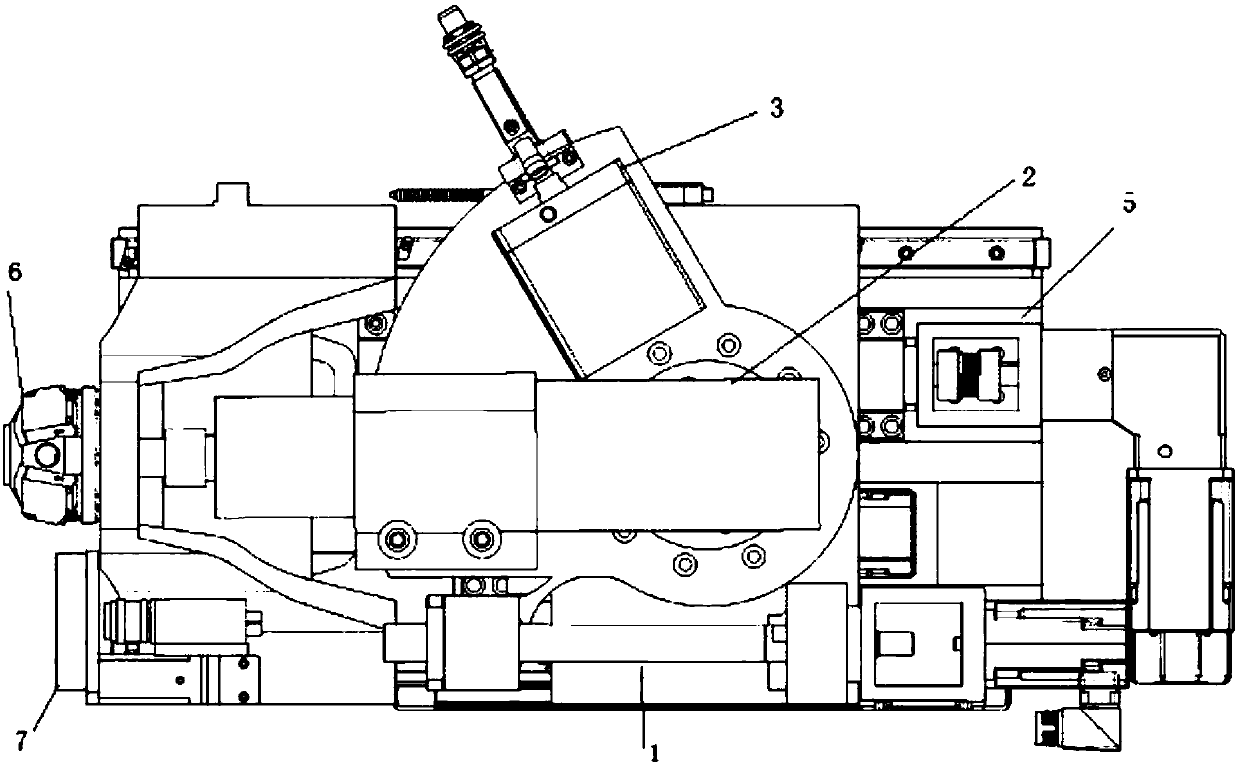

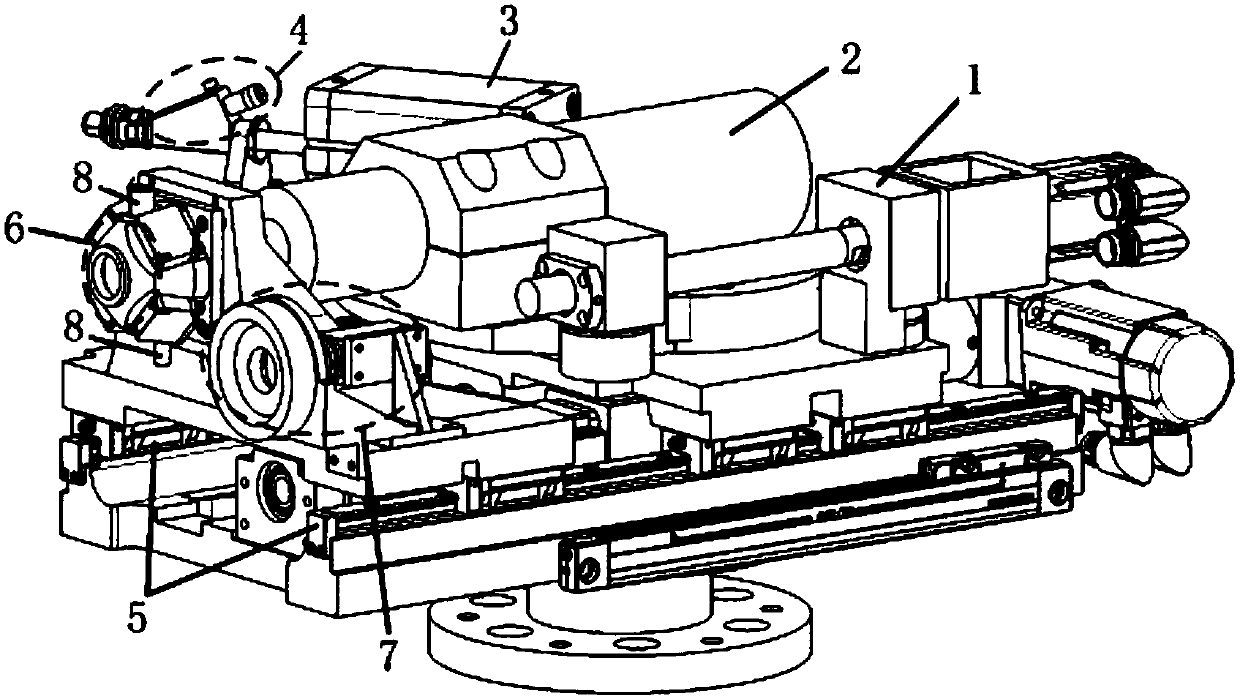

Drilling and interference bolt-inserting integrated device and method

ActiveCN107554813ARealize integrationSolve the defect of finding the position information of the nail hole againAutomatic control devicesSheet joiningDrill holeWall plate

The invention discloses a drilling and interference bolt-inserting integrated device and method. The drilling and interference bolt-inserting integrated device comprises a station conversion module, aspindle module and a bolt-inserting module. The station conversion module comprises a driving mechanism, a double-station connecting plate and a connecting belt mechanism connected between the driving mechanism and the double-station connecting plate; the spindle module is arranged at a first station of the double-station connecting plate and used for drilling and dimpling of wall plate connecting holes; the bolt-inserting module is arranged at a second station of the double-station connecting plate and used for interference bolt-inserting of high-locking bolts; and the driving mechanism of the station conversion module drives the connecting belt mechanism to rotate, so that station conversion of the first station and the second station is achieved. Thus, by adopting the drilling and interference bolt-inserting integrated device, after the to-be-drilled holes are drilled, the station conversion module is rotated by a fixed angle, then the station states of the spindle module and the bolt-inserting module can be switched, thus interference bolt-inserting of the high-locking bolts is completed, and the anti-fatigue property and assembly efficiency are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

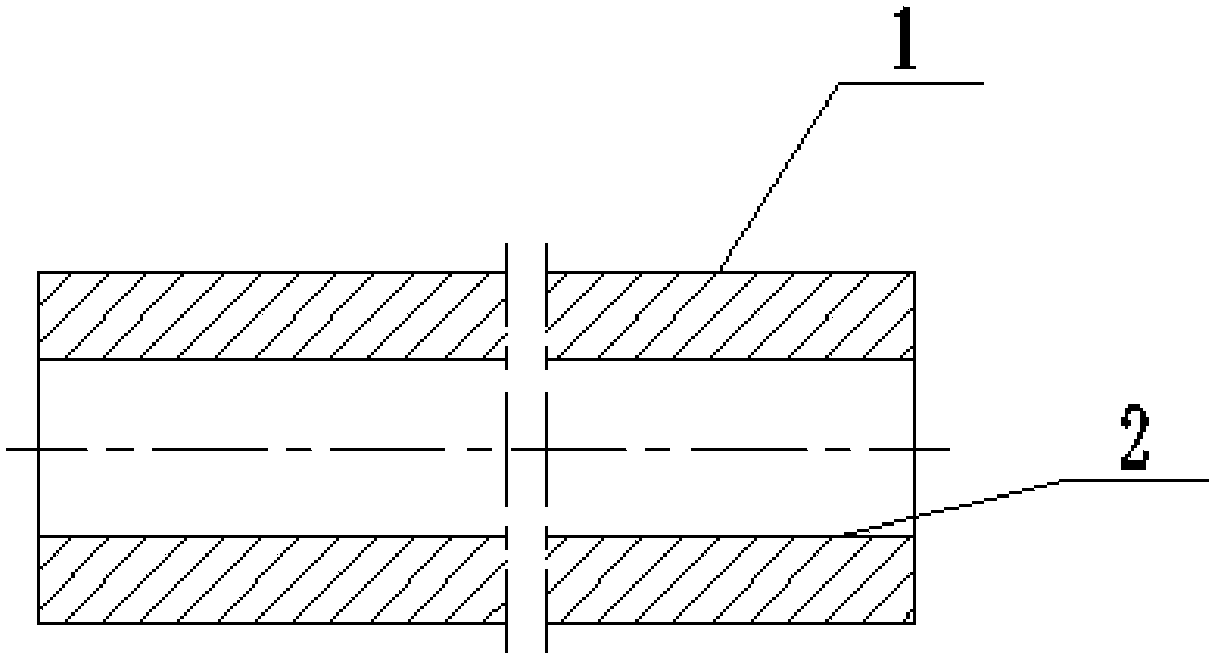

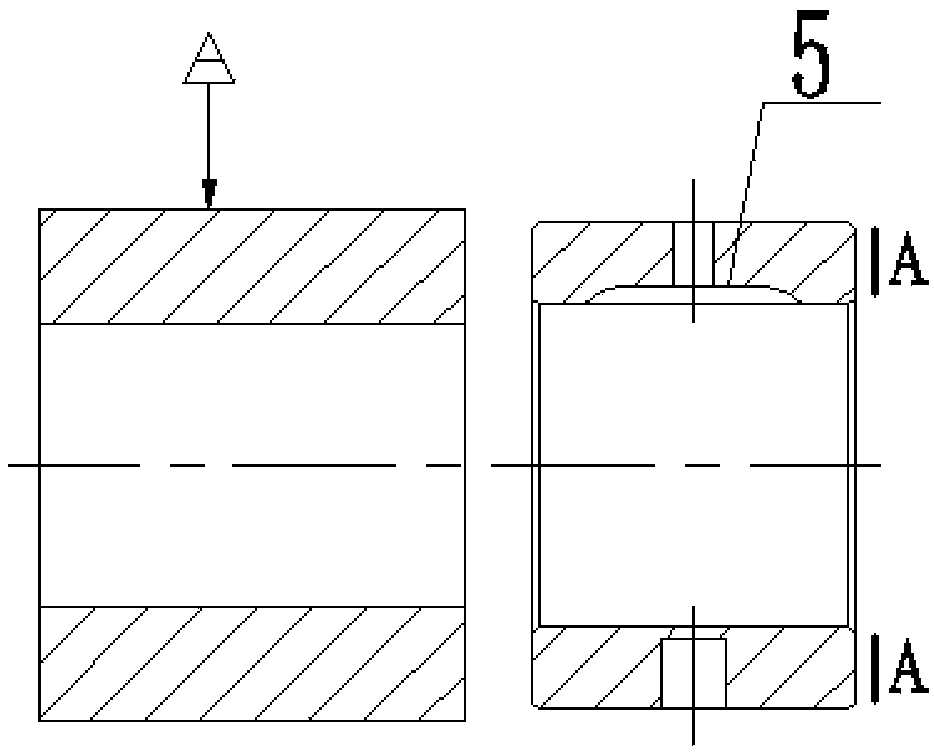

Machining method for floating bush of turbocharger

The invention discloses a machining method for a floating bush of a turbocharger. The machining method comprises the following steps: roughly turning the outer circle and an inner hole; turning the inner hole and the outer circle by a numeric control turn-milling center; drilling three oil inlet holes and an anti-rotating pin hole; milling oil tanks corresponding to the three oil inlet holes; performing finish turning on the outer circle and performing semi-finish turning on the inner hole; chamfering the outer circle and the inner hole of a non-cut end; cutting lengthwise; marking the non-cut end face; turning round; chamfering the outer circle and the inner hole of the cut end; removing all burrs at the orifices; grinding the cut end face; milling the inner hole and the oil tanks; removing all burrs; performing comprehensive inspection. The machining method for the floating bush of the turbocharger guarantees the accuracy of the inner hole, the oil tanks and oil wedge surfaces and improves the production efficiency, so that the machining time is shortened from original 3.93m / piece to 2.35m / piece.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

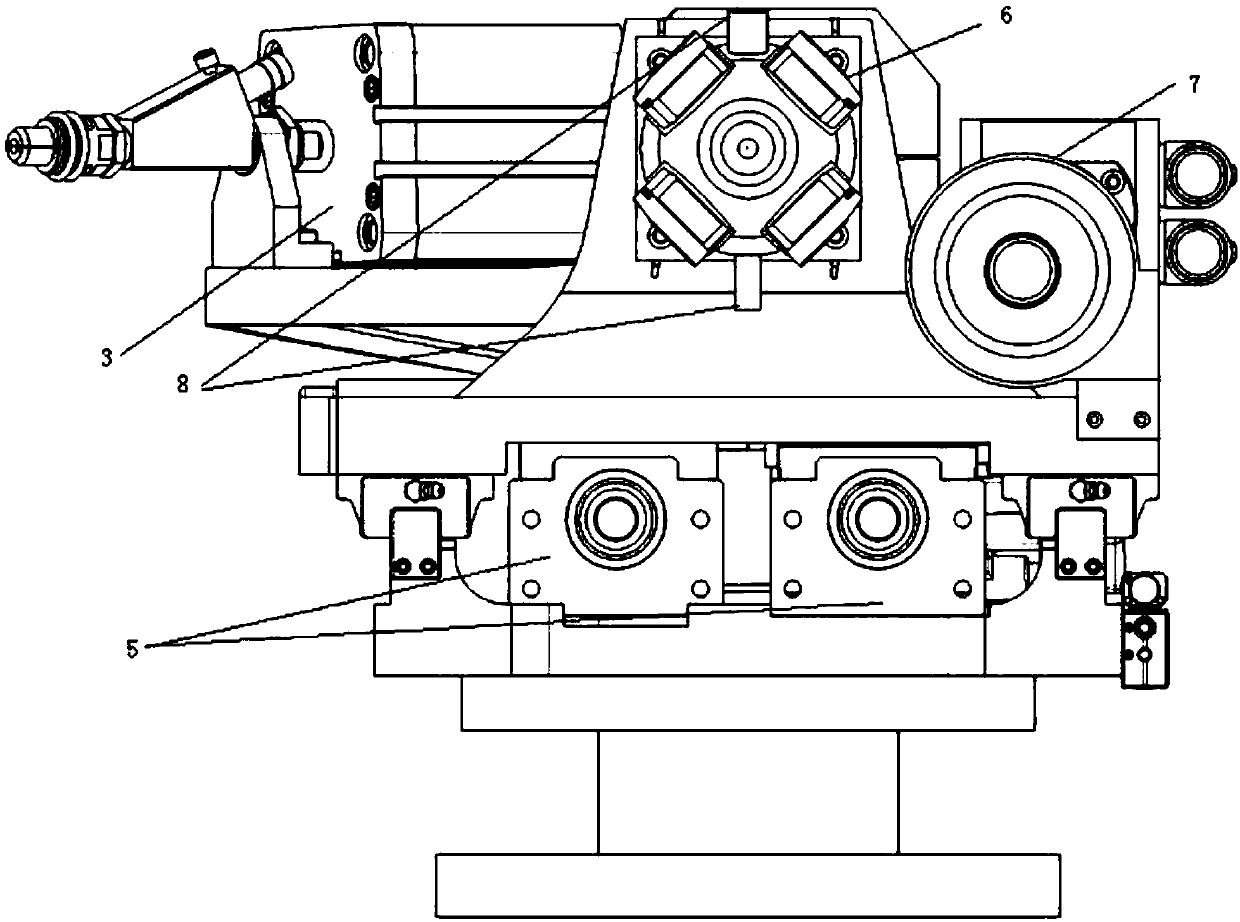

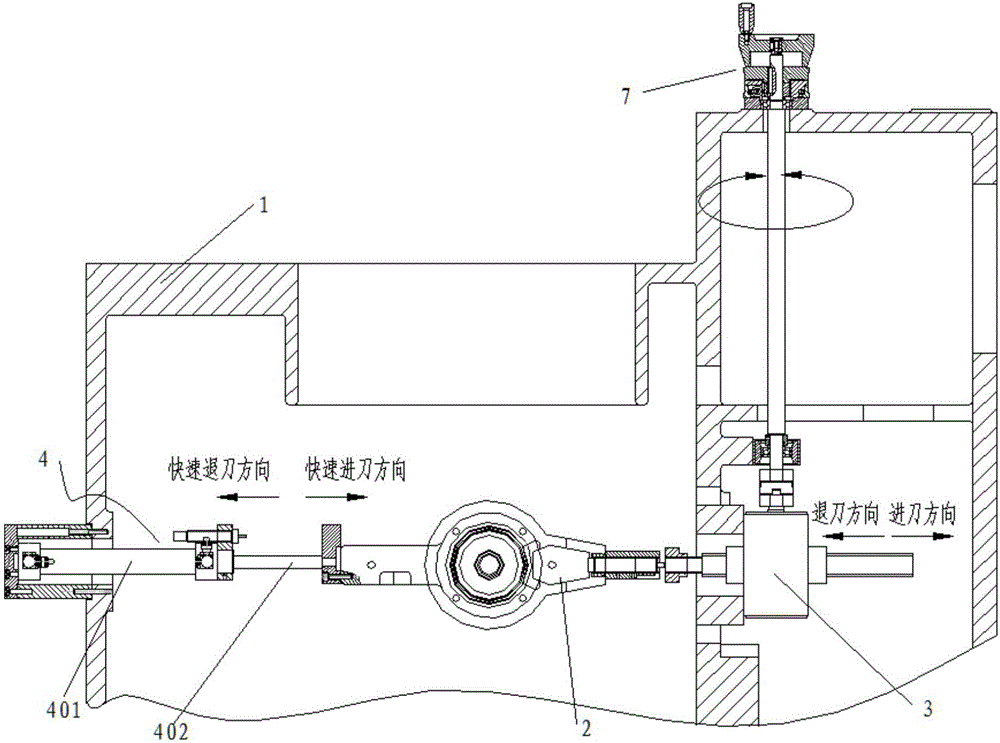

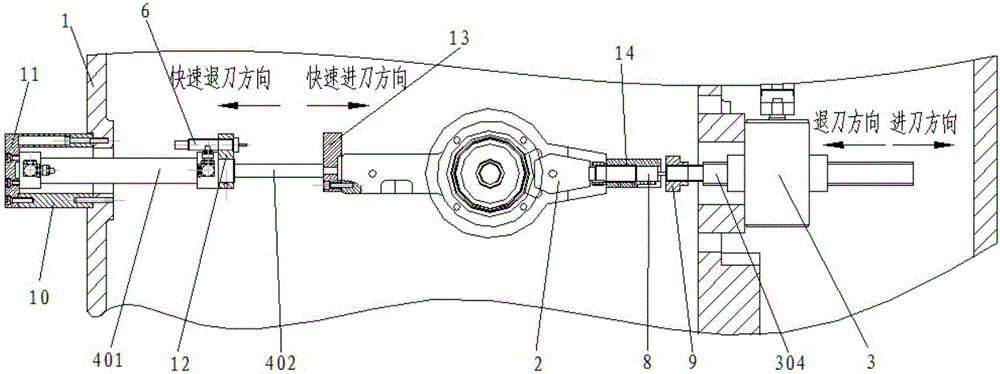

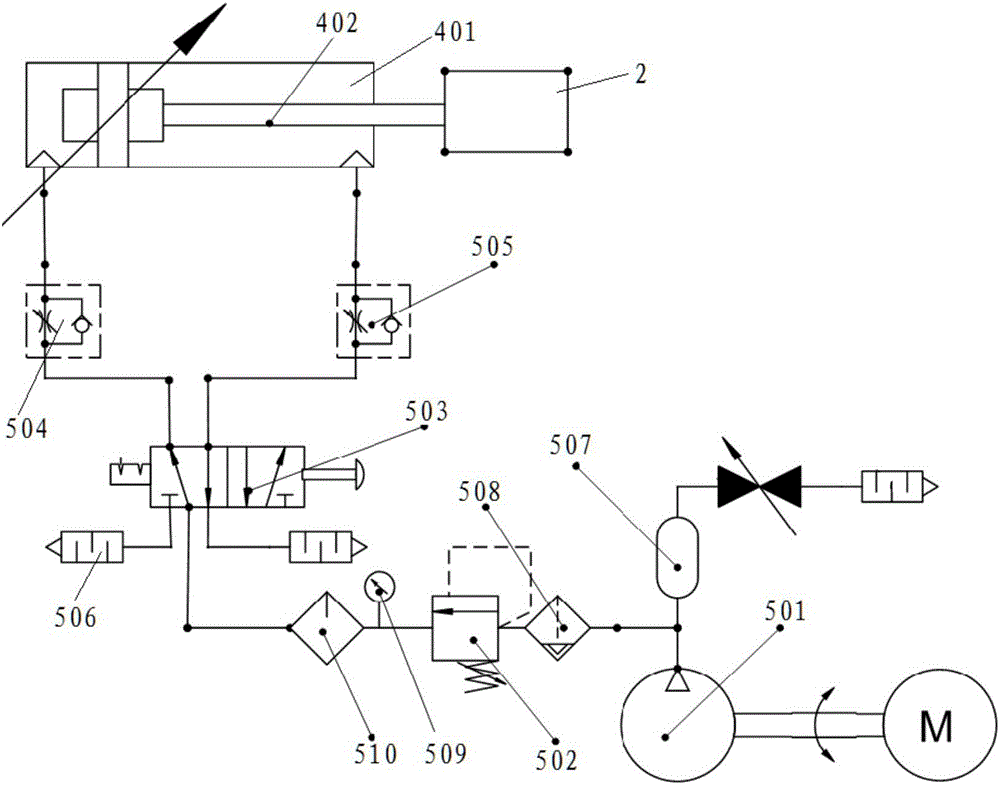

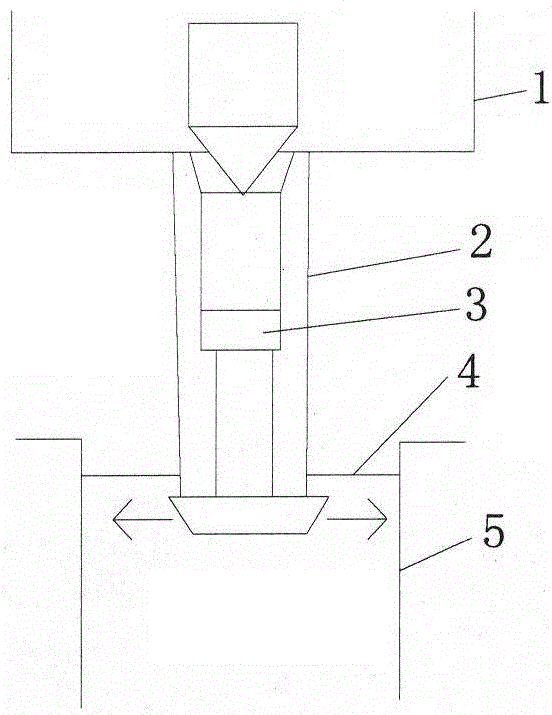

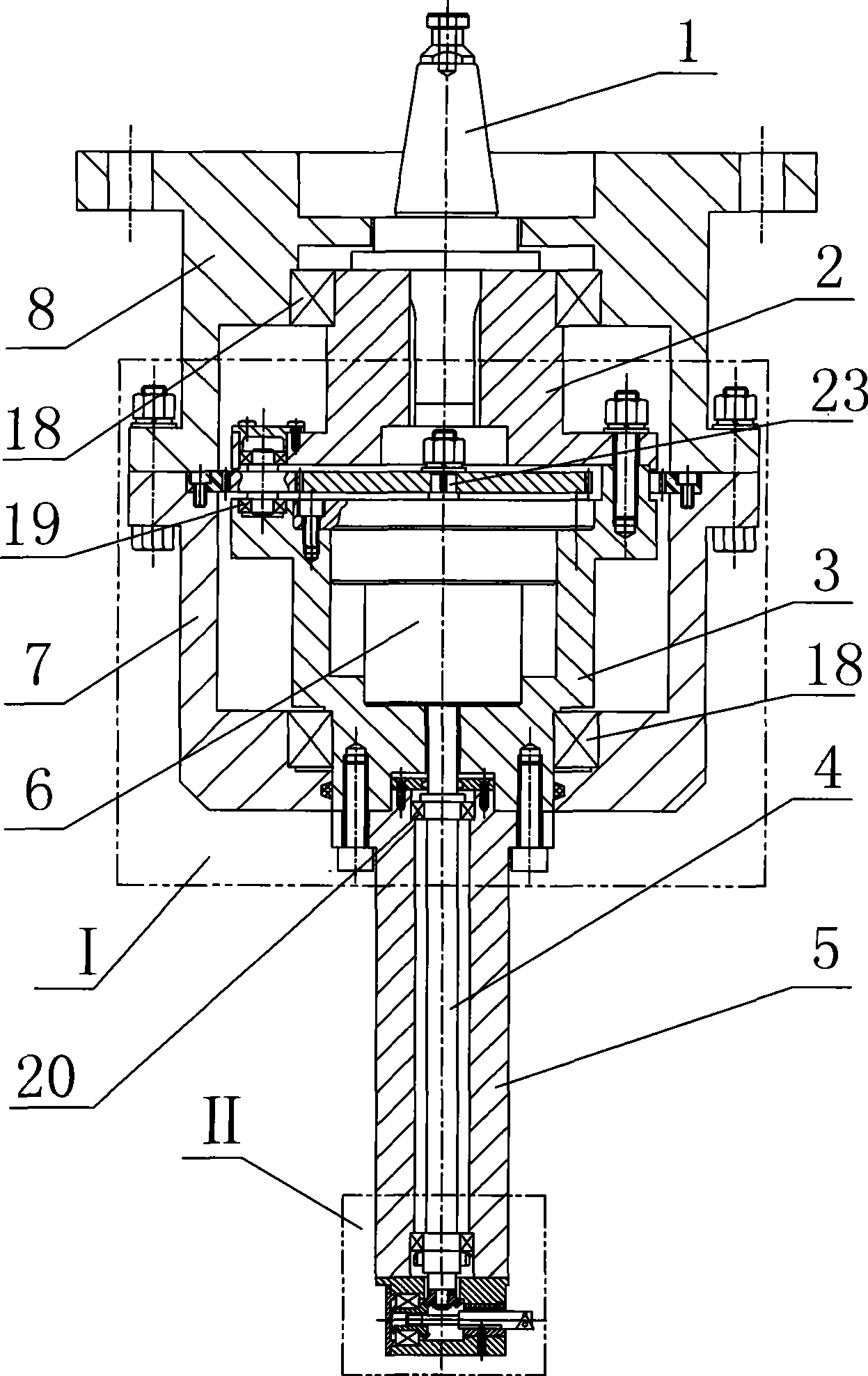

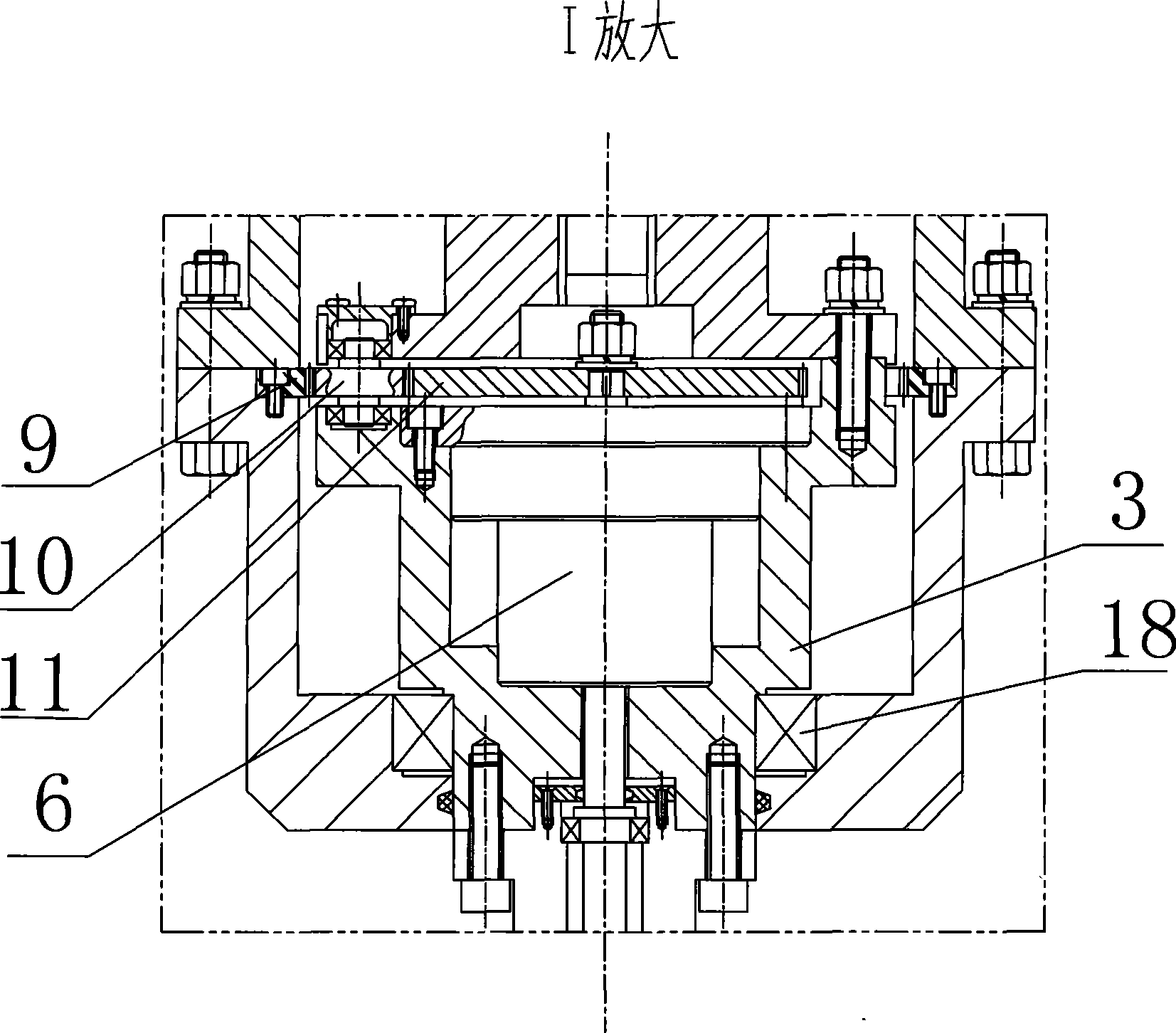

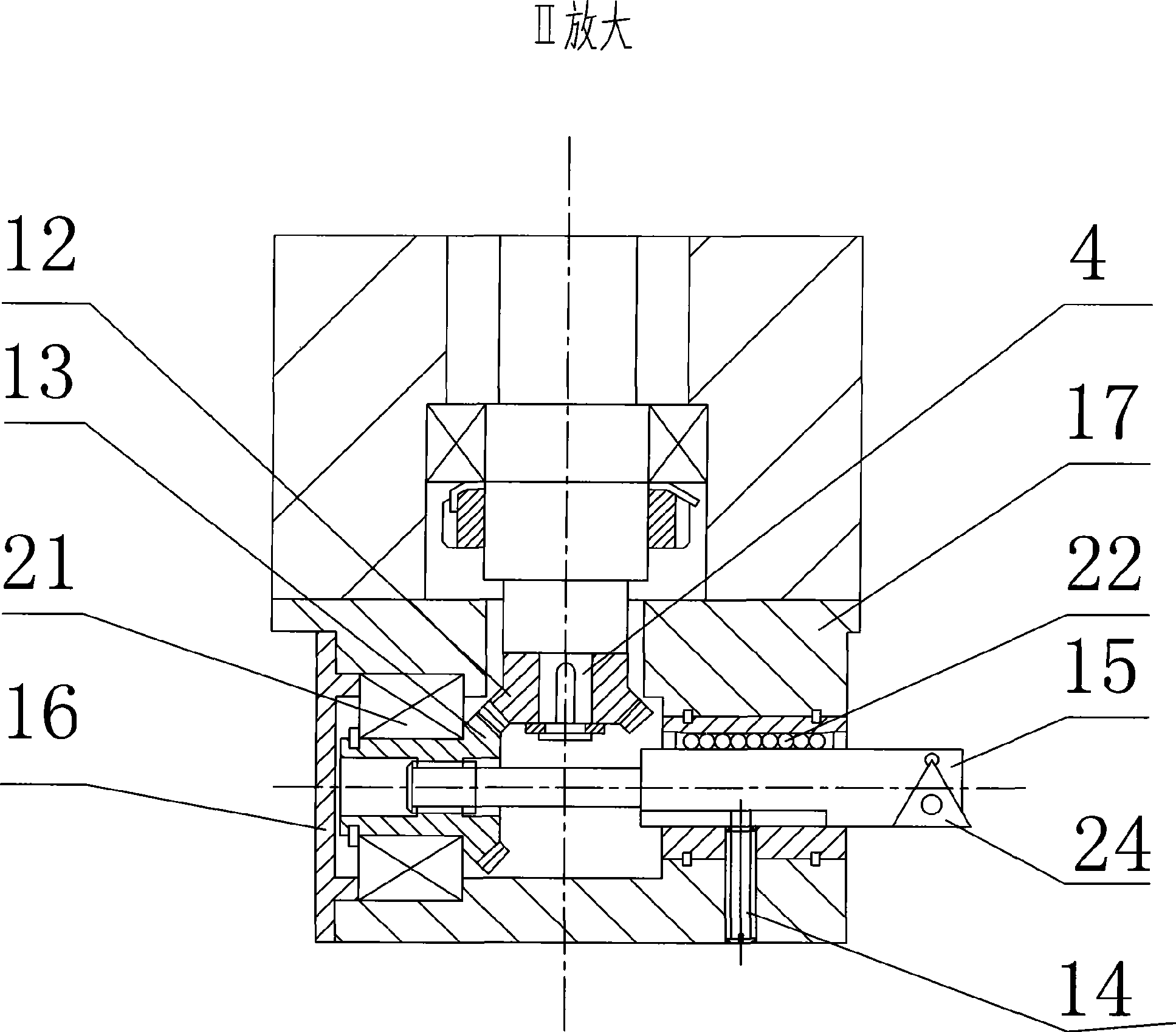

Quick cutter feeding/retreating and constant-pressure feeding mechanism

ActiveCN106625241ARapid advance and retreatRealization of constant pressure feedGrinding carriagesGrinding drivesPressure transmissionControl system

The invention relates to the technical field of machining, in particular to a quick cutter feeding / retreating and constant-pressure feeding mechanism. The mechanism comprises a slideable feeding carriage, a screw speed reducer, a feeding hand wheel mechanism, a buffer device and an air-pressure transmission system; one end of the feeding carriage is connected with the air-pressure transmission system, and the other end of the feeding carriage is connected with a second buffer; the second buffer tightly presses a screw of the screw speed reducer when a cutter enters a machining station; the air-pressure transmission system includes a cylinder and an air-pressure transmission control system; a first buffer is arranged at the head part of a cylinder body of the cylinder; the outer end of a piston rod is rigidly connected with the feeding carriage; the air-pressure transmission control system includes an air compressor, a pressure relief valve, a two-position five-way valve and a one-way throttling valve module connected in sequence; and an input shaft of the screw speed reducer is connected with the feeding hand wheel mechanism. The quick cutter feeding / retreating and constant-pressure feeding mechanism adopts a mode of combining mechanical feeding with the air-pressure transmission system to realize quick cutter feeding and retreating, guarantees repeated positioning precision of quick movement of the feeding carriage, and meanwhile, realizes constant-pressure feeding in cutter machining.

Owner:北京市电加工研究所有限公司

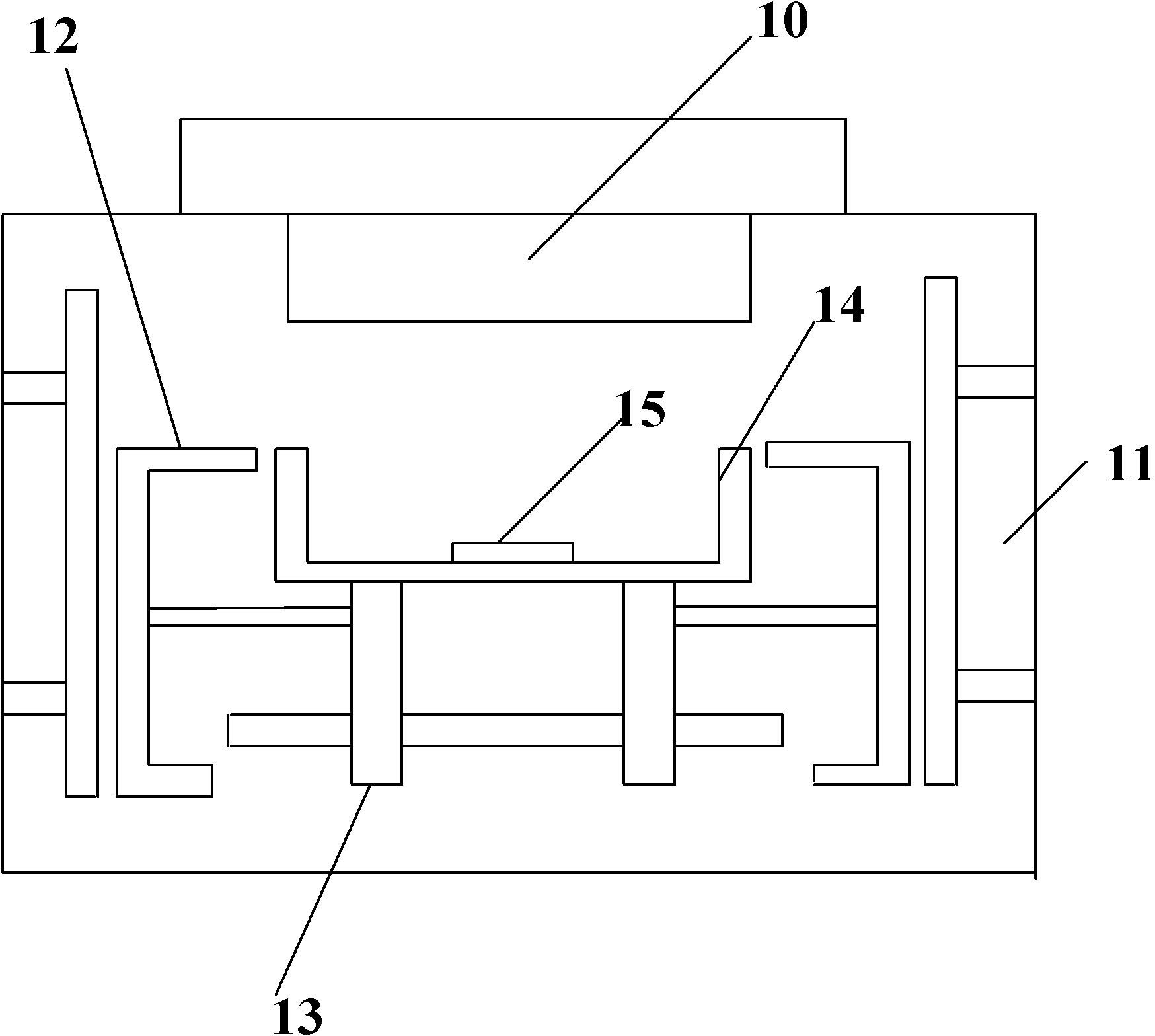

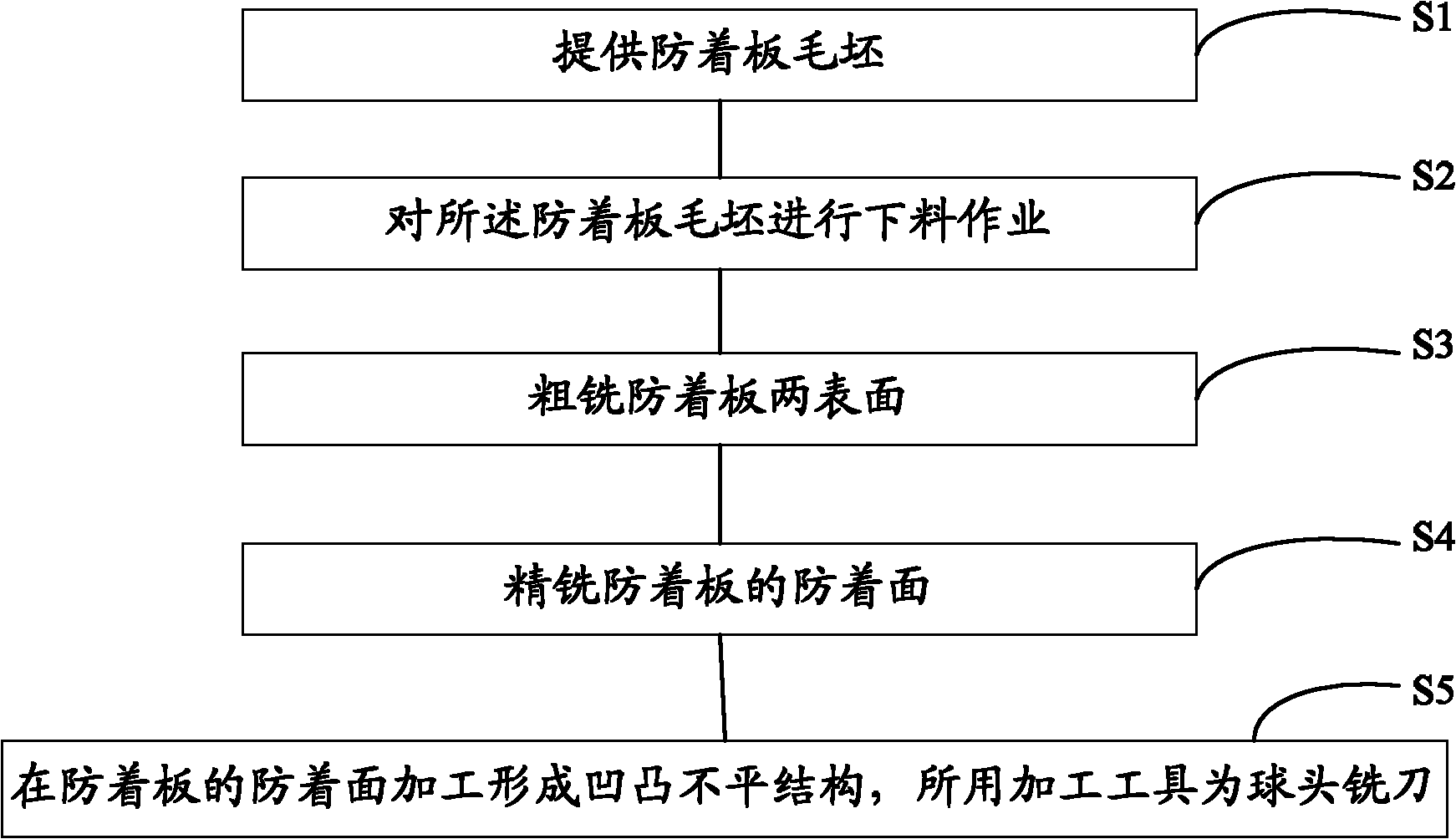

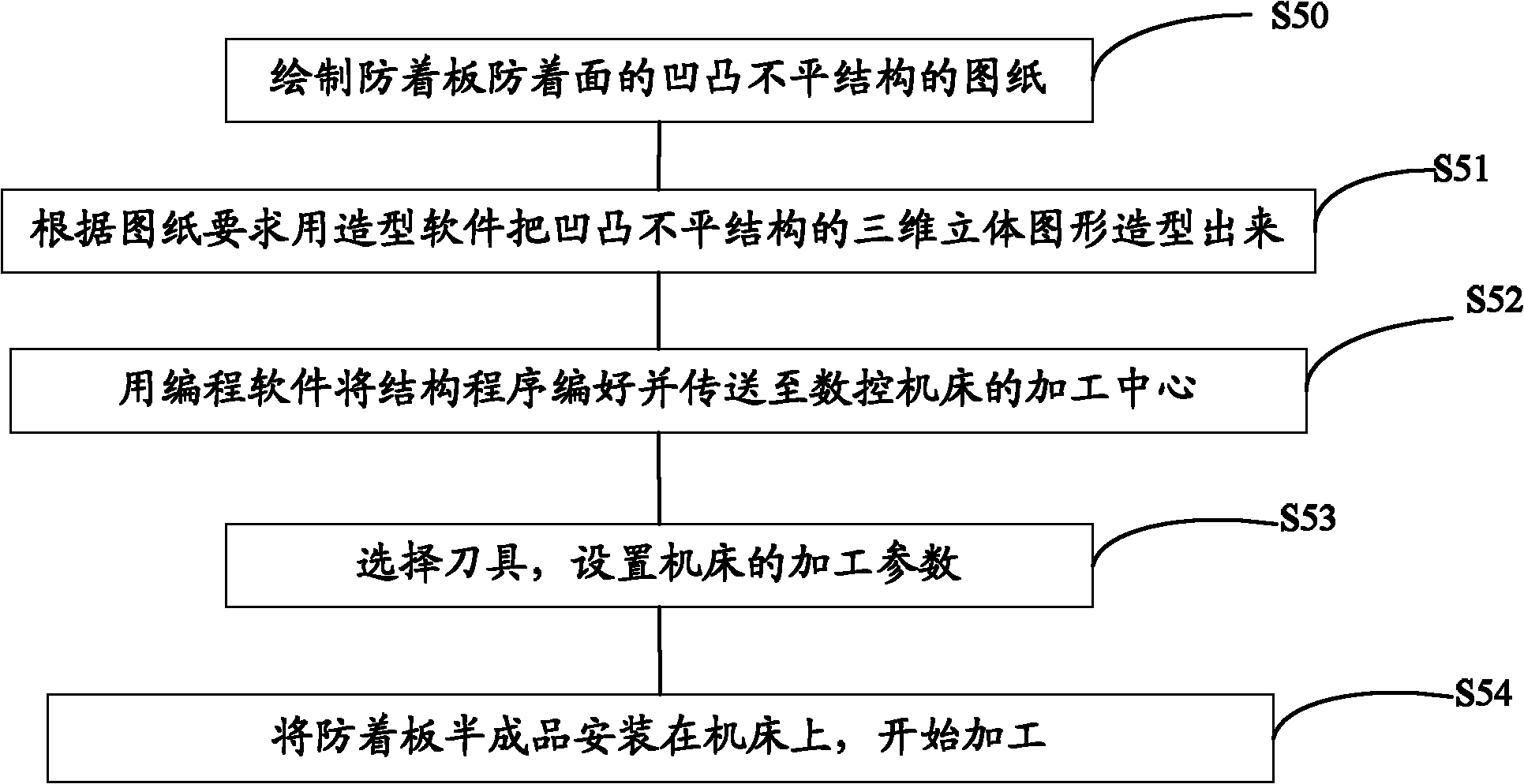

Method for processing defensive move plate structure

ActiveCN102069359AUniform structureNot misplacedMilling equipment detailsSurface finishMilling cutter

The invention relates to a method for processing a defensive move plate structure. The method comprises the following steps: providing a defensive move plate blank; blanking a defensive move plate; rough milling the two surfaces of the defensive move plate; carrying out fine milling on the defensive move surface of the defensive move plate; and processing the defensive move surface of the defensive move plate to form an uneven structure, wherein a ball head milling cutter is used as a processing tool. By using the processing method provided by the invention, the problems that the uneven structure of the defensive move surface of the defensive move plate is irregular and easy to deform are solved; and the obtained uneven structure of the defensive move surface of the defensive move plate is uniform, and has the advantages of high dimension accuracy and good surface finish quality.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Process for repairing piston ring groove

InactiveCN104141131AExtended service lifeGreat suctionMetallic material coating processesSocial benefitsThermal insulation

The invention discloses a process for repairing a piston ring groove. The process includes the following steps of firstly, cleaning away carbon deposits and greasy dirt in the piston ring groove; secondly, roughly machining the ring groove before fusion covering so that mesh-shaped lines can be produced, and conducting measuring and grouping on the size of the ring groove in the rough machining process; thirdly, spreading fusion covering materials; fourthly, melting the fusion covering materials through a laser device, wherein a piston uniformly rotates in the process, and meanwhile lasers are controlled through programs so that the irradiation angle and the irradiation range can be ensured and the covering materials and base materials on the same plane can be evenly and effectively combined; fifthly, placing the piston in a well type electric furnace to be heated after laser melting is conducted, and conducting thermal insulation; sixthly, conducting turning on the ring groove; seventhly, conducting fine machining on the ring groove; eighthly, conducting fluorescent magnetic particle flaw detection on the repaired part of the ring groove so that the piston cracking in the fusion covering process can be prevented from being put into use. The piston ring groove which is repaired can completely replace a newly-manufactured piston, the service life of the product is prolonged, and obvious social benefits and economic benefits are achieved.

Owner:CRRC CHANGZHOU DIESEL ENGINE COMPONENTS CO LTD

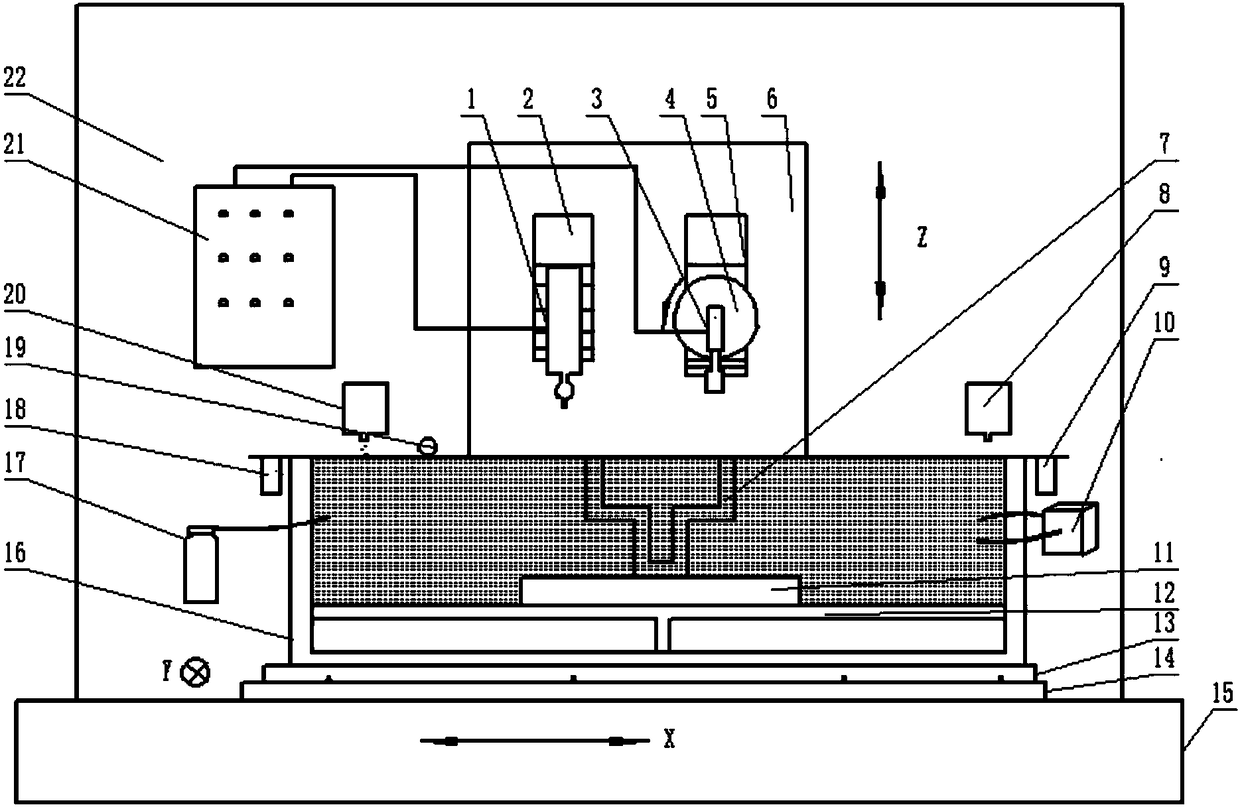

Selective laser cladding and grinding in-situ composite manufacturing device

InactiveCN108161009AGuaranteed dimensional accuracyGuaranteed surface roughnessAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyGrinding wheel

The invention belongs to the field of additional material and subtractive material composite manufacturing, and concretely relates to a selective laser cladding and grinding in-situ composite manufacturing device. The device is formed by a laser cladding head, a laser cladding head Z-direction moving mechanism, a fine grinding wheel, a rotation B shaft, a grinding head Z-direction moving mechanism, a lathe bed, a forming parts, a first powder supply tank, a powder recovery tank, a powder dust collector, a base plate, a lifting table, a Y-direction moving platform, an X-direction moving platform, a machine tool base, a forming chamber, a protection air source, a powder recycle bin, a powder paving wheel, a second powder supply tank, a control cabinet, a machine tool protection cover and thelike. Two processing methods, i.e. additive material manufacturing and subtractive material manufacturing are integrated on one device, and are used for in-situ composite manufacturing, so that not only can the defects of dimensional accuracy and surface quality in a single additive material manufacturing technology be overcome, but also the restriction of grinding process in parts complexity canbe overcome, and high-efficient precision laser additive material manufacturing of various complex metal parts is hopefully realized.

Owner:HUNAN UNIV

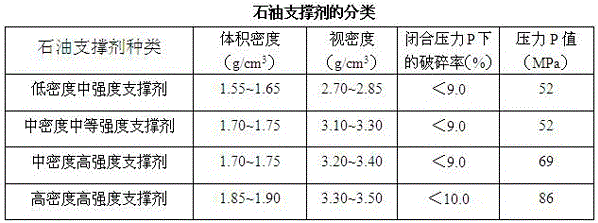

Ultralow-density cordierite petroleum fracturing propping agent and preparation method thereof

ActiveCN106431349AHigh hardnessHigh mechanical strengthFluid removalDrilling compositionCordieriteManganese oxide

The invention provides an ultralow-density cordierite petroleum fracturing propping agent and a preparation method thereof. A principal crystalline phase of the popping agent is of a cordierite structure and is formed by firing coal ash, caustic-burned magnesia powder, Jiaozuo clay and a composite mineralizer, and the composite mineralizer is formed by mixing manganese oxide and barium carbonate according to the equal weight ratio. A large amount of high-silicone, low-aluminum, low-calcium and low-ignition-loss neutral coal ash is adopted as a main raw material, and the density index of the popping agent is effectively reduced; through the special processing and treating processes such as special pre-sintering on an important raw material magnesite and ultrafine grinding on batches and the composite mineralizer technology, it is effectively guaranteed that high-hardness and low-density principal crystalline phase minerals are formed in a system at high temperature, therefore, and it is guaranteed that the finished ultralow-density popping agent has high mechanical strength; the firing temperature of the popping agent is reduced, and the purposes of energy saving and consumption reduction are achieved.

Owner:洛阳赛罗帕陶瓷科技有限公司 +1

Cold-working boring and milling composite technology for automobile front axle

ActiveCN1593841AGuaranteed Aperture SizeGuaranteed surface roughnessOther manufacturing equipments/toolsEngineeringSpring steel

The invention relates to a kind of cold boring and milling technique to process the foreside axis of the car. The main technique is: locate the two spring steel seats, drill ten holes in each steel board, and drill the holes again with U drilling technology to finish the primary process. Fine the holes and corner, the upper and the under board faces with the boring bed. Only one setting and clumping step is needed to finish the holes process. The invention overcomes the excursion phenomenon by combining the boring and milling technology with three work position machine bed to take the drill-bore-drill-hinge procedure. It limits the warp between the chief pin hole and the locking pin hole. The technology is simple and has high processing precision. So the product is high quality, and needs few device and cost. The production efficiency is high and the work steam intensity between the procedures is low. In addition, it can make sure clean working circumstance.

Owner:HUBEI TRI RING AXLE

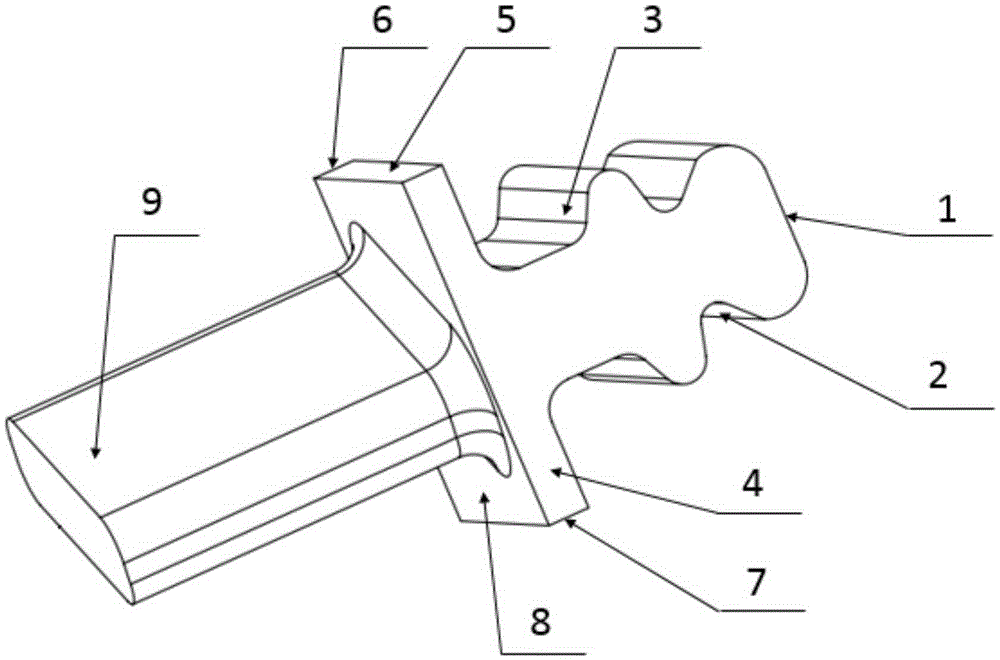

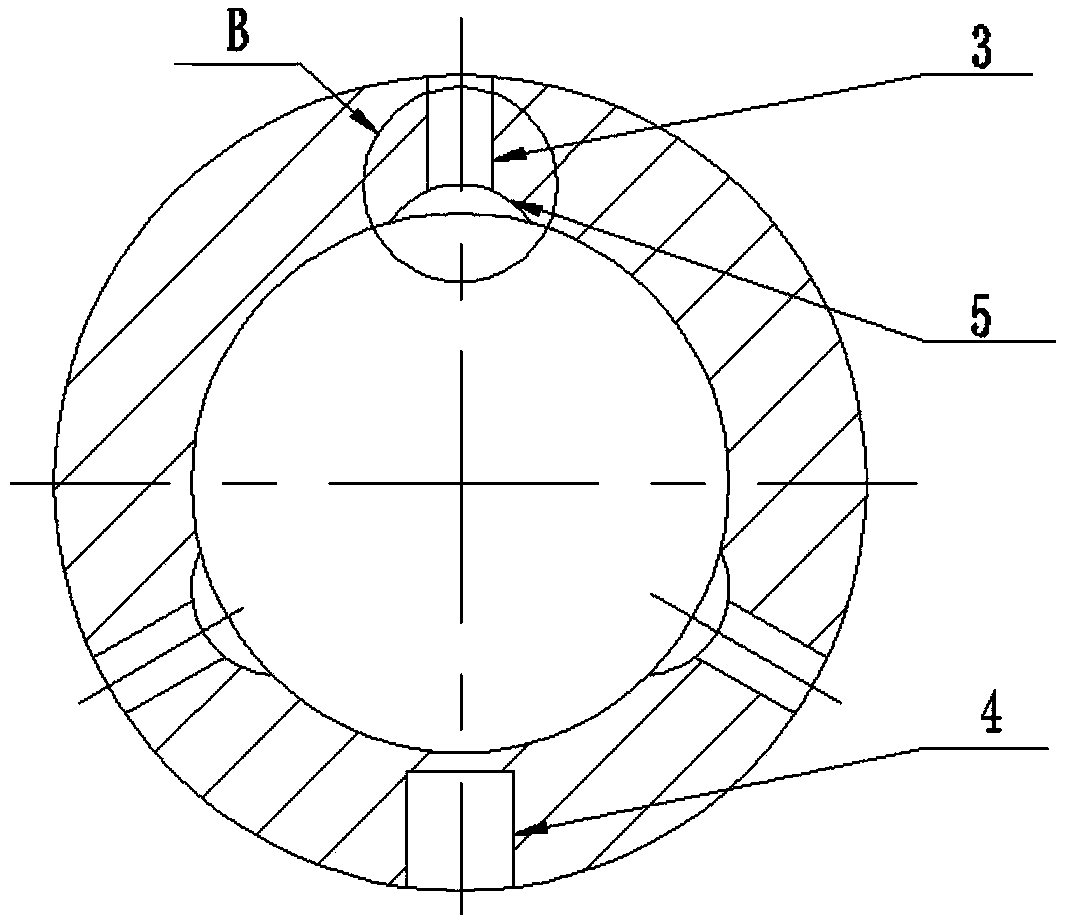

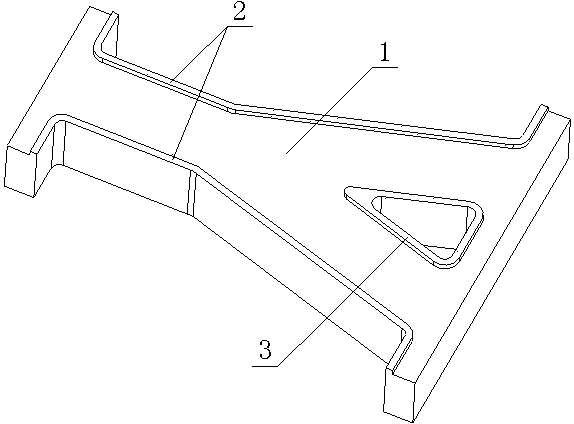

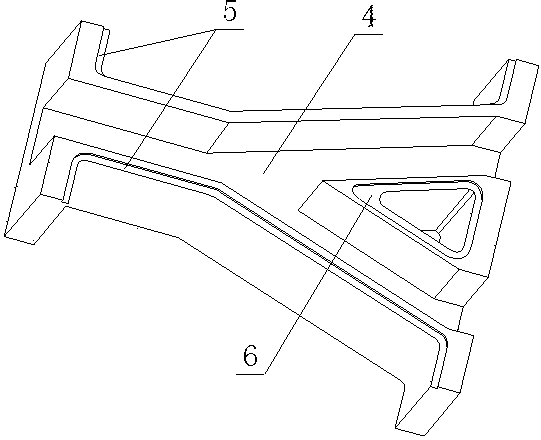

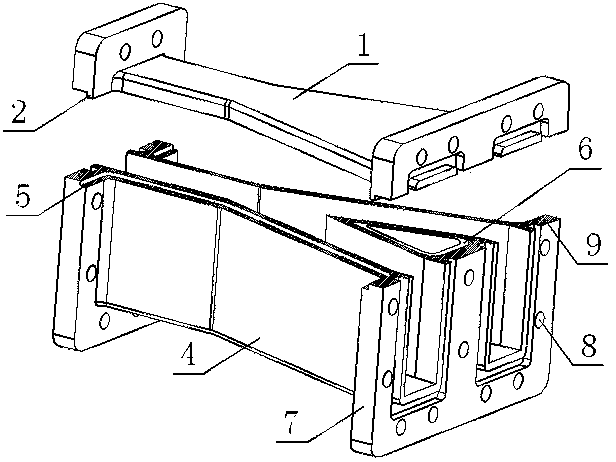

Y-shaped power divider manufacturing technology

InactiveCN104347923AHigh dimensional accuracyQuality improvementCoupling devicesNumerical controlManufacturing technology

The invention discloses a Y-shaped power divider manufacturing technology which comprises upper cover plate processing, lower cavity processing and vacuum brazing molding and specifically comprises the steps of S31: mounting an upper cover plate and a lower cavity in trial, and guaranteeing that an edge boss (2) and an edge groove (5) as well as a Y-branch slot convex bayonet (3) and a Y-branch slot concave bayonet (6) are tightly attached; S32: performing pickling to remove impurities; S33: assembling the upper cover plate, the lower cavity and a brazing material; S34: performing vacuum brazing; S35: performing numerical control processing on the appearance of a power divider and a flange disk; S36: drilling and hinging pin holes; S37: performing electrochemical treatment; S38: testing telecommunications parameters. According to the Y-shaped power divider manufacturing technology, the welding deformation caused by multi-time manual flame welding is avoided; the upper cover plate and the lower cavity are positioned by the boss, the groove and the bayonets, so that the size consistency and the precision of the power divider are guaranteed; when the parts such as the boss, the groove and the bayonets are designed, the embedding thickness of a welding sheet is considered; furthermore, a fit clearance is increased to 0.02-0.04mm, so that the flowability of brazing material joint filling is guaranteed during welding, and the cavity size precision of the assembled power divider is guaranteed.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

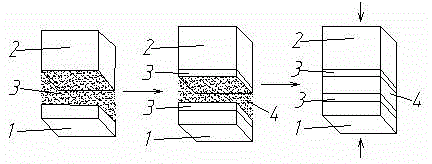

Novel metal diffusion bonding technology

ActiveCN103337464AGuaranteed uniformityImprove bonding abilitySemiconductor/solid-state device manufacturingWorking temperatureHigh pressure

The invention discloses a novel metal diffusion bonding technology. Main steps comprises steps that: two parts on which a bonding metal layer is deposited are packaged in a vacuum sealing soft bag, the vacuum sealing soft bag is then put in a container filled with liquid, the container is connected with a pressure device, pressure generated by the pressure device is exerted on a part needing bonding through the liquid in the container and the vacuum sealing soft bag, temperature rising is further realized simultaneously, so metal diffusion bonding is realized under effects of the temperature and the pressure. The novel metal diffusion bonding technology can guarantee uniform bonding pressure in each direction and does not easily cause rupture damage to a crimping material even under high pressure intensity, so a bonding effect is improved. The exerted pressure is great, so reliable bonding can further be realized even under lower temperature, lowest work temperature can be 80 DEG C, moreover, the novel metal diffusion bonding technology can reduce requirements for technology clamps and physical dimensions of bonding materials.

Owner:CETC CHIPS TECH GRP CO LTD

Valve retainer

The invention discloses a valve retainer, which is made of a powdered metal material that comprises the following components in percentage by weight: 0.8 to 1.3 percent of C, 2.0 to 4.0 percent of Cr, 1.0 to 3.0 percent of Mo, 3.0 to 6.5 percent of Co, 0.5 to 2.0 percent of Ni, 0.8 to 1.5 percent of Mns, 0.05 to 0.1 percent of P, 0.2 to 0.5 percent of V, less than or equal to 3 percent of other elements and the balance of Fe. A prevention segregation agent is added into the powdered metal material which can make valve retainer. The valve retainer disclosed by the invention can resist high temperature and wear, and resist the high temperature of over 800 DEG C. In a bench test of more than 300 hours, the valve retainer does not generate segregation, which is favorable for cutting and ensuring the size precision and surface roughness of a cut face.

Owner:CHANGSHU SHUANGYUE MACHINERY

Machining method of ultra-slender shaft

InactiveCN104308477AGuaranteed dimensional accuracyGuaranteed shape accuracySurface roughnessHardness

The invention relates to the field of machining, in particular to a machining method of an ultra-slender shaft. The method comprises the following steps of preparing a material, namely selecting a blank of which the machining allowance is 5mm; performing heat treatment normalization, wherein the hardness is 185-215HB; straightening a workpiece by using a reverse straightening method, wherein the total length curvature is smaller than or equal to 0.5mm; milling and grinding two claws of a follow rest; positioning the workpiece; grinding the workpiece; roughly lathing the workpiece; finely lathing the workpiece. According to the machining method, the dimension accuracy, the shape accuracy and the surface roughness of parts can be guaranteed, the machining process is simple and convenient, and the method is simple and easy to learn.

Owner:SHAANXI QIYUAN TECH DEV

Processing method of rolled copper foil mother material

ActiveCN104057260AGood electrical conductivityHigh dimensional accuracyMetal rolling arrangementsCopper foilSurface layer

The invention discloses a processing method of a rolled copper foil mother material, and belongs to a high-precision soft-state red copper belt. According to the method, the conventional flow process for the red copper belt processing is changed from the production flow process, firstly, from cast ingots, high-quality raw materials are adopted for producing the cast ingots with compact tissues and qualified ingredients through semi-continuous casting; after hot rolling cogging, four-side milling is carried out for milling out surface layer scales; then, a rolling machine is adopted for rolling finished products through adopting short-rolling-process and large-processing-rate processing; in addition, the belt material plate type is improved through a stretch bender; next, the annealing is carried out through a gas pad type continuous annealing furnace; and finally, the shearing and trimming is carried out, and the operation turns to a copper foil workshop. The processing method provided by the invention has the characteristics that the conductivity is good, the dimension precision is good, the surface quality is good, the internal tissue is good, the performance is uniform, the plate shape is flat and straight, no burr exists at the edges, and the like. Therefore good popularization and application values are achieved.

Owner:CNMC ALBETTER ALBRONZE

Numerically controlled machine taper-hole boring device and method

InactiveCN101362221AGuaranteed accuracyGuaranteed surface roughnessBoring/drilling componentsBoring/drilling machinesSatelliteProcessing accuracy

The invention discloses a boring and countersunk device of a digit control machine tool, and a boring and countersunk method, which comprises a taper-shank arbor, an internal gear, a satellite gear, a main gear, and a tool bar, and is characterized in that the device also comprises a main bevel gear, an auxiliary bevel gear, a speed reducer and a base; a boring cutter radial driving mechanism is arranged in the base; the automatic boring of a taper hole is realized by inputting the thread pitch value of a digital thread instruction; the boring and countersunk device of the digit control machine tool, and the boring and countersunk method have the advantages of simple structure, high production efficiency, shortened time for processing the taper hole, guaranteed processing precision and surface roughness of the taper hole, and lowered production cost.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

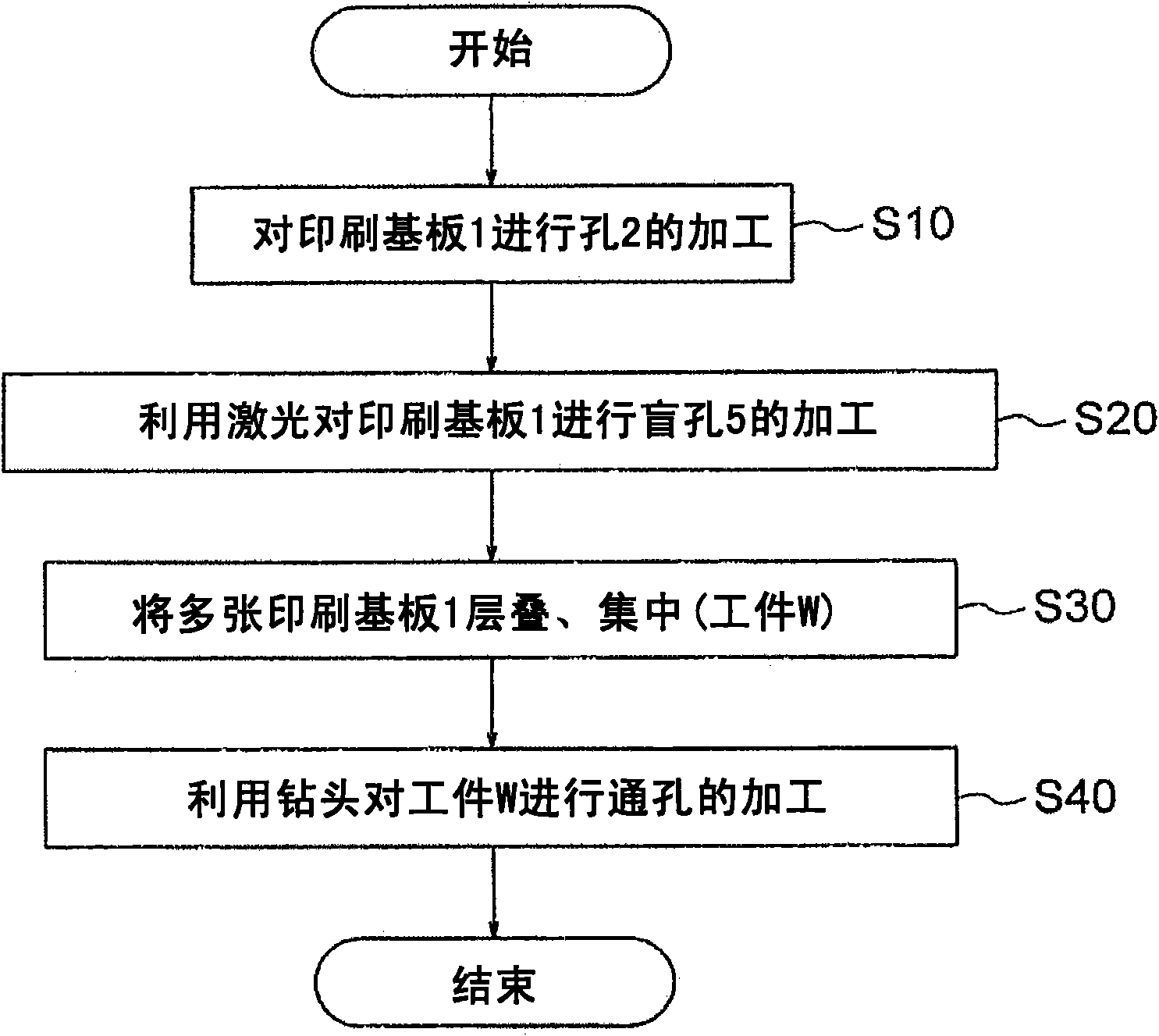

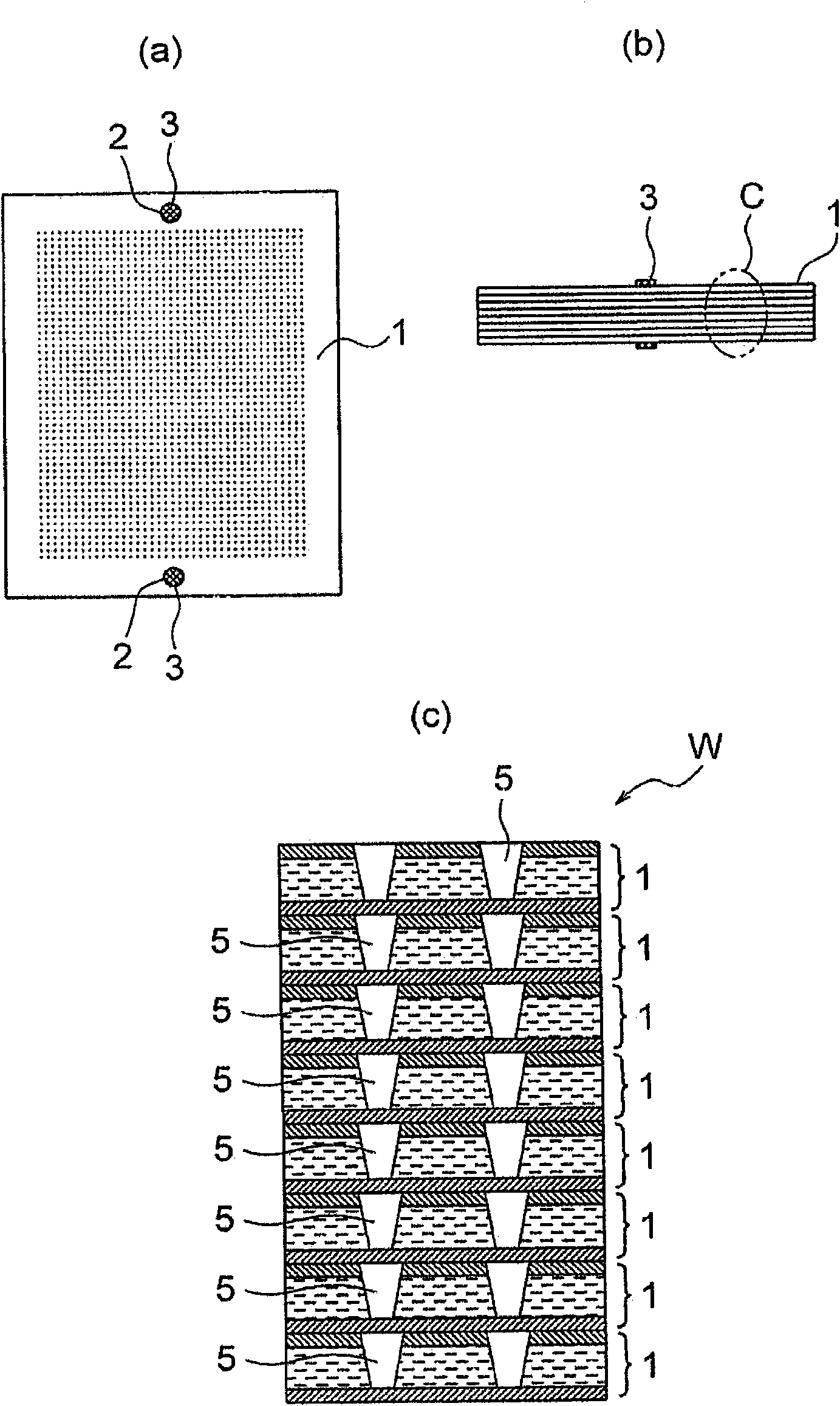

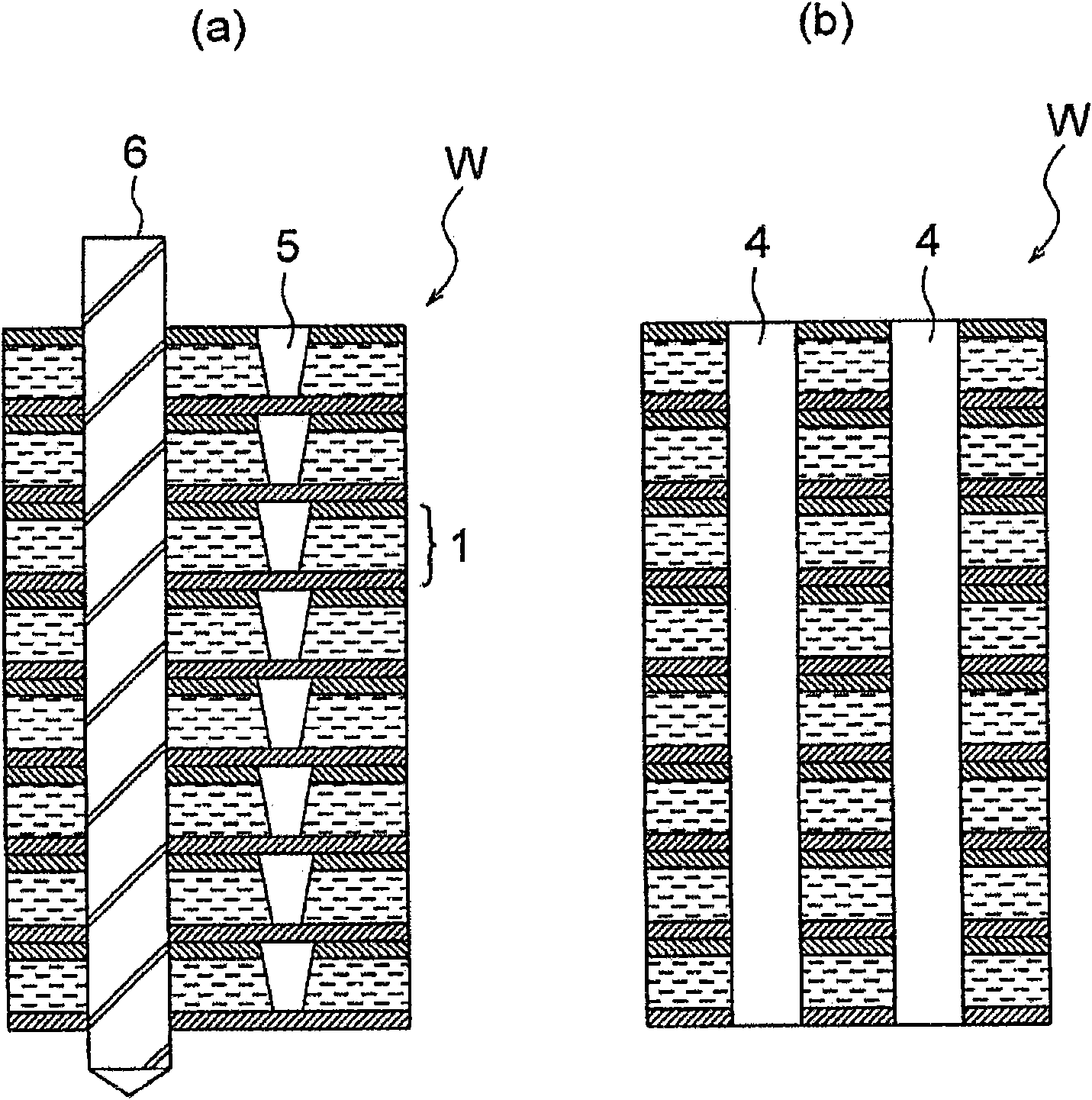

Perforation processing method for printing substrate

InactiveCN101932199AGuaranteed surface roughnessImprove reliabilitySemiconductor/solid-state device manufacturingPrinted circuit manufactureEngineeringMaterial Perforation

The invention provides a perforation processing method for printing substrates, which can effectively utilize laser and a drill bit to conveniently perform perforation processing with high accuracy and high efficiency but is not limited by the overlapping number of the substrates. In the method, after a process (S10) that periphery holes (2) for positioning and fixing are formed at predetermined positions of the periphery parts of the substrates (1) is carried out, a process (S20) that laser is adopted to process blind holes (5) in the substrates (1) at the set positions outside the periphery parts is carried out, and then after a process (S30) that each substrate (1) in which blind holes are processed is alternately superposed to form a workpiece (W) of a superposed body, lamination pins are inserted in the periphery holes (2) of the workpiece (W) of the superposed body, and each substrate is superposed and concentrated (workpiece (W)) is carried out, the process (S40) that a drill bit of which the diameter (expressing the diameter of a hole at the inlet side of the blind holes (5)) is larger than that of the blind holes (5) is adopted to perforate the workpiece (W) is carried out.

Owner:HITACHI SEIKO LTD

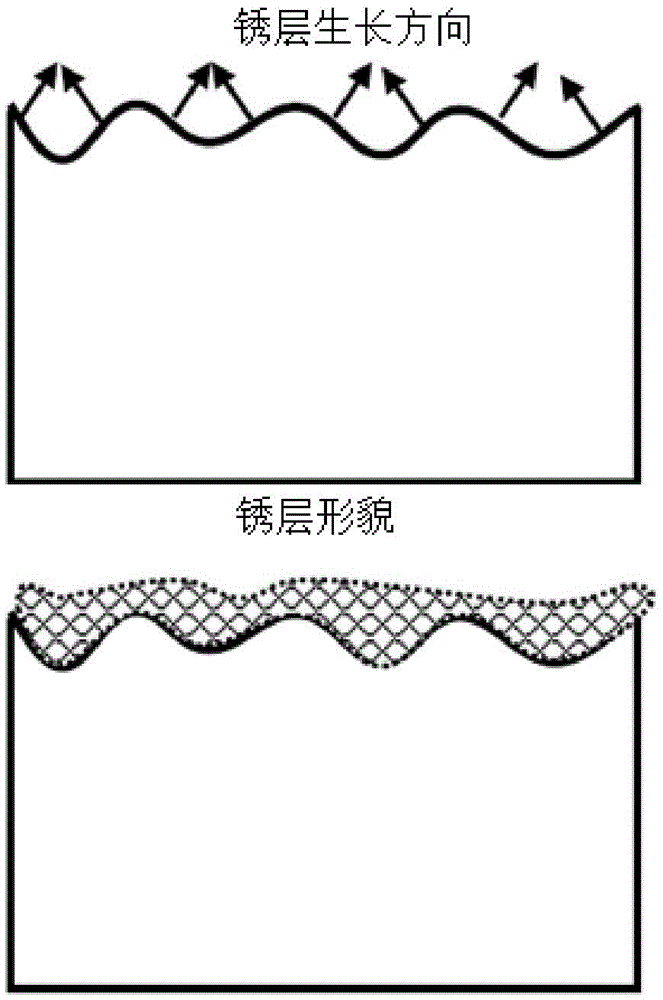

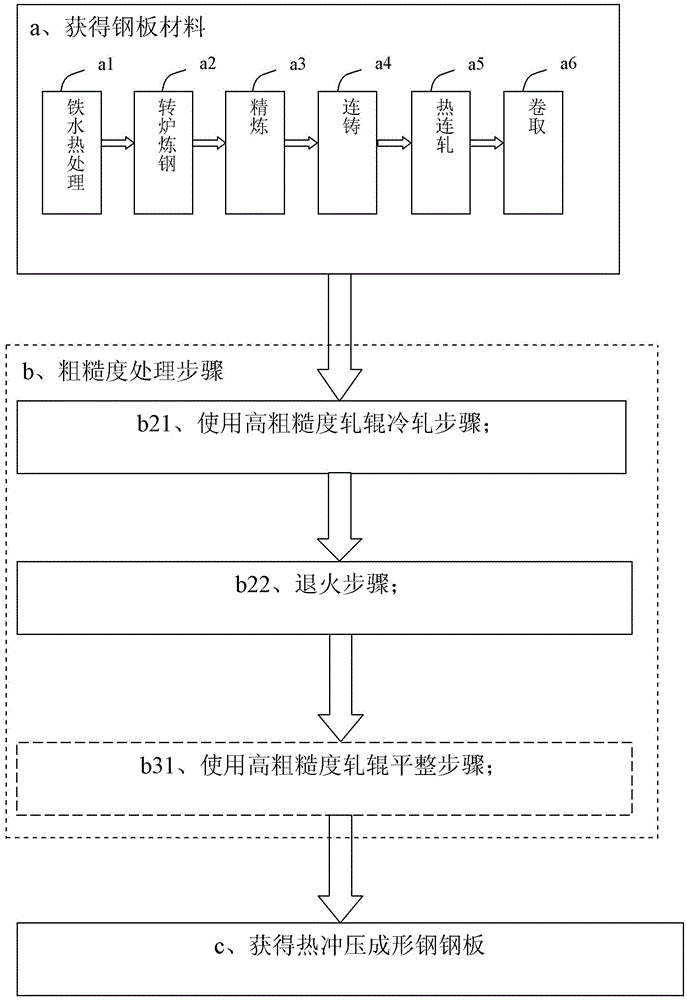

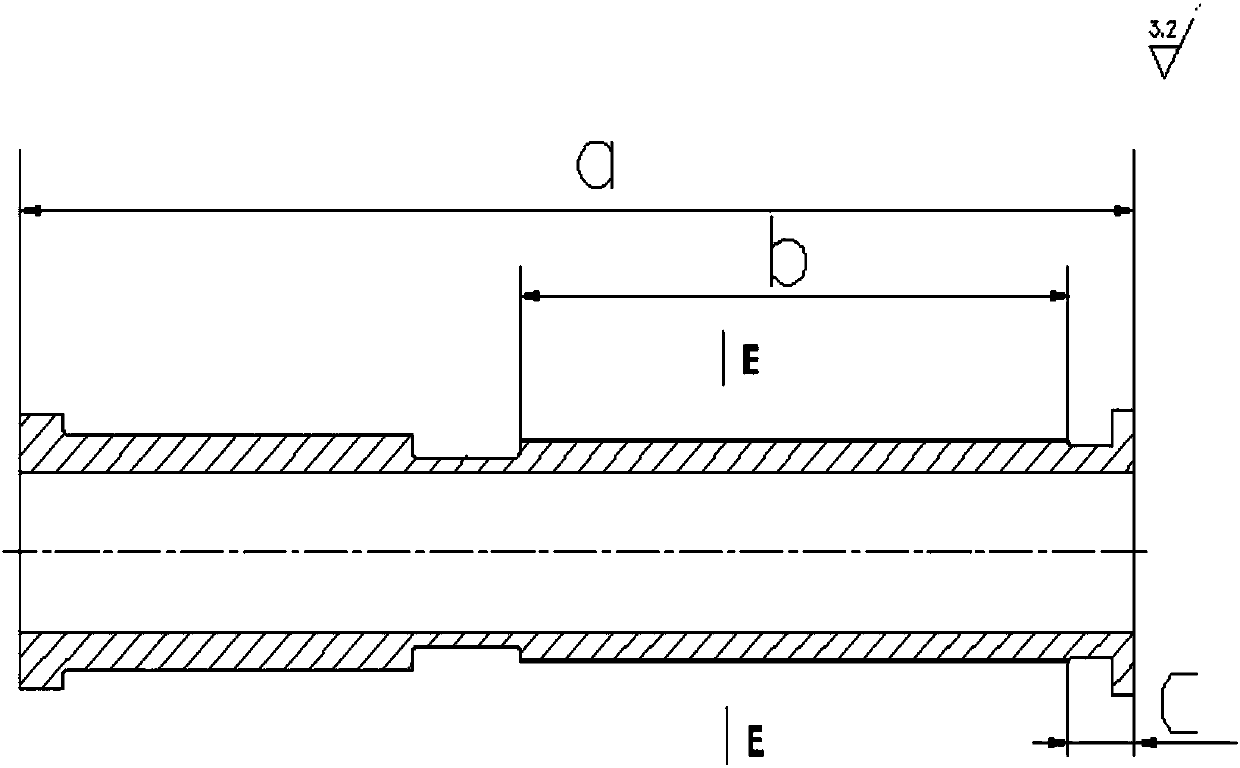

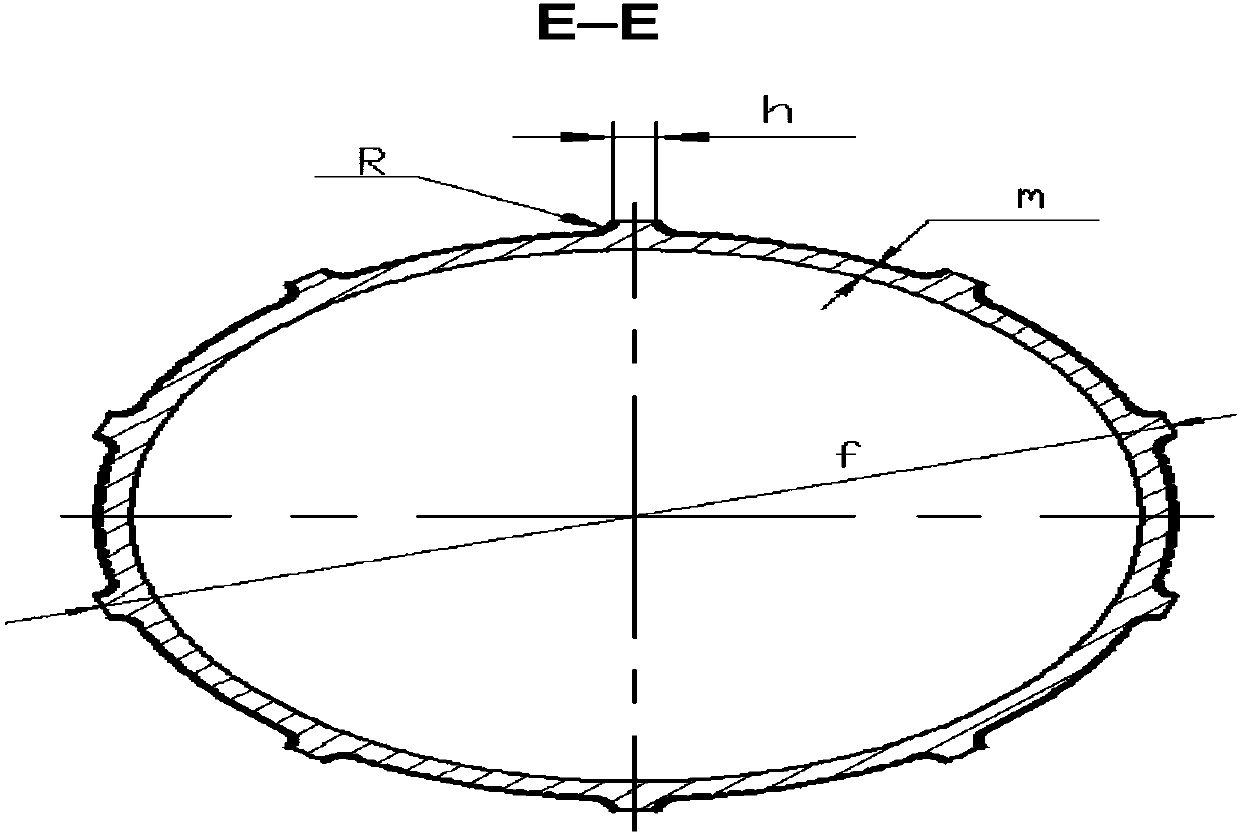

Hot stamping forming steel board for restraining falling off of oxide layer in hot stamping process and production method thereof

InactiveCN105543685AImprove densification performanceReduce sheddingWork treatment devicesRollsHot stampingSurface roughness

The invention discloses a hot stamping forming steel board for restraining falling off of an oxide layer in the hot stamping process and a production method thereof. The hot stamping forming steel board comprises, by weight, 0.19%-0.27% of C, at most 0.50% of Si, 1.00%-1.50% of Mn, at least 0.010% of Al, at most 0.010% of N, 0.01%-0.055% of Ti, at most 0.35% of Cr, 0.0005%-0.004% of B, at most 0.50% of one or more of Mo, W, Cu and Ni and at most 0.10% of one or more of Nb, Zr and V, and the surface roughness of the steel board is 1.1-2.0 microns. The production method comprises the following steps that a, steel board raw materials are obtained according to the elements of the claim 1; b, roughness treatment is conducted; and c, hot stamping forming steel is obtained.

Owner:BENGANG STEEL PLATES +1

Processing method of titanium alloy TA15 thin-wall long boss

ActiveCN107717030AReduce distortionReduced milling distortionWorkpiecesMilling equipment detailsNumerical controlMachining deformation

The invention relates to the technical field of machining, in particular to a processing method of a titanium alloy TA15 thin-wall long boss. The processing method particularly comprises the followingsteps: removing the margin of a middle arm, removing the margin of the right side of the boss, removing the margin of the left side of the boss, finish-milling the middle arc, finish-milling the right side of the boss and finish-milling the left side of the boss. The processing method is mainly applied to milling of an axial long boss of the new generation aero-engine titanium alloy TA15 material, the adverse effects of machining deformation of thin part structure wall and long axial size in the processing process of thin-wall guide pipe parts are avoided, the technical bottlenecks of programming of milling processing numerical control program and determination of milling processing process parameters are overcome, and the shape and the size precision requirements of the titanium alloy TA15 material thin-wall long boss parts are guaranteed effectively.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Double strong copper strip production technology for automobile connector

The invention discloses a double strong copper strip production technology for an automobile connector, and belongs to the technical field of a copper strip production technology. The double strong copper strip production technology comprises the following steps of (1), smelting and ingot casting; (2), hot rolling; (3), milling; (4), rough rolling; (5), once annealing; (6), once cleaning; (7), medium rolling; (8),twice annealing and cleaning; (9), finish rolling; (10), three times annealing and cleaning; (11), finish rolling; (12), four times cleaning; (13), leveling; and (14), examining and delivering; and specified thickness of strip coil after rough rolling is 2.5 mm. According to the technical scheme, brass products can meet the double requirements of tensile strength and elongation index of automobile connector industry.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

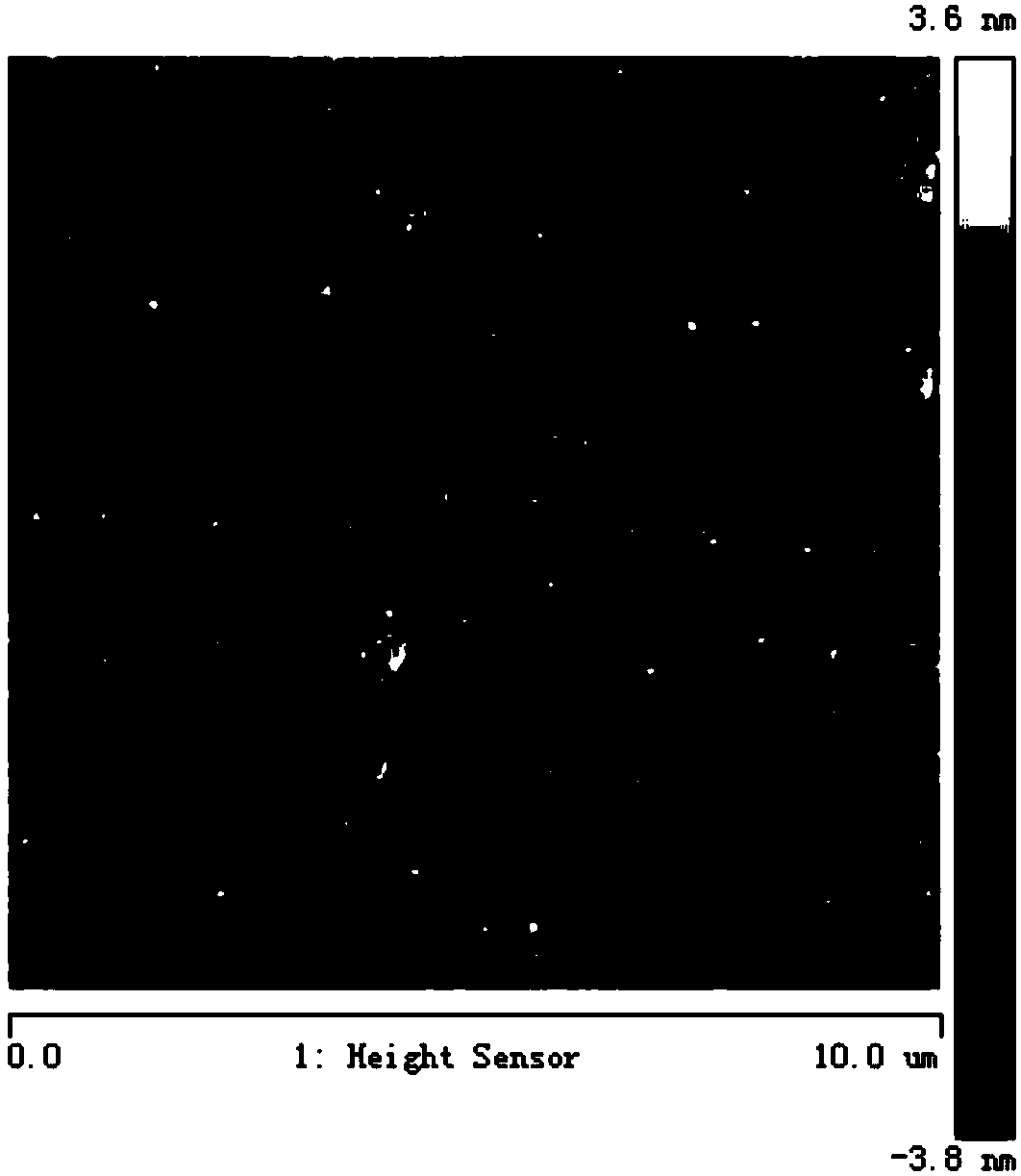

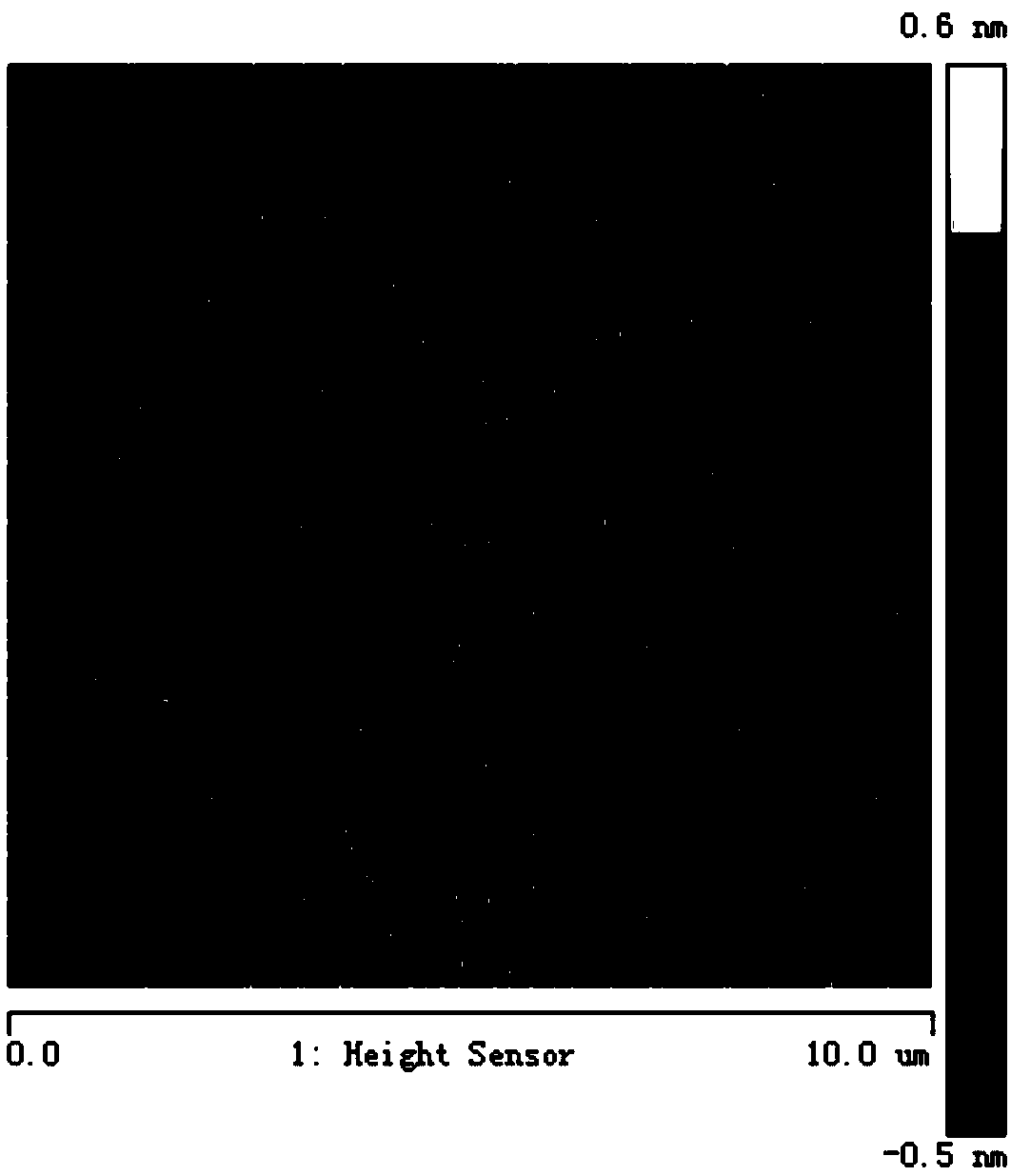

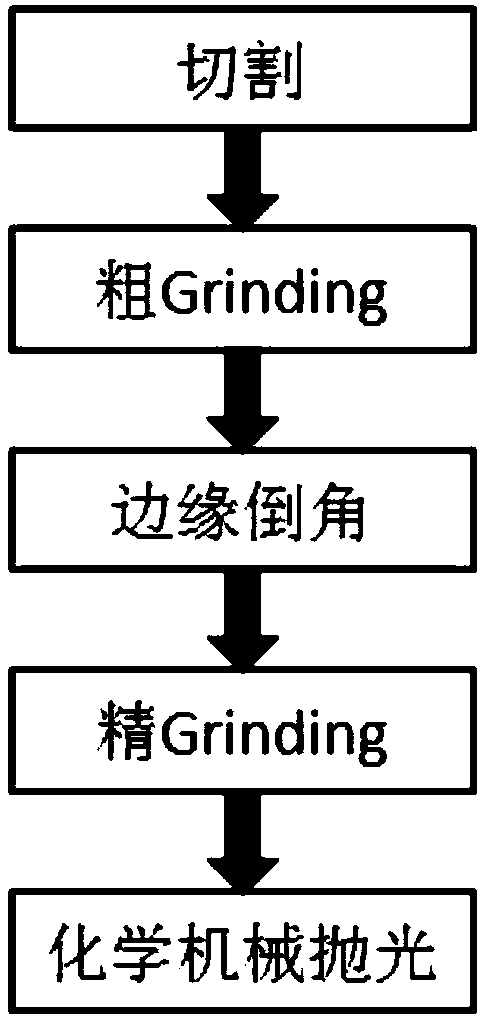

Rapid preparation method of high flatness and low damage single crystal silicon carbide substrate

ActiveCN109545680AImprove flatnessAvoid deformationSemiconductor/solid-state device manufacturingCarbideWire cutting

The invention provides a rapid preparation method of a high flatness and low damage single crystal silicon carbide substrate. The method is characterized by comprising steps that fully-solidified abrasive treatment of the single crystal silicon carbide is performed, chemical mechanical polishing treatment is then performed, the high-flatness and low-damage single crystal silicon carbide substrateis obtained, solidified abrasive treatment includes line cutting and grinding wheel grinding, abrasive particles are consolidated on cutting lines, and the abrasive particles are consolidated on a grinding wheel. The method is advantaged in that surface roughness, a scratch die ratio, a pit ratio and bump of the prepared single crystal silicon carbide substrate are relatively low, surface data isgood, thickness deviation is small, curvature is small, and warpage is small.

Owner:SICC CO LTD

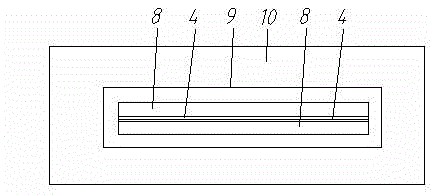

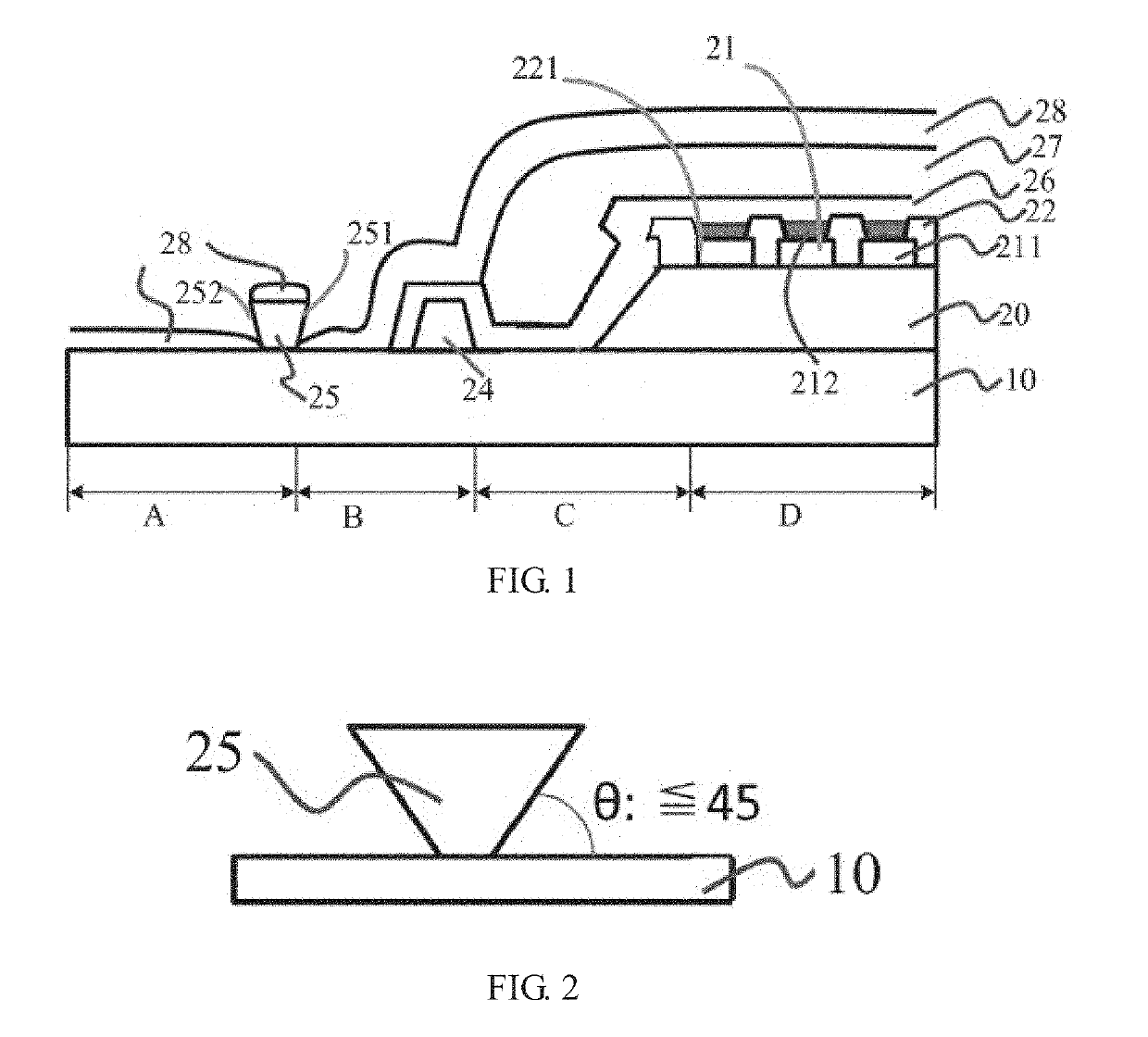

OLED display device

InactiveUS20190267570A1Effectively prevent the film from breakingGuaranteed surface roughnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight emitting device

An OLED display device is disclosed. The device includes: a base substrate; a planarization layer disposed on the substrate, an outer barrier wall, and an inner barrier wall; multiple light emitting devices and a pixel defining layer disposed on the planarization layer; a first inorganic layer covering the pixel defining layer and each light emitting device, wherein the first inorganic layer is extended to the inner barrier wall and covering the inner barrier wall; an organic layer disposed on the first inorganic layer, and an extending length of the organic layer is less than an extending length of the first inorganic layer; and a second inorganic layer disposed on the organic layer, the first inorganic layer, the outer barrier wall and the base substrate; wherein, the second inorganic layer is in a discontinuous connection state using the outer barrier wall as a breakpoint.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

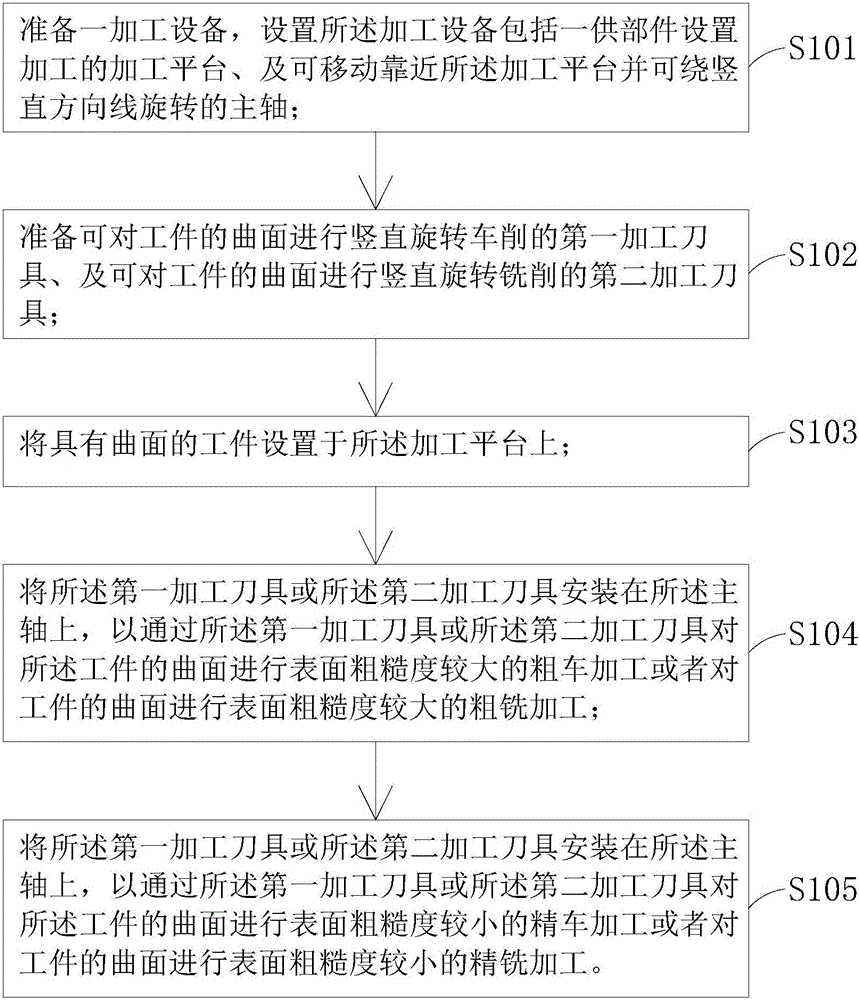

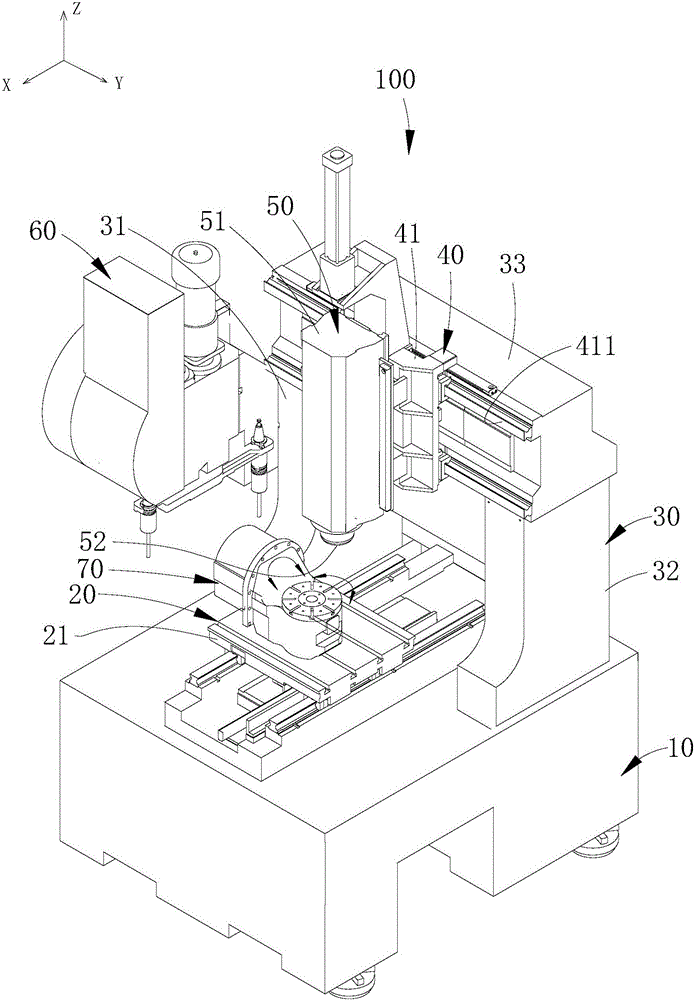

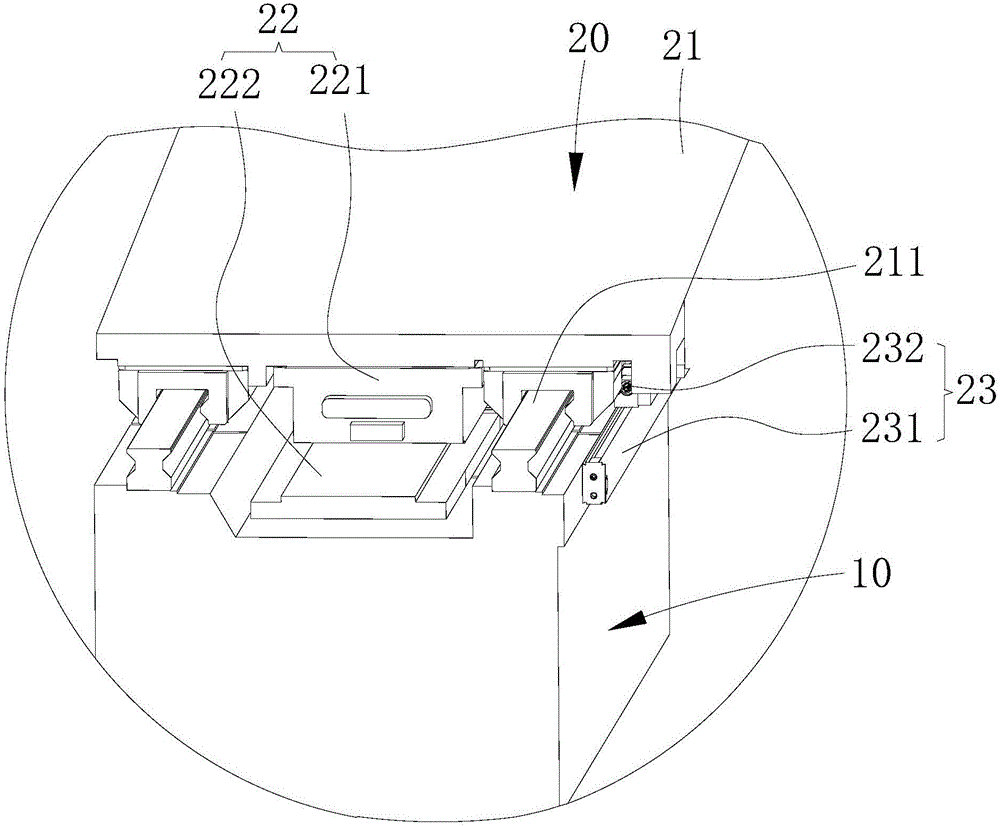

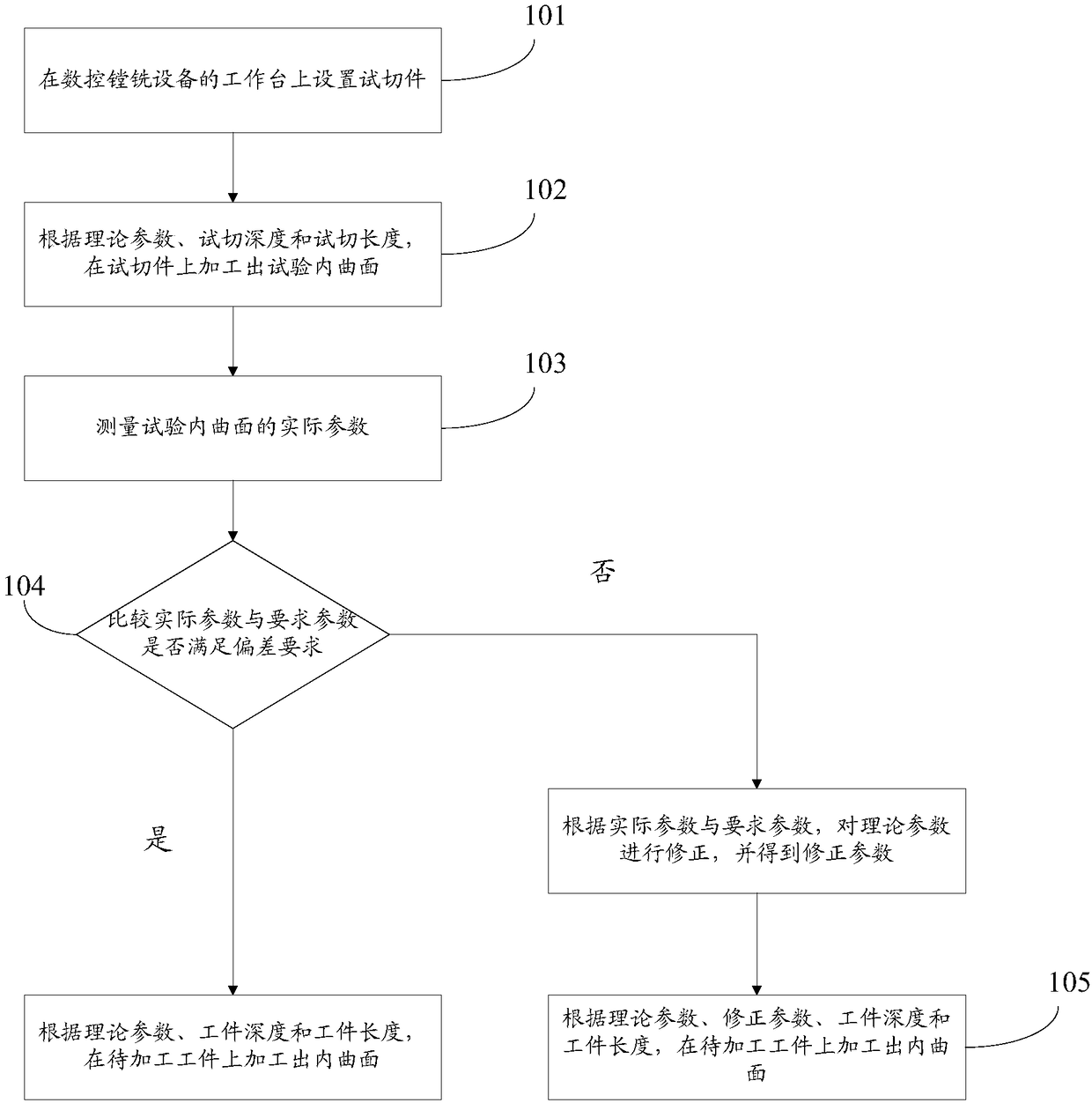

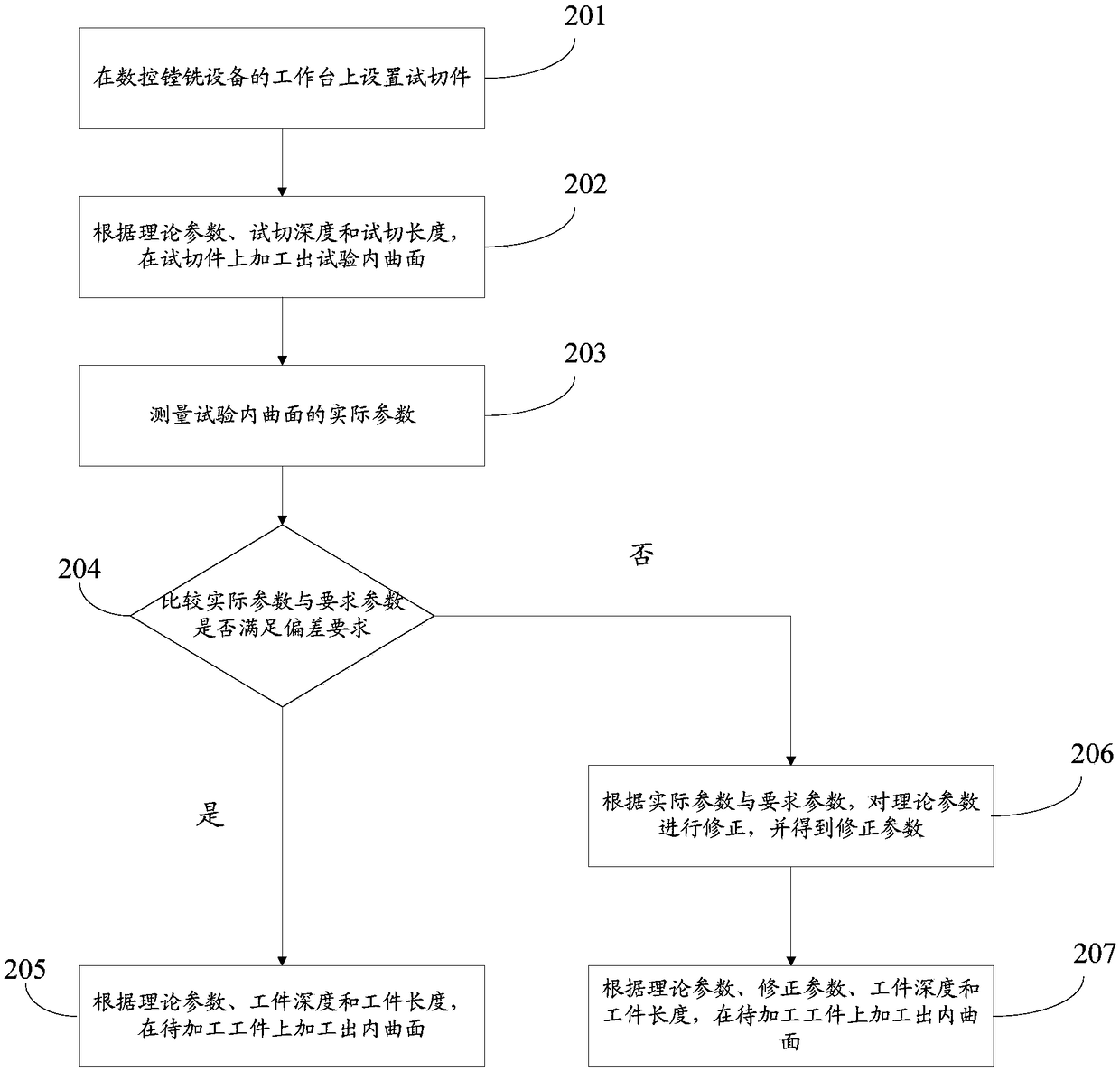

Curved surface machining method

InactiveCN105935860AGuaranteed surface roughnessReduce manufacturing costOther manufacturing equipments/toolsLarge fixed membersSurface roughnessMachine tool

A curved surface machining method includes the steps that a machining device is prepared; a first machining tool capable of performing vertical rotary turning on the curved surface of a workpiece and a second machining tool capable of performing vertical rotary milling on the curved surface of the workpiece are prepared; the workpiece with the curved surface is arranged on a machining platform; the first machining tool or the second machining tool is installed on a main shaft so that the curved surface of the workpiece can be subjected to rough turning machining or rough milling machining through the first machining tool or the second machining tool; and the first machining tool or the second machining tool is installed on the main shaft so that the curved surface of the workpiece can be subjected to fine turning machining or fine milling machining through the first machining tool or the second machining tool. By means of the arrangement of the first machining tool and the second machining tool, the curved surface of the workpiece can be subjected to turning machining or milling machining on one machining device, the trouble that the workpiece needs to be disassembled and assembled is avoided, the production efficiency can also be greatly improved, and therefore the surface roughness of the curved surface of the workpiece can be effectively guaranteed.

Owner:深圳市万嘉科技有限公司 +1

Processing method of inner surface

The invention discloses a processing method of an inner surface and belongs to the field of machining. The processing method comprises: setting a cutting sample on a workbench of a numerical control boring-milling apparatus; processing a test inner surface on the cutting sample according to theoretical parameters, test cutting depth and test cutting length, wherein the theoretical parameters are parameters that allows an inner surface to be processed theoretically on a workpiece under processing, and the theoretical parameters include theoretical tool speed and theoretical feeding speed; measuring actual parameters of the test inner surface; comparing the actual parameters with required parameters; if deviation requirements are met, processing an inner surface on the workpiece under processing according to the theoretical parameters, workpiece depth and workpiece length; if the deviation requirements are not met, correcting the theoretical parameters according to the actual parametersand the required parameters to obtain corrected parameters; processing an inner surface on the workpiece under processing according to the theoretical parameters, the corrected parameters, the workpiece depth and the workpiece length. The processing method provides improved processing precision for an inner surface.

Owner:WUHAN MARINE MACHINERY PLANT

Method for deplating sapphire plated layer by using waste polishing solution

The invention relates to a method for deplating a sapphire plated layer by using a waste polishing solution, belongs to the technical field of glass surface treatment and aims at realizing reuse of the waste polishing solution in an AG (anti-glare glass) process and further ensuring the performance of sapphire after deplating. The invention provides the method for deplating the sapphire plated layer by using the waste polishing solution. The method comprises the following steps: mixing the waste polishing solution produced in the AG process and water to form a mixed solution, and controlling the pH value below 1 for further deplating treatment; soaking the surface-coated sapphire to be deplated in the mixed solution, performing deplating treatment, and cleaning with the water after deplating treatment to obtain a corresponding product. By adopting the method provided by the invention, the reuse of the waste polishing solution is realized, thereby turning waste into treasure, improving economic benefits and further ensuring the crystal purity, the surface roughness and the transmittance of the sapphire after deplating; and furthermore, the process flow is simple and the operation is easy.

Owner:ZHEJIANG XINGXING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com