On-site test method for pearlite spheroidization grade of No.20 steel

An on-site inspection and grade technology, applied in the direction of testing material hardness, etc., can solve the problems of cumbersome inspection procedures, high requirements for operator knowledge and experience, and damage to working parts, achieving low knowledge and experience requirements, low cost, and damage. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

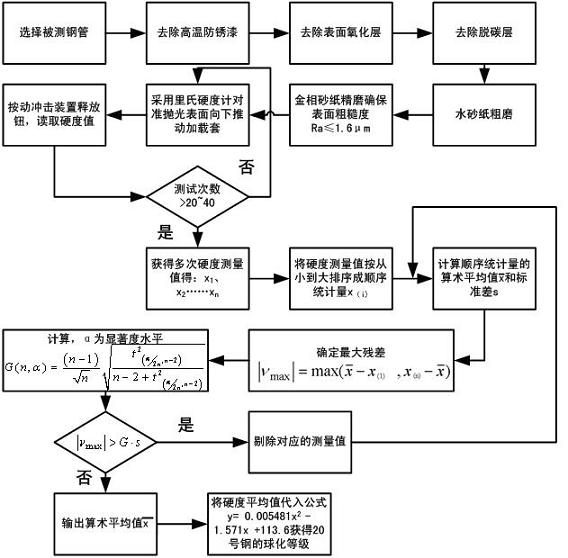

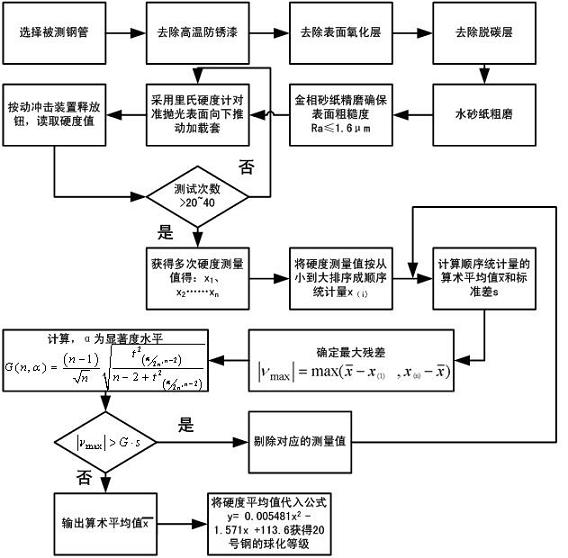

Method used

Image

Examples

Embodiment 1

[0017] Select the steel parts to be tested on site, generally steel parts that are prone to overtemperature and overpressure, and then use an angle grinder equipped with a grinding wheel to remove the high-temperature anti-rust paint, surface oxide layer and decarburization layer on the surface to be exposed. The state of organization within the metal. After the decarburized layer is completely removed, stop the mechanical grinding work immediately. Use an angle grinder to install a self-stick polishing disc, and then replace it with 180, 400, and 600 water sandpaper for rough grinding in sequence. Then replace it with No. 01 and No. 02 metallographic sandpaper for fine grinding to ensure that the surface roughness Ra≤1.6μm. The grinding surface should be cleaned before each replacement of different types of sandpaper. During the entire mechanical grinding process, water should be sprayed at the same time to reduce the temperature of the grinding surface, so as to prevent th...

Embodiment 2

[0019] In 2008, a superheater tube was selected as the tested part in a thermal power plant in Yangzhou. The material of the superheater tube was No. 20 steel, and the design temperature was 450°C. At that time, the steel pipe had been in service for 100,000 hours. Use an angle grinder with a grinding wheel to remove the high-temperature anti-rust paint, surface oxide layer and decarburization layer on the surface to be tested. After the decarburization layer is completely removed, stop the mechanical grinding work immediately. Use an angle grinder to install a self-stick polishing disc, and then replace it with 180, 400, and 600 water sandpaper for rough grinding in sequence. Then replace it with No. 01 and No. 02 metallographic sandpaper for fine grinding to ensure that the surface roughness Ra≤1.6μm. Clean the grinding surface before changing different types of sandpaper each time. Spray water at the same time during the whole mechanical grinding process to reduce the te...

Embodiment 3

[0021] In 2009, a superheater tube was selected as the tested part in a thermal power plant in Taizhou. The material of the superheater tube was No. 20 steel, and the design temperature was 450°C. At that time, the steel pipe had been in service for 80,000 hours. Use an angle grinder with a grinding wheel to remove the high-temperature anti-rust paint, surface oxide layer and decarburization layer on the surface to be tested. After the decarburization layer is completely removed, stop the mechanical grinding work immediately. Use an angle grinder to install a self-stick polishing disc, and then replace it with 180, 400, and 600 water sandpaper for rough grinding in sequence. Then replace it with No. 01 and No. 02 metallographic sandpaper for fine grinding to ensure that the surface roughness Ra≤1.6μm. Clean the grinding surface before changing different types of sandpaper each time. Spray water at the same time during the whole mechanical grinding process to reduce the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com