Processing method of rolled copper foil mother material

A processing method and technology of rolling copper foil, which is applied in metal rolling and other directions, can solve the problems that restrict the production of rolled copper foil base material, and achieve the effect of excellent internal structure, uniform performance and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

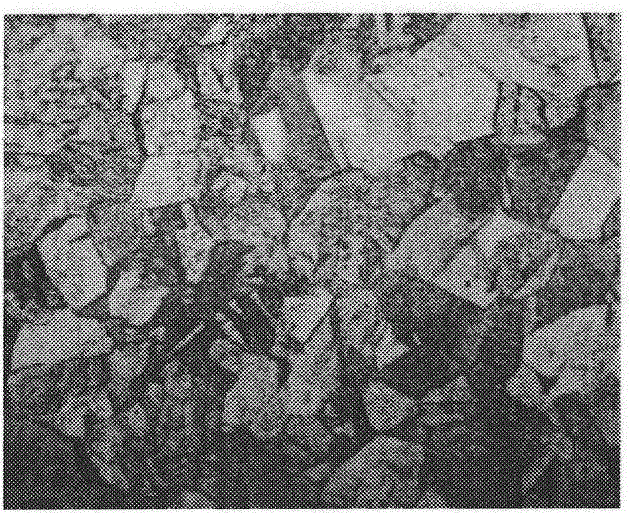

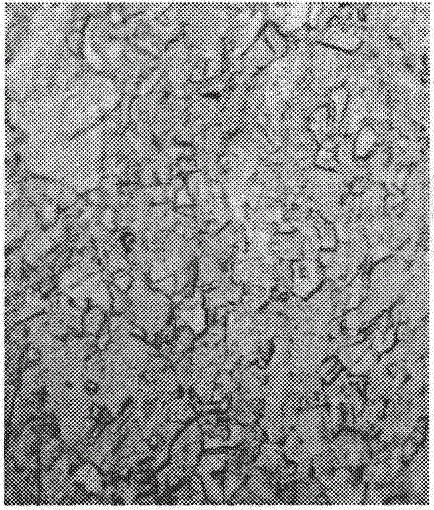

Examples

Embodiment Construction

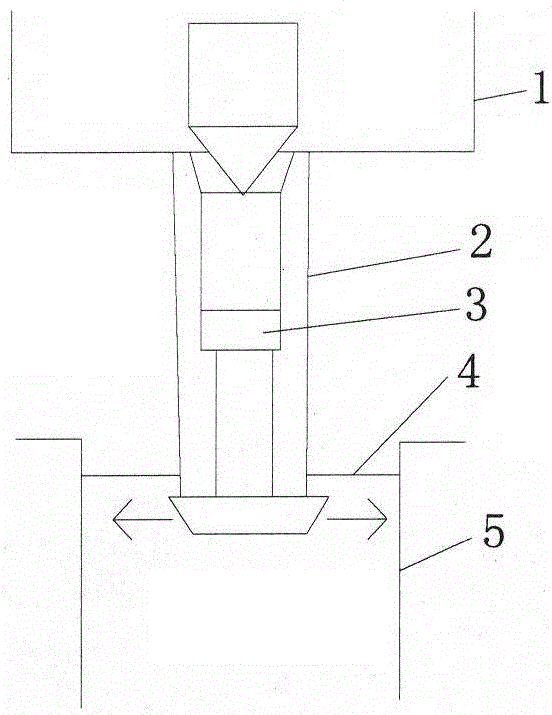

[0035] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0036] A method for processing a rolled copper foil base material, comprising the following steps:

[0037] (1) Material selection: In order to reduce the impurity content of the product and improve the material purity, high-purity cathode copper (copper content greater than 99.95%) is used as raw material, and the electrolytic copper is passed through dilute sulfuric acid with a concentration of 6-10% After washing, it is dried under a nitrogen protective atmosphere to remove the scale and impurities on the surface of the raw material.

[0038] (2) Smelting: Send the processed raw materials into the melting furnace for melting. The melting furnace in this embodiment adopts a self-developed furnace cover. The furnace cover is basically sealed and only a switchable feeding window is left, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com