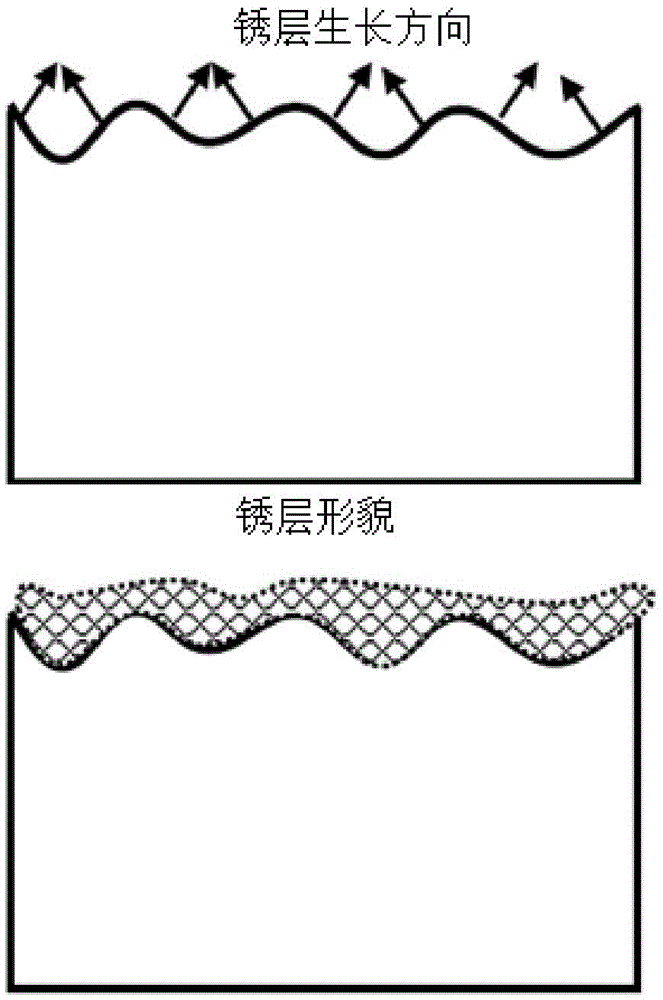

Hot stamping forming steel board for restraining falling off of oxide layer in hot stamping process and production method thereof

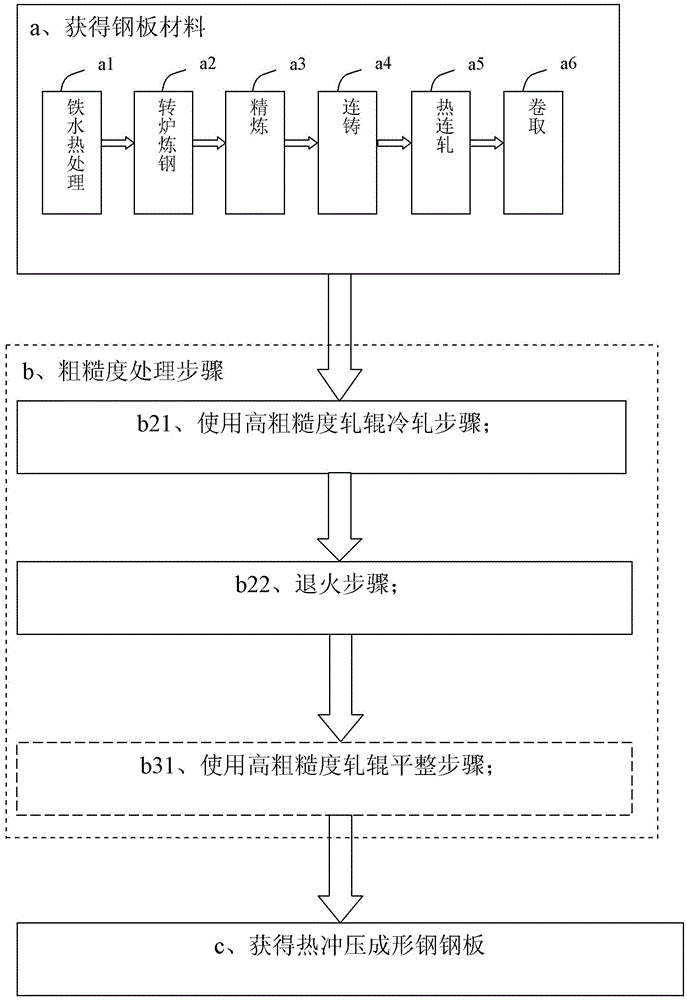

A technology of hot stamping and production methods, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of iron scale shedding, production cost increase, production workers' health impact, etc., to improve compactness and reduce shedding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

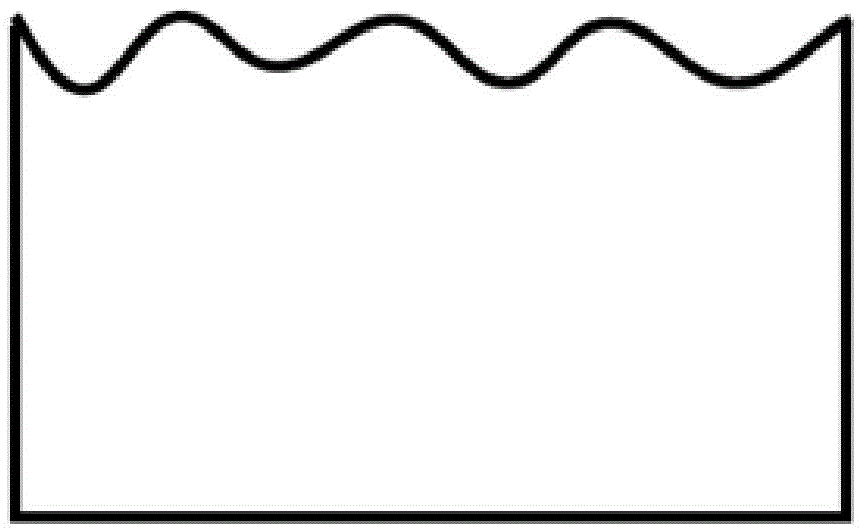

[0045] The invention provides a steel sheet for hot stamping forming which suppresses the shedding of an oxide layer during the hot stamping process. The composition includes, by weight percentage: the content of C is 0.19-0.27, the content of Si is at most 0.50, and the content of Mn is 1.00-0. 1.50, the content of Al is at least 0.010, the content of N is at most 0.010, the content of Ti is 0.01~0.055, the content of Cr is at most 0.35, the content of B is 0.0005~0.004; and the content of Mo, W, Cu at most 0.50 One or more of , Ni; one or more of Nb, Zr, and V with a content of at most 0.10, and the surface roughness of the steel plate is 1.1-2.0 μm. In this embodiment, the composition of the formed steel can also be set by using the chemical composition ratio of the traditional hot-formed steel 22MnB5, see Table 1 .

[0046] element C Si mn als N Ti Cr B Element 0.19~0.27 ≤0.50 1.00~1.50 ≥0.010 ≤0.010 0.020~0.055 ≤0.35 0.0005~0.004 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com