Numerically controlled machine taper-hole boring device and method

A technology of CNC machine tools and boring taper holes, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machines/drilling machines, etc., which can solve the problems of limited flat rotary table, high price, low production efficiency, etc. , to achieve the effect of ensuring precision and surface roughness, reducing production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

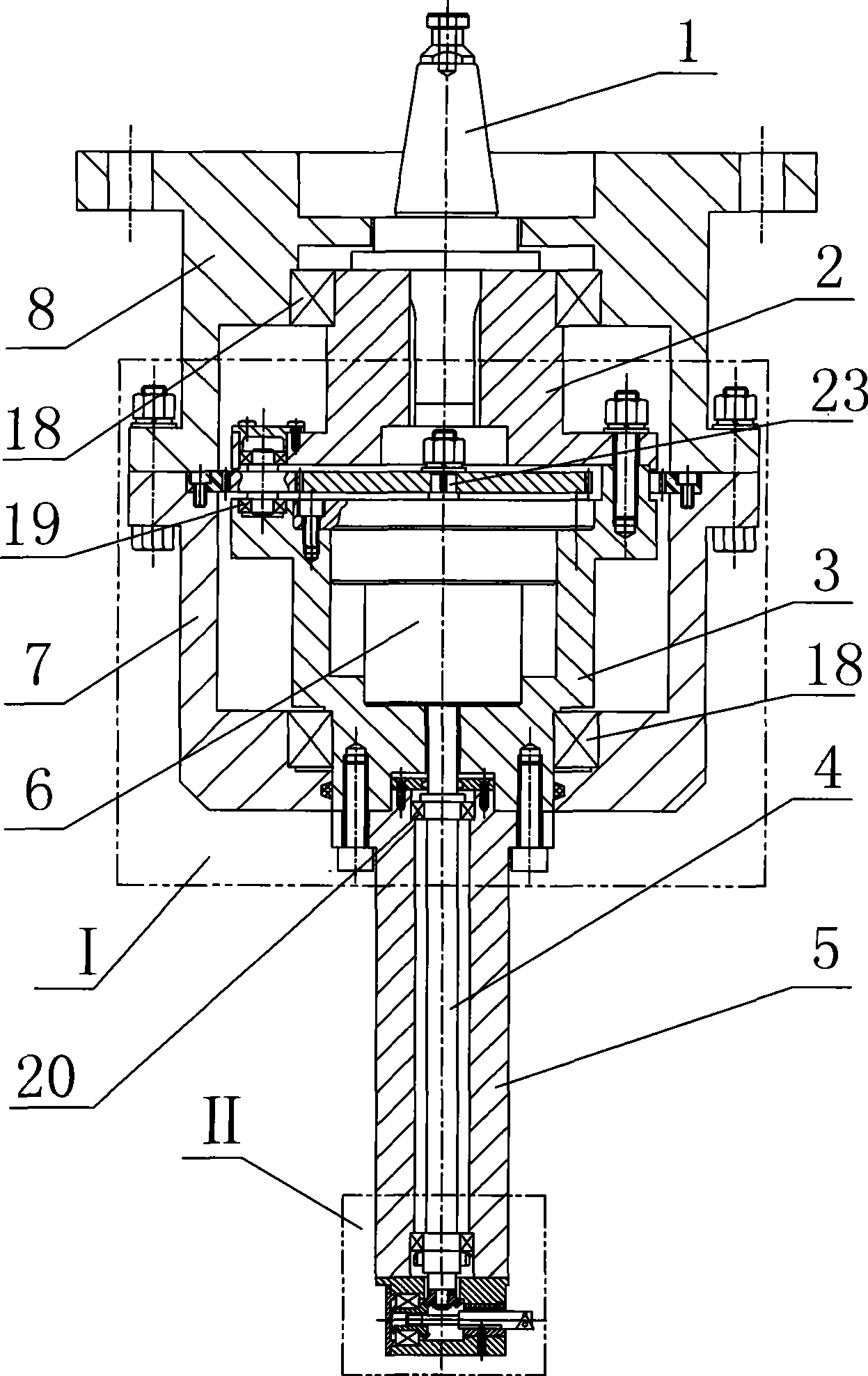

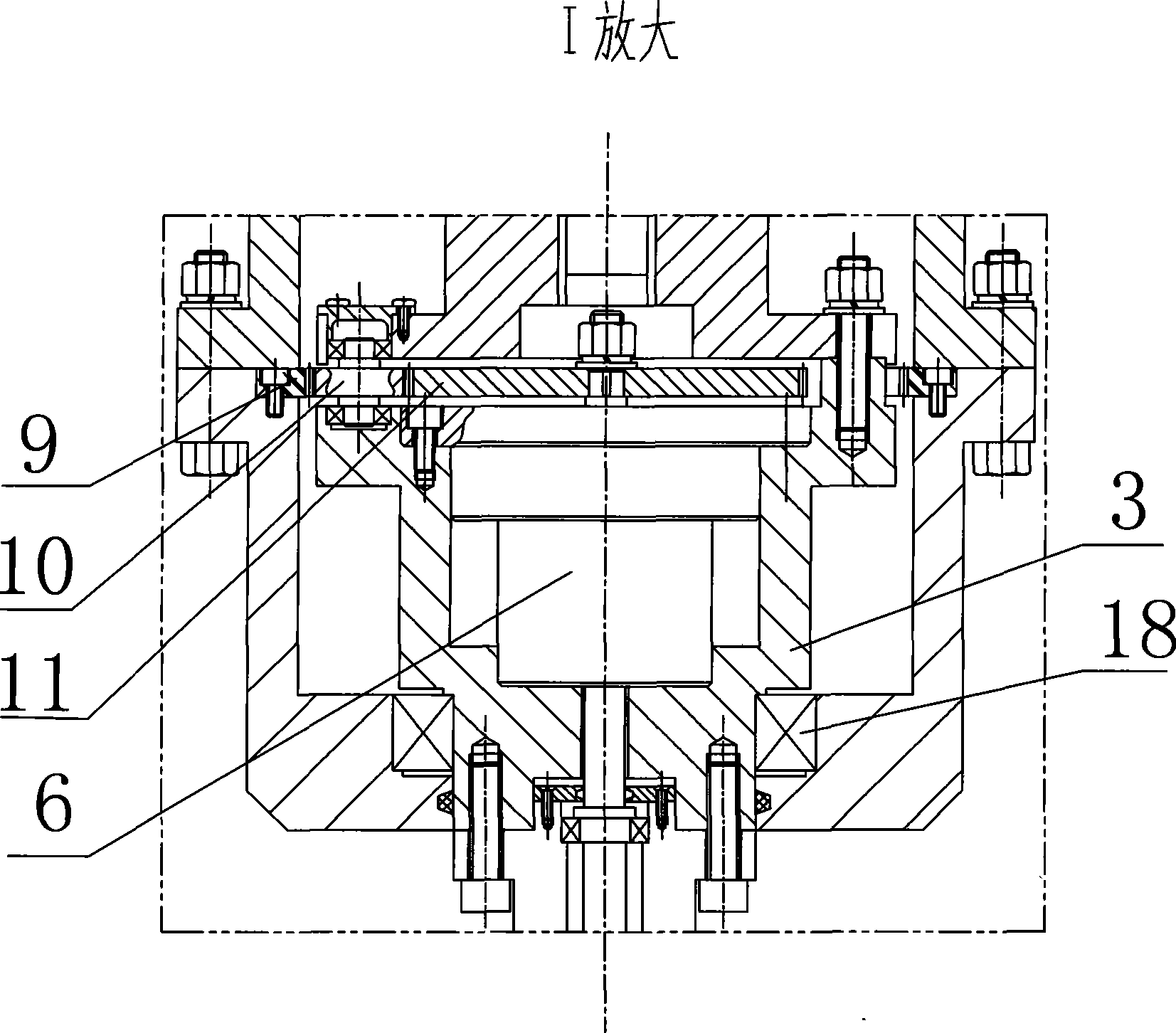

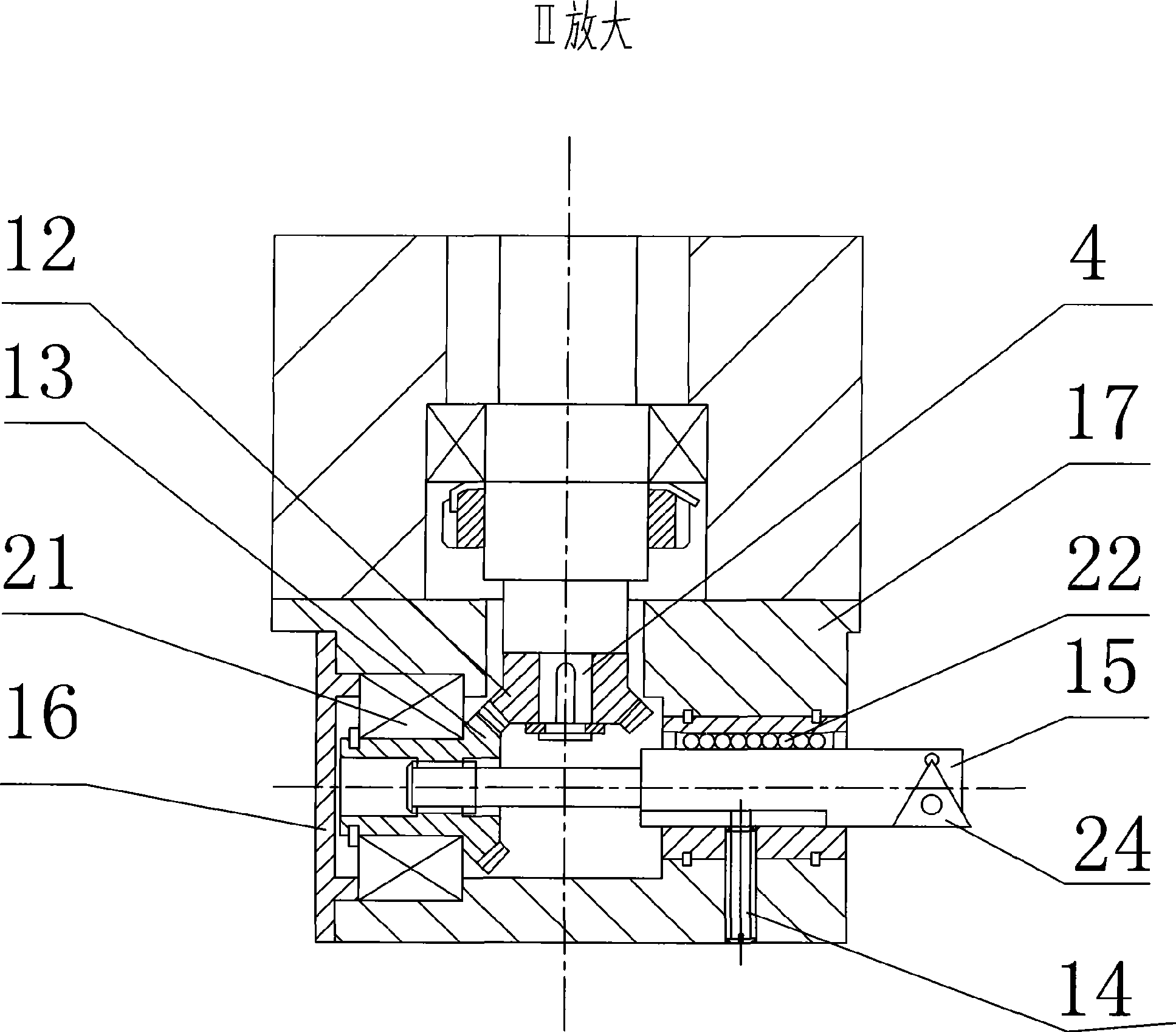

[0024] Such as Figure 1 ~ Figure 3 The shown boring and taper device for a CNC machine tool includes a taper shaft 1, an upper sleeve 2, a lower sleeve 3, a reducer output shaft 4, an adapter rod 5, a reducer 6, a lower casing 7, an upper casing 8, Inner ring gear 9, planetary gear 10, main gear 11, main bevel gear 12, auxiliary bevel gear 13, stop pin 14, cutter bar 15, bearing end cover 16, seat body 17, bearing I18, bearing II19, bearing III20, bearing IV21, bearing V22, reducer input shaft 23, boring tool 24, taper shaft 1 is inserted into the upper casing 8 and connected with the inner hole of the upper casing 2 by a spline, the inner ring gear 9 is fixed on the lower casing 7 by bolts, and the planetary gear 10 is respectively connected with The inner ring gear 9 meshes with the main gear 11; the planetary gear 10 is respectively supported in the upper sleeve 2 and the lower sleeve 3 by the bearing II19, the reducer 6 is fixed in the lower sleeve 3 by bolts, and the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com