Patents

Literature

42results about How to "Stable and reliable processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

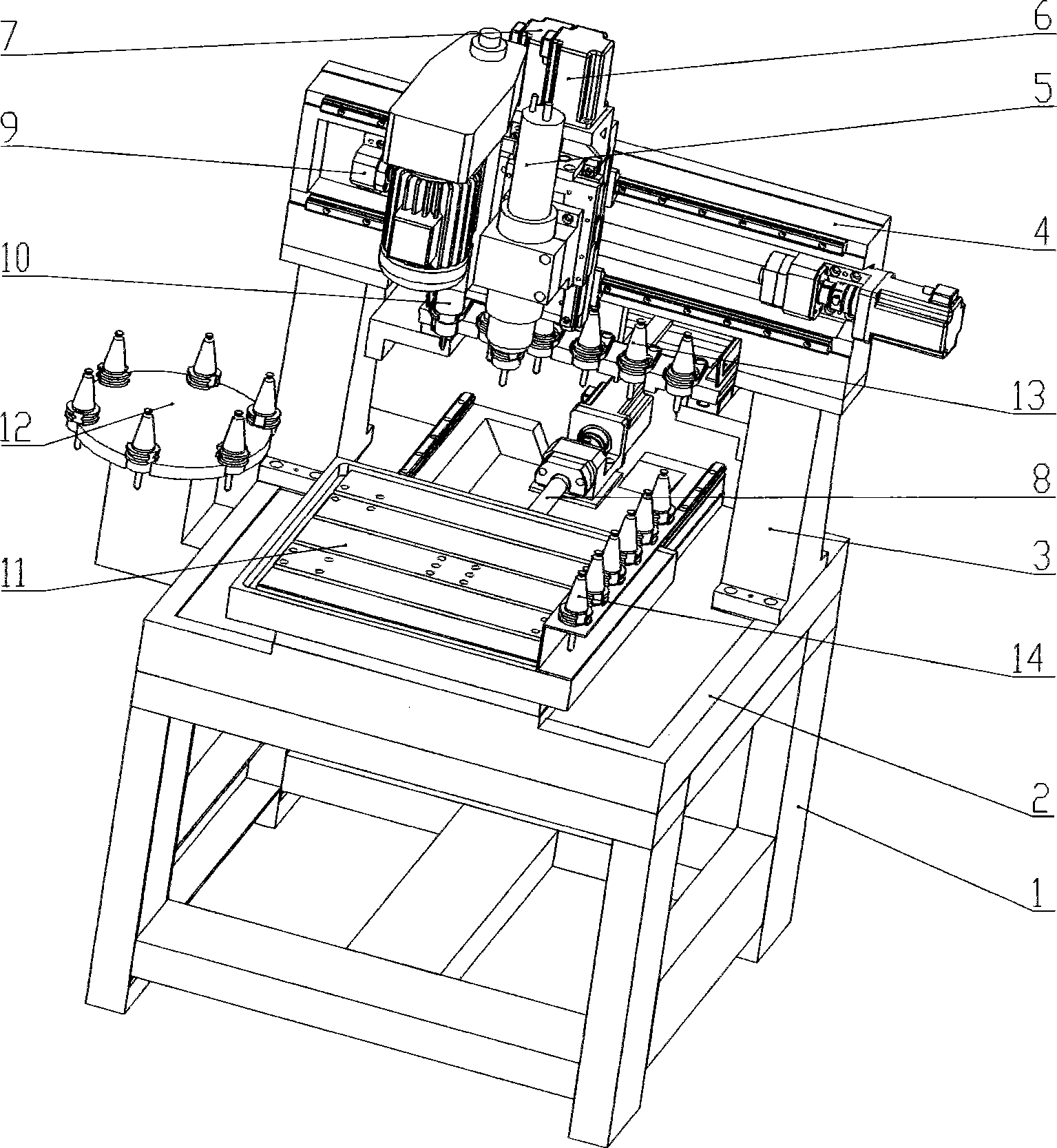

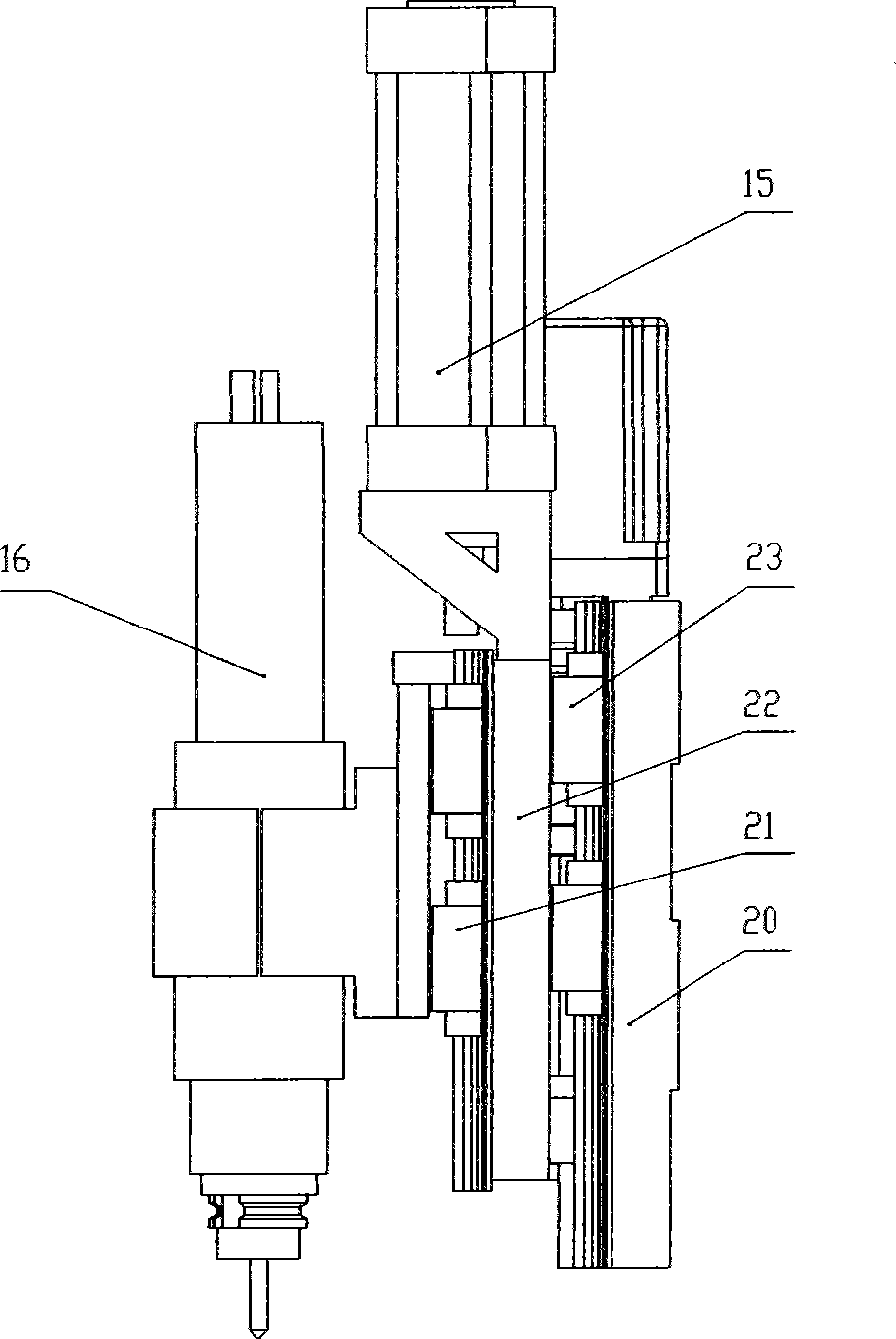

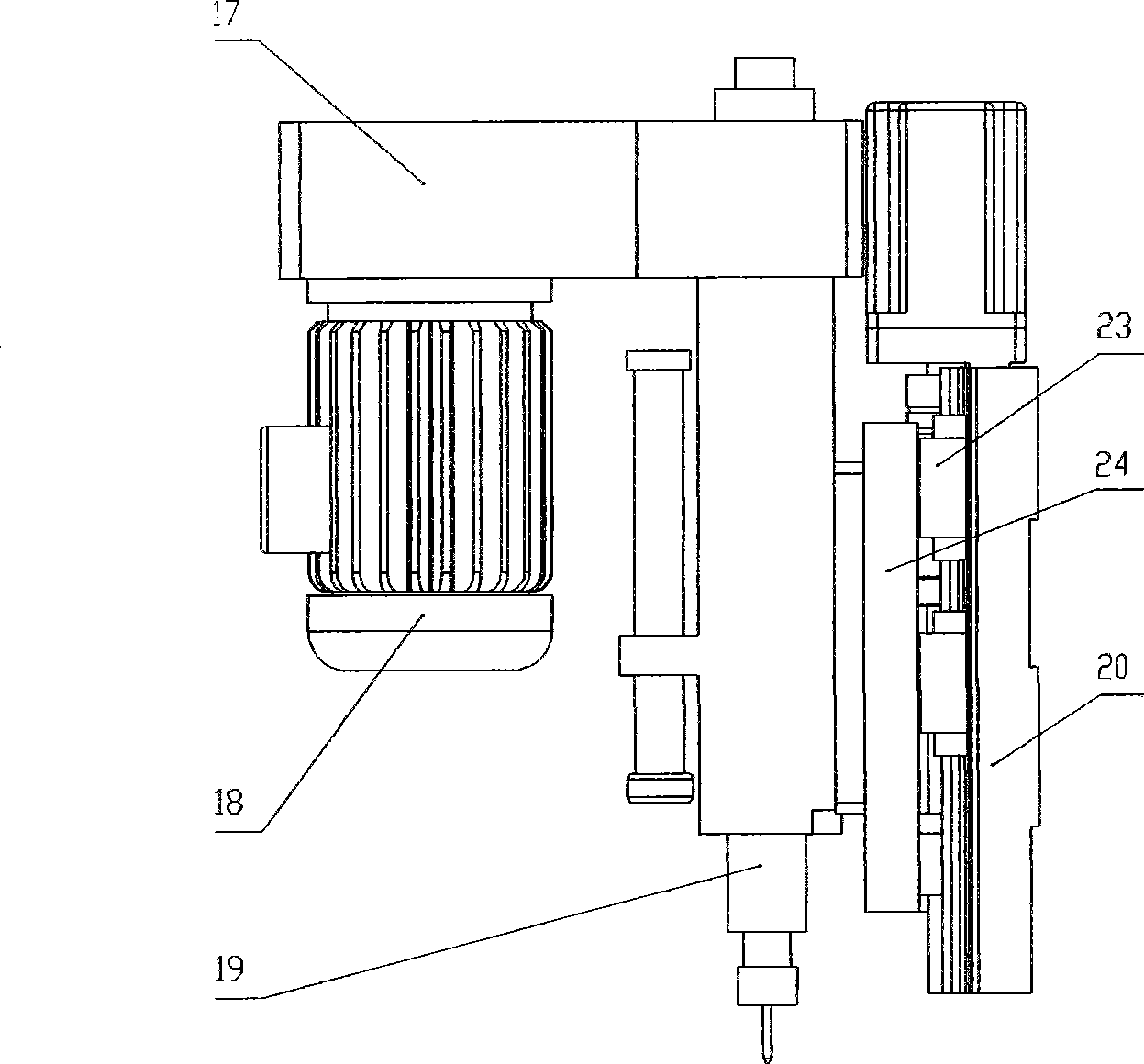

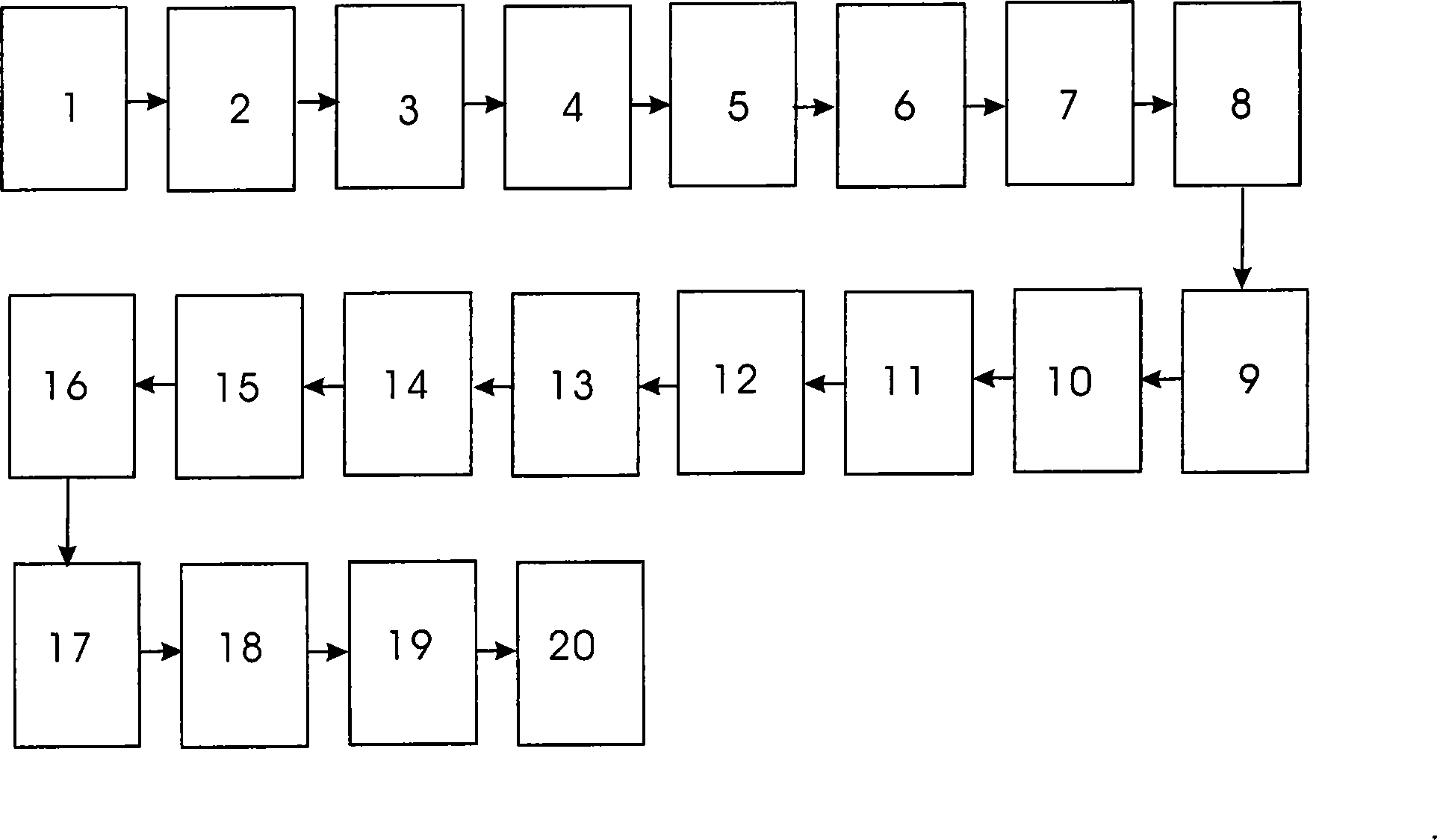

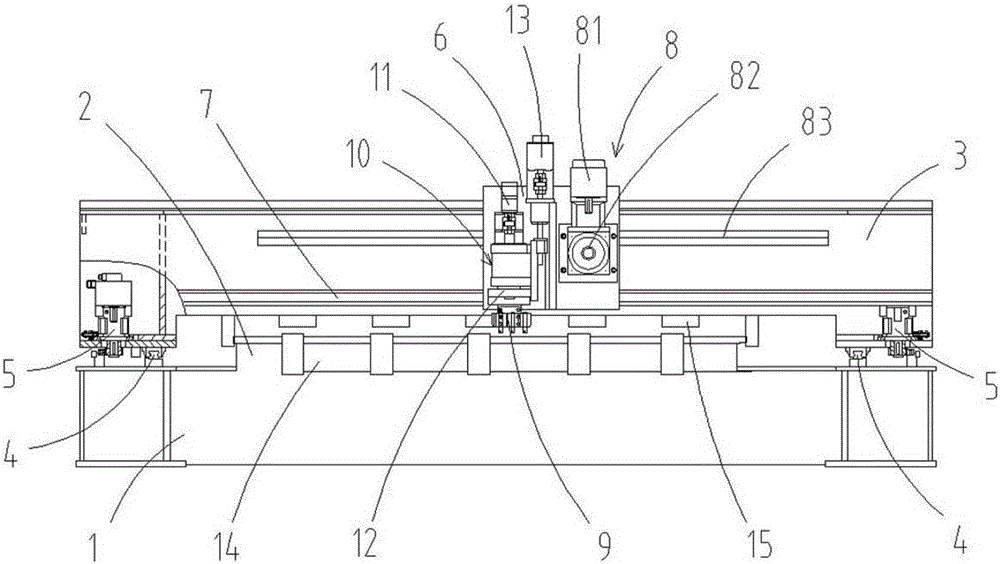

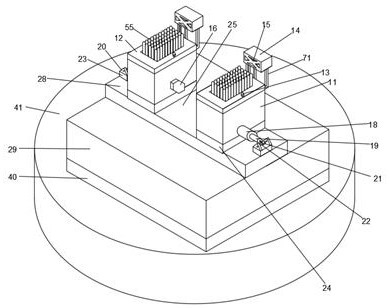

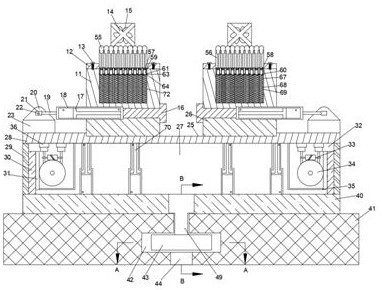

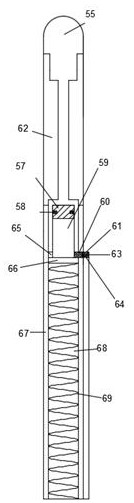

Small-sized gantry double-main shaft numerical control machine for drilling, milling and tapping

InactiveCN101502932AIncrease feed rateHigh positioning accuracyOther manufacturing equipments/toolsPositioning apparatusElectricityNumerical control

The invention relates to a small gantry dual-spindle drilling milling tapping numerical control machine. The small two-axis gantry drilling tapping digital control machine essentially solves the technical problem of providing a drilling milling tapping machine with low cost and high efficiency for the light metal hardware processing of the communication and the consumption electronic industry, and the machine has the advantages of simple structure and stable and reliable operation. The technical proposals for solving this problem is as follows: a frame structure support welded with channel steel, a diamond-shaped rib square structure soleplate and a gantry beam are adopted; a sliding plate of the beam is equipped with dual spindles, and the dual spindles are respectively a high-speed drilling milling head spindle and a high-speed tapping head spindle. The drilling milling head spindle uses a high-speed knife replaceable electric spindle; the tapping head spindle uses a self-invented mechanical tapping spindle able to carry out the screw distance selection automatically. The drilling milling head spindle can install the tool magazine on the rear, left and right positions of the machine; the tool magazine uses row-type tool magazine, inverted bamboo hat style tool magazine or row-type tool magazine and the arbitrary combination methods of inverted bamboo hat tool magazine.

Owner:深圳市康铖机械设备有限公司

Method for processing fast cooking germination husked rice and germination dehusked rice maded thereout

The invention relates to a processing method of quick cooking germinated brown rice and the germinated brown rice made by the method. The control starts from paddy which is stored in a cryogenic thermostat warehouse after the dried in a drying tower. Afterward, the paddy was processed into brown rice which is used as raw material by cleaning, stoning, deshelling, rolling by a vertical rice mill, polishing and color-selecting. The brown rice is processed in sequence in the steps as follows: preparing phytase operating fluid, adding the brown rice in accordance with a particularly mixture of 1 to 1 brown rice and phytase pressure fluid, immersing the mixed liquid of brown rice in an ultrasonic field for 45 to 75 minutes; the brown ice germinates on a tunnel germinating bed in the temperature of 30 to 35 DEG C, which needs to be sprayed automatically with the gibberellin liquid every two hours; the germinated brown rice which is cooked in the high temperature for 30 minutes and then is dried in low temperature for 4 to 6 hours, after microwave sterilizing and subpackaging, is formed into the finished products of germinated brown rice. The invention particularly relates to that the germinated brown rice has better taste by the control of the germinating, is easier for cooking in the home and boiled with the rice simultaneously, and has higher safety for the microbial contamination.

Owner:刘来法

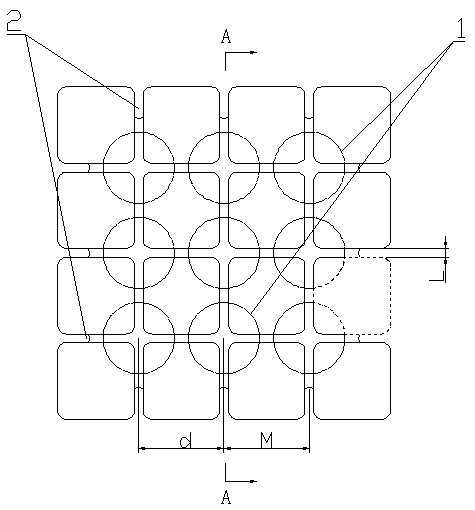

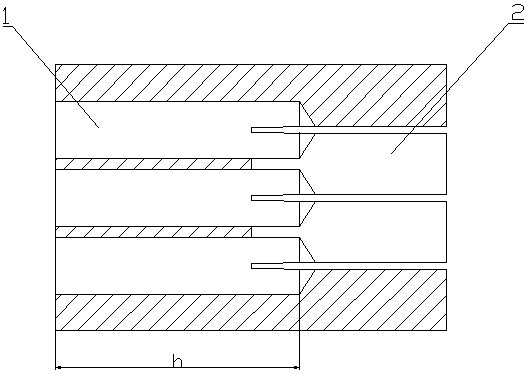

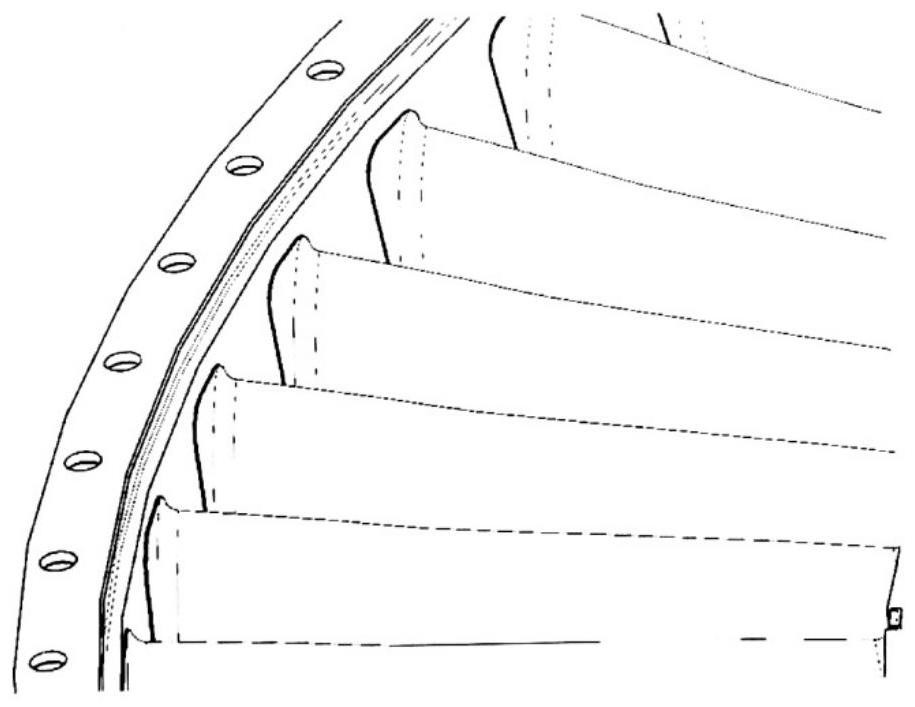

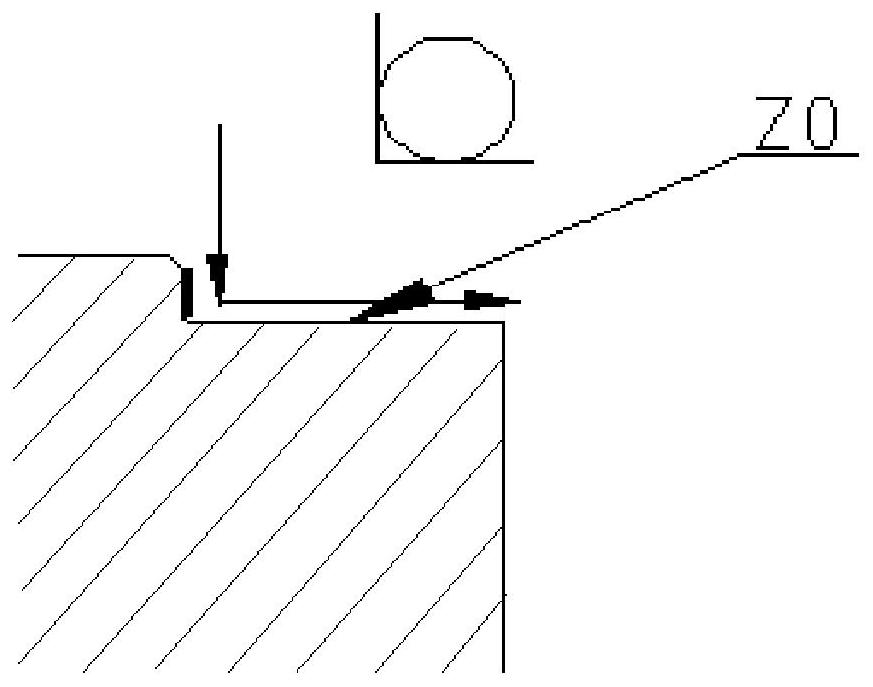

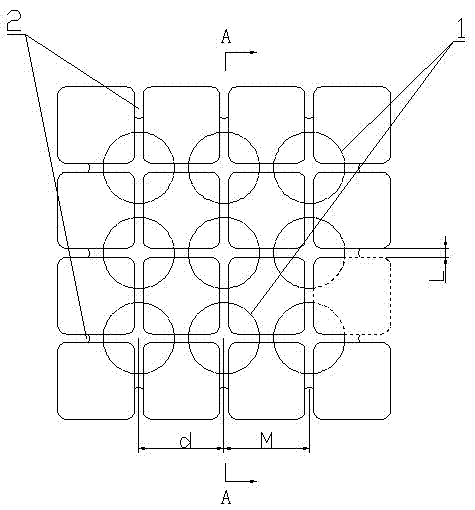

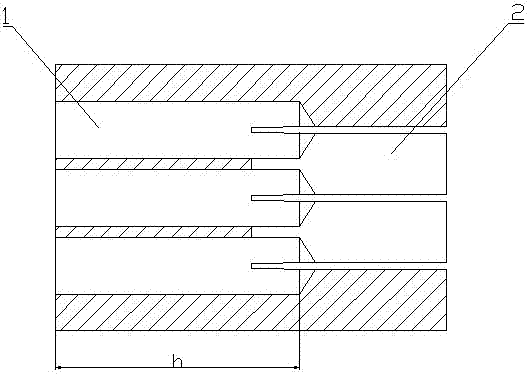

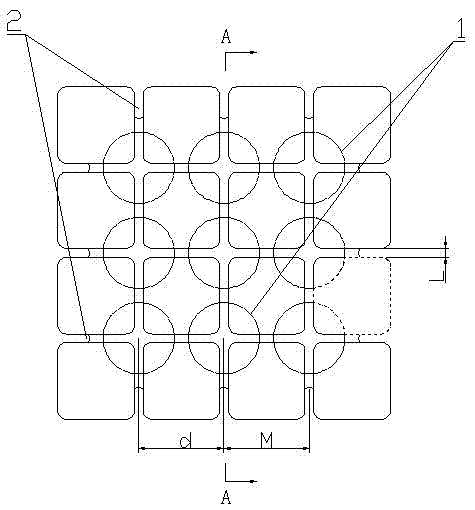

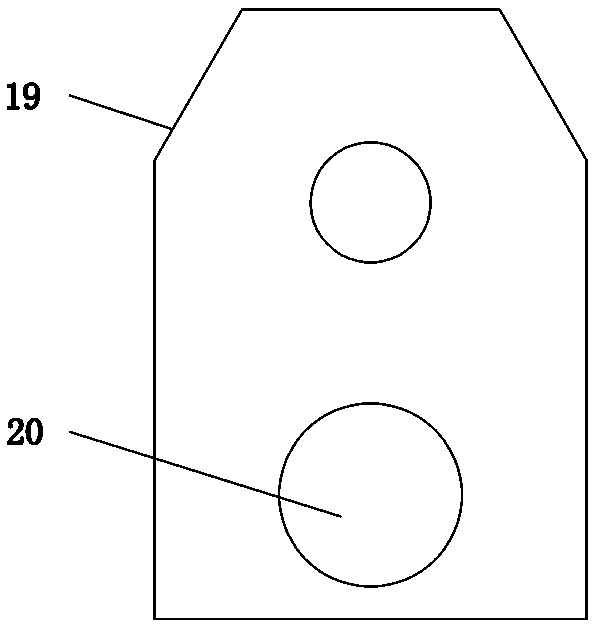

Manufacturing process of high-precision extrusion die for DeNOx catalyst

ActiveCN102039519AGuaranteed surface roughnessGuaranteed shape and position accuracySurface roughnessMachining process

The invention discloses a manufacturing process of a high-precision extrusion die for a DeNOx catalyst. The manufacturing process comprises the following steps: discharging, thermal refining, grinding, rough machining, grinding, boring holes, semi-fine grinding, thermal treatment, groove linear cutting, benching, fine grinding and protective treatment. In the process, by means of the methods such as reasonable control of machining amount, reasonable selection of equipment parameters and the like in the steps, the surface roughness, the dimensional precision and the form and position accuracy of holes (grooves) of machined parts of the extrusion die with multiple deep holes (grooves) for the catalyst are effectively ensured, wherein, the machining precision reaches 0.01mm, and the surface roughness reaches over Ra0.8; the machining process is stable and reliable; the qualification rate of the die product reaches over 99%; and the difficulty in manufacturing the complicated die with the multiple deep holes (grooves) is overcome. Compared with the prior art, the manufacturing process disclosed by the invention has the advantages of effectively avoiding scrap caused by size and location out-of-tolerance, greatly lowering production cost, improving machining efficiency and shortening production cycle.

Owner:CHONGQING YUANDA CATALYST MFG

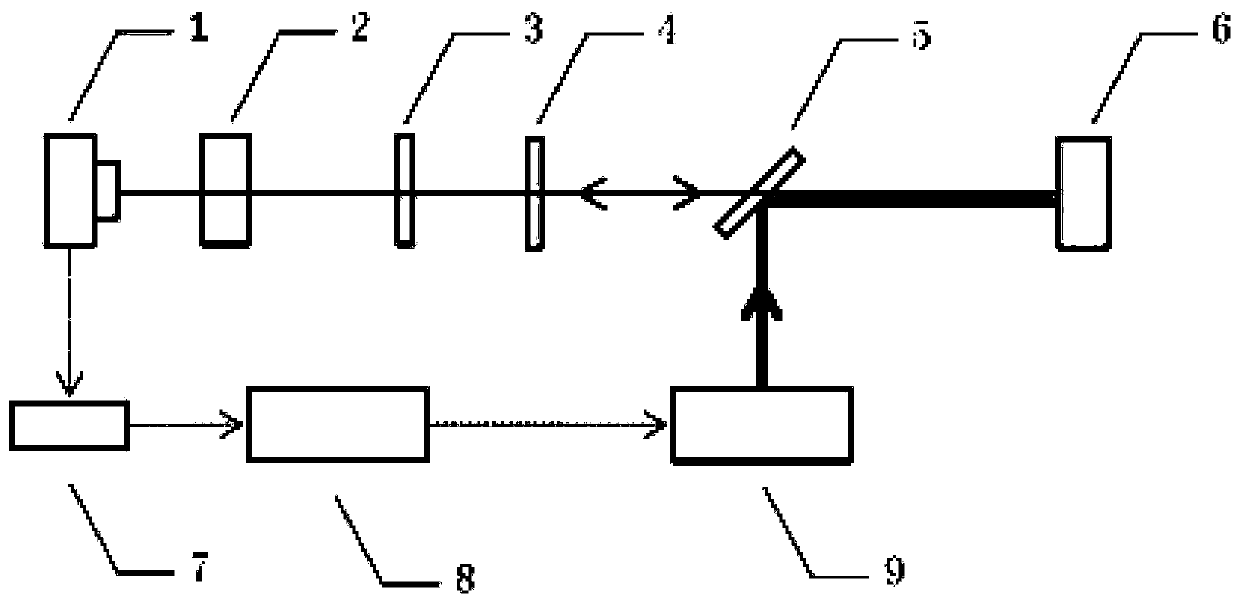

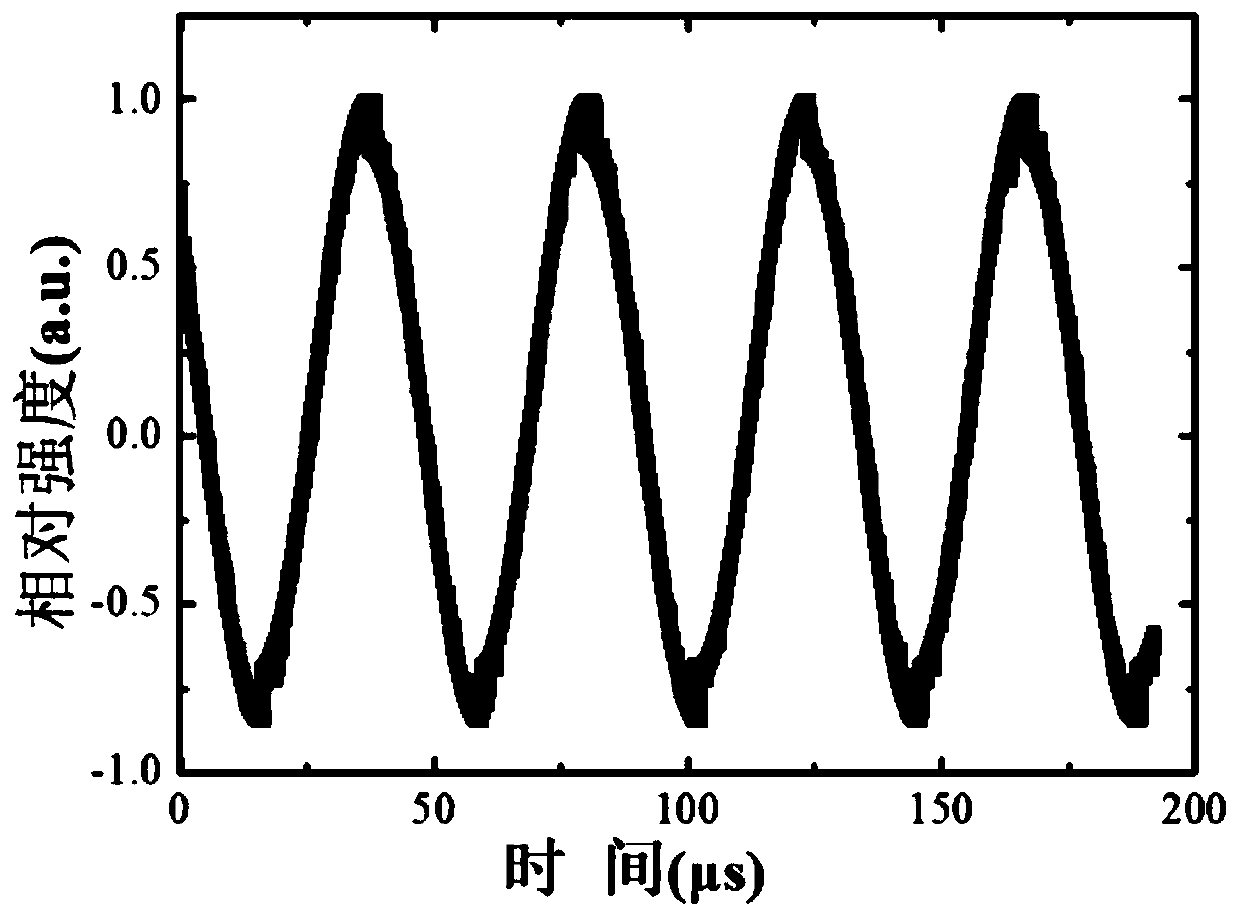

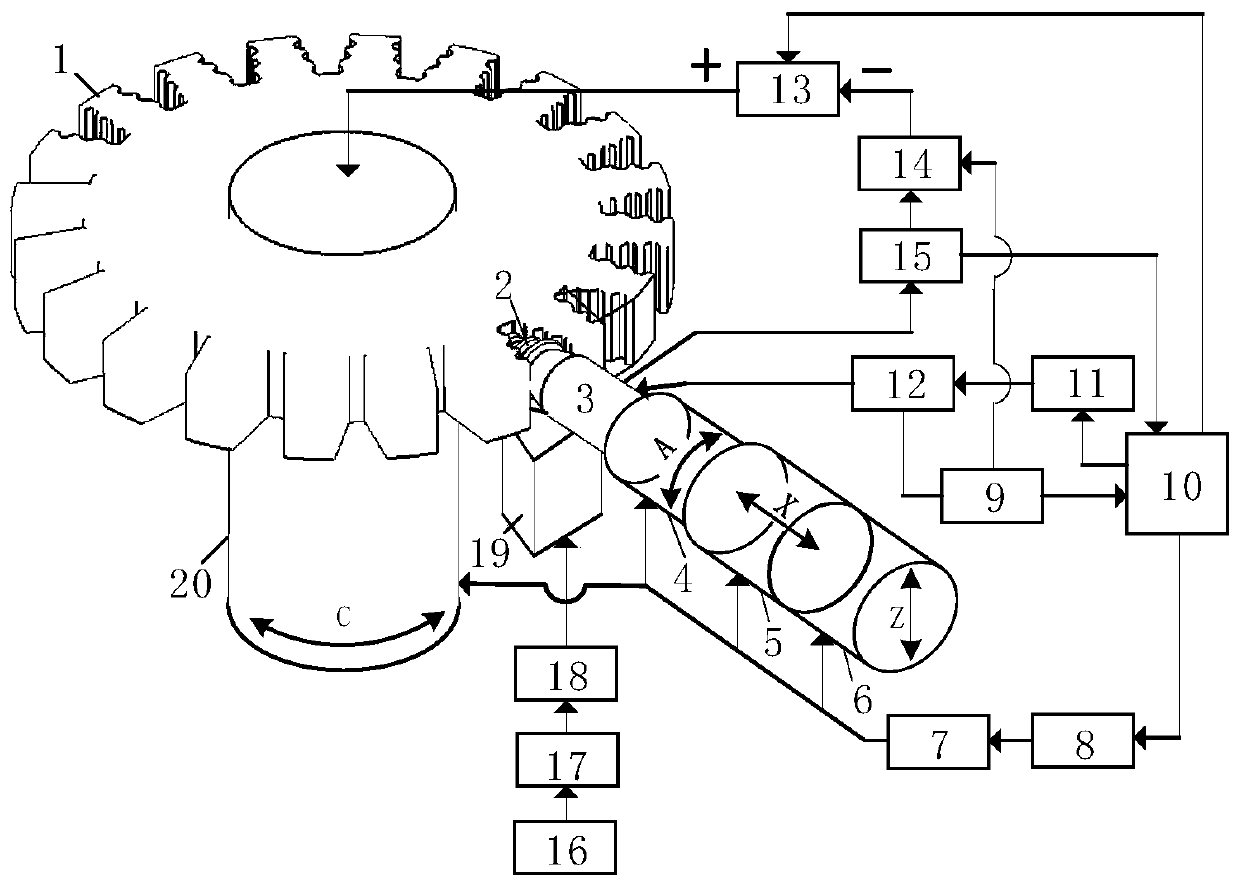

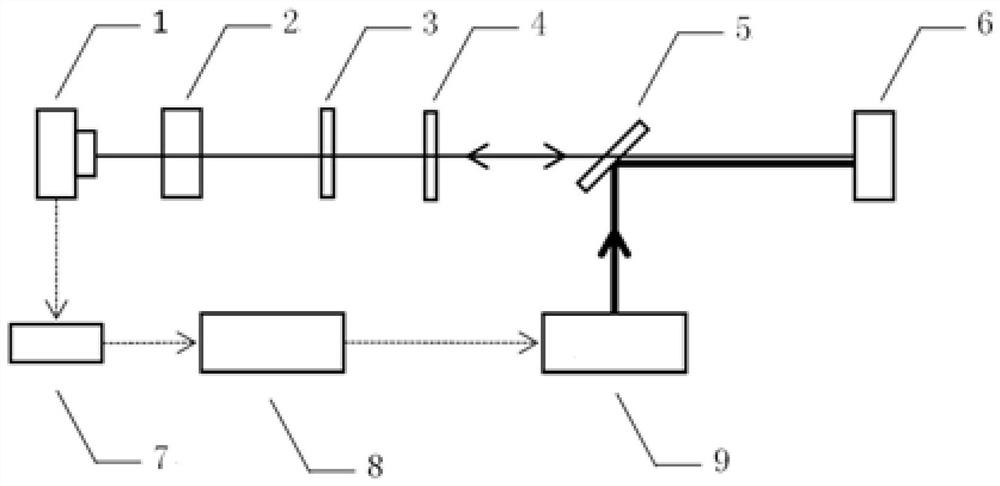

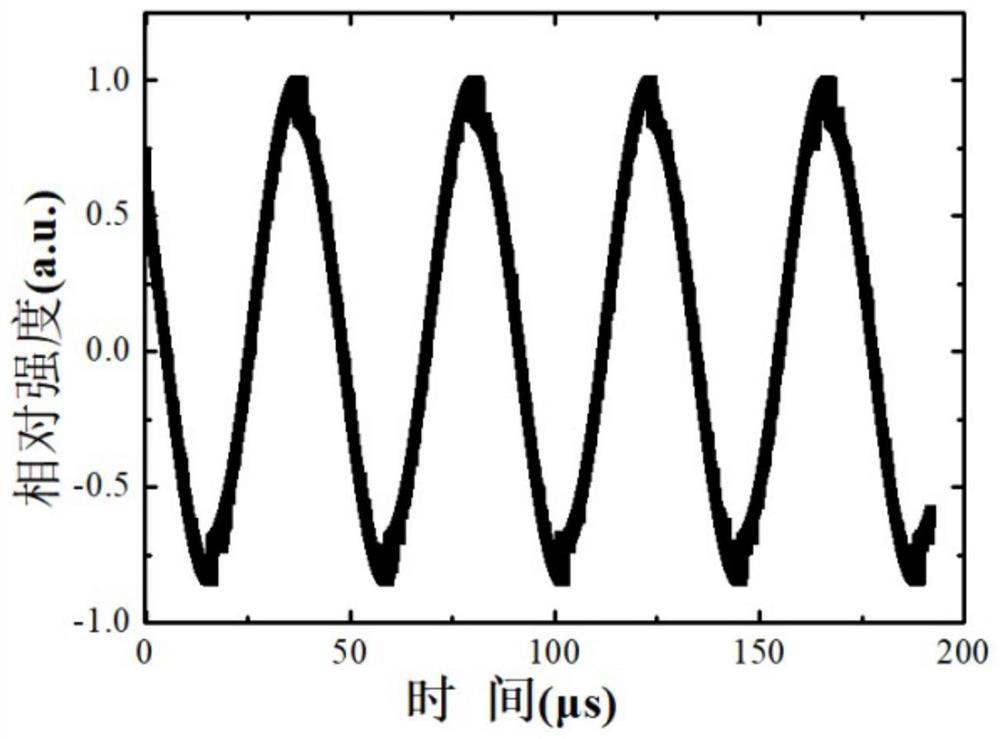

Laser hole processing system and method with processing and real-time detection capability

ActiveCN110744211ALow costSimple structureUsing optical meansLaser beam welding apparatusBeam splitterEngineering

The invention provides a laser hole processing system and method with processing and real-time detection capability. The problems that in an existing ultra-fast laser micro-nano processing hole depthnon-contact real-time detection mode, detection equipment is complex in structure and the detection cost is high are solved. The system comprises a semiconductor laser device, a beam collimation unit,a polarizer, a quarter wave plate, a dichroic beam splitter, a data acquisition unit, a data processing unit and a laser processing device. The semiconductor laser device emits lasers, and the lightwhich passes through the beam collimation unit and the polarizer and is emitted to the dichroic beam splitter and the laser processing device is emitted to a processed part together; and semiconductorlaser reflected light is returned into a cavity of the semiconductor laser device along the original optical path, a change curve of relative intensity change signals of the semiconductor laser device and processing time is obtained, and the depth of a laser processed hole can be calculated in real time through the data processing unit.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

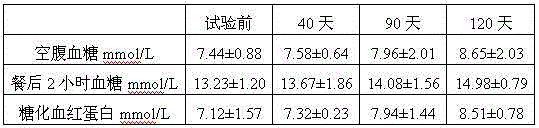

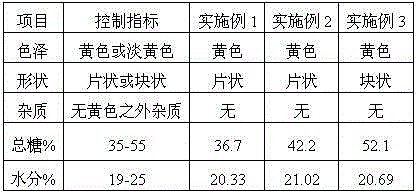

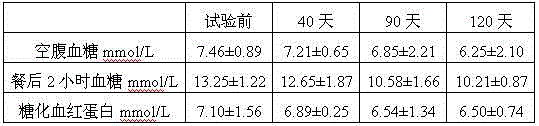

Processing method of low blood glucose index preserved mango fruits with effect of regulating intestinal function

ActiveCN104381559APromote natural proliferationGood for healthConfectionerySweetmeatsBiotechnologyMango fruit

The invention discloses a processing method of low blood glucose index preserved mango fruits with effect of regulating the intestinal function. The processing method sequentially comprises the following steps: fruit selecting, fruit cleaning and slicing, color-protecting, sugaring, secondary powder-wrapping and drying, wherein the sugaring process adopts L-arabinose for sugaring for 24-48 hours; the secondary powder-wrapping adopts a mixture of 80-95% of L-arabinose and 5-20% of oligosaccharide. The sugaring processing process of the preserved mango fruits processed by the processing method disclosed by the invention can keep the mouthfeel, and also has good effects of lowering the blood glucose index, restraining the development of hyperglycemia and relieving the pathogenetic condition of a patient with hyperglycemia.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

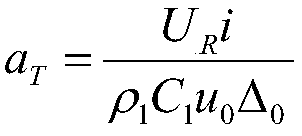

Blade machining process

The invention discloses a blade machining process. The process dispersion principle is fully adopted; by utilizing a common plane abrasion device, the cost of the device is reduced and, flow line production can be carried out on a production site in batches; meanwhile, a low-melting-point alloy precise positioning mode is adopted, the machining benchmark is converted, a space positioning point isconverted into a plane, so that the machining process is reliable and stable, the production efficiency is improved, the machining quality is guaranteed, large-batch turbine guide blade production canbe met, and the process can be widely applied to machining of aero-engines and turbine guide blades of gas turbines.

Owner:AECC AVIATION POWER CO LTD

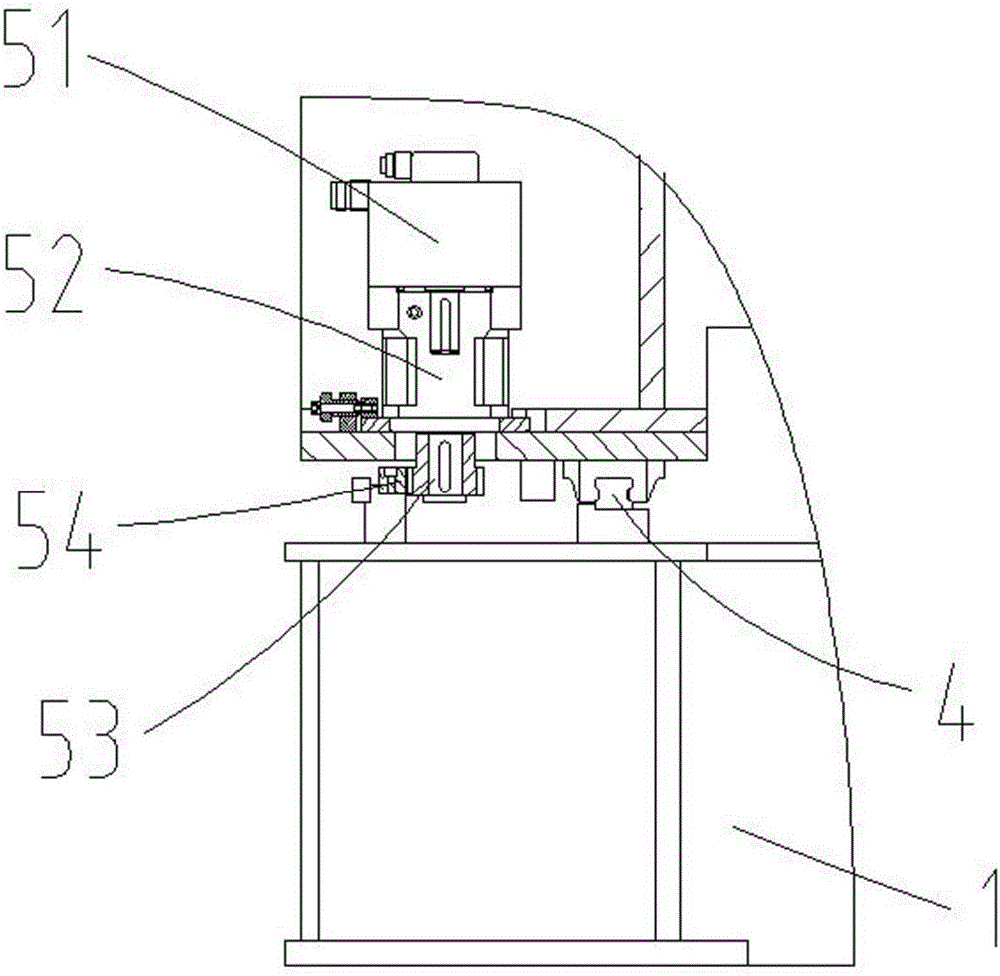

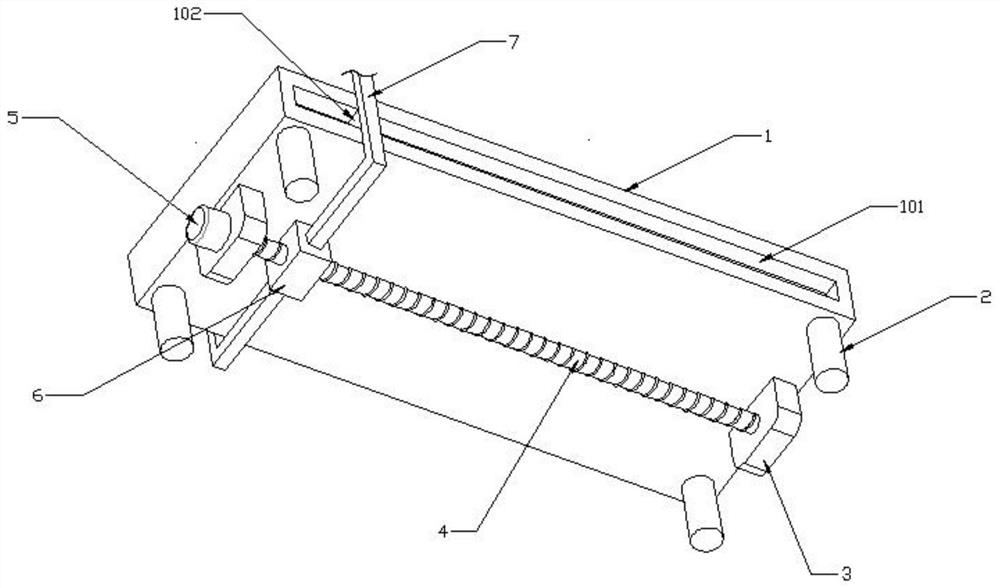

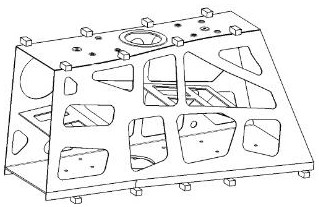

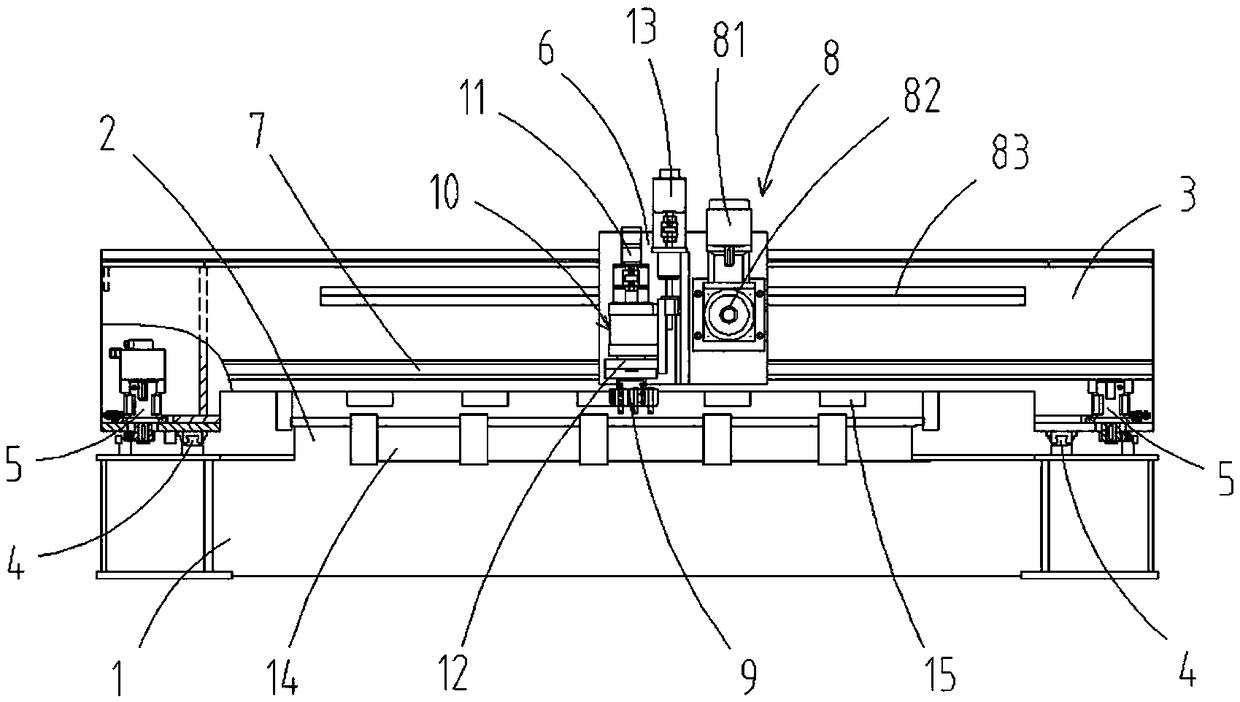

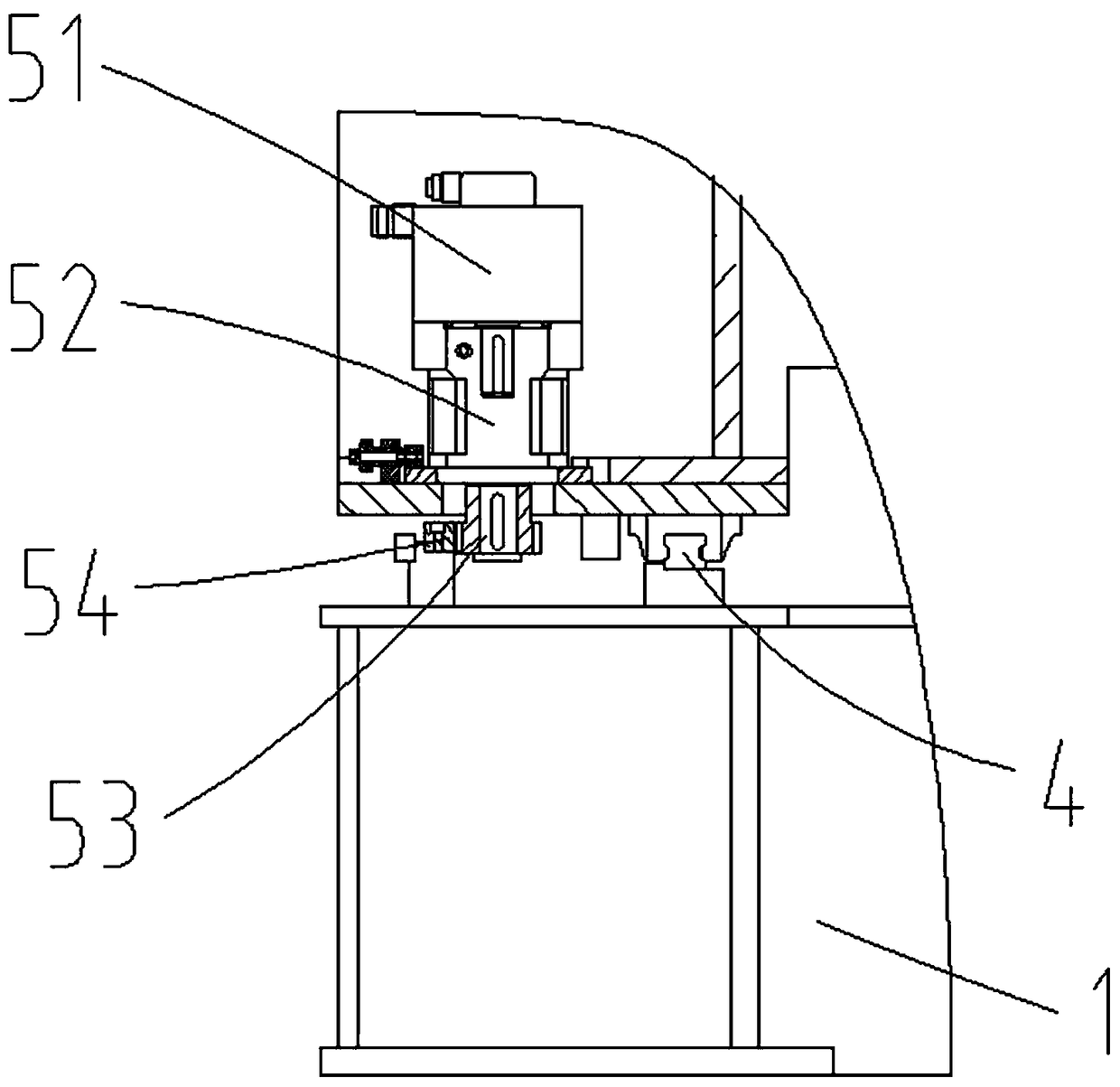

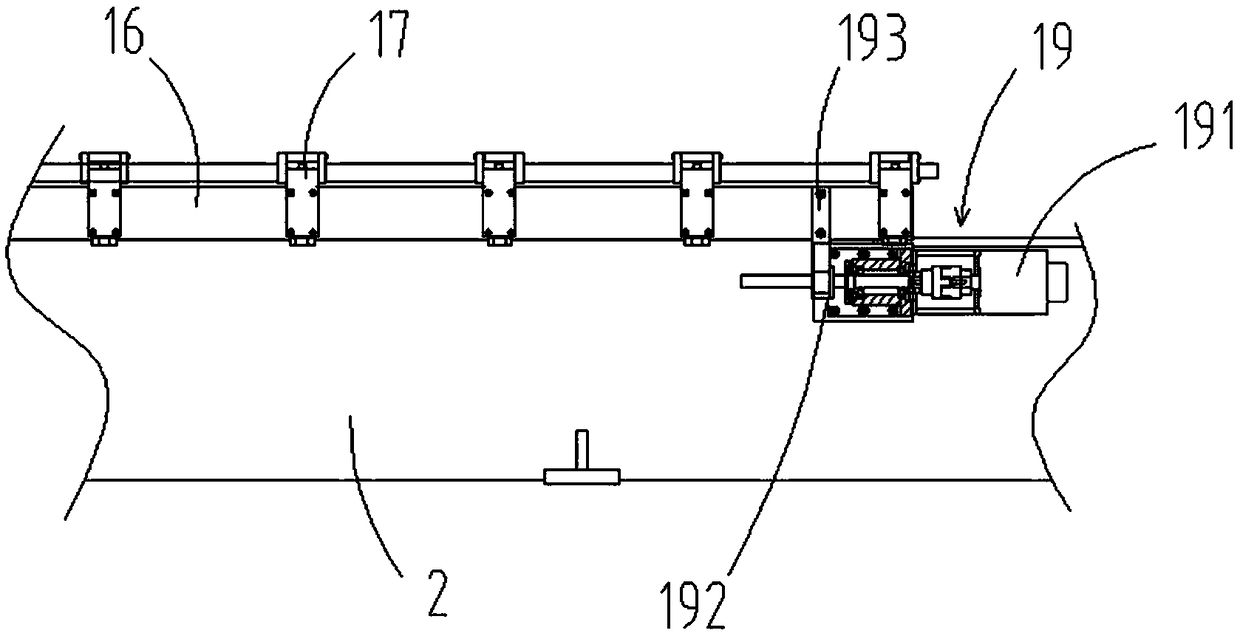

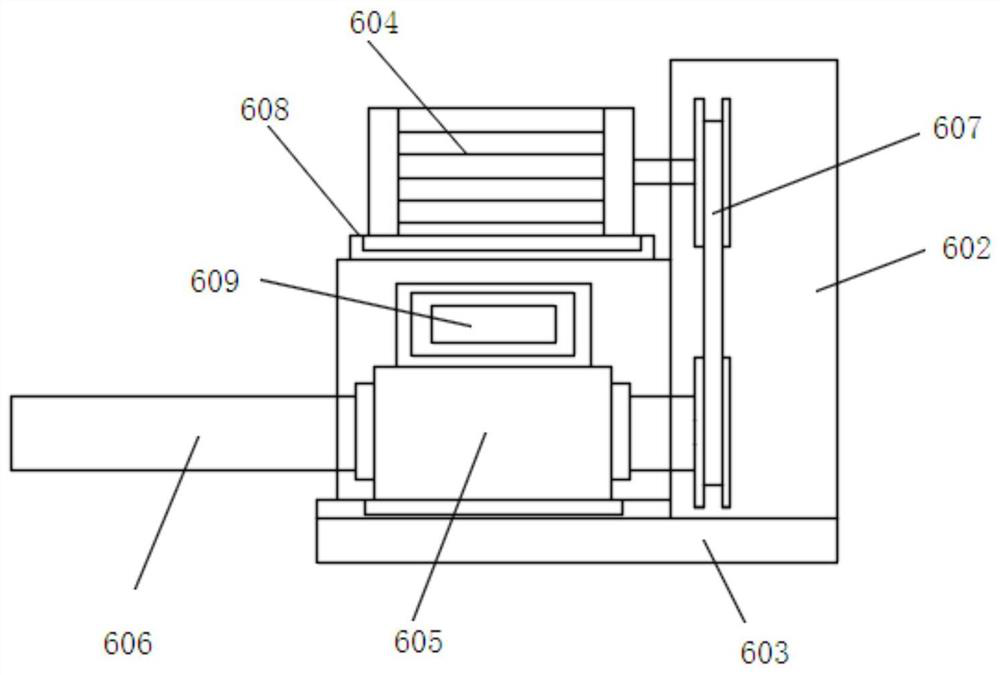

All-dimensional planar planing equipment with intelligent pressing system

ActiveCN106077784AReduce contact surfaceAutomatic height adjustmentPlaning/slotting machinesPositioning apparatusSlide plateEngineering

The invention discloses all-dimensional planar planing equipment with an intelligent pressing system. The all-dimensional planar planing equipment comprises a machine frame, a work table arranged on the upper surface of the machine frame and a moving beam suspended above the work table, wherein the two ends of the moving beam are connected to the machine frame through transverse guide rails and transverse drive devices are arranged at the two ends of the machine frame; a longitudinal sliding plate device is arranged on one side of the moving beam and is connected to the moving beam through a longitudinal guide rail; and a longitudinal driving device is arranged on one side of the longitudinal sliding plate device, a cutter box is arranged at the lower end of the longitudinal sliding plate device, and a set of cutters are arranged inside the cutter box. According to the design, bidirectional planing and slotting in the longitudinal direction and the transverse direction can be realized, inclined planing and slotting can be realized through simultaneous moving of the moving beam and the longitudinal sliding plate device, and inclined planing and slotting at different angles can be realized by controlling the moving speed of the moving beam and the moving speed of the longitudinal sliding plate device.

Owner:施泰德精密机械(太仓)有限公司

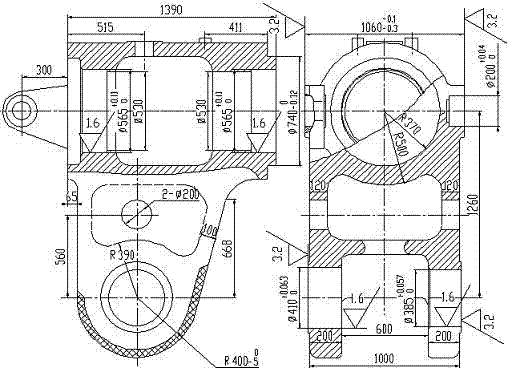

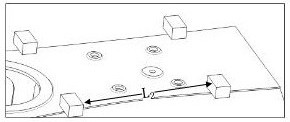

Vehicle lathe rough machining tool for upper rocker arm of vertical milled large-scale key part

InactiveCN105436959AImprove stabilityIncrease contactWork clamping meansPositioning apparatusLathe faceplateMachine tool

The invention discloses a vehicle lathe rough machining tool for an upper rocker arm of a vertical milled large-scale key part. The vehicle lathe rough machining tool comprises a tool base parallel to a vertical lathe faceplate. Tool clamping jaw clamping positions are arranged in one end of the tool base in the four directions respectively and used for allowing clamping jaws in the center of the faceplate to clamp and fix the tool base. A shaft hole positioning block is connected with the top face located at the end of the tool base. The shaft hole positioning block is further sleeved with a replaceable shaft hole positioning ring. The shaft hole positioning block and the shaft hole positioning ring are used for extending into an upper rocker arm shaft hole and supporting a first step of an inlet of the shaft hole through the shaft hole positioning ring. A height-adjustable pressing plate is further connected with the center of the top of the shaft hole positioning block through a tool pressing bolt and a nut. During usage, the pressing plate is tightly pressed on an inner cavity of the upper rocker arm shaft hole and position the shaft hole together with the shaft hole positioning block. Two height-adjustable supporting bolts and nuts are symmetrically installed on the other end top face of the tool base relative to the central axis of the other end face and used for supporting the long-arm end of the upper rocker arm. After usage, the production efficiency is remarkably improved, and the production cost is greatly reduced.

Owner:SINOMA TECH (XUZHOU) HEAVY MASCH CO LTD

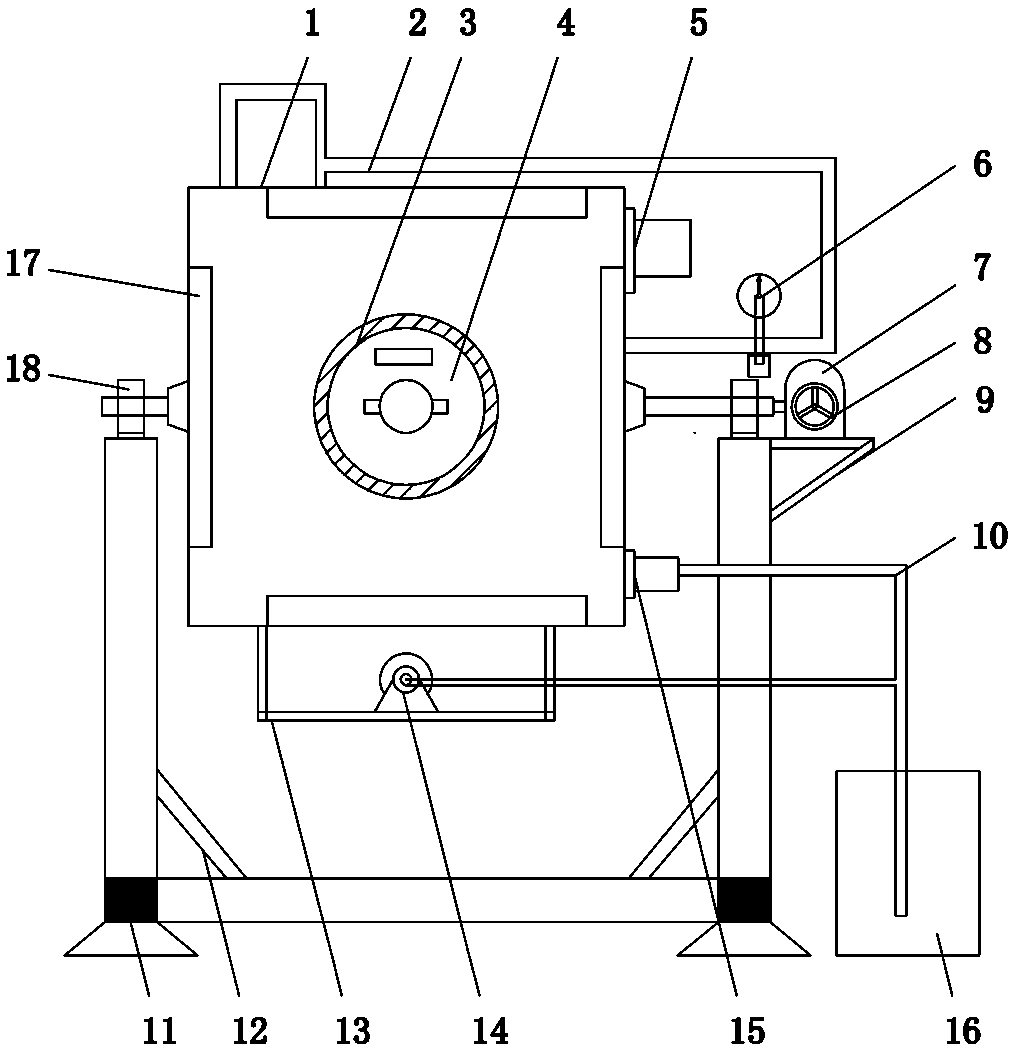

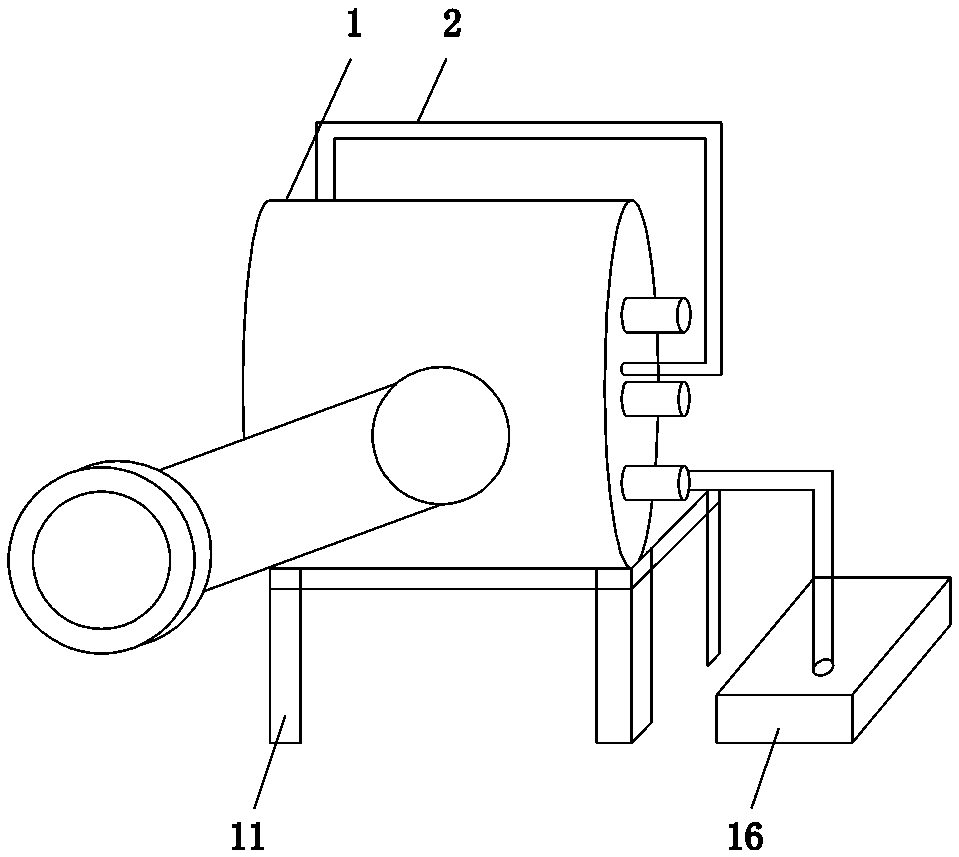

Workpiece painting processing equipment

ActiveCN107755176AAvoid wastingImprove processing efficiencyPretreated surfacesCoatingsSprocketPulley

The invention relates to workpiece painting processing equipment which comprises a control mechanism and an execution mechanism, wherein the control mechanism is positioned above the execution mechanism and comprises a cross beam, two fixed pulleys, a fan, a rotation motor, a chain, a vent hood and a vent hose; the two fixed pulleys and the rotation motor are fixed on the cross beam; the rotationmotor is arranged between the two fixed pulleys; the chain is wound on the two fixed pulleys; a chain wheel meshed with the chain is fixed on a rotation shaft of the rotation motor; the rotation shaftof the rotation motor is coaxially connected with the fan; the vent hood is arranged outside the two fixed pulleys and the rotation motor; two ends of the vent hood are connected with the vent hose respectively; a free end of the vent hose is level with the chain; a working mechanism comprises two working grooves and a balance hose; the two working grooves are fixedly connected with two ends of the chain respectively and are communicated through the balance hose. By adopting the technical scheme of the invention, the two working grooves can work circularly while a workpiece can be dried. Therefore, the workpiece painting processing equipment provided by the invention can be widely applied to the processing technologies for workpiece painting.

Owner:重庆达小丰机械有限公司

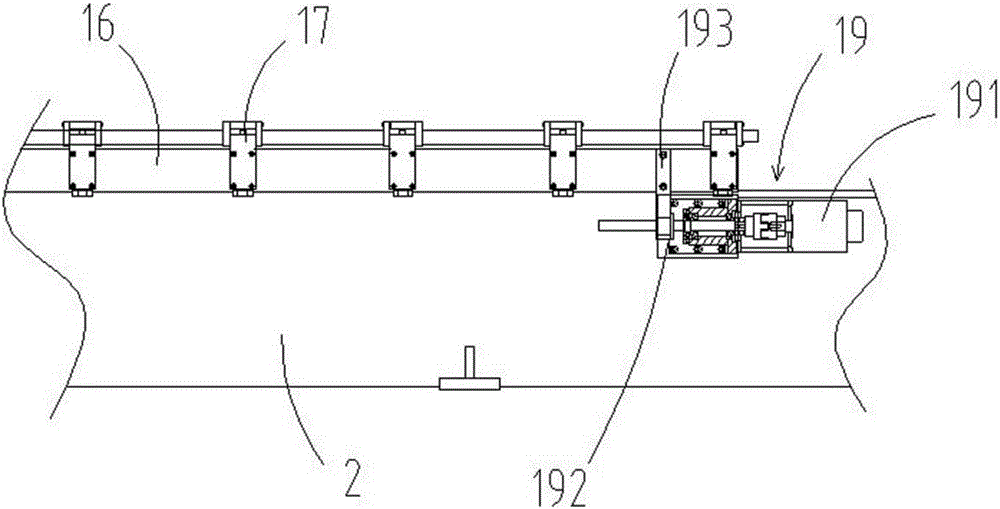

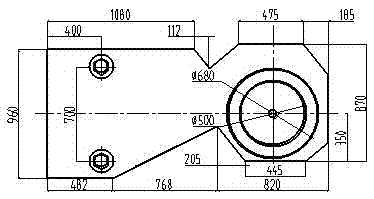

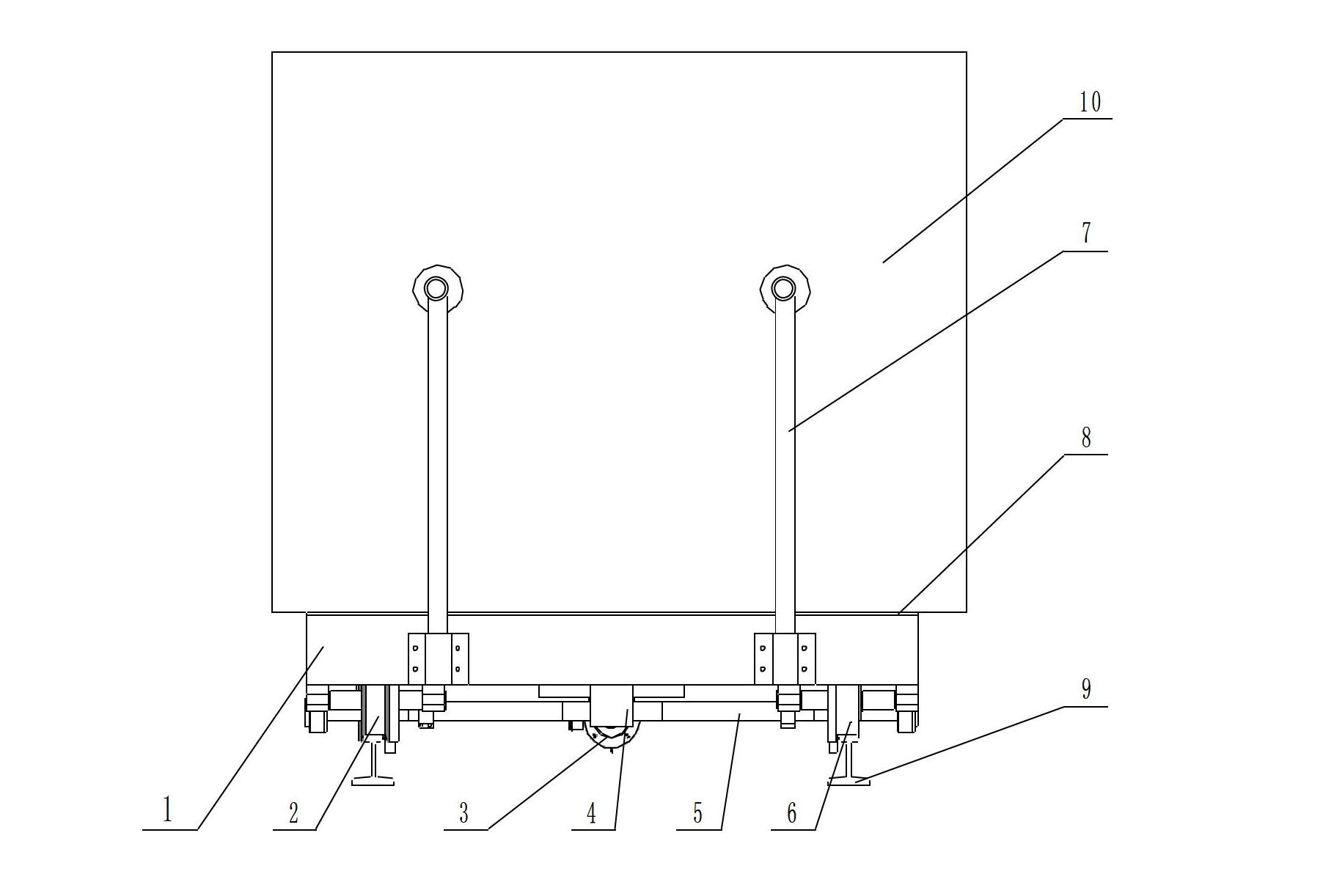

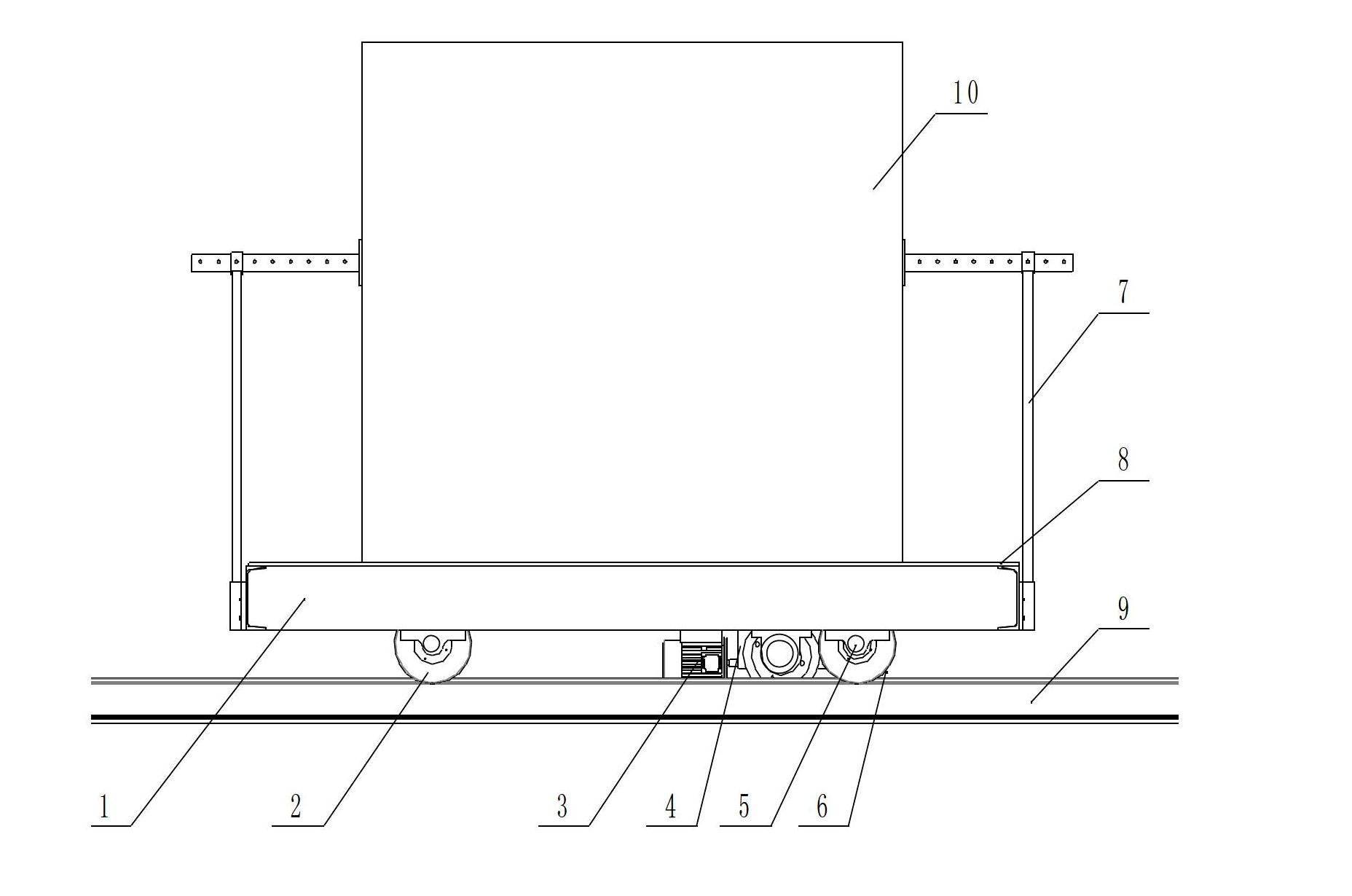

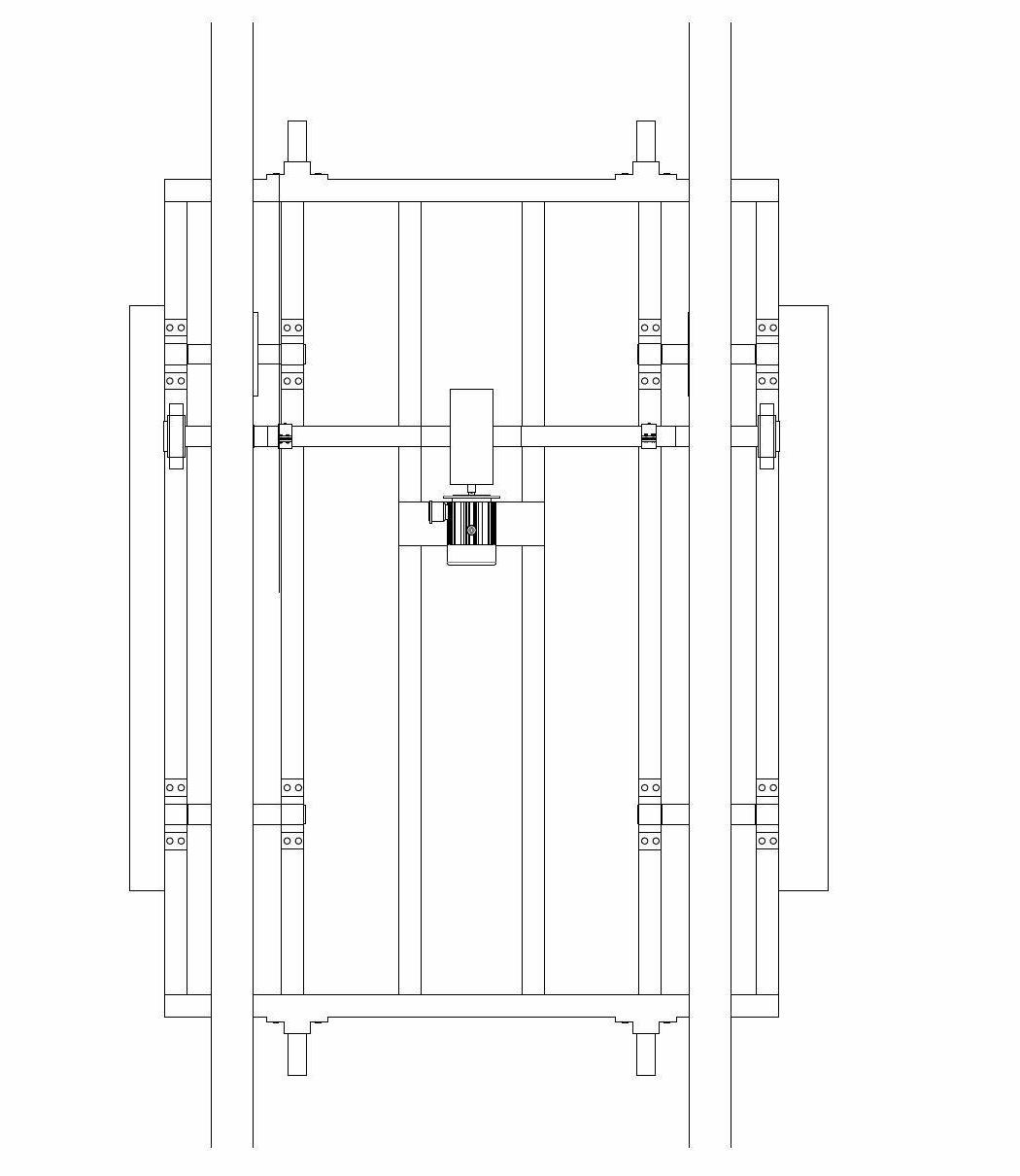

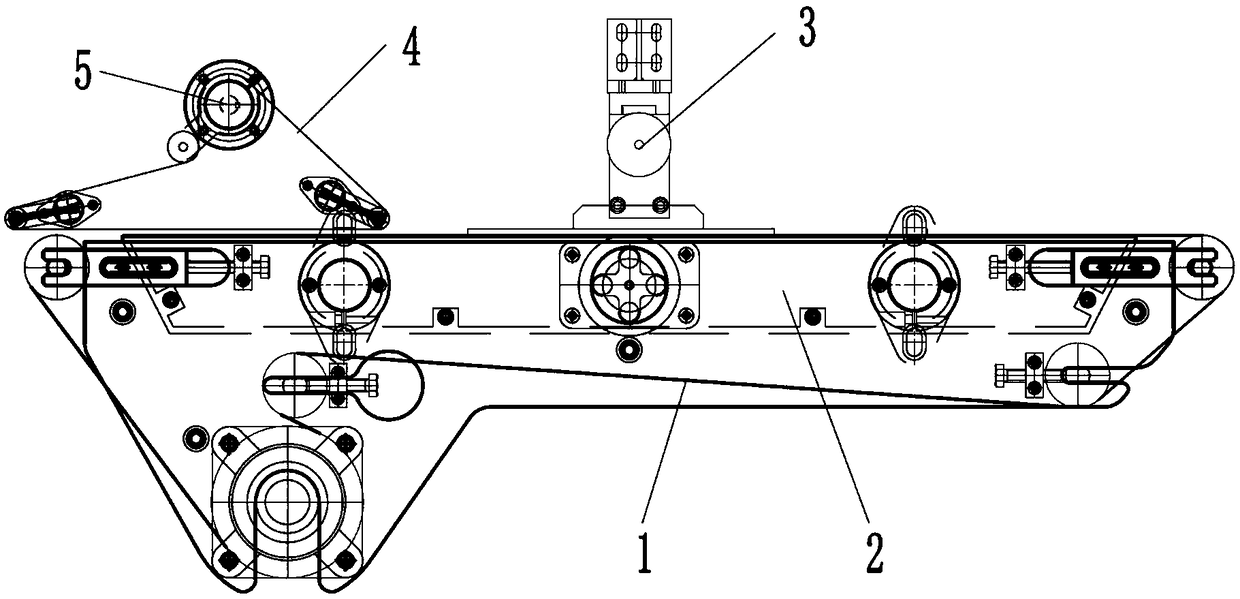

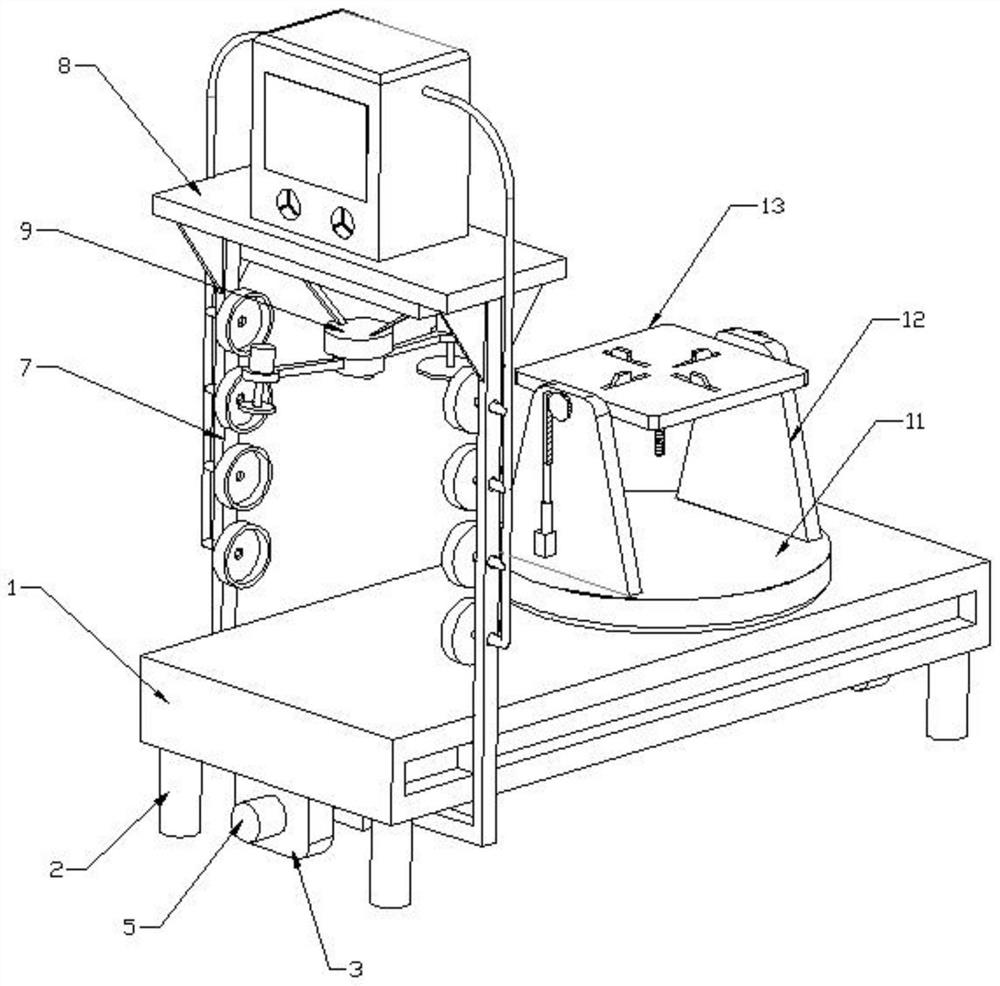

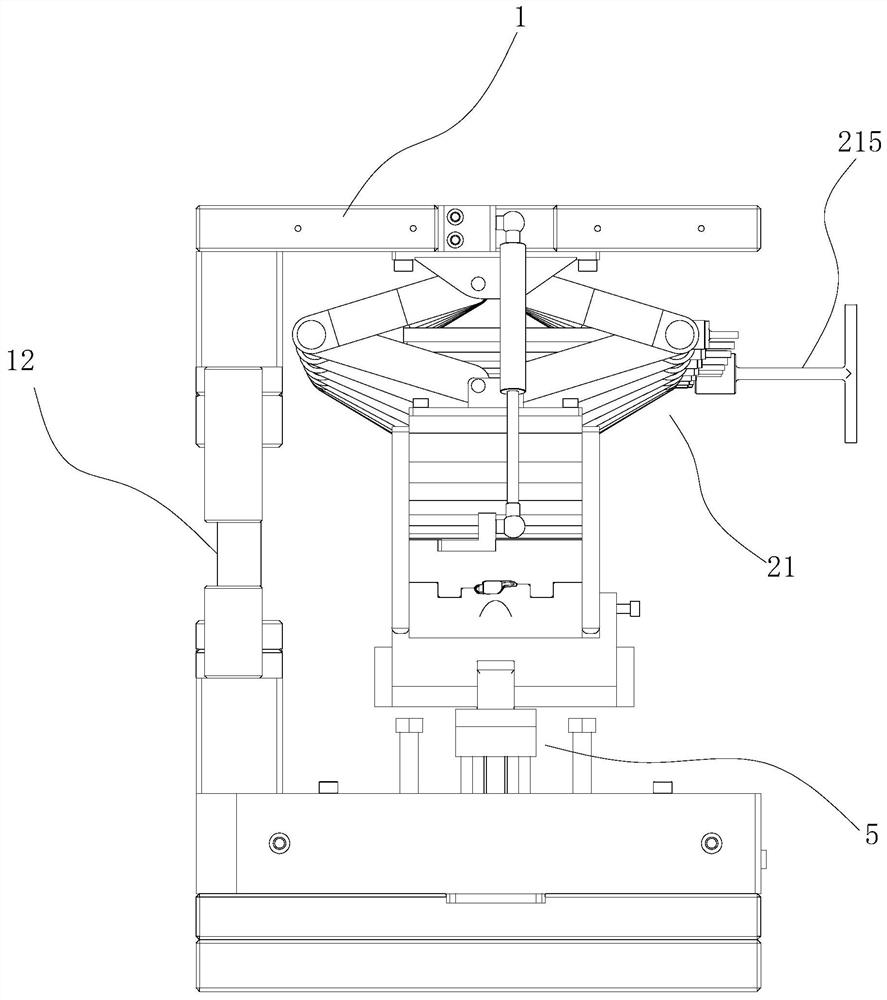

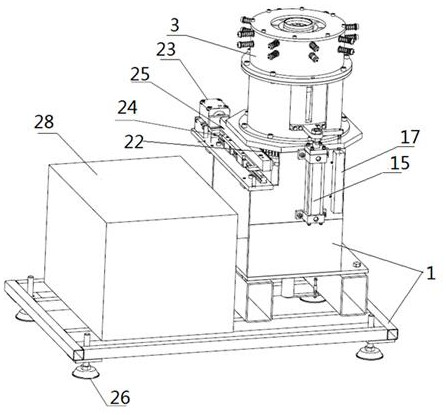

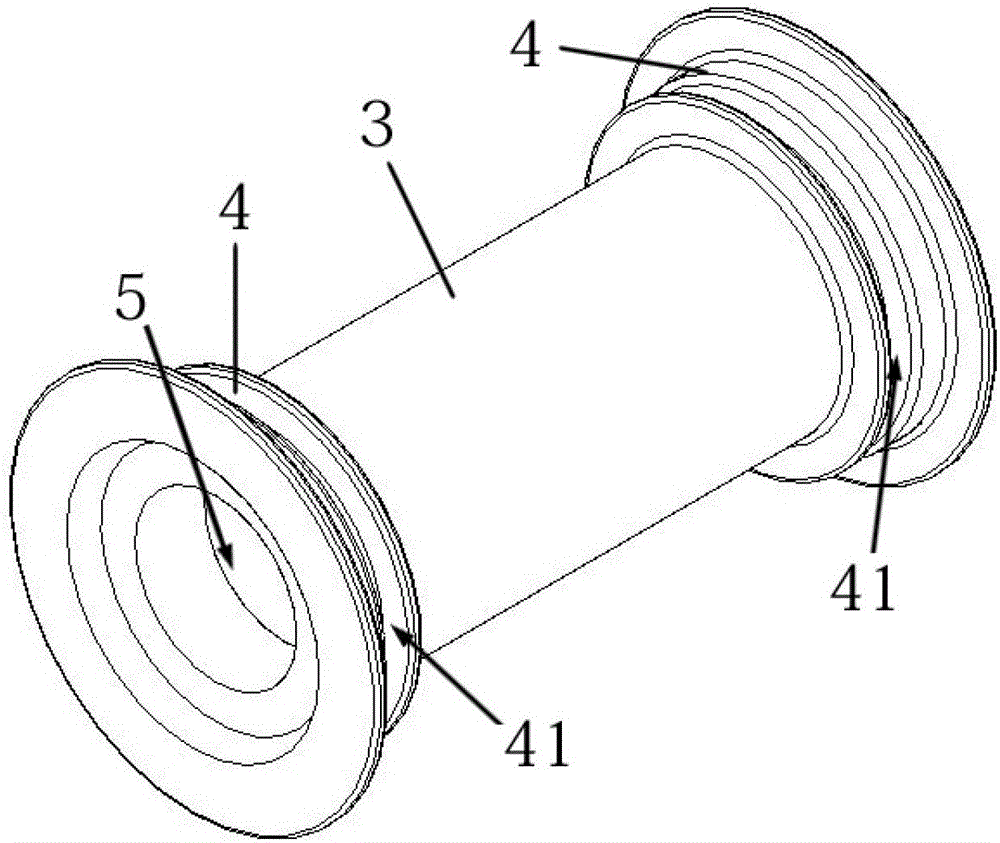

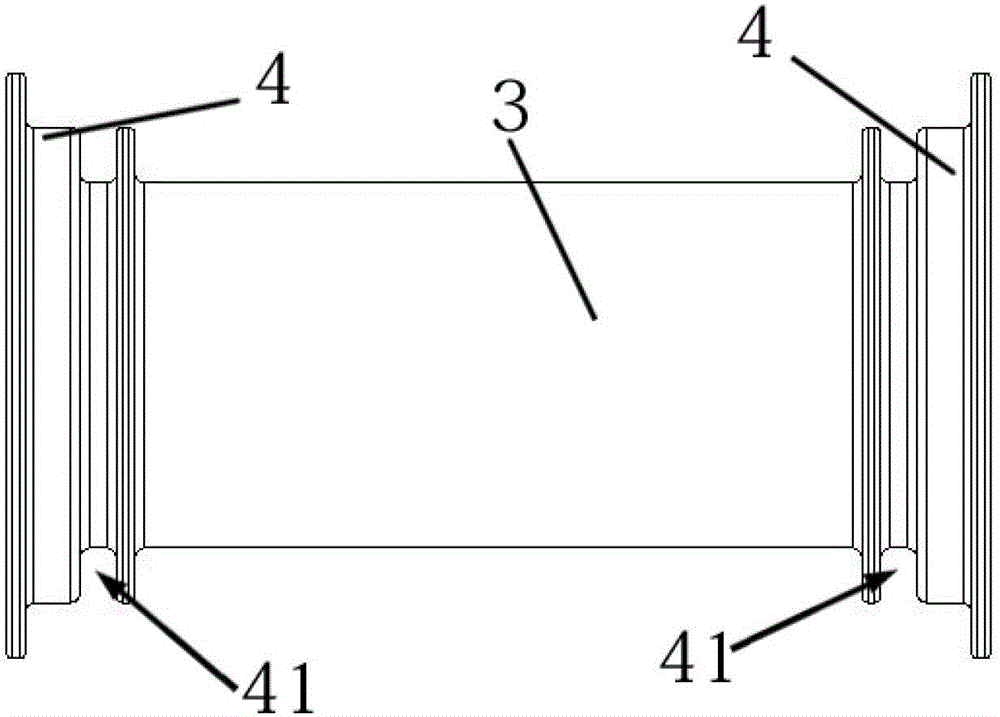

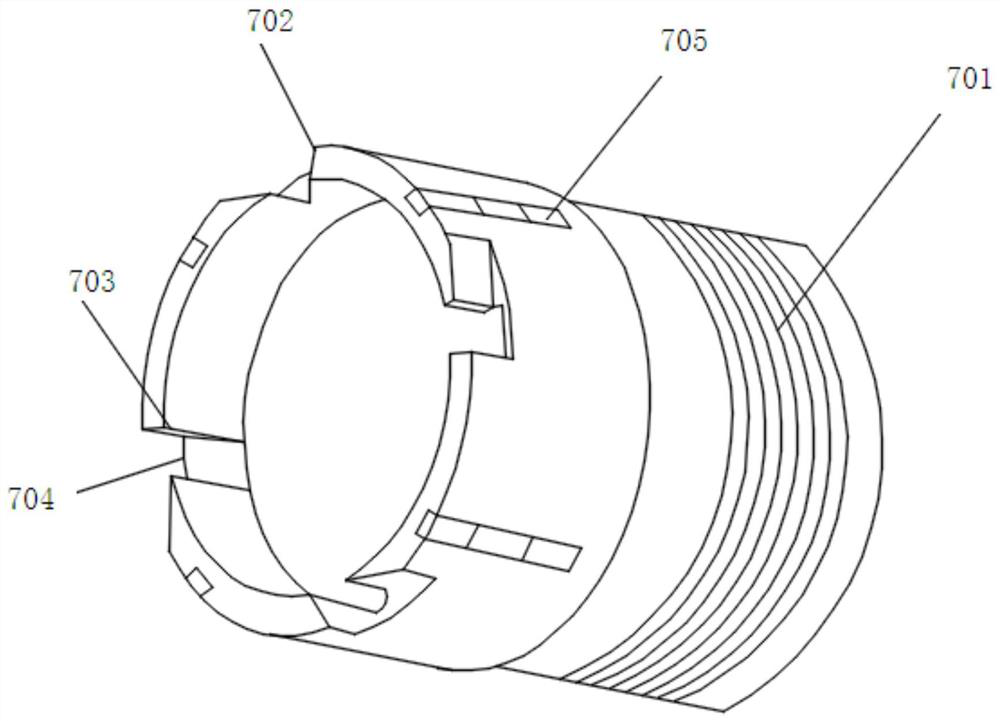

Novel block car mechanism for multi-rope diamond wire-saw

InactiveCN102689778APrevent free movementStable and reliable processingMechanical conveyorsDiamond wire sawEngineering

The invention discloses a novel block car mechanism for a multi-rope diamond wire-saw, and the mechanism comprises a car body. A motor is arranged below the car body; the motor is connected with a reduction box; the reduction box is connected with a transmission shaft; the transmission shaft is connected with the car body through a bearing; the transmission shaft is connected with a driving wheel arranged on a lead rail; a clamping mechanism is also arranged on the car body; the clamping mechanism comprises vertical rods fixed at two ends of the car body, and the upper ends of the vertical rods are connected with an adjusting rod. The block is arranged on a block car loading bench in use, and the moving part of the clamping mechanism is adjusted according to the size of the block; the degree of freedom of the stone block is restrained, and the motor drives the driving wheel to move on the lead rail, so the block car achieves a processing position of the blocks. The novel block car mechanism for the multi-rope diamond wire-saw can be used for effectively preventing the block from freely moving in a machining process by adjusting the size of the clamping part of the block, so the entire machining process is stable and reliable.

Owner:SHANDONG UNIV

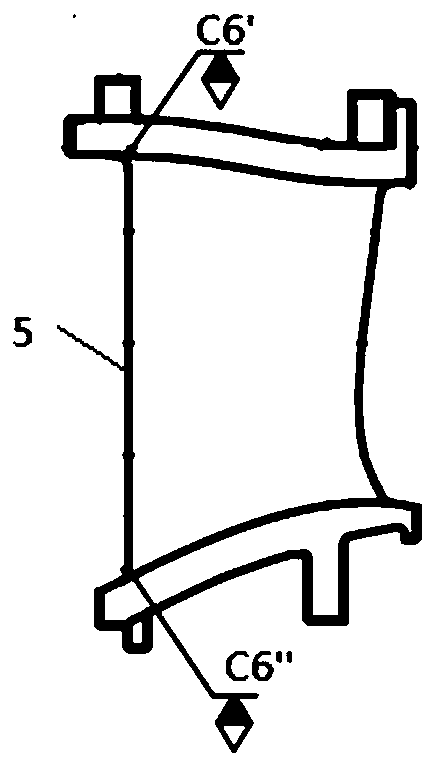

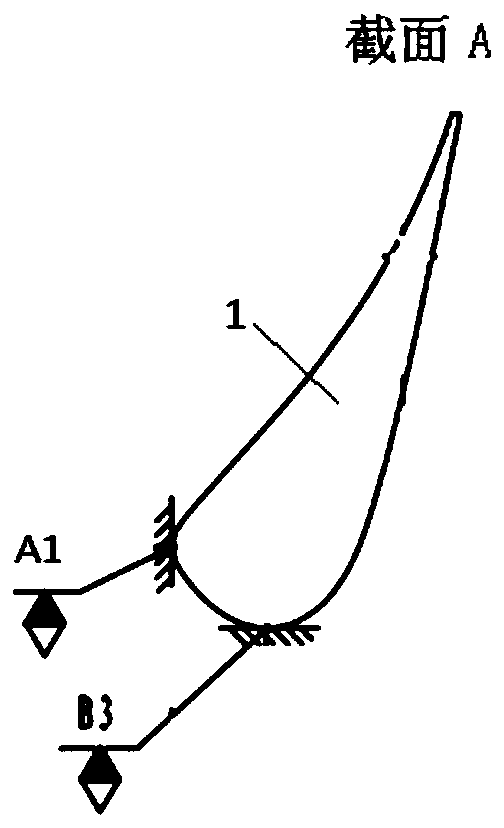

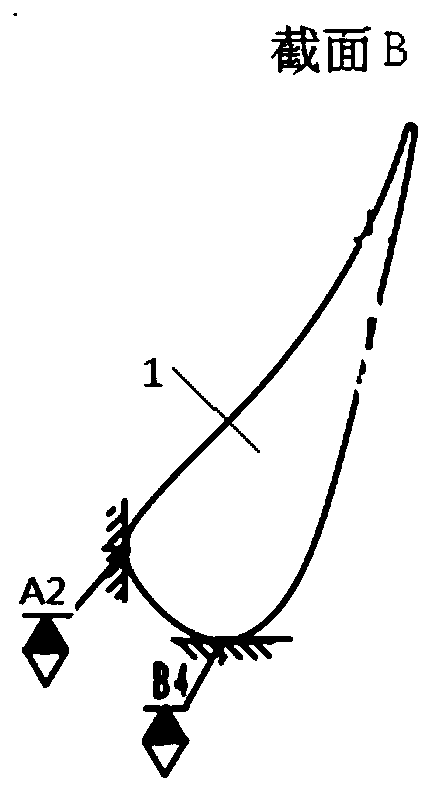

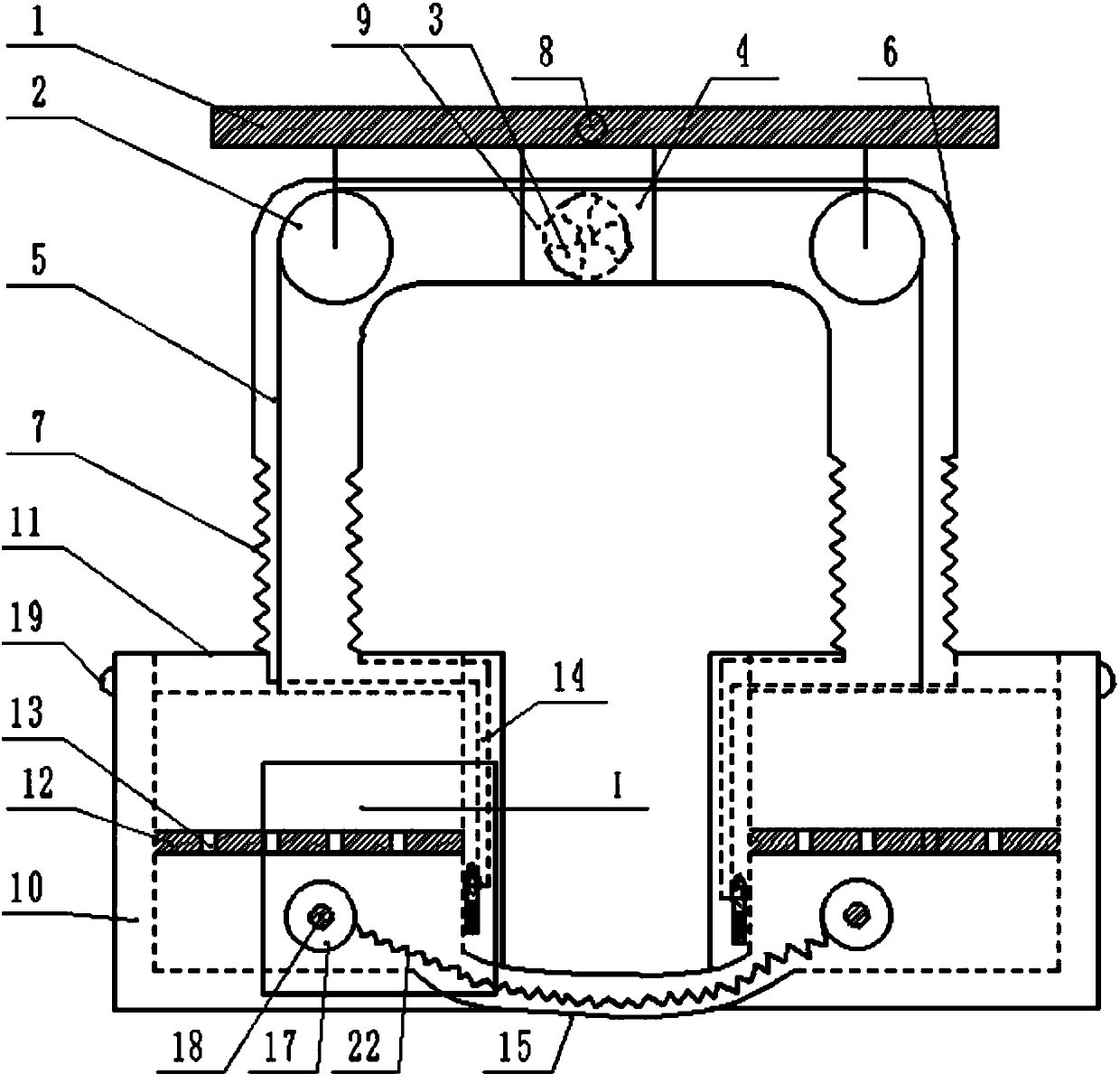

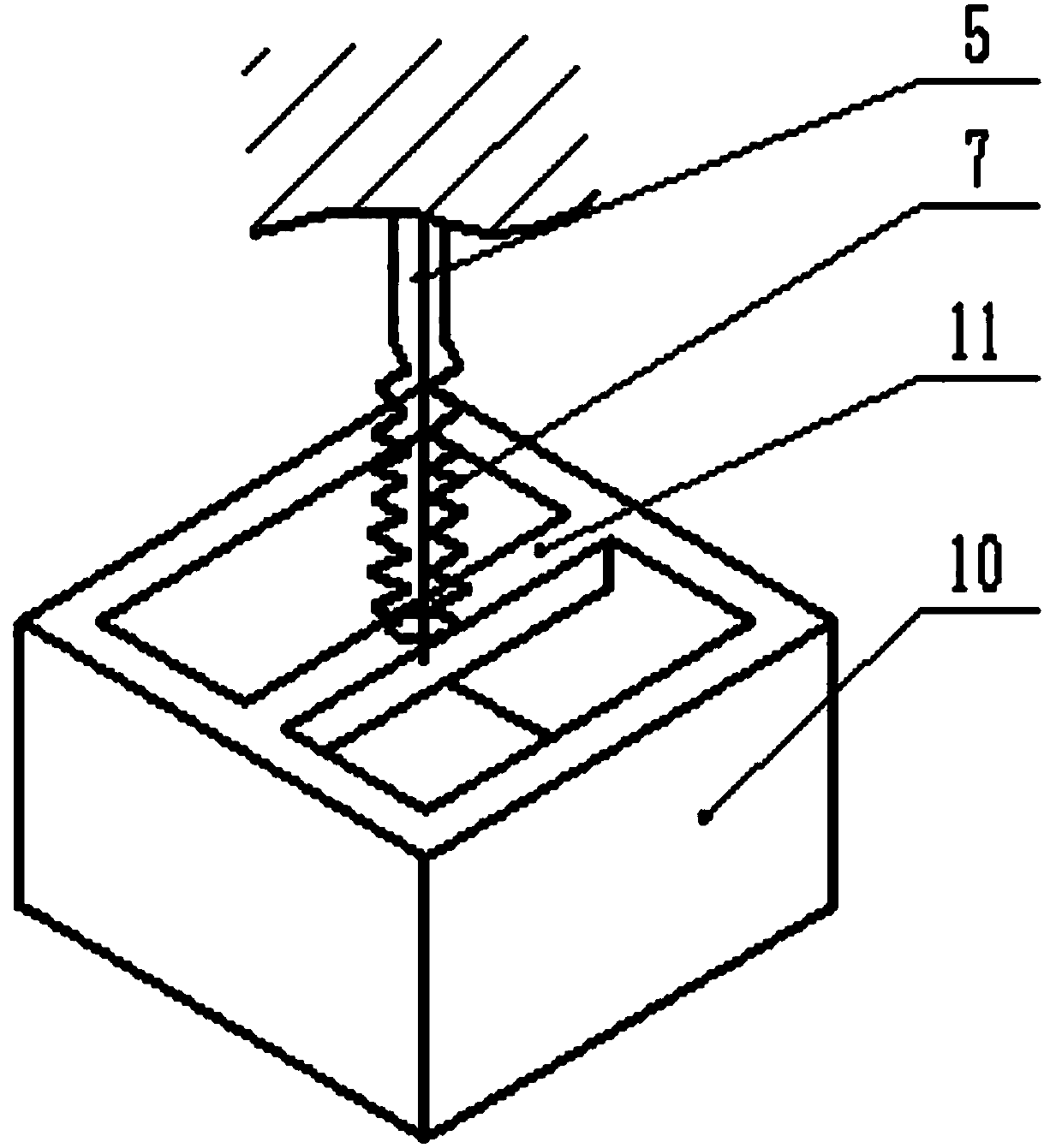

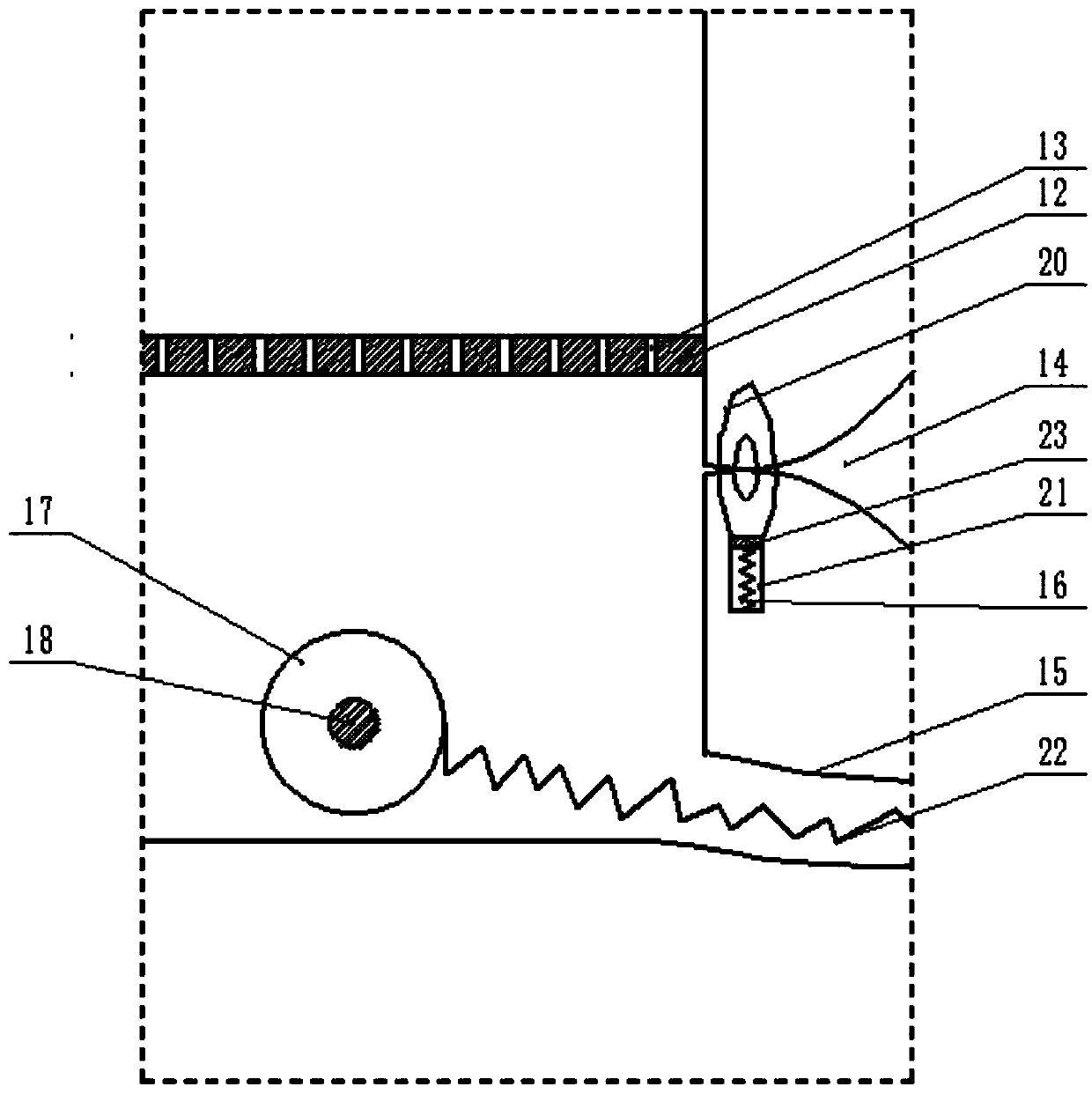

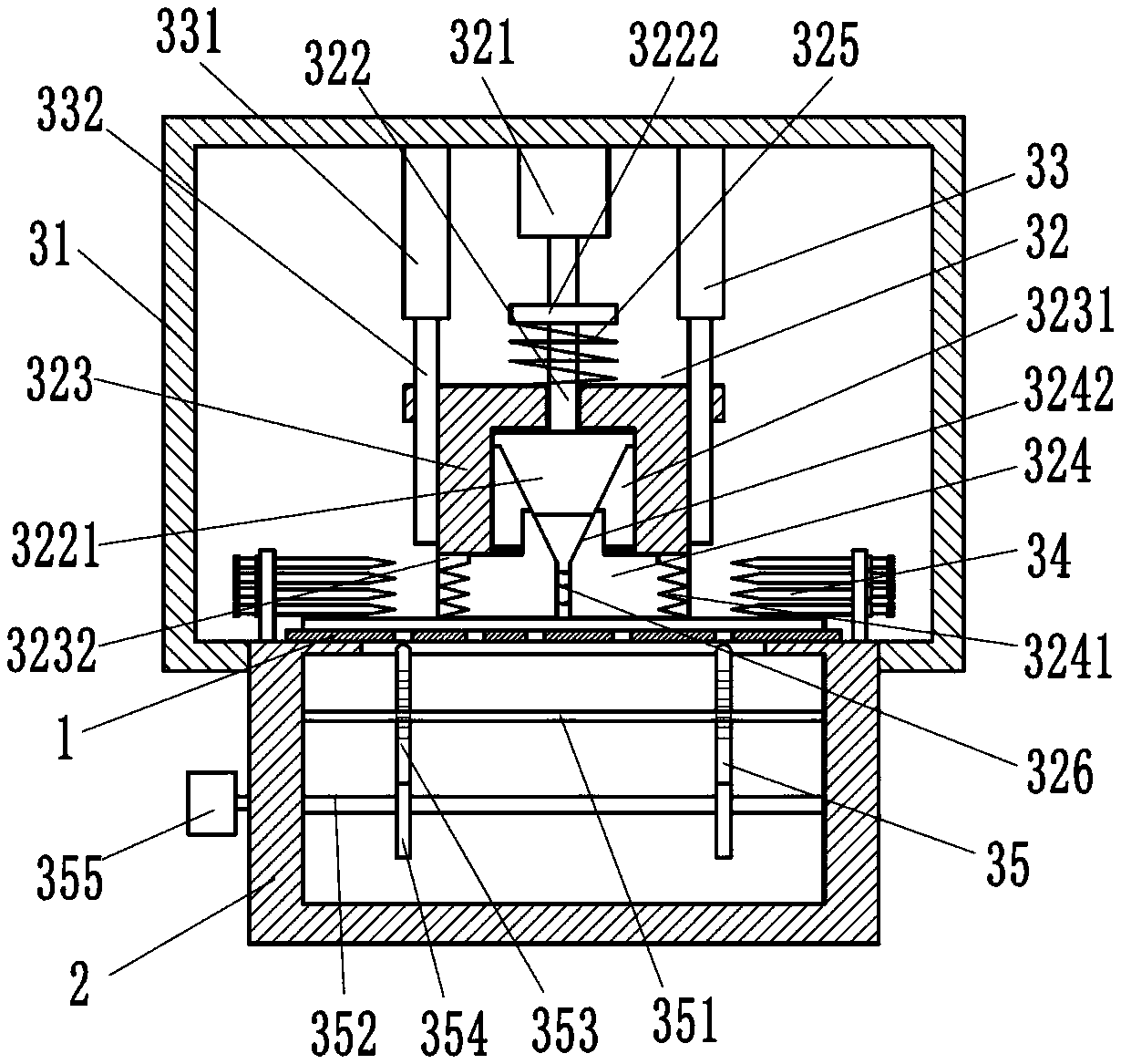

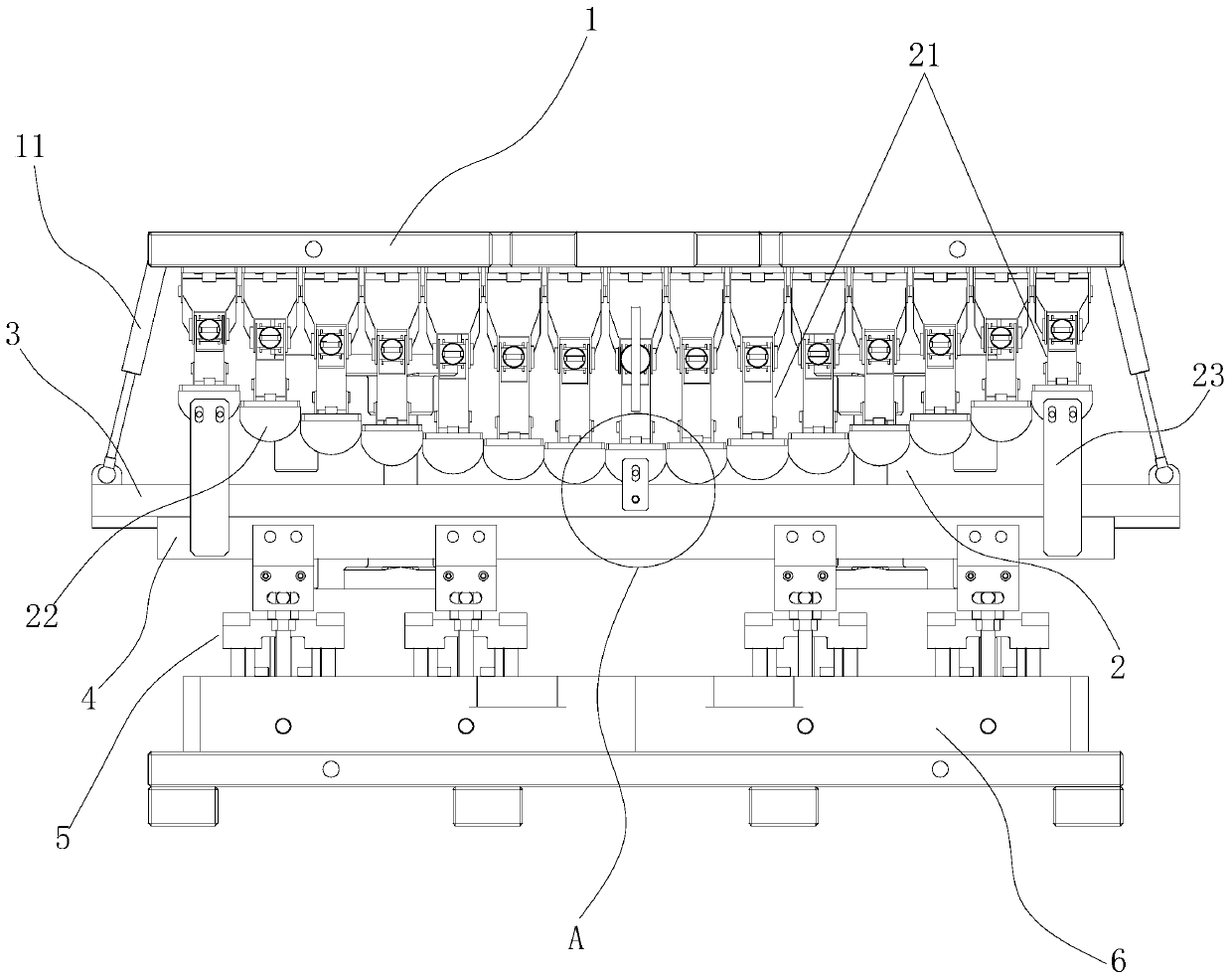

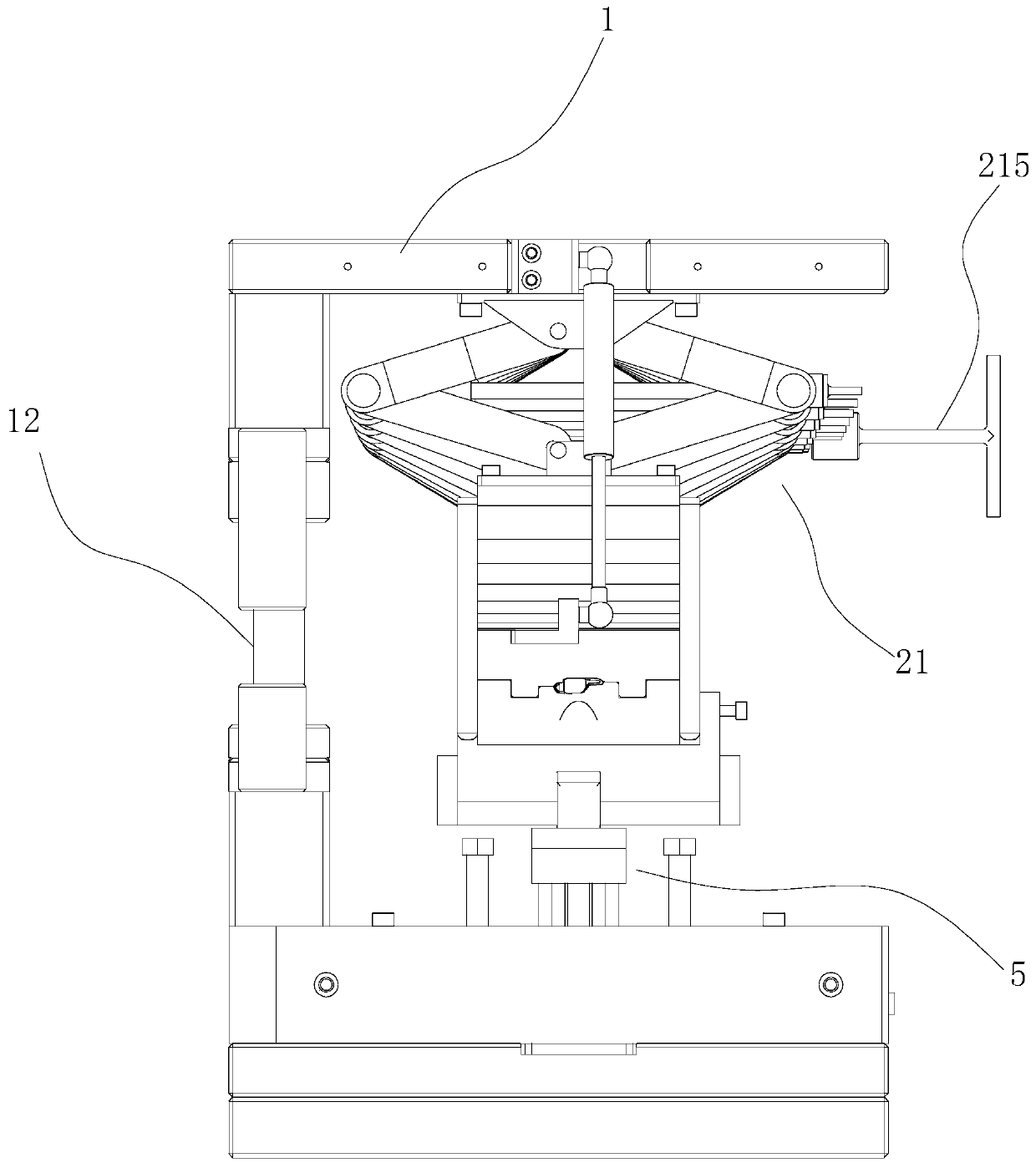

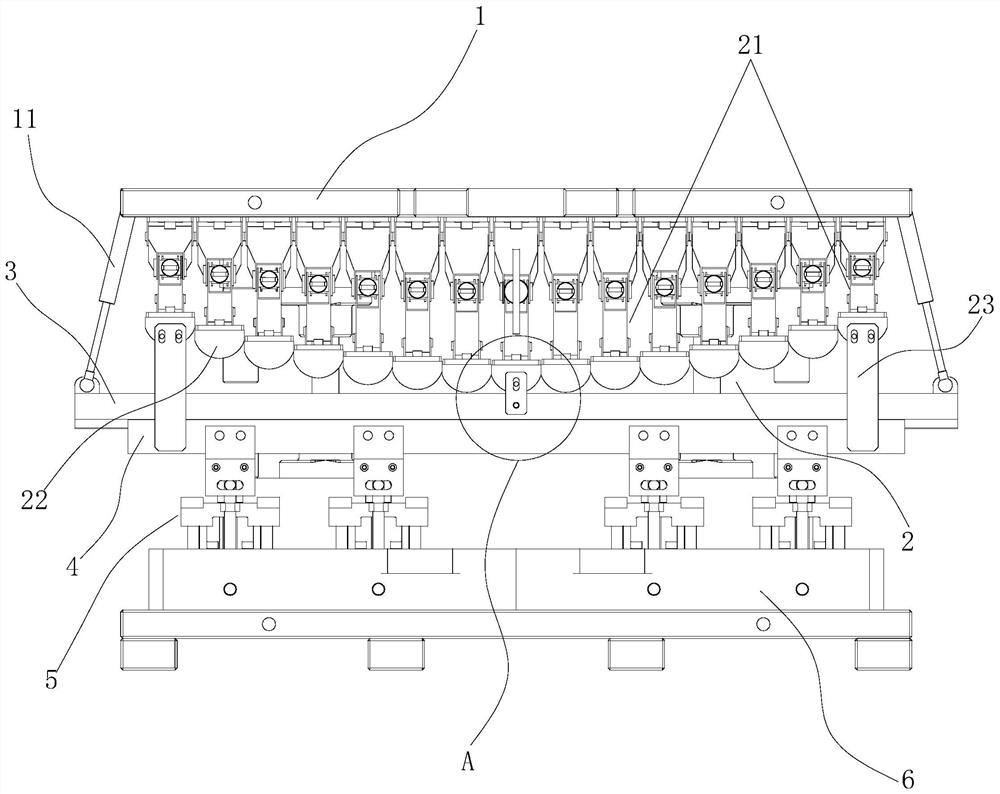

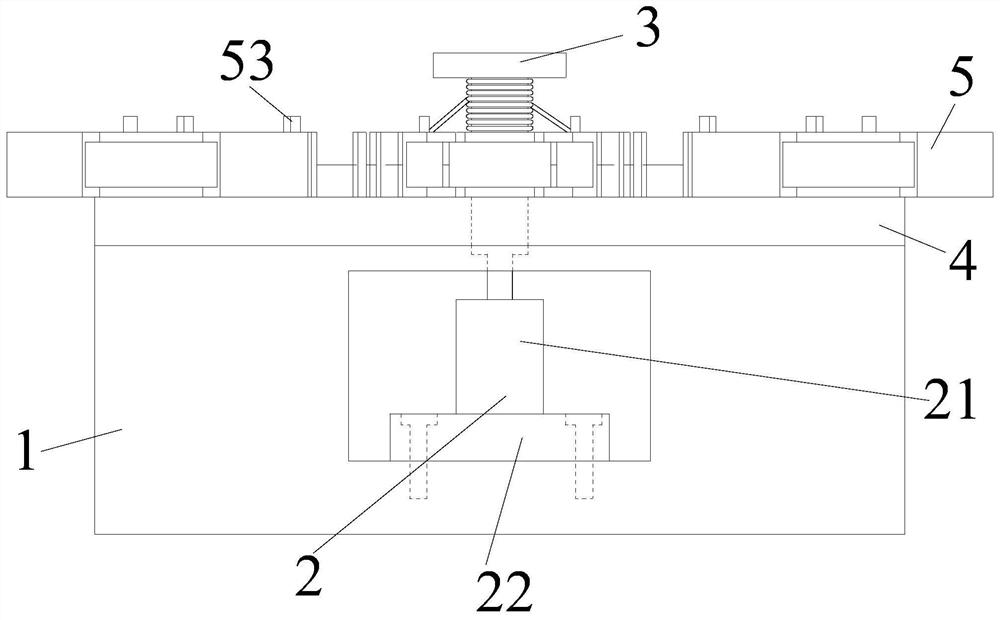

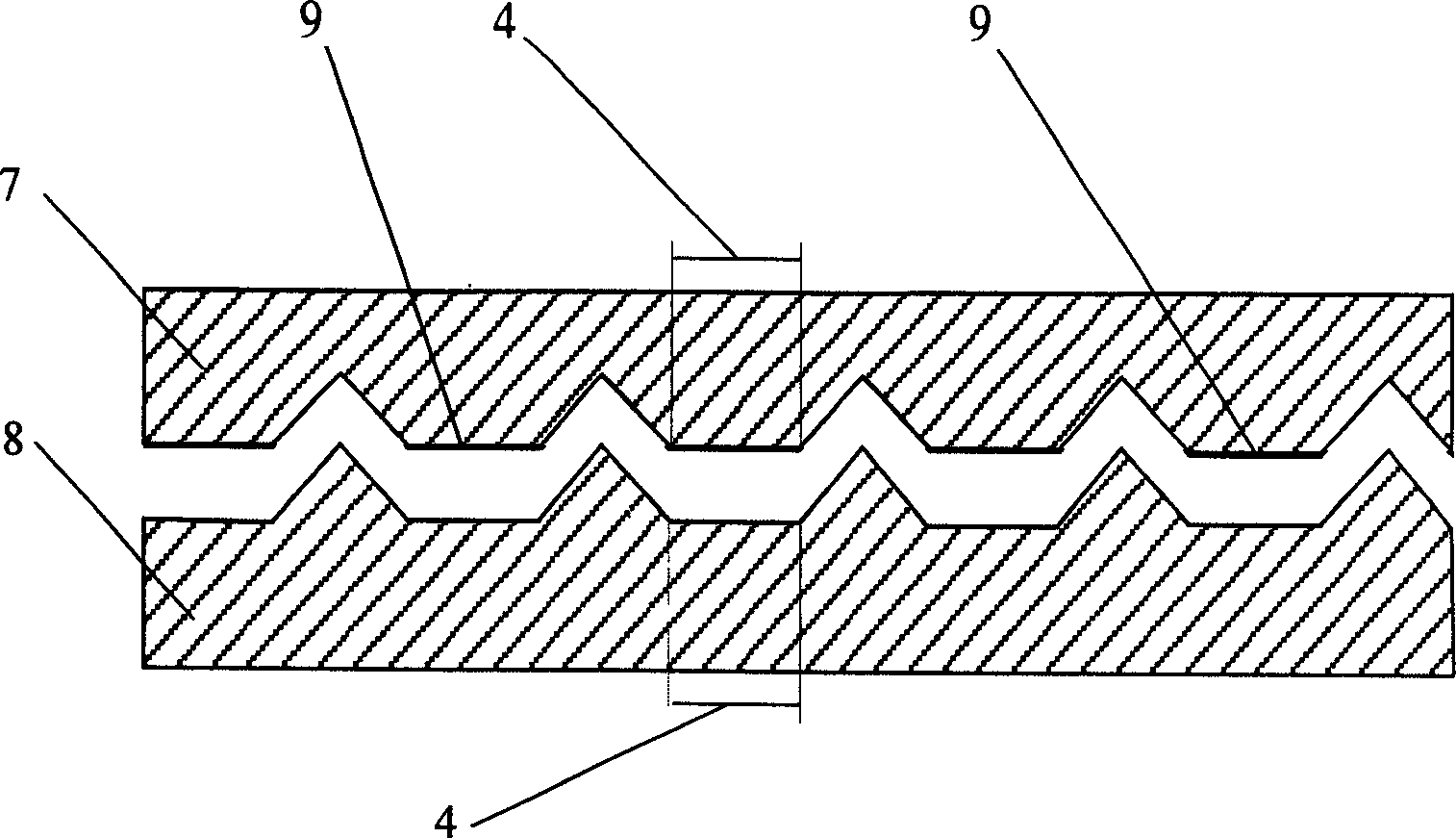

Folding and forming device for lifting part

InactiveCN109009677AStable processingStable and reliable processingSanitary towelsBaby linensEngineeringPortal frame

The invention provides a folding and forming device for a lifting part. The folding and forming device comprises a rack, a conveying belt, a conveying air box, a folding mechanism and a press-conveying belt, and the conveying belt, the conveying air box, the folding mechanism and the press-conveying belt are arranged on the rack. The folding mechanism comprises a portal frame arranged on the rack,a pressing assembly arranged on the portal frame, a flanging assembly arranged in a negative pressure cavity of a conveying air box, and a pair of folding cutter assemblies arranged on the rack. Thepressing assembly comprises a pair of modules arranged slidingly, and a plurality of tooth grooves are formed in the outer side face of the module. The flanging assembly comprises a pair of push plates, the push plates can penetrate through holes located in the conveying belt to move upwards, and two side wings of the lifting part are limited between the corresponding push plates and the corresponding modules respectively. The folding cutter assembly comprises a plurality of parallel blades, and the blades sequentially penetrate through corresponding channels located on the corresponding pushplates to be meshed with the corresponding tooth grooves to achieve folding of the side wings of the lifting part. According to the folding and forming device, the folding section of the lifting partcan be stably and continuously processed, and use is reliably.

Owner:SONGJIA QUANZHOU MACHINERY

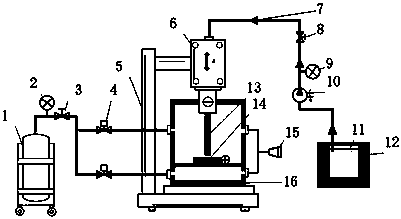

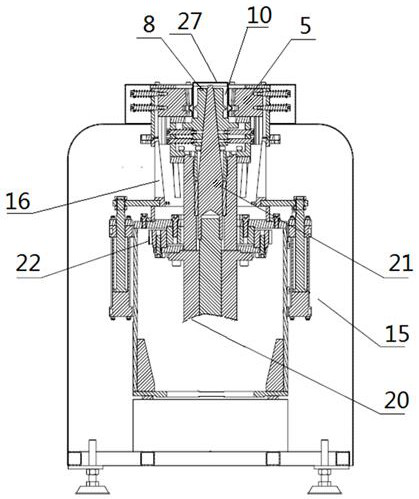

Ultrasonic-assisted precision electrolytic grinding system and method for turbine mortise

ActiveCN110524377AStable and adjustable electrolytic machining parametersTimely updateGrinding machinesAutomatic grinding controlWorking fluidElectrolysis

The invention discloses an ultrasonic-assisted precision electrolytic grinding system and method for a turbine mortise, and belongs to the technical field of electrolytic grinding combined machining.According to the present invention, during the process of electrolytic grinding the turbine mortise, a multi-dimensional ultrasonic vibration effect is added, a working fluid flow field in a gap is improved, the loss of a tool grinding wheel is reduced, and the high-quality and low-cost machining of the turbine mortise structure are realized. The ultrasonic-assisted precision electrolytic grindingsystem is constructed, and all-direction vibration of multi-dimensional ultrasound is regulated and controlled through a control computer, the follow-up ultrasonic vibration effect of the tool grinding wheel in a feeding direction is achieved and is coupled with the parameters of an electrolytic machining pulse power source, so that the stability of the machining process is guaranteed, and the reliable guarantee is provided for the application and popularization of the electrolytic grinding machining technology in the turbine mortise structure machining process. By replacing the tool grindingwheels and the working fluid nozzles of different structures, the system and the method are suitable for the precision machining of the turbine mortise structures of different types.

Owner:YANGZHOU UNIV

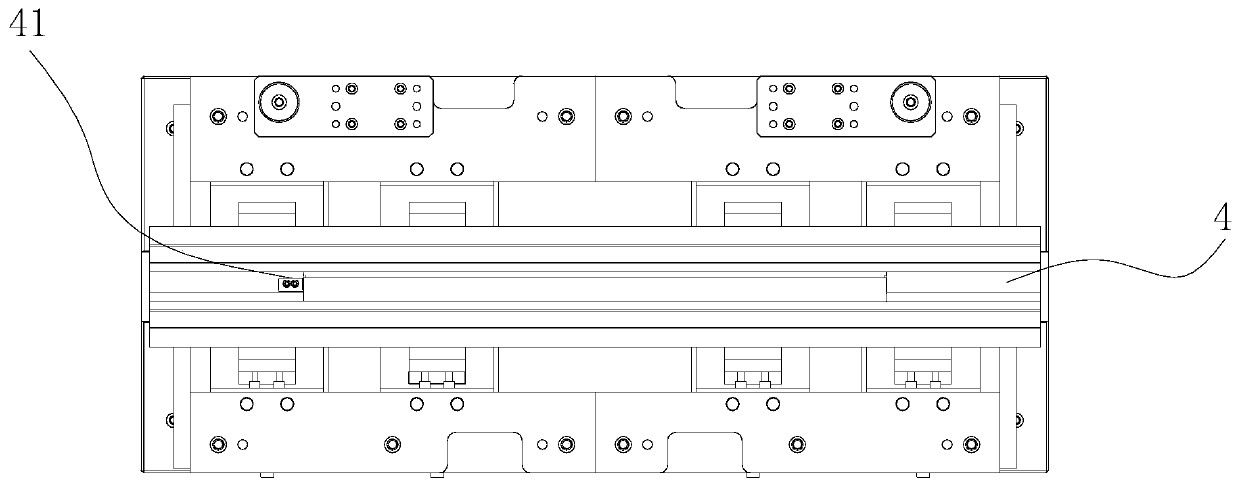

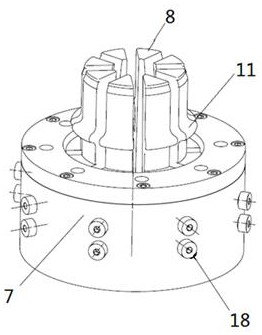

Clamping system

InactiveCN114227308AAvoid damageStable processingPositioning apparatusMaintainance and safety accessoriesEngineeringMachining process

The clamping system comprises a main box body, a rotating plate is rotationally arranged on the upper end face of the main box body, the lower end face of the rotating plate is tightly attached to the main box body, a rotating shaft is rotationally connected to the inner circle of the center of the rotating plate, a rotating cavity is formed in the main box body, a rotating assembly is arranged in the rotating cavity, and the rotating assembly is used for controlling the rotating angle of the rotating plate. By means of the design of the clamping fixture, the content optimization of the clamping and machining problem of complex parts in work is achieved, the machining position of the parts can be accurately positioned, the machining efficiency is improved, the machining precision is improved, and the machining efficiency is improved. The parts are prevented from shaking and being damaged in the machining process, the parts which are complex and difficult to clamp are accurately clamped, different parts of the parts are fixed according to the shapes of the parts and different degrees of ascending and descending of surface contacts, the parts are stable and reliable in the machining process, meanwhile, the machining time is shortened, and the machining efficiency is improved.

Owner:孙璐

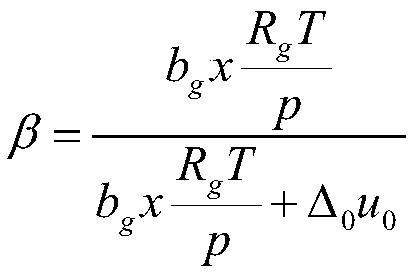

Low-temperature precision electrolytic machining method

InactiveCN110394519APromote localizationAdd nonlinearityMachining working media supply/regenerationElectrolysisMachining

The invention discloses a low-temperature precision electrolytic machining method, and belongs to the field of special machining. The method is characterized in that a machining area is in a low-temperature environment, and the temperature can be as low as zero DEG C or lower; a specific electrolyte is prepared, the freezing point of the specific electrolyte is lower than zero DEG C, and thus thefluidity can still be kept in the low-temperature environment; during machining, a workpiece and a tool can be placed in the low-temperature environment, meanwhile, in order to strengthen the freezingeffect, the workpiece can be placed on a specially-made low-temperature clamp, and an inner cooling device can be installed in the tool, so that further cooling of the workpiece and the tool is realized; or an auxiliary conductive ice layer or an auxiliary non-conductive ice layer is frozen in the machining area or a non-machining area of the workpiece, and low-temperature electrolytic machiningassisted with the ice layer is carried out. Under a low-temperature condition, the ion movement capacity in a solution is weakened, the non-linearity of the electrolyte is remarkably enhanced, the electrolytic machining defects such as stray corrosion and pitting corrosion can be reduced or eliminated, and the machining locality is improved, so that precise and ultra-precise electrolytic machiningis realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mounting edge repairing method

ActiveCN113732616AGuaranteed StrengthImprove adhesionStructural engineeringUltimate tensile strength

The invention provides a mounting edge repairing method, which comprises the following steps: step 1, turning a mounting edge; step 2, spraying a KF306 coating on the inner spigot of the lathed mounting edge; step 3, turning the sprayed mounting edge; and step 4, trimming an over-spraying face, and completing repairing of the mounting edge. By means of the method, the inner spigot of the mounting edge of a fan casing is subjected to supplementary machining, on one hand, the size requirement can be met, on the other hand, the strength and service life requirements of the fan casing are met, high-value fan casing parts are saved, cost is greatly saved, and waste of resources is avoided. Due to the fact that the mode that the sprayed mounting edge is turned with higher efficiency is adopted by summarizing past experiences and conducting on-site repeated tests, the repair time is well controlled, and the requirement for the production cycle of overhaul of the fan casing can be met.

Owner:AECC AVIATION POWER CO LTD

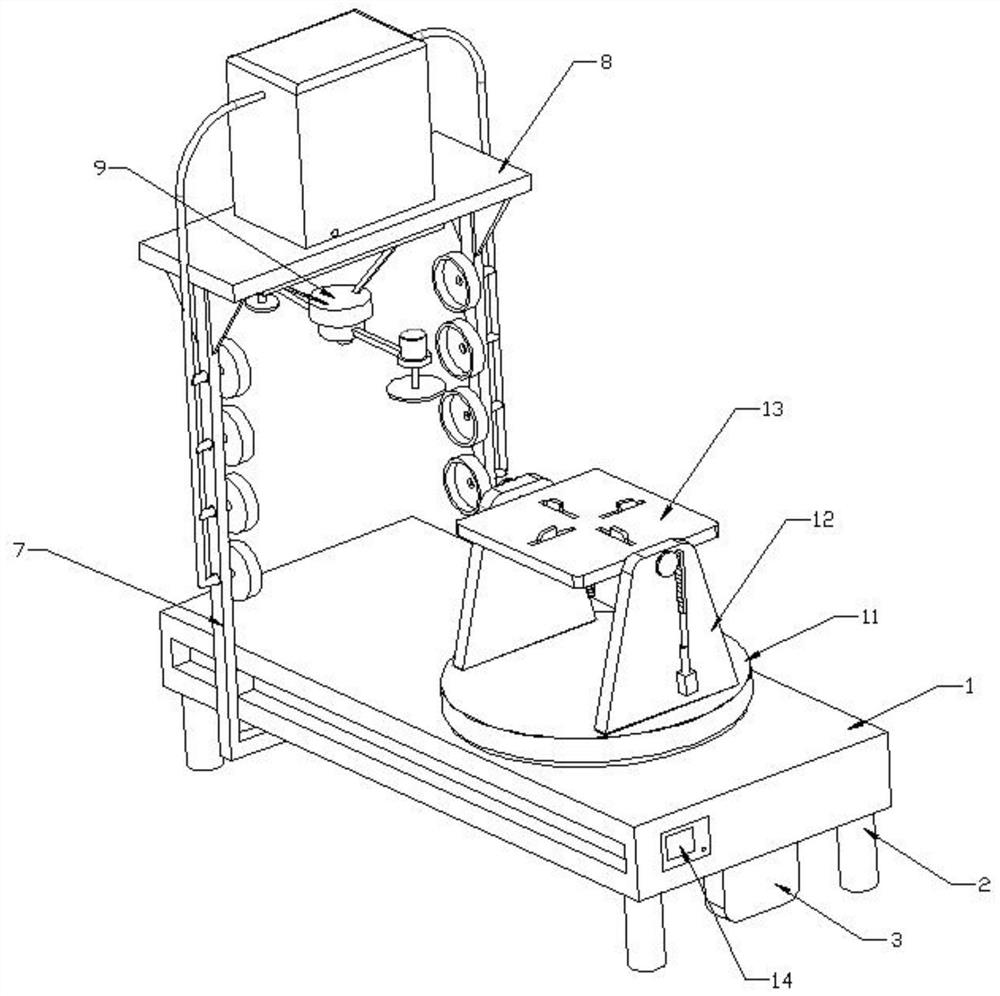

Polishing mechanism for robot machining

InactiveCN113641142AChange the vertical relative positionReasonable structural designProgramme control in sequence/logic controllersElectric machineryEngineering

The invention discloses a polishing mechanism for robot machining. The polishing mechanism comprises a workbench, wherein stand columns are connected to the four corners of the bottom part of the workbench, fixing blocks are connected to the left side and the right side of the bottom part of the workbench, a lead screw is rotationally connected between the two fixing blocks, a lead screw motor is connected to the left end of the lead screw, a nut base is in threaded connection with the outer wall of the lead screw, supporting frames are symmetrically connected to the front end and the rear end of the nut base, the upper ends of the two supporting frames are jointly connected with a horizontal plate, the bottom part of the horizontal plate is connected with a polishing assembly, a middle rotating shaft is rotationally connected to the right side of the top part of the workbench, a steering table is connected to the top part of the middle rotating shaft, a turnover frame is connected to the top part of the steering table, a clamping assembly is installed at the upper end of the turnover frame, and the right side wall of the workbench is connected with a PLC. The polishing device is reasonable in structural design, robot parts can be polished and machined in multiple directions, frequent loading and unloading are avoided, the machining efficiency can be improved, the machining process is stable and reliable, the machining quality can be effectively guaranteed, and a good machining environment can be kept.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Manufacturing process of high-precision extrusion die for DeNOx catalyst

ActiveCN102039519BGuaranteed surface roughnessGuaranteed shape and position accuracyEngineeringDimensional precision

The invention discloses a manufacturing process of a high-precision extrusion die for a DeNOx catalyst. The manufacturing process comprises the following steps: discharging, thermal refining, grinding, rough machining, grinding, boring holes, semi-fine grinding, thermal treatment, groove linear cutting, benching, fine grinding and protective treatment. In the process, by means of the methods suchas reasonable control of machining amount, reasonable selection of equipment parameters and the like in the steps, the surface roughness, the dimensional precision and the form and position accuracy of holes (grooves) of machined parts of the extrusion die with multiple deep holes (grooves) for the catalyst are effectively ensured, wherein, the machining precision reaches 0.01mm, and the surface roughness reaches over Ra0.8; the machining process is stable and reliable; the qualification rate of the die product reaches over 99%; and the difficulty in manufacturing the complicated die with themultiple deep holes (grooves) is overcome. Compared with the prior art, the manufacturing process disclosed by the invention has the advantages of effectively avoiding scrap caused by size and location out-of-tolerance, greatly lowering production cost, improving machining efficiency and shortening production cycle.

Owner:CHONGQING YUANDA CATALYST MFG

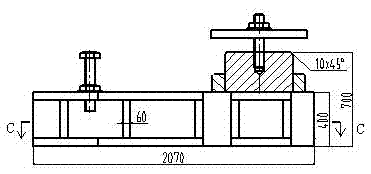

Mould used for bending machining of adjustable vehicle sunshade curtain handle

The invention relates to the technical field of vehicle part manufacturing. The invention aims to solve the problems that a mould needs to be milled when the hardness of the vehicle sunshade curtain handle is greatly changed or the arc of the vehicle sunshade curtain handle is changed, and operation is inconvenient, and discloses a mould used for bending machining of a mould used for bending machining of an adjustable vehicle sunshade curtain handle; the mould sequentially comprises a liftable upper mould base, a bending moulding part connected to the upper mould, a bendable upper mould and abendable lower mould, lower mould fixing blocks for supporting the lower mould and a mould base from top down; two ends of the upper mould base and two ends of the upper mould are connected through elastic ejection components; a outwards-convex arc lower edge is arranged on the bending moulding part; during bending moulding of the mould, the middle part of the lower edge firstly ejects the upper mould; and the lower mould fixing blocks are arranged on two sides of the middle part of the lower mould in a distributive manner. The mould has the advantages that the bending arc of the mould can beadjusted according to the material hardness and arc of the handle; milling machining on the mould is avoided; operation flexibility and working efficiency are improved; besides, the machining processis stable and reliable; and machining precision can also be ensured and improved.

Owner:宁波裕民机械工业有限公司

A mold for bending the handle of adjustable car sunshade

The invention relates to the technical field of automobile parts manufacturing. Aiming at the problem that the handle of an automobile sunshade needs to be milled when the hardness changes greatly or the arc changes, and the operation is inconvenient, a mold for bending the handle of an adjustable automobile sunshade is disclosed. , from top to bottom are the liftable upper mold base, the bending forming part connected with the upper mold base, the bendable upper mold and the lower mold, the lower mold fixing block supporting the lower mold, and the mold base; the two parts of the upper mold base The end and the two ends of the upper mold are connected by elastic pressing parts; the bending forming part is provided with a convex arc-shaped lower edge. When the mold is bent, the middle of the lower edge first presses the upper mold, and the fixing blocks of the lower mold are scattered. On both sides of the middle part of the lower mold. The mold of the present invention can adjust the bending radian of the mold according to the hardness and radian requirements of the handle material, avoids the milling process of the mold, improves the operational flexibility and work efficiency, and the machining process is stable and reliable, and the machining accuracy can also be guaranteed and improved.

Owner:宁波裕民机械工业有限公司

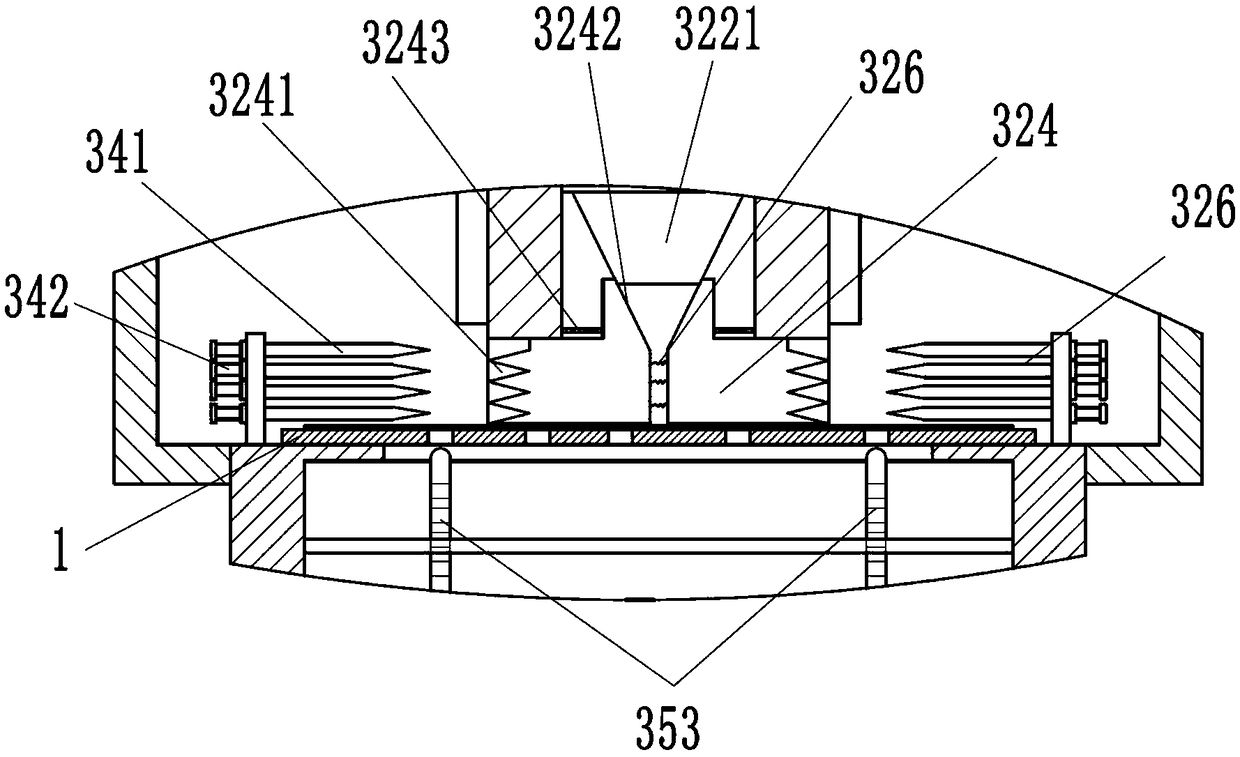

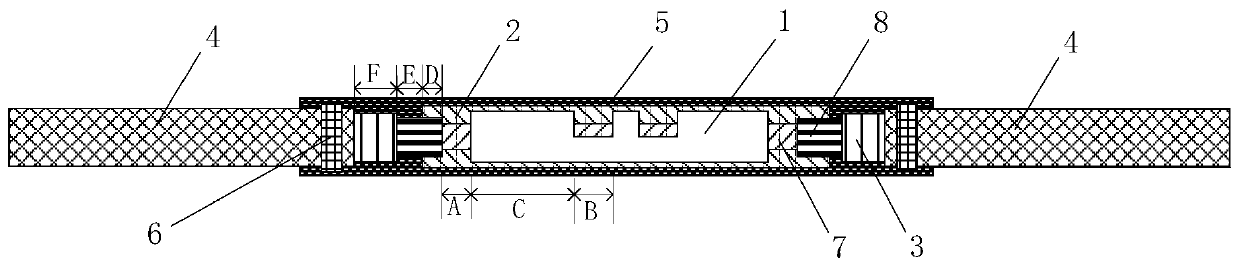

Stainless steel pipe clamping and pressing type connector machining device and machining method

PendingCN112091079AStable processingStable and reliable processingShaping toolsPipe fittingStructural engineering

The invention relates to a stainless steel pipe clamping and pressing type connector machining device and a machining method, and belongs to the field of pipe fitting machining. The stainless steel pipe clamping and pressing type connector machining device comprises a rack, an inner mold assembly and an outer mold assembly, wherein the outer mold assembly is fixedly connected with the rack; the inner mold assembly is rotationally connected with the rack; the outer mold assembly comprises an outer barrel and a plurality of outer mold plates; the plurality of outer mold plates are arranged in the outer barrel and define a columnar structure, and the outer mold plates slide in the radial direction of the outer barrel; the inner mold assembly comprises an inner barrel and a plurality of innermold plates; the plurality of inner mold plates are arranged in a cavity of the inner barrel and define a columnar structure, and the inner mold plates are in sliding connection in the radial direction of the inner barrel; and the inner mold plates are sleeved with the outer mold plates. According to the stainless steel pipe clamping and pressing type connector machining device and the machining method, the machining efficiency is high, and safety is high.

Owner:豪德博尔(山东)智能装备有限公司

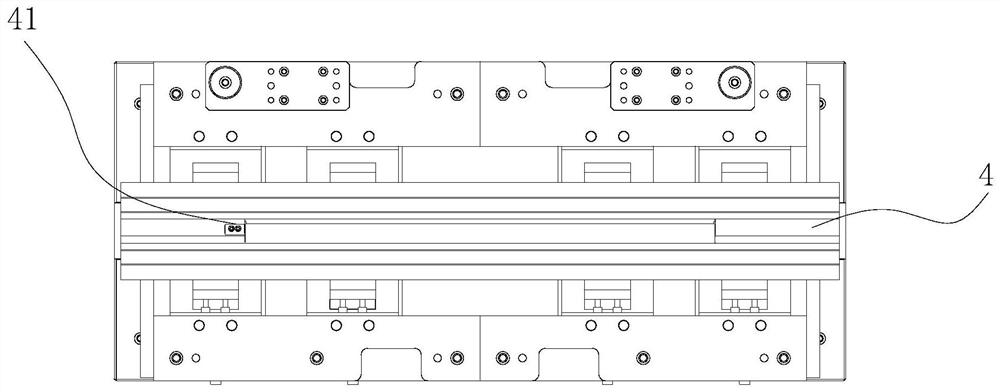

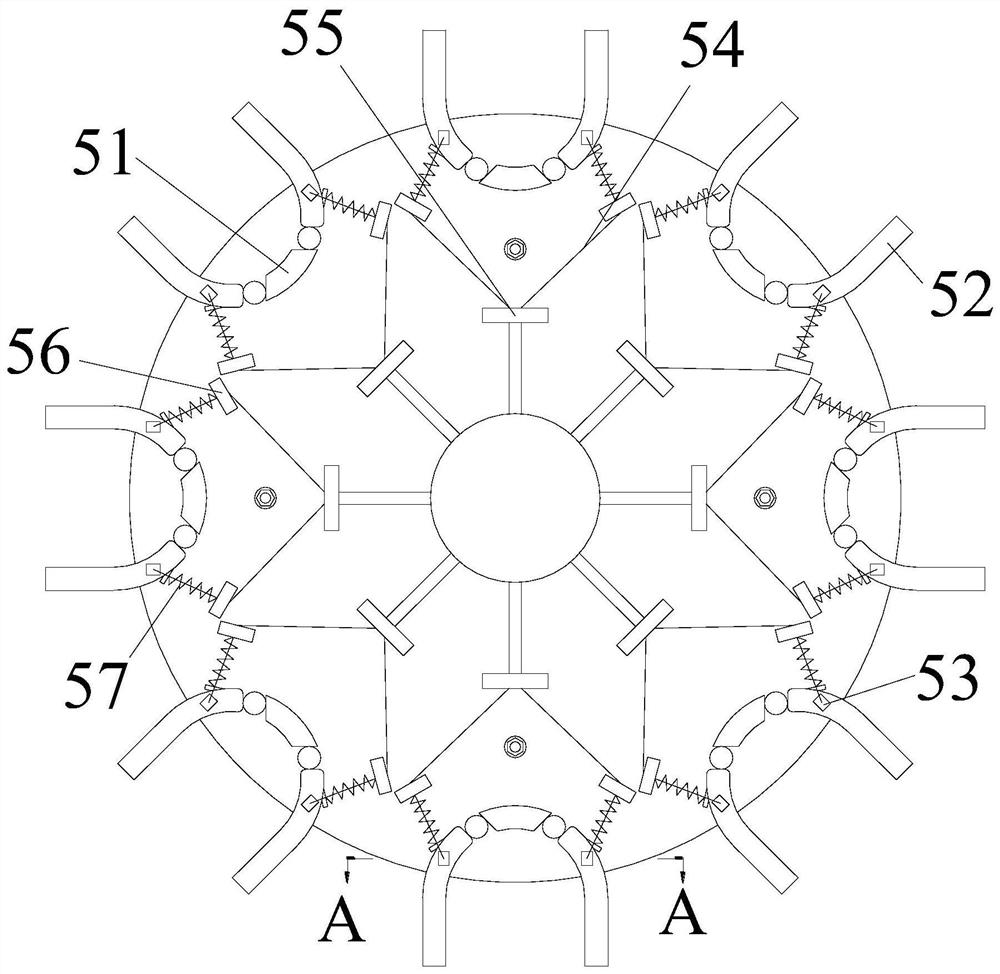

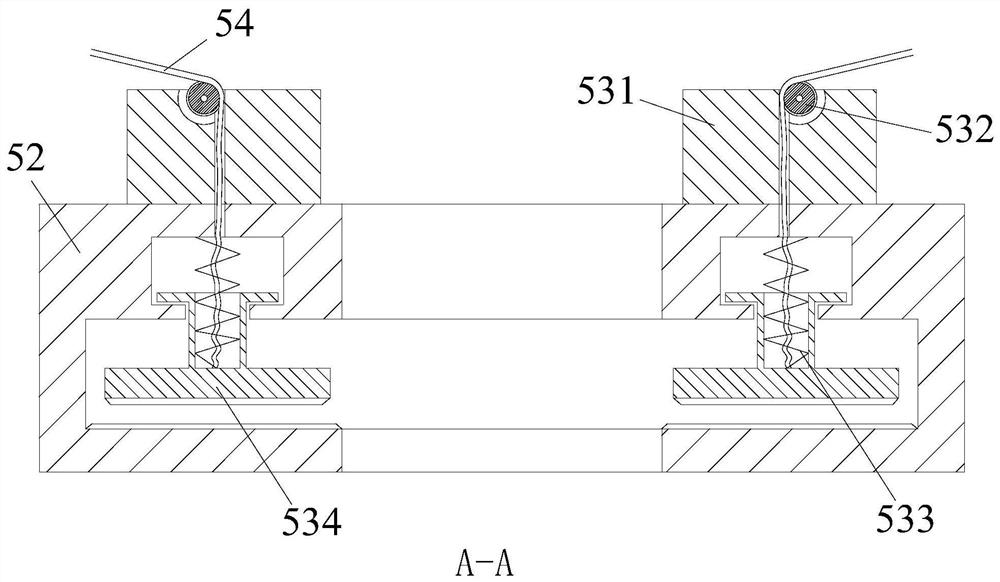

A multi-station fixture for PCB board welding

ActiveCN110394588BIncrease the amount of workpieces processed at a timeAvoid shaking situationsWelding/cutting auxillary devicesAuxillary welding devicesRotational axisEngineering

The invention relates to a multi-station clamp for PCB welding. The multi-station clamp for PCB welding comprises a workbench, a driving device, a rotating shaft, an installation plate and clamping devices, wherein the driving device is mounted inside the workbench, the rotating shaft is mounted at the upper end of the driving device, the installation plate is mounted at the upper end of the workbench, and the clampingdevices are uniformly distributed in the circumferential direction on the installation plate. The multi-station clamp for PCB welding solves the problems that conventional PVC welding tool clamps are mostly single station tool clamps which can only be used for clamping and processing a single PCB, the PCB replacement process is relatively tedious, after the PCB and the conventional PCB welding tool clamps are involved in clamping, since the conventional clamp structure is fixed, a gap is reserved between the conventional clamps and the PCB, waggles can be probably causedduring a PCB processing process, and difficulties in element inserting and mounting or wrong element pin welding can be caused.

Owner:众潮电科(深圳)有限公司

Special rolling drum furnace for calcining U-shaped silicon carbide rod

PendingCN108120273AQuality improvementImprove bindingRotary drum furnacesWater pipePressure measurement

The invention discloses a special rolling drum furnace for calcining a U-shaped silicon carbide rod. The special rolling drum furnace comprises a furnace body, a furnace door, a transmission device, awater pump, a support and a heating device. A ventilation pipe is installed on the furnace body, a pressure measurement device is fixedly installed on the ventilation pipe, a ventilation hole is formed in the furnace body, the furnace door is arranged on the furnace body, and a sealing device is installed between the furnace door and the furnace body; the furnace body is connected with the support through bolts, a reinforcing device is installed on the support, the transmission device is connected with the furnace body, the transmission device is stored on a supporting platform, and the supporting platform is fixedly installed on the support; and a water inlet is formed in the furnace body, the water inlet is connected with a water tank through a water pipe, the water pump is stored on awater pump supporting frame, the heating device is installed in the furnace body, and a U-shaped silicon carbide rod supporting frame is installed in the furnace body. According to the special rollingdrum furnace, the structure is simple, the heating rate is high, the airtightness is good, the stability and the safety are high, and the quality of the manufactured silicon carbide rod is reliable.

Owner:登封市宏远电热元件有限公司

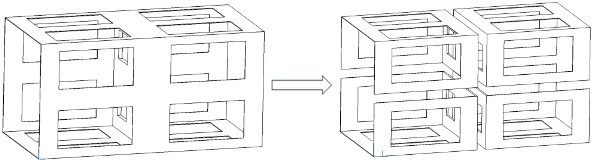

Large thin-wall frame type precision casting part clamping device and clamping method

ActiveCN113182896AImprove rigidityImprove the level of CNC machiningPositioning apparatusMetal-working holdersMachining processRigid structure

The invention discloses a large thin-wall frame type precision casting part clamping device and clamping method. The upper surface and the lower surface of a part are each provided with two rows of semi-suspended bosses in the parallel side length direction, an end opening area pressing device is arranged in an end opening area of the part, a top face boss pressing device and a bottom face positioning boss pressing device are arranged on the upper surface and the lower surface of the part respectively, and a middle web plate hole area pressing device is arranged in the middle of the part and used for conducting double-face pressing on a web plate of the part. According to the clamping device, the rigidity of precision casting parts can be effectively enhanced, the problems of cutter bouncing, vibration and the like caused by insufficient rigidity of the parts in the machining process are reduced, and the stability and reliability of the machining process are guaranteed. The clamping method is suitable for large thin-wall frame type precision casting parts, the stability of the weak rigidity structure of the parts in the machining process can be improved, and the clamping method is stable, reliable and flexible and has good practicability.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

A scraper machine tail drum

The invention discloses a scraper tail drum which is provided with a barrel structure with a bearing hole. The scraper tail drum comprises a middle cylinder and outer drums with chain grooves, wherein the middle cylinder is of a hollow cylinder, the outer drums which have diameters larger than that of the middle cylinder and are provided with the chain grooves and are arranged at two ends of the middle cylinder, and the middle cylinder, the outer drums and the chain grooves are integrally cast at a time together with the bearing whole. The integrated cast is of a lost foam casting. The material is of iron alloy which comprises chemical components percentage by weight: 0.01-0.15 of carbon, 0.2-0.5 of silicon, 0.4-1.0 of manganese, 0.5-2.0 of nickel, 10.0-12.0 of chromium, 0.2-0.3 of vanadium, 0.01-0.02 of phosphorus, 0.01-0.02 of sulphur and the rest of ferrum. The scraper tail drum has the beneficial effects of being simple to machine, saving the machining time, lowering the machining difficulty, being simple in structure, fewer in consumable materials, lower in cost and lighter in weight; the materials have high high-temperature creep rupture strength, good oxidation resistivity, good thermal stress and stable and reliable mechanical property; and the machining process is safe and reliable, and accordingly the machining failure possibility and the consequent cost are reduced.

Owner:GUIZHOU HONGSHI COAL MACHINE MFG

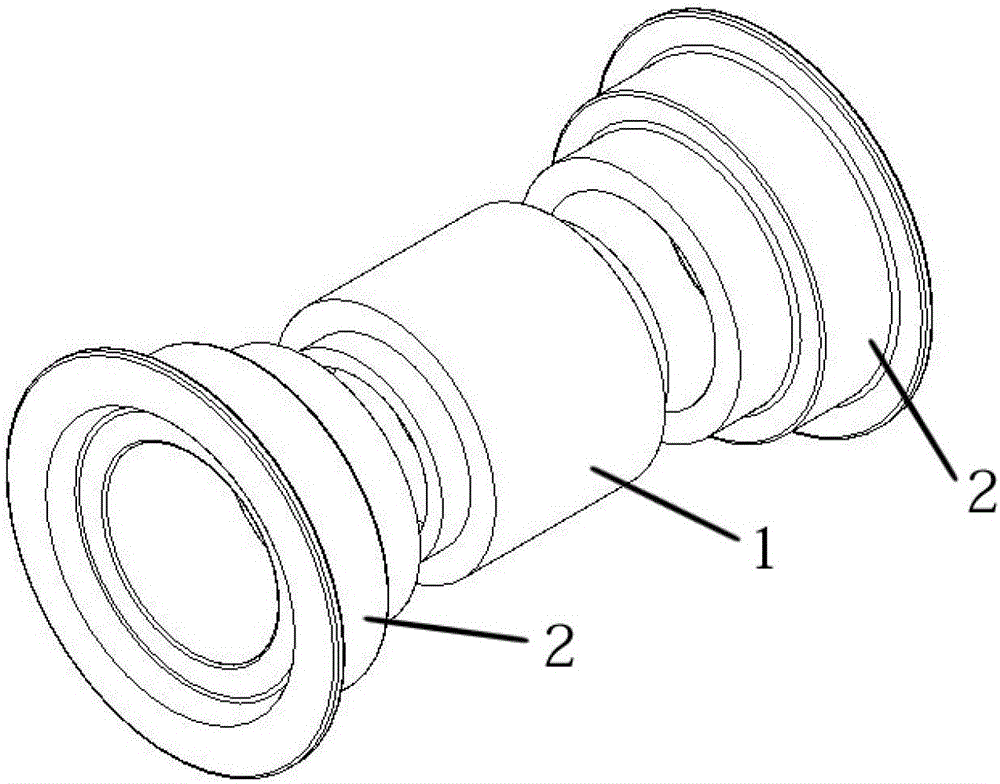

A laser hole processing system and method with both processing and real-time detection capabilities

ActiveCN110744211BLow costSimple structureUsing optical meansLaser beam welding apparatusBeam splitterEngineering

The invention provides a laser hole processing system and method with processing and real-time detection capability. The problems that in an existing ultra-fast laser micro-nano processing hole depthnon-contact real-time detection mode, detection equipment is complex in structure and the detection cost is high are solved. The system comprises a semiconductor laser device, a beam collimation unit,a polarizer, a quarter wave plate, a dichroic beam splitter, a data acquisition unit, a data processing unit and a laser processing device. The semiconductor laser device emits lasers, and the lightwhich passes through the beam collimation unit and the polarizer and is emitted to the dichroic beam splitter and the laser processing device is emitted to a processed part together; and semiconductorlaser reflected light is returned into a cavity of the semiconductor laser device along the original optical path, a change curve of relative intensity change signals of the semiconductor laser device and processing time is obtained, and the depth of a laser processed hole can be calculated in real time through the data processing unit.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

An all-round plane planing equipment with intelligent pressing system

ActiveCN106077784BReduce contact surfaceAutomatic height adjustmentPlaning/slotting machinesPositioning apparatusEngineeringSlide plate

The invention discloses all-dimensional planar planing equipment with an intelligent pressing system. The all-dimensional planar planing equipment comprises a machine frame, a work table arranged on the upper surface of the machine frame and a moving beam suspended above the work table, wherein the two ends of the moving beam are connected to the machine frame through transverse guide rails and transverse drive devices are arranged at the two ends of the machine frame; a longitudinal sliding plate device is arranged on one side of the moving beam and is connected to the moving beam through a longitudinal guide rail; and a longitudinal driving device is arranged on one side of the longitudinal sliding plate device, a cutter box is arranged at the lower end of the longitudinal sliding plate device, and a set of cutters are arranged inside the cutter box. According to the design, bidirectional planing and slotting in the longitudinal direction and the transverse direction can be realized, inclined planing and slotting can be realized through simultaneous moving of the moving beam and the longitudinal sliding plate device, and inclined planing and slotting at different angles can be realized by controlling the moving speed of the moving beam and the moving speed of the longitudinal sliding plate device.

Owner:施泰德精密机械(太仓)有限公司

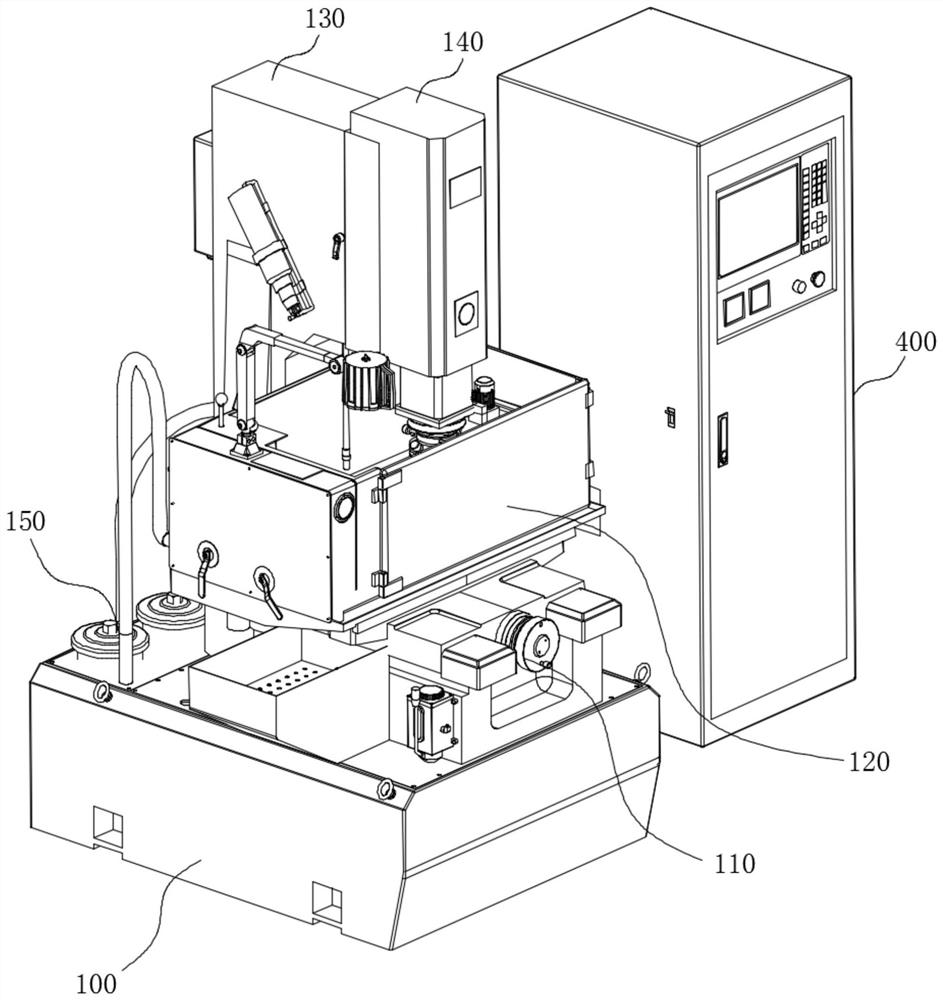

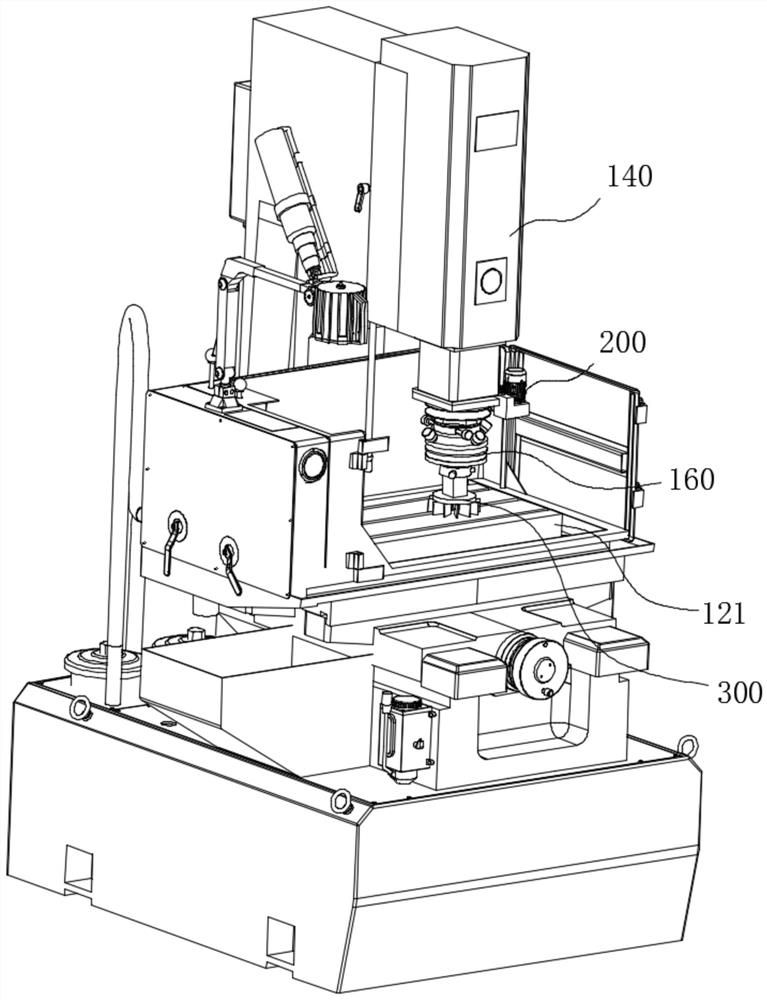

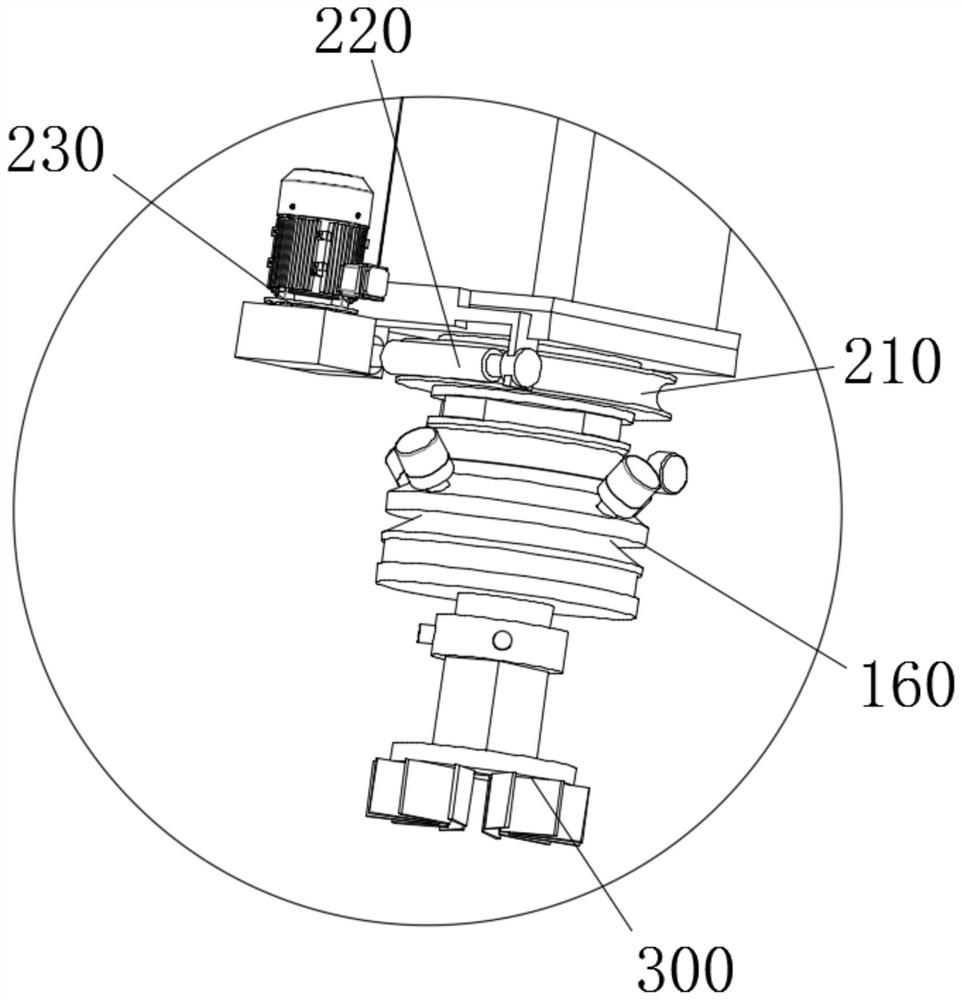

An electric discharge machine tool for inner cavity treatment of metal products

ActiveCN112453601BImprove processing efficiencyEasy dischargeElectrical-based machining electrodesWorking fluidMachine tool

The invention discloses an electric discharge machine tool for internal cavity treatment of metal products, which comprises a bed and a column, a workbench is arranged on the bed, a spindle head is arranged on the upright column, the spindle head and the workbench are arranged correspondingly, and a water tank is arranged on the workbench. The bottom of the tank is equipped with a fixture for clamping the workpiece. The water tank is connected to the working fluid circulation system. The electrode chuck is installed at the lower end of the spindle head. The tool electrode is installed on the electrode chuck. The cavity structure of the tool electrode matches the workpiece, and the workpiece is horizontal on the fixture. Arrangement, the electrode chuck is connected with the adjustment mechanism, and the adjustment mechanism is used to adjust the rotation of the electrode chuck around the height direction of the machine tool. The structure of the invention is stable and the layout is reasonable. Through the setting of the tool anode and the adjustment mechanism, the tool anode is electroeroded first and then slotted. The purpose of widening and forming the wall of the electro-erosion tank significantly improves the processing efficiency of the special-shaped tank, reduces power consumption, and the electro-erosion products are discharged quickly, and the processing process is stable and reliable.

Owner:江苏德瑞加数控机床有限公司

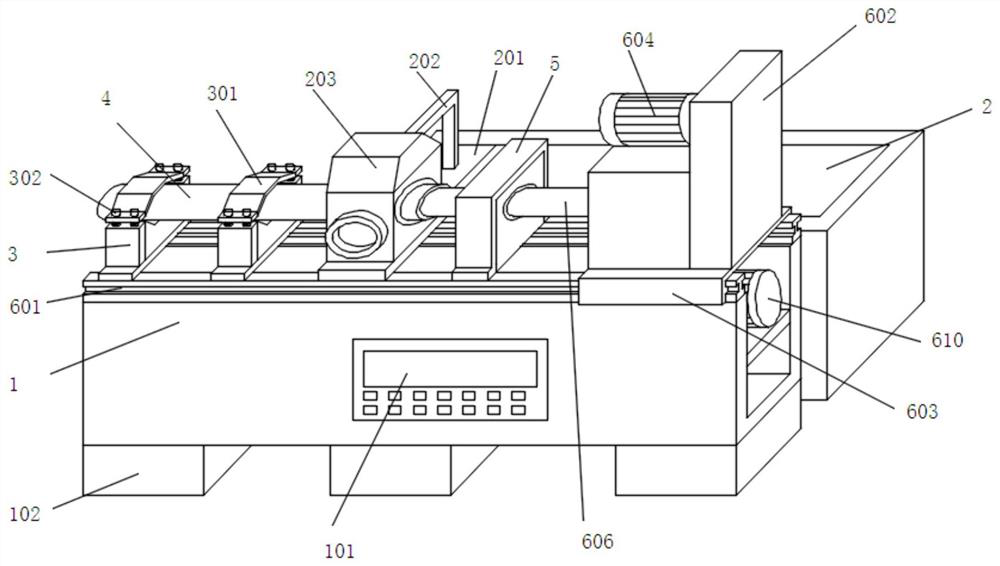

Deep hole trepanning machining forming device for alloy cast iron profile and application method of deep hole trepanning machining forming device

PendingCN113798551AImprove cooling effectImprove the lubrication effectTransportation and packagingMeasurement/indication equipmentsTool bitEngineering

The invention discloses a deep hole trepanning machining forming device for an alloy cast iron profile and an application method of the deep hole trepanning machining forming device. The deep hole trepanning machining forming device comprises a lathe bed, an oil tank, a workpiece, a tool bar, a drilling mechanism and a tool bit mechanism, wherein a controller used for conducting coordinated control on all components of the device is installed at one side of the surface of the lathe bed; the oil tank used for storing cutting fluid is installed at one side of the lathe bed; an oil pump station is installed at one side in the oil tank; two V-shaped tables are installed at the left end of the top of the lathe bed; the workpiece is borne by the tops of the V-shaped tables; the drilling mechanism used for controlling the tool bar to operate is installed at the right side of the top of the lathe bed; and the tool bit mechanism used for conducting drilling operation on the workpiece is installed at the tail end of the tool bar. Vibration cutting and trepanning drilling are combined, the cutting output is effectively reduced, green and energy-saving cutting is achieved, the system is compact in structure, simple in transmission, high in kinematic accuracy, convenient to operate, and stable and reliable in machining process.

Owner:JIANGSU HUALONG CAST IRON BAR SECTION CO LTD

Wiring terminal connecting structure and processing method thereof

ActiveCN110943310AImprove reliabilityGuarantee processing qualityLine/current collector detailsElectric connection structural associationsStructural engineeringElectrical and Electronics engineering

The invention relates to a wiring terminal connecting structure and a processing method thereof, belongs to the technical field of electric fittings, and solves the problems that an existing wiring terminal is poor in reliability, complex in processing and large in cable diameter at the joint. A wiring terminal connecting structure comprises a wiring terminal, a wiring terminal heat-shrinkable sleeve, a wire shielding layer inner protection heat-shrinkable sleeve, a wire shielding layer and a shielding heat-shrinkable sleeve. A wire core wire of a wire to be connected sequentially comprises awire insulating layer, a wire shielding layer inner protection heat-shrinkable sleeve and a wire shielding layer from inside to outside. The wiring terminal heat-shrinkable sleeve is sleeved outside the wiring terminal and envelops the wire insulating layers at the two ends of the wiring terminal; and the shielding heat-shrinkable sleeve is sleeved outside the wiring terminal heat-shrinkable sleeve and envelops the sleeving length of the wire shielding layers at the two ends of the wiring terminal. The device is simple in structure, high in reliability, simple in processing technology, easy toprocess and small in cable diameter at the joint.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

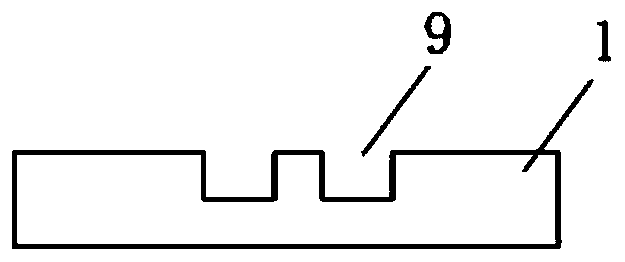

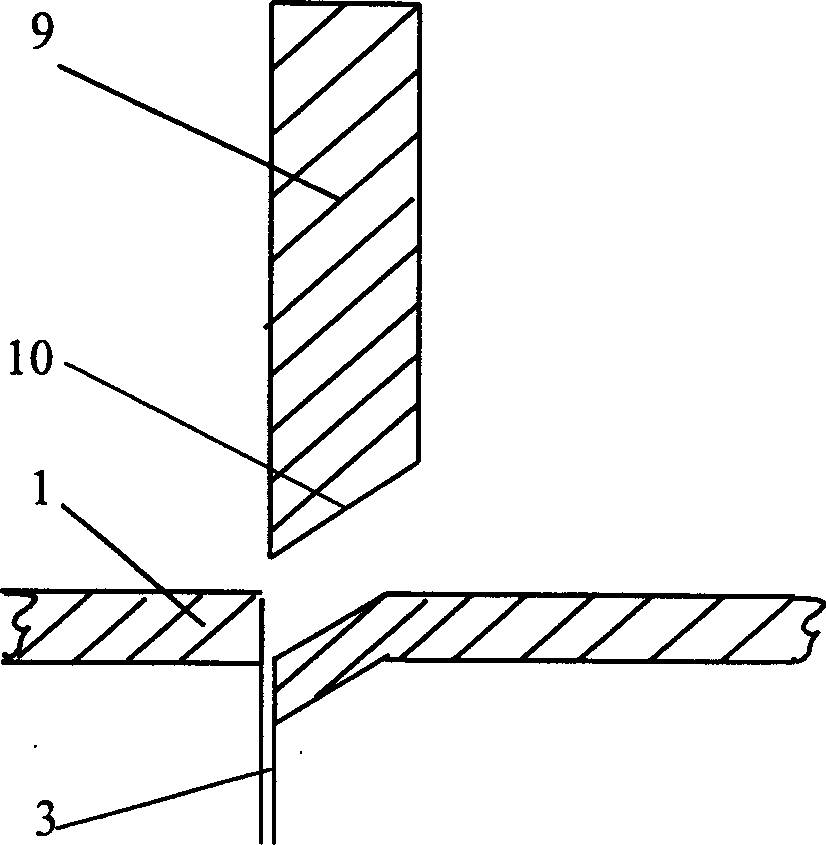

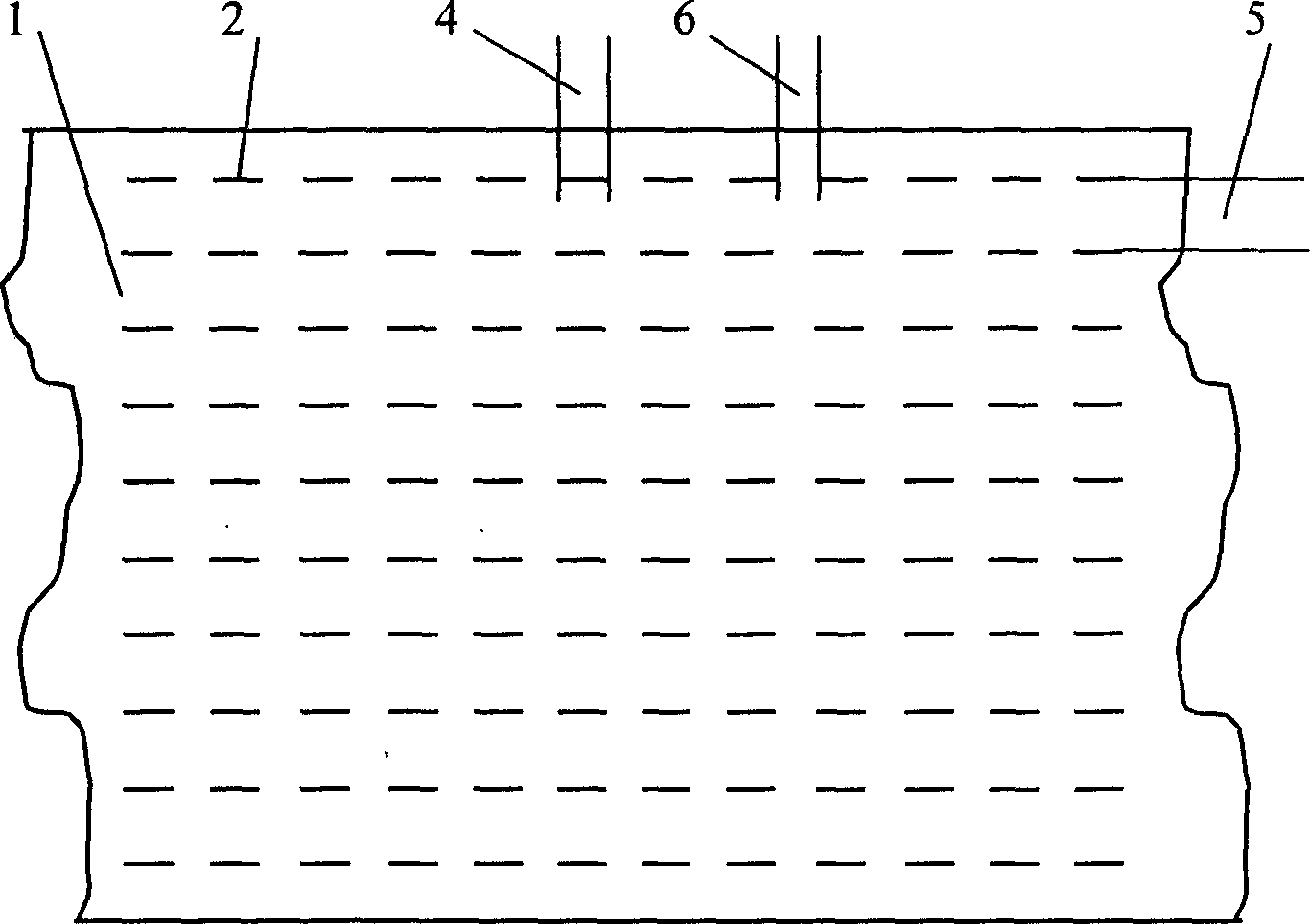

Equipment and technique for producing micro seam acoustic board

InactiveCN1733382ACooperate closelyNumber of slotsPerforating toolsOther manufacturing equipments/toolsPunch pressEngineering

This invention discloses manufacturing facility for micro seam sound-absorbing panel, which comprises joined power system, hand-operated or automatic step precise press system with punch rotation arms to control vertical motion of convex mould with a plurality of press heads with end of inclined surface structure distributed single row or multiple rows, parameter determination system and parameter detection device belonged to JT-9 optical projection detector and composed of light source, lens and reflector; wherein, the travel of press head motion controls gap width of sound-absorbing panel between 20~50 microns, the length of press head is 1.5~5.0mm. the invention also discloses the corresponding manufacture technique.

Owner:INST OF HYGIENE & ENVIRONMENTAL MEDICINE PLA ACAD OF MILITARY MEDICAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com