Wiring terminal connecting structure and processing method thereof

A technology of terminal and connection structure, applied in the direction of connection, connection insulation, conductive connection, etc., can solve the problems of complex processing, large diameter of the cable at the connection, low reliability, etc., to achieve reliable connection structure, ensure processing quality, improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

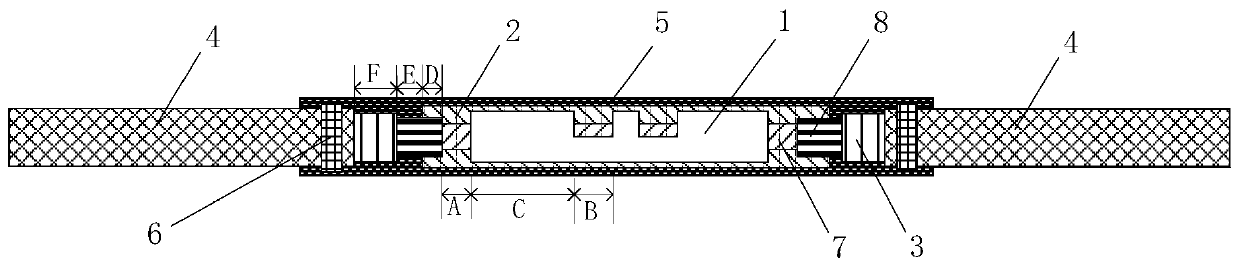

[0038] A specific embodiment of the present invention discloses a connection structure of a terminal, such as Figure 1 to Figure 2 As shown, it includes terminal 1, terminal heat-shrinkable tube 2, wire shielding inner protective heat-shrinkable tube 3, wire shielding layer 4, and shielded heat-shrinkable tube 5; among them, terminal 1 has a cavity structure, and the wiring The cavity of the terminal 1 is for the core wire 7 of the wire to be connected to penetrate. The wire to be connected is sequentially sheathed with a wire shielding layer inner protective heat shrinkable tube 3 and a wire shielding layer 4, that is, the wire core 7 is a wire insulation layer 8 and a wire shielding layer inner protective heat shrinkable tube 3 from the inside to the outside. The distance between the wire shielding layer 4, the wire insulation layer 8, the protective heat shrinkable sleeve 3, the wire shielding layer 4 and the end surface of the terminal 1 increases in turn, and the optical ...

Embodiment 2

[0054] Another specific embodiment of the present invention discloses the processing method of the connection terminal connection structure in embodiment 1, which specifically includes the following steps:

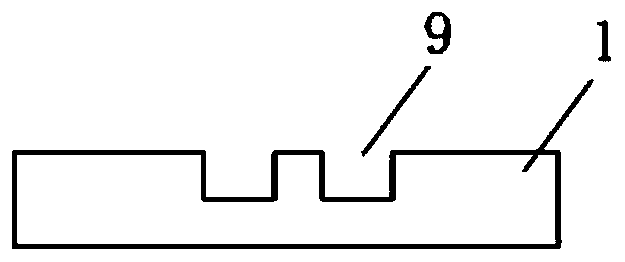

[0055] Step 1: Disconnect the ends of the two wires to be connected to leak the wire core 7; insert the leaked wire core 7 into the internal cavity of the terminal 1, and observe whether the wire core 7 is in place through the observation hole 9 . Among them, the stripping length, that is, the length of the insulation layer of the hot stripping wire end is A+B+C. The wire after the end treatment should be guaranteed to be free of damage, no broken wires, no residues, and no Rust and no loose wire.

[0056] Step 2: Put the terminal heat shrinkable tube 2 on the terminal 1, make the terminal heat shrinkable tube 2 wrap around the terminal 1 and the wire insulation layer 8 on both sides of the terminal 1, and connect the terminal heat shrinkable tube 2 Perform heat shrinkage tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com