Patents

Literature

242results about How to "The connection structure is stable and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

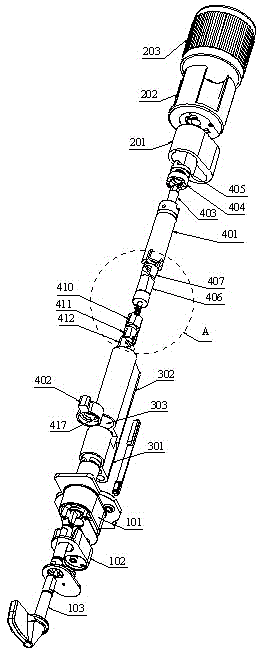

Infrared transmitting device and infrared receiving device of atmospheric infrared detection equipment

PendingCN107064006AImprove efficiencyHigh precisionOptically investigating flaws/contaminationReflecting telescopeEngineering

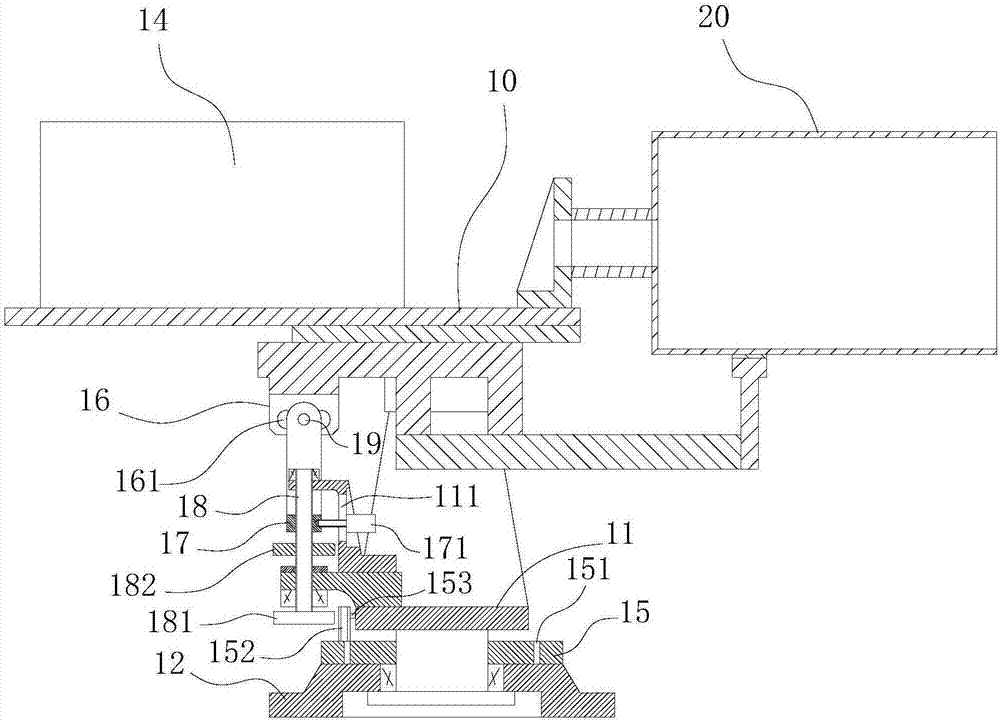

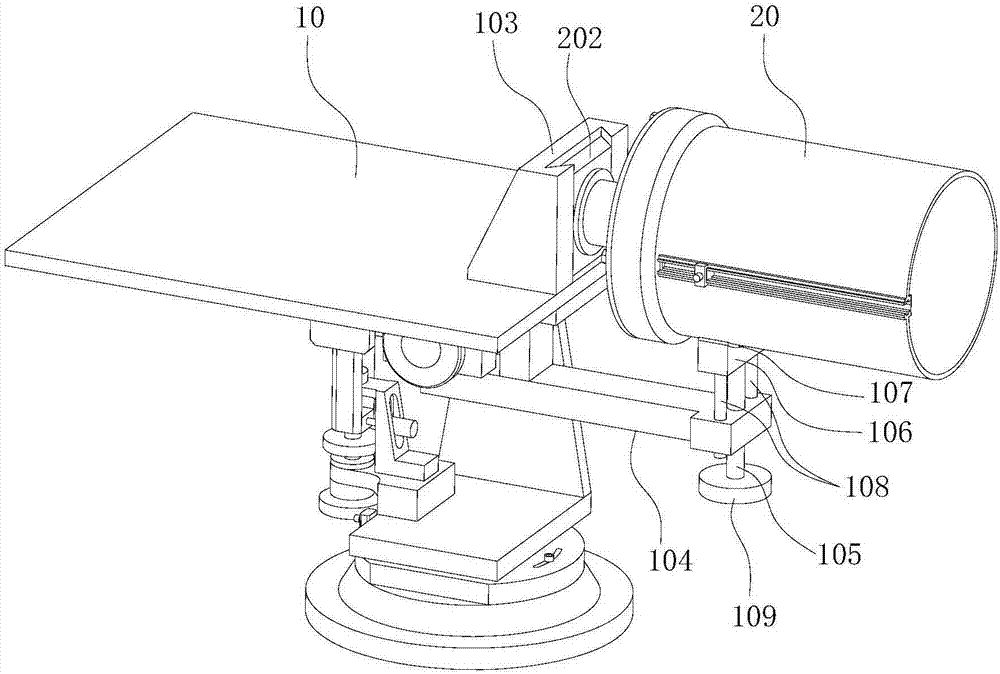

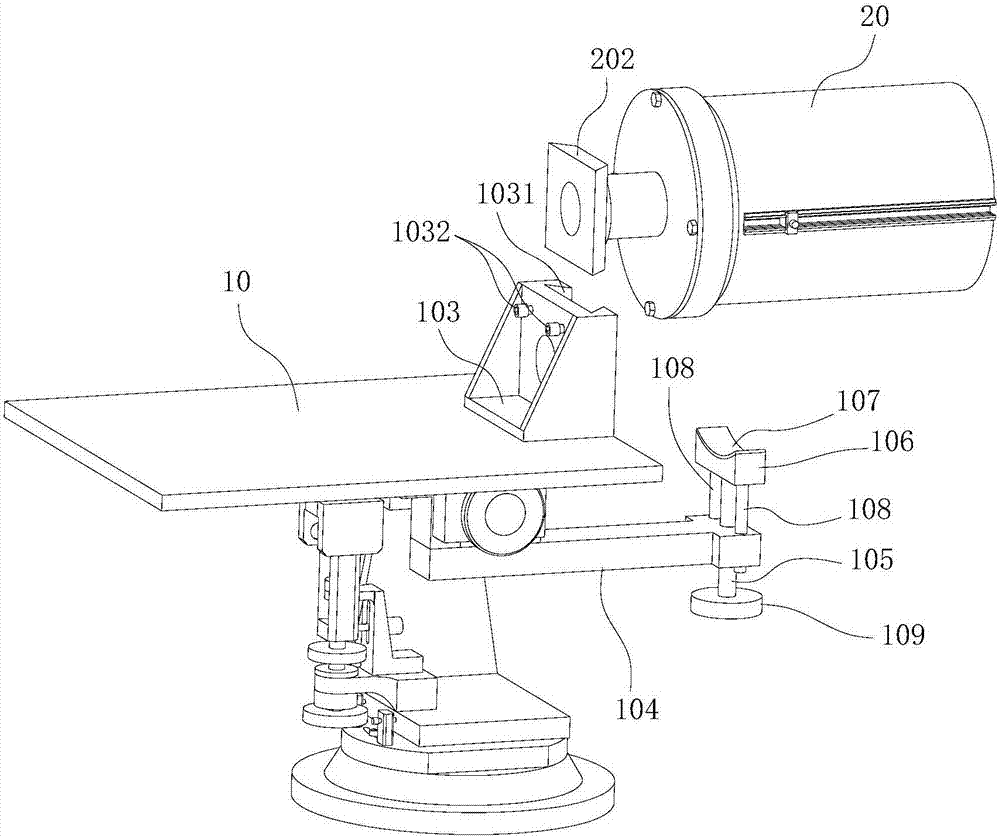

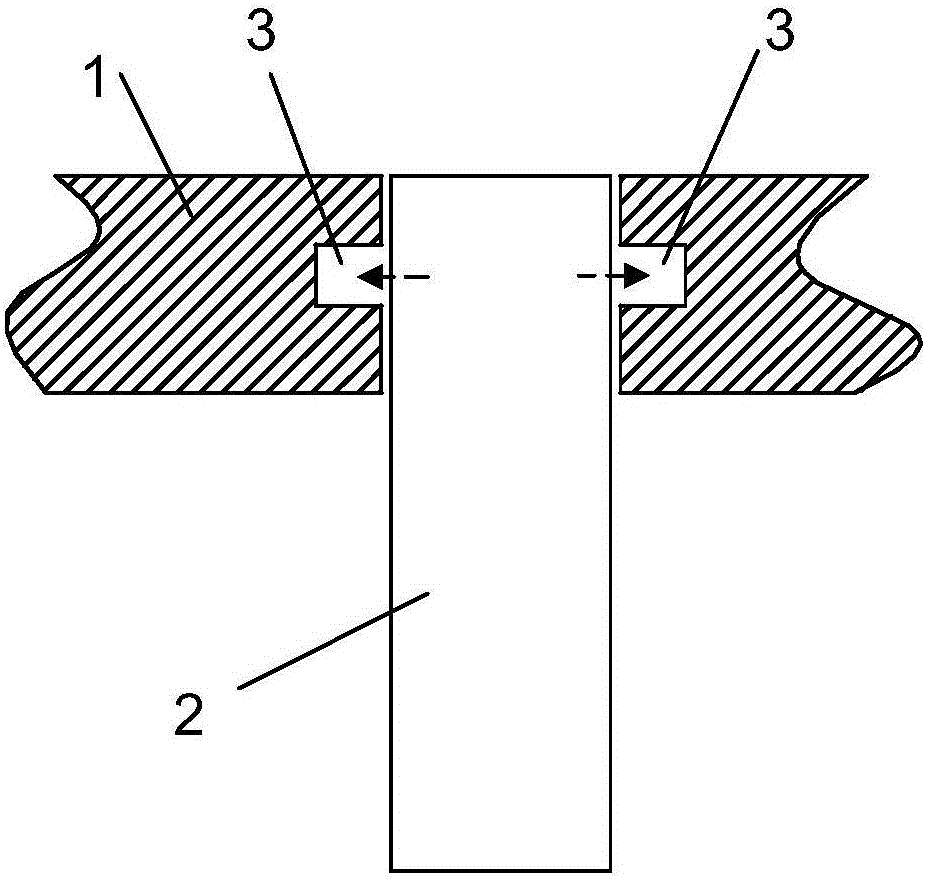

The invention belongs to the technical field of atmospheric infrared detection equipment, and particularly relates to an infrared transmitting device and an infrared receiving device of the atmospheric infrared detection equipment. The overall pitching and left and right sweeping of the infrared detection equipment are achieved through a two-axis turntable. The equipment is simple in transmission structure, good in stability and high in adjustment precision, thus the installation and focusing efficiency and focusing precision of the infrared detection equipment are greatly improved. According to the equipment, a lens is installed on a movable support; the movable support is installed on a slider arranged on the barrel wall of a Casher reflection telescope; the position of the lens in the Casher reflection telescope can be adjusted in real time from the outside of the Casher reflection telescope; the operation is simple and convenient; the equipment assembly and maintenance efficiency are improved; the fast connection and positioning of the Casher reflection telescope and the turntable are achieved by using a dovetail type plug-in structure; the connecting structure is stable and reliable; the installation precision is high.

Owner:安徽星源环境科技有限公司

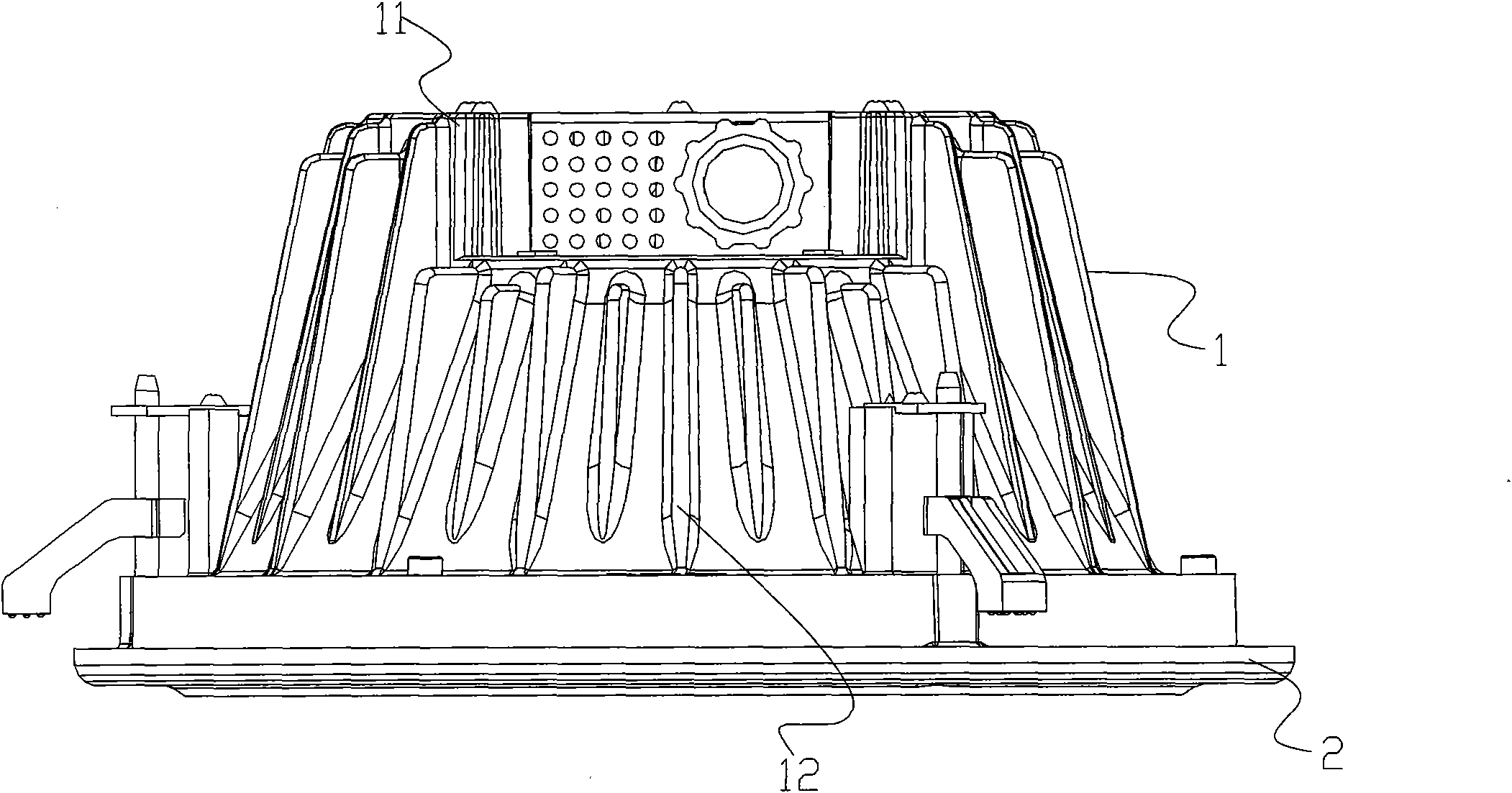

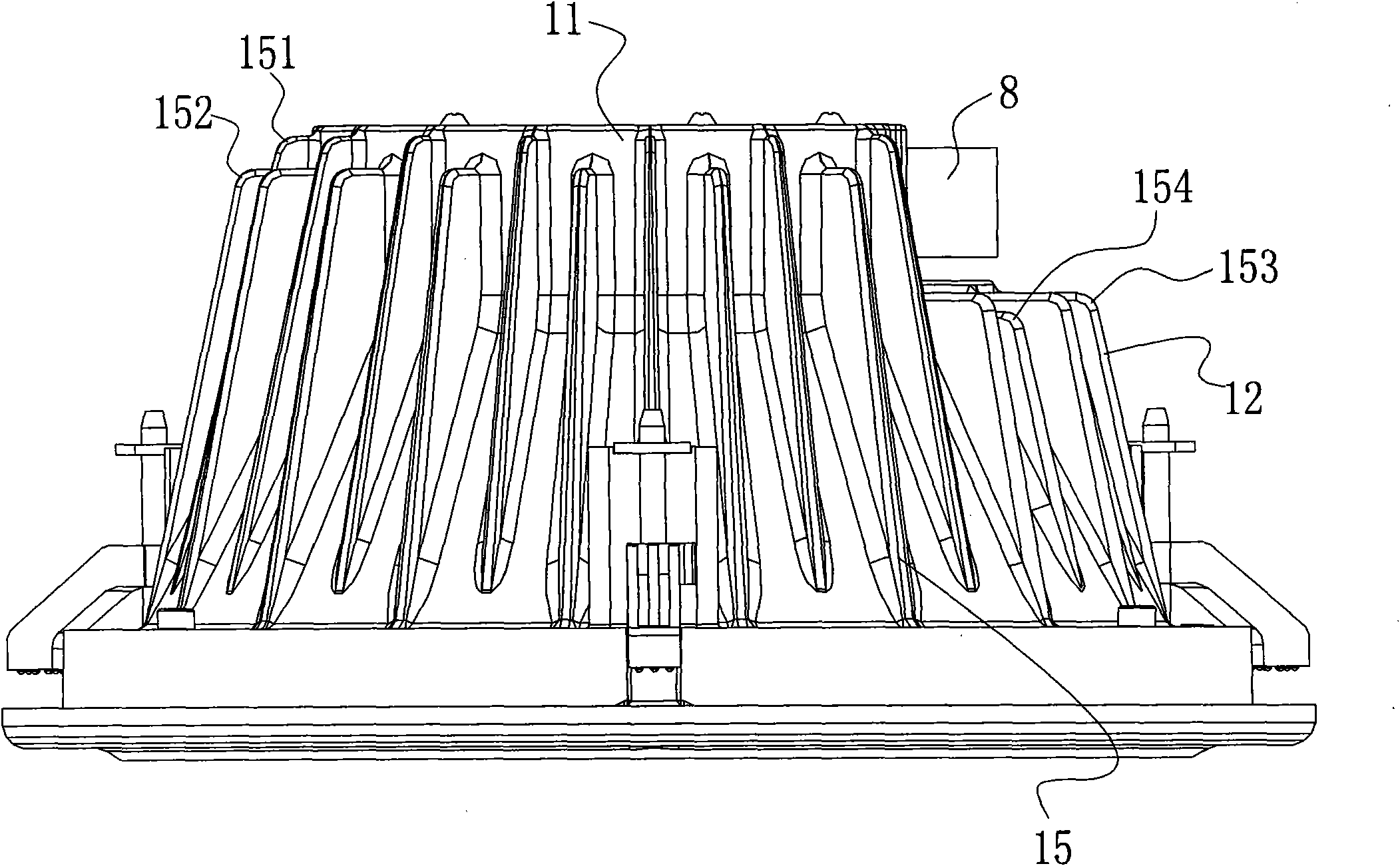

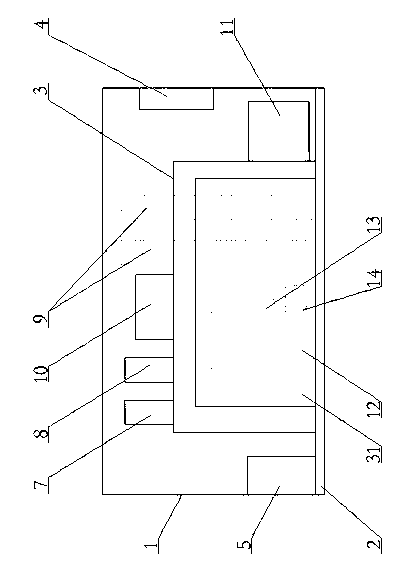

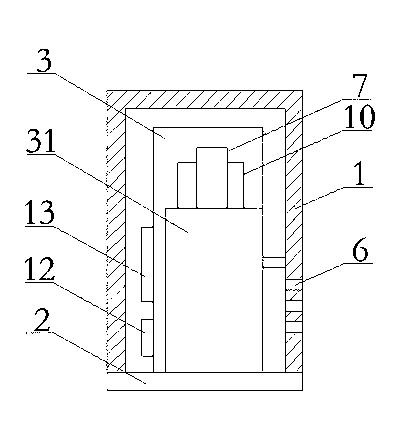

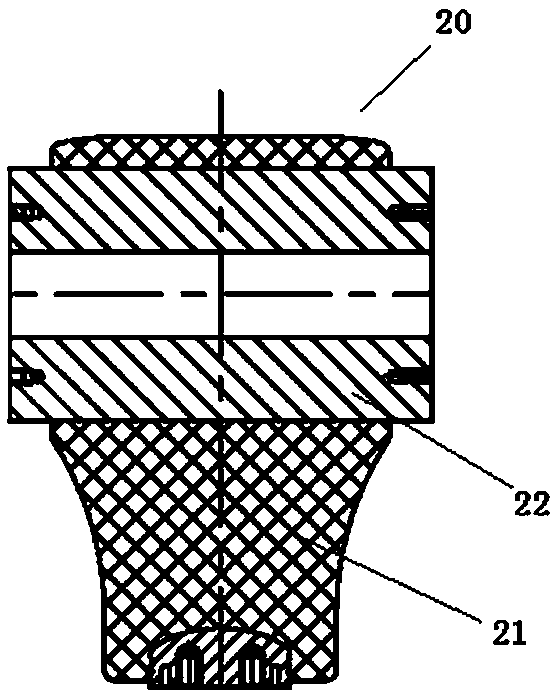

LED (Light-Emitting Diode) embedded barrel lamp

InactiveCN102022682ACompact structureSimple structurePoint-like light sourceElectric circuit arrangementsLight-emitting diodeEmbedded system

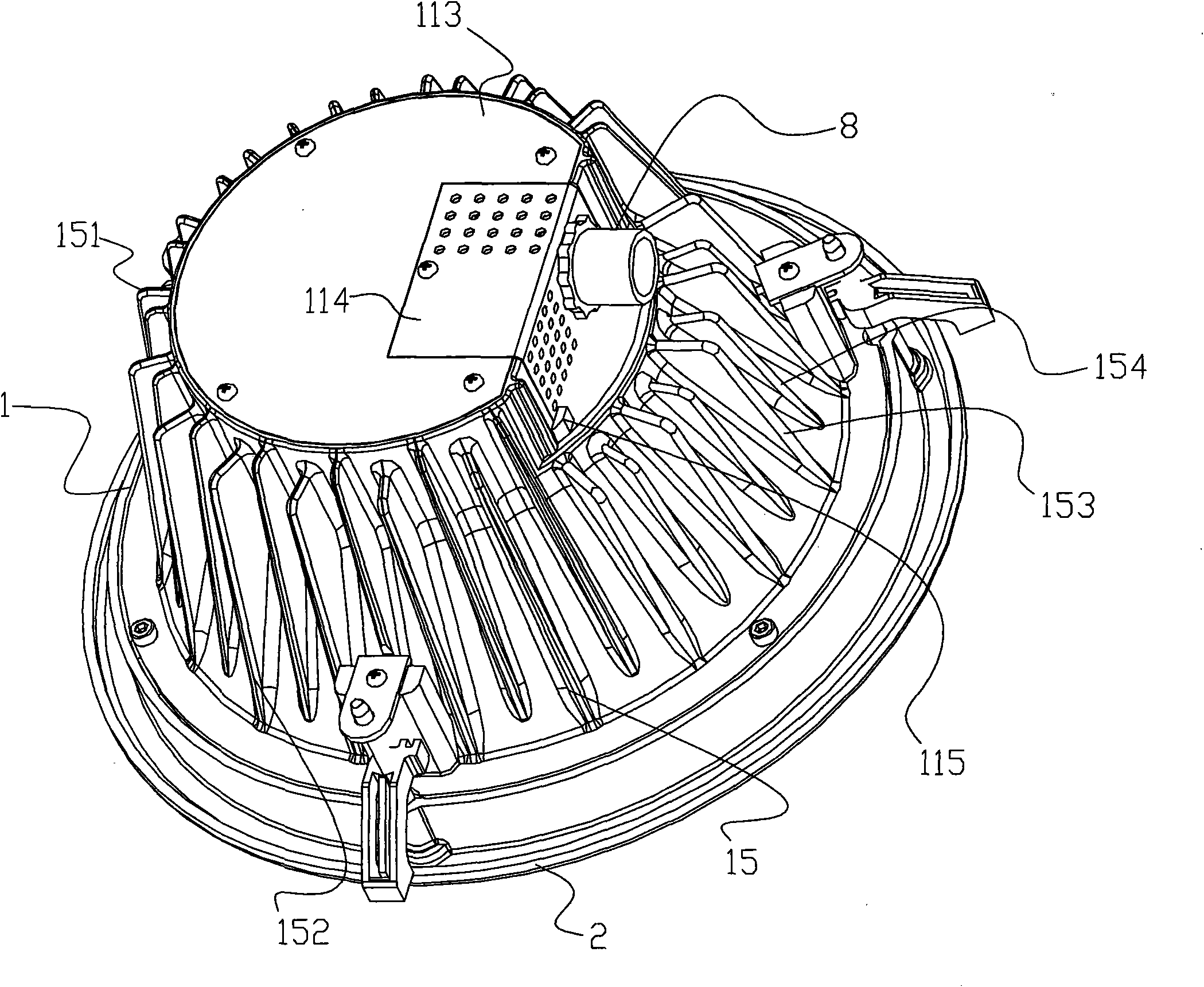

The invention discloses an LED embedded barrel lamp which comprises a front cover and a radiator, wherein the front cover and the radiator are matched and connected together, the radiator comprises a radiator body and a protecting cavity which is positioned outside the radiator body and shares the same bottom surface with the radiator body, and the inside of the protecting cavity body is provided with two chambers which are respectively a driving chamber for installing a driver and a terminal chamber for installing a wiring terminal. Through the invention, the structure of the LED embedded barrel lamp becomes concise, the LED embedded barrel lamp is beautified, and moreover, the structural layouts of the driving chamber and the terminal chamber are compact, and the manufacturing cost of the radiator can not be markedly increased. In addition, the driver and an LED light-source module of the invention are respectively arranged in different chambers, and the driver and the LED light-source module do not directly contact, thus, the heat transferred from the LED light-source module to the driver can be reduced, and the service life of the driver is prolonged.

Owner:上海城上通数字科技有限公司

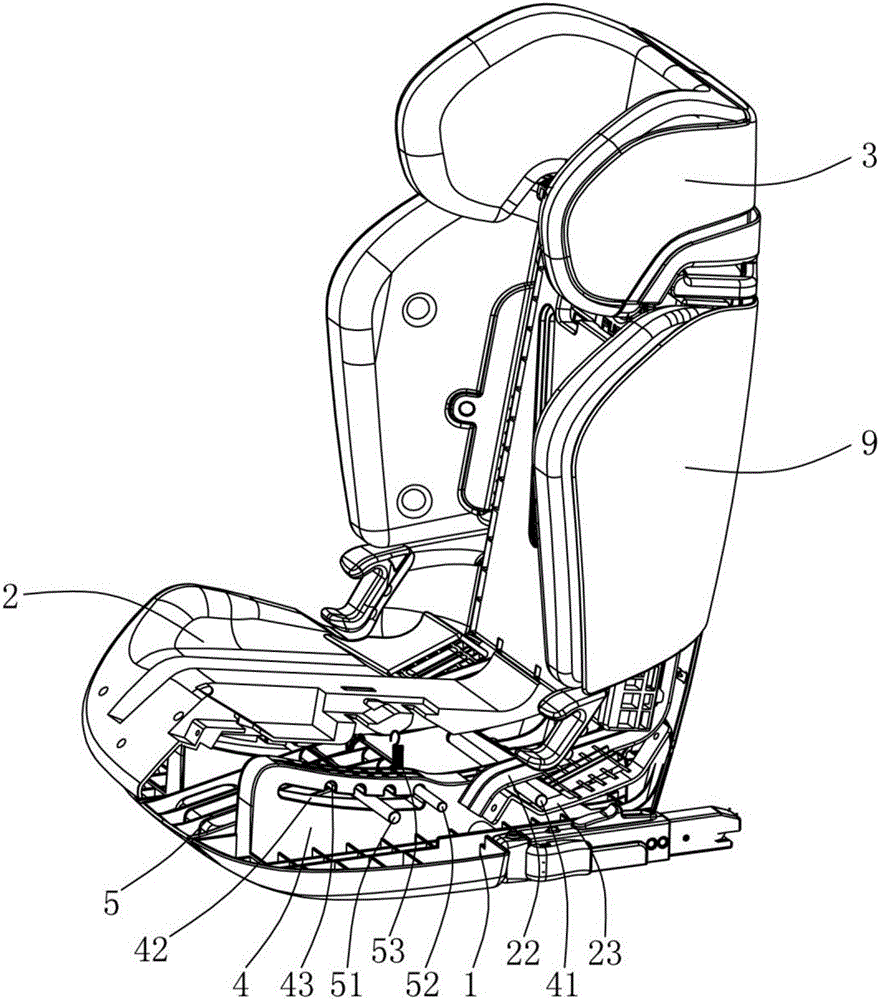

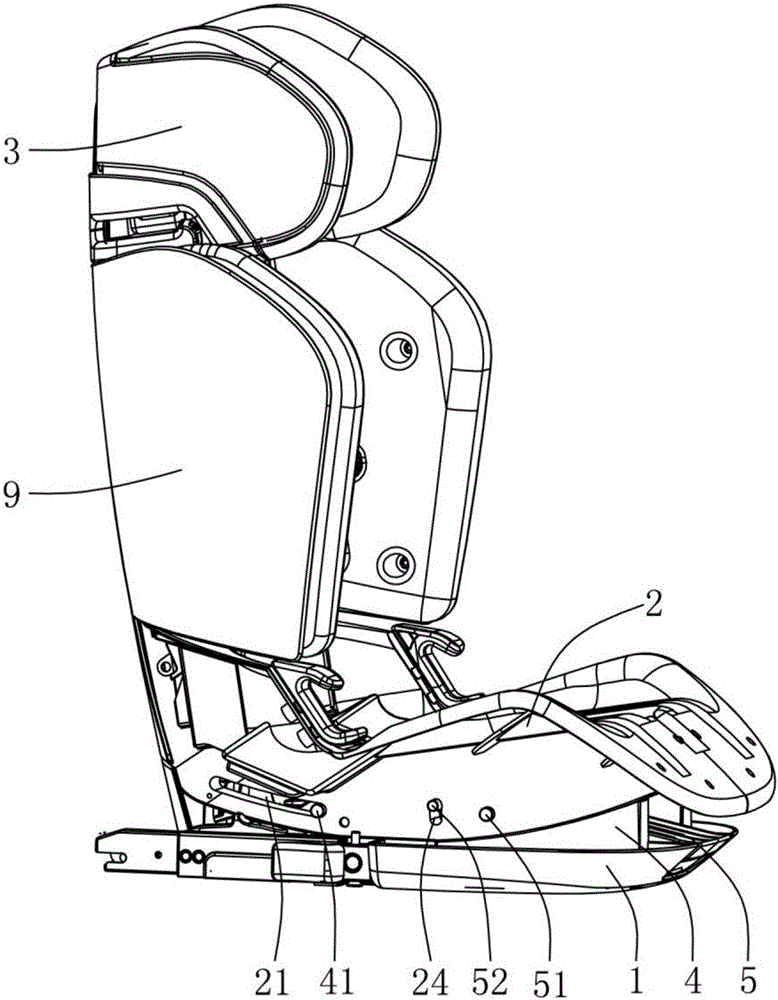

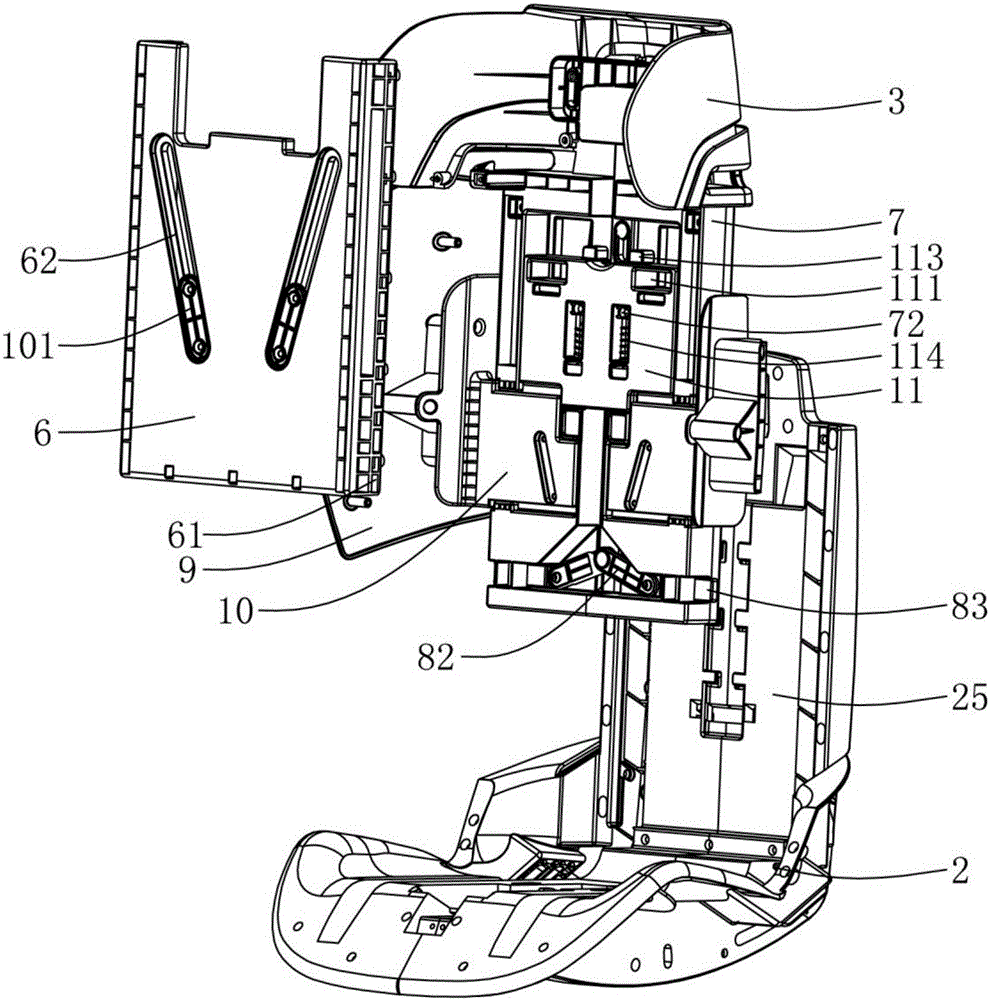

Automobile safety chair for child

ActiveCN105857131AThe connection structure is firm and reliableStrong connectionChild seatsAutomobile safetyEngineering

The invention discloses an automobile safety chair for a child. The automobile safety chair comprises a base, a chair body and a headrest; a slideway seat is arranged on the base; a first guide chute is formed in the bottom of the chair body; a first slide rod which is in sliding fit with the first guide chute is arranged on the slideway seat; a lifting block is arranged between the chair body and the base; a second guide chute is formed in the slideway seat; a second slide rod and a third slide rod which are in sliding fit with the second guide chute are respectively mounted on the lifting block; a plurality of limiting grooves are formed in the wall of the second guide chute in parallel; a back plate is fixedly connected to a chair back of the chair body, and a headrest plate is arranged between the chair back and the back plate; a pull rod is vertically arranged on the headrest plate, and a pull rod spring is arranged between the pull rod and the headrest plate; a lower locking block is hinged to the bottom end of the pull rod through a lower linkage arm, and a plurality of back plate locking holes which are in locking fit with the lower locking block are formed in the side of the back plate from top to bottom. The automobile safety chair disclosed by the invention is simple and reasonable in structure, convenient to operate, reliable in position adjustment and higher in safety.

Owner:NINGBO BOLENN MFG

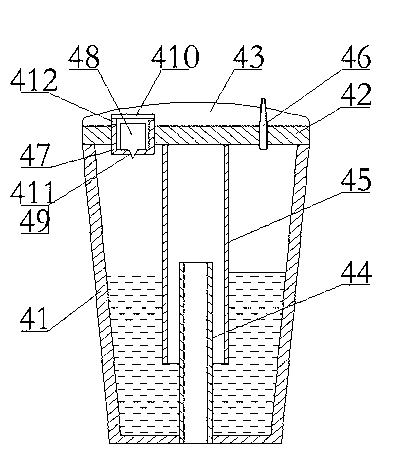

Aerospace oxygenerator

InactiveCN103072948AExtended service lifeImprove the comfort of the use environmentOxygen preparationMolecular sieveGas cylinder

The invention relates to an aerospace oxygenerator which comprises a case, a compressor, a distribution valve, a gas cylinder and two molecular sieves, wherein a bottom plate for packaging is arranged at the bottom of the case; a compression system box is arranged on the bottom plate; the compressor is supported in the compression system box; a gas inlet mechanism is arranged at the lower part of the front end face and / or the rear end face of the case, and communicated with the compressor by a gas inlet silencer; the compressor is connected with the two parallel molecular sieves by the distribution valve respectively; the two molecular sieves are connected with the gas cylinder by the distribution valve; the distribution valve is communicated with a gas outlet silencer; the gas outlet silencer is communicated with the compression system box; and the compression system box is communicated with an exhaust mechanism arranged at the lower part of the left side face and / or the right side face of the case. The aerospace oxygenerator is compact in structure, convenient, quick, stable and safe to use, easy to dismount and clean, and noise-free; the use comfort can be ensured effectively; and the service life can be prolonged.

Owner:江苏徕普医疗器械有限公司

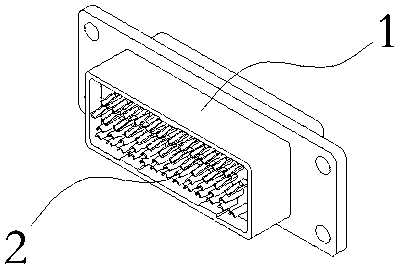

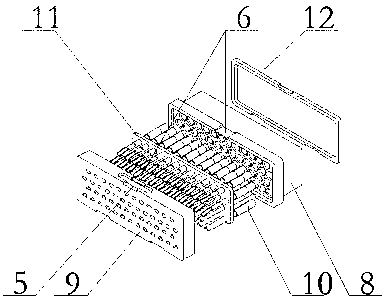

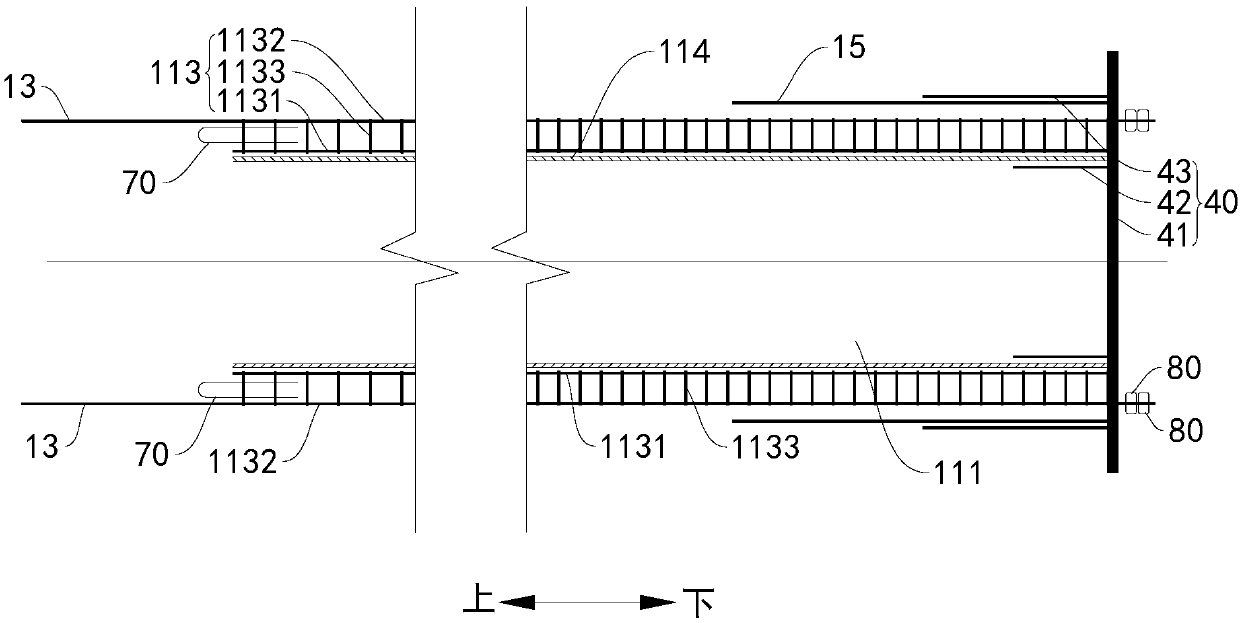

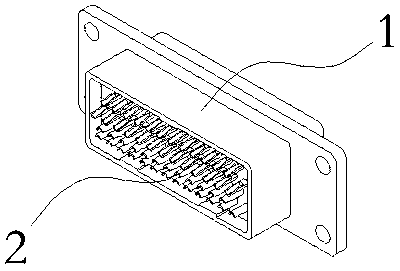

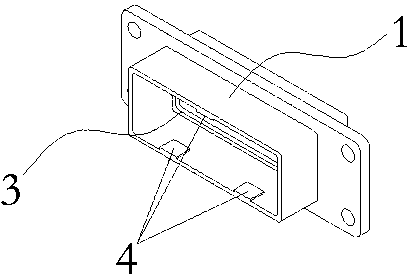

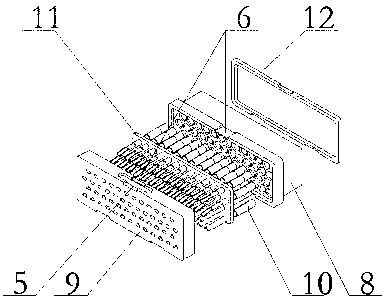

Snap spring fixing type rectangular electric connector, assembly tool thereof and assembly method thereof

ActiveCN103001052AReduce connection gapsImprove performanceContact member assembly/disassemblyCouplings bases/casesEngineeringElectrical and Electronics engineering

The invention relates to a snap spring fixing type rectangular electric connector. The electric connector comprises a housing and an insulating assembly, wherein the inner end face of the insulating assembly is attached to a heavy platform in the housing correspondingly, more than one snap spring slots are arranged on one or more side walls of the insulating assembly, more than one positioning bosses are arranged on one or more inner walls of the housing, snap springs which are pressed in the snap slots tightly by the housing inner walls are arranged in snap spring slots, and the snap springs abut against the sides of the positioning bosses, which face to the inside of the housing. The snap spring slots and through slots which are communicated are arranged on the insulating assembly, positioning bosses in the housing are inserted in through slots correspondingly, snap springs in snap spring slots press tightly, and the insulating assembly and the housing are clamped fixedly. The connector is simple in structure, firm, free from clearance, suitable to harsh environment, not easy to damage, stable in use and long in service life.

Owner:CHINA NORTH IND GRP HANGLIAN TECH CO LTD

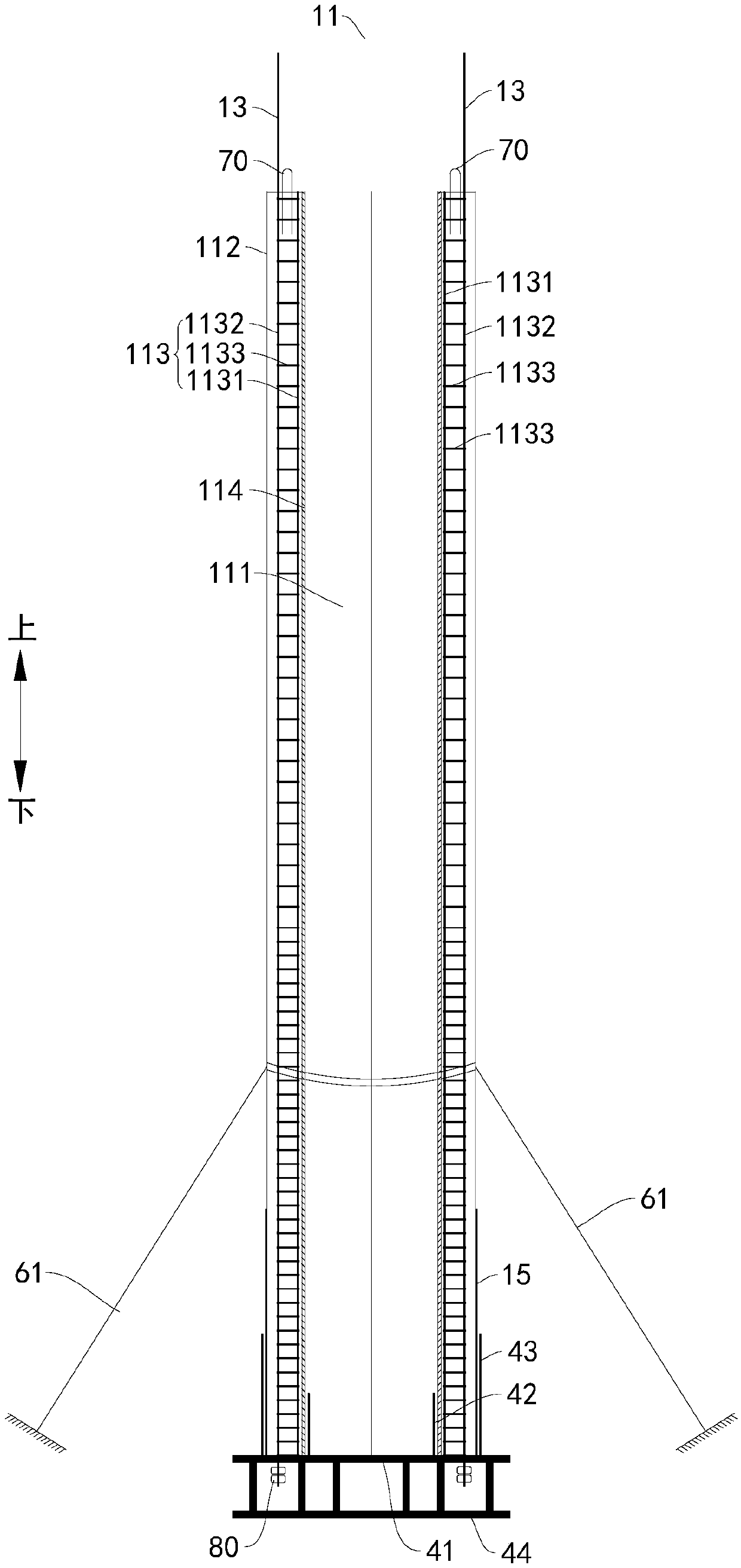

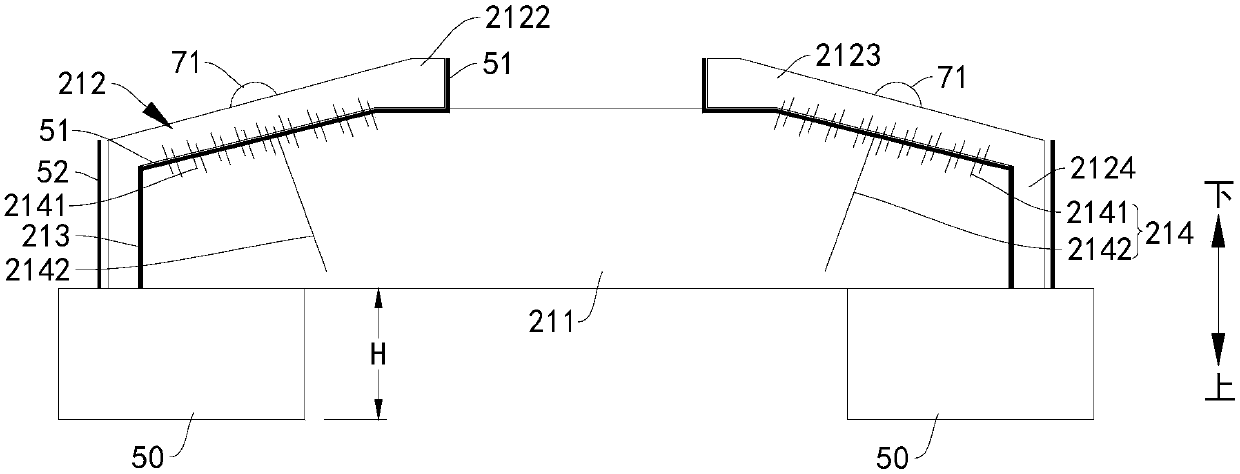

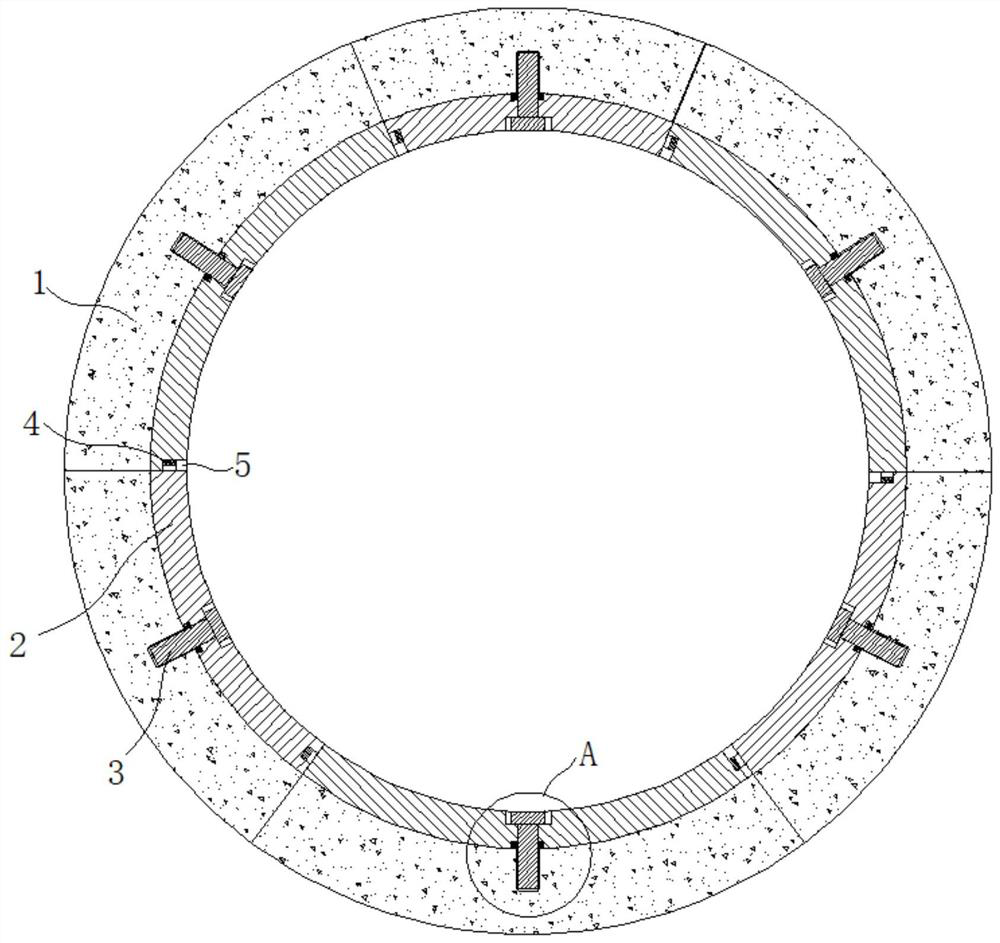

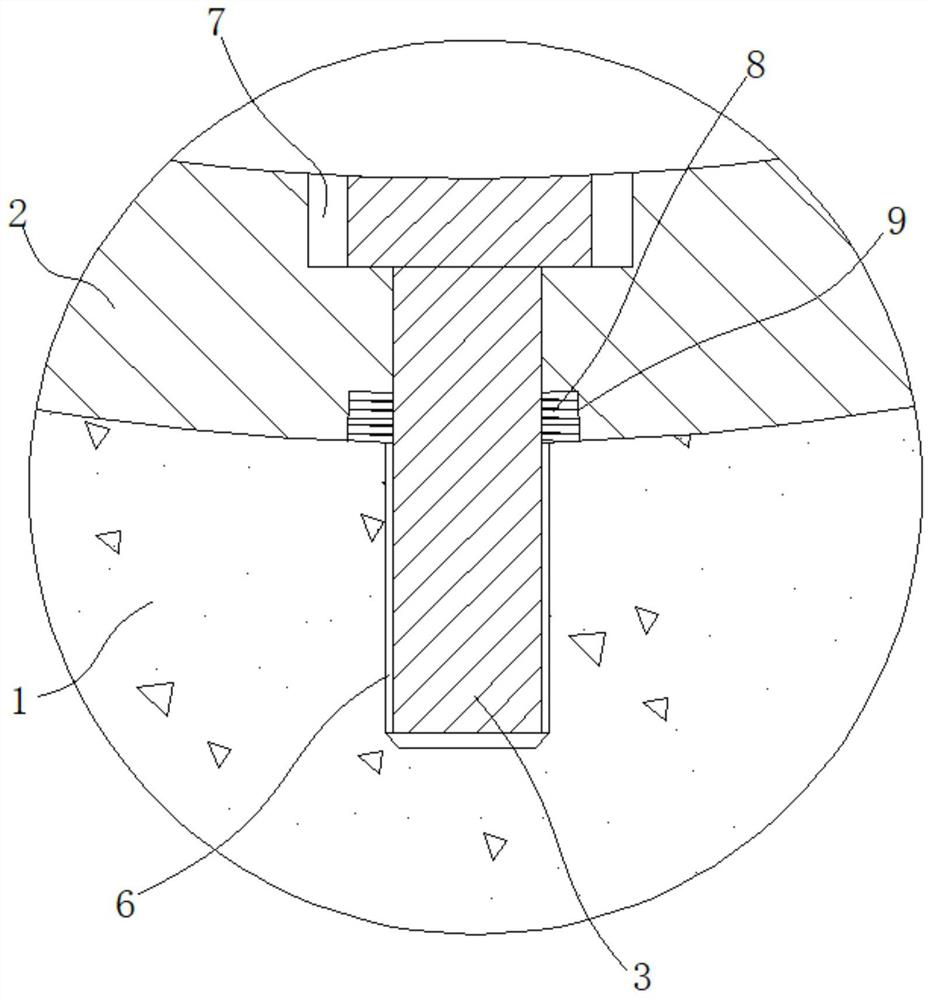

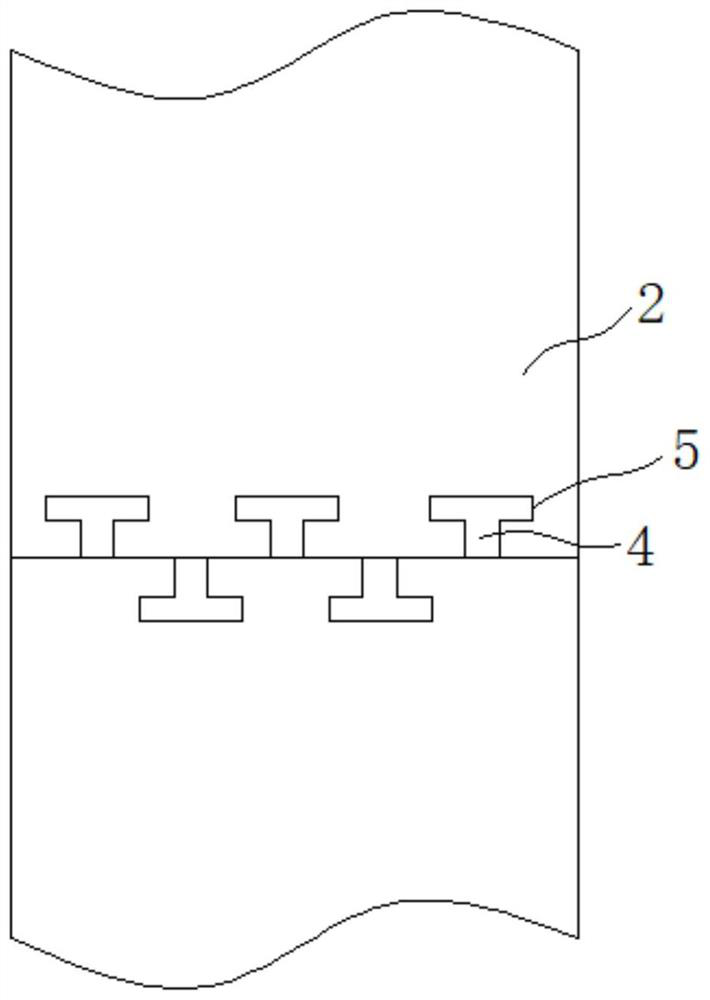

Manufacturing method of bridge pier

ActiveCN110656574AReduce adverse effectsThe connection structure is stable and reliableCeramic shaping apparatusBridge structural detailsArchitectural engineeringPier

The invention discloses a manufacturing method of a bridge pier. The manufacturing method of the bridge pier comprises the following steps of obtaining a pier stud prefabricated part and a capping beam prefabricated part, wherein a pier stud prefabrication chamber extending in the axial direction is formed in the pier stud prefabricated part; a capping beam prefabrication chamber is formed in thepier stud prefabricated part; a connecting rib extending upwards is arranged on the pier stud prefabricated part; the pier stud prefabricated part is placed on a mounting surface; concrete is injectedinto the pier stud prefabrication chamber from an opening in the upper end of the pier stud prefabrication chamber to be cured to form a pier stud concrete layer; the capping beam prefabricated partis mounted at the upper part of the pier stud prefabricated part, and the connecting rib is enabled to extend into the capping beam prefabrication chamber; and concrete is injected into the capping beam prefabrication chamber to be cured to form a capping beam concrete layer connected with the pier stud concrete layer and the connecting rib. According to the manufacturing method of the bridge pierdisclosed by the embodiment of the invention, the site construction procedure is simple, the construction speed is increased, the construction safety is enhanced, adverse effect of a traditional fullcast-in-situ process on traffic environment is avoided, and moreover, the connection between a pier stud and a capping beam is firmer.

Owner:BYD CO LTD

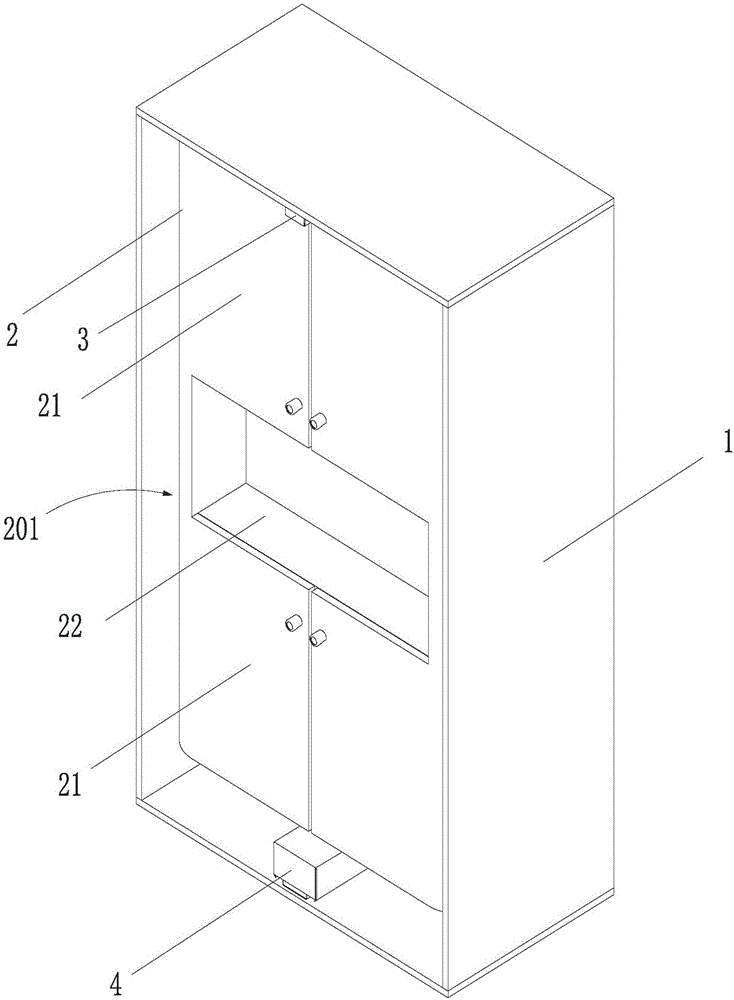

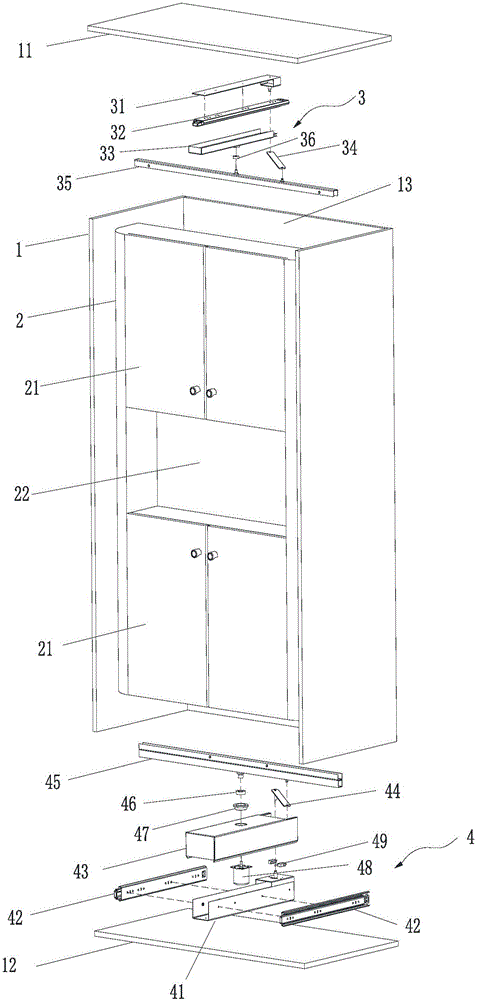

Turnover cabinet

ActiveCN106343738ASave internal spaceSimple connection and flip structureRevolving cabinetFittingEngineering

Owner:广东顶固集创家居股份有限公司

Shield interval tunnel connection channel segment supporting structure

ActiveCN111894636ADoes not hinder accessShorten the construction periodUnderground chambersTunnel liningEngineeringScrew thread

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

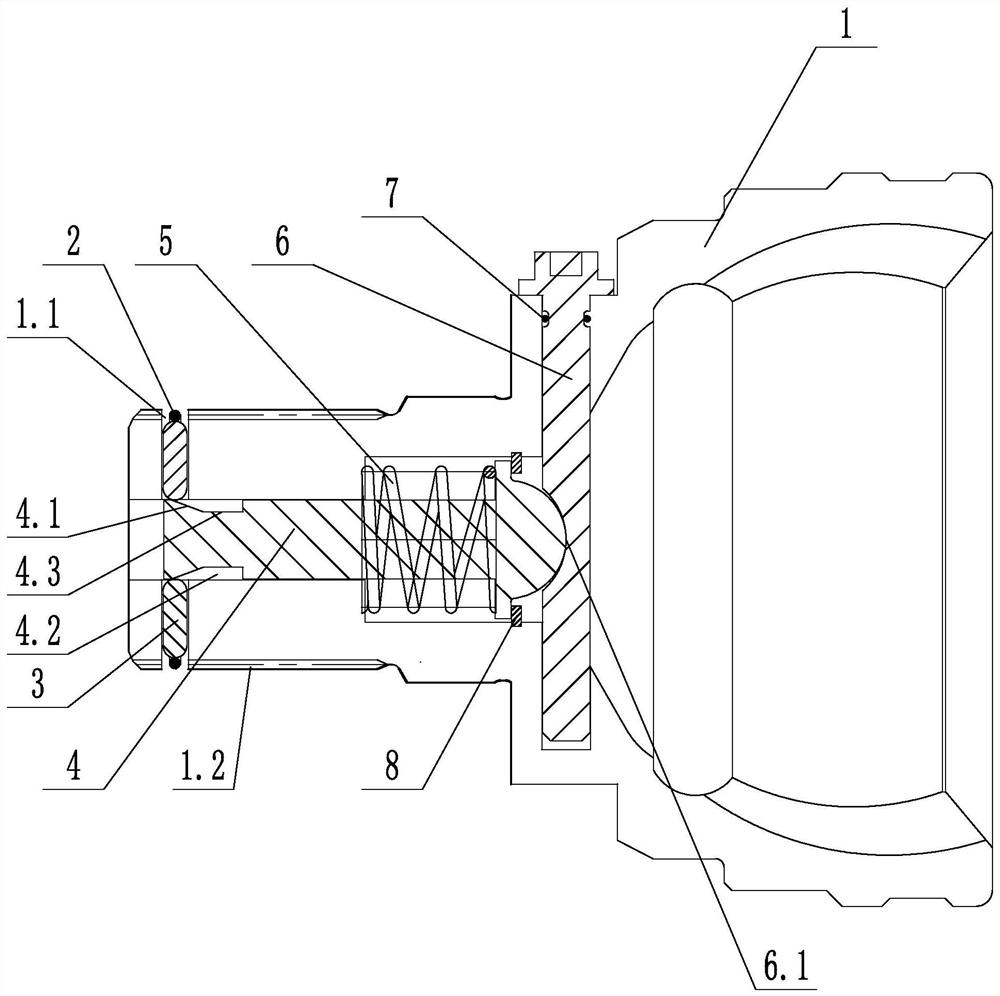

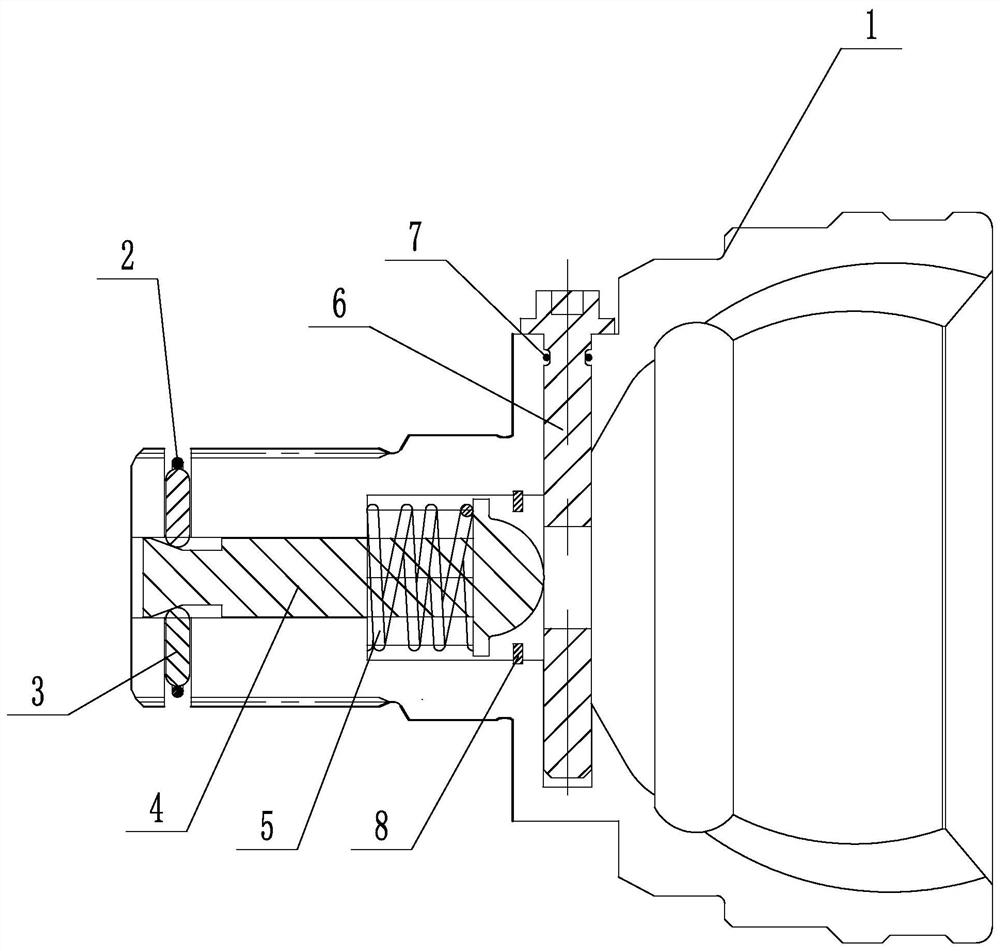

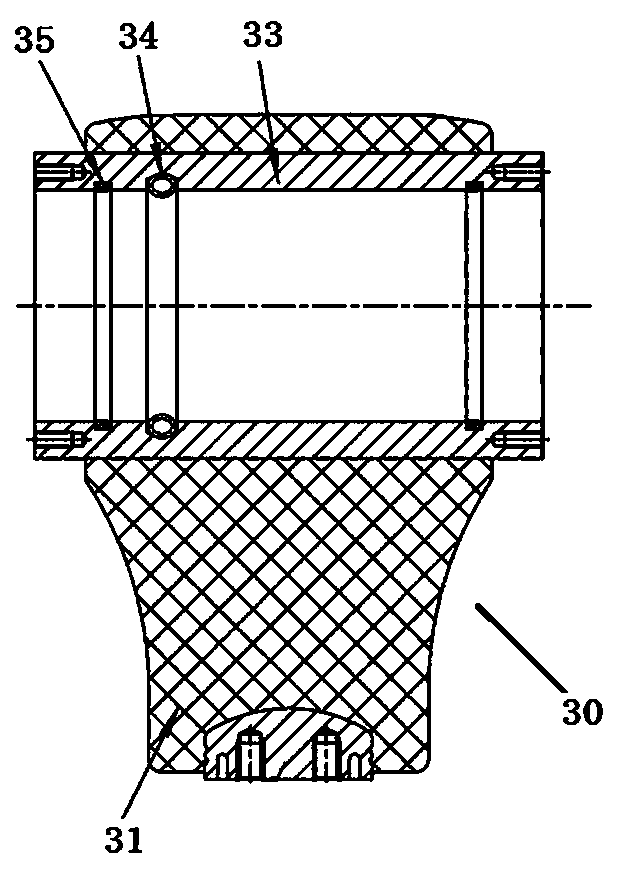

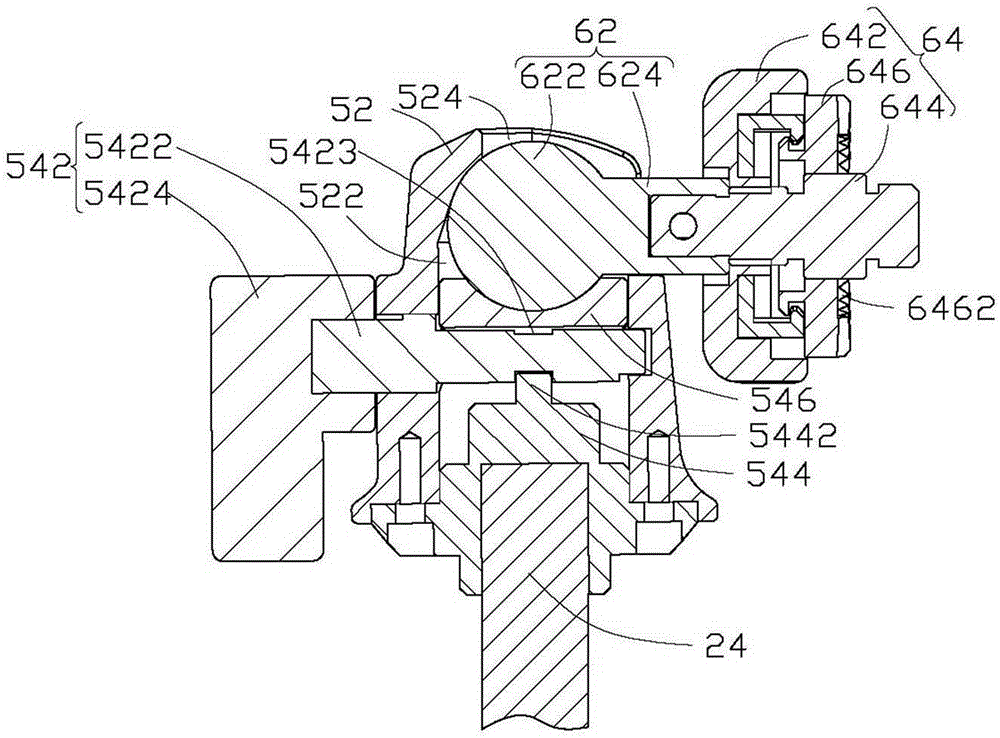

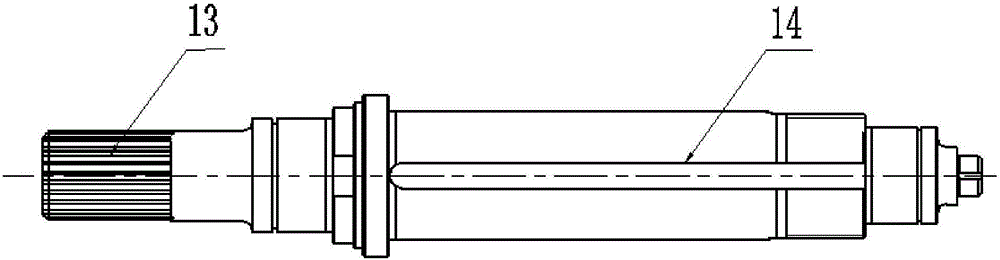

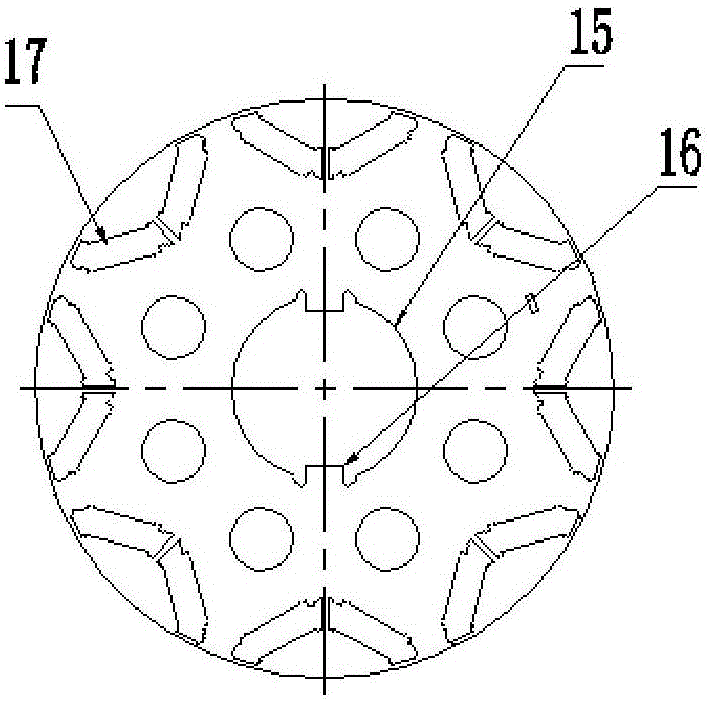

Constant velocity universal joint structure with locking structure

PendingCN113074192AThe connection structure is stable and reliableEasy to disassembleYielding couplingUniversal jointConstant velocity

The invention discloses a constant velocity universal joint structure with a locking structure. The constant velocity universal joint structure comprises a ball cage body, a clamp spring, a locking rod, a push rod, a telescopic spring and a locking rod. The push rod is connected with the ball cage body in a sliding manner, one end of the telescopic spring is connected with the push rod, the other end of the telescopic spring is connected with the ball cage body, and the locking rod is rotationally connected with the ball cage body. A clamping groove is formed in the side wall of one side of the locking rod, one end of the push rod is matched with the clamping groove and arranged in the clamping groove, a locking inclined face is arranged on the side wall of the push rod, a limiting ring groove is formed in the outer side wall of the ball cage body, the clamp spring is arranged in the limiting ring groove in a sleeved mode, one end of the locking rod makes contact with the locking inclined face, and the other end of the locking rod makes contact with the inner wall of the clamp spring. According to the constant velocity universal joint structure with the locking structure, the connecting structure of the ball cage body is convenient to disassemble and assemble and is slightly limited by space; and the connecting structure of the ball cage body is more reliable.

Owner:WONH IND

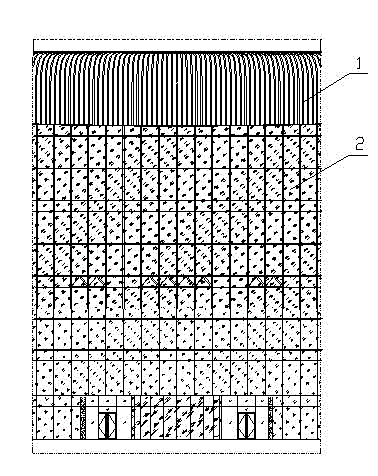

Integrated wood formwork

InactiveCN103306474ASimple connection structureThe connection structure is stableForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSteel tubeSurface plate

The invention relates to an integrated wood formwork. The integrated wood formwork comprises a face plate, a plurality of wood longitudinal beams and a plurality of steel pipe horizontal beams; the plurality of wood longitudinal beams are pressed on the outer side surface of the face plate through the plurality of horizontally arranged steel pipe horizontal beams; a plurality of cotter holes respectively corresponding to the plurality of steel pipe horizontal beams are formed in the wood longitudinal beams; a plurality of U-shaped cotters are inserted in the plurality of cotter holes respectively; and the two ends of each U-shaped cotter are fastened and connected on each steel pipe horizontal beam corresponding to each U-shaped cotter. According to the invention, the integrated wood formwork is formed by locking and pressing the wood longitudinal beams and the steel pipe horizontal beams on the face plate through the U-shaped cotters and 3-shaped clips, and has the advantages that the structure is simple, the connection is stable and firm, the assembly and disassembly are convenient, the service life of the material is long, recoverability is realized and the resource is saved; a plurality of integrated wood formworks can be jointed together and used in a combined manner, so as to meet the requirements of different application specifications; and the applicability is wide.

Owner:TAIXING FIRST CONSTR INSTALLATION

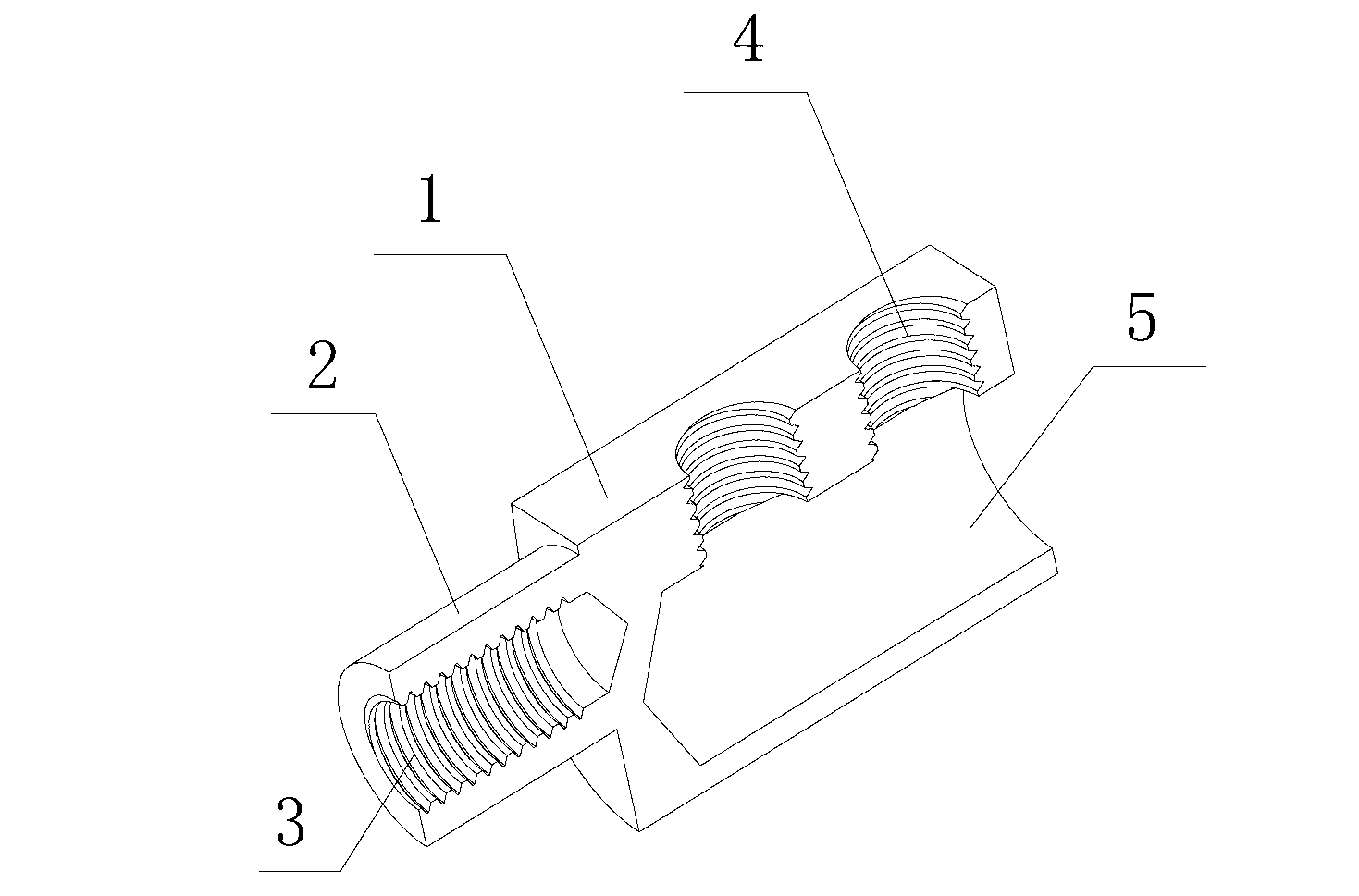

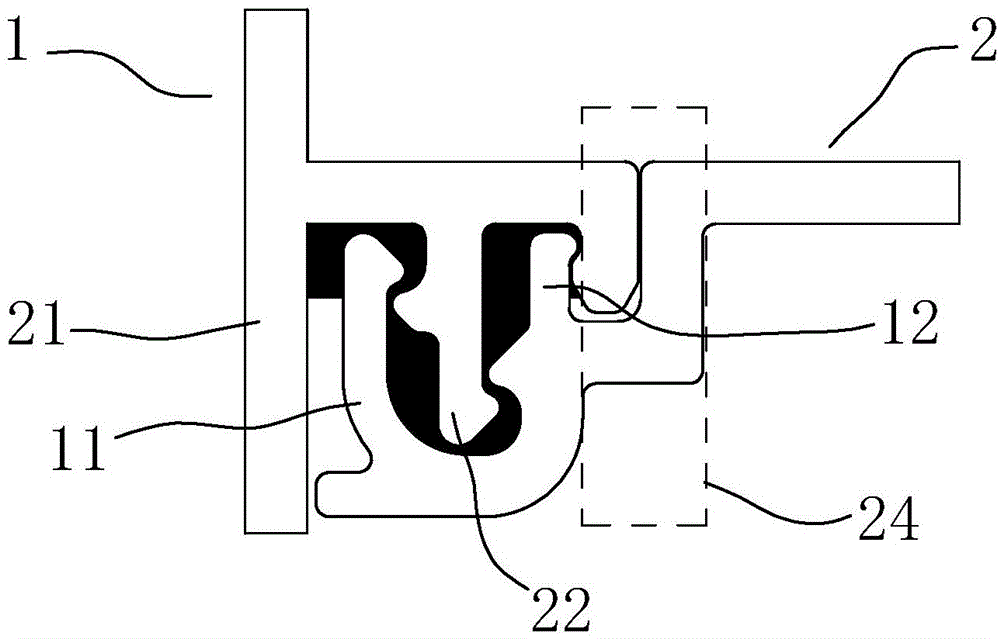

Connection structure of connection end of component and connection terminal

ActiveCN102842780ASelf-maintaining performanceEasy to useContact member manufacturingClamped/spring connectionsContact positionElectric power

The invention provides a connection structure of a connection end of a component and a connection terminal used in instruments and meters, discloses the connection structure of the connection end of the component and the connection terminal which is especially suitable for the field of electric energy meters, and aims at providing the connection structure of the connection end of the component and the connection terminal which is simple in structure, low in resistance in a contact position of the connection end of the component and the connection terminal, large in axial torsion of the connection terminal and low in self-power-consumption. The connection structure of the connection end of the component and the connection terminal comprises the connection terminal and a sampling device, wherein the connection terminal is a metal connection cylinder. Two ends of the metal connection cylinder are respectively provided with opposite holes, and the opposite holes are not communicated with each other. One end of the connection terminal is provided with a connection hole used for input and output of meter external power, and the other end of the connection terminal is connected with an input and output end binding post of the component, and a compression joint structure is formed by the other end of the connection terminal and the input and output end binding post of the component. The connection structure of the connection end of the component and the connection terminal has the advantages of being simple in structure, and convenient to produce and assemble. Meanwhile, the connection structure of the connection end of the component and the connection terminal can not loose or fall off easily and can improve usability of the component and the like.

Owner:TONGXIANG WEIDA ELECTRONICS

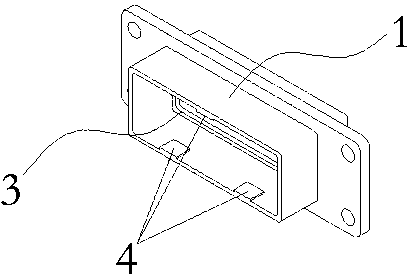

Snap spring fixing type rectangular electric connector

ActiveCN103001043AReduce connection gapsFirmly positionedCouplings bases/casesEngineeringElectrical and Electronics engineering

The invention relates to a snap spring fixing type rectangular electric connector. The connector comprises a housing and an insulating assembly, wherein the inner end face of the insulating assembly is attached to a heavy platform in the housing correspondingly, more than one snap spring slots are arranged on one or more side walls of the insulating assembly, more than one positioning bosses are arranged on one or more inner walls of the housing, snap springs which are pressed in the snap slots tightly by the housing inner walls are arranged in snap spring slots, and the snap springs abut against the sides of the positioning bosses, which face to the inside of the housing. The snap spring slots and through slots which are communicated are arranged on the insulating assembly, positioning bosses in the housing are inserted in through slots correspondingly, snap springs in snap spring slots press tightly, and the insulating assembly and the housing are clamped fixedly. The connector is simple in structure, firm, free from clearance, suitable to harsh environment, not easy to damage, stable in use and long in service life.

Owner:CHINA NORTH IND GRP HANGLIAN TECH CO LTD

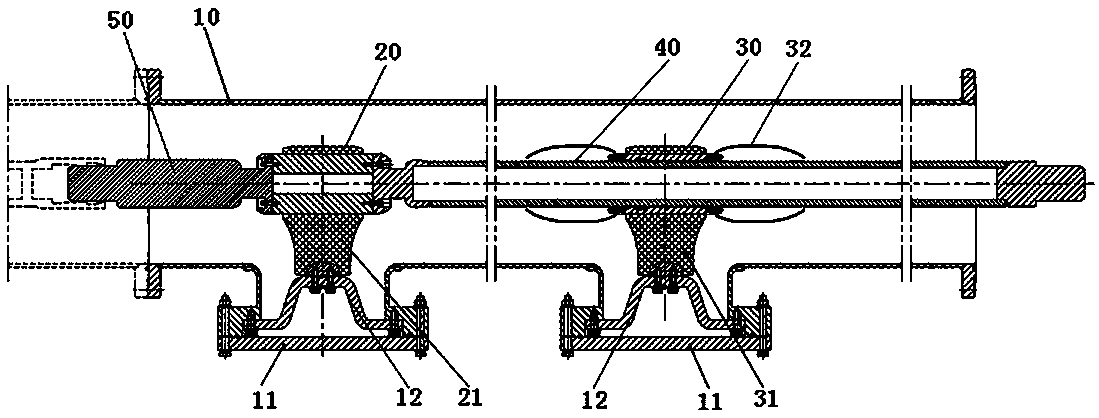

Pipeline bus and detachable bus unit of pipeline bus

ActiveCN110224360AEasy to disassembleAchieve conductionTotally enclosed bus-bar installationsSupporting insulatorsEngineering

The invention relates to a pipeline bus and a detachable bus unit of the pipeline bus, which can be used to solve the technical problem that the bus unit is inconvenient to disassemble in the prior art. The detachable bus unit of the pipeline bus includes a cylinder, a conductive rod and insulators supporting the conductive rod. The conductive rod includes a conductive connecting rod and an adapter. The insulators include a fixed supporting insulator and a movable supporting insulator. The fixed supporting insulator is equipped with a conductive insert. An adapter fixing structure is arrangedat the left end of the conductive insert, and a connecting rod fixing structure is arranged at the right end of the conductive insert. The overall length of the conductive connecting rod is less thanthe length of the cylinder, and is larger than the distance between the right end of the fixed supporting insulator and the right opening of the cylinder. The overall length of the adapter is larger than the distance between the left end of the fixed supporting insulator and the left opening of the cylinder, and the length of the adapter for insertion fit with the conductive rod in an adjacent busunit on the left is smaller than the dimension of the fixed supporting insulator in the left-right direction.

Owner:PINGGAO GRP +1

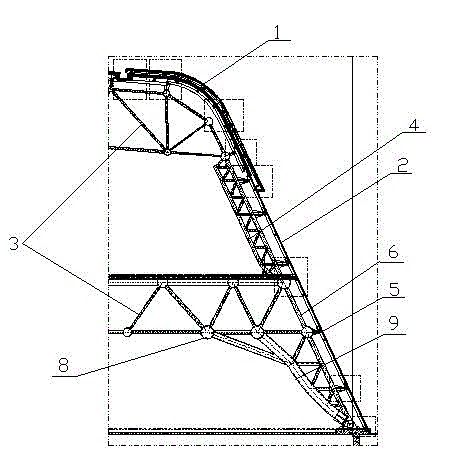

Inclined hidden-frame glass curtain wall connecting structure

ActiveCN104453034AGood heat protectionExtended service lifeWallsArchitectural engineeringSteel frame

The invention discloses an inclined hidden-frame glass curtain wall connecting structure. The inclined hidden-frame glass curtain wall connecting structure comprises a ceiling and a plurality of pieces of hidden-frame glass. The ceiling and the hidden-frame glass are all fixed through trusses. The trusses are arranged in multiple layers. Every two layers of trusses are welded and fixed through a steel frame. Each piece of hidden-frame glass is fixed to a cross beam through a corresponding stand column. Each stand column is fixed to a strut. The struts support a whole hidden-frame glass curtain wall. The trusses support the ceiling and the cross beams. The cross beams and the steel frames are integrally welded. The cross beams are fixedly connected with the trusses through joints. An inclined bracket is fixedly connected between the truss located at the lowermost position and the bottom of the corresponding cross beam, and each endpoint of the inclined bracket is fixedly connected with one corresponding joint of the truss. By the adoption of the technical scheme, the inclined hidden-frame glass curtain wall connecting structure has the advantages of being simple, good in stability and anti-seismic property, long in service life, convenient to construct and safe.

Owner:JIANGSU HEFA GROUP

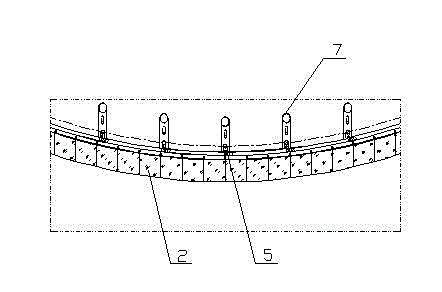

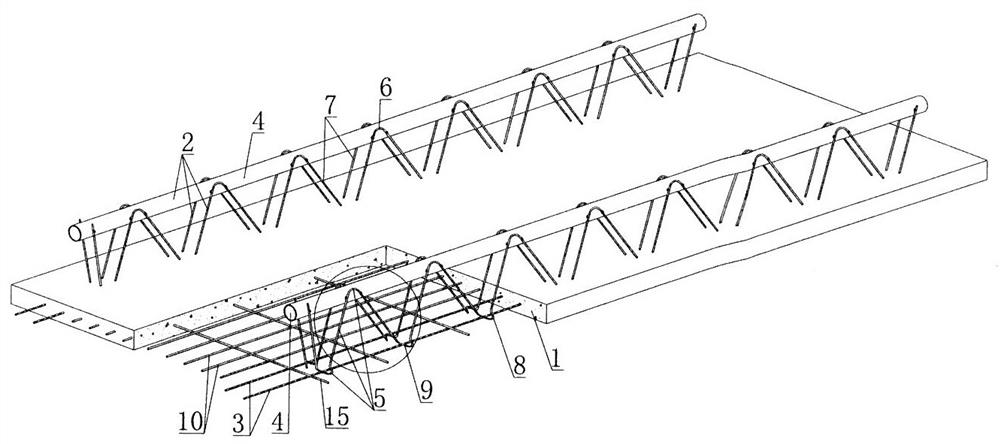

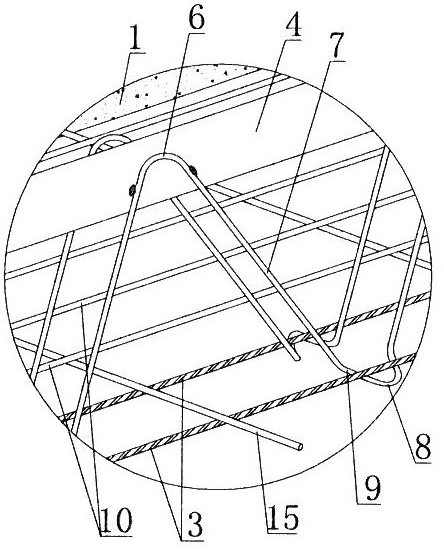

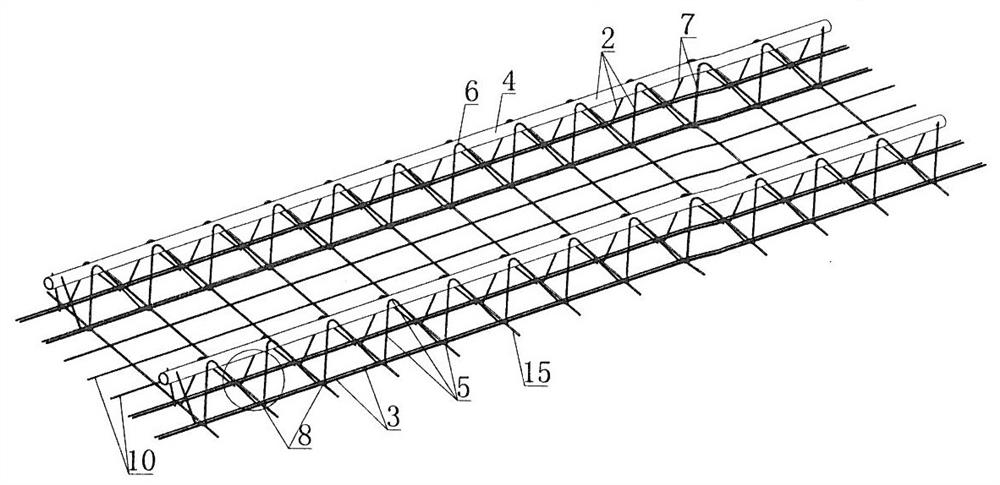

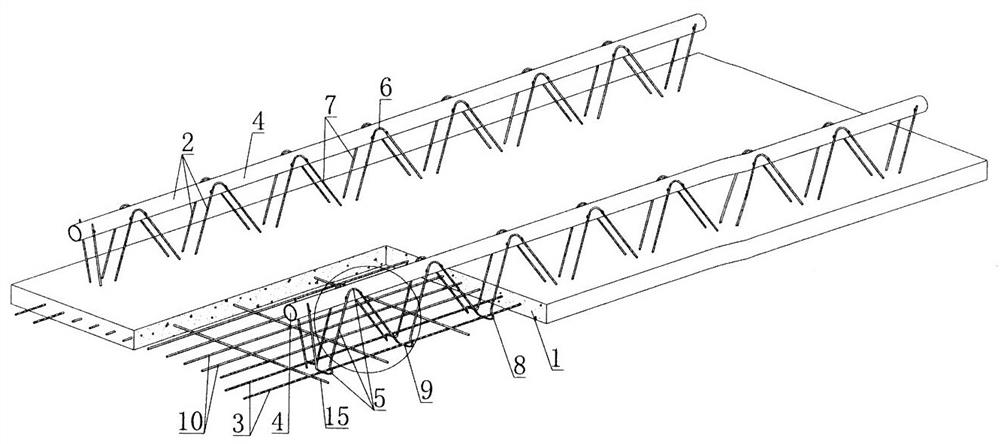

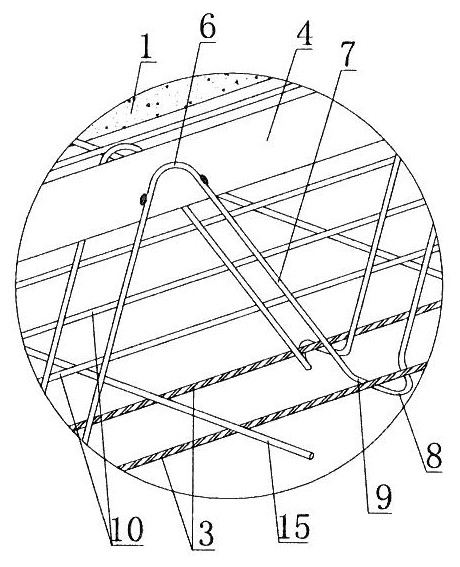

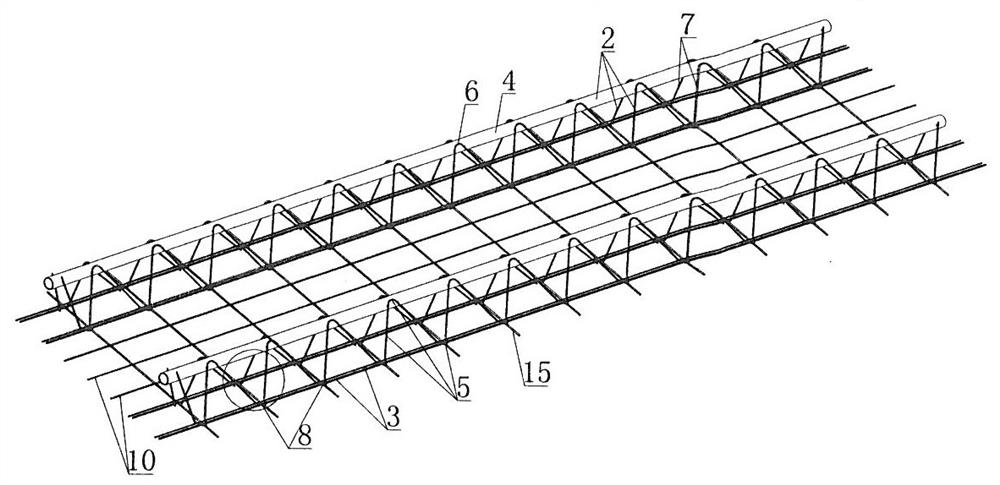

Steel pipe truss prestressed concrete laminated slab

ActiveCN113089920AHold up firmlyPlay the role of lifting prestressed steel barsConstruction materialFloorsReinforced concretePre stress

The invention discloses a steel pipe truss prestressed concrete laminated slab which comprises a reinforced concrete bottom plate and a steel pipe truss; a plurality of longitudinal prestressed steel bars are distributed in the reinforced concrete bottom plate; the steel pipe truss comprises a steel pipe and wavy steel bars welded to the two sides of the steel pipe; a wave trough section or / and a web member lower section of each wave steel bar is / are transversely bent to form a bent V-shaped bearing force transmission component; the wave trough section or / and the transverse lower section of a transverse bent web member is / are transversely embedded into the reinforced concrete bottom plate; the vertical lower section of the web member is embedded into the concrete bottom plate; longitudinal prestressed steel bars are arranged on the bent V-shaped bearing force transmission component; and the longitudinal prestressed steel bars and the bent V-shaped bearing force transmission component are glued into a whole by concrete. The structure strength is guaranteed, and meanwhile the characteristics of being convenient for industrial, standardized and mechanical production and the like are achieved.

Owner:湖南邱则有专利战略策划有限公司

Steel structure node connecting structure for building and connecting method thereof

ActiveCN110886387AThe connection structure is stable and reliablePlay a buffer roleProtective buildings/sheltersShock proofingEngineeringMechanical engineering

Owner:TANGSHAN SINOMA HEAVY MASCH CO LTD

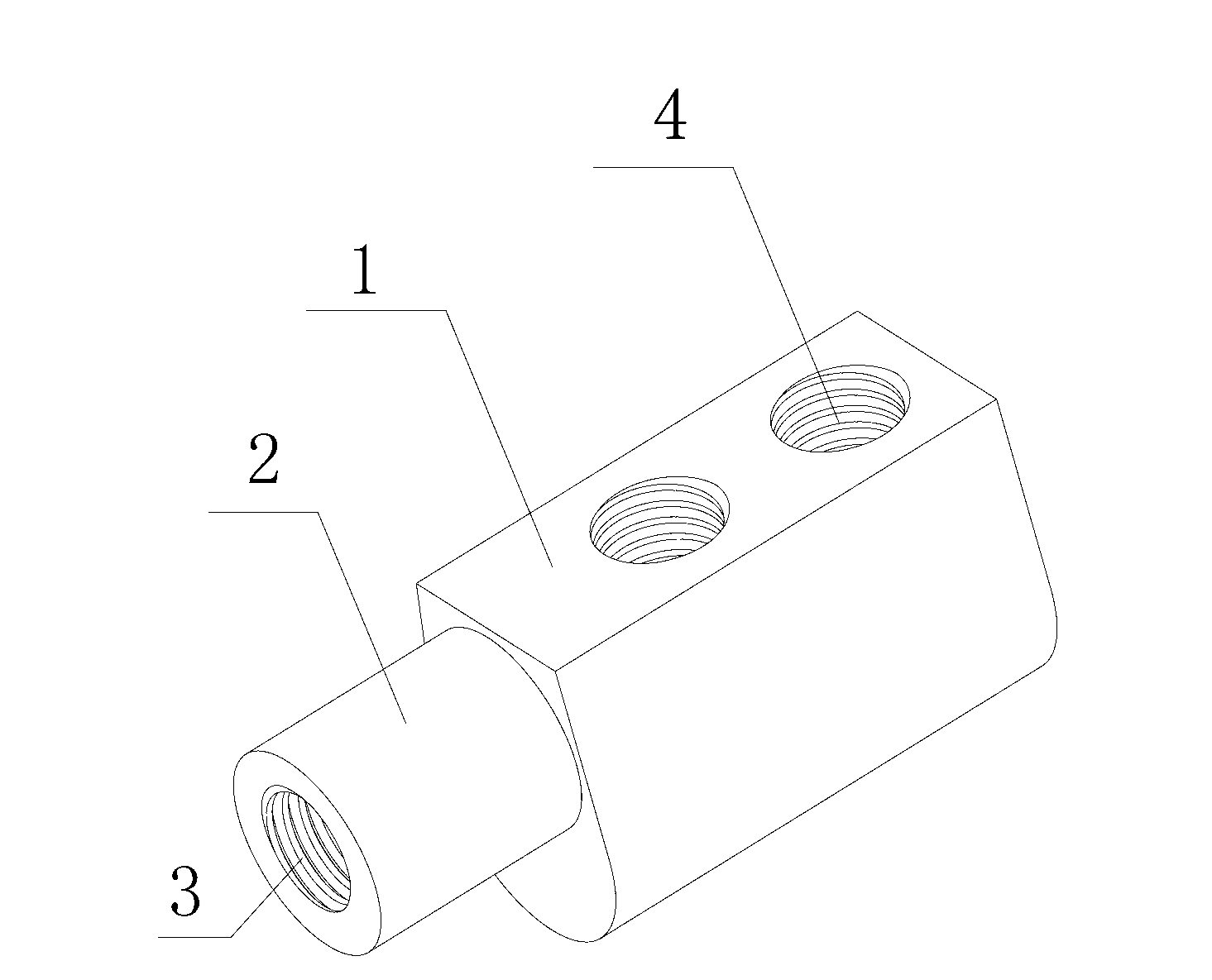

Test leakage machine plugging assembly

InactiveCN105628306ASimple connection structureThe connection structure is stable and reliableFluid-tightness measurement using fluid/vacuumEngineeringWrench

The invention relates to a test leakage machine plugging assembly. The test leakage machine plugging assembly includes a movable bushing, a sealing ring, a movable bushing sleeve rod and a fixing rod; the movable bushing sleeve rod comprises a sleeve rod segment; two ends of the sleeve rod segment are a screw rod segment and a wrench segment; the diameter of the sleeve rod segment is greater than the diameter of the screw rod segment and is smaller than the diameter of the wrench segment; one end of the fixing rod is a fixing rod mounting portion, and the other end of the fixing rod is a movable bushing connection portion; the diameter of the fixing rod mounting portion is smaller than the diameter of the movable bushing connection portion; a movable bushing connection counter bore is formed at the movable bushing connection portion; a screw rod segment connection screw hole is formed at the bottom of the movable bushing connection counter bore; the movable bushing is a stepped bushing; the movable bushing movably sleeves the sleeve rod segment; the small end of the movable bushing is inserted into the movable bushing connection counter bore; an gap is left between the free end surface of the small end of the movable bushing and the bottom of the movable bushing connection counter bore; the sealing ring sleeves the small end of the movable bushing; the diameter of the large end of the movable bushing is equal to the diameter of the movable bushing connection portion and is larger than the diameter of the wrench segment.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS +1

Magic cube

ActiveCN105413156AAvoid loose frameImprove installation accuracyIndoor gamesEngineeringStructural engineering

Owner:GUANGZHOU GANYUAN INTELLIGENT TECH CO LTD

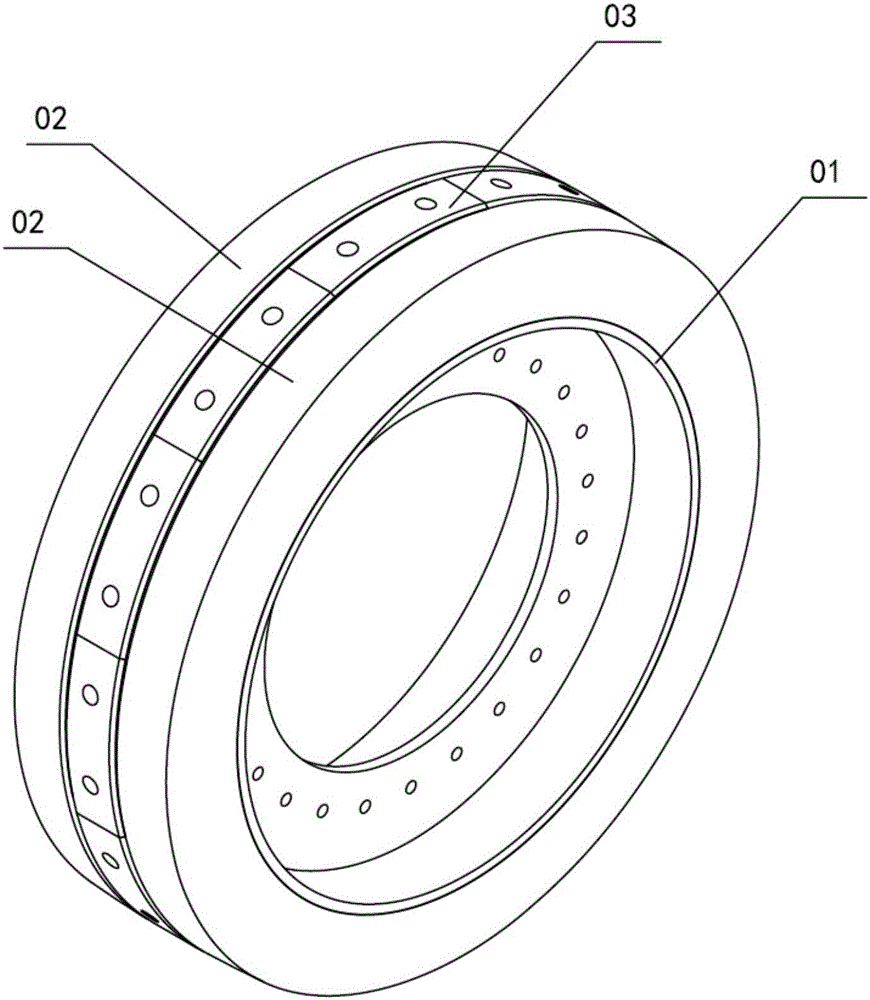

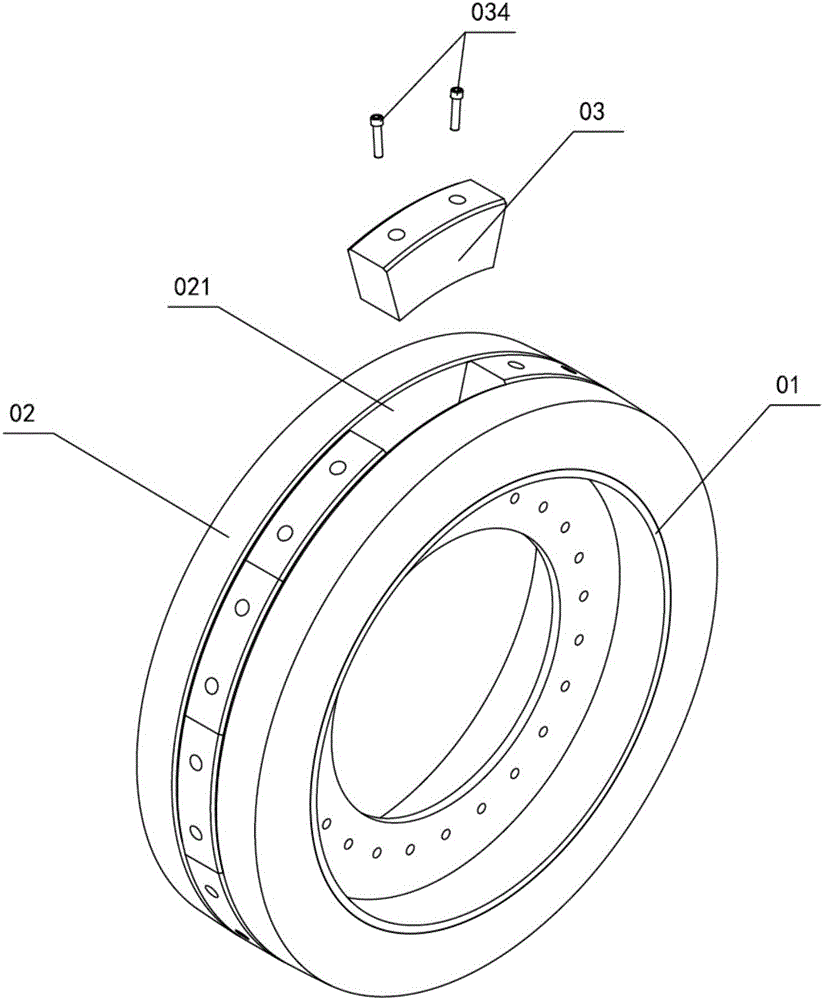

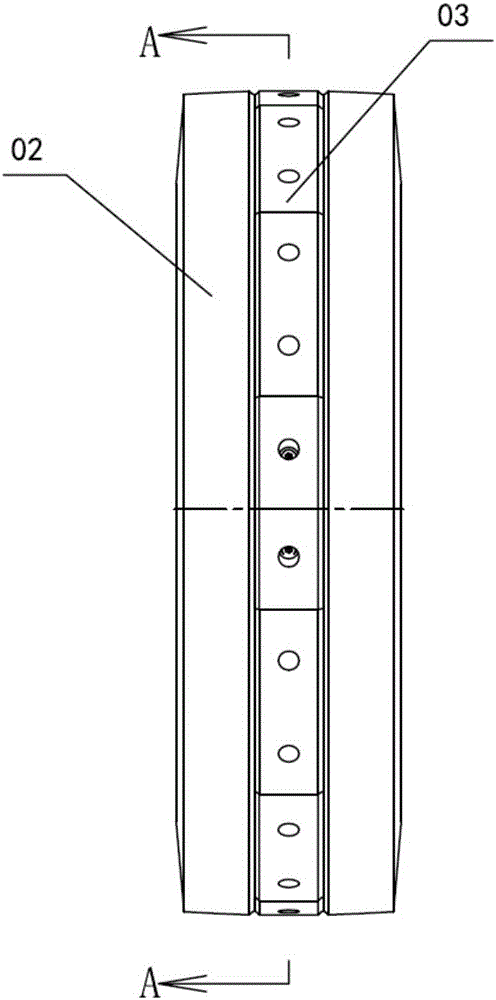

Solid tire with replaceable abrasion-resistant rubber

ActiveCN105922816AExtended service lifeImprove fixed reliabilityRoad vehicle tyresNon-inflatable tyresEngineeringMechanical engineering

The invention provides a solid tire with replaceable abrasion-resistant rubber. The solid tire comprises a rim, two tire side bodies and a plurality of movable abrasion-resistant rubber blocks. The two tire side bodies are nested in the outer side of the rim and are parallelly arranged on two sides of the rim, abrasion-resistant tire mounting grooves are formed in positions between the two tire side bodies, the multiple movable abrasion-resistant rubber blocks are arranged in the abrasion-resistant tire mounting grooves and are detachably connected with the rim, and solid tire working surfaces are jointly formed by the outer surfaces of the two tire side bodies and the outer surfaces of the movable abrasion-resistant rubber blocks. The solid tire has the advantages that the movable abrasion-resistant rubber blocks arranged in the middle of the solid tire are the most vulnerable to abrasion in solid tire working procedures, the movable abrasion-resistant rubber blocks can be directly replaced if replacement standard requirements are met by abrasion degrees of the movable abrasion-resistant rubber blocks in service procedures, and accordingly the service life of the solid tire can be greatly prolonged.

Owner:SHANDONG DONGCHE GONGTIE DUAL PURPOSE TRACTION VEHICLE CO LTD

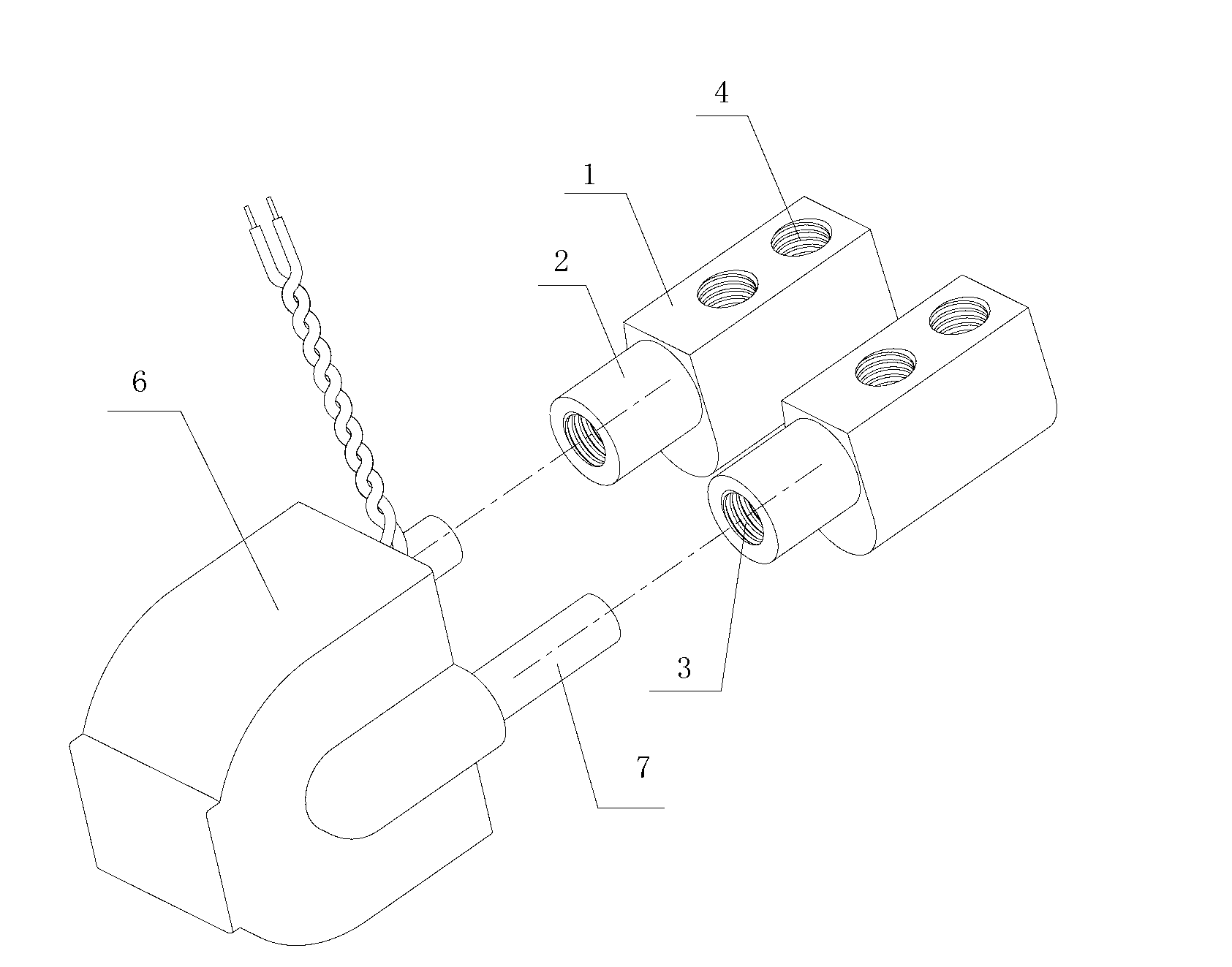

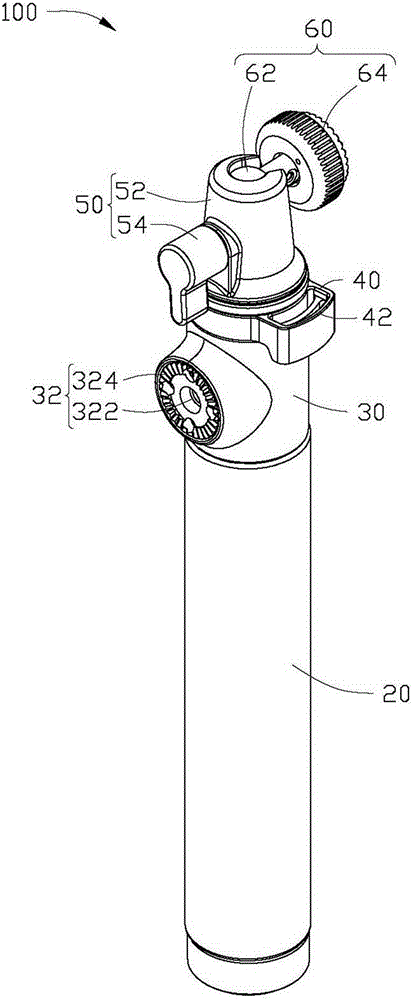

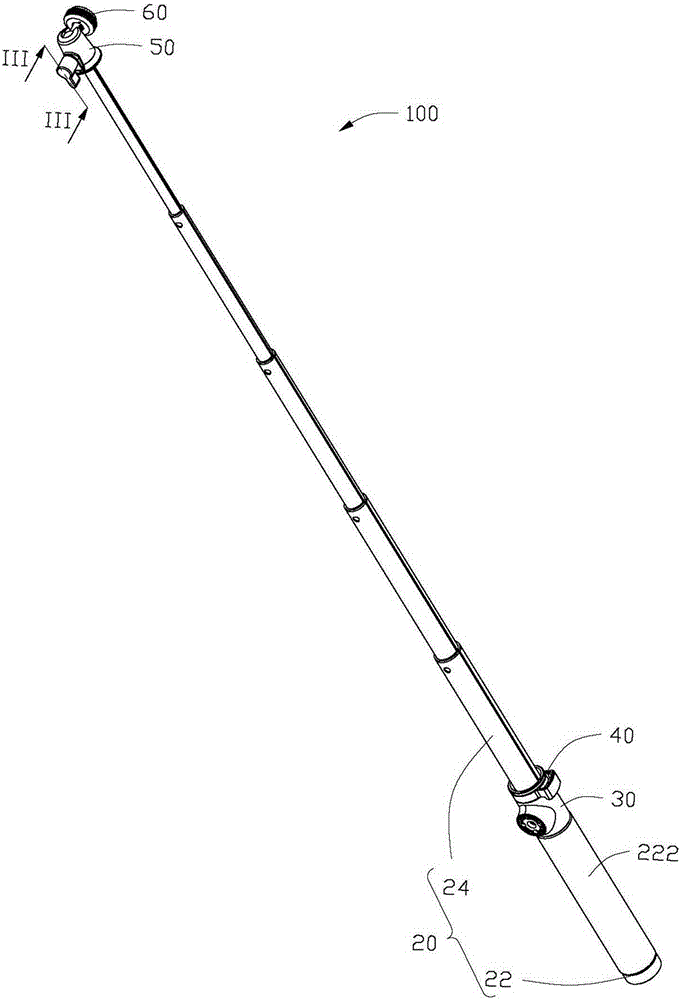

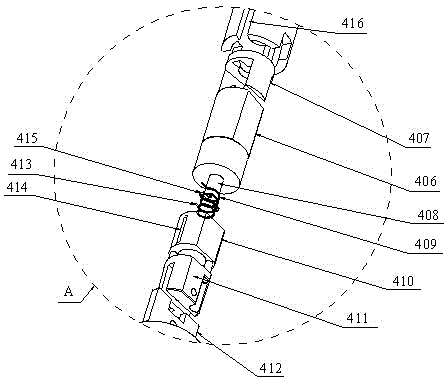

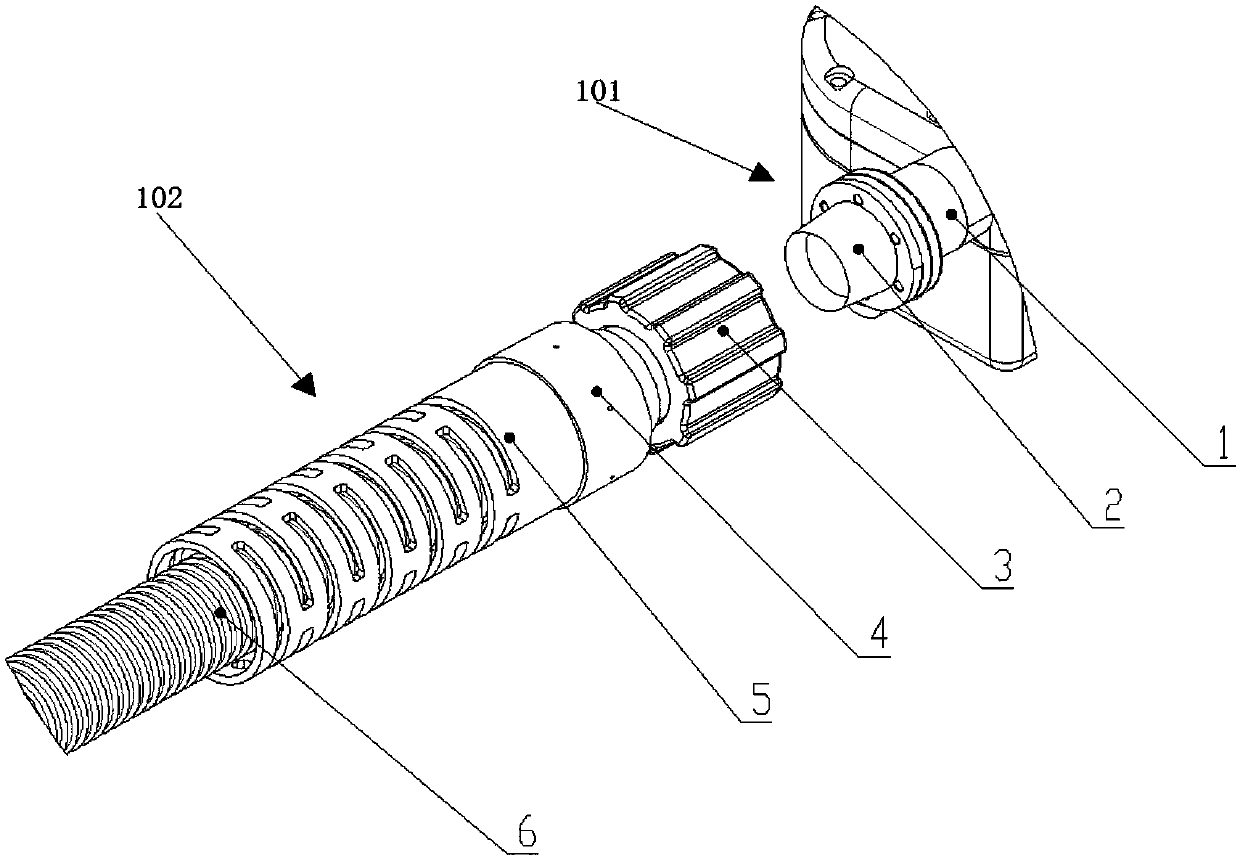

Auxiliary shooting rod, bearing seat and supporting and connecting assembly

InactiveCN105240657AImprove scalabilityImprove stabilityStands/trestlesEngineeringMechanical engineering

The invention discloses a supporting and connecting assembly used for being extended and connected with external equipment. The supporting and connecting assembly comprises an auxiliary shooting rod and a bearing seat. The auxiliary shooting rod comprises a rod body and a connecting part which is movably arranged at the tail end of the rod body, and the rod body comprises a holding rod which a user can hold with hands. The connecting part comprises an extending joint which is provided with an anti-slip area. The bearing seat comprises a seat body and accommodating space which is used for supporting the bottom of the external equipment, and the seat body comprises an extending joint which is arranged at the bottom and far from one side of the accommodating space. The extending joint of the bearing seat can be matched and connected with the extending joint of the auxiliary shooting rod, and the anti-slip area can make contact with the bottom surface of the seat body and is used for preventing the bearing seat from sliding. The extending joint of the auxiliary shooting rod of the supporting and connecting assembly is provided with the anti-slip area, and the connection stability of the auxiliary shooting rod and the bearing seat is improved.

Owner:SZ DJI OSMO TECH CO LTD

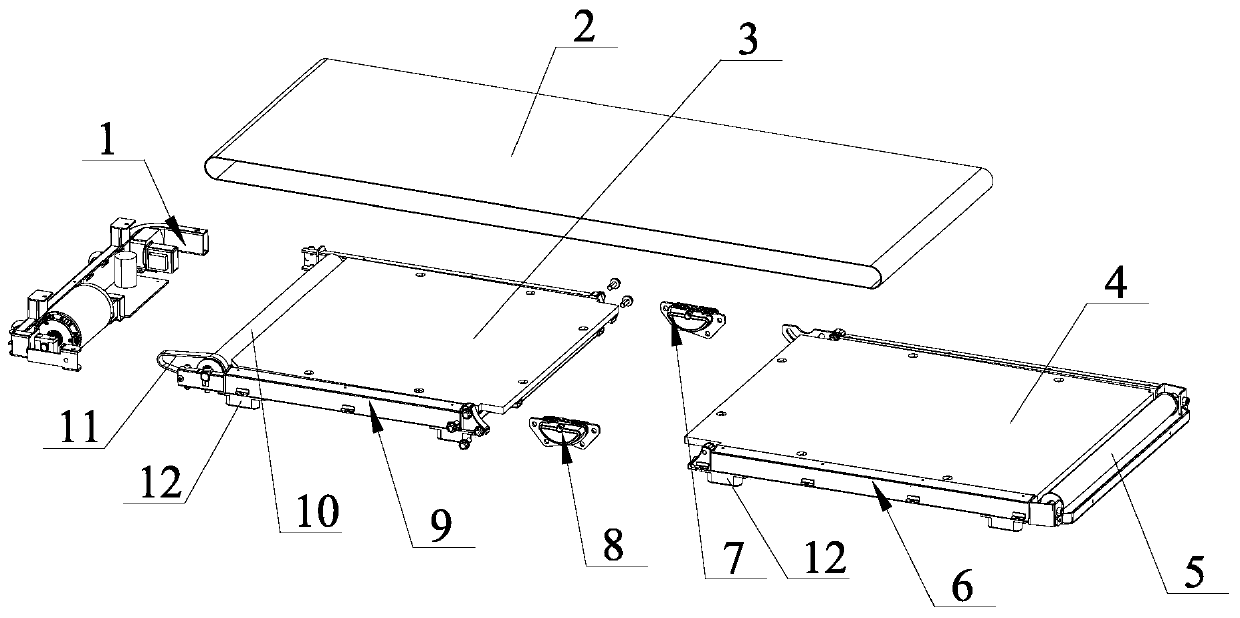

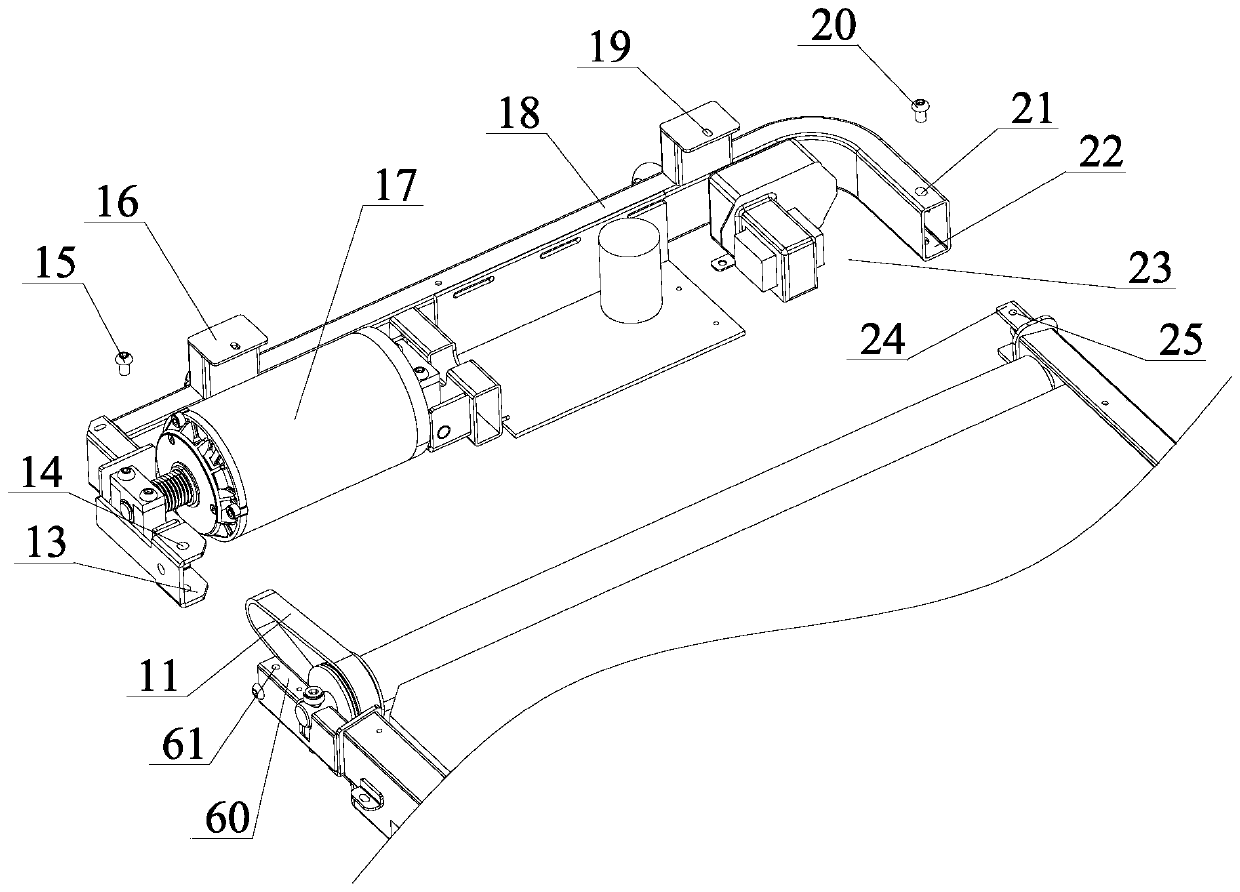

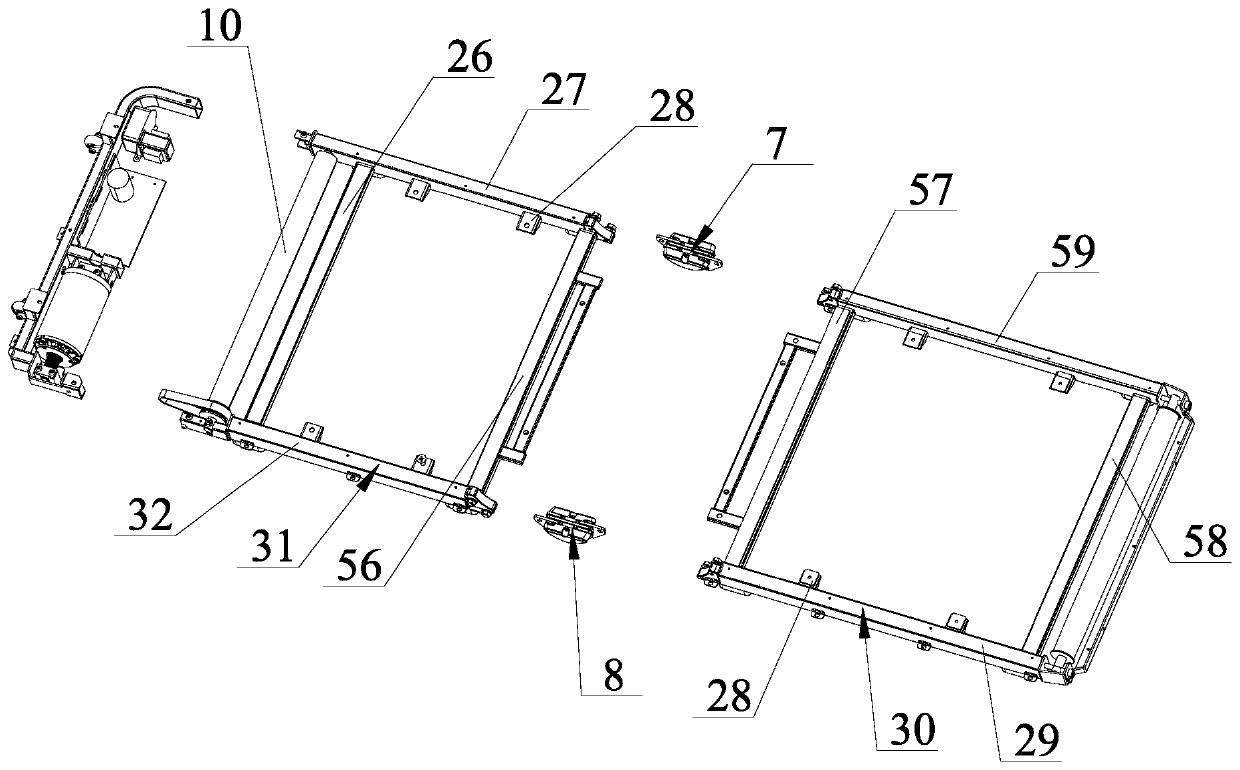

Running machine

PendingCN110559604AReduce volumeImprove yieldMovement coordination devicesCardiovascular exercising devicesMaterials preparationEconomic benefits

The invention discloses a running machine. The running machine comprises a front running table provided with a front roller at the front end, a rear running table provided with a rear roller at the rear end, and a running belt tensioned on the front roller and the rear roller and covering a front running board of the front running table and a rear running board of the rear running table; the running machine further comprises an electric appliance module for assembling a driving transmission mechanism and a control electric appliance on a front frame; the electric appliance module is detachablyconnected with the front end of the front running table; the front running table and the rear running table are detachably connected through a folding mechanism; the front frame of the electric appliance module is provided with an opening facing the front running table; and the rear end parts of two straight rods of the front frame and the front end parts of two side plates of the front running table are of male and female insertion structures and are in threaded connection. The running machine realizes modular assembly, has few parts during assembly, and is simple in structure, convenient inassembly and material preparation, and convenient and rapid to install; the installation procedures and the assembly processes are reduced; the production efficiency is greatly improved; the production cost is greatly reduced; and the economic benefits are is obvious.

Owner:LOCTEK ERGONOMIC TECH CORP

Steel pipe truss prestressed concrete composite slab

ActiveCN113089920BHold up firmlyPlay the role of lifting prestressed steel barsConstruction materialFloorsReinforced concretePre stress

The invention discloses a steel pipe truss prestressed concrete laminated slab, which comprises a reinforced concrete bottom plate and a steel pipe truss. A plurality of longitudinal prestressed steel bars are arranged inside the reinforced concrete bottom plate. The steel pipe truss includes steel pipes and steel pipes welded on both sides. The wavy steel bar, the trough section or / and the lower section of the web bar of the wavy steel bar is transversely bent to form a bent V-shaped supporting force transmission component, and the trough section or / and the transversely bent lower section of the web bar are laterally embedded in the reinforced concrete bottom plate Inside, the vertical lower section of the web bar is embedded in the concrete floor, and the bent V-shaped supporting force-transmitting part is provided with longitudinal prestressed steel bars, and the longitudinal pre-stressed steel bar and the bent V-shaped supporting force-transmitting part are bonded together by concrete. While ensuring the structural strength, it has the characteristics of being convenient for industrialization, standardization, and mechanized production.

Owner:湖南邱则有专利战略策划有限公司

Electronic lock

ActiveCN104863419AThe principle is simpleStrong anti-theft functionBuilding locksEngineeringTorsion spring

The invention discloses an electronic lock. The electronic lock comprises a front-end structure, a lock part and a rear-end structure provided with a circuit structure inside. The lock part comprises a lock shell and a lock cylinder structure. The lock shell is divided into a front-end part, a groove and a rear-end part. The lock cylinder structure comprises a motor base and a lock shifting fork, wherein the motor base is connected with the circuit structure through a linkage rod, and the lock shifting fork is embedded in the groove and arranged on the front end of the motor base in a sleeving mode. A motor assembly is embedded in the motor base and is provided with a transmission shaft forwards. The rotary shaft is sleeved with a torsion spring capable of rotating along with the rotary shaft and moving forwards and backwards. The torsion spring is sleeved with a rear push block and a front push block, the rear push block and the front push block can move along with the torsion spring, a clutch clamping piece capable of moving along with the front push block is fixedly clamped to the front end of the front push block, a first clamping groove is formed in the front end of the motor base, and a second clamping groove is formed in the lock shifting fork. The clutch clamping piece is clamped and inserted into the second groove from the rear end, can move forwards and backwards in the first clamping groove and in the second clamping groove along with the front push block, and accordingly idling or meshing linkage between the motor base and the lock shifting fork is achieved.

Owner:ZHONGSHAN EFUD ELECTRONICS TECH

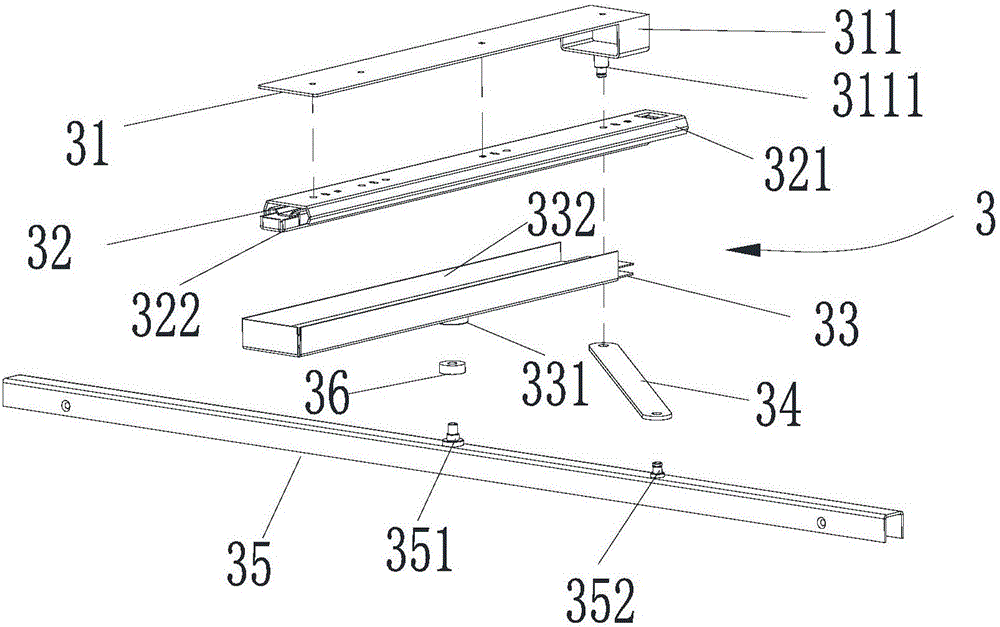

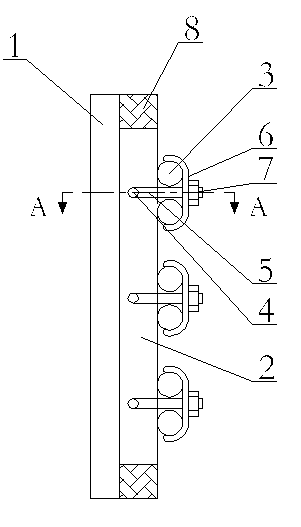

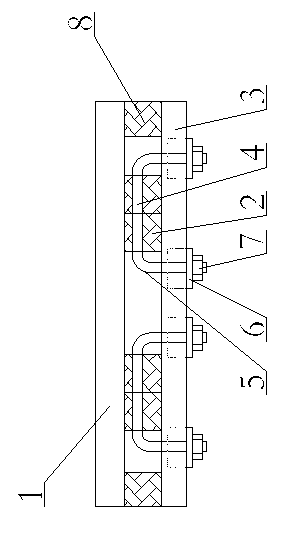

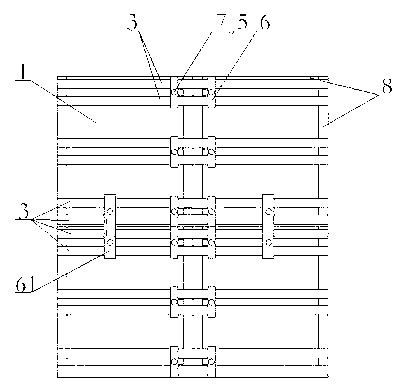

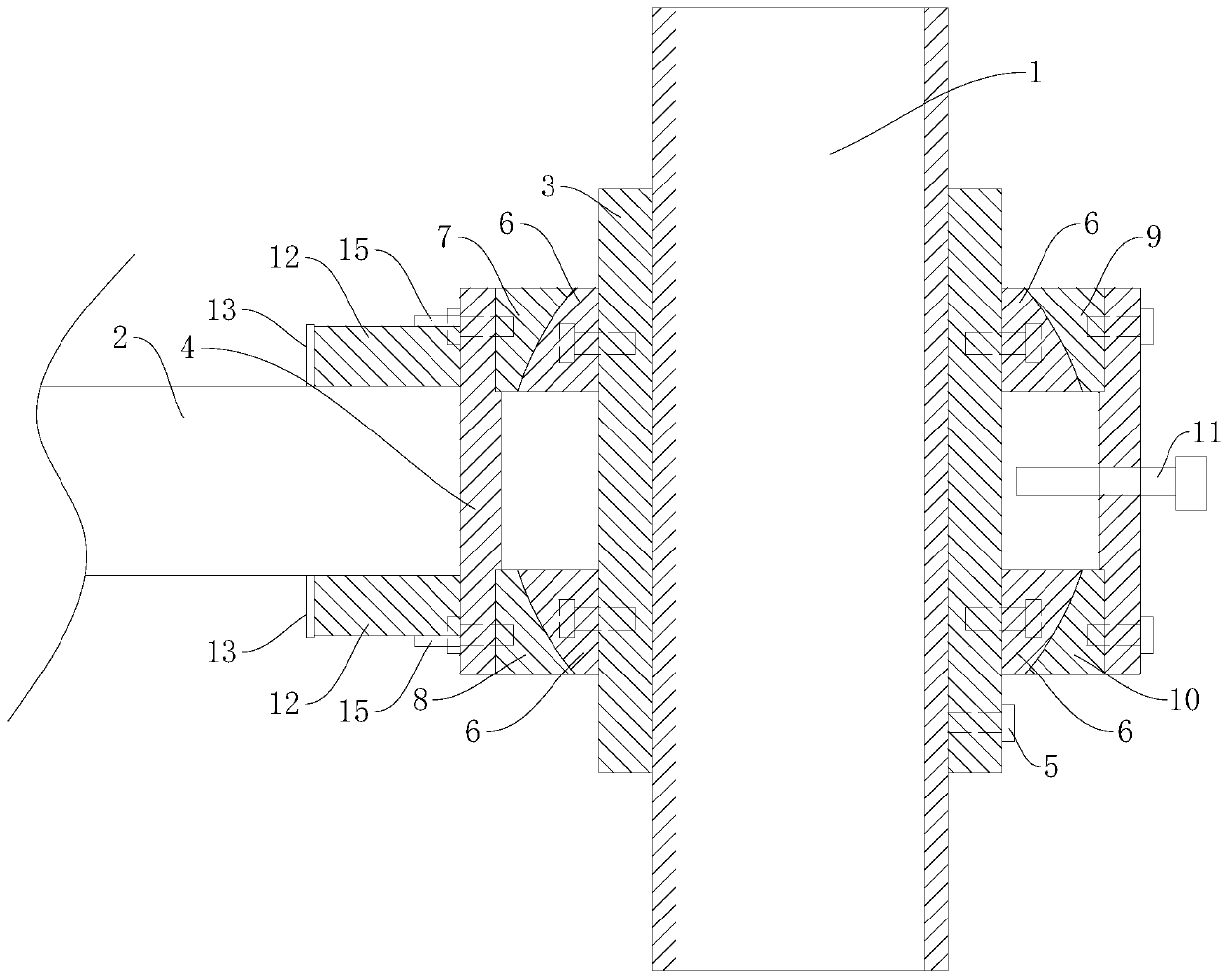

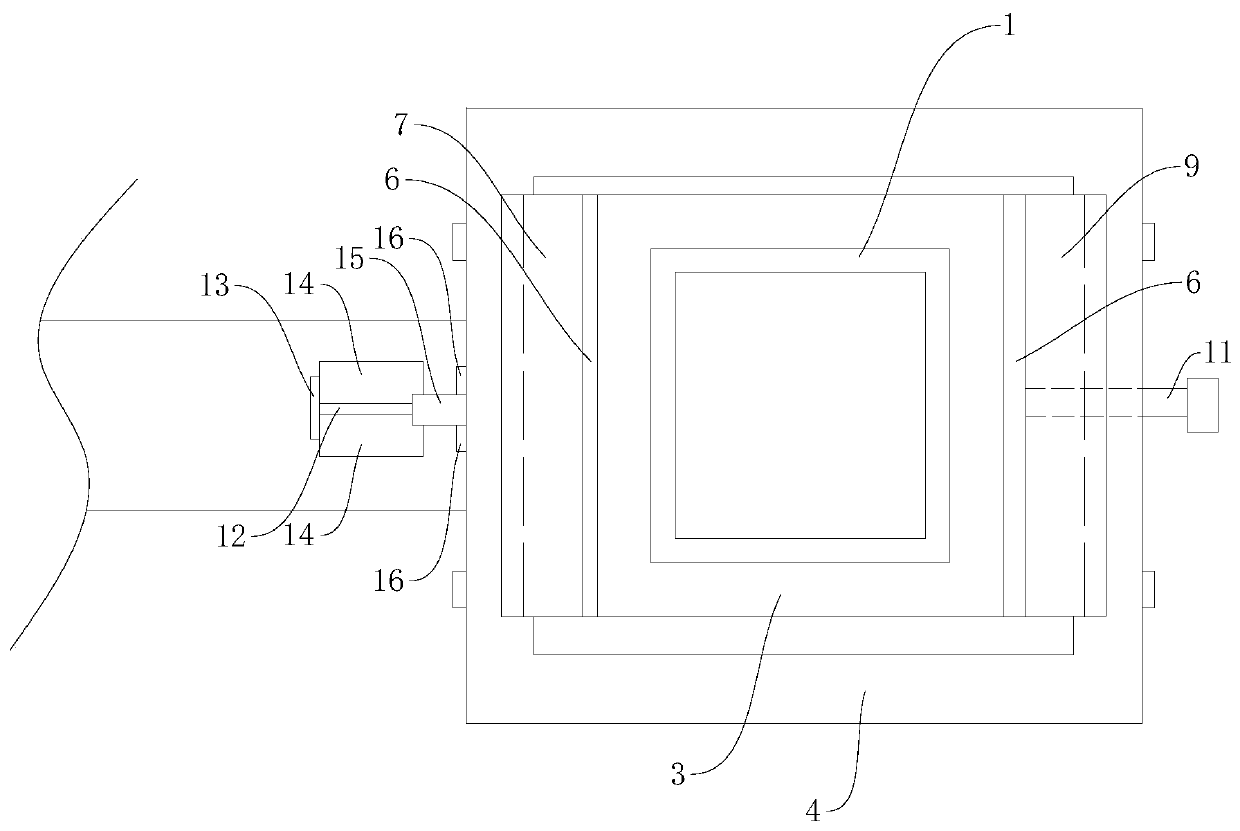

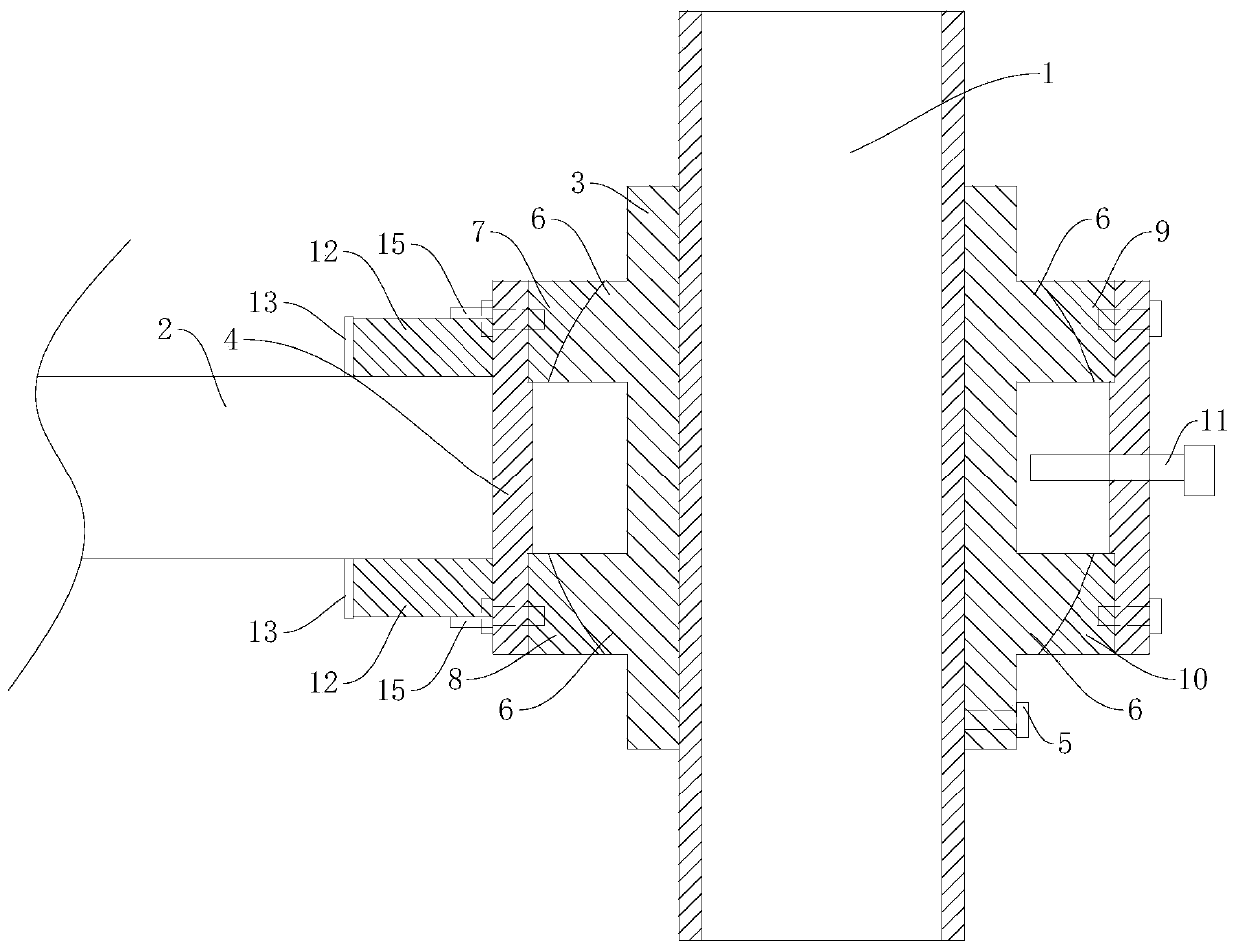

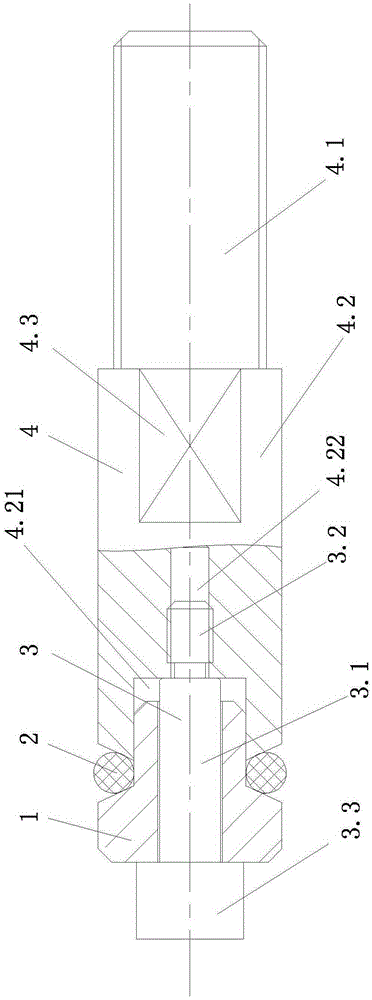

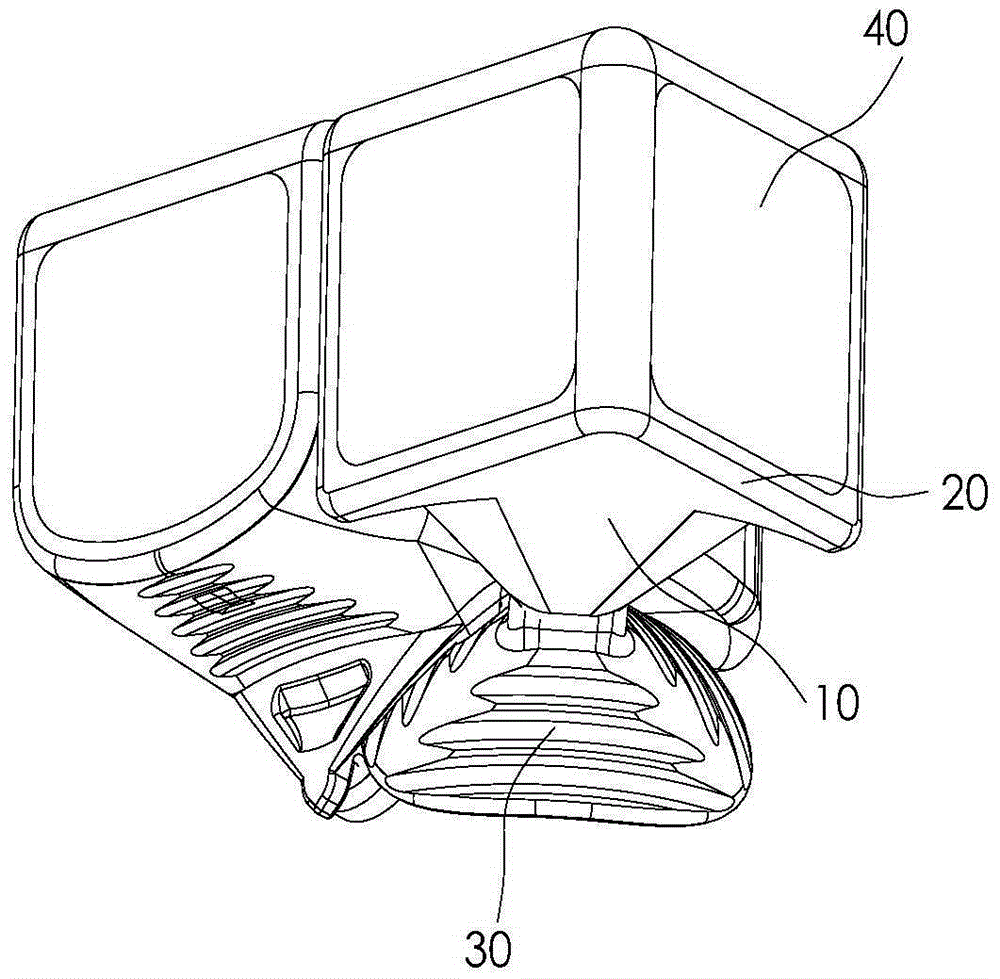

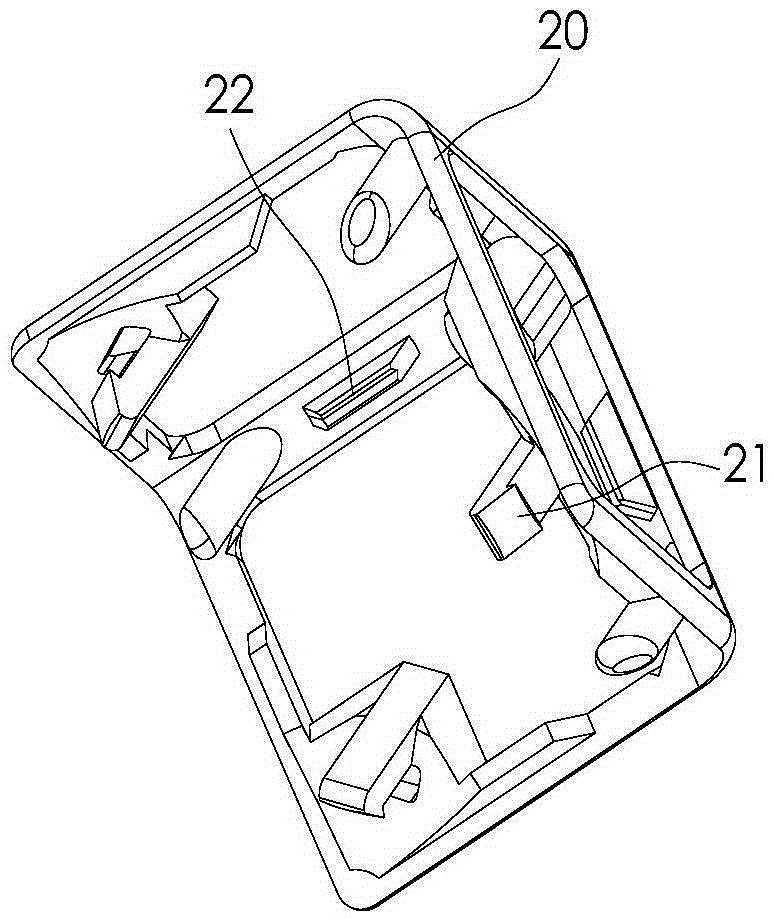

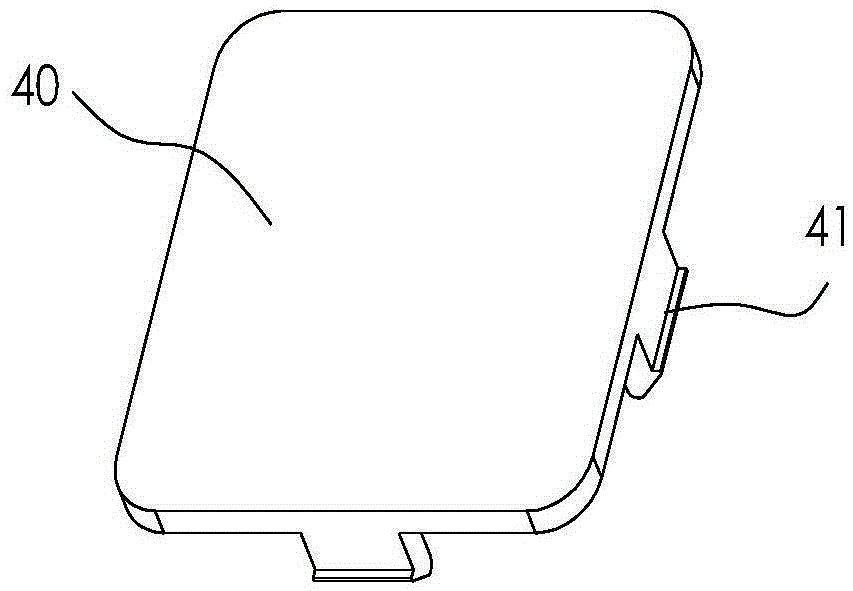

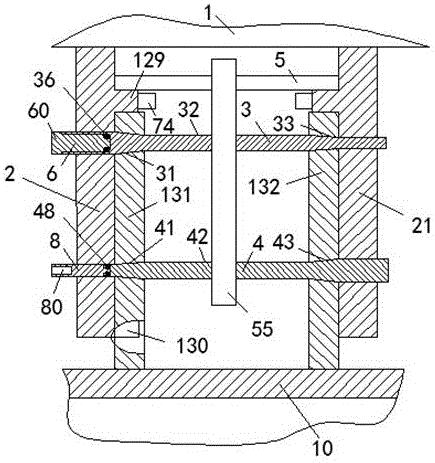

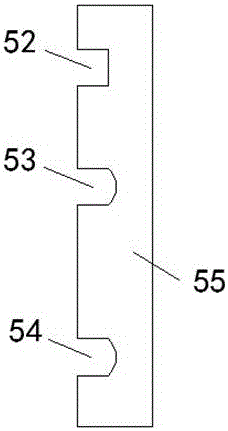

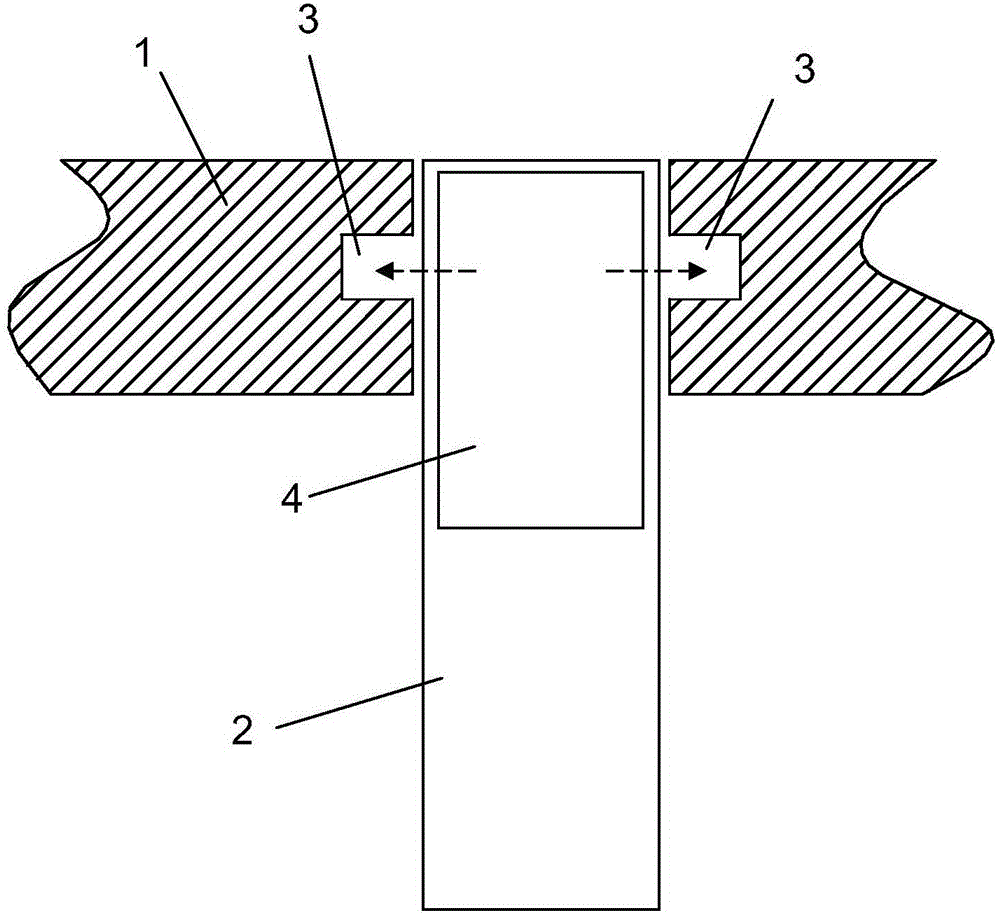

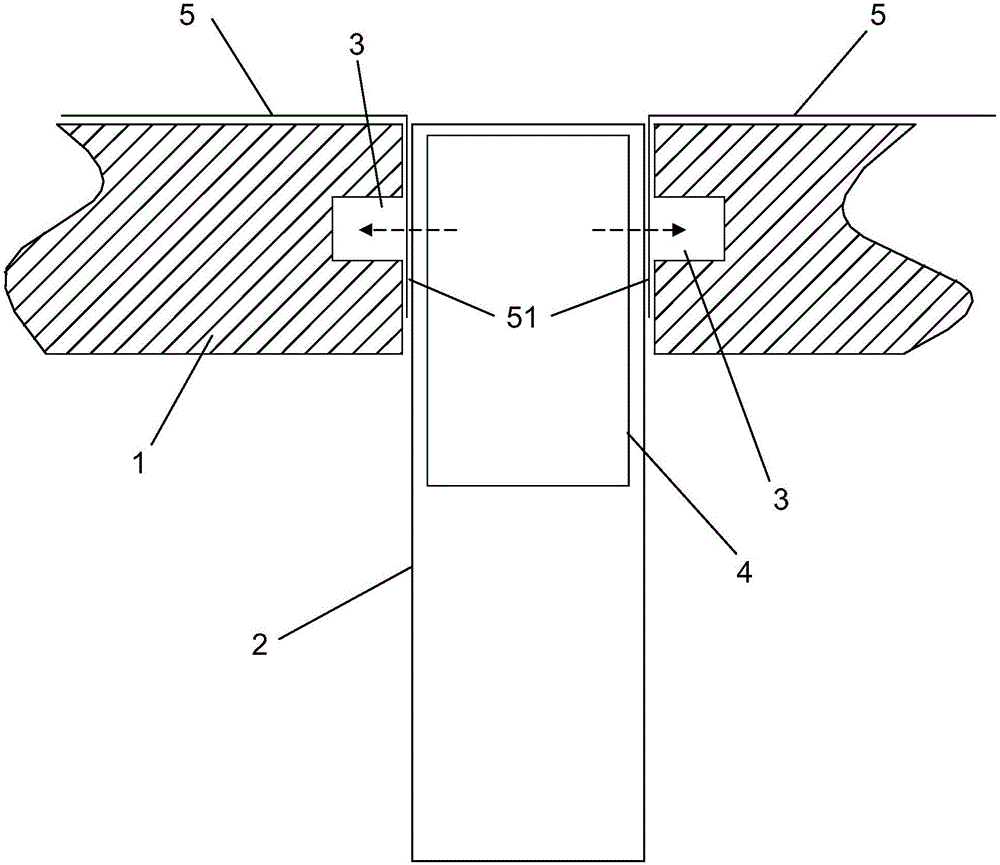

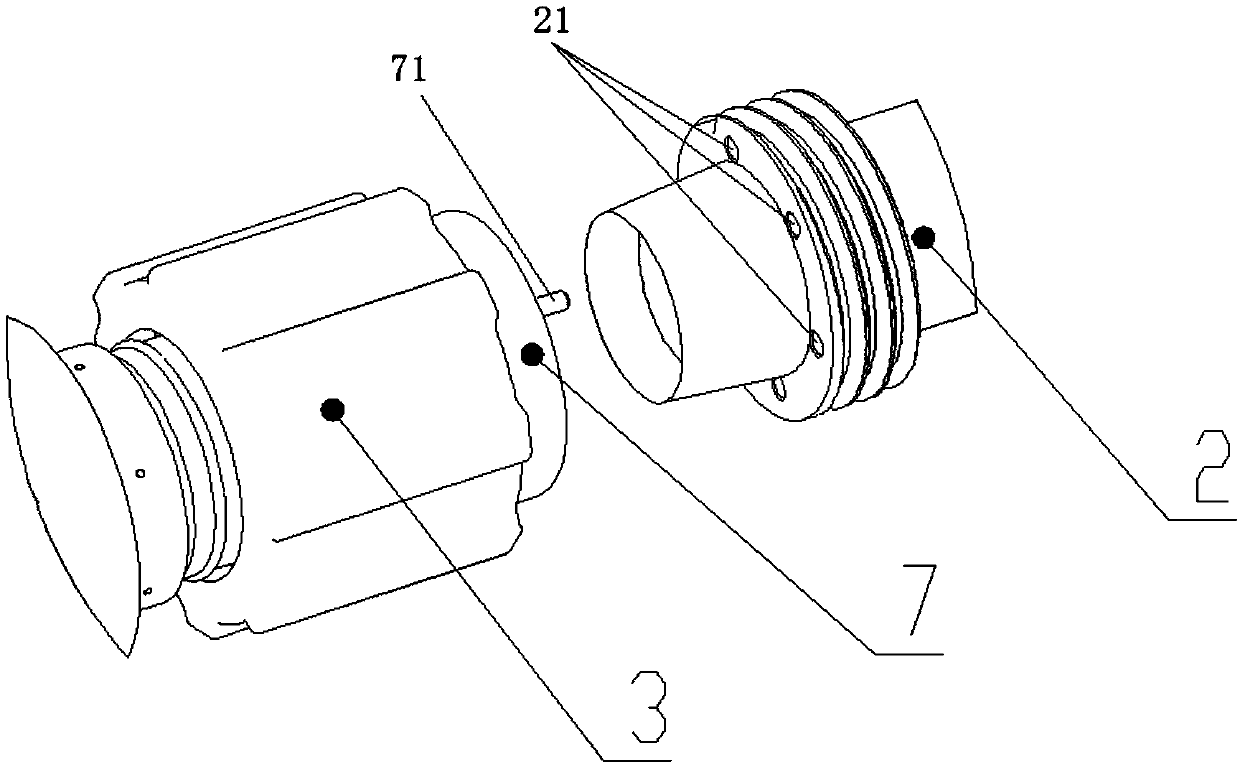

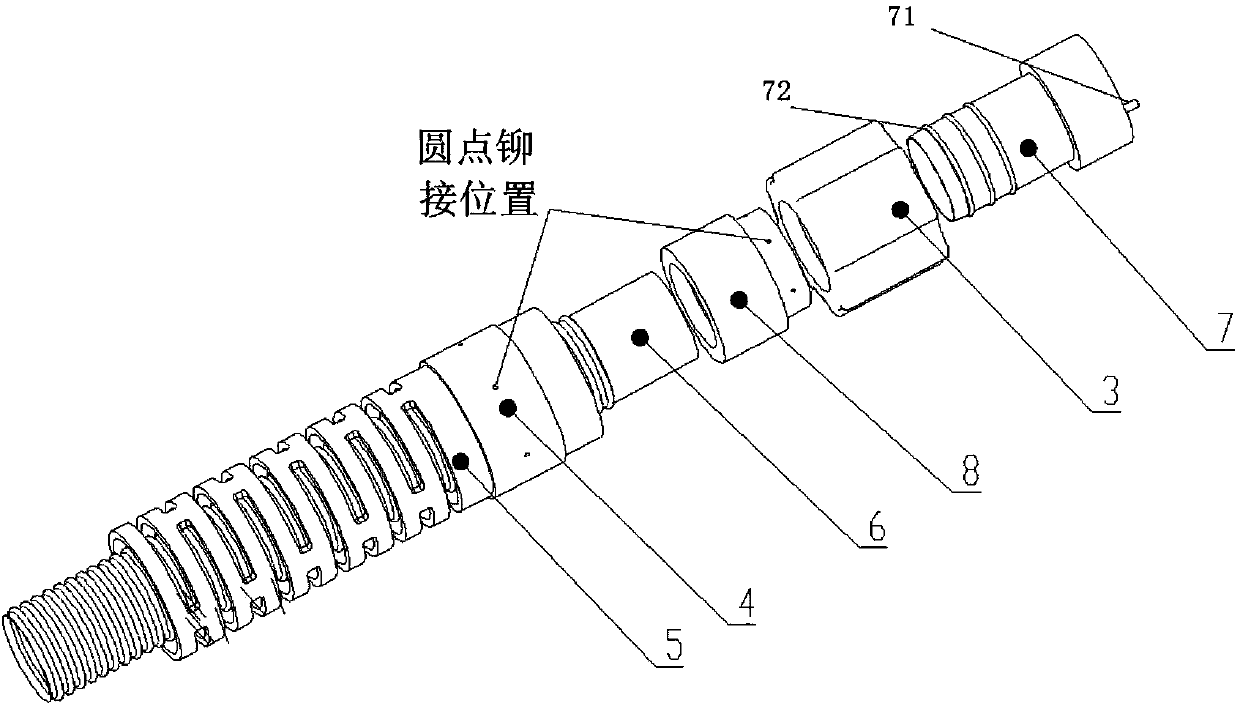

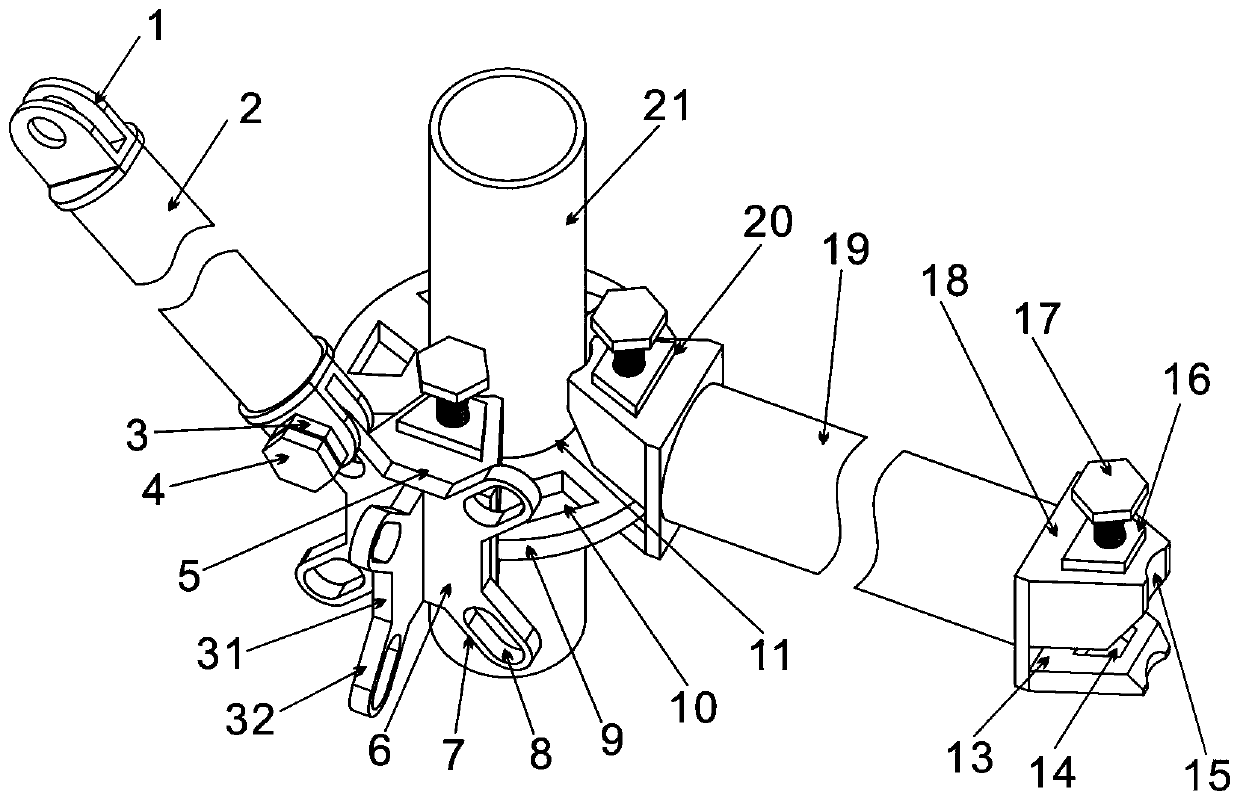

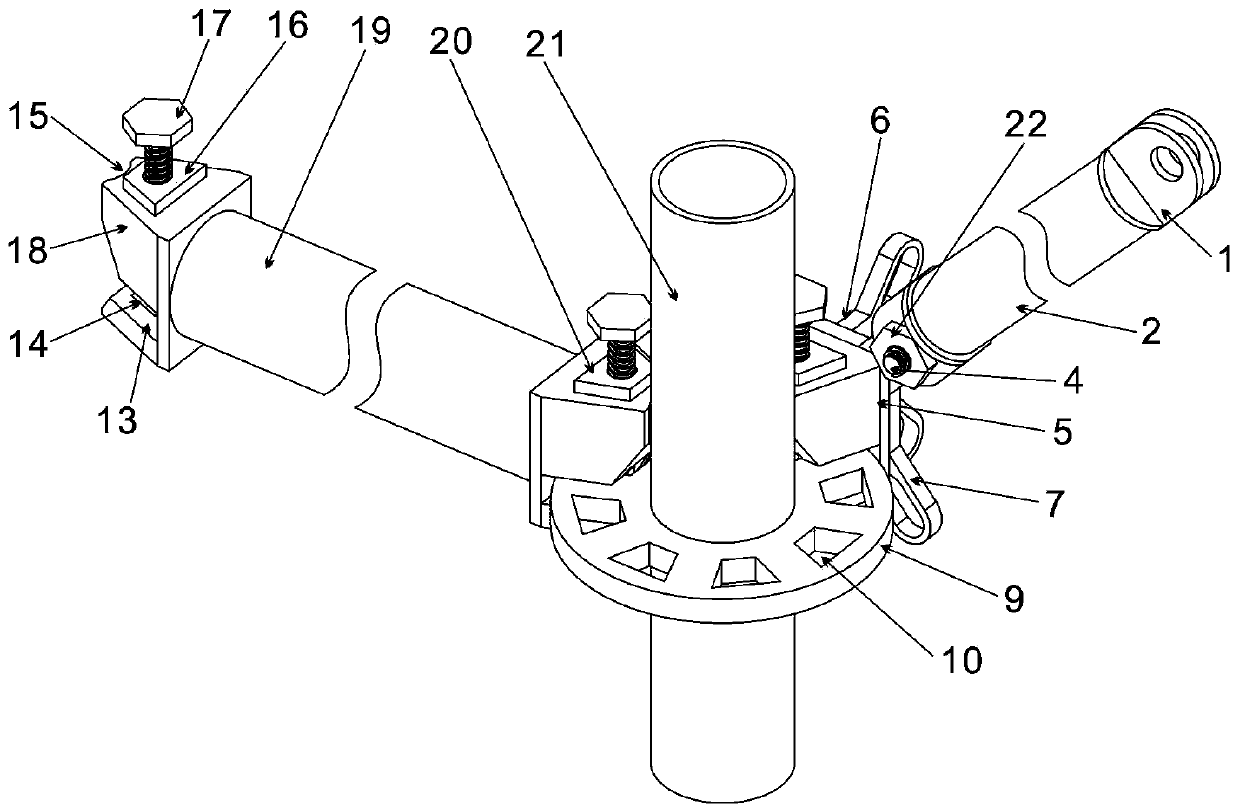

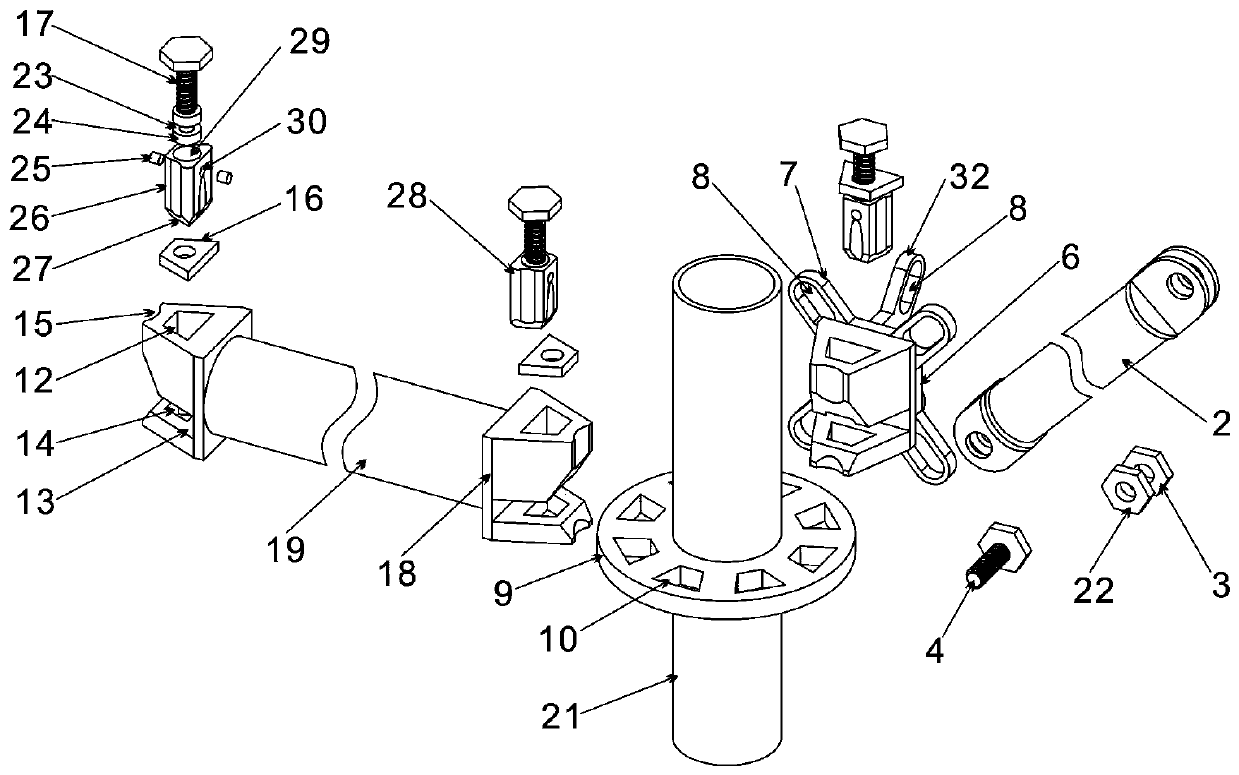

Stable-connection displayer suspending assembly

The invention discloses a stable-connection displayer suspending assembly. The stable-connection displayer suspending assembly is used for carrying a displayer in a suspended mode, and comprises a left arm plate (2), a right arm plate (21), an upper supporting rod (3), a lower supporting rod (4) and a displayer carrying frame (10), wherein the left arm plate (2) and the right arm plate (21) are used for being fastened to a top wall (1) in a spaced mode, the upper supporting rod (3) and the lower supporting rod (4) penetrate through the left arm plate (2) and the right arm plate (21) in the left-and-right direction, and the displayer carrying frame (10) is fixedly connected with the displayer. The upper supporting rod (3) comprises an upper supporting rod body and a thread pushing driving piece (6) axially and fixedly connected with the left end of the upper supporting rod body through an upper thrust bearing (36), and the lower supporting rod (4) comprises a lower supporting rod body and a thread pulling driving piece (8) axially and fixedly connected with the left end of the lower supporting rod body through a lower thrust bearing (48).

Owner:董海斌

Connecting structure of non-metallic pipe and metal plate

InactiveCN105822854AThe connection structure is stableFirmly connectedNon-disconnectible pipe-jointsUltimate tensile strengthFluorine containing

The invention discloses a connecting structure of a non-metallic pipe and a metal plate; and the connecting structure can realize connection between the non-metallic pipe and a hole in the metal plate by a connecting mode of a concave cavity and internal extrusion without needing chemical bonding, and is stable and reliable. The connecting structure is more suitable for connection of a fluorine-contained plastic pipe with high chemical stability and the metal plate, can be effectively applied to sealing connection between a heat exchange pipe of a heat exchanger and a metal pattern plate under the working conditions of high temperature and high corrosion, can save the cost, greatly improves the sealing strength, and prolongs the equipment service life.

Owner:江苏金由新材料有限公司

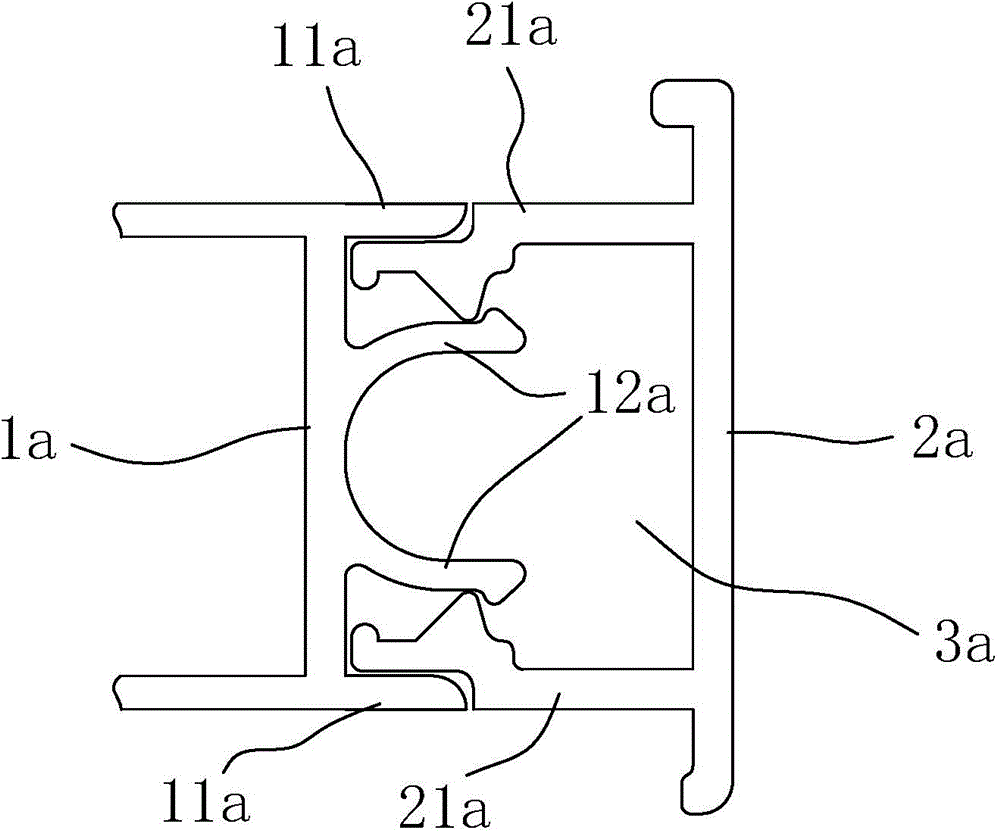

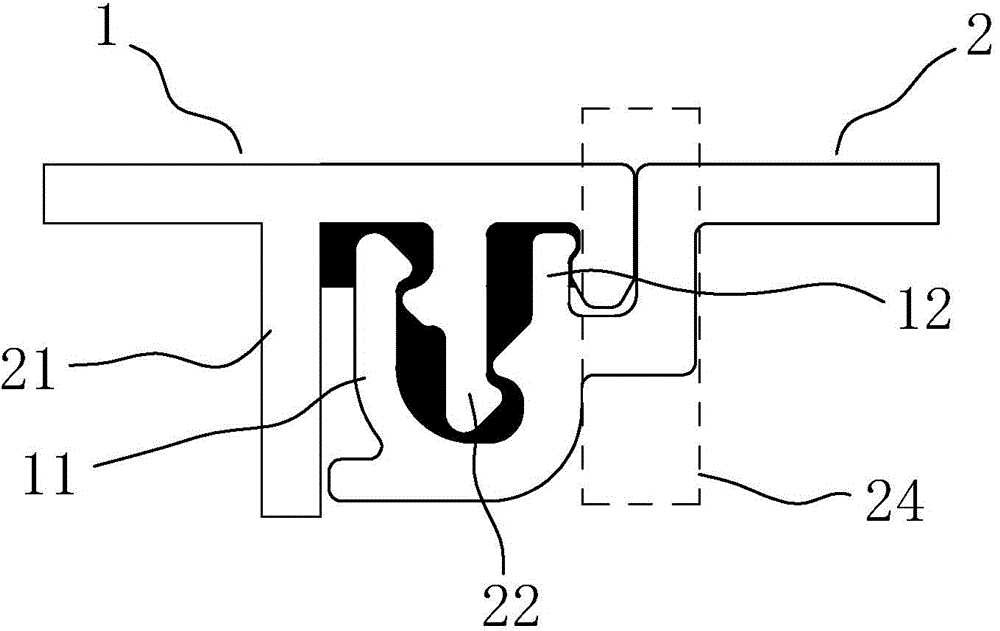

Firm section material connection structure

ActiveCN104565791ALarge design spaceIngenious structureElongated constructional elementsEngineeringMiddle column

The invention discloses a firm section material connection structure. The section material connection structure comprises a first section material unit and a second section material unit, wherein the first section material unit comprises a first embedding pit of which the left wall is a left side plate and the right wall if a middle column, and a second embedding pit of which the left wall of the middle column and the right wall is a right side plate or a right side plate combination; the second section material unit comprises a middle column containing pit; the left wall of the middle column containing pit is a first connecting hook of which the tail end is fixed in the first embedding pit, and the right wall of the middle column containing pit is a second connecting hook of which the tail end is fixed in the second embedding pit; the tail end of the middle column is positioned in the middle column containing pit; the first embedding pit, the middle pit containing pit, and the second embedding pit are arranged in order from left to right. According to the firm section material connection structure, the situation that a traditional dual-edge clip hook structure must forms a cavity is omitted, so that the volume of the connection structure is greatly reduced. The connection structure is ingenious in structure, is safe and stable, is quick and convenient to assemble, and can be widely used in connection structures of section material units.

Owner:佛山市三水和美斯金铝业有限公司

Outlet connecting mechanism of artificial blood pump and assembling method of outlet connecting mechanism

The invention provides an outlet connecting mechanism of an artificial blood pump. The outlet connecting mechanism comprises a first part and a second part, wherein the first part comprises the artificial blood pump and a blood pump outlet adapter connected with the artificial blood pump, the second part comprises an artificial blood vessel, an artificial blood vessel sleeve connected with the artificial blood vessel and a locking ring, and the locking ring is arranged on the artificial blood vessel sleeve, is axially fixed to the artificial blood vessel sleeve, is movably connected with the artificial blood vessel sleeve in the circumferential direction and is connected with the blood pump outlet adapter through threads. The invention further provides an assembling method of the outlet connecting mechanism of the artificial blood pump. The outlet connecting mechanism of the artificial blood pump and the assembling method of the outlet connecting mechanism have the beneficial effects that the use of bolts is avoided, the operation is relatively convenient, the difficulty of operation is relatively low, and the connecting structure is simple and reliable.

Owner:SHENZHEN CORE MEDICAL TECH CO LTD

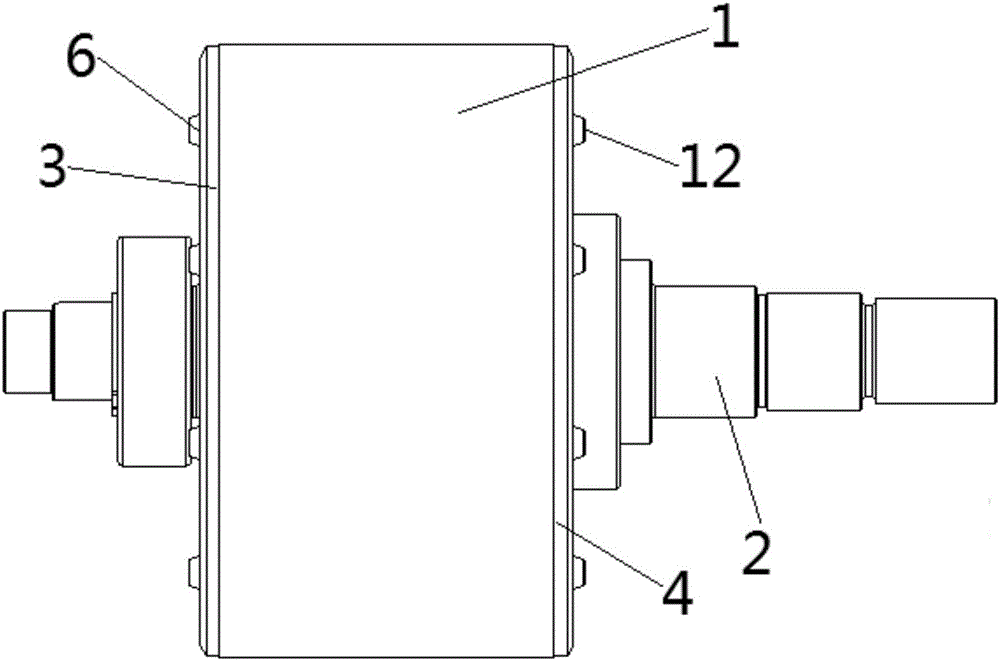

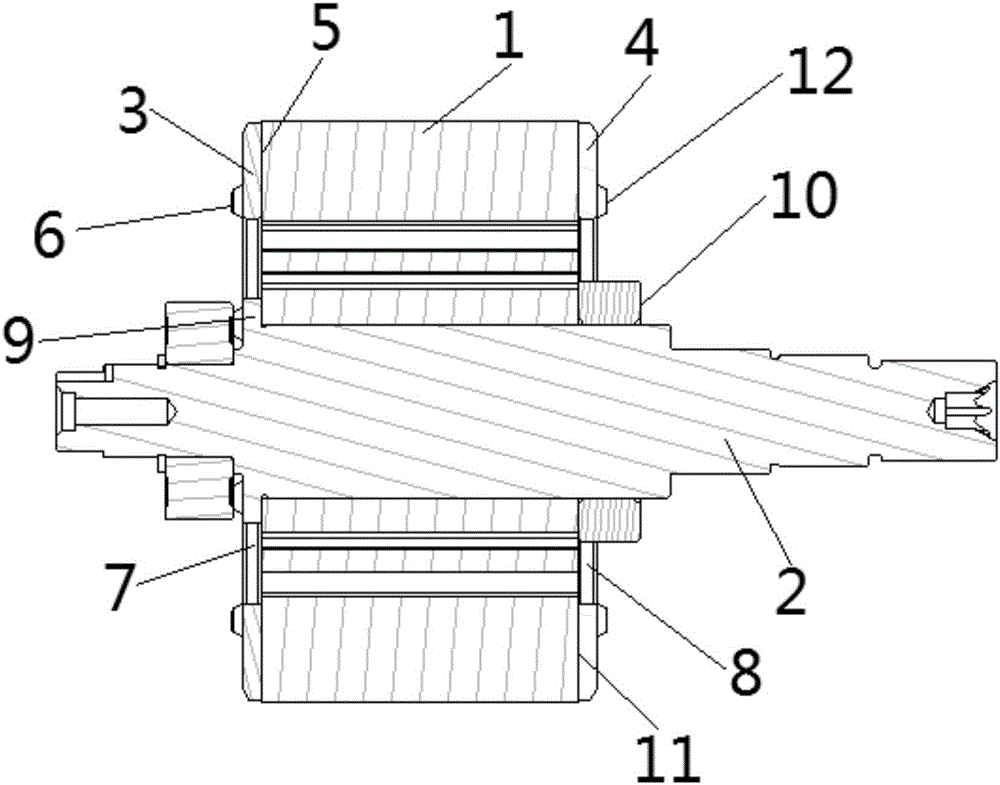

Motor rotor structure of electric vehicle

InactiveCN106026468ASimple structureReduce weightMagnetic circuit rotating partsElectric machinesElectric machineEngineering

The invention provides a motor rotor structure of an electric vehicle, wherein the motor rotor structure is used in the technical field of motors of electric vehicles. The motor rotor structure comprises a rotor core body (1), wherein the middle part of the rotor core body (1) is provided with a rotor shaft (2), a front pressing plate (3) of the motor rotor structure is adhered to an iron core front end surface (5) of the rotor core body (1), a rear pressing plate (4) is adhered to an iron core rear end surface (11) of the rotor core body (1), a rivet (6) passes through the front pressing plate (3), the rear pressing plate (4) and the rotor core body (1), and each rivet (6) is configured to be a structure capable of fixedly riveting and connecting the front pressing plate (3), the rear pressing plate (4) and the rotor core body (1). The motor rotor structure of the electric vehicle has the advantages of being simple in structure, low in manufacturing cost, capable of reducing axial size of the motor rotor structure by simple improvement on the basis of an original motor, reducing weight of the rotor structure, reducing rotational inertia, and decreasing processing cost.

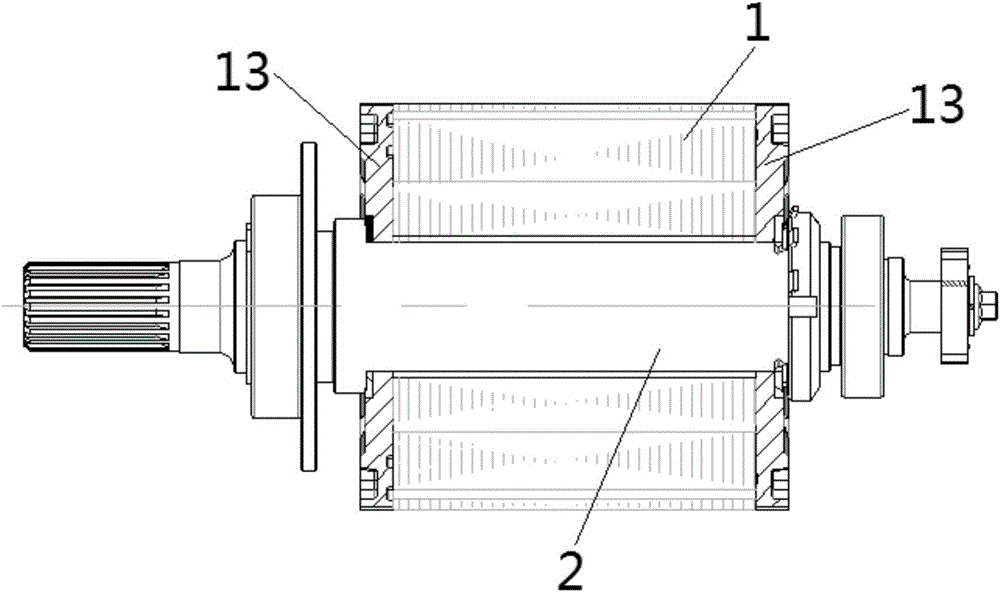

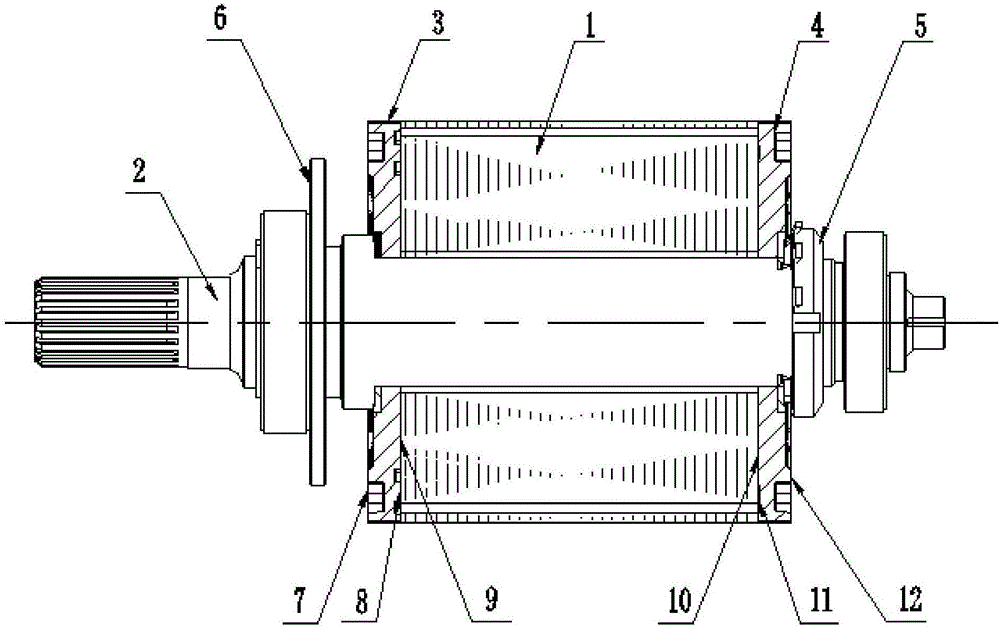

Rotor of drive motor of new energy automobile

PendingCN106655571AReduce unbalanceAchieve direct fixationMagnetic circuit rotating partsSupports/enclosures/casingsNew energyDrive motor

The invention discloses a rotor of a drive motor of a new energy automobile. The rotor is provided with a rotor iron core, wherein the rotor iron core is provided with a permanent magnet groove extending from the upper end face of the lower end face of the iron core and, the middle part of the rotor iron core is provided with an axial iron core inner round hole and the inner wall of the inner round hole of the rotor iron core is provided with a boss; a rotor shaft fitting with the inner round hole of the rotor iron core and provided with an axial open groove fitting with the boss; an upper end board whose lower end face fits the upper end face of the iron core and is provided with a first guide groove communicating with a permanent magnet groove and also provided with an air inlet and air outlet both communicating with the first guide groove; a lower end board whose upper end face fits the lower end face of the iron core and provided with a second guide groove communicating with the permanent magnet groove. Therefore, rotor structural weight and rotation inertia are reduced; the manufacture cost is reduced; and the integral performance of the drive motor is improved.

Owner:芜湖杰诺瑞汽车电器系统有限公司

Multifunctional wheel-disc-type scaffold

PendingCN110453908AThe connection structure is stable and reliableImprove structural strengthScaffold connectionsThree-dimensional spaceStructural engineering

The invention discloses a multifunctional wheel-disc-type scaffold. The multifunctional wheel-disc-type scaffold comprises a plurality of vertical rods, a plurality of cross rods and diagonal supporting rods, wherein the vertical rods, the cross rods and the diagonal supporting rods are connected with one another. The vertical rods are provided with bearing connecting disks, a plurality of connecting through holes are uniformly distributed on the bearing connecting disks, assembled connecting parts are arranged at two ends of the cross rods, diagonal supporting connecting parts which are detachably connected to one ends of the diagonal supporting rods are arranged on the bearing connecting disks; the diagonal supporting connecting parts comprise assembled connecting parts and diagonal connecting plates, and the assembled connecting parts are detachably connected with the connecting through holes in the bearing connecting disks; and the diagonal connecting plates are hinged to one endsof the diagonal supporting rods. The assembled connecting parts comprise fixing bolts, special-shaped pins, fixing nuts and connectors. The special-shaped pins can be rotated arbitrarily, and the diagonal connecting plates are located at the back of the connectors. After the installation of the vertical rods, the cross rods and the diagonal supporting rods, the requirements of enabling the scaffold as a whole to be high in three-dimensional space structure and good in overall stabilityare met, only the fixing bolts are required to be tightened or loosened in the disassembly process, and the construction efficiency is high.

Owner:成都方鸿科力建筑工程安全防护科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com