Inclined hidden-frame glass curtain wall connecting structure

A technology of hidden frame glass curtain wall and connection structure, which is applied in the direction of walls, building components, building structures, etc., can solve the problems affecting the stability of glass curtain wall, the stability is not necessarily high, and the production cost increases, so as to increase the sense of art and Aesthetic feeling, construction cost saving, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

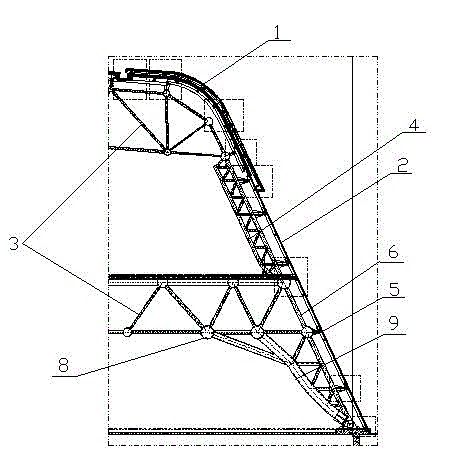

[0020] Embodiment: in practice concrete application can implement according to following technical scheme:

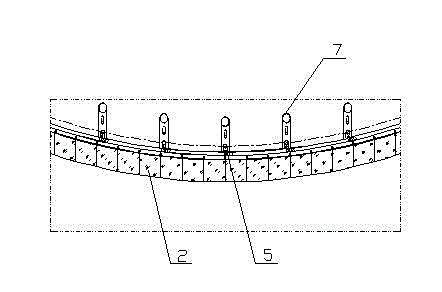

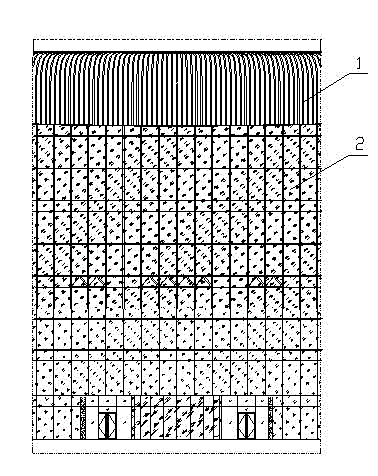

[0021] A building body, the building body is 60 meters high and 100 meters long. The building body is sequentially provided with a ceiling 1, a number of hidden frame glasses 2 and a building door body from top to bottom. The height of the ceiling 1 is 16 meters, and the height of the building door body is It is 4 meters long, and there are two building doors on each side of the building. The ceiling 1 is made of stainless steel and has an arc shape. The surface of the ceiling 1 is provided with several lines, and several hidden frame glasses 2 are arranged in several rows. Form a hidden-frame glass curtain wall, each row is a hidden-frame glass strip, wherein, every two rows of longer hidden-frame glass strips correspond to a row of shorter hidden-frame glass strips, and the height of the longer hidden-frame glass 2 is 4 meters. The height of the shorter hidden frame g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com