Conveying manipulator and handling device

A technology of manipulators and carrying arms, which is applied in the direction of manipulators, transportation and packaging, and conveyor objects. It can solve the problems of unsatisfactory heat protection, low precision requirements, and heavy handling manipulators, so as to improve batch processing capacity. , less affected by heat, and enhance the effect of heat protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

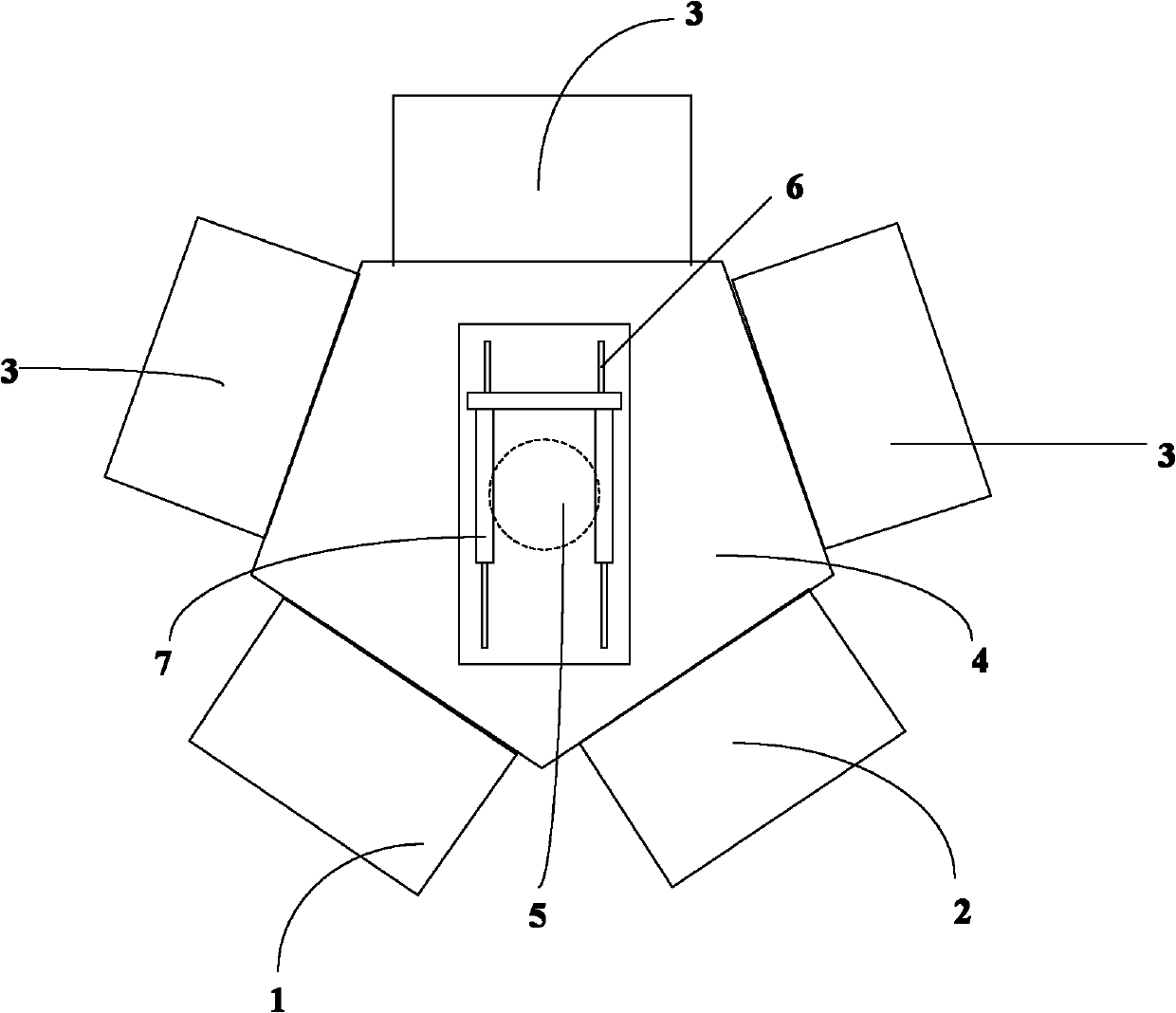

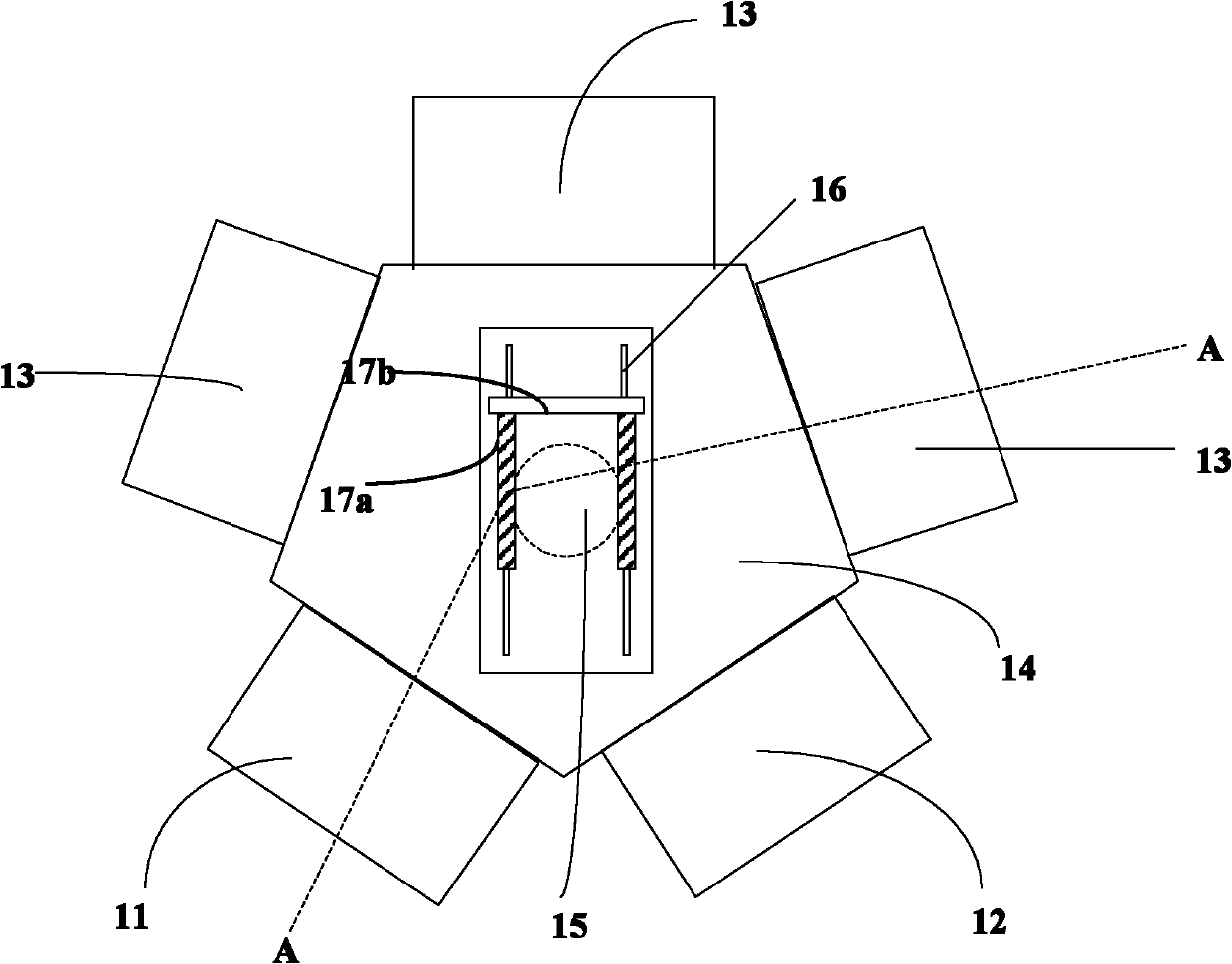

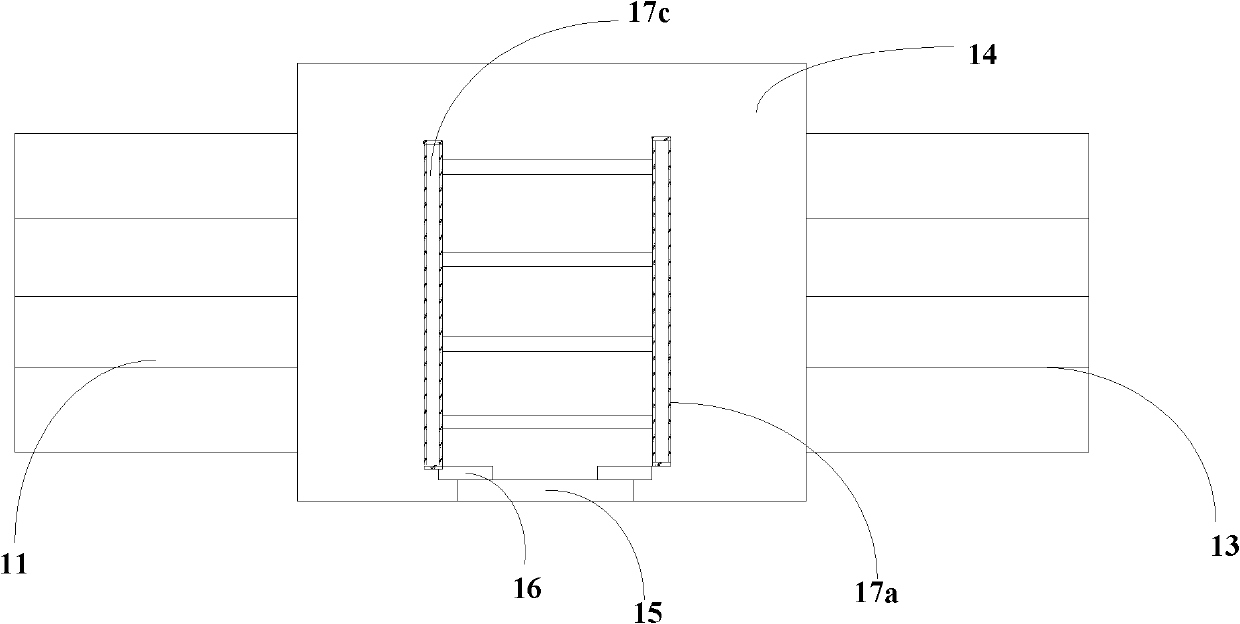

[0052]This embodiment provides a handling device, such as figure 2 As shown, the manufacturing equipment of the thin film solar cell includes: a substrate loading platform 11, a substrate unloading platform 12, a processing chamber 13, a vacuum transfer chamber 14 and a handling device, wherein: the handling device is arranged in the vacuum transfer chamber 14 is used for transferring the substrate from the substrate loading table 11 to the processing chamber 13 , and then transferring the processed substrate from the processing chamber 13 to the substrate unloading table 12 . Described handling device comprises: turntable 15, slide rail 16 and handling manipulator, wherein said slide rail 16 is positioned on described turntable 15, and described handling manipulator is positioned on described slide rail 16, and described handling manipulator moves along described slide rail 16 to slide to perform the moving action, and the turntable 5 is used to rotate the handling manipulat...

Embodiment 2

[0064] The handling manipulator in this embodiment includes: a carrying arm and a heat-resistant casing located on the surface of the carrying arm.

[0065] The carrying arm of this embodiment is a single layer, and can carry one substrate at a time.

[0066] The material of the carrying arm in this embodiment is a polymer material, and the hardness of the material becomes worse as the temperature increases. Therefore, in this embodiment, a heat-proof casing is provided on the surface of the carrying arm, and the material of the heat-proof casing is aluminum foil, which can reflect heat energy, thereby preventing the carrying arm from heating up.

[0067] The thickness range of the heat-proof casing is 0.001mm-0.3mm, preferably, the thickness range of the heat-proof casing is 0.007mm-0.1mm. The thickness of the heat-proof shell in this embodiment is specifically 0.001mm, 0.004mm, 0.007mm, 0.0085mm, 0.0095mm, 0.1mm, 0.018mm, 0.022mm, 0.026mm or 0.3mm. Compared with the stainl...

Embodiment 3

[0075] The handling manipulator in this embodiment includes: a carrying arm and a heat-resistant casing located on the surface of the carrying arm.

[0076] The carrying arms in this embodiment are arranged in a fork shape, specifically ten layers, and when carrying the substrates, one substrate can be placed on each layer, thereby improving the efficiency of transportation.

[0077]The thickness range of the heat-proof casing is 0.001mm-0.3mm, preferably, the thickness range of the heat-proof casing is 0.007mm-0.1mm. The thickness of the heat-proof shell in this embodiment is specifically 0.001mm, 0.0025mm, 0.007mm, 0.008mm, 0.009mm, 0.1mm, 0.016mm, 0.020mm, 0.026mm or 0.3mm. Compared with the stainless steel heat-proof plate in the prior art, the thickness of the heat-proof shell in this embodiment is very thin, and the volume of the handling manipulator is reduced; the density of the aluminum foil is 2.702g / cm 3 , the density of stainless steel is about 7.85g / cm 3 , so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com