Firm section material connection structure

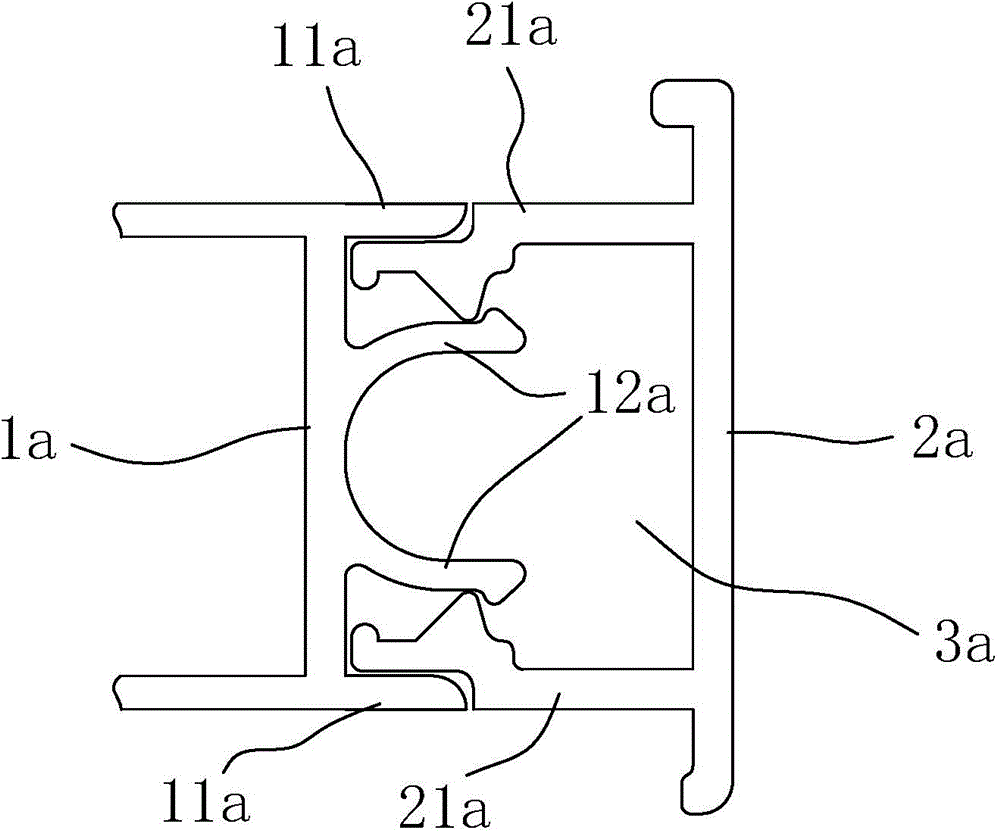

A technology for connecting structures and profiles, applied in the direction of slender elements, building elements, etc., can solve the problems of cavity 3a, such as bulky, occupying space, panel deformation, etc., and achieve the effect of ingenious structure, fast assembly, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

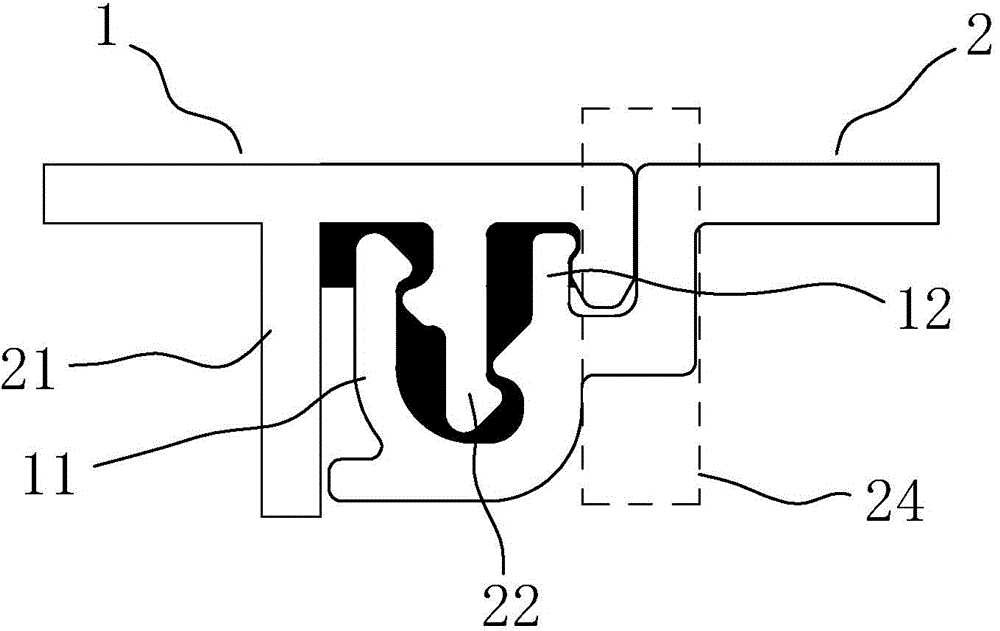

[0021] Embodiment 1: refer to figure 2 , a reliable profile connection structure, including a first profile unit 1 and a second profile unit 2, the first profile unit 1 includes: a first scarfing pit, the left pit wall is a left side plate 21, and the right pit wall It is the center column 22; the second embedding pit, the left pit wall is the center column 22, and the right pit wall is the right side plate body 23 or the right side plate assembly 24; the second profile unit 2 includes: the center column The accommodating pit, the left pit wall is the first connecting hook 11 whose end is fixed in the first embedding pit, the right pit wall is the second connecting hook 12 whose end is fixed in the second embedding pit, and the central column 22 The end of the center column is located in the accommodating pit of the center pillar; the first embedding pit, the accommodating pit of the center pillar and the second embedding pit are arranged sequentially from left to right.

[...

Embodiment 2

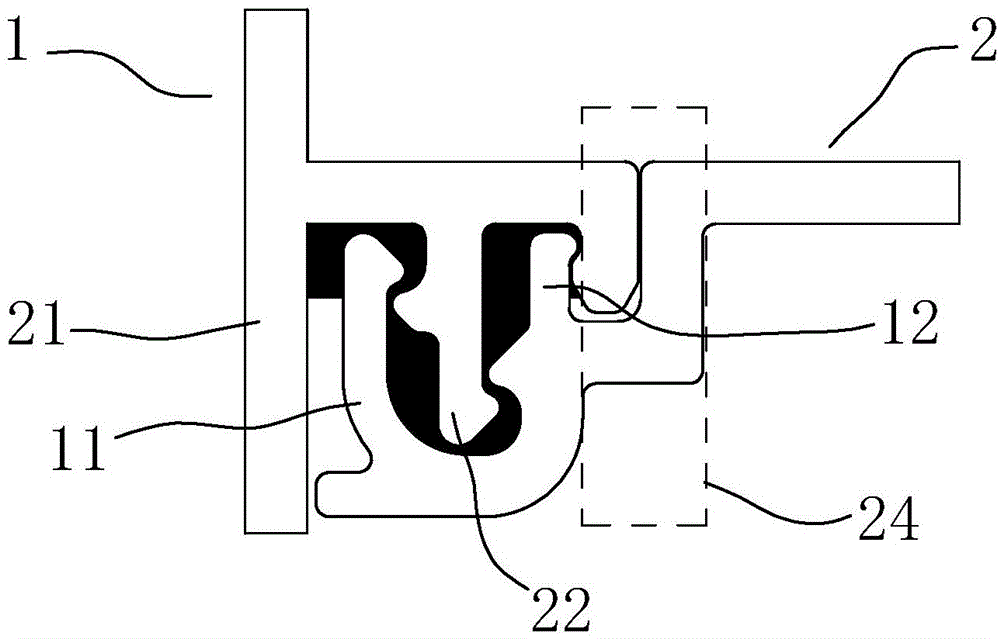

[0025] Embodiment 2: refer to image 3 , the structure of embodiment 2 is basically the same as that of embodiment 1, except that after the design space has been vacated on the left and above the left side panel 21, the left side panel 21 continues to extend upwards so that the whole presents a horizontal "T" The state of the glyph.

Embodiment 3

[0026] Embodiment 3: refer to Figure 4 , the structure of embodiment 3 is basically the same as that of embodiment 1, but the right wall of the second embedding pit is the right side plate body 23, and the right side plate body 23 has such a structure: it is the first profile unit 1 The right end protrudes, and the end of the right plate body 23 abuts against the second profile unit 2 or wraps around the end of the second connecting hook 12 . More specifically, in this embodiment, the end of the right plate body 23 abuts against the second profile unit 2 . In this way, the second profile unit 2 is more difficult to overturn. The left side of the left side plate 21 continues to extend leftwards to become a flat plate, and the right side of the right side plate body 23 also continues to extend rightwards to form a flat plate, and the two form a flat-top composite profile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com