Patents

Literature

47results about "Corrosion preventing fuel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

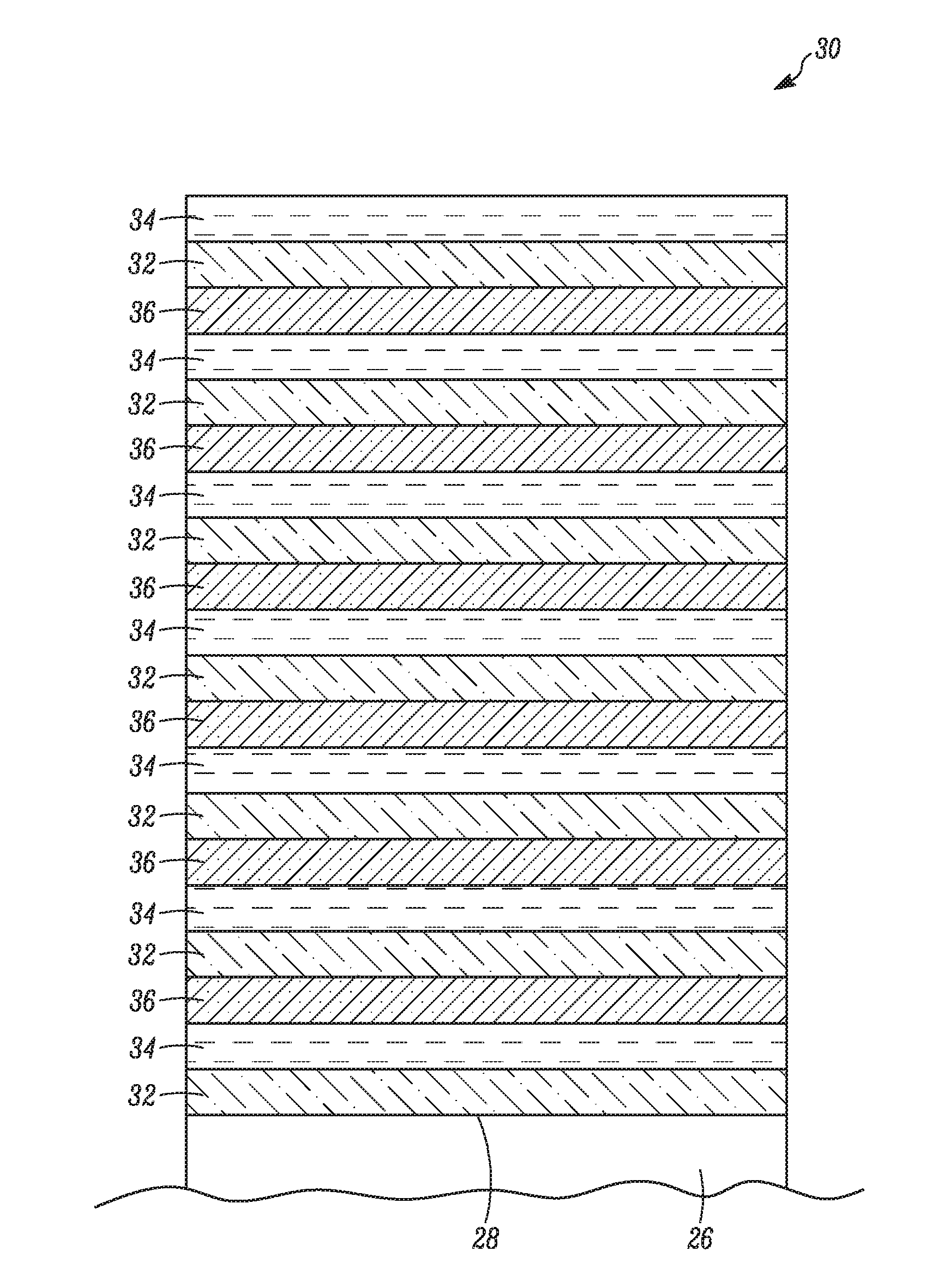

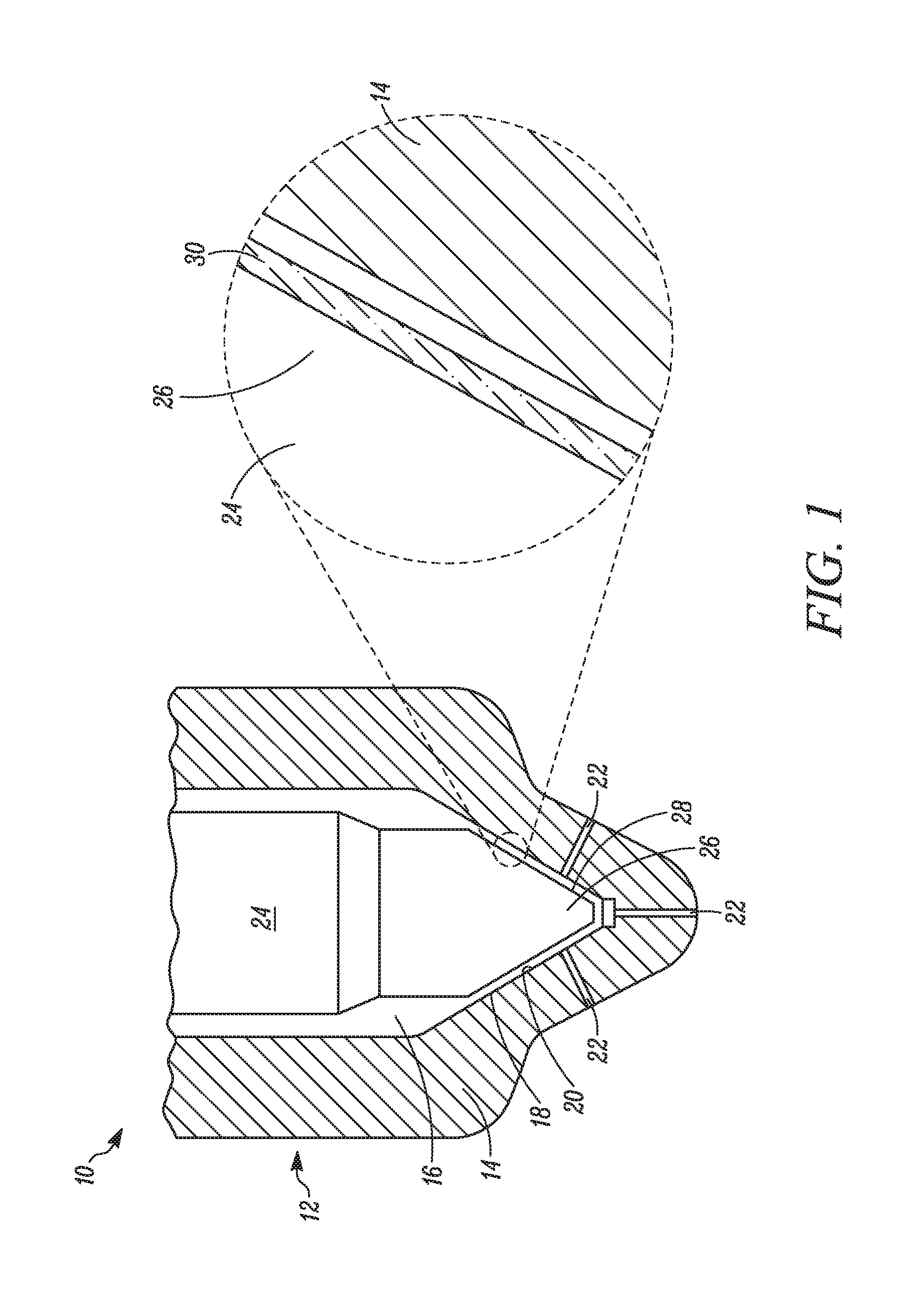

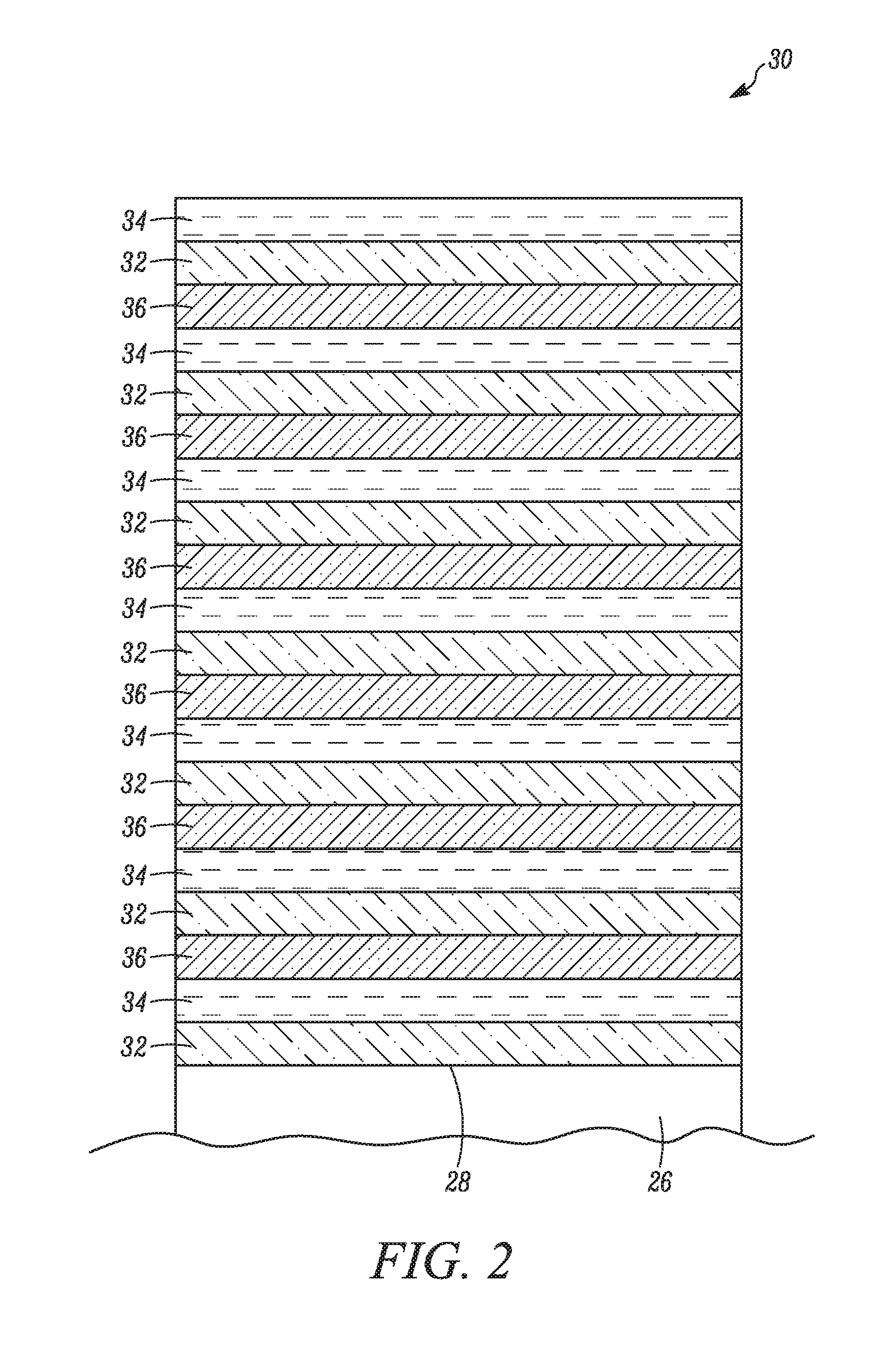

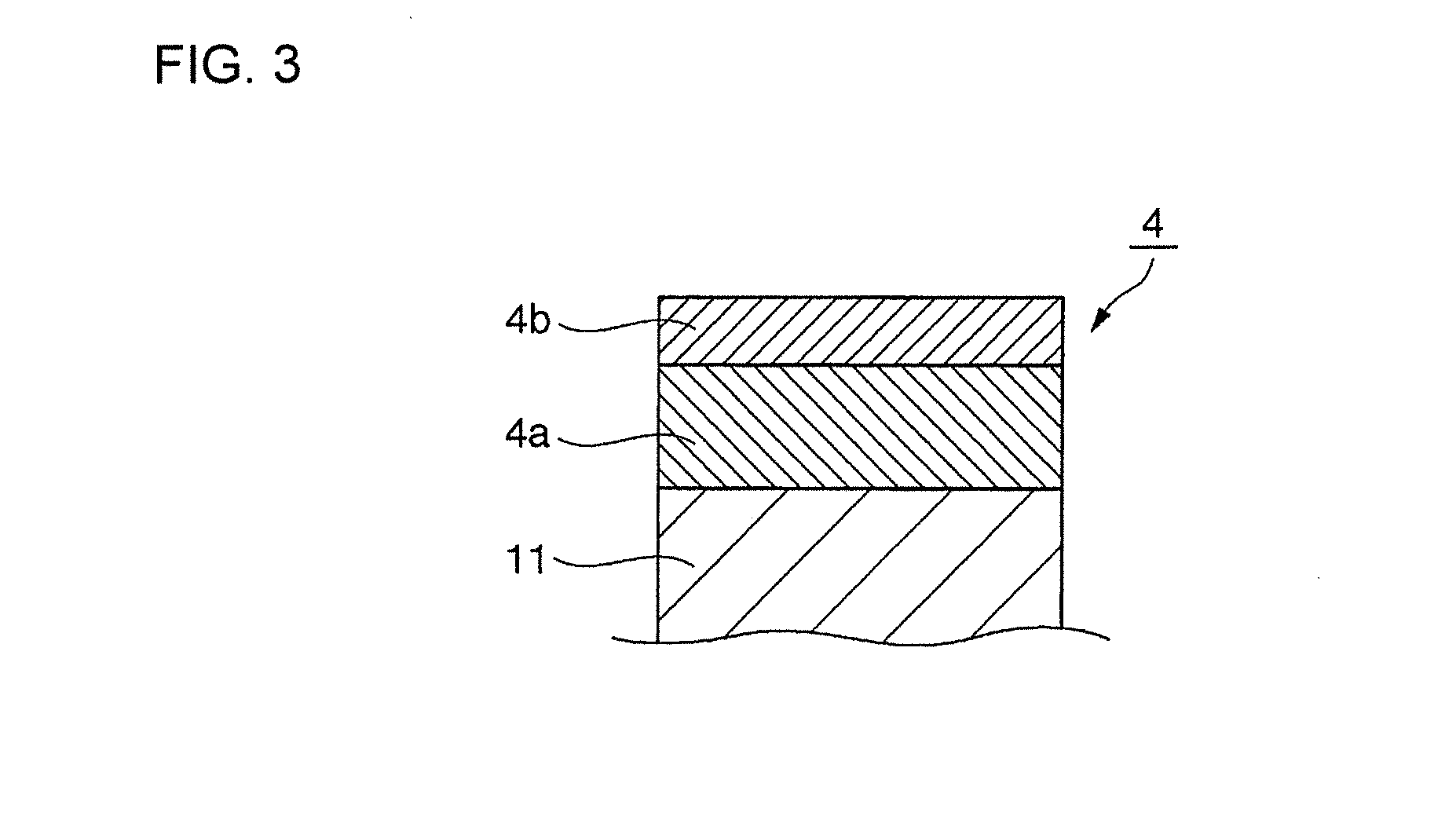

Multilayer coating for a component

InactiveUS20160230274A1Wear reducing fuel injectionCorrosion preventing fuel injectionDiamond-like carbonHardness

A multilayer coating for a metallic surface of a component is provided. The multilayer coating includes a first coating having a metal nitride. The first coating at least partially overlaps the metallic surface. The multilayer coating also includes a second coating having a metal. The second coating at least partially overlaps the first coating. The multilayer coating further includes a third coating having a Diamond Like Carbon (DLC) material. The third coating at least partially overlaps the second coating. The first coating, the second coating, and the third coating differ from one another with respect to at least one of hardness, elasticity, corrosion resistance, and lubricity. The multilayer coating includes at least ten overlapping layers having successive layers of the first coating, the second coating, and the third coating in repeating sequence.

Owner:CATERPILLAR INC

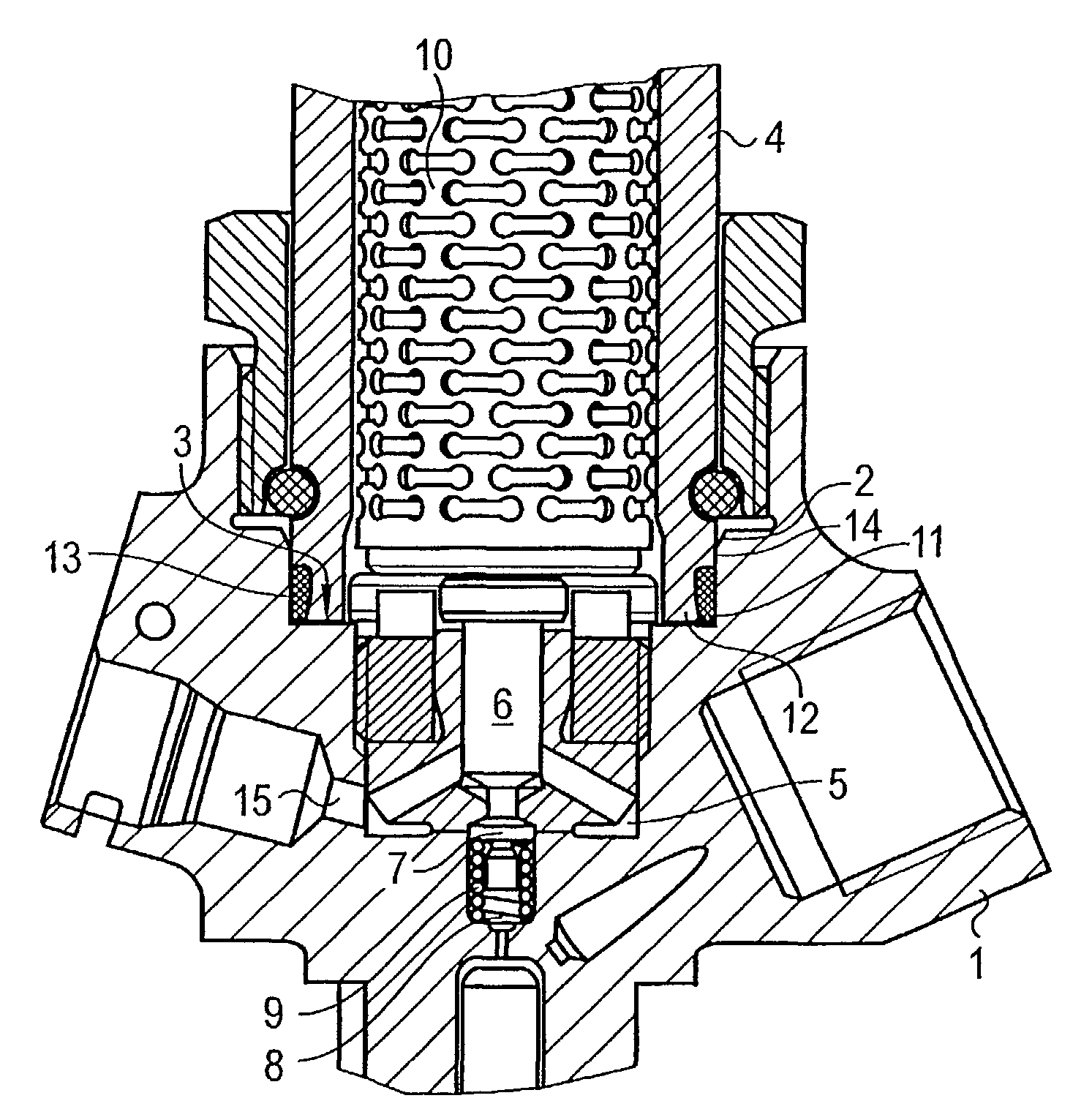

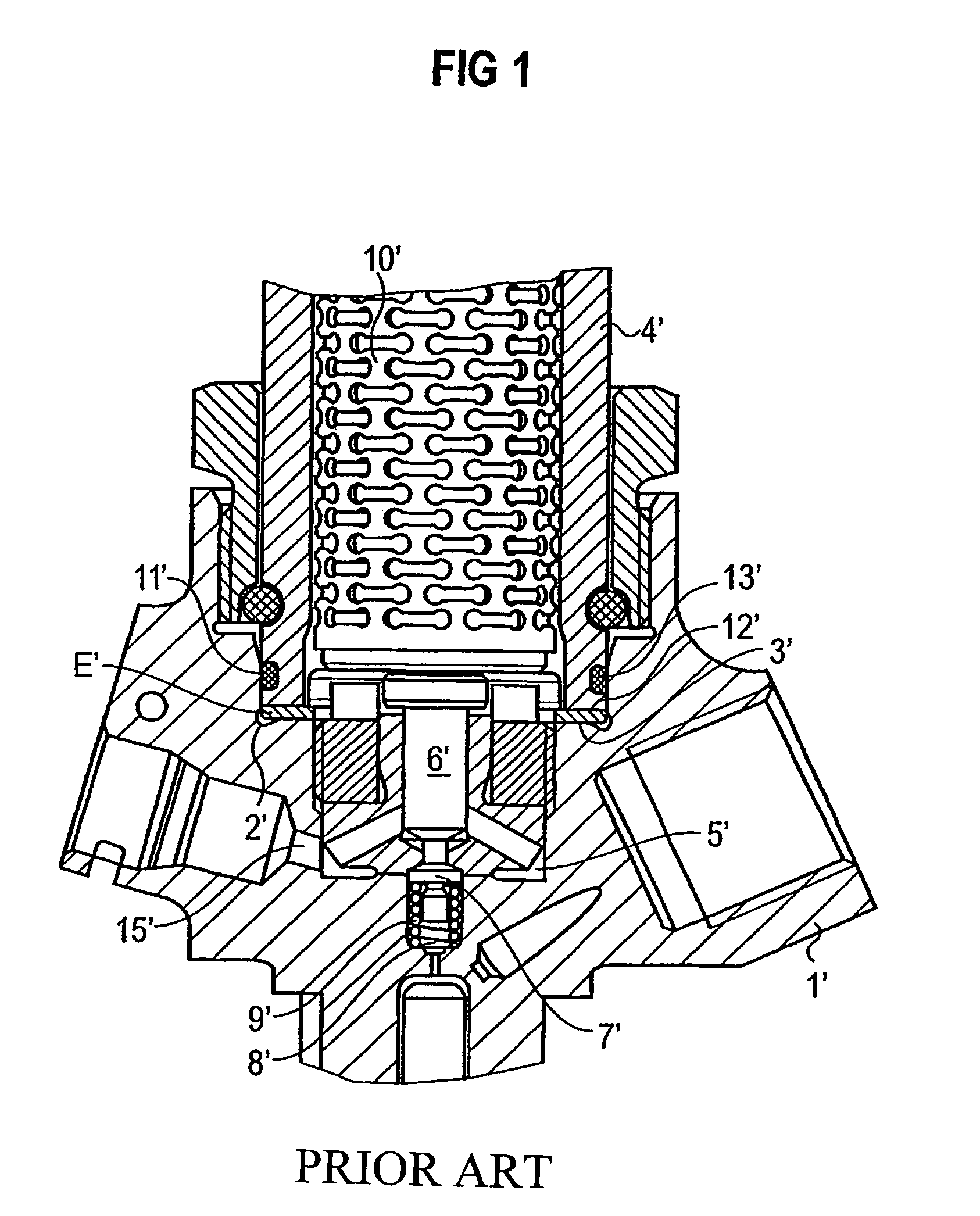

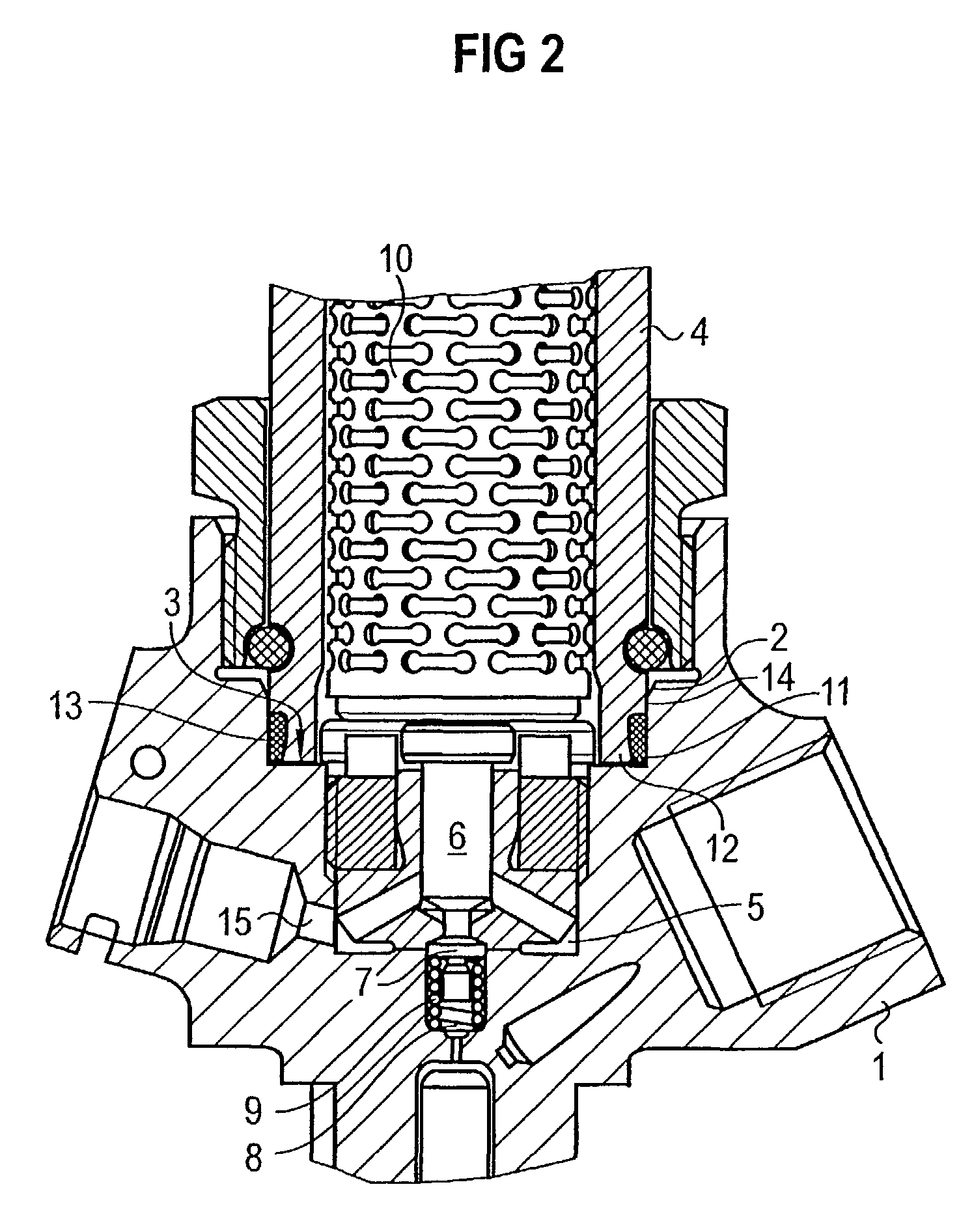

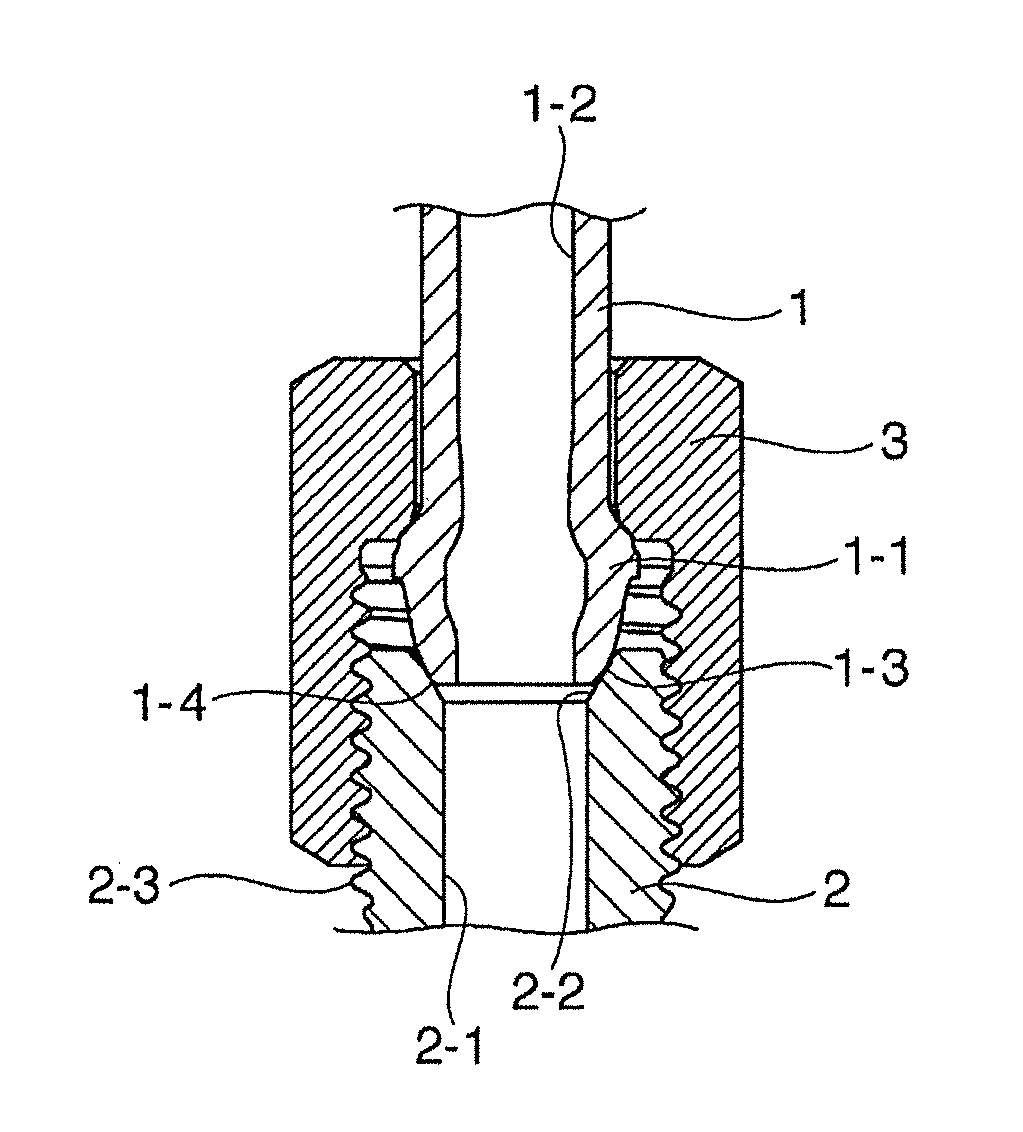

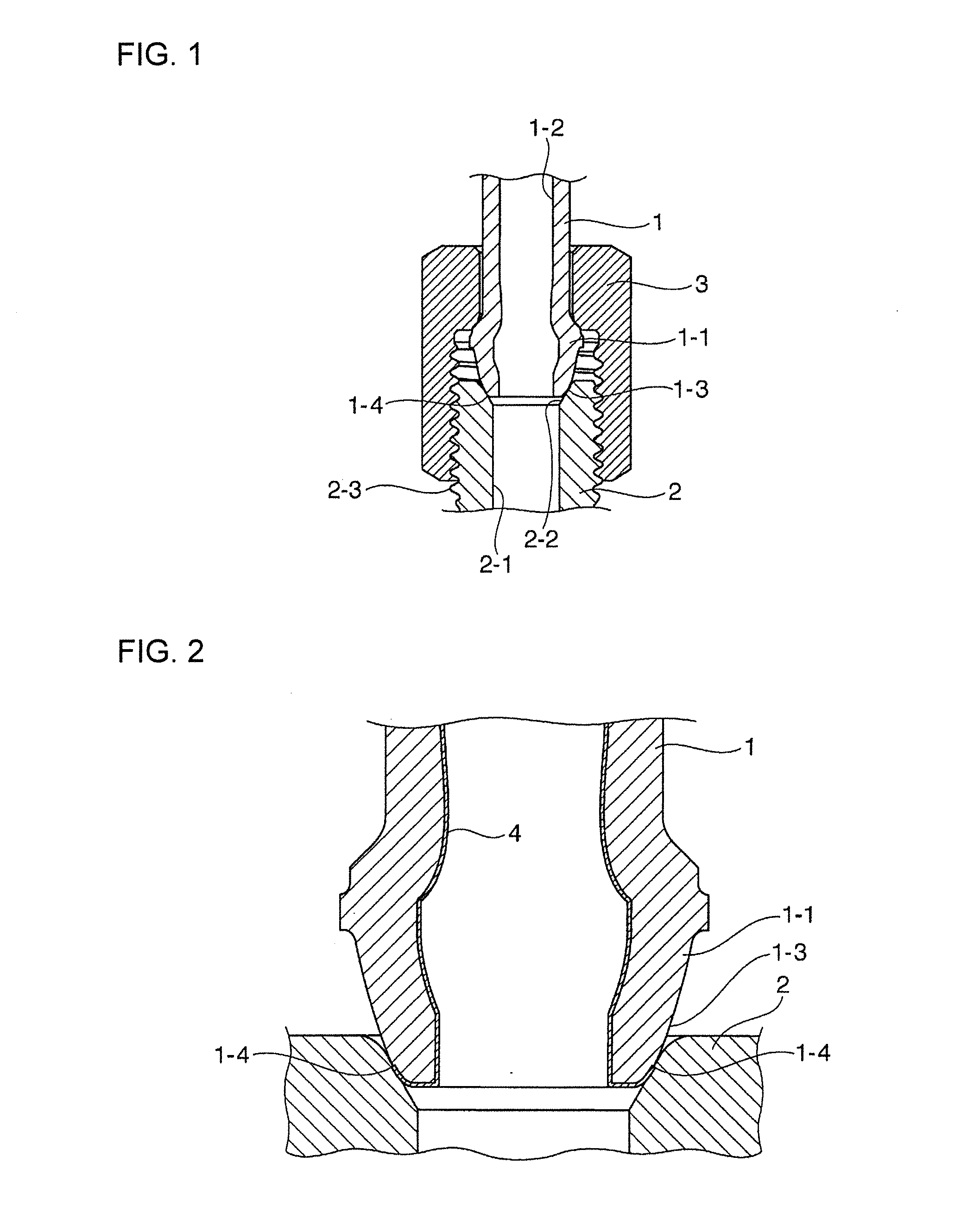

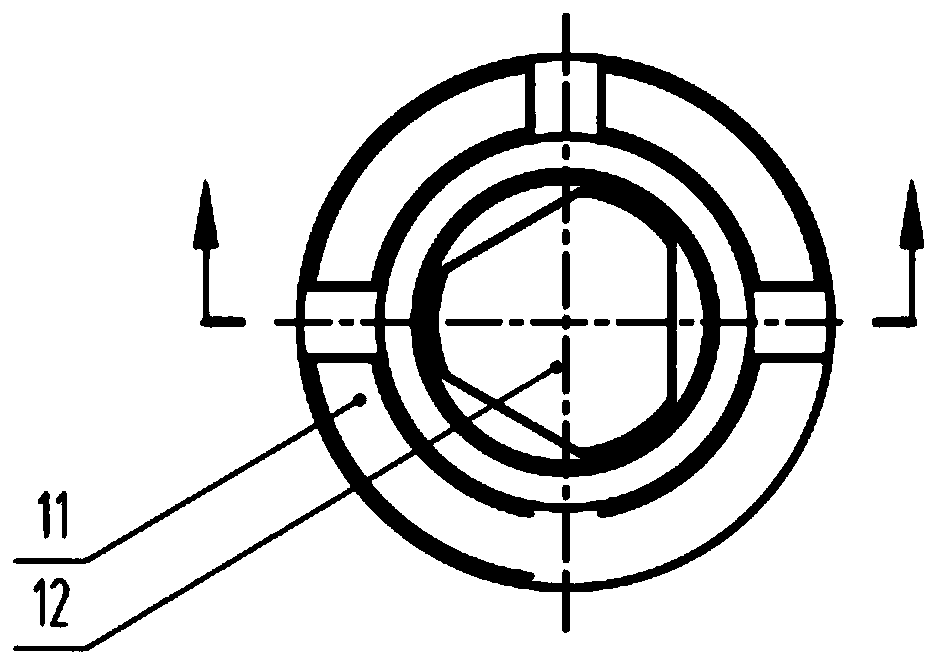

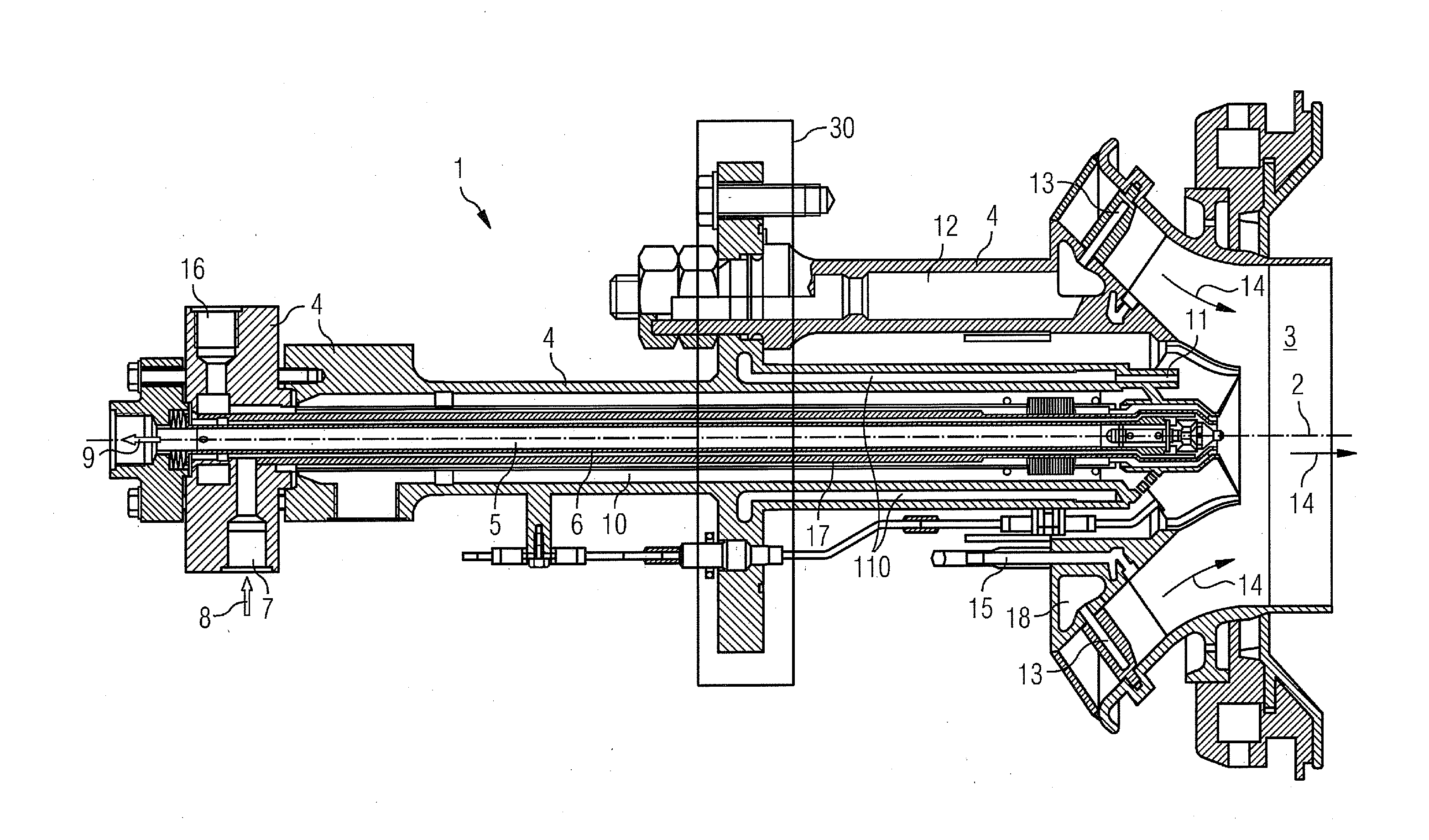

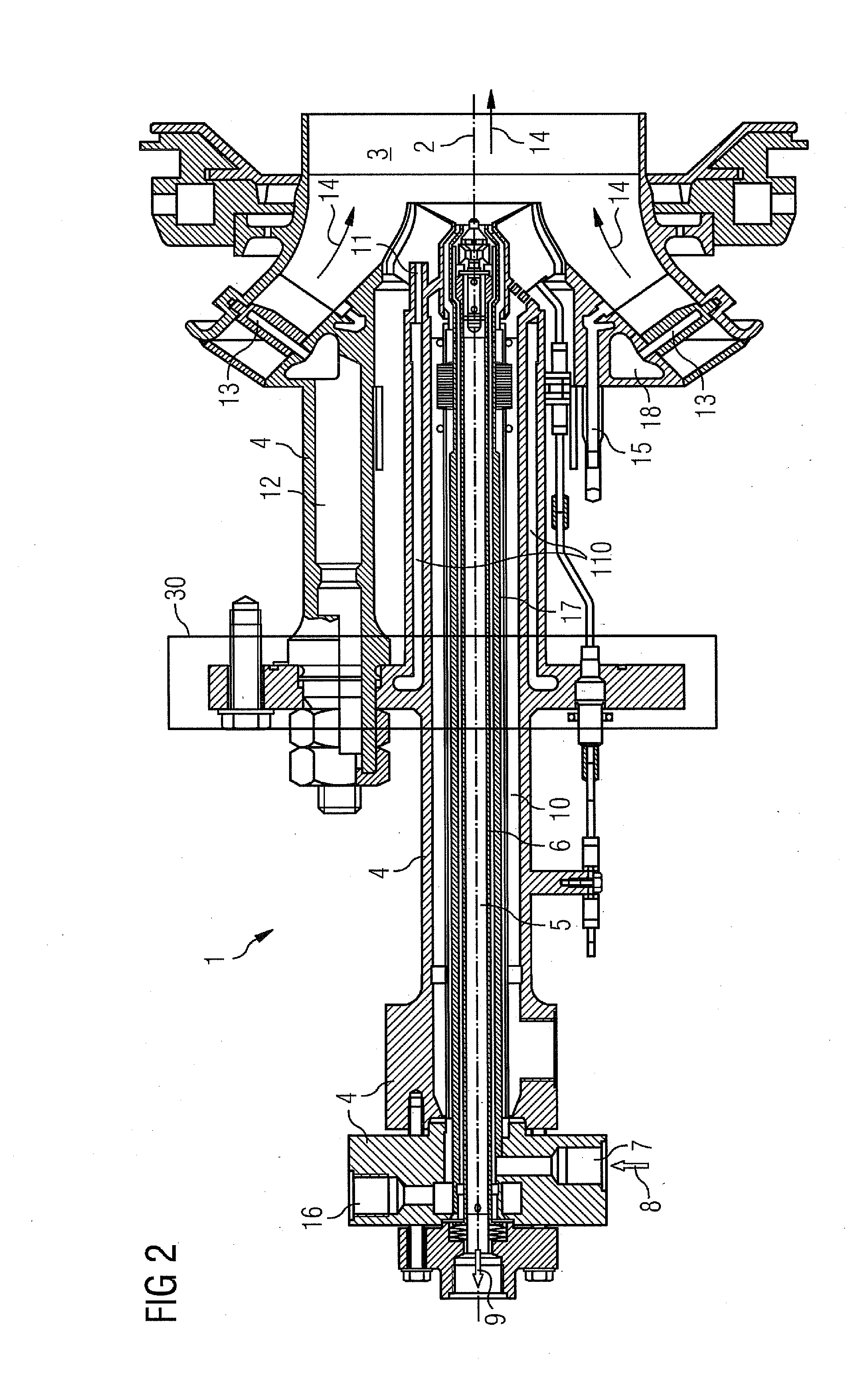

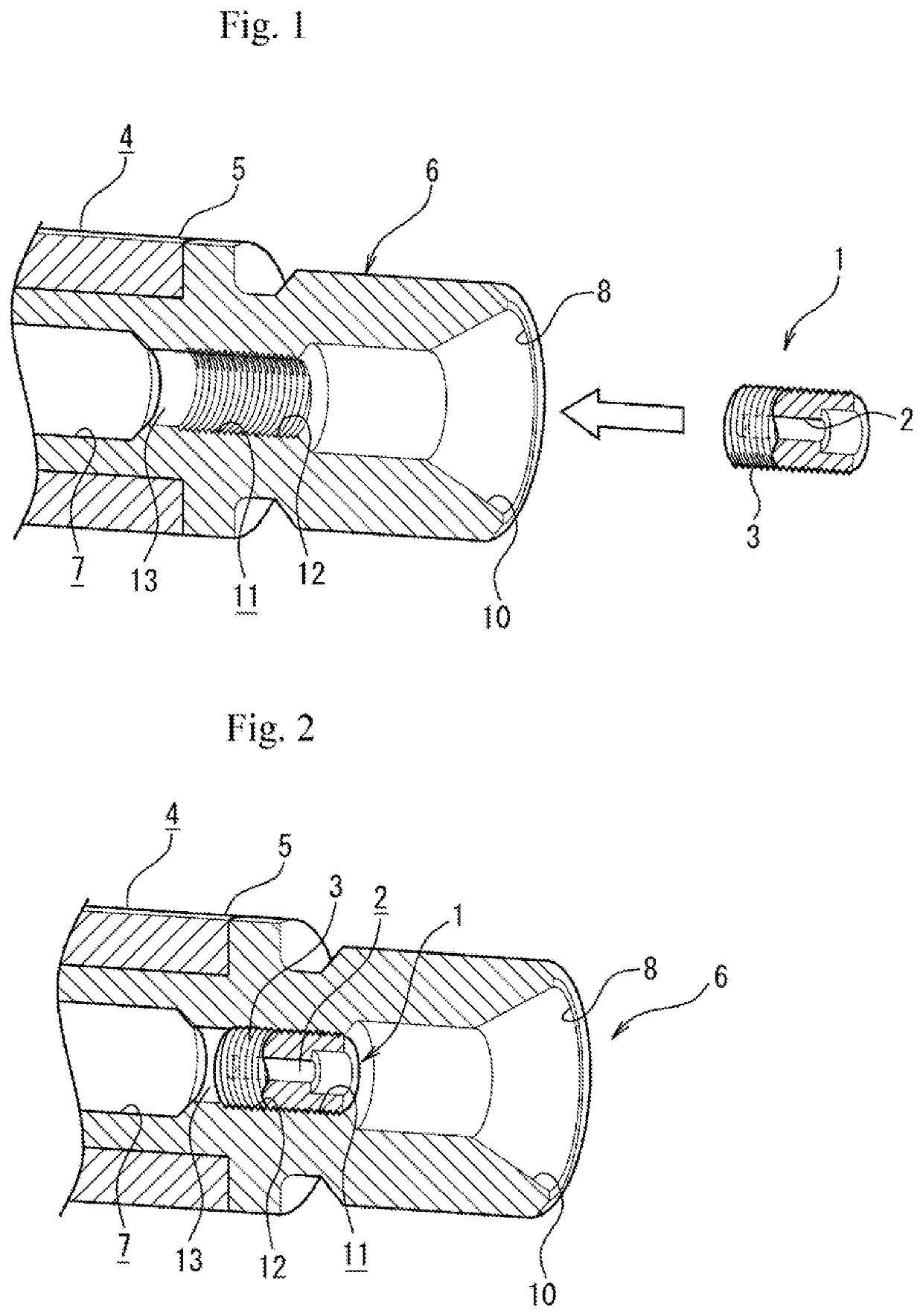

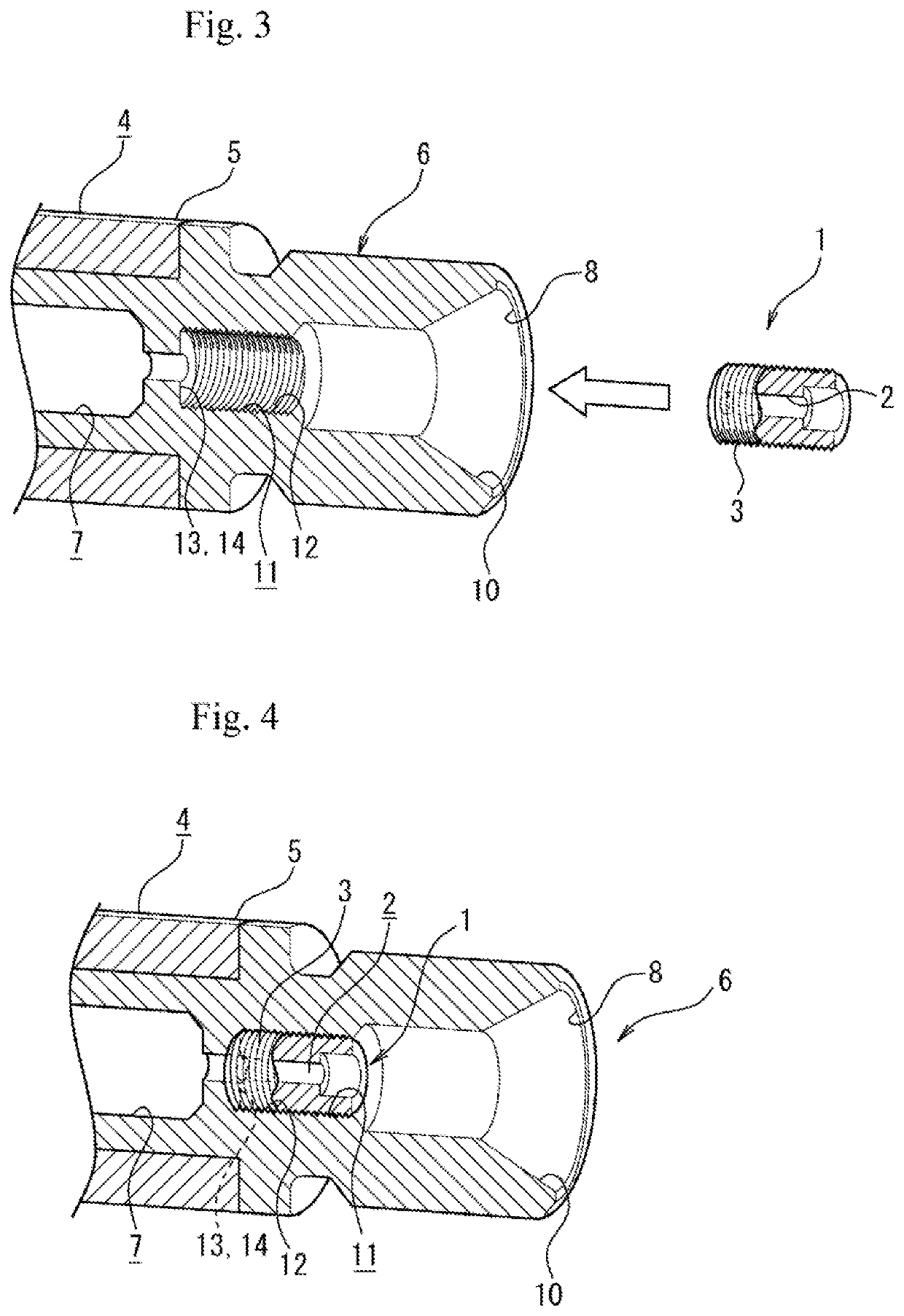

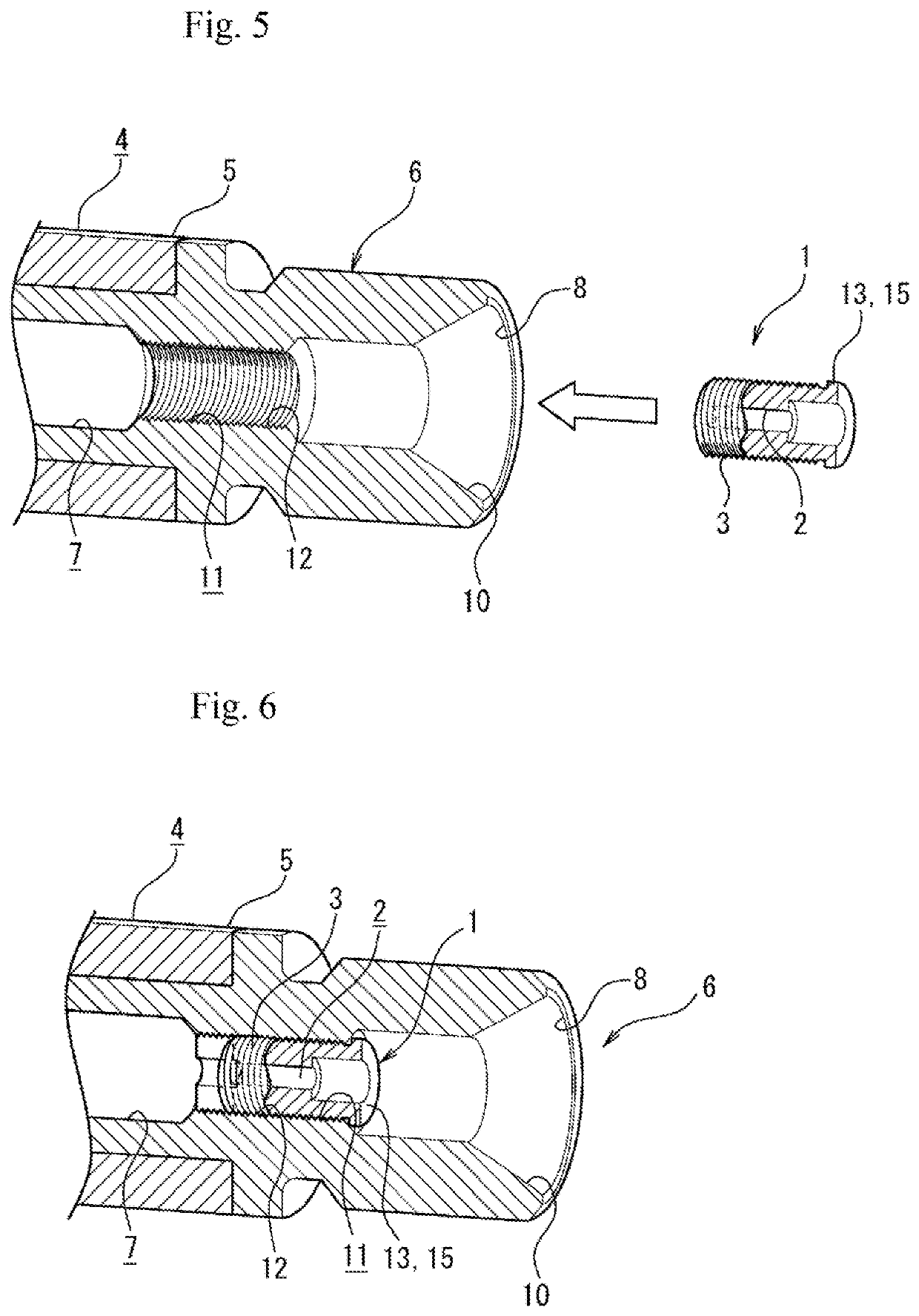

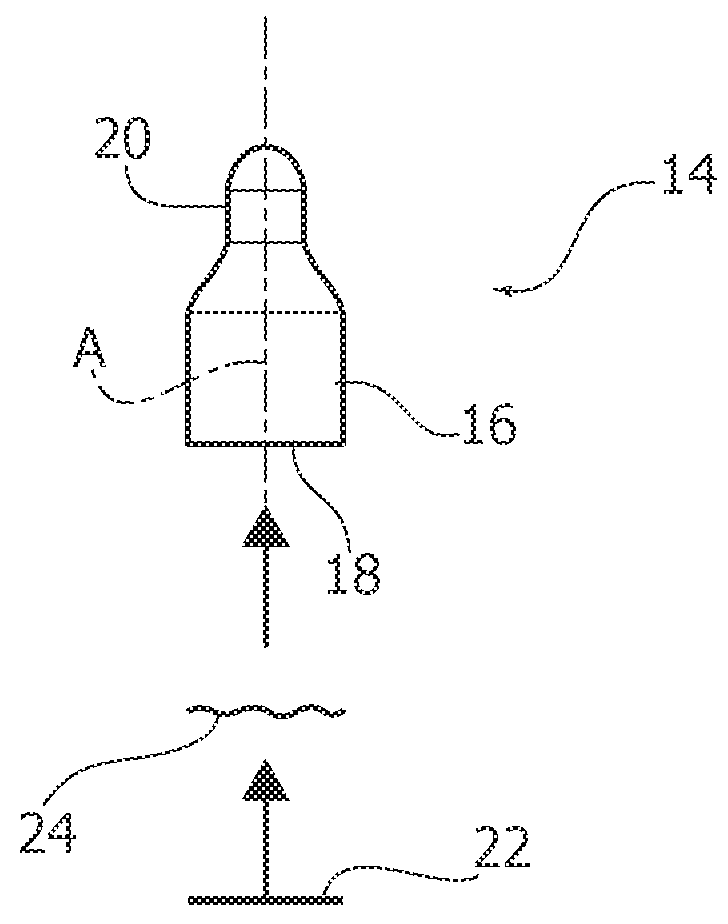

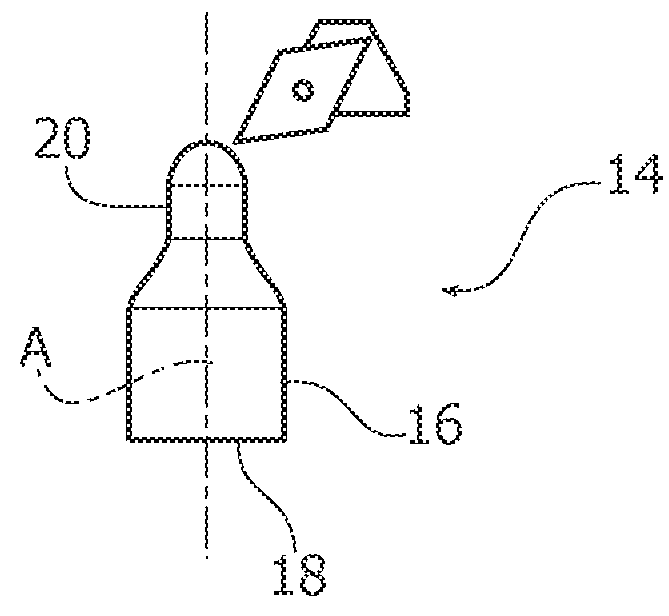

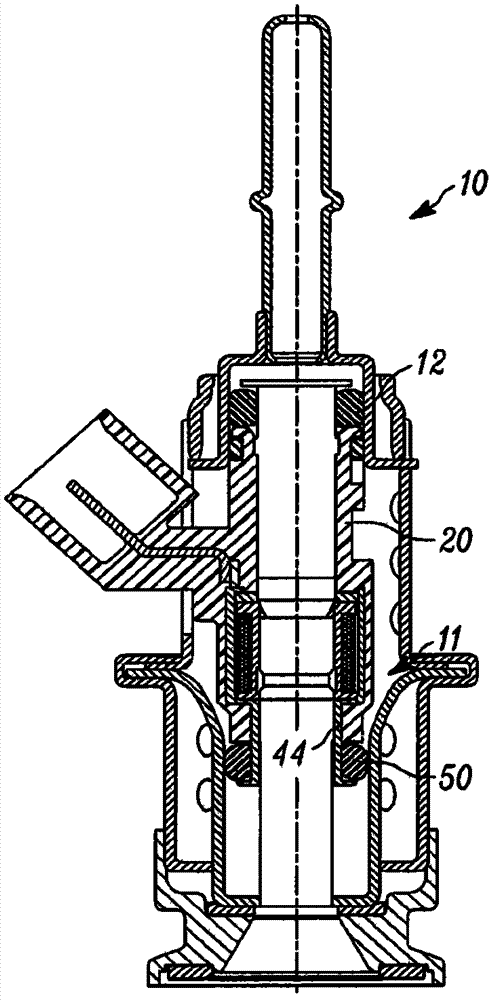

Injector to inject fuel into a combustion chamber

InactiveUS7025292B2Prevent leakageAdd extensionsOperating means/releasing devices for valvesCorrosion preventing fuel injectionCombustion chamberEngineering

An injector housing (1) of the injector has an indentation (2) in which a part of an actuator housing (4) of the injector is located. A floor of said indentation (2) is formed by a peripheral support surface (3) for the actuator housing (4). A bottom surface of the actuator housing (4) is oriented towards the support surface (3) and has a peripheral recess (11). This recess (11) is such that the bottom surface of the actuator housing (4) has at least one peripheral projection (12), which is oriented towards the support surface (3) and is adjacent to the support surface (3). A seal (13) for preventing leakage along interfaces between the injector housing (1) and the actuator housing (4) is locate din the recess (11) and is adjacent to the support surface (3).

Owner:VITESCO TECH GERMANY GMBH

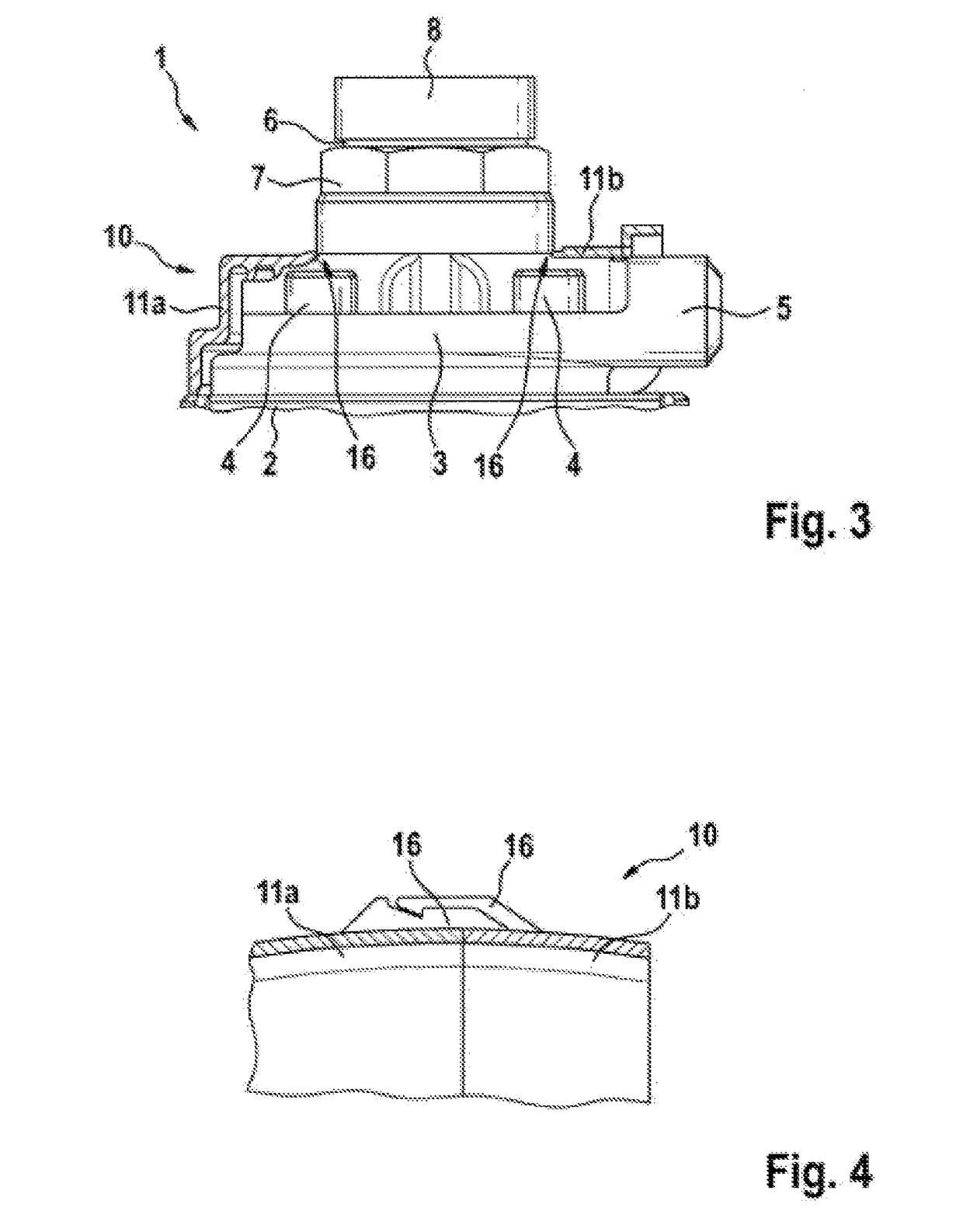

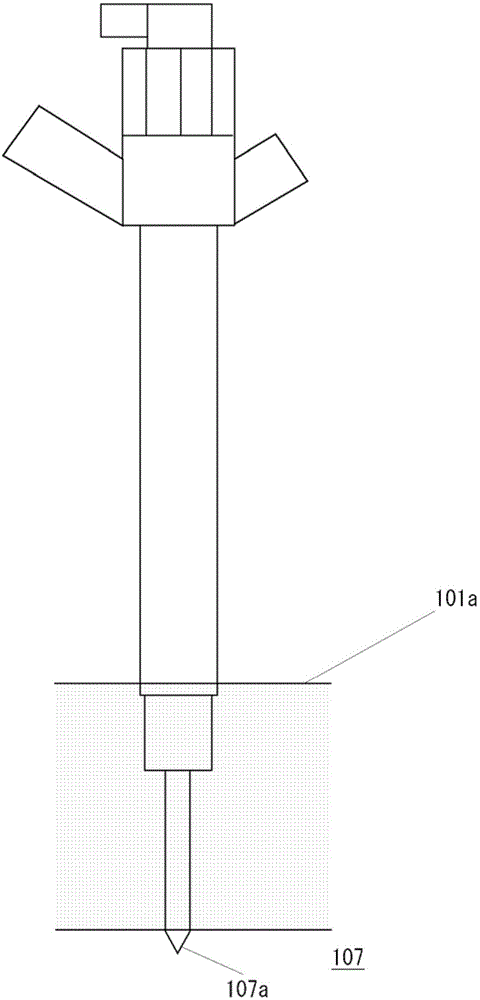

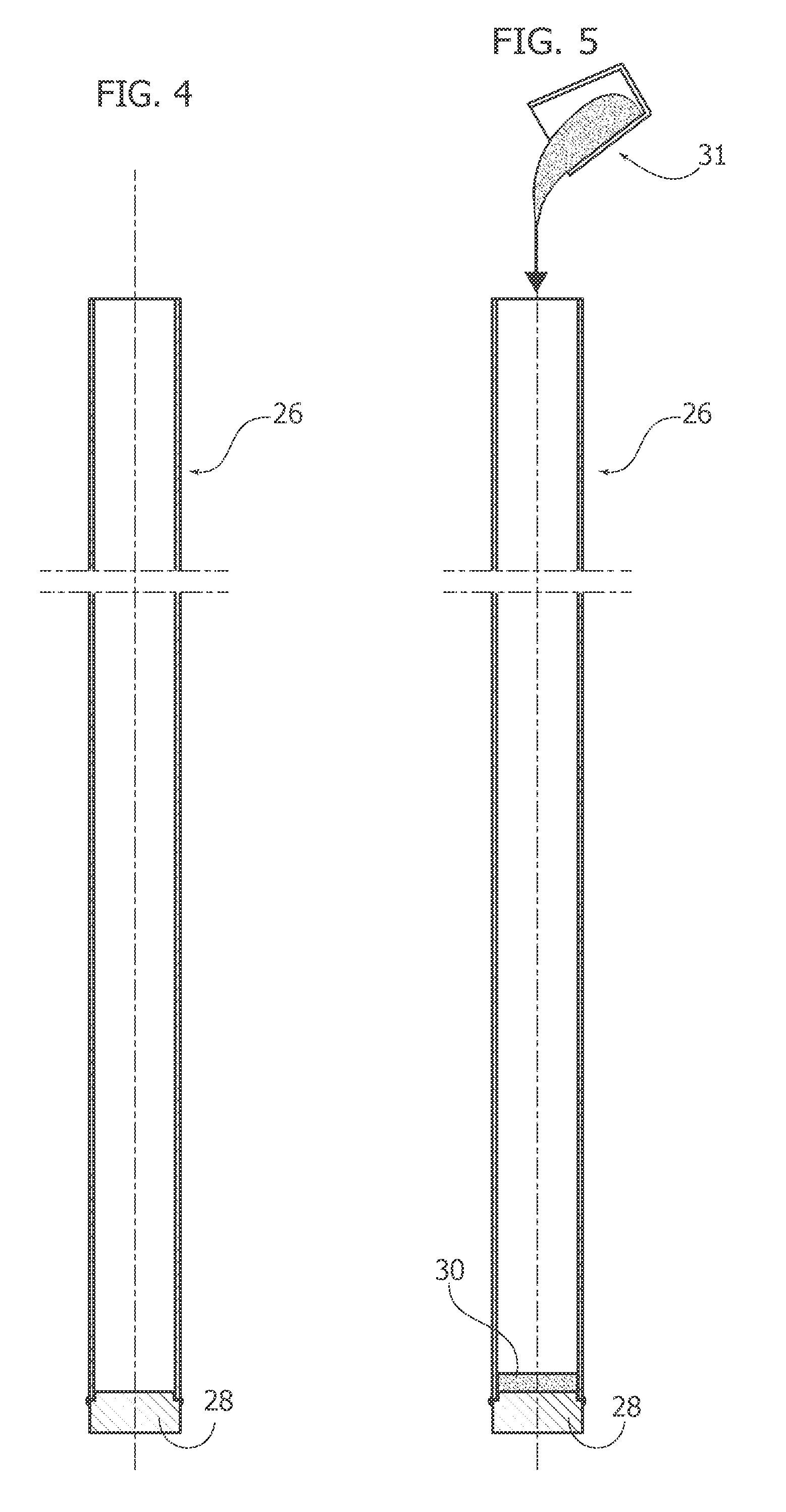

High-pressure fuel pump

ActiveUS20180306151A1Improve installation reliabilityAvoid problemsPositive displacement pump componentsCorrosion preventing fuel injectionCommon railCylinder head

The invention relates to a high-pressure fuel pump (1), in particular of a common rail injection system of an internal combustion engine, having a pump cylinder head (3), having an intake valve (6) arranged in the pump cylinder head (3) in the direction of a pump cylinder axis, and a high-pressure fuel outlet (5) arranged laterally on the pump cylinder head (3), wherein a protective cap (10, 10a) at least partly covering the high-pressure fuel pump (1) is provided. According to the invention, a high-pressure fuel pump (1) having a protective cap (10, 10a) is provided, in which the protective cap (10, 10a) can be mounted without difficulty on an assembled high-pressure fuel pump (1). This is achieved in that a plug (8) having a lateral lead connection (9) is placed on the electrically operated intake valve (6), and the protective cap (10) is formed in two pieces and has two protective cap parts (11a, 11b) that can be fitted to each other, or else in that a plug (8) having a lateral lead connection (9) is placed on the electrically operated intake valve (6), and the protective cap (10a) is formed annularly and has a free clearance slot (19) interrupting the ring.

Owner:ROBERT BOSCH GMBH

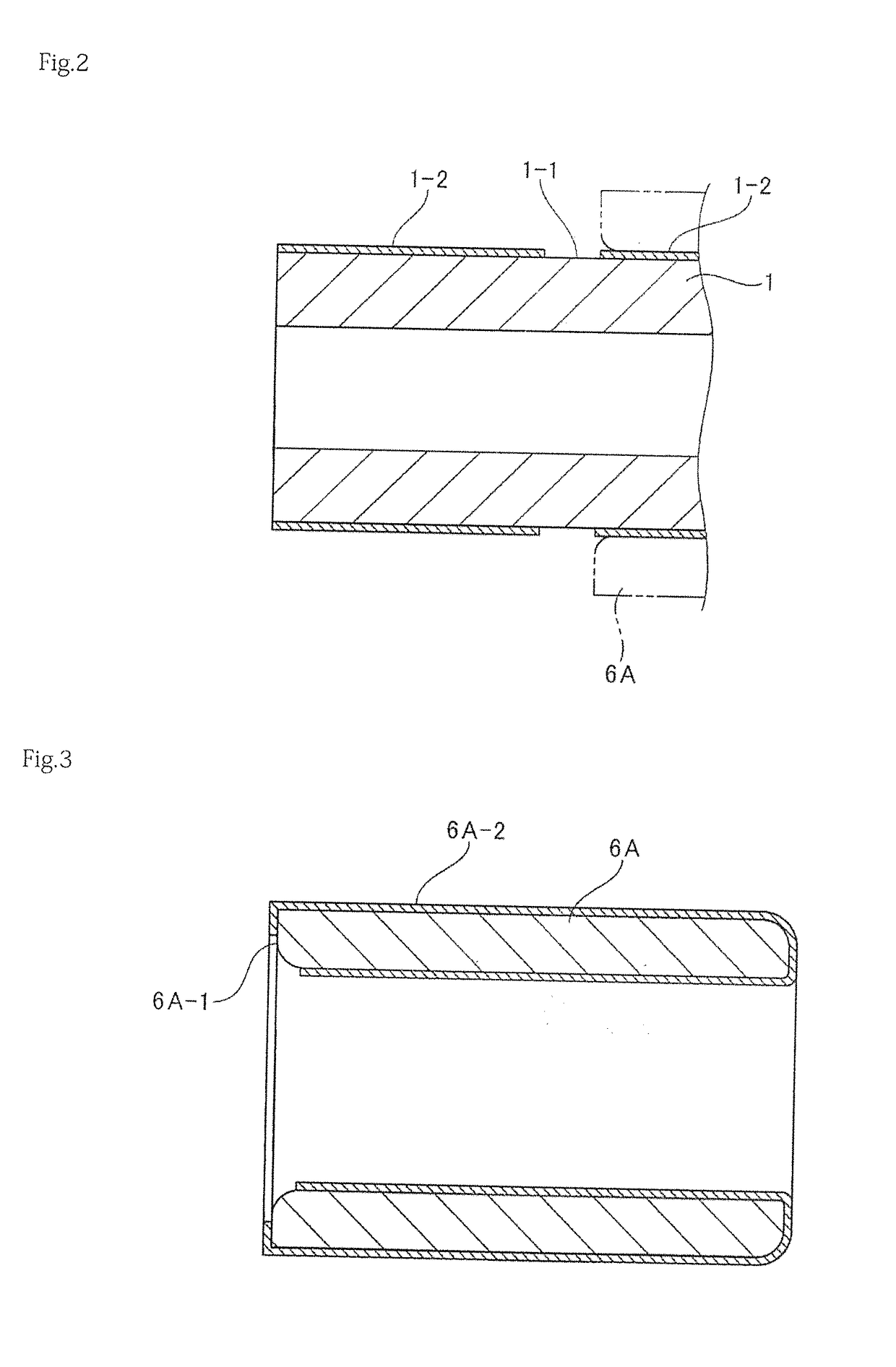

Steel fuel conveying pipe

ActiveUS20160230725A1Improve anti-corrosion performanceImprove reliabilityJoints with sealing surfacesCorrosion preventing fuel injectionHigh resistanceLayer thickness

Provided is a steel fuel conveying pipe with high quality which has high resistance to corrosive fuel and followability, and allows working after plating. The steel fuel conveying pipe is characterized in that a Ni-plate layer is formed on an inner surface of a steel pipe of base material, the Ni-plated layer is wholly composed of a mutual diffusion layer including the base material and Ni and a non-mutual diffusion layer including only Ni formed on an outermost surface of the diffusion layer, a layer thickness of the non-mutual diffusion layer is 3 μm or more, and a total layer thickness of the mutual diffusion layer and the non-mutual diffusion layer is 10 μm or more and 25 μm or less.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

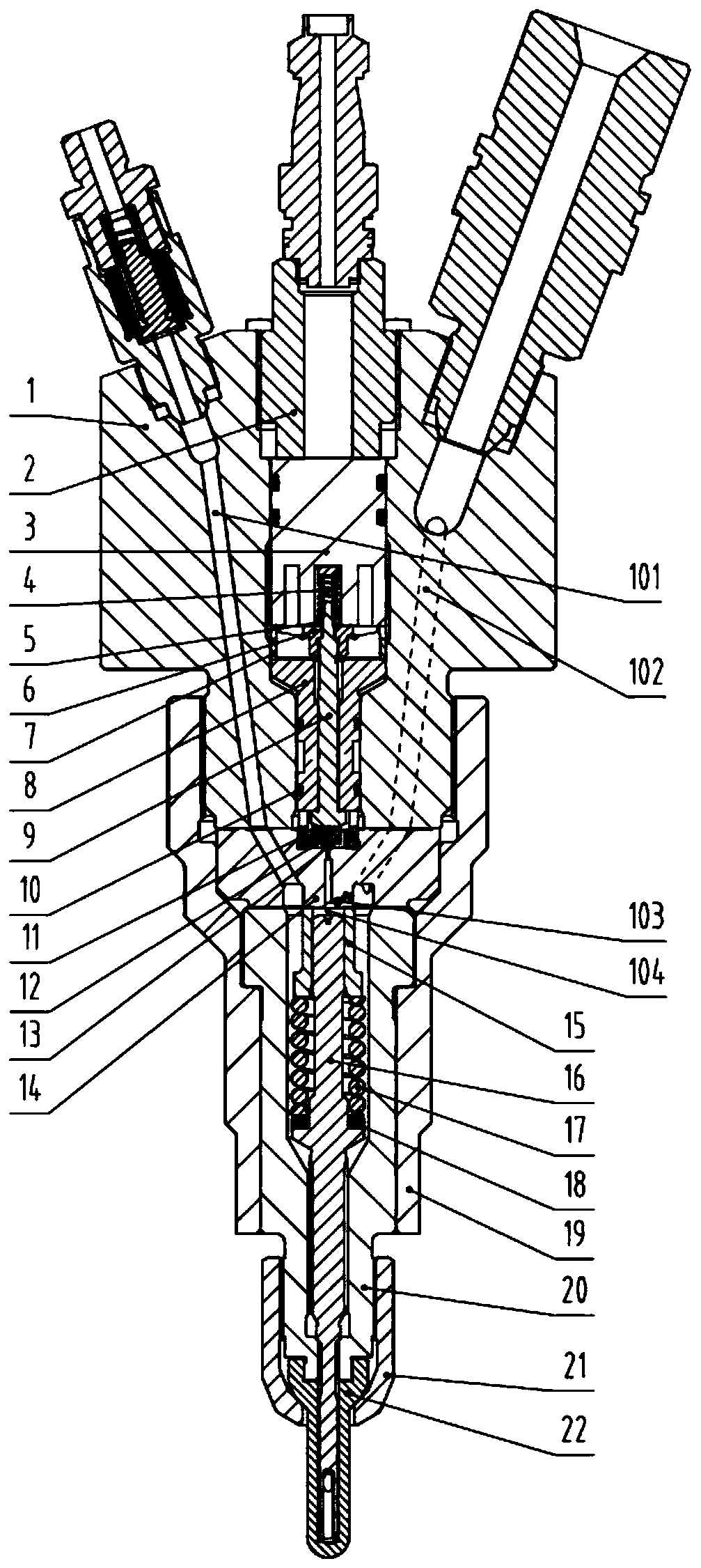

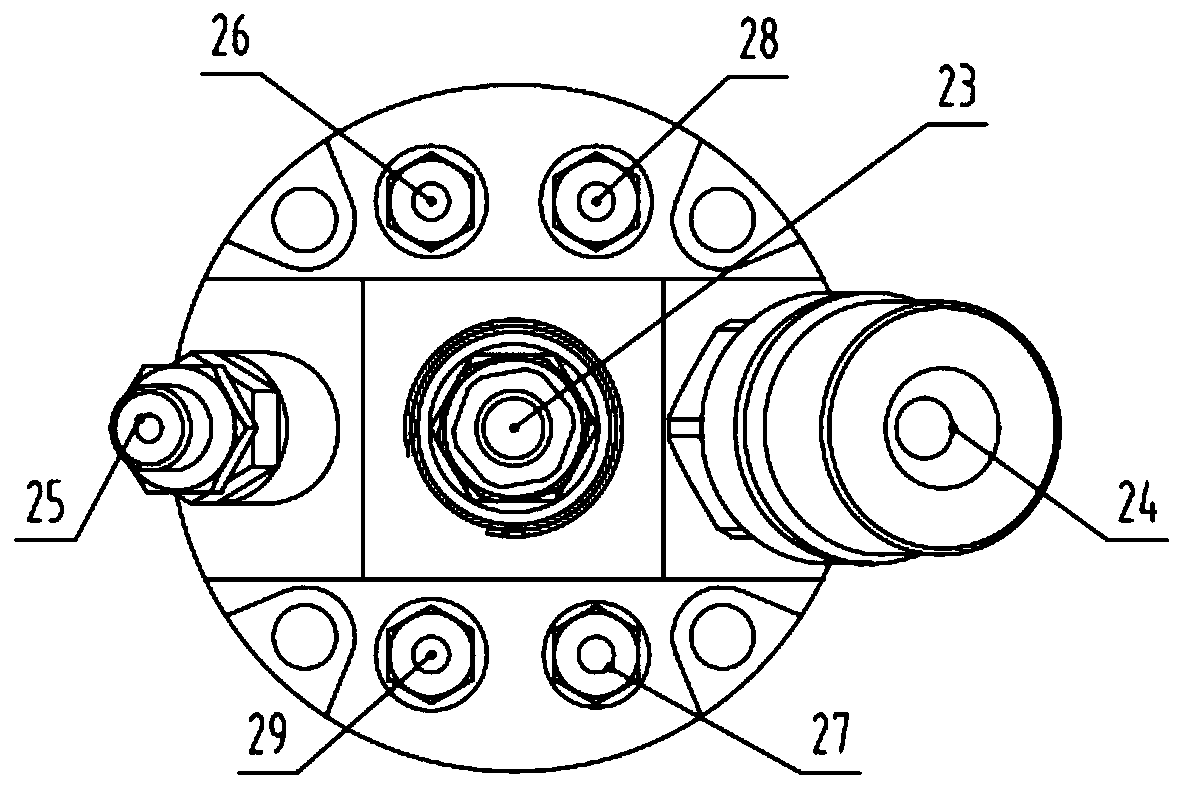

Electronically-controlled common rail heavy oil injector

ActiveCN110594061AChange the work schedule at any timeSave spaceCorrosion preventing fuel injectionMachines/enginesVena contracta diameterCommon rail

The invention relates to an electronically-controlled common rail heavy oil injector which comprises an injector body, an electro-hydraulic control member and a nozzle member. In the electro-hydrauliccontrol member, a ring groove is formed in the middle of the outer side of a guide sleeve, a transverse through hole is formed in the middle of the groove to directly communicate with a middle hole of the guide sleeve, the two sides of the ring groove are provided with seal rings, and the interior of the oil injector is divided into three chambers. A control valve core guide section is provided with three ring grooves, and the second ring groove is in communication with the transverse through hole in the middle of the guide sleeve. An electromagnetic component is in contact with cooling oil,a cooling oil circuit is isolated from a fuel oil circuit by means of dynamic sealing, static sealing and drainage manners, and corroding and thermal damage of heavy oil to electronic components can be effectively prevented; and a sinking groove is formed in the middle of the top end of an orifice plate, a ball valve seat guide sleeve can be sleeved with the sinking groove of the orifice plate tobe in clearance fit with a ball valve seat, and a certain guiding ability for axial movement of the ball valve seat is achieved.

Owner:CHONGQING HONGJIANG MACHINERY

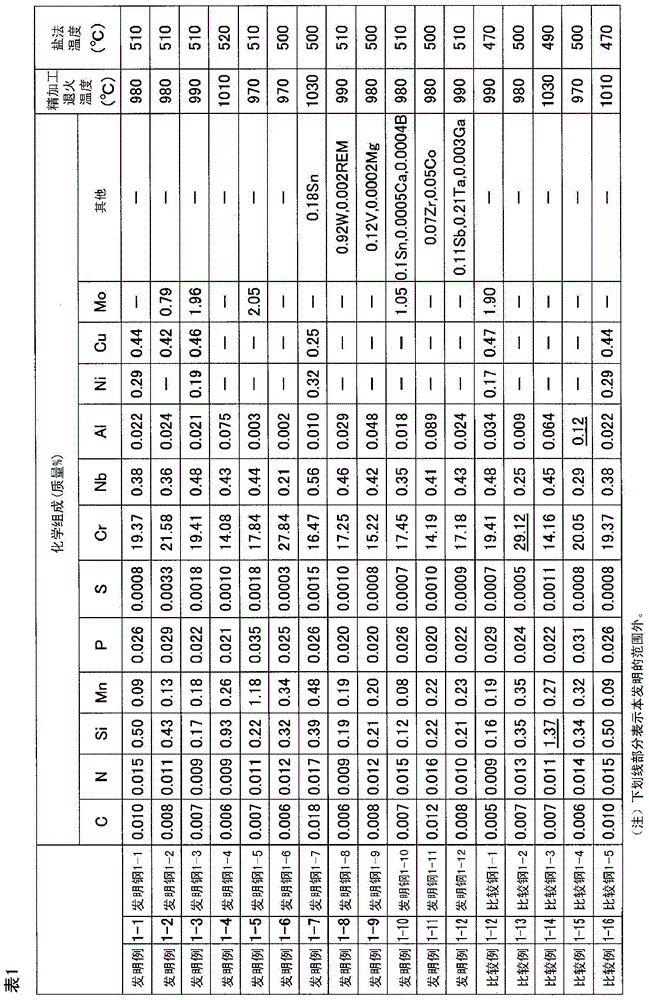

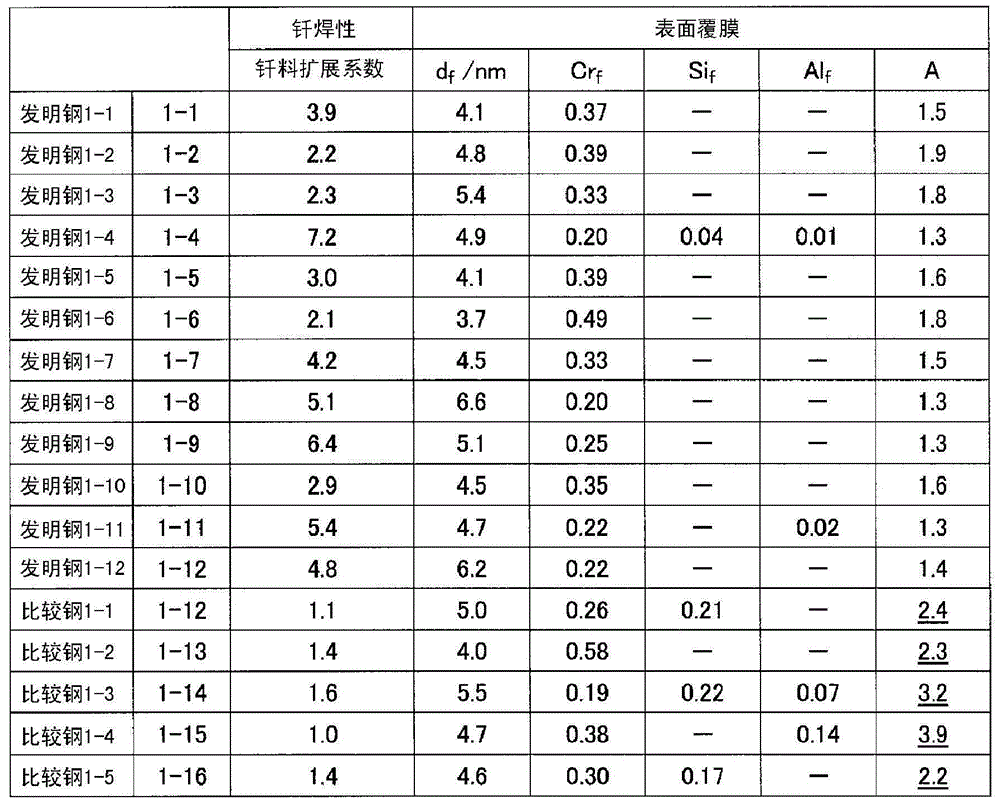

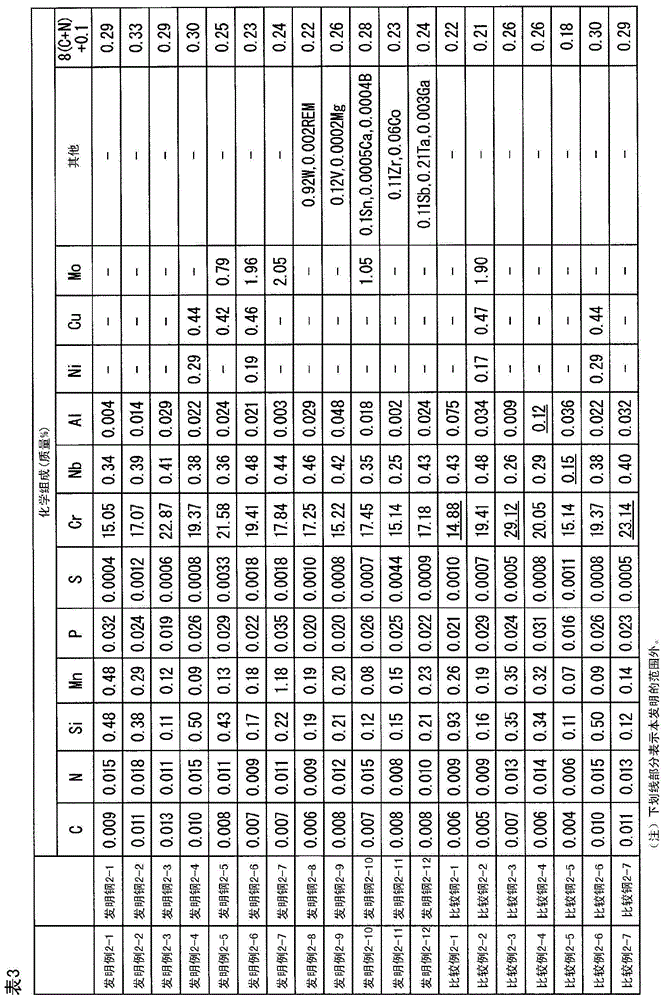

Ferritic stainless steel sheet having excellent brazability, heat exchanger, ferritic stainless steel sheet for heat exchangers, ferritic stainless steel, ferritic stainless steel for members of fuel supply systems, and member of fuel supply system

ActiveUS20160002760A1Excellent brazeabilityPart can be usedRecuperative heat exchangersCorrosion preventing fuel injectionMetallurgyFuel supply

One aspect of this ferritic stainless steel sheet contains, by mass %, C: 0.03% or less, N: 0.05% or less, Si: 1% or less, Mn: 1.2% or less, Cr: 14% or more and 28% or less, Nb: 8(C+N) or more and 0.8% or less, and Al: 0.1% or less, with a balance being Fe and inevitable impurities, in which a film satisfying Expression 1 is formed in a surface thereof.df×Crf+5(Sif+3Alf)≦2.0 (Expression 1)In Expression 1, df represents a thickness (nm) of the film, Crf represents a Cr cationic fraction in the film, Sif represents a Si cationic fraction in the film, and Alf represents an Al cationic fraction in the film.

Owner:NIPPON STEEL STAINLESS STEEL CORP

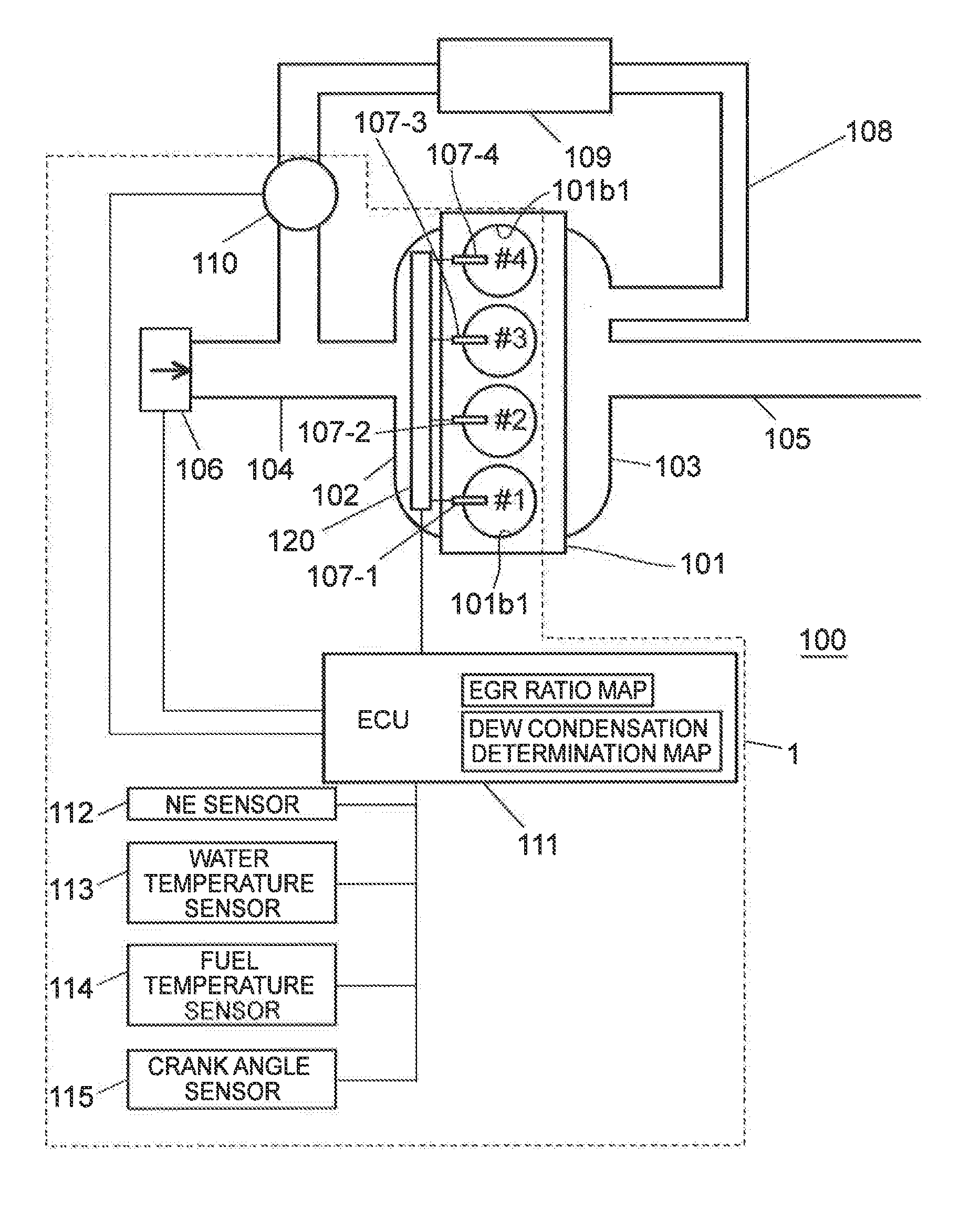

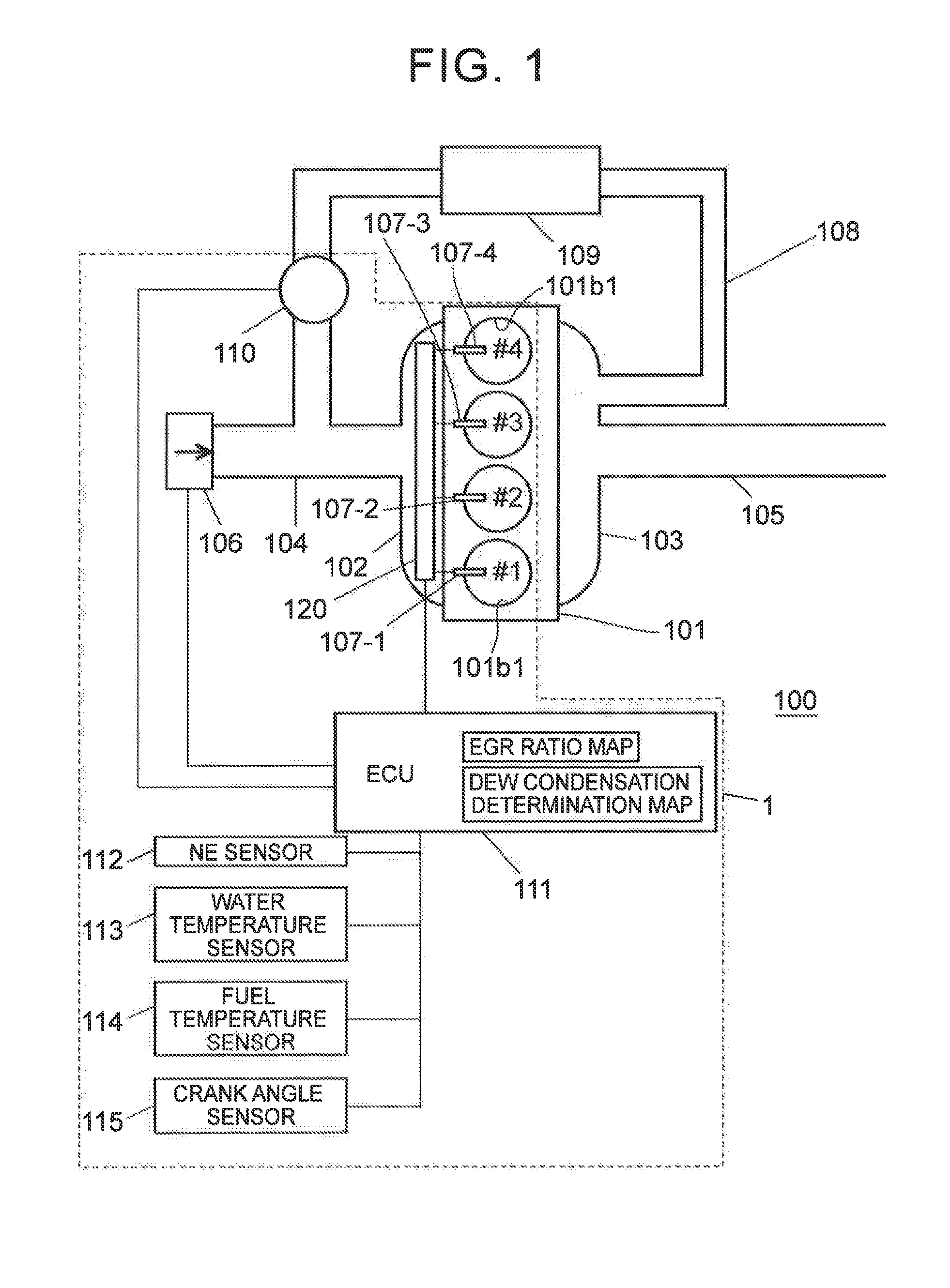

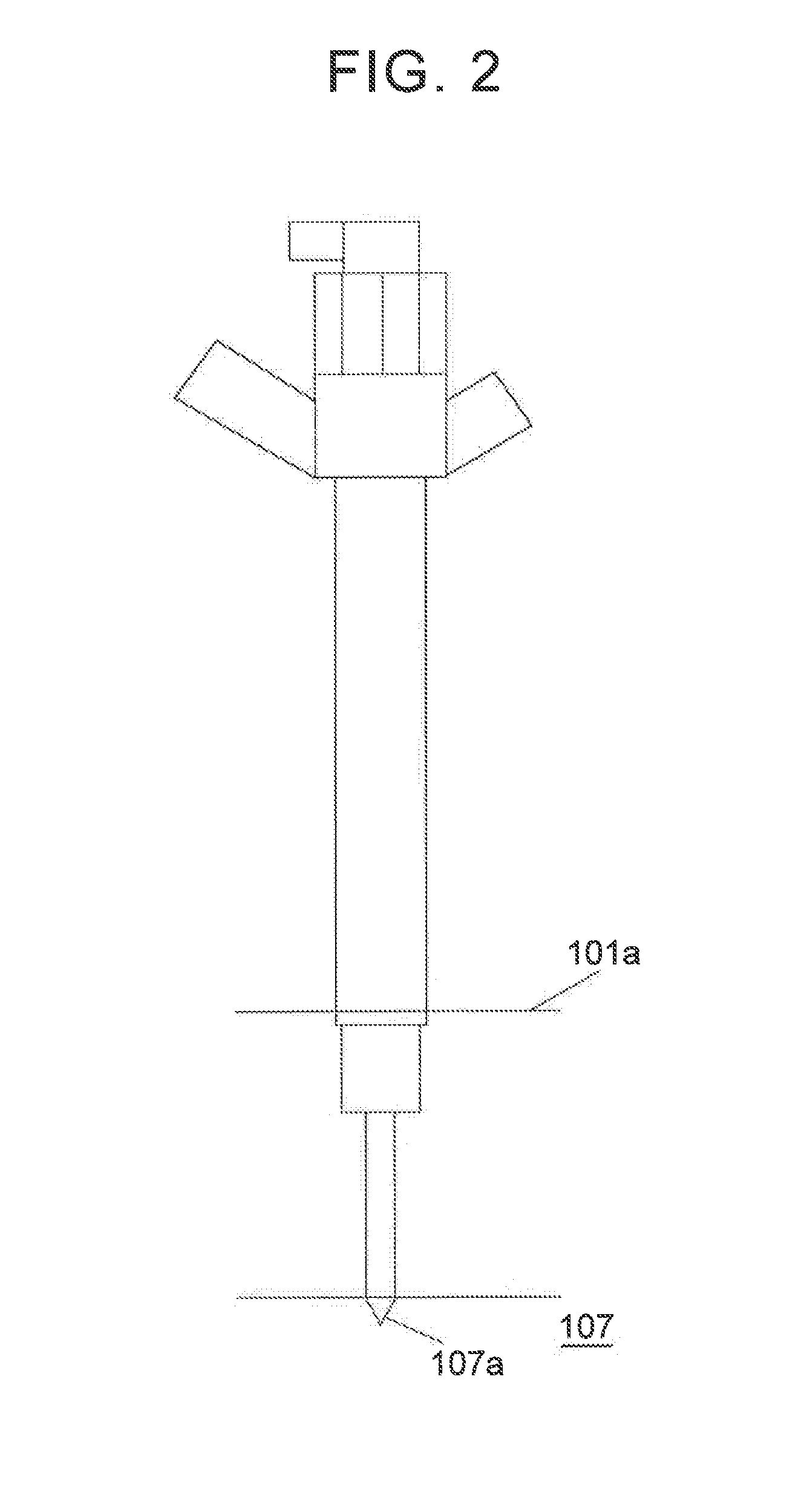

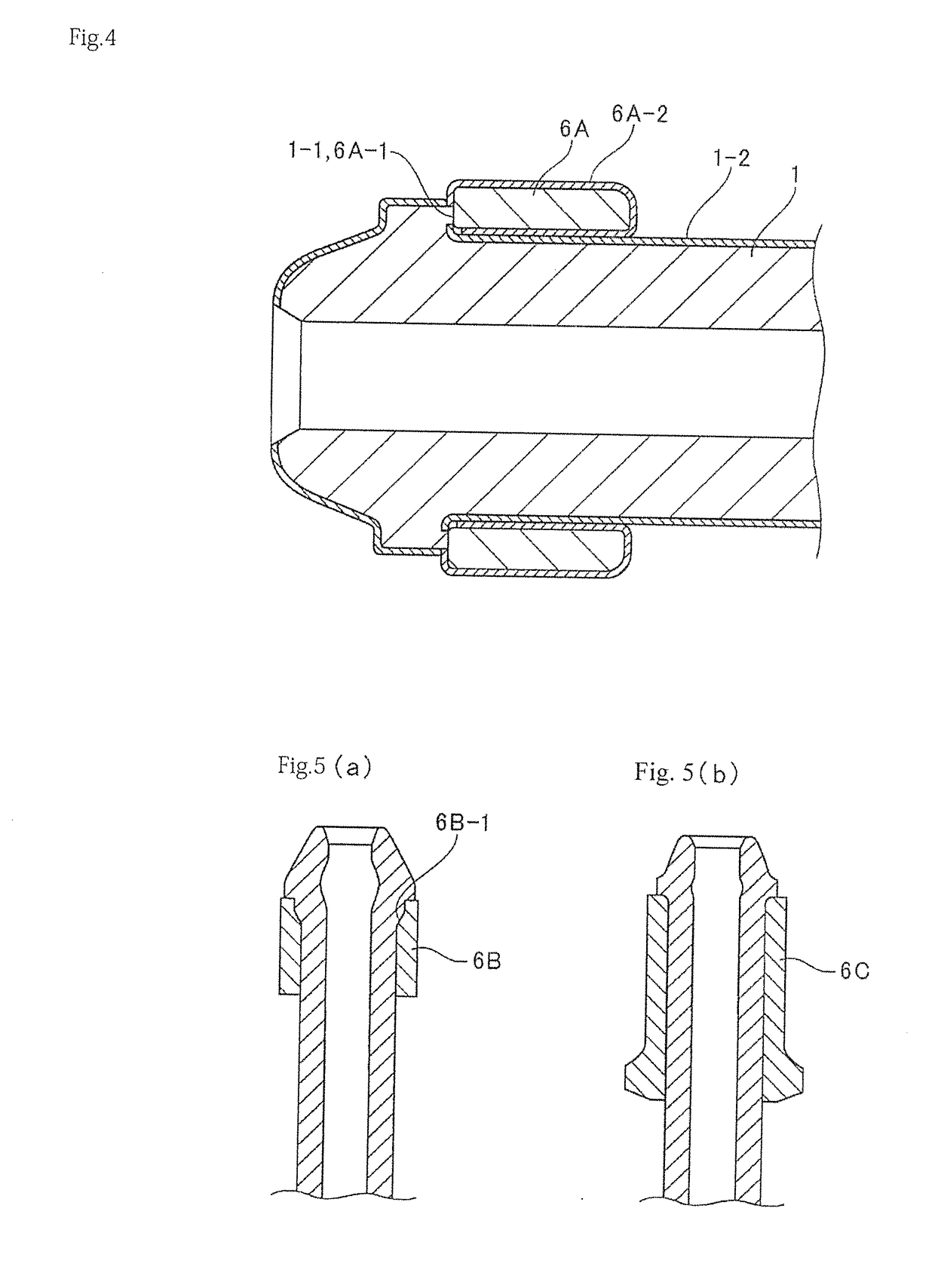

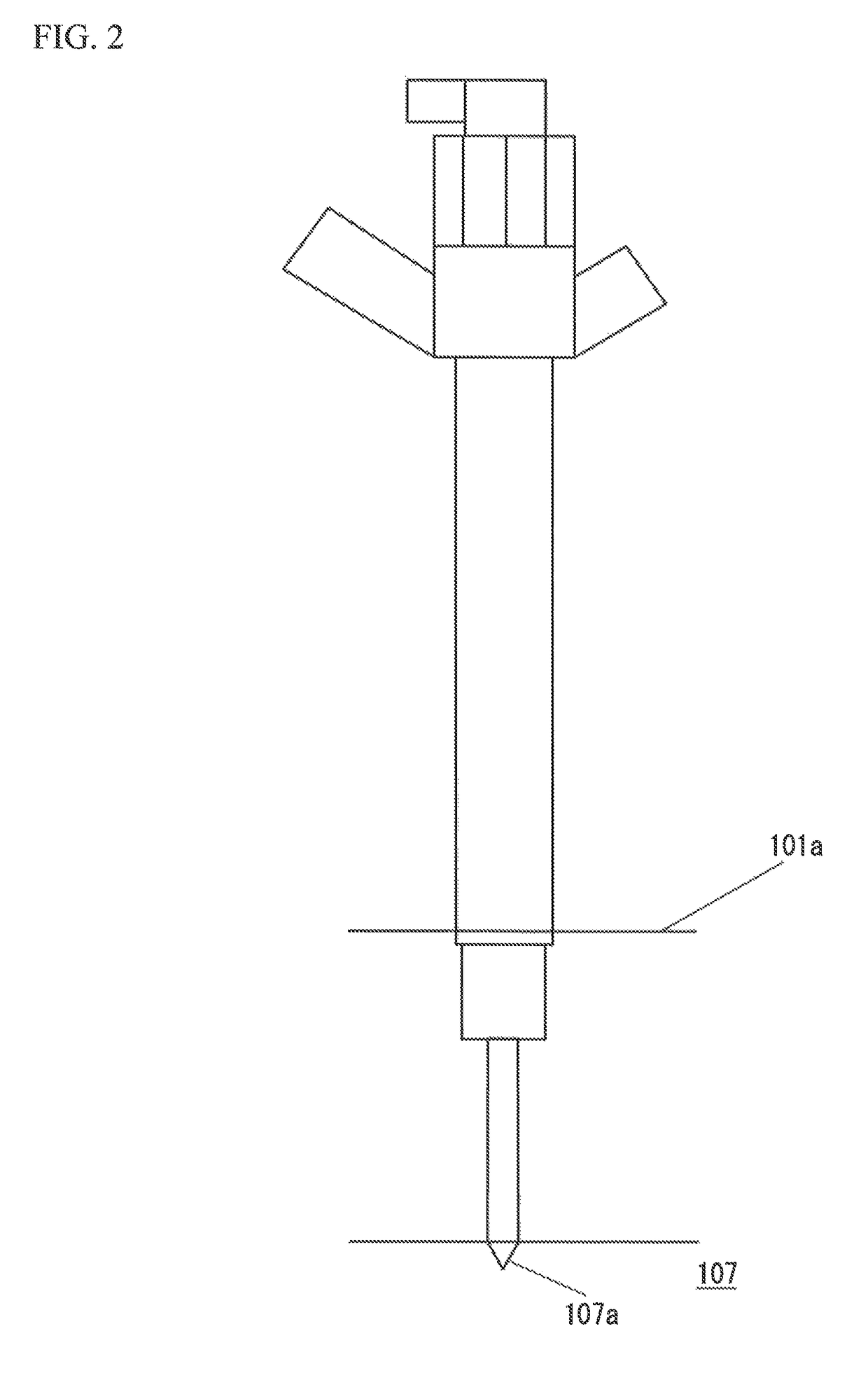

Internal combustion engine

ActiveUS20150354475A1Increase volumeReduce probabilityAir-treating devicesElectrical controlReduction rateExternal combustion engine

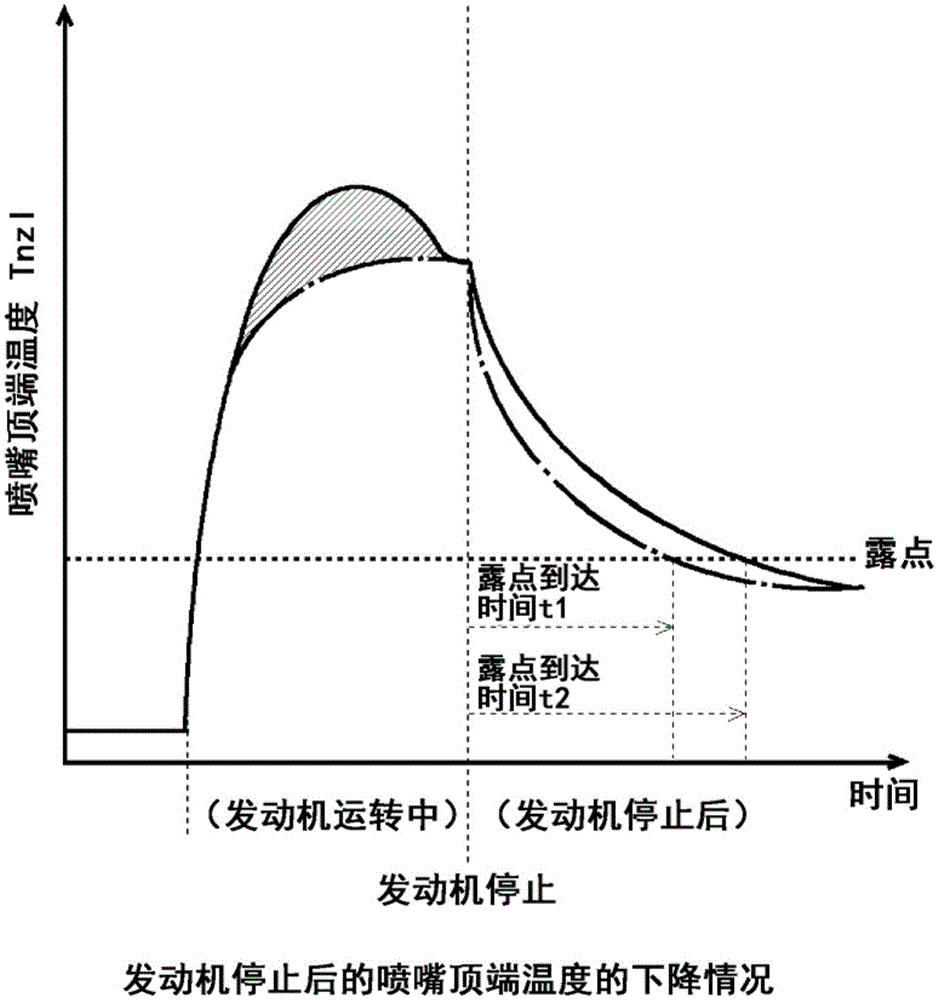

An internal combustion engine includes a control unit determining the occurrence or non-occurrence of dew condensation in a tip portion of a nozzle based on a nozzle heat receiving amount of an injector and a nozzle tip temperature of the injector at a point in time when ignition is turned OFF and performing nozzle corrosion prevention control when the dew condensation is determined to occur in the nozzle tip portion. The control unit calculates a nozzle tip temperature reduction rate based on the nozzle heat receiving amount, calculates a dew point arrival time based on the reduction rate, and determines the occurrence or non-occurrence of the dew condensation in the nozzle tip portion based on the dew point arrival time.

Owner:TOYOTA JIDOSHA KK

Ferritic stainless steel sheet having excellent brazability, heat exchanger, ferritic stainless steel sheet for heat exchangers, ferritic stainless steel, ferritic stainless steel for members of fuel supply systems, and member of fuel supply system

ActiveCN105008590AExcellent brazeabilityImprove corrosion resistanceRecuperative heat exchangersCorrosion preventing fuel injectionMetallurgyFuel supply

One embodiment of a ferritic stainless steel sheet contains, in mass%, 0.03% or less of C, 0.05% or less of N, 1% or less of Si, 1.2% or less of Mn, 14 to 28% inclusive of Cr, 8(C+N) to 0.8% inclusive of Nb, 0.1% or less of Al and a remainder made up by Fe and unavoidable impurities, and has, formed on the surface thereof, a coating film that satisfies formula (1). df×Crf+5(Sif+3Alf) ≤ 2.0 ···(formula (1)) In the formula, df represents the thickness (nm) of the coating film; Crf represents the Cr cation fraction in the coating film; Sif represents the Si cation fraction in the coating film; and Alf represents an Al cation fraction in the coating film.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Steel fuel conveying pipe

ActiveUS20130098496A1Reliable lifeAvoid corrosionCorrosion preventing fuel injectionCorrosion preventionHigh resistanceGasoline direct injection

To provide a steel fuel conveying pipe which has high resistance to corrosive fuel and maintains reliability without damaging a direct-injection engine, and connects a high-pressure pump and a direct-injection rail with each other in a gasoline direct-injection engine system, and a fuel conveying pipe suitable as a bypass pipe for coupling direct-injection rails with each other in a V-type gasoline engine. A steel fuel conveying pipe for conveying gasoline is characterized in that a Ni-plated layer is provided on the whole inner circumferential face of the fuel conveying pipe, and an anti-rust film layer composed of a Zn-plated layer and a Zn-based alloy-plated layer is further provided on the Ni-plated layer at at least one end of the fuel conveying pipe.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

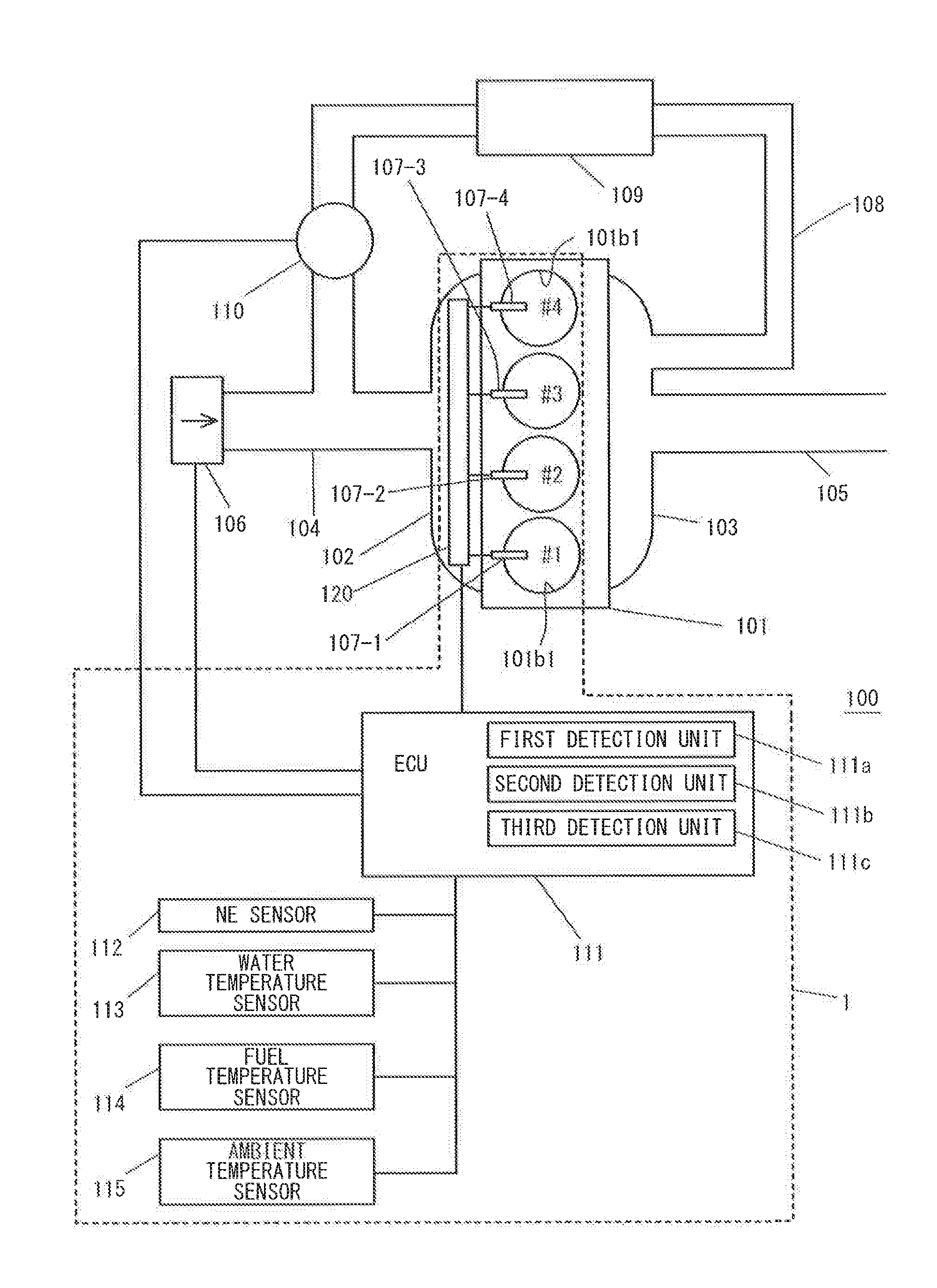

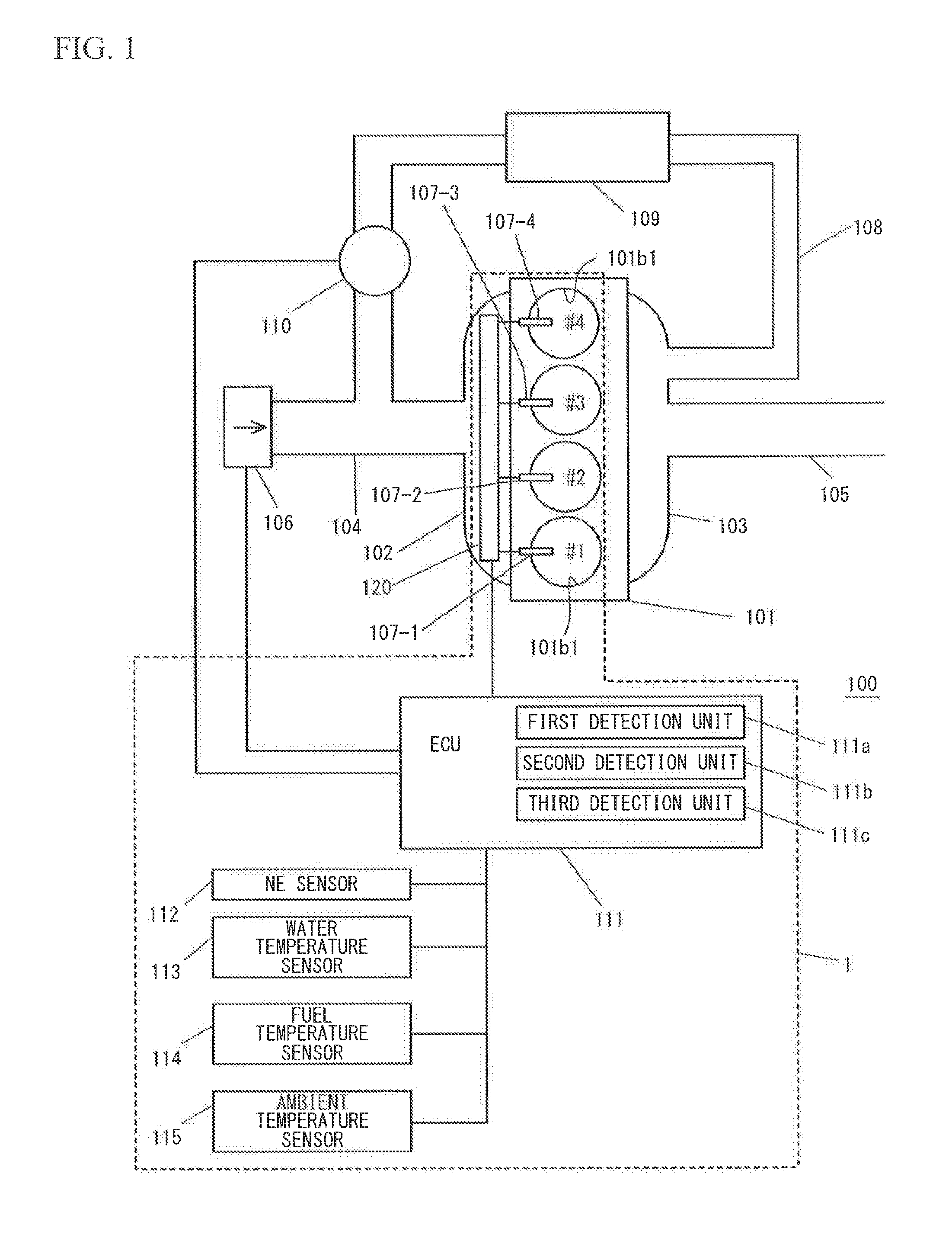

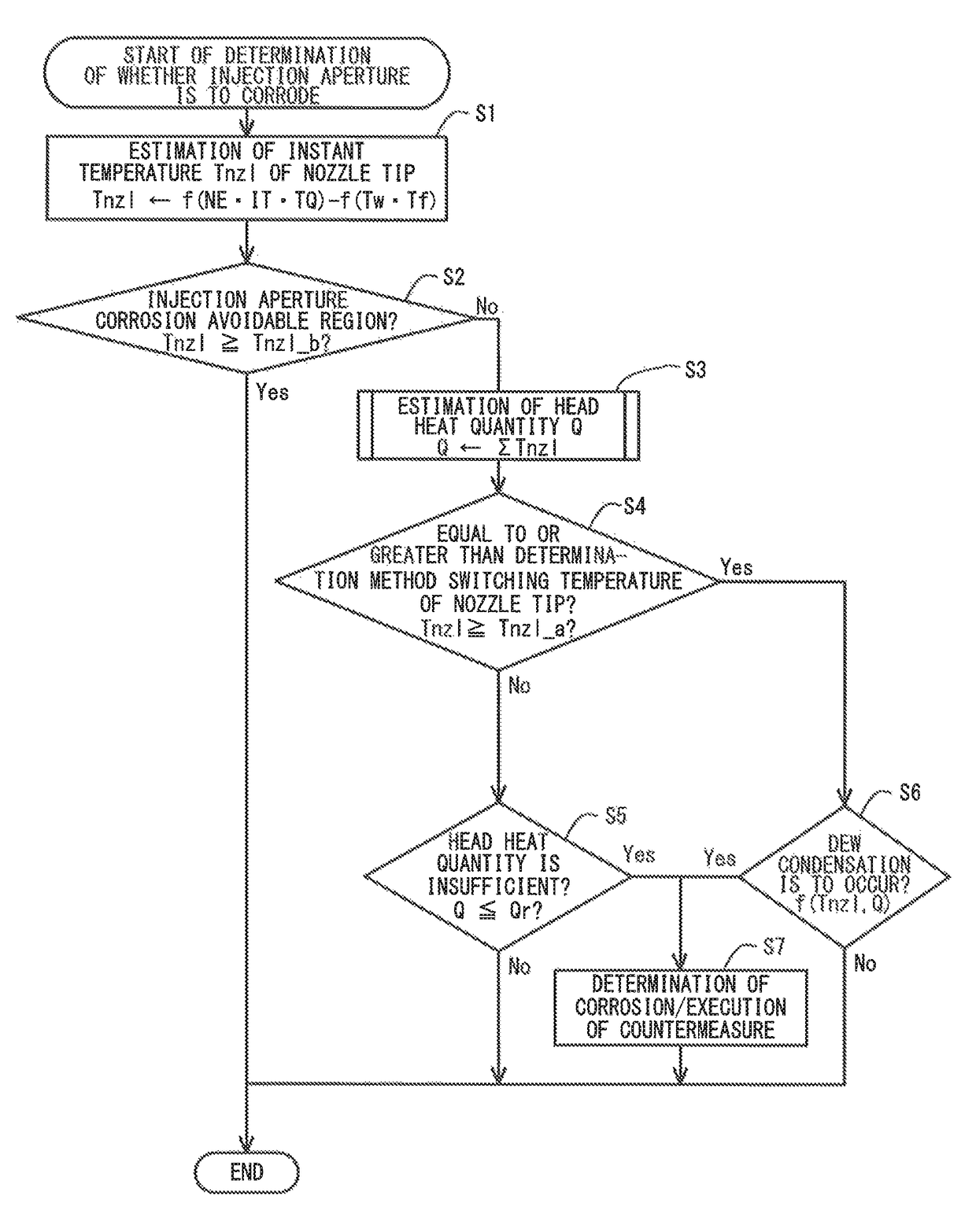

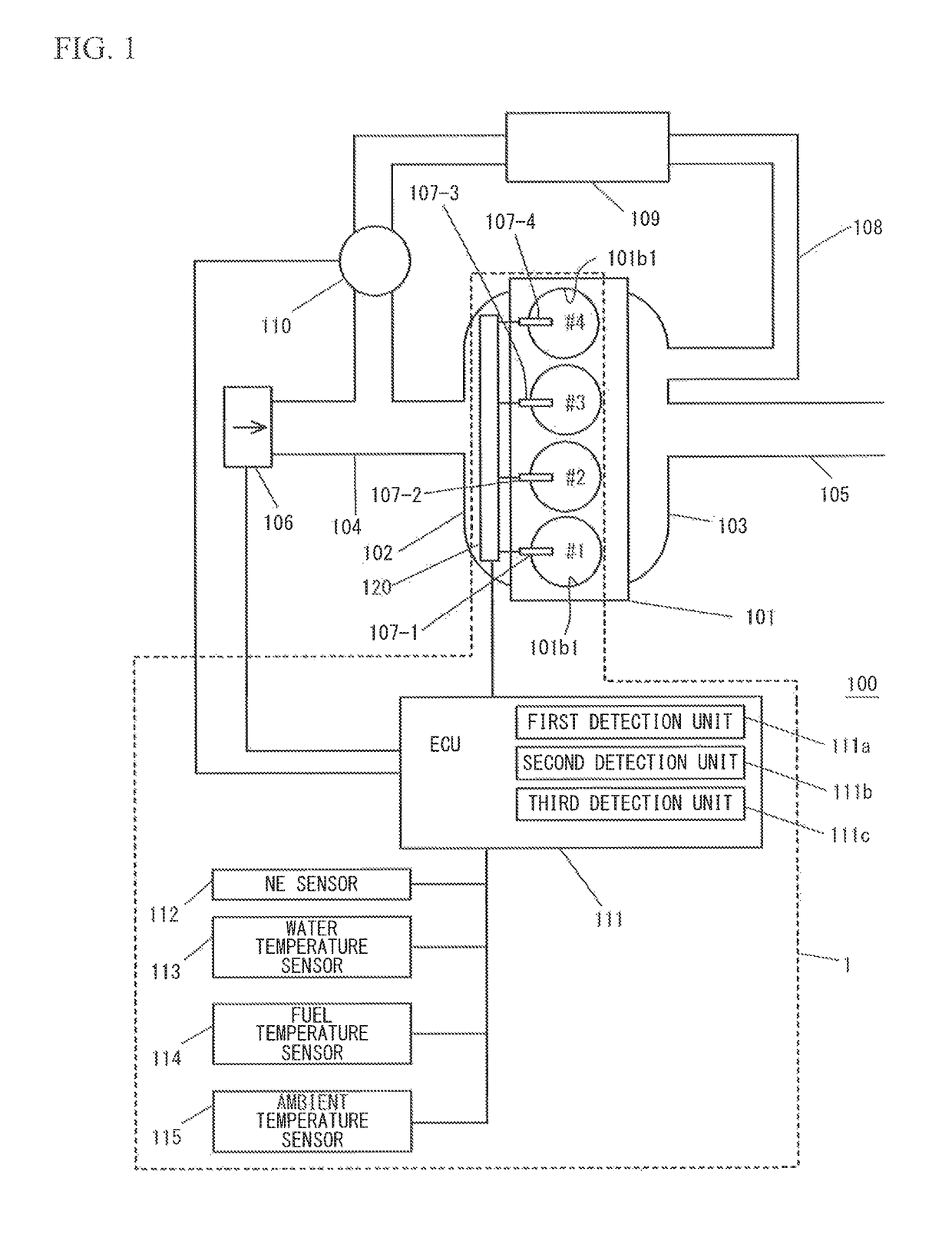

Control device for internal combustion engine

ActiveUS20160334304A1Reduce computing loadInternal-combustion engine testingLiquid coolingCylinder headDew

A control device for an internal combustion engine that includes: a first detection unit detecting, as a first parameter, a temperature of a nozzle tip of an injector; and a second detection unit detecting, as a second parameter, a heat quantity of a cylinder head, and executes a dew condensation determination by using at least one of the first parameter and the second parameter, the control device includes: a third detection unit detecting an evaluation value allowing to evaluate a state of the internal combustion engine, a threshold value for selecting which parameter of the first and second parameters is selected being set with respect to the evaluation value, wherein the control device switches a parameter to be used to the first parameter, to the second parameter, or to both the first and second parameters in accordance with the evaluation value when executing the dew condensation determination.

Owner:TOYOTA JIDOSHA KK

High-pressure fuel injection pipe with connection head and method of molding connection head

ActiveUS20180355829A1High outer-surfaceReduce axial forceJoints with sealing surfacesCorrosion preventing fuel injectionSurface cleaningThick wall

Provided is a high-pressure fuel injection pipe with a connection head which achieves an improvement in outer-surface cleanliness and prevention of a decrease in axial force and fastening strength. The pipe having, at a connection end of a narrow-diameter thick-wall steel pipe having a rust-inhibiting coating applied to an outer surface of the pipe, the connection head composed of a spherically-shaped seat surface, an annular flange, and a conical surface and having an outside peripheral surface forming formed into seat surface in a truncated conical shape or truncated arc shape for a mating seat; and a washer fitting in a neck lower part of the connection head and having a rust-inhibiting coating applied to an outer surface of the washer, wherein a contact part between the neck lower part of the connection head and an end part of the washer has a metal-to-metal contact structure without having the rust-inhibiting coating.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Methanol fuels for internal combustion engines

InactiveUS20160237362A1Reduce dependenceStable costOrganic chemistryInternal combustion piston enginesCombustionMethanol fuel

The common interchangeable use of a high methanol content fuel for use in all types of internal combustion engines, including cars, trucks, vehicles for transportation use (ships, boats, locomotives, airplanes, etc.), various other equipment and turbines. The engines are converted to be able to use these fuels although further vehicles can be made with components that would allow such fuels to be used. These methanol fuels are renewable and environmentally benign when produced from carbon dioxide capture and recycling of their combustion or other use.

Owner:UNIV OF SOUTHERN CALIFORNIA

Internal combustion engine

InactiveCN104937246ALiquid coolingElectrical controlExternal combustion engineInternal combustion engine

An internal combustion engine equipped with a control unit, which determines whether condensation has occurred at the tip of the nozzle of an injector, on the basis of the amount of heat received by the nozzle when the ignition is turned off and the temperature at the tip of the nozzle, and which executes a nozzle corrosion prevention control when it has been determined that condensation has occurred at the nozzle tip. The control unit calculates the rate of decrease of the nozzle tip temperature on the basis of the amount of heat received by the nozzle and calculates the time at which condensation will occur on the basis of the rate of decrease, and determines whether condensation has occurred at the nozzle tip on the basis of the calculated condensation time.

Owner:TOYOTA JIDOSHA KK

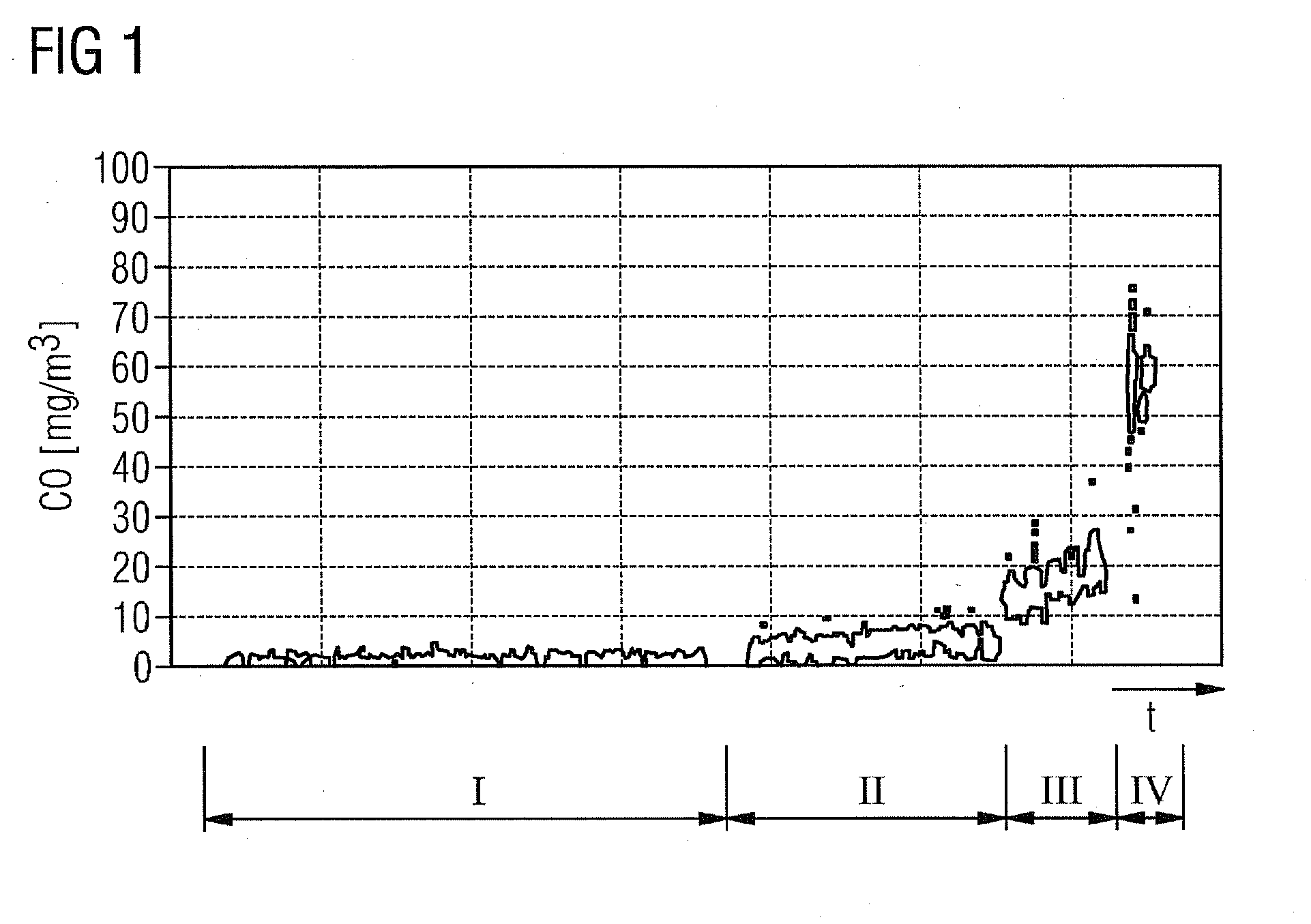

Burning element and burner with a corrosion-resistant insert

InactiveUS20110104626A1Reduce cleaning costsInhibition formationContinuous combustion chamberCorrosion preventing fuel injectionCombustorEngineering

A burner carrier flange and a burner with such a burner carrier flange are provided. A surface of the burner carrier flange potentially comes into contact with fuel. The burner carrier element includes a base material and a corrosion-resistant material and the surface that potentially comes into contact with fuel is made of the corrosion-resistant material.

Owner:SIEMENS AG

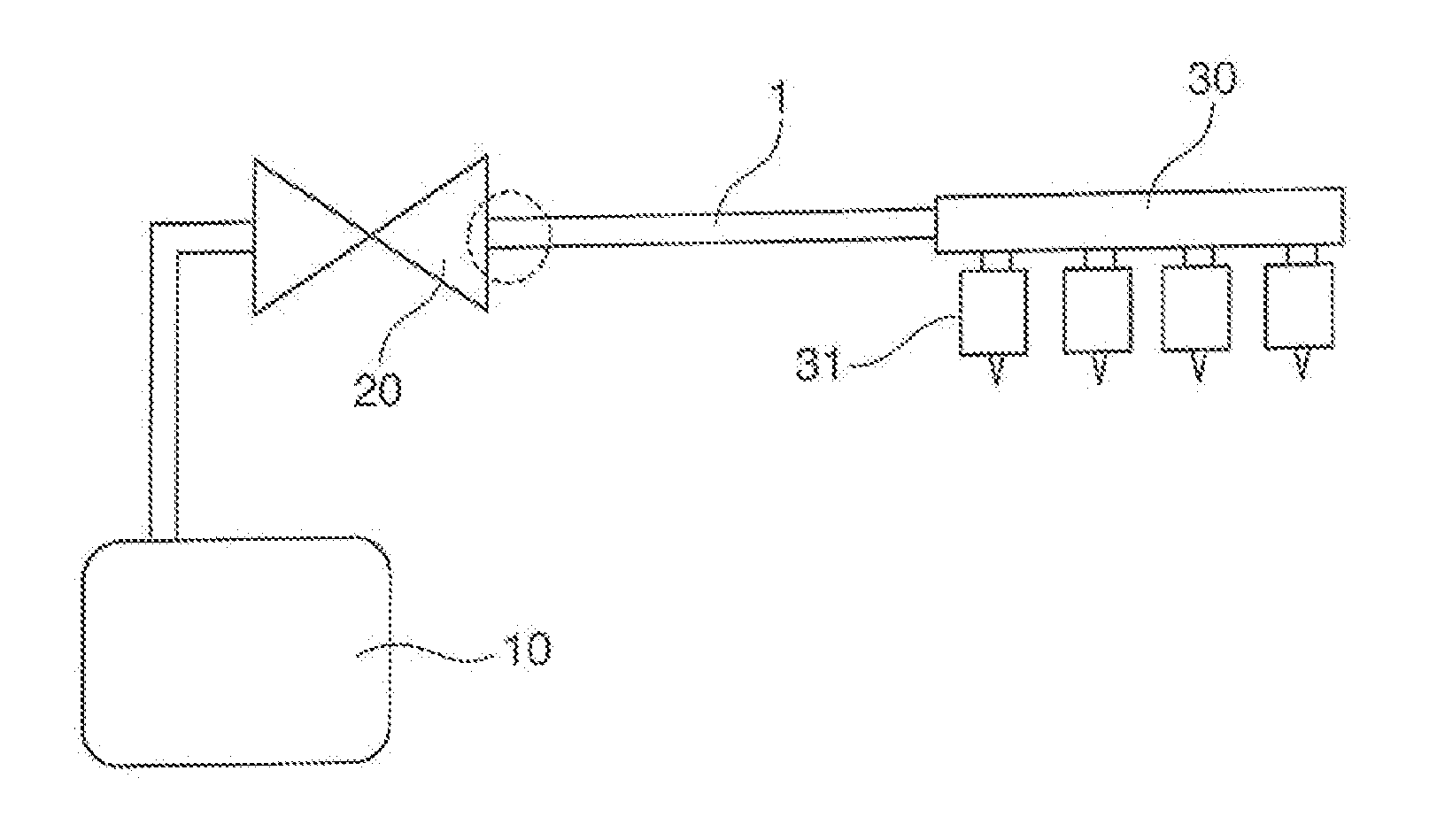

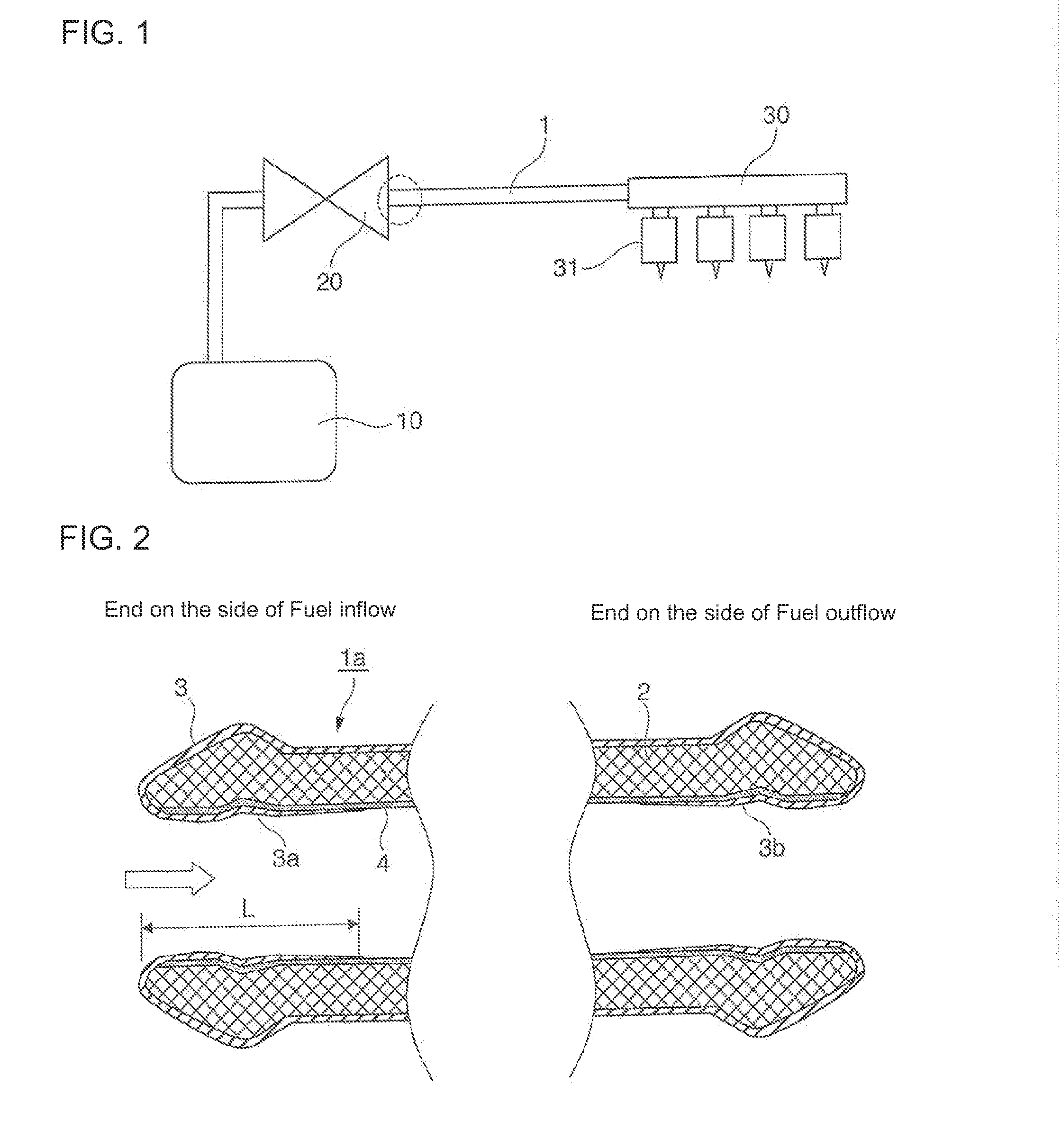

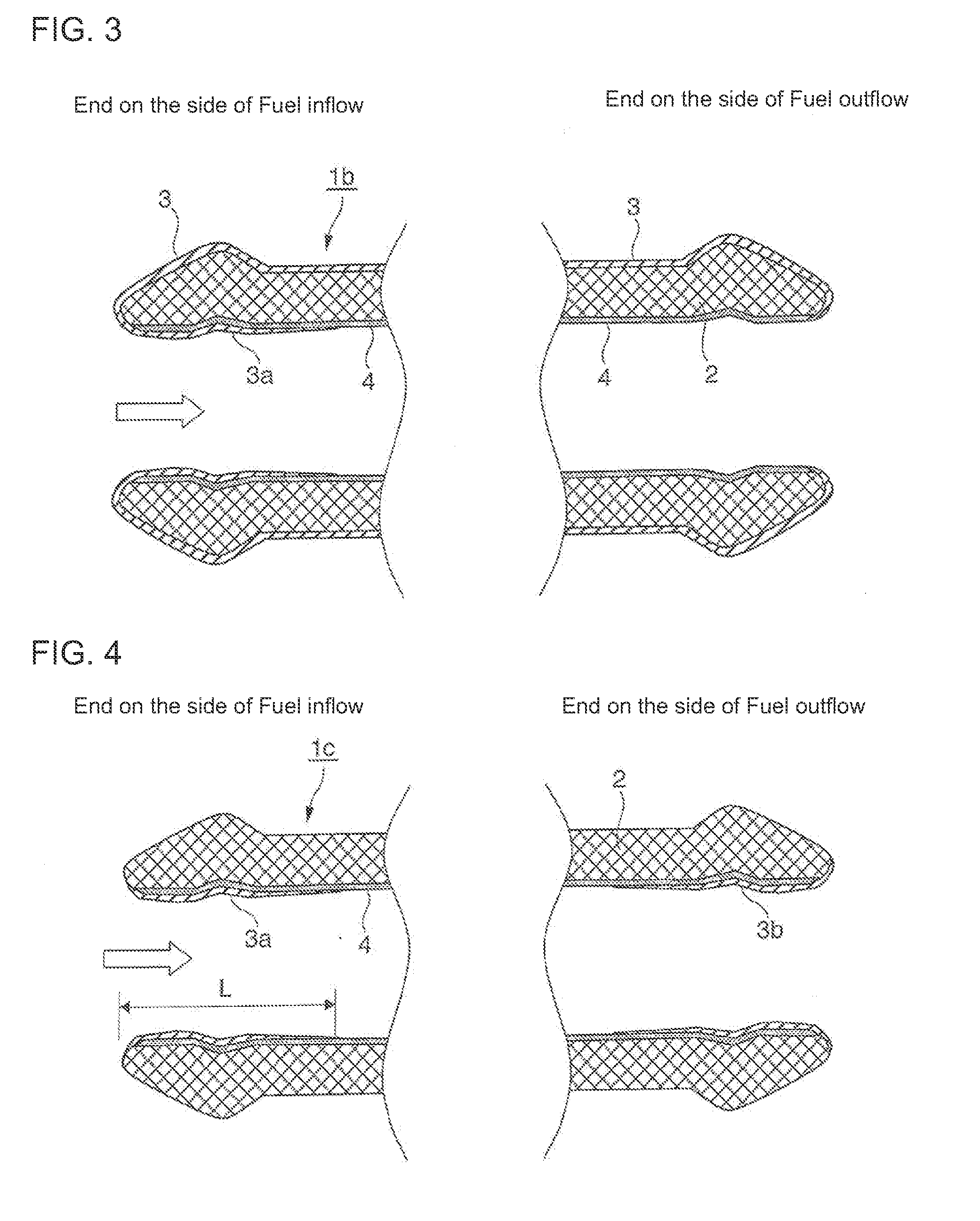

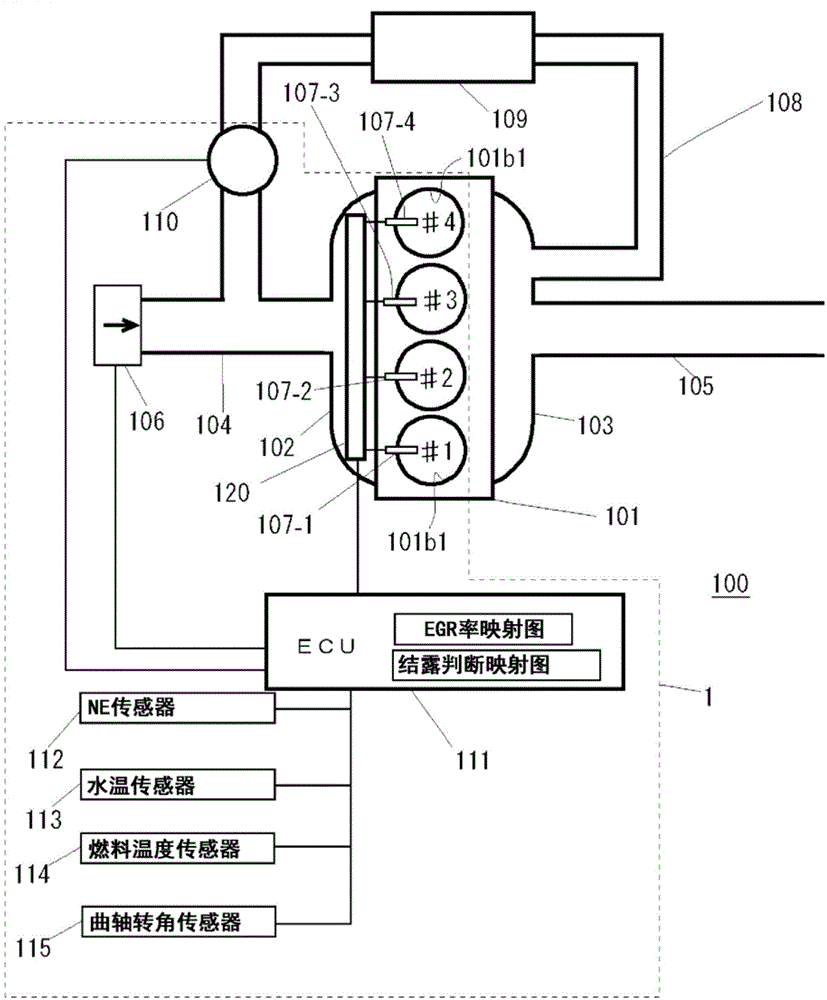

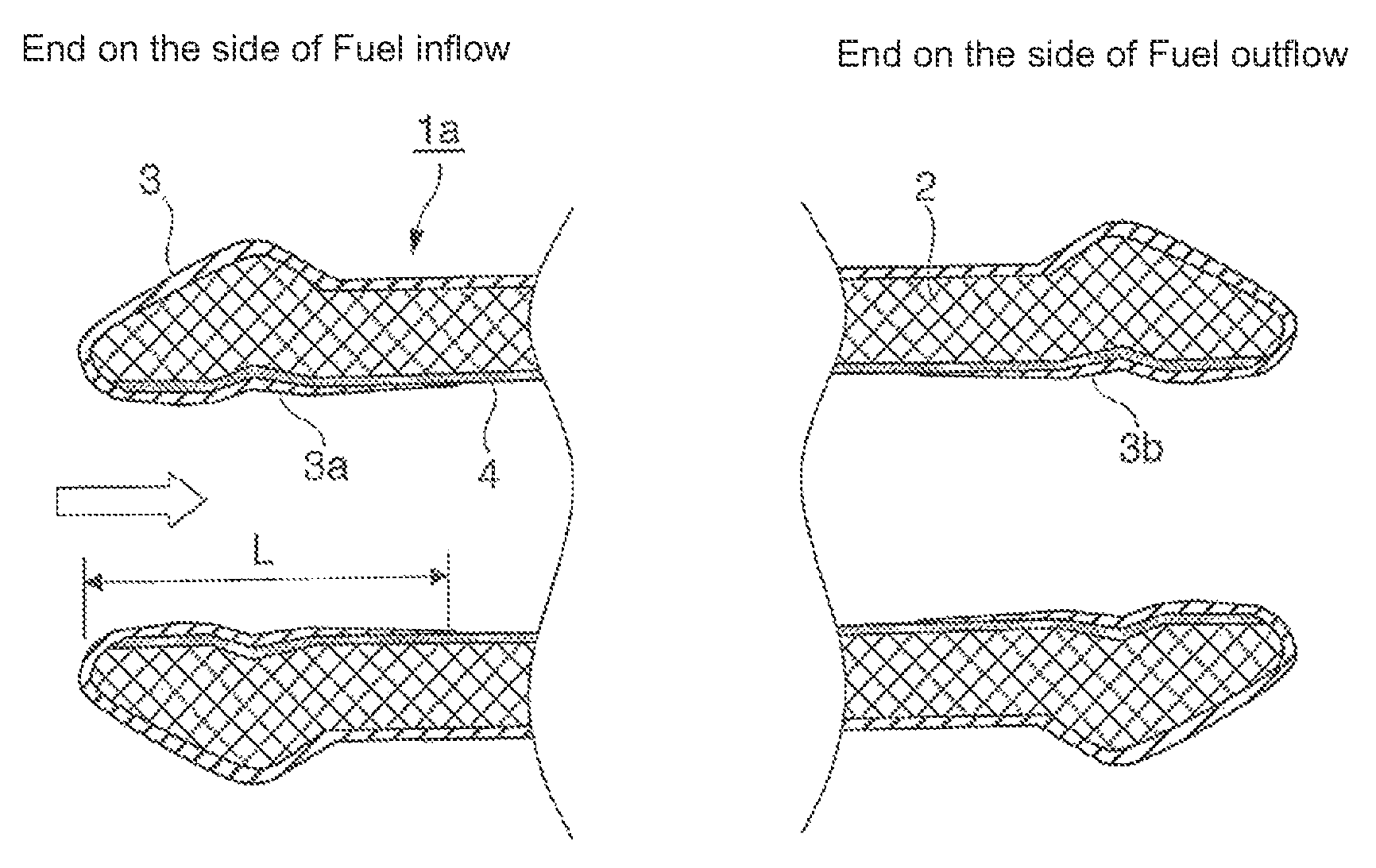

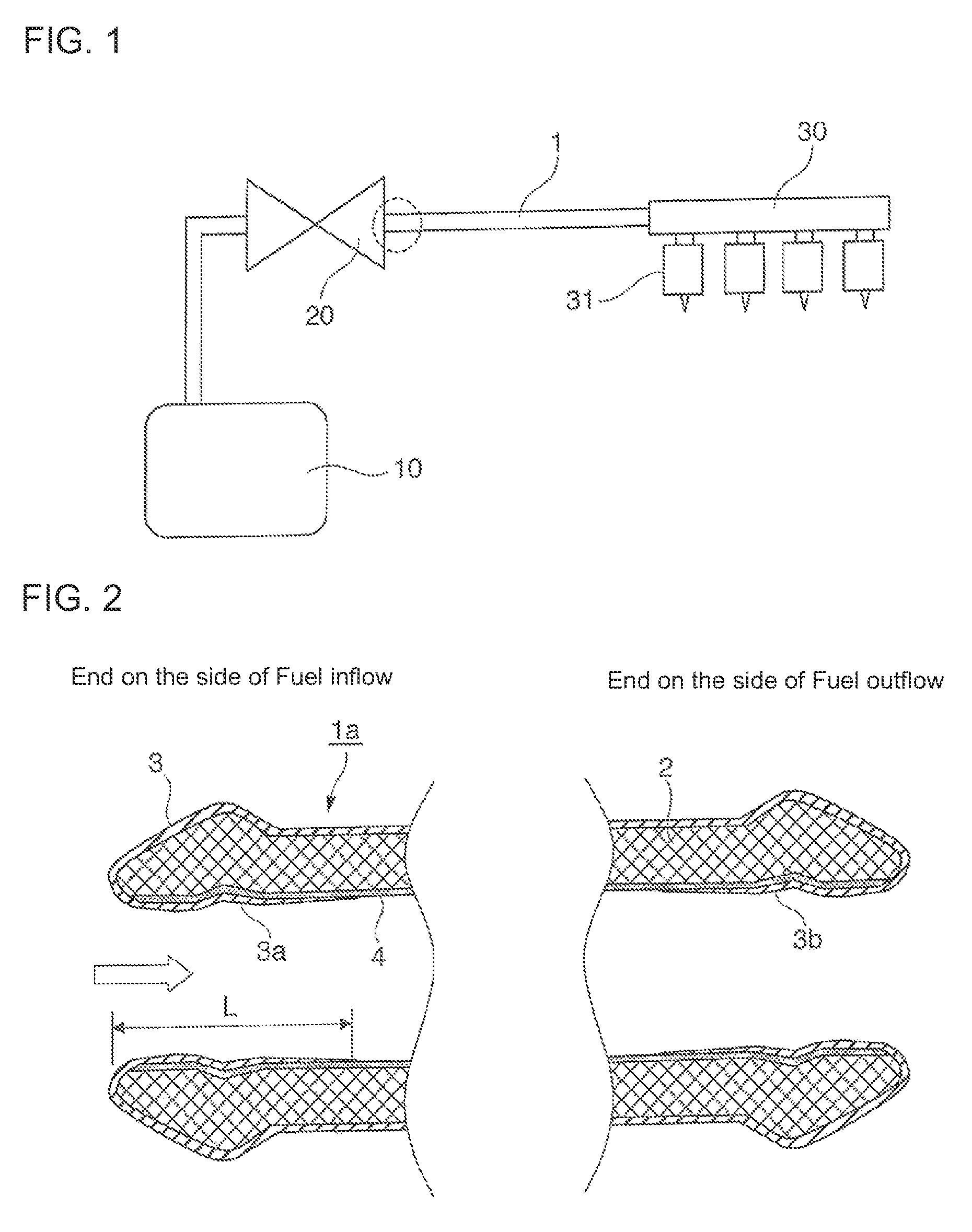

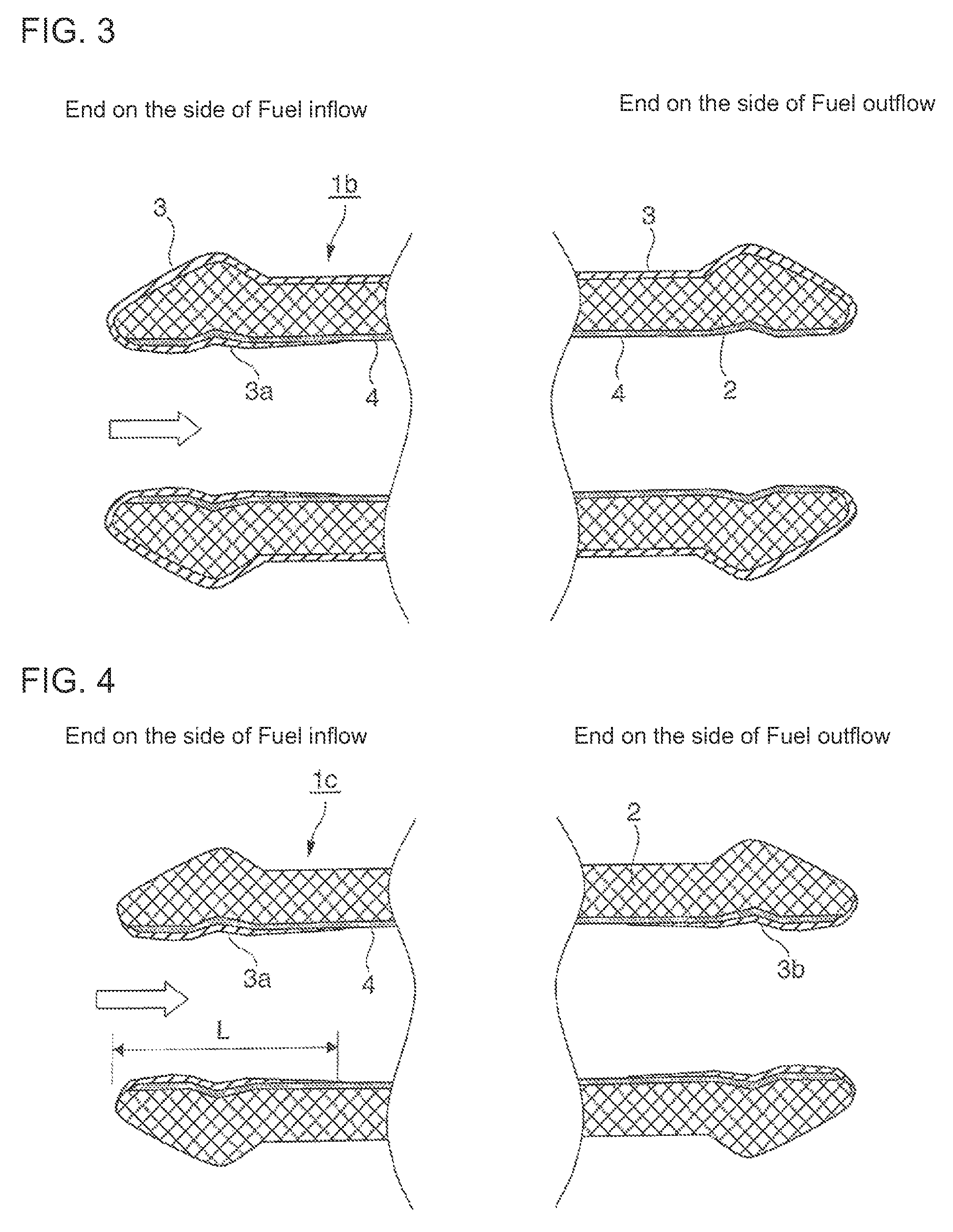

Gasoline direct injection rail

ActiveUS10655584B2Speed up the flowEasy to implementInternal combustion piston enginesCorrosion preventing fuel injectionGasoline direct injectionControl theory

To obtain a gasoline direct injection rail that enables plating treatment to be easily and reliably performed on the inside of a rail body and an inlet part, also, that includes an orifice, and that has excellent mechanical properties. In a gasoline direct injection rail comprising a steel rail body 4, an inlet part 6 provided integrally with or separately from a first end 5 of the rail body 4 and comprising therein a communication passage 7 in communication with a fuel passage of the rail body 4, and a plurality of injector holders in communication with the fuel passage, a stainless orifice member 1 formed separately from the rail body 4 is securely disposed in the communication passage 7 of the inlet part 6.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Ferritic stainless steel sheet having excellent brazability, heat exchanger, ferritic stainless steel sheet for heat exchangers, ferritic stainless steel, ferritic stainless steel for members of fuel supply systems, and member of fuel supply system

ActiveUS10131977B2Excellent brazeabilityPart can be usedRecuperative heat exchangersCorrosion preventing fuel injectionMetallurgyFuel supply

One aspect of this ferritic stainless steel sheet contains, by mass %, C: 0.03% or less, N: 0.05% or less, Si: 1% or less, Mn: 1.2% or less, Cr: 14% or more and 28% or less, Nb: 8(C +N) or more and 0.8% or less, and Al: 0.1% or less, with a balance being Fe and inevitable impurities, in which a film satisfying Expression 1 is formed in a surface thereof. Expression 1 is df×Crf+5(Sif+3Alf)≤2.0. In Expression 1, df represents a thickness (nm) of the film, Crf represents a Cr cationic fraction in the film, Sif represents a Si cationic fraction in the film, and Alf represents an Al cationic fraction in the film.

Owner:NIPPON STEEL STAINLESS STEEL CORP

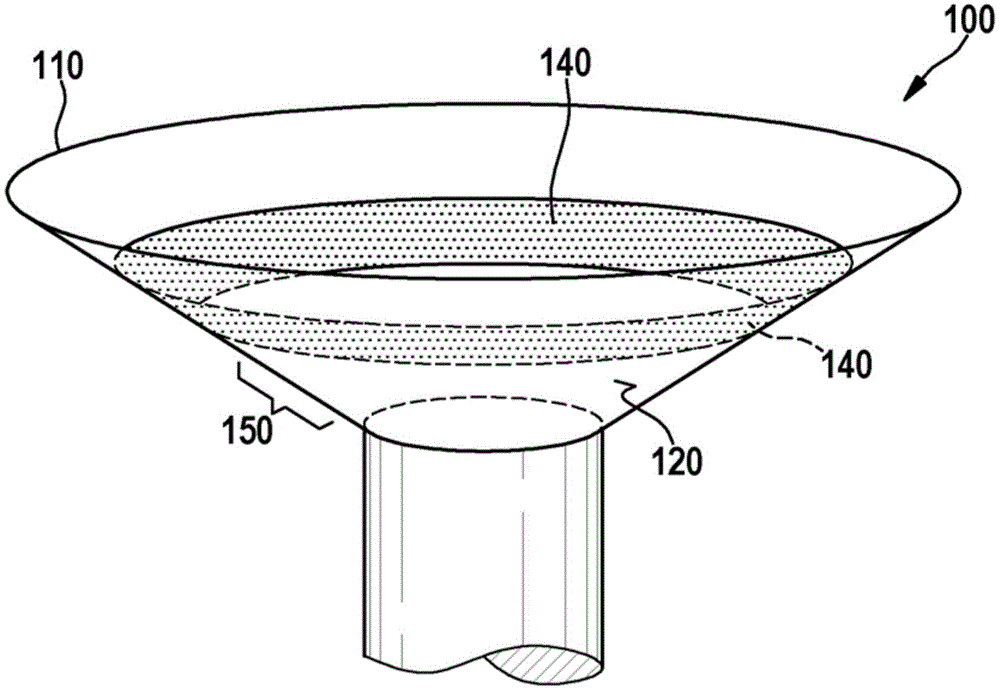

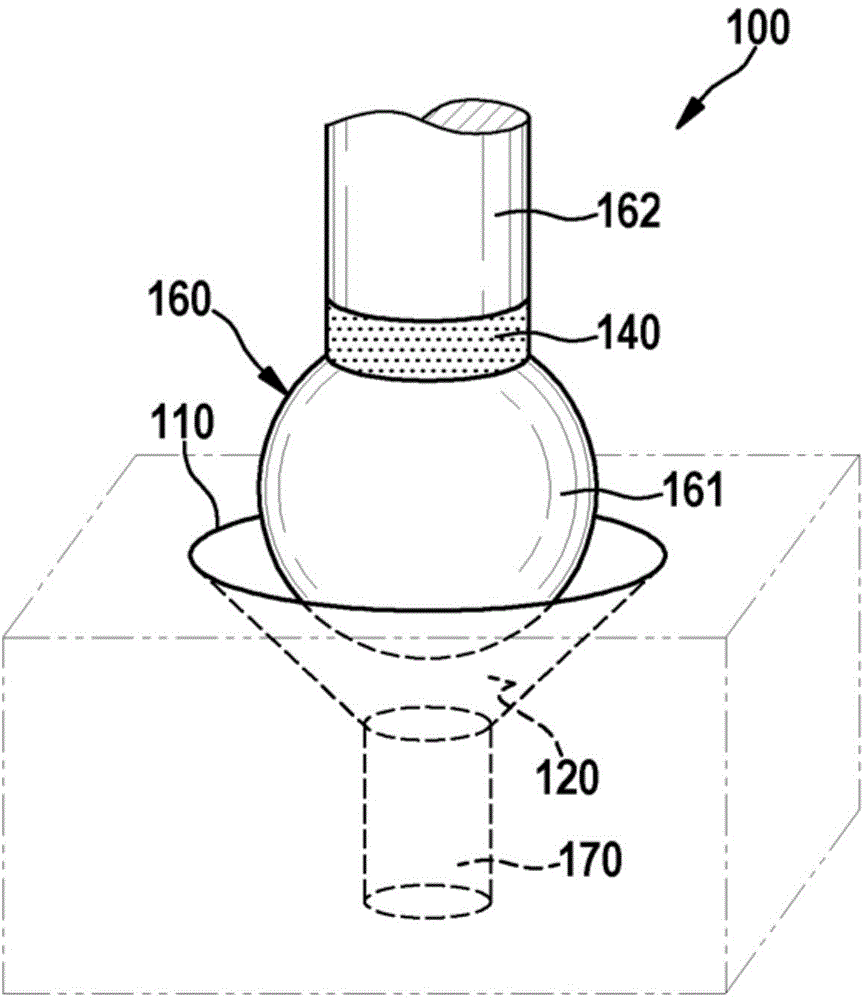

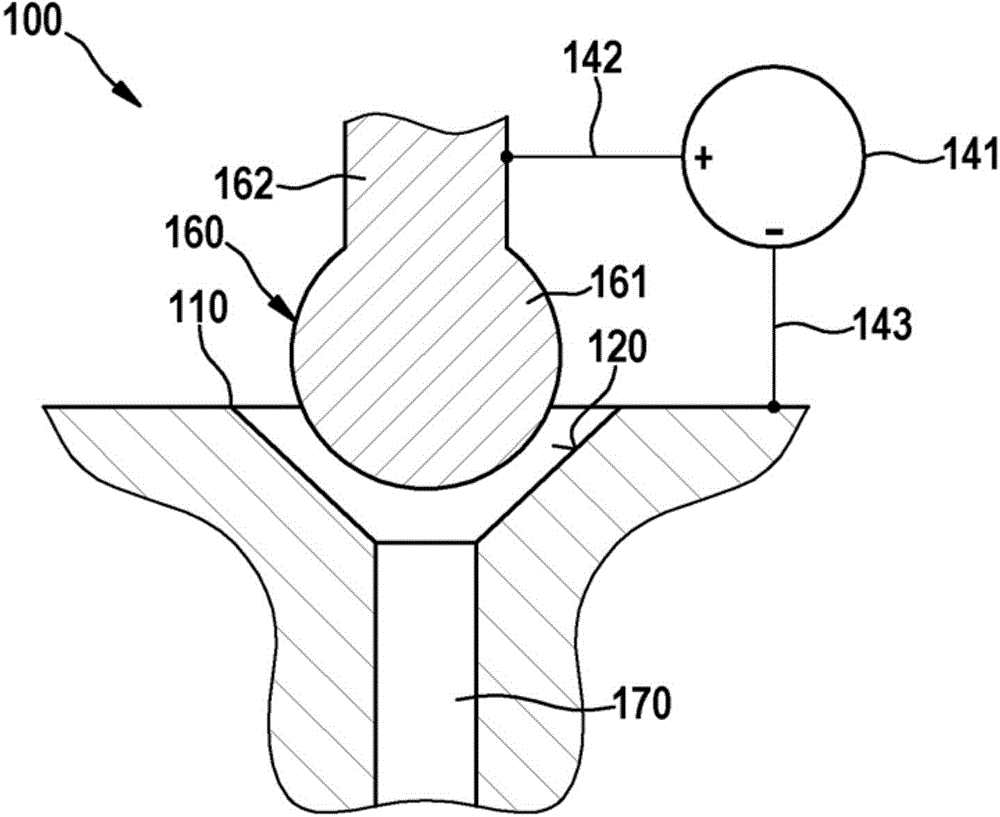

Component of a fuel injection system

InactiveCN104870804AImprove corrosion resistanceExtended service lifeCorrosion preventing fuel injectionFuel injecting pumpsAlloyMetal

The invention relates to a component (100) with at least two subcomponents made of metal. According to the invention, an alloy layer (140) is applied to the surface of a valve funnel (110) functioning as the subcomponent in a valve (100) functioning as the component, wherein the alloy layer (140) is made from a metal less noble than the valve funnel (110). The alloy layer (140) is arranged on a portion of the valve funnel (110) which is situated outside the direct mechanical action region (150) of the closing member (160) functioning as the second subcomponent, and is arranged as an annular portion running around the surface of the valve funnel (110), outside the mechanical action region of the closing member (160) relative to the closing member (160) resting in the valve seat (120) of the valve funnel in the closed state.

Owner:ROBERT BOSCH GMBH

Fuel injection valve

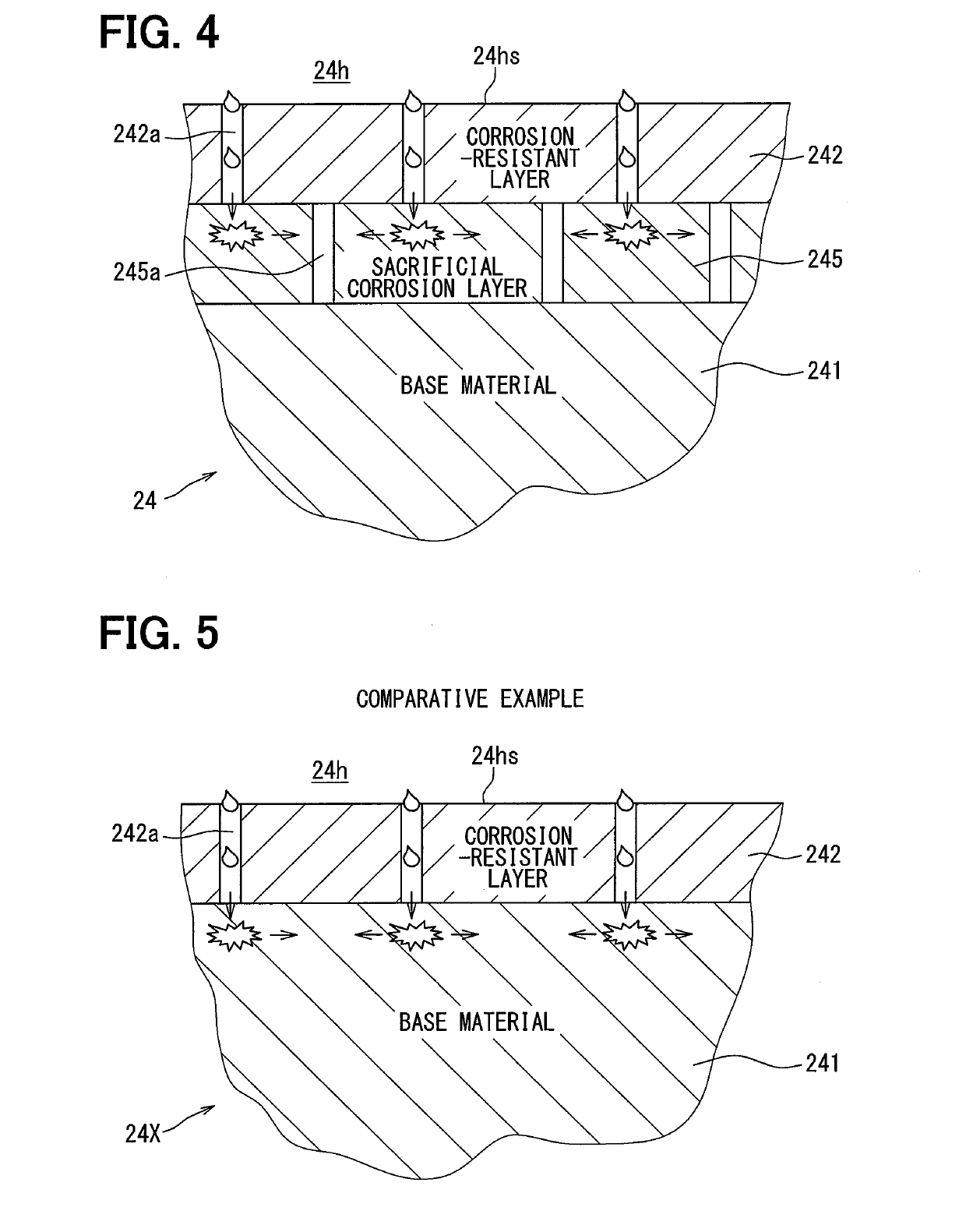

ActiveUS20190162148A1Easy to measureCorrosion preventing fuel injectionMachines/enginesMaterials scienceMetal

A fuel injection valve includes a body that includes an injection hole through which fuel is injected, and a valve element that opens or closes the injection hole. The body includes a metallic base material configured to form the injection hole, a corrosion-resistant layer covering a surface of at least a part of the base material that forms the injection hole and being made of a less corrosive material than the base material, and a sacrificial corrosion layer located between the base material and the corrosion-resistant layer and made of a more corrosive material than the corrosion-resistant layer.

Owner:DENSO CORP

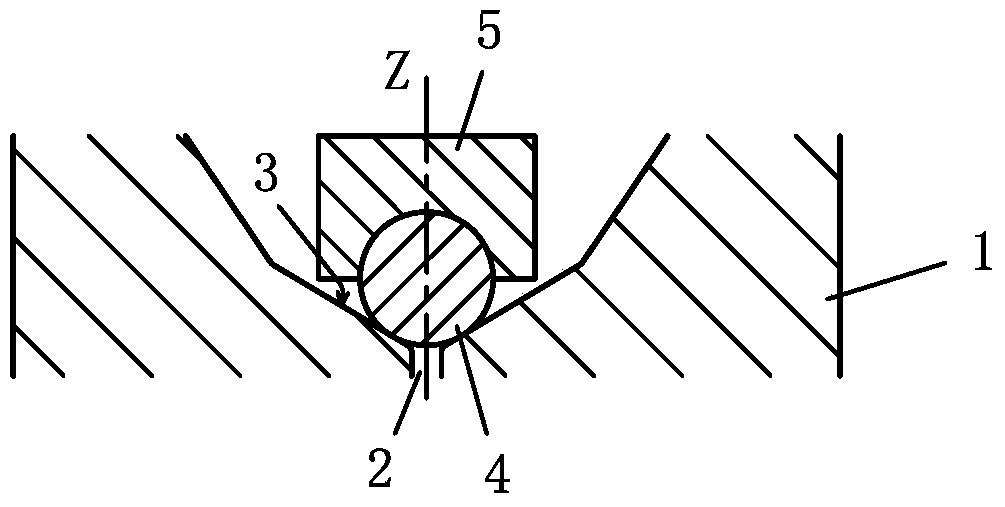

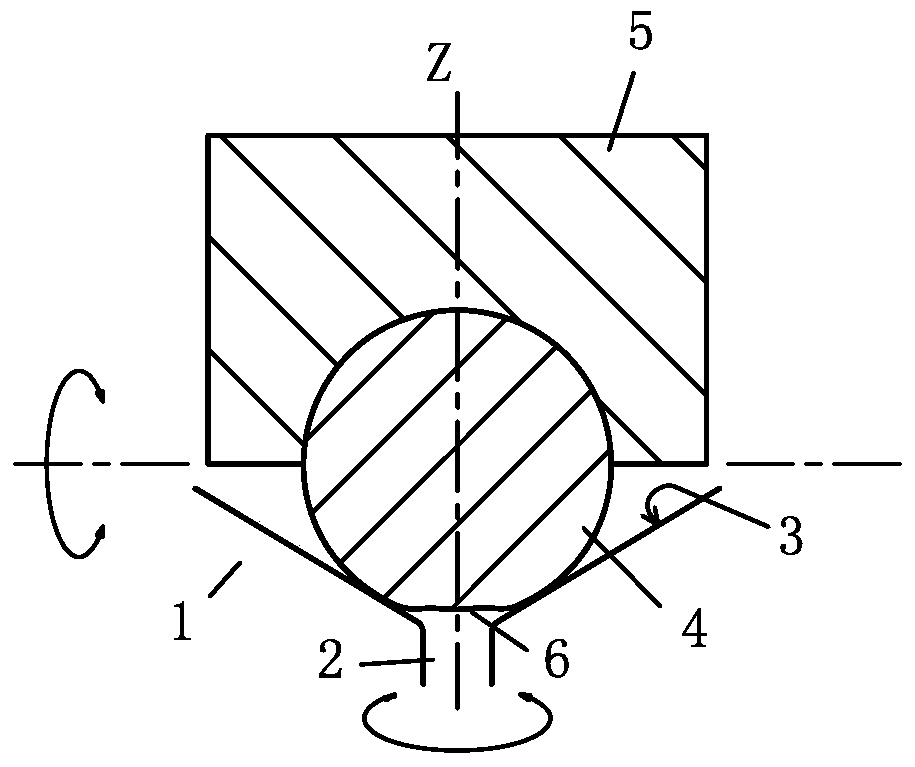

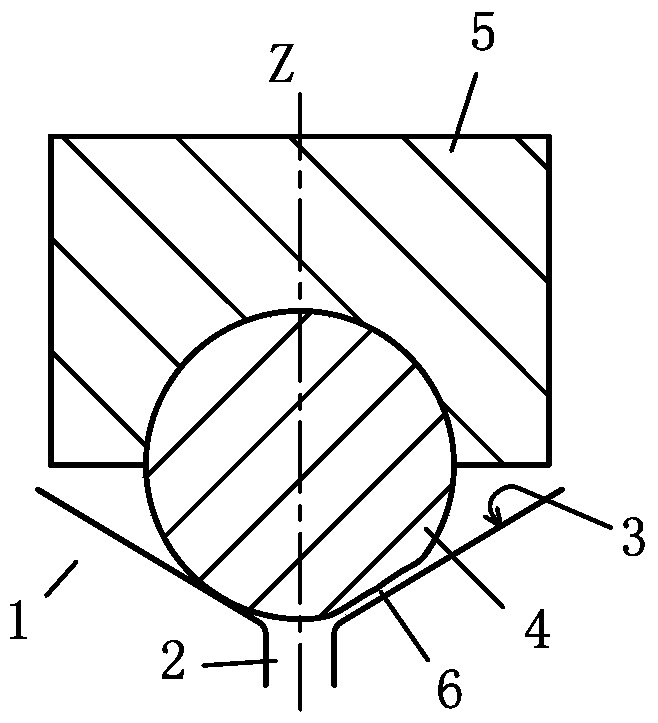

Fuel injector and its control valve

ActiveCN106321307BClosed tightlyCorrosion preventing fuel injectionMachines/enginesEngineeringControl valves

A fuel injector and a control valve used in it are disclosed. The control valve comprises: a valve seat defining a valve seating surface and a valve hole extending through a center portion of the valve seating surface in a longitudinal direction, the valve hole and the valve seating surface defining a longitudinal central axis, and the valve hole being in fluid communication with an injection valve of the fuel injector; a valve element configured to be moved between a closed position and an opened position along the longitudinal central axis, the valve element contacting and cooperating with the valve seat in the closed position to close the valve hole, and the valve element being moved away from the valve seat in the opened position to open the valve hole; and a holding block having an accommodating recess for holding the valve element; wherein the valve element is in the form of a solid of revolution, with the longitudinal central axis being the revolution axis of the solid of revolution, and the solid of revolution having a non-circular section in a longitudinal plane in which the longitudinal central axis lies so that the valve element is able to rotate around the longitudinal central axis but cannot rotate around any transverse central axis that is perpendicular to the longitudinal central axis.

Owner:ROBERT BOSCH GMBH

Gasoline direct injection rail

InactiveCN107429647ANo problems with plating treatmentPlating process is easyInternal combustion piston enginesCorrosion preventing fuel injectionGasoline direct injectionMechanical property

To obtain a gasoline direct injection rail for which plating treatment of a rail body and the inside of an inlet part can be simply and reliably performed, and which has an orifice and has superior mechanical properties. This gasoline direct injection rail is provided with: a steel rail body 4, an inlet part 6 integrally or separately provided on one end 5 of the rail body 4 and having a communication passage 7 therein which communicates with a fuel passage of the rail body 4; and a plurality of injector holders communicating with the fuel passage, the gasoline direct injection rail being characterized in that a stainless steel orifice member 1 formed separately from the rail body 4 is fixedly disposed in the communication passage 7 of the inlet part 6.

Owner:USUI CO LTD

Method for reducing injector deposits

PendingCN114450478ALess quantityReduce sedimentCorrosion preventing fuel injectionReverse osmosisFuel efficiencyEngineering

A method for reducing injector deposits in an internal combustion engine fueled with a fuel composition includes contacting the fuel composition with a metal selective membrane located in a fuel delivery system. The reduction of such deposits provides fuel efficiency, an increase in fuel thermal stability, an increase in engine cleanliness, improves fuel economy and makes it possible to reduce the amount of expensive detergent used in the fuel composition.

Owner:SHELL INT RES MAATSCHAPPIJ BV

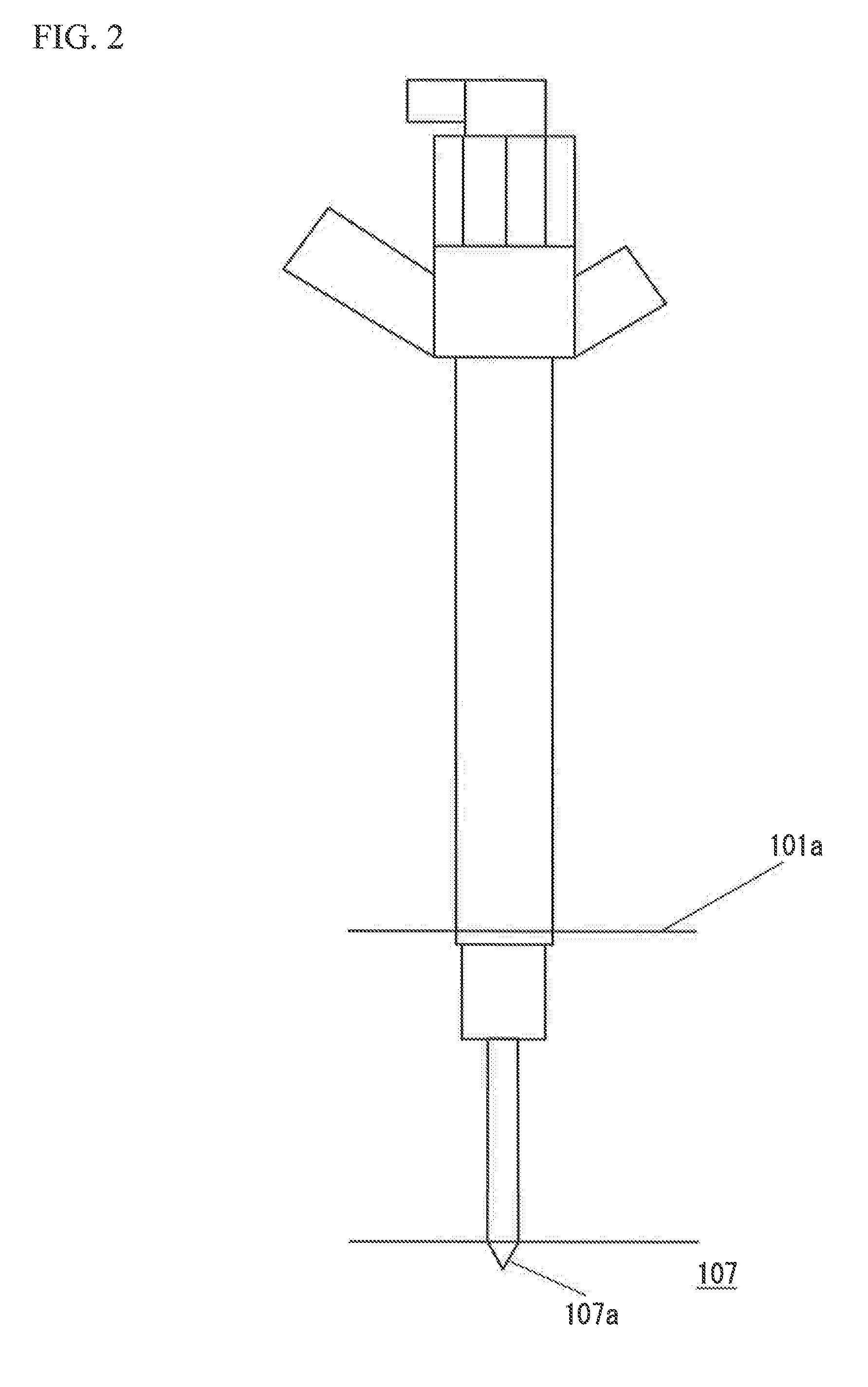

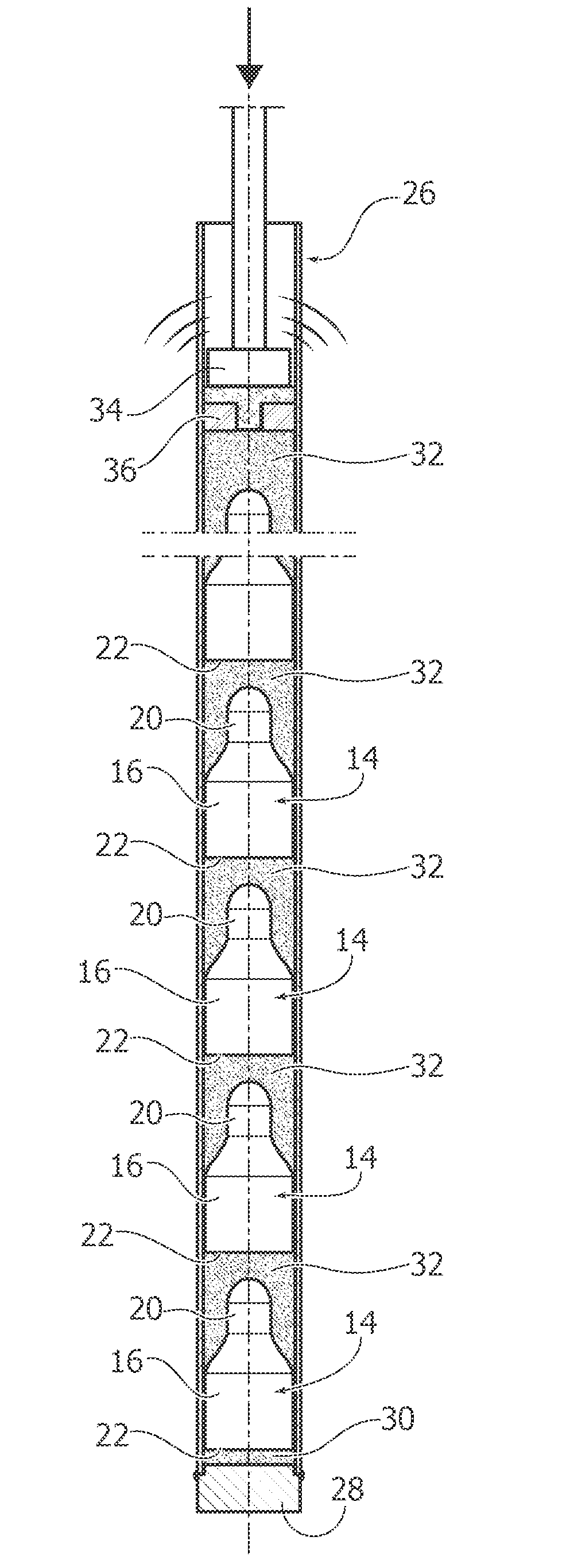

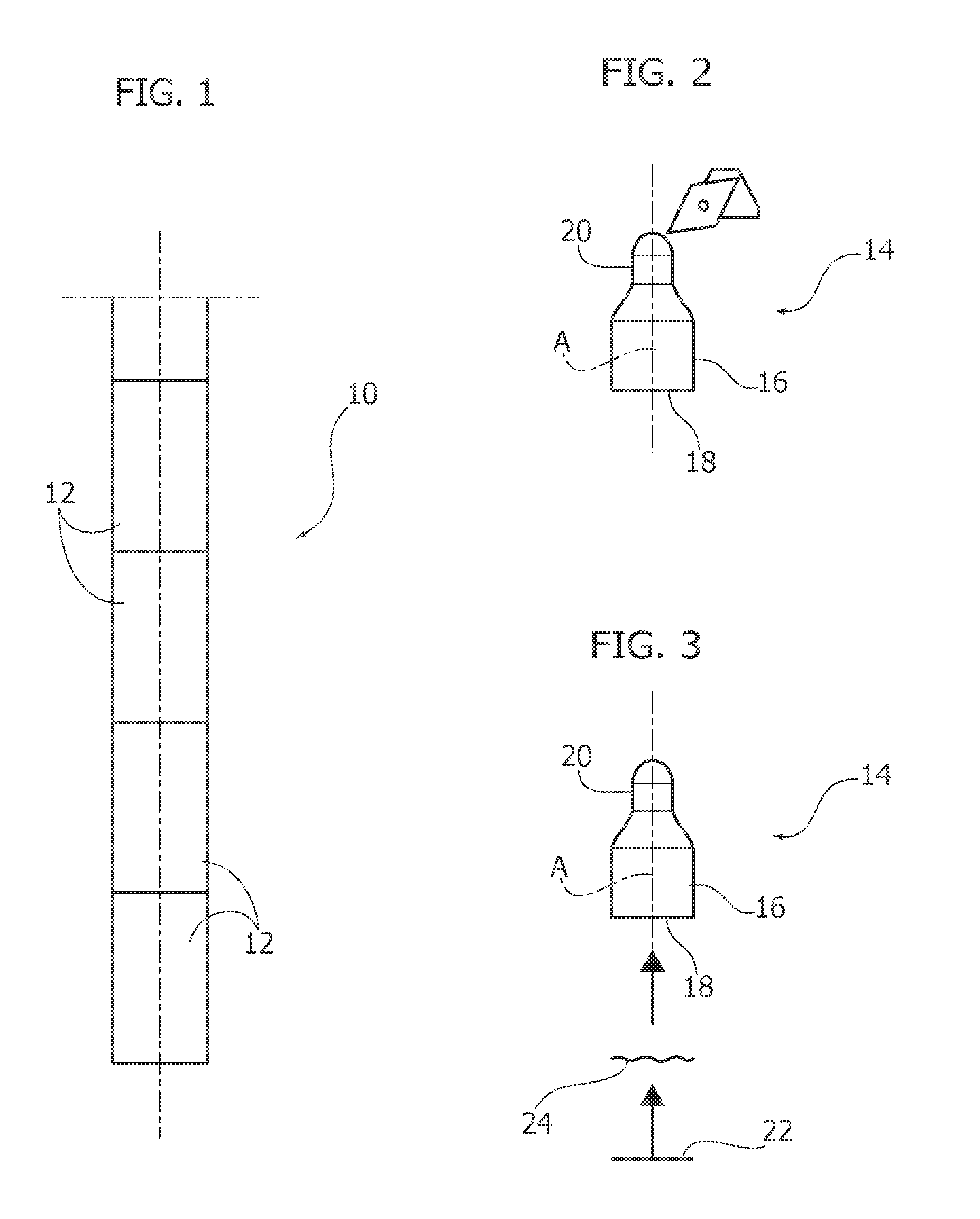

Method for producing a nozzle for injectors of internal combustion engines

InactiveUS9964087B2Improve uniformitySimpler and cheapCorrosion preventing fuel injectionMachines/enginesCombustionEngineering

A method for producing nozzles for injectors of internal combustion engines comprising machining nozzle blanks, each having a cylindrical surface with first and second ends, a flat reference surface at the first end and a nozzle tip projecting from the second end, applying a protective disc onto each flat reference surface, providing a containment tube with a closed first end, sequentially inserting the nozzle blanks into the containment tube and completely filling a space delimited from an outer surface of the nozzle tip of the respective nozzle blank to an inner wall of the containment tube after each insertion, compacting the metal powder, evacuating a second end of the containment tube, hot isostatic pressing the containment tube, cutting the containment tube along cutting sections aligned with the protective discs to form separate sections, and machining the sections to form a metallic coating on each nozzle tip.

Owner:OMT OFF MEC TORINO

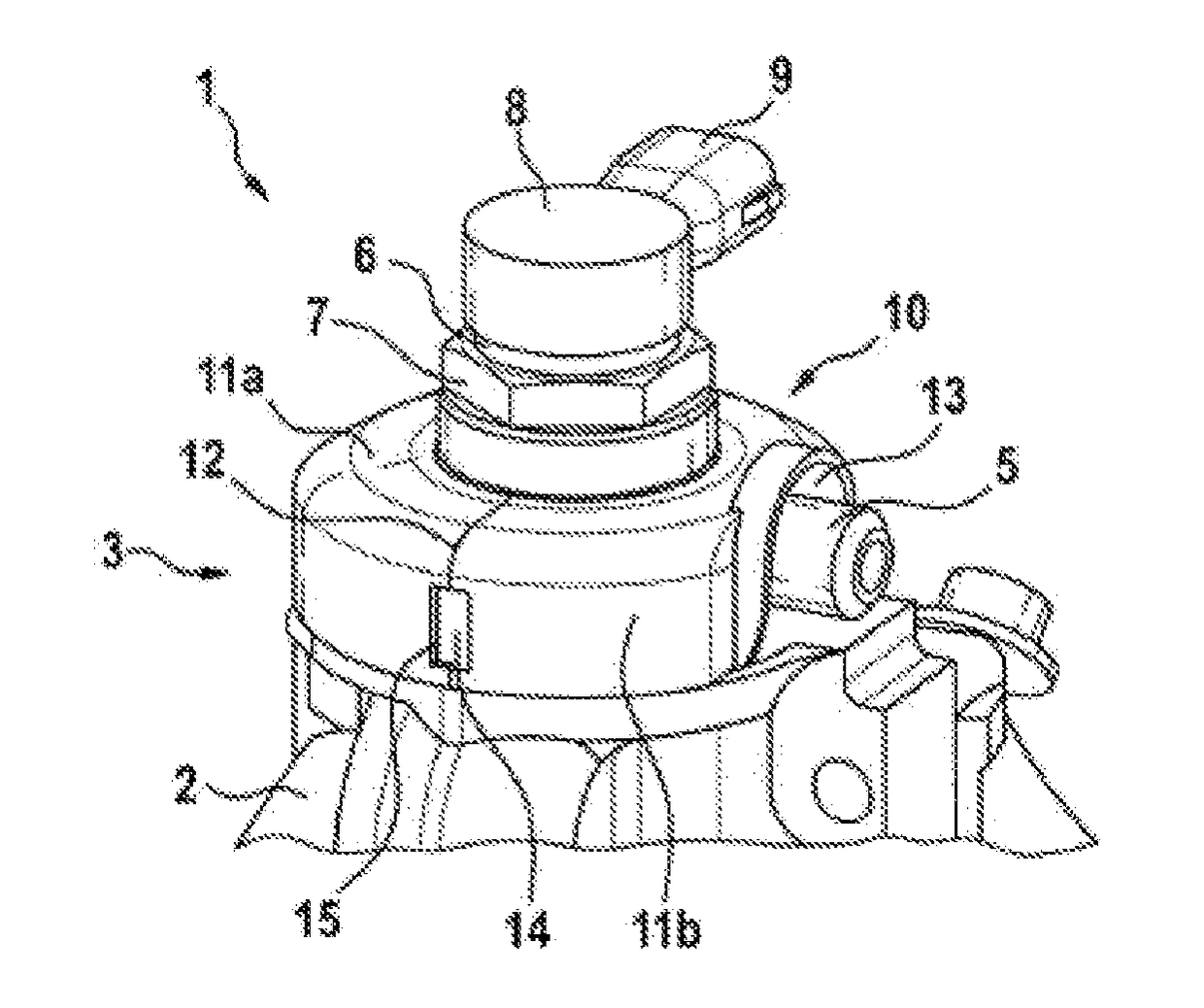

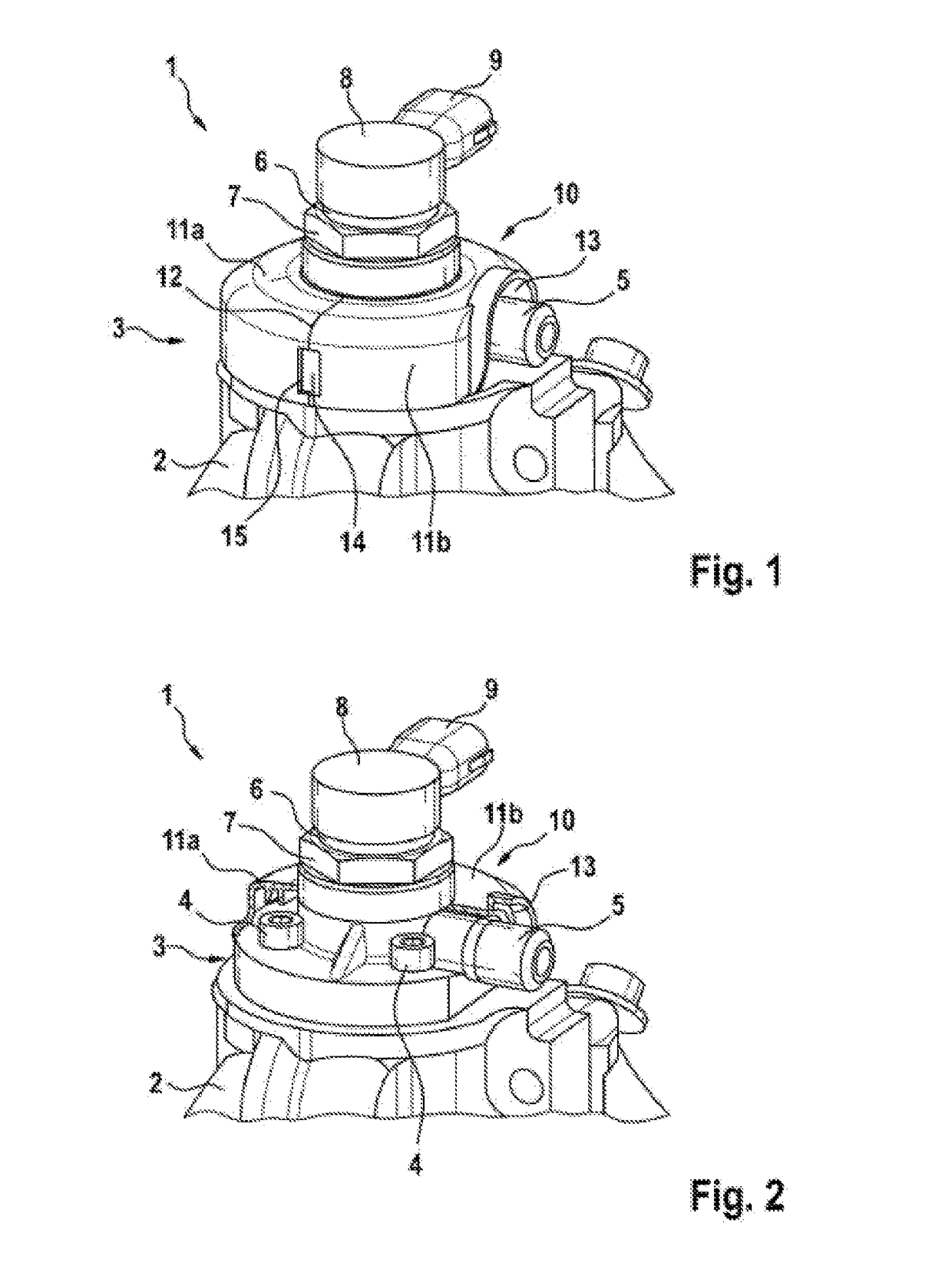

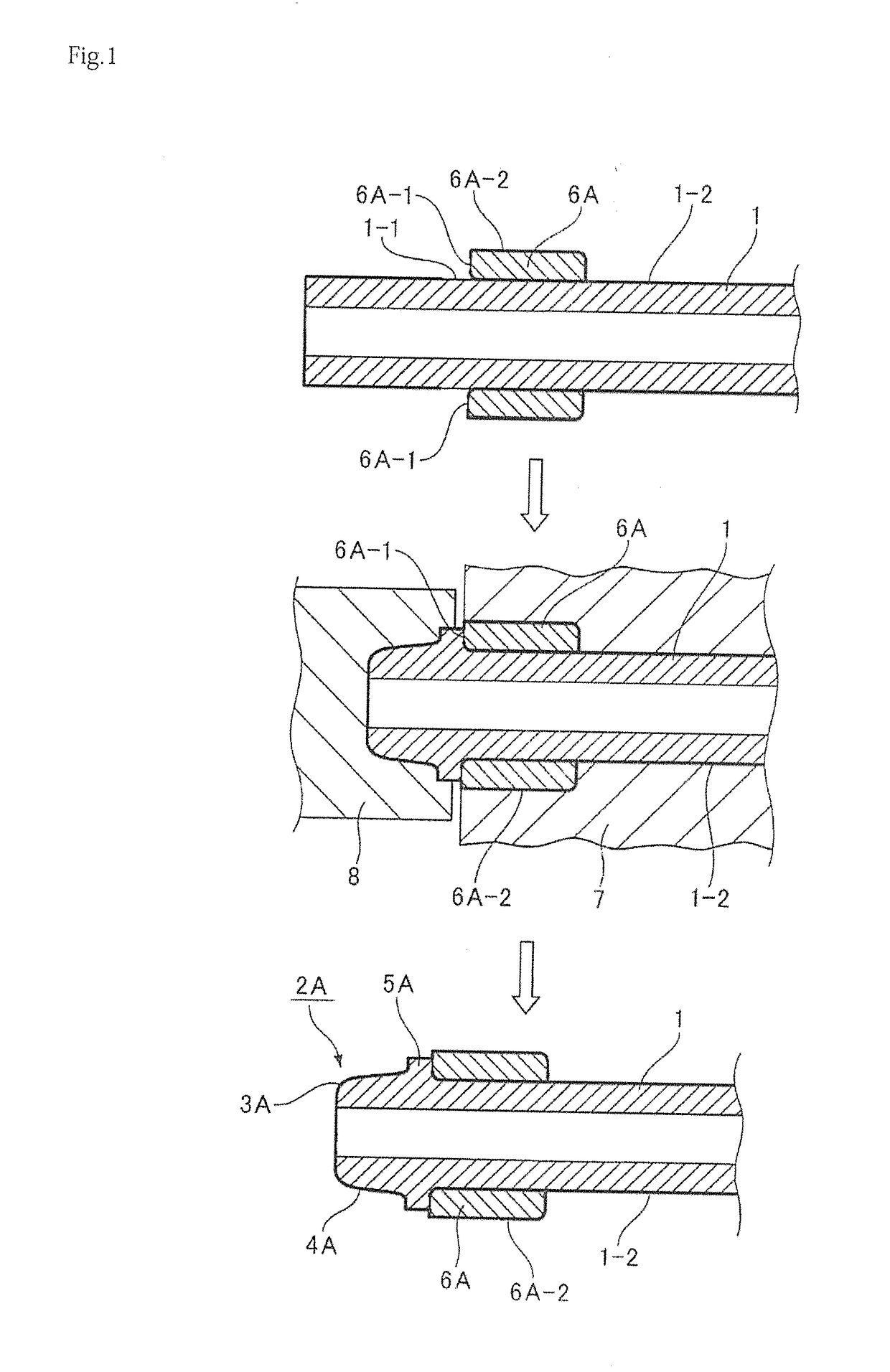

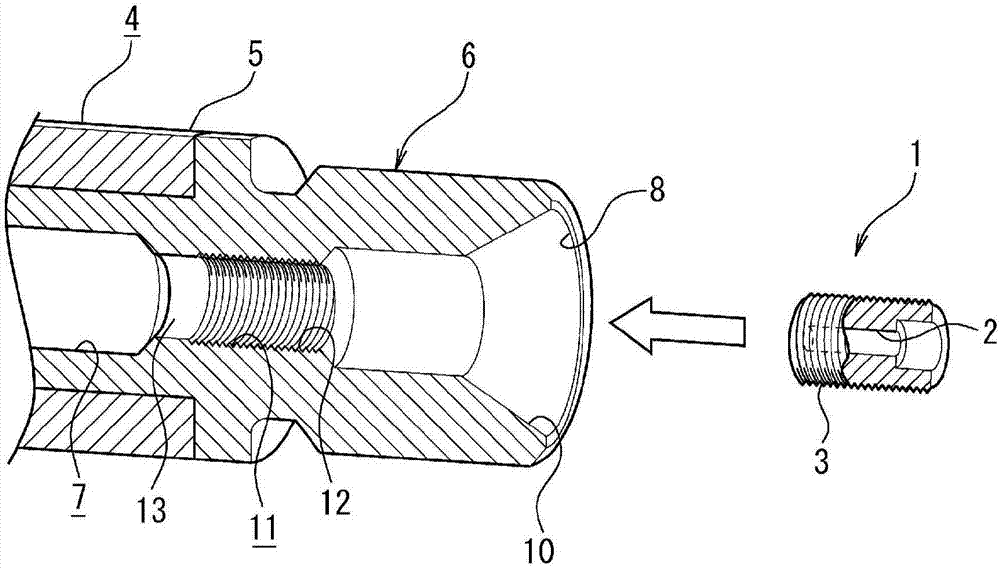

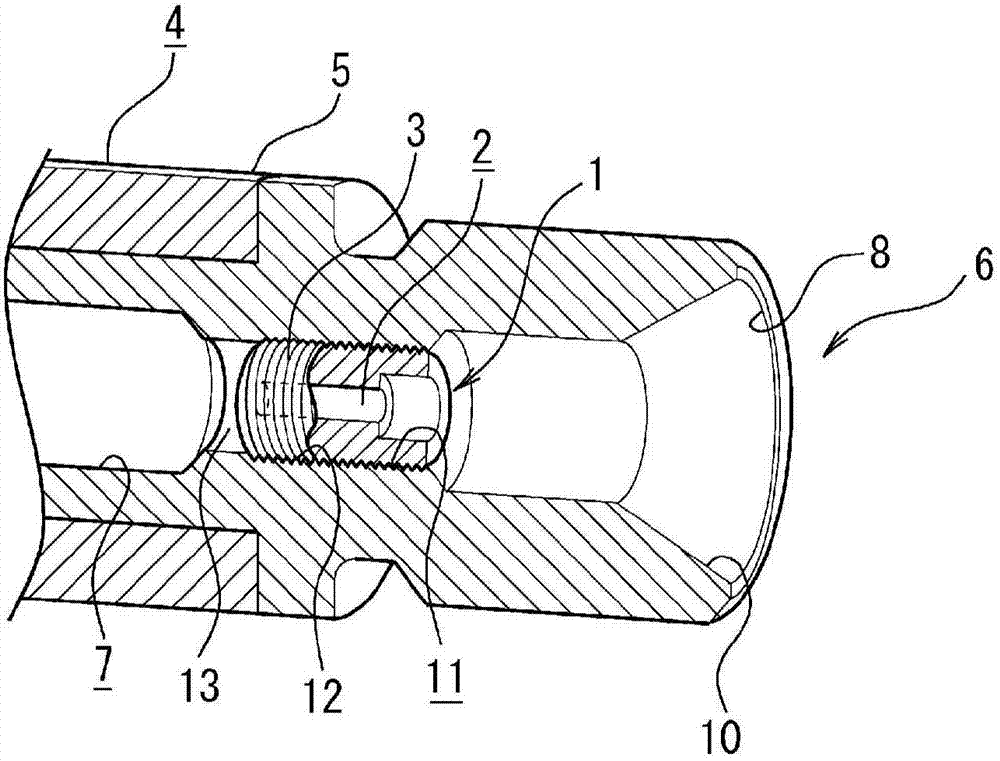

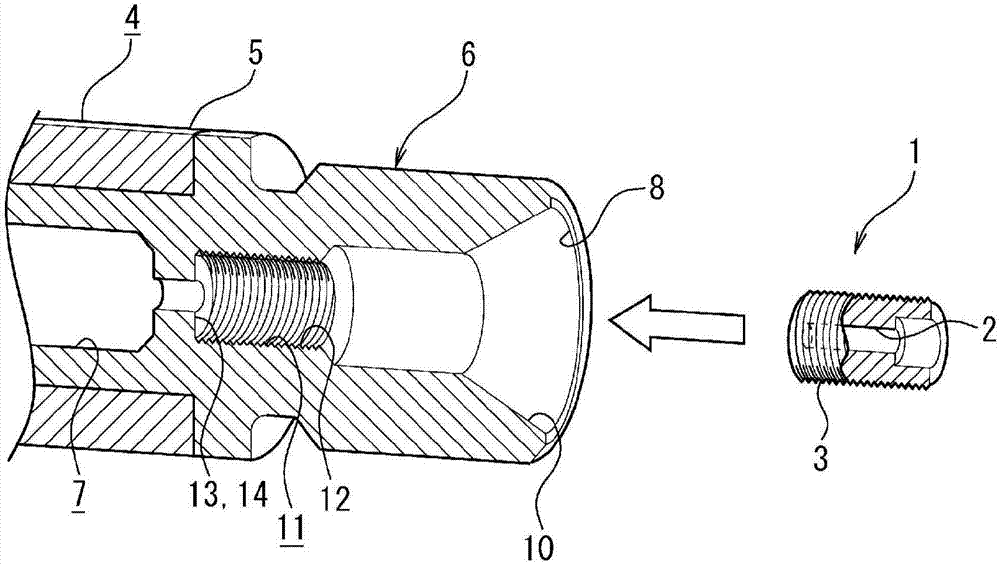

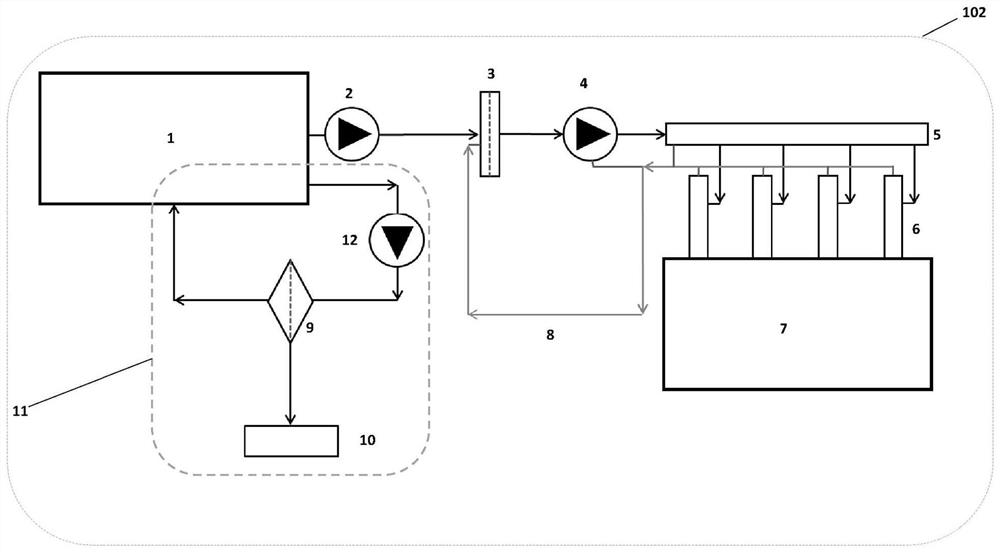

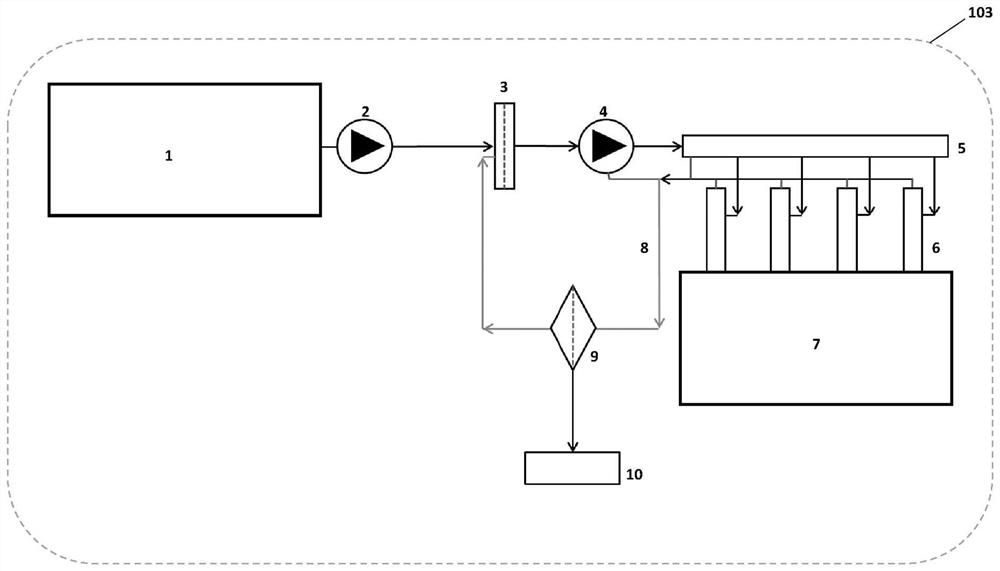

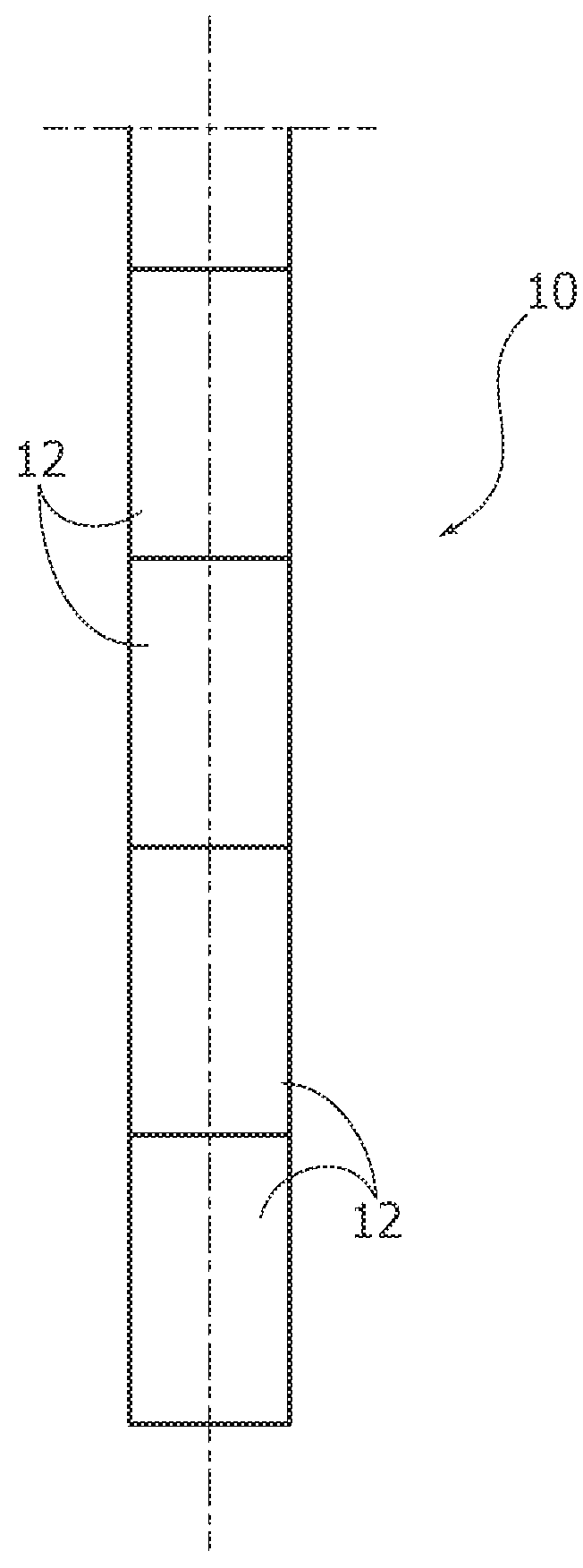

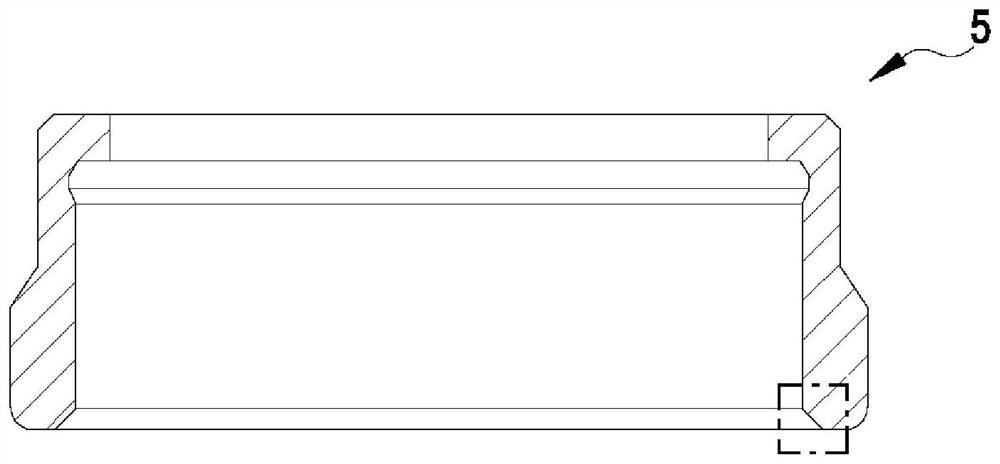

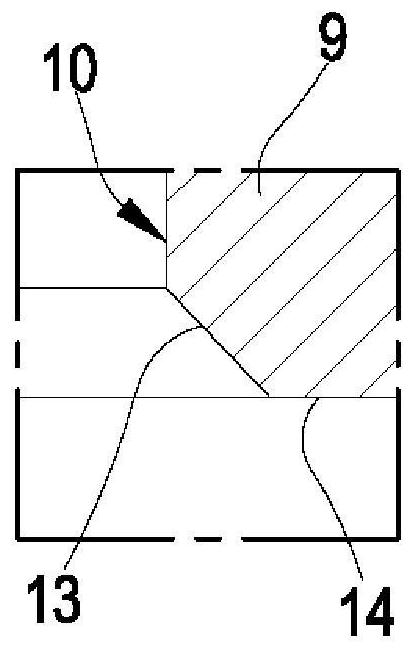

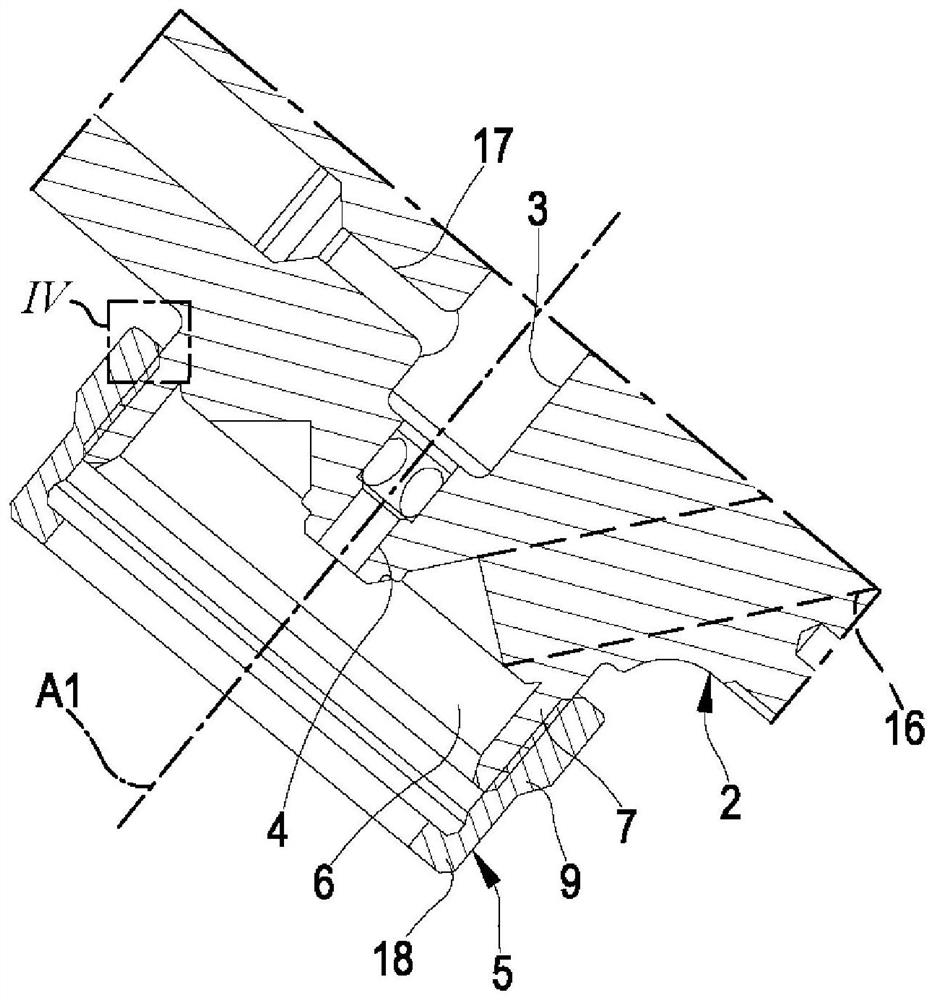

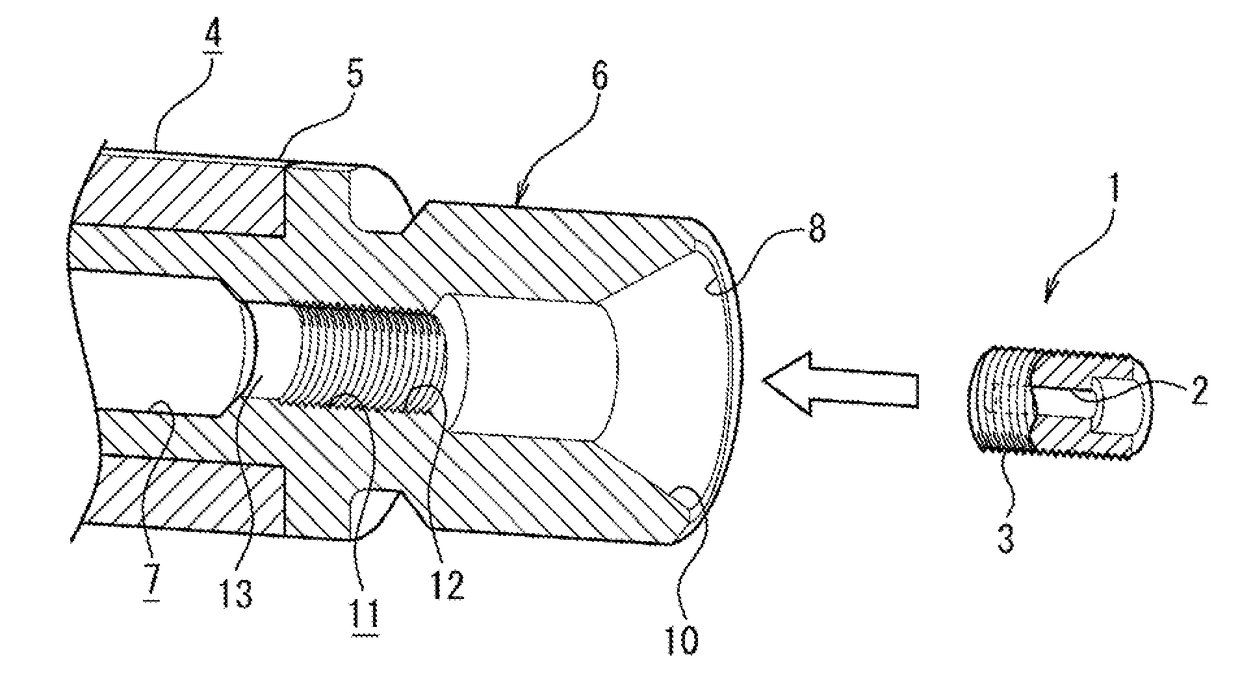

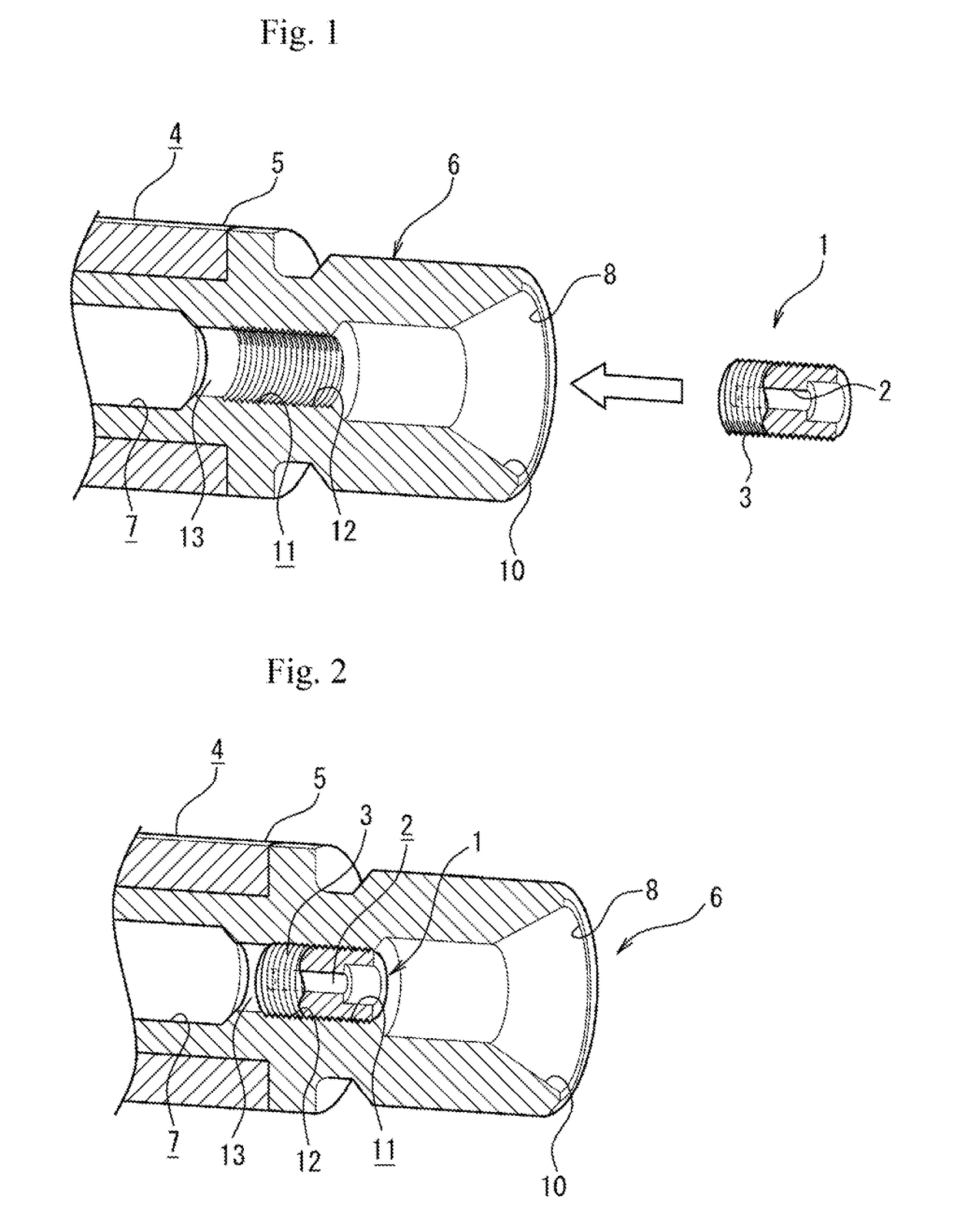

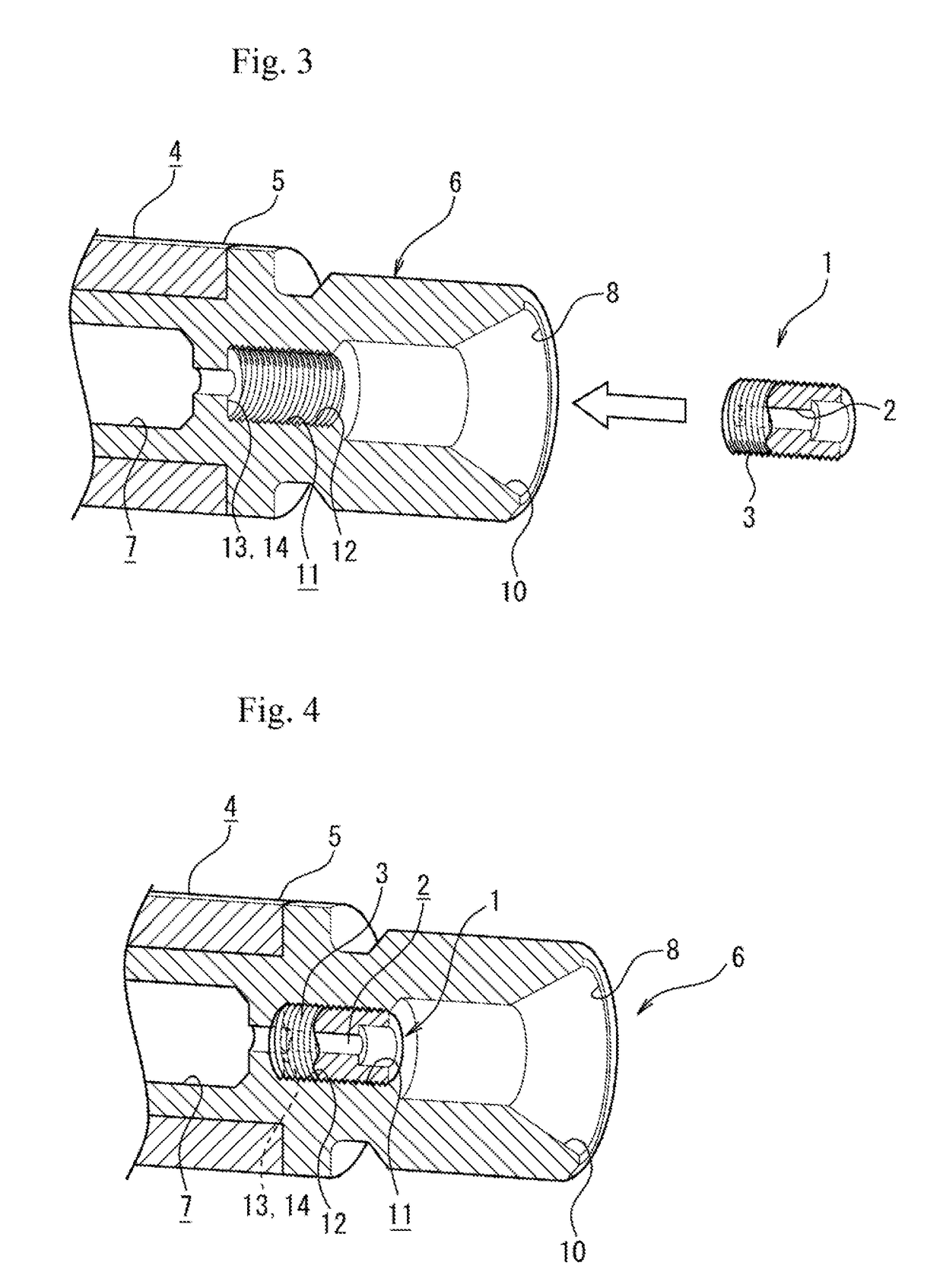

Pump assembly for supplying fuel, preferably diesel fuel, to an internal combustion engine

ActiveCN108071538BEasy to manufactureLow costPositive displacement pump componentsCorrosion preventing fuel injectionCouplingInternal combustion engine

A pump assembly for supplying fuel to an internal combustion engine; said pump assembly (1) comprising: - a pump head (2) in which a cylinder (3) for accommodating a sliding pumping piston is formed; - a through hole (4) extending from the cylinder (3) to the outside of the pump head (2); - a plug (5) coupled to the pump head (2) for defining the through hole (4) A suction chamber (6) communicating with the cylinder (3); wherein, the coupling between the blocking member (5) and the pump head (2) is the outer surface (8) of the surrounding wall (7) of the pump head (2) and A threaded coupling between the inner surface (10) of the surrounding wall (9) of the blocking member (5); wherein the surrounding wall (9) of the blocking member (5) comprises an inclined surface provided with a connection to the inner surface (10) The lower edge (12) of (13); wherein the projection (H) of the inclined surface (13) along a plane orthogonal to the inner surface (10) is less than twice the height (h) of the thread of the blocking member (5) .

Owner:ROBERT BOSCH GMBH

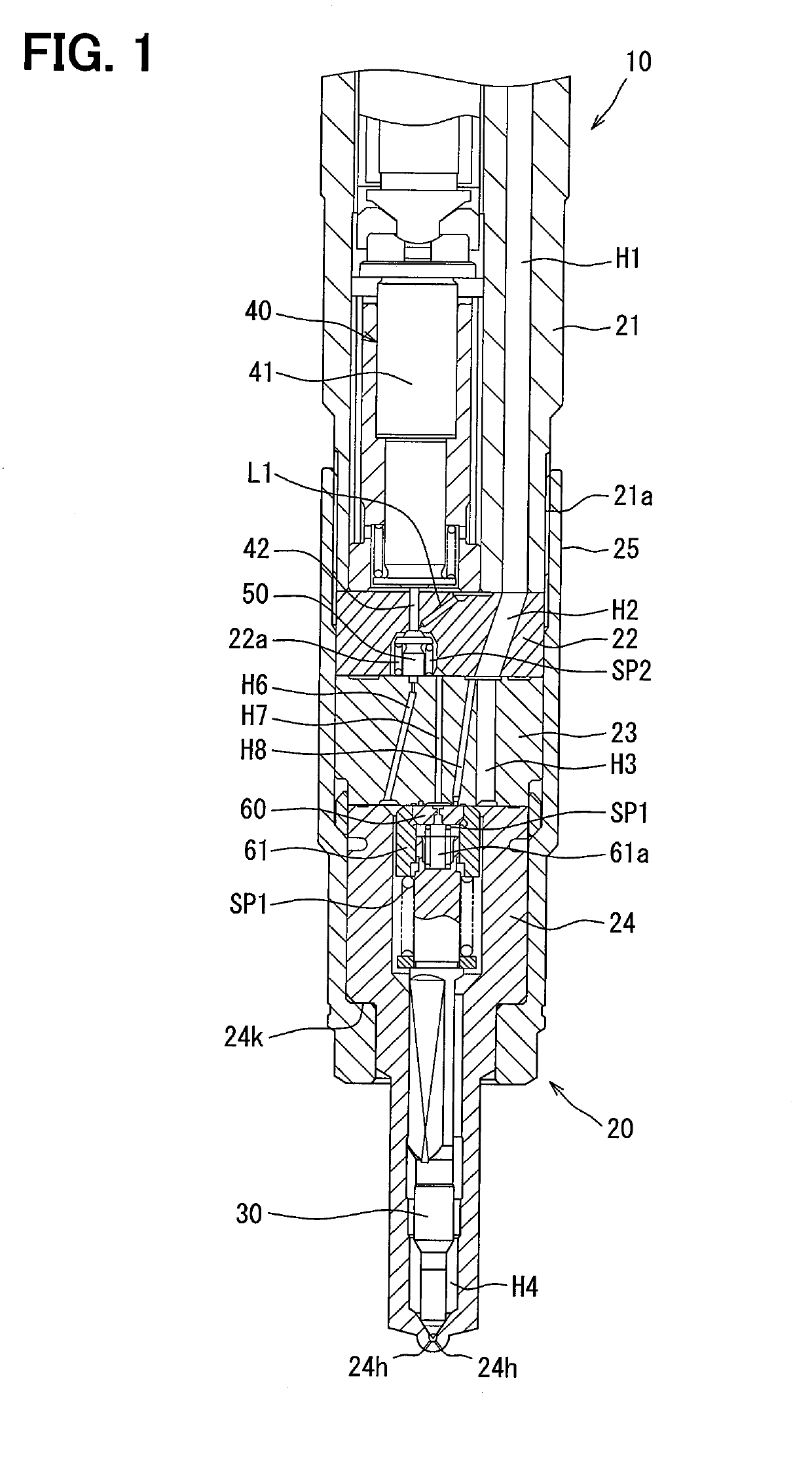

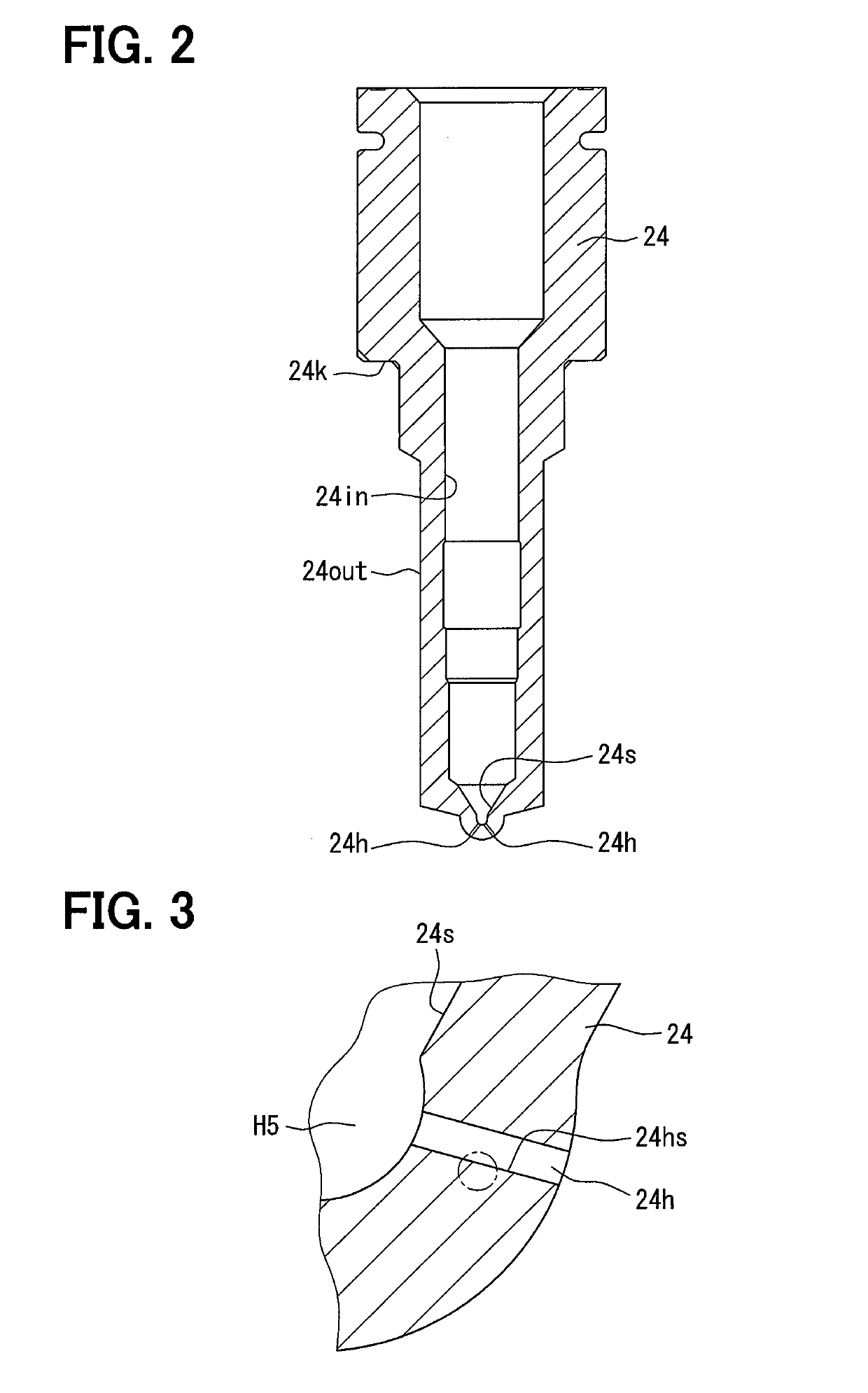

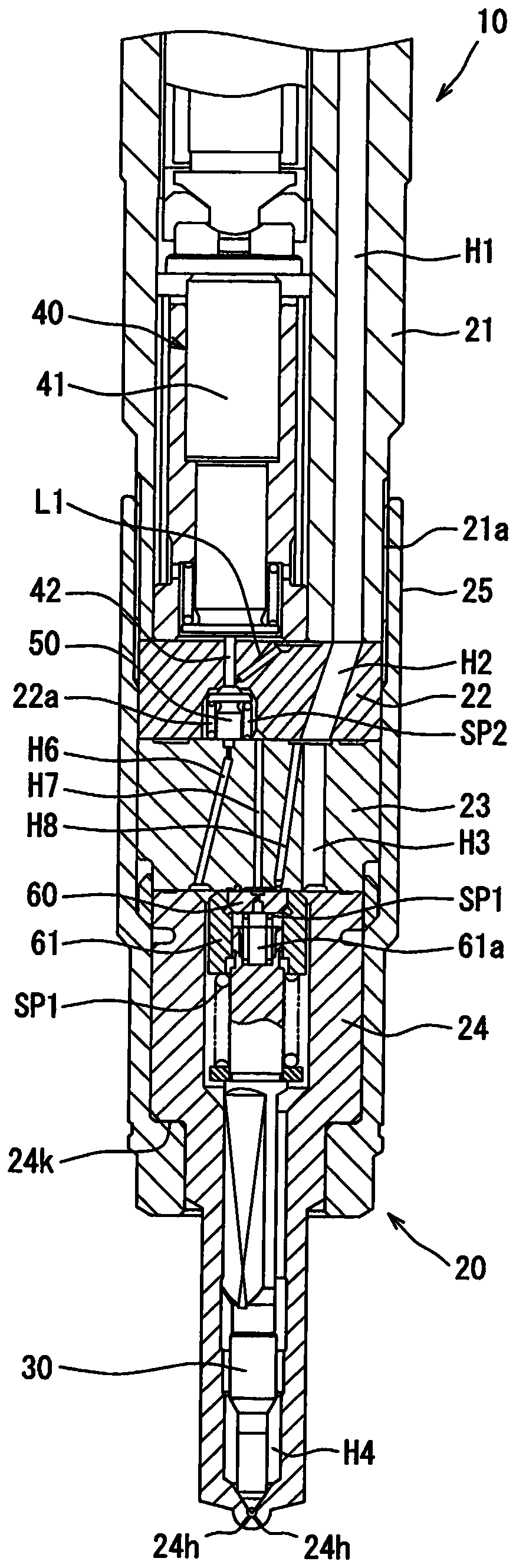

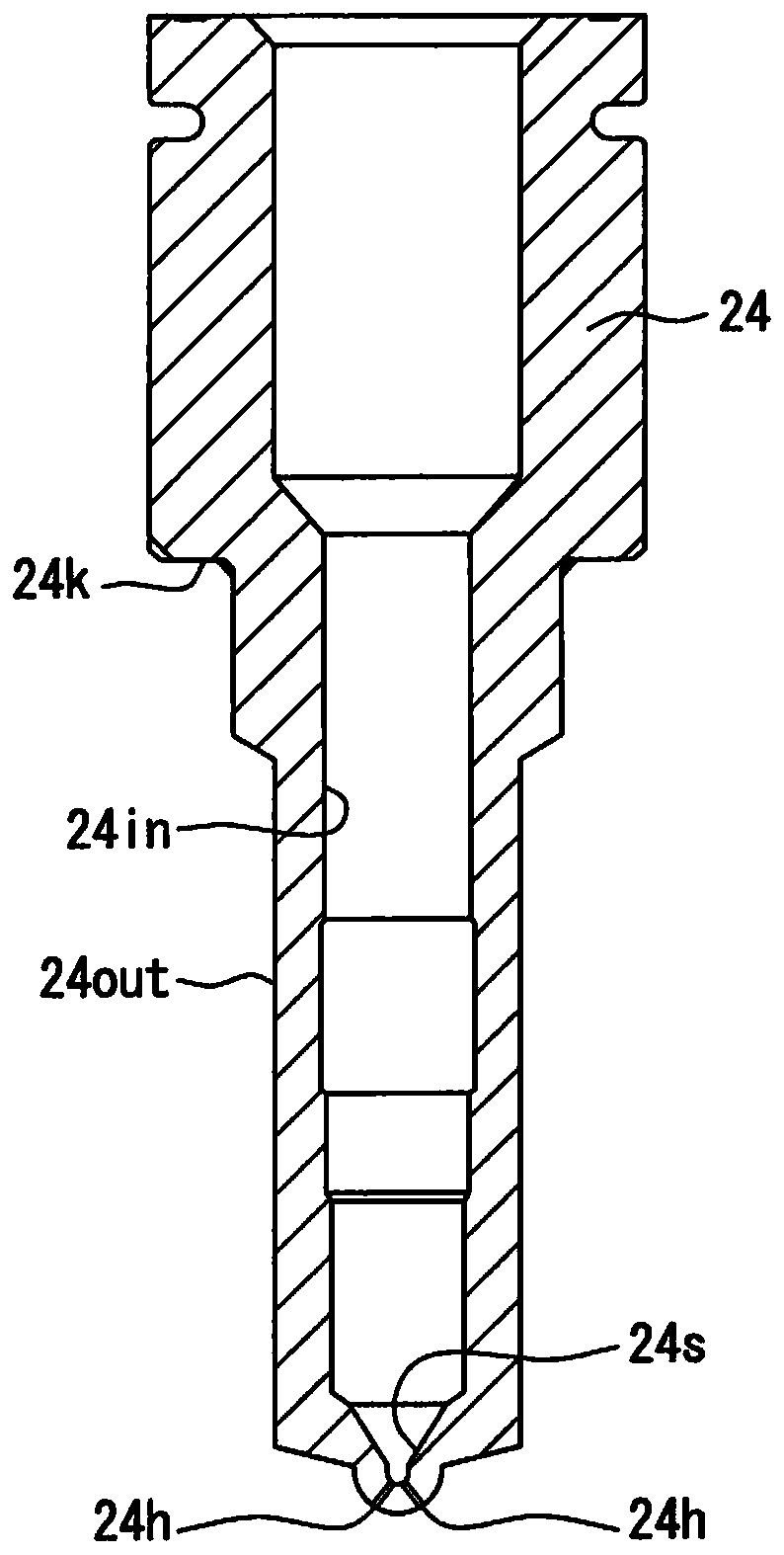

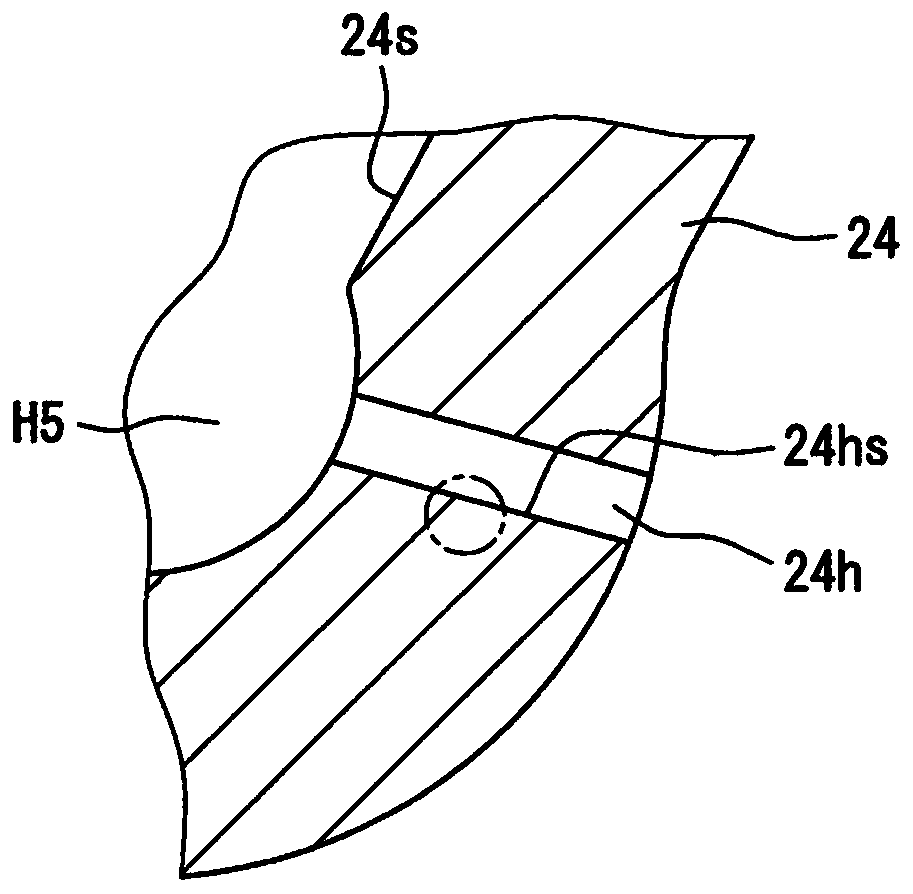

Fuel injection valve

ActiveCN109944726AImprovement of anti-corrosion measuresCorrosion preventing fuel injectionMachines/enginesBiomedical engineeringMetal

A fuel injection valve includes a body (24, 24A, 24B, 24C, 24D) that includes an injection hole (24h) through which fuel is injected, and a valve element (30) that opens or closes the injection hole (24h). The body (24, 24A, 24B, 24C, 24D) includes a metallic base material (241) configured to form the injection hole (24h), a corrosion-resistant layer (242) covering a surface of at least a part ofthe base material (241) that forms the injection hole (24h) and being made of a less corrosive material than the base material, and a sacrificial corrosion layer (245) located between the base material and the corrosion-resistant layer (242) and made of a more corrosive material than the corrosion-resistant layer.

Owner:DENSO CORP

Method for producing a nozzle for injectors of internal combustion engines

InactiveUS20160290301A1Improve uniformitySimpler and cheapCorrosion preventing fuel injectionMachines/enginesCombustionEngineering

A method for producing a nozzle for injectors of internal combustion engines, comprising the steps of: forming nozzle blanks by machining, each having a cylindrical surface, a flat reference surface at a first end of said cylindrical surface and a nozzle tip projecting from a second end of said cylindrical surface and having a longitudinal axis, orthogonal to said flat reference surface, applying a protective disc onto said flat reference surface, providing a containment tube with a closed first end.

Owner:OMT OFF MEC TORINO

Steel fuel conveying pipe

ActiveUS9012031B2Reliable lifeAvoid corrosionCorrosion preventing fuel injectionCorrosion preventionHigh resistanceGasoline direct injection

To provide a steel fuel conveying pipe which has high resistance to corrosive fuel and maintains reliability without damaging a direct-injection engine, and connects a high-pressure pump and a direct-injection rail with each other in a gasoline direct-injection engine system, and a fuel conveying pipe suitable as a bypass pipe for coupling direct-injection rails with each other in a V-type gasoline engine. A steel fuel conveying pipe for conveying gasoline is characterized in that a Ni-plated layer is provided on the whole inner circumferential face of the fuel conveying pipe, and an anti-rust film layer composed of a Zn-plated layer and a Zn-based alloy-plated layer is further provided on the Ni-plated layer at at least one end of the fuel conveying pipe.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Gasoline direct injection rail

ActiveUS20180051665A1Easy to implementImprove mechanical propertiesInternal combustion piston enginesCorrosion preventing fuel injectionGasoline direct injectionEngineering

To obtain a gasoline direct injection rail that enables plating treatment to be easily and reliably performed on the inside of a rail body and an inlet part, also, that includes an orifice, and that has excellent mechanical properties. In a gasoline direct injection rail comprising a steel rail body 4, an inlet part 6 provided integrally with or separately from a first end 5 of the rail body 4 and comprising therein a communication passage 7 in communication with a fuel passage of the rail body 4, and a plurality of injector holders in communication with the fuel passage, a stainless orifice member 1 formed separately from the rail body 4 is securely disposed in the communication passage 7 of the inlet part 6.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Martensitic stainless steel for fuel injection member and fuel injection member using same

PendingUS20190211429A1High degreeIncrease resistanceCorrosion preventing fuel injectionMachines/enginesMetallurgyMartensitic stainless steel

A martensitic stainless steel for a fuel injection member contains, in mass %, at least 0.35% and less than 0.50% of C, more than 0.20% and at most 0.40% of Si, 0.2-0.4% of Mn, 0.25% or less of Ni, 15.0-17.0% of Cr, more than 2.0% and at most 3.0% of Mo, 0.1-0.3% of W, 0.001-0.003% of B, and at least 0.15% and less than 0.20% of N, with the remainder comprising Fe and inevitable impurities, which include 0-0.025% of P, 0-0.005% of S, 0-0.2% of Cu, 0-0.05% of Al, 0-0.02% of Ti, 0-0.02% of Nb, 0-0.15% of V, 0-0.003% of O, and 0-0.001% of H.

Owner:PROTERIAL LTD

Control device for internal combustion engine

ActiveUS9885635B2Reduce computing loadInternal-combustion engine testingLiquid coolingCylinder headDew

A control device for an internal combustion engine that includes: a first detection unit detecting, as a first parameter, a temperature of a nozzle tip of an injector; and a second detection unit detecting, as a second parameter, a heat quantity of a cylinder head, and executes a dew condensation determination by using at least one of the first parameter and the second parameter, the control device includes: a third detection unit detecting an evaluation value allowing to evaluate a state of the internal combustion engine, a threshold value for selecting which parameter of the first and second parameters is selected being set with respect to the evaluation value, wherein the control device switches a parameter to be used to the first parameter, to the second parameter, or to both the first and second parameters in accordance with the evaluation value when executing the dew condensation determination.

Owner:TOYOTA JIDOSHA KK

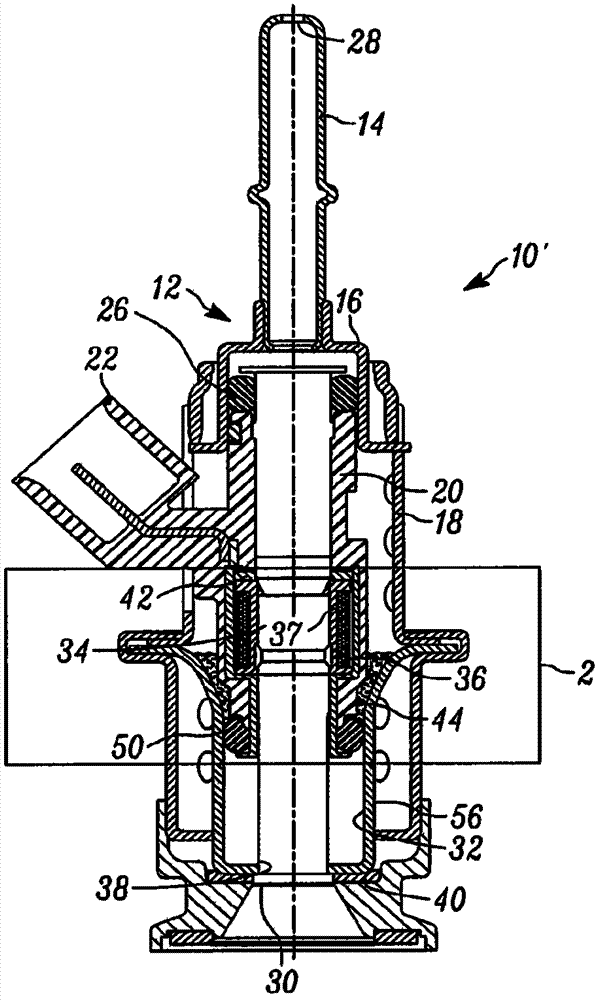

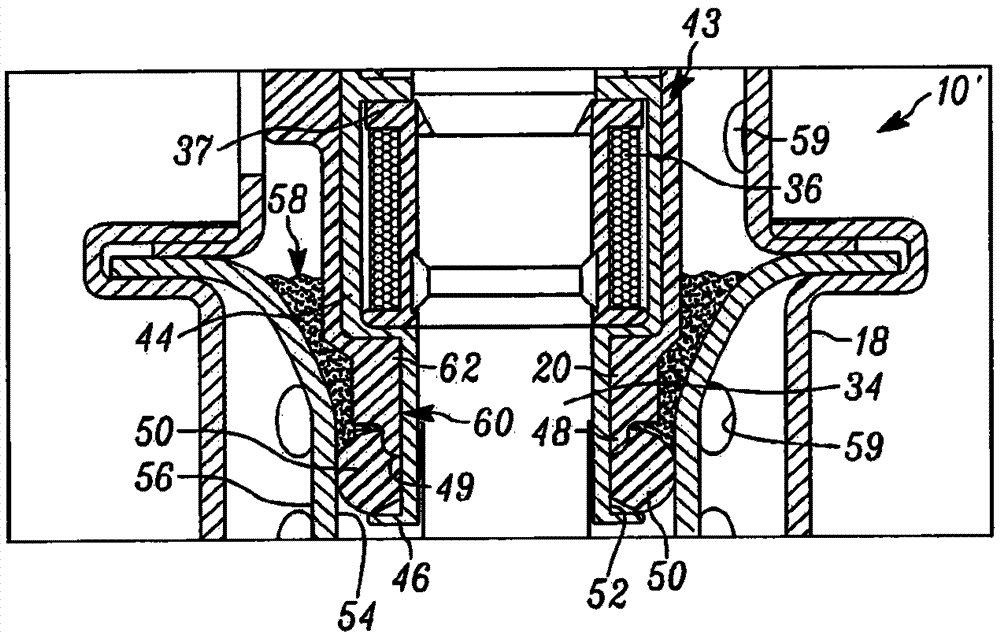

Injector Corrosion Isolation Seals

ActiveCN104948274BAvoid enteringEngine sealsInternal combustion piston enginesInsertion stentBiomedical engineering

A fluid injector includes a valve assembly constructed and arranged to control the flow of fluid from an inlet to an outlet of the injector. A metal housing surrounds at least a portion of the valve assembly. A plastic body is molded over at least a portion of the housing. The distal end of the body defines an integral stepped portion extending from the body. The stent surrounds at least the distal end of the body. The sealing member contacts at least surfaces of the stepped portion and the bracket to prevent liquid from entering a space between the case and the body.

Owner:VITESCO TECH USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com