Gasoline direct injection rail

A gasoline direct injection, main body technology, used in low pressure fuel injection, low pressure fuel injection, fuel injection devices, etc., can solve problems such as stress corrosion cracking, and achieve the effects of excellent mechanical properties and rich strength changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

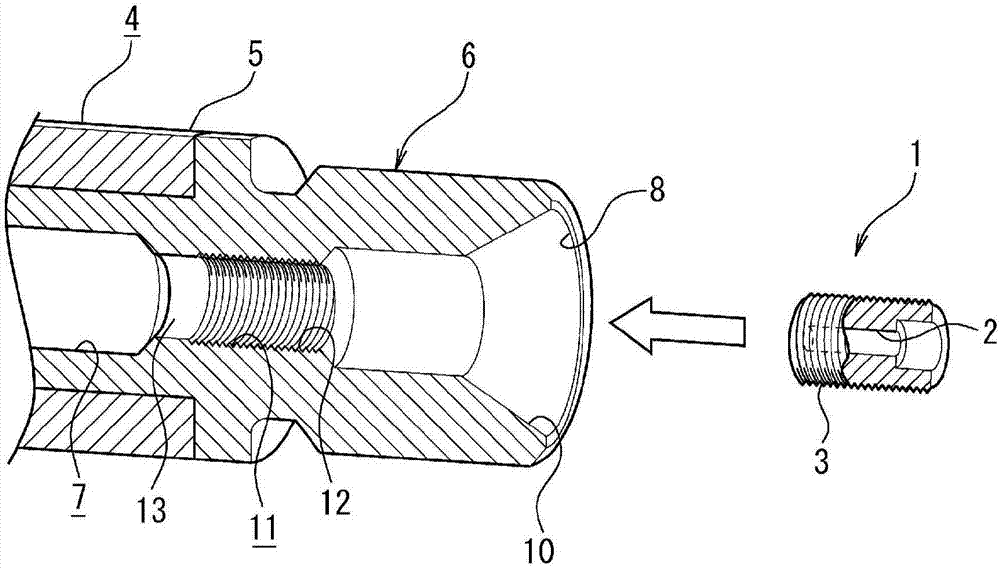

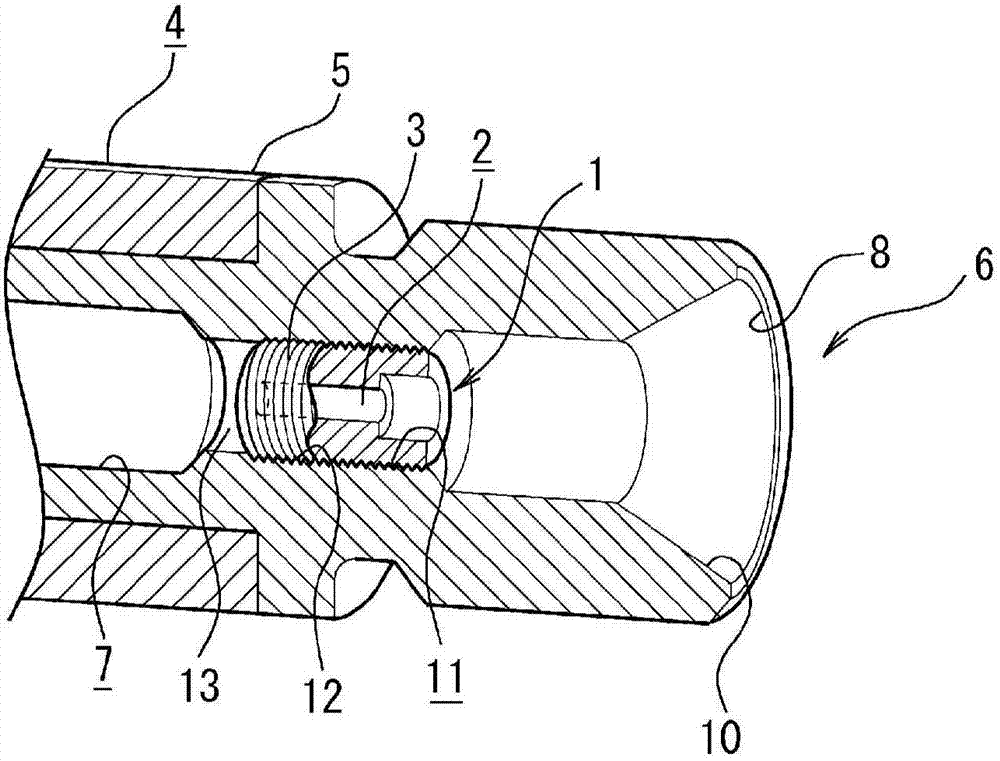

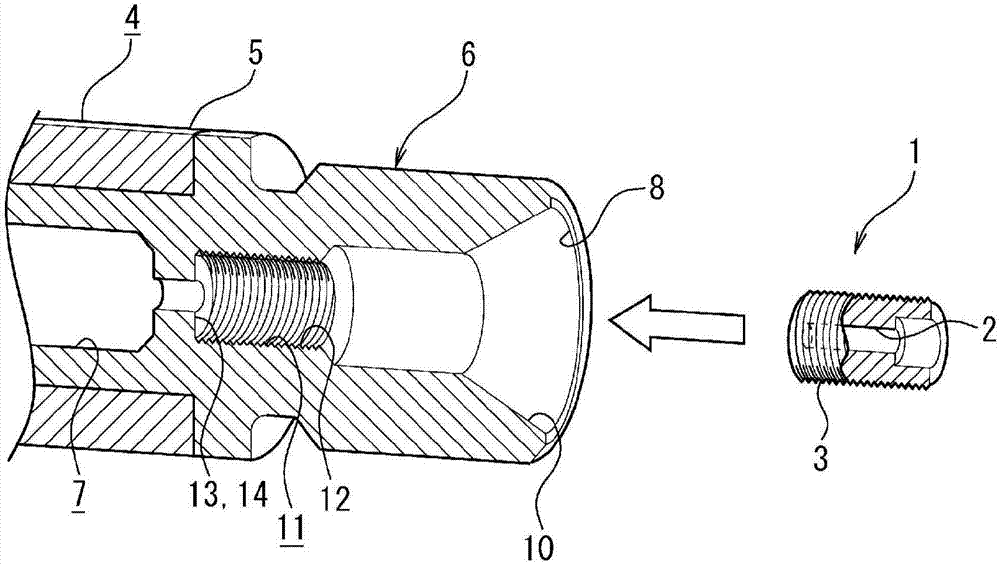

[0020] in figure 1 , 2 In the description of Example 1 of the present invention, reference numeral 1 is an orifice member, which is formed of a stainless steel material. By forming the orifice member 1 from a stainless steel material in this way, it is not necessary to perform plating treatment to prevent rust and corrosion. In addition, the orifice member 1 is formed into a cylindrical shape provided with an orifice 2 in the longitudinal direction, and the outer peripheral surface thereof is as figure 1 A peripheral screw groove 3 is provided as shown.

[0021] On the other hand, on one end 5 of the rail main body 4 of the gasoline direct injection rail, an introduction portion 6 formed separately from the rail main body 4 is fixedly arranged. In addition, in this embodiment, as described above, the introduction portion 6 is formed separately from the rail main body 4, and the introduction portion 6 is fixedly arranged at the end 5 of the rail main body 4. However, in other diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com