Patents

Literature

85results about How to "Reliable life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

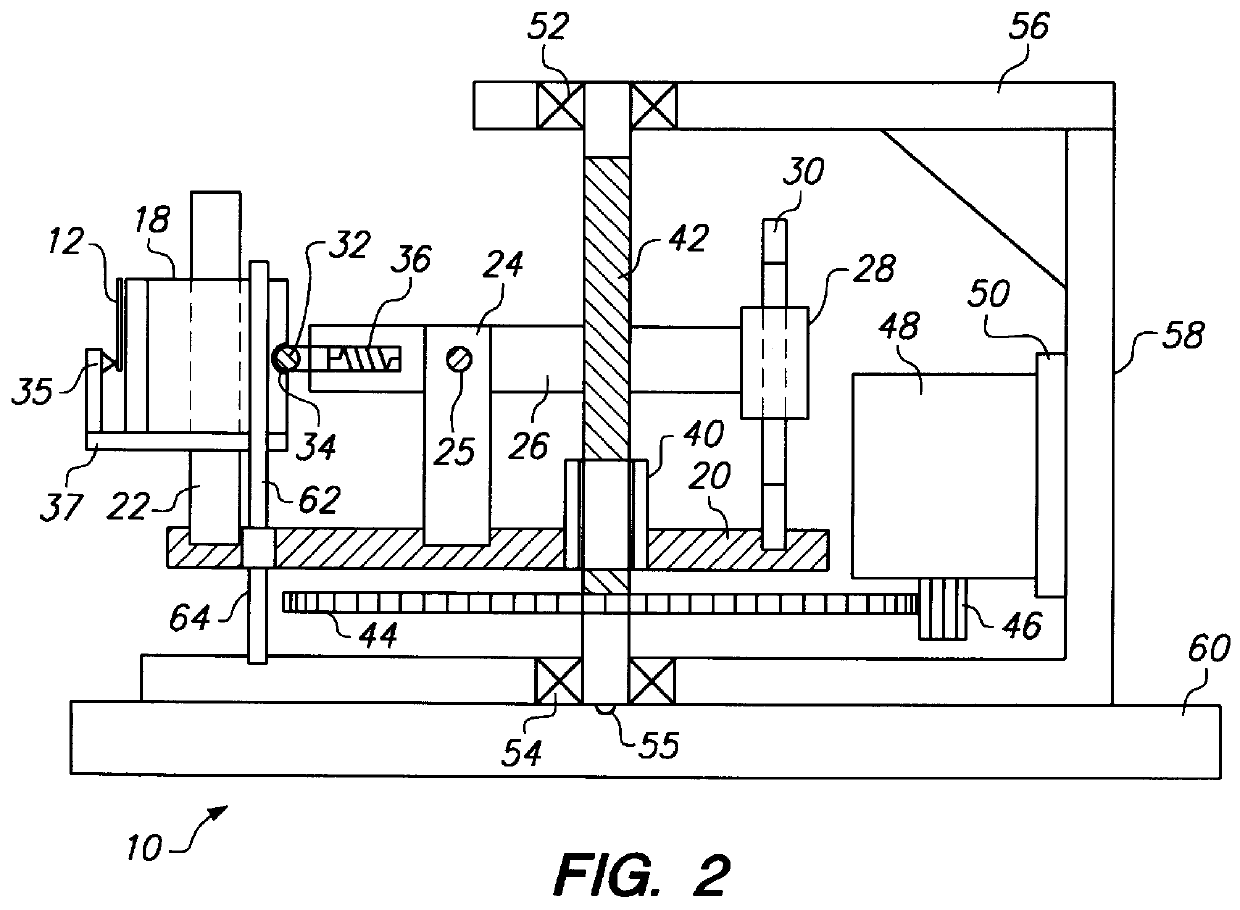

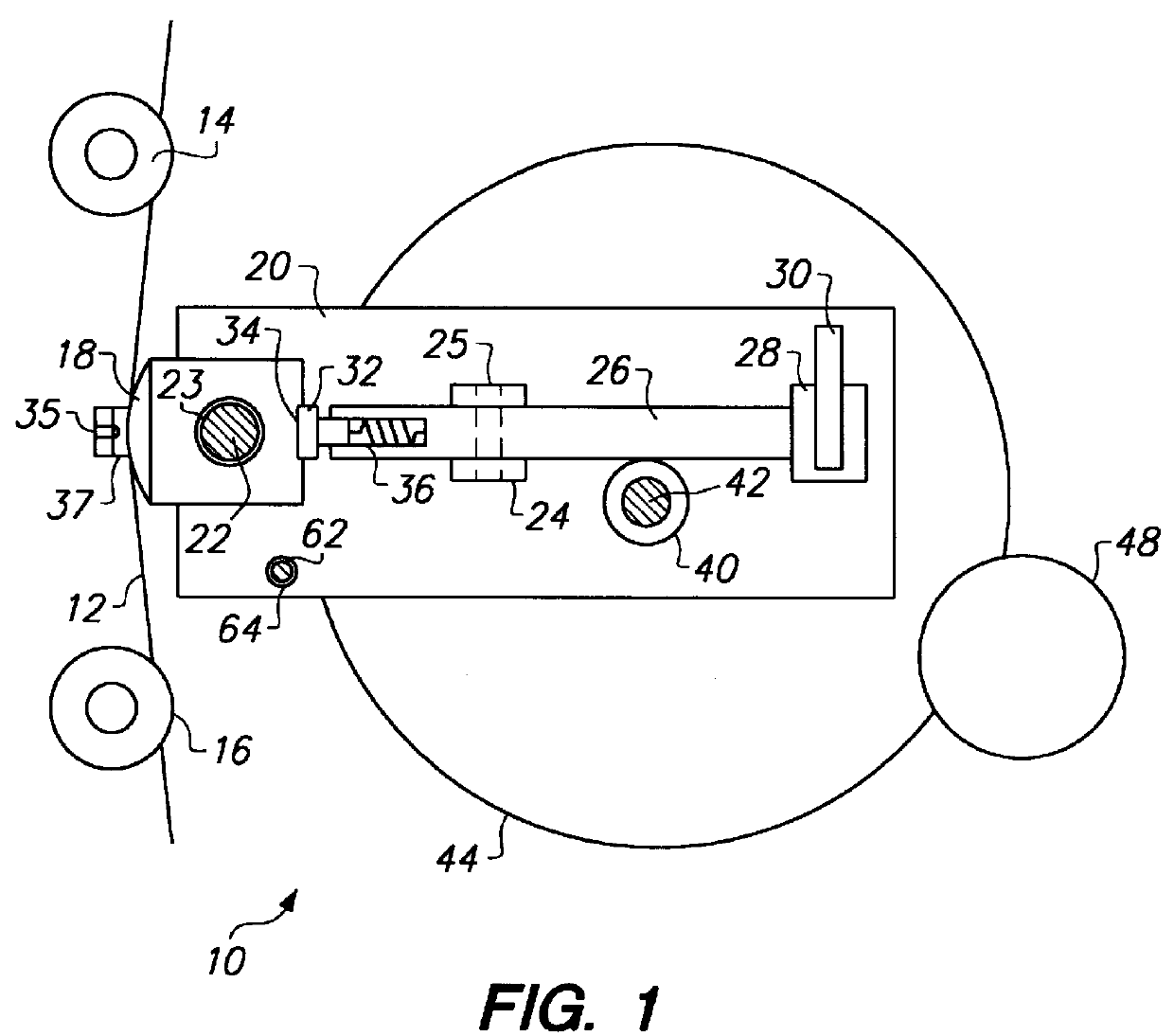

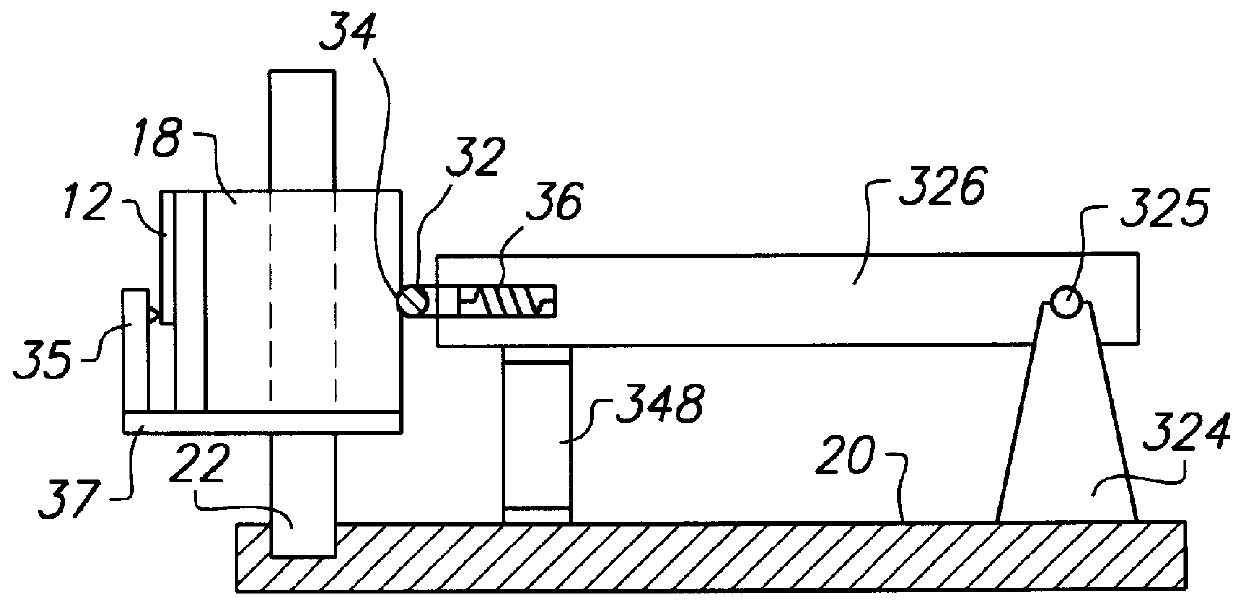

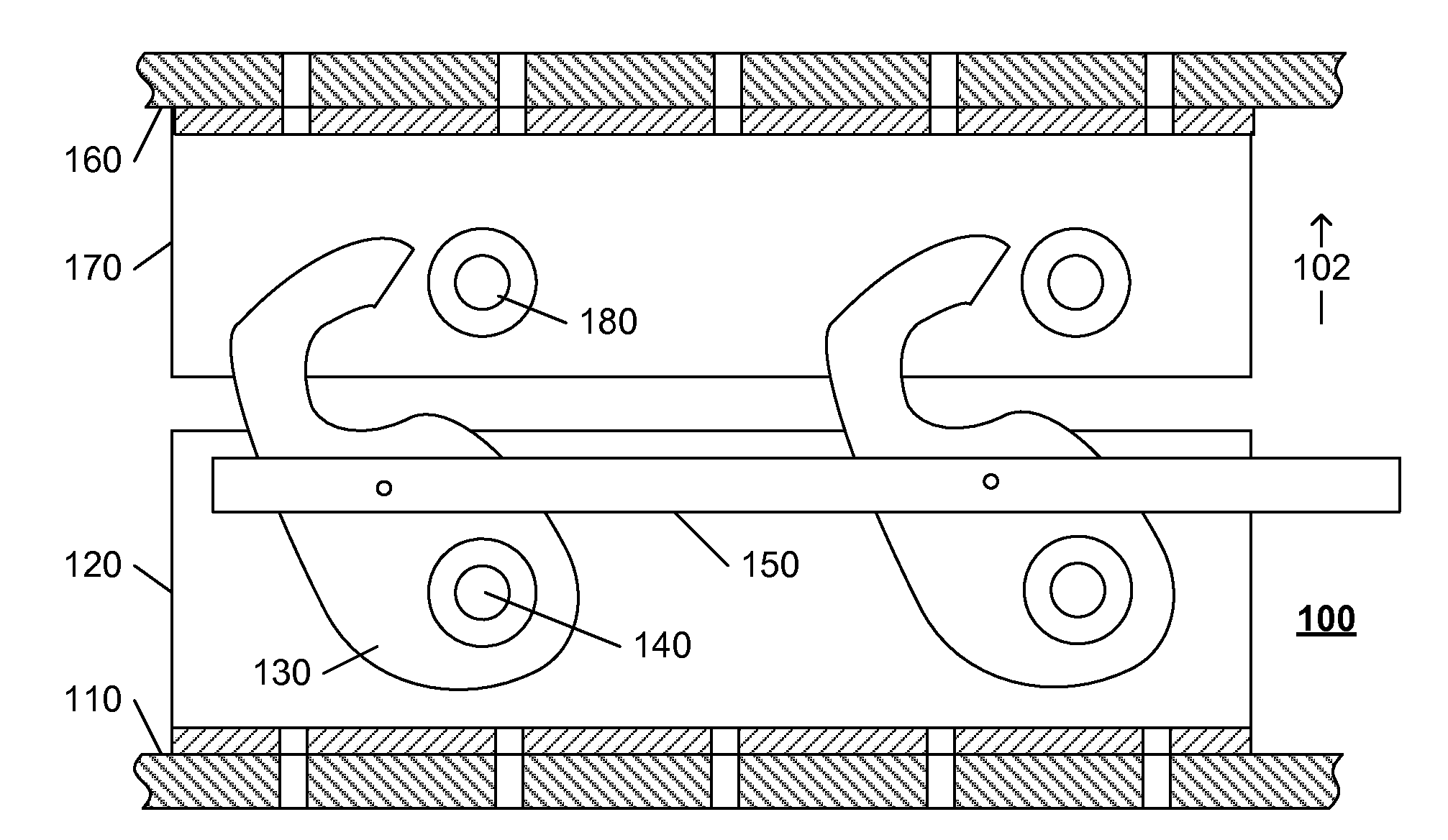

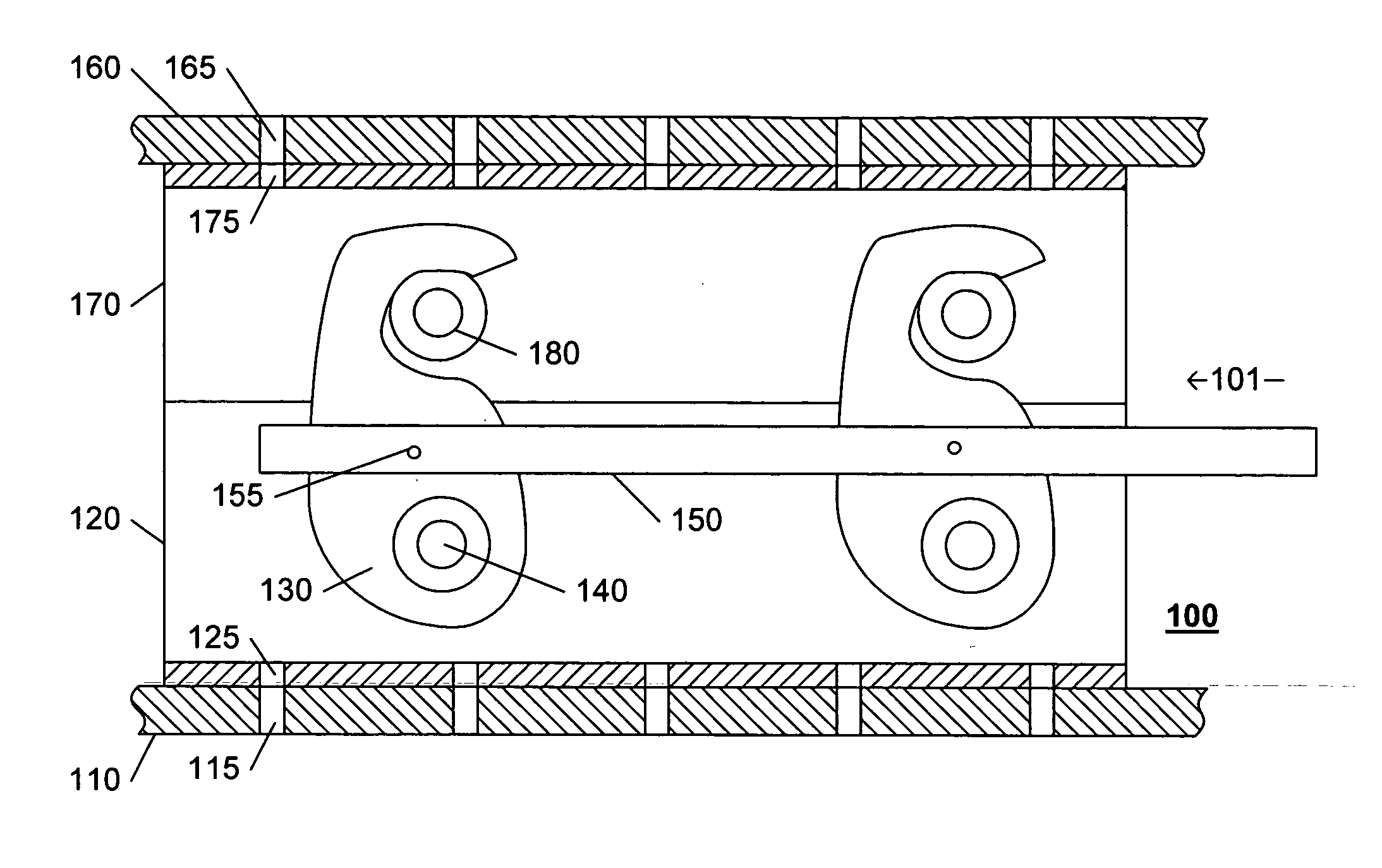

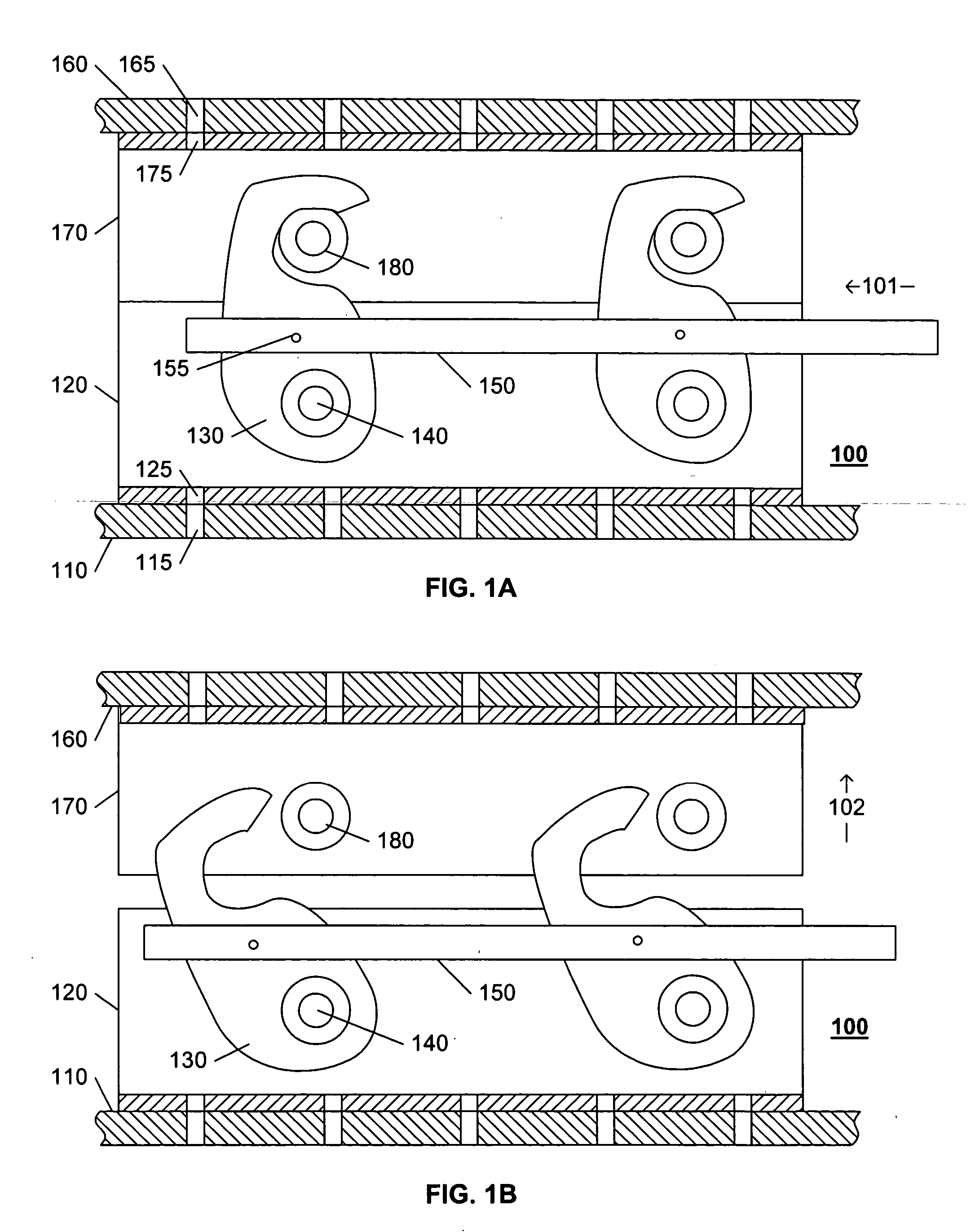

Pivoting lever cam guide tape head positioner

InactiveUS6075678AImprove mechanical rigidityHigh of resistance to vibrationTrack finding/aligningAlignment for track following on tapesLight beamEngineering

A fine lateral head positioner for a tape drive includes a frame mounted to a base of a tape transport. A tape head slides laterally along a head guide. A guide beam actuated by a fine position actuator applies limited transverse adjustments to the tape head relative to a tape transport path via a cam and cam-follower arrangement. A coarse positioner between the frame and the base provides coarse position adjustment of the tape head laterally among multiple sets of parallel tracks defined along a longitudinal direction of a magnetic tape moving along the tape transport path, and the guide beam provides fine position adjustment of the tape head enabling it to follow in real time a particular set of parallel tracks of the tape during each data writing or reading operation.

Owner:QUANTUM CORP

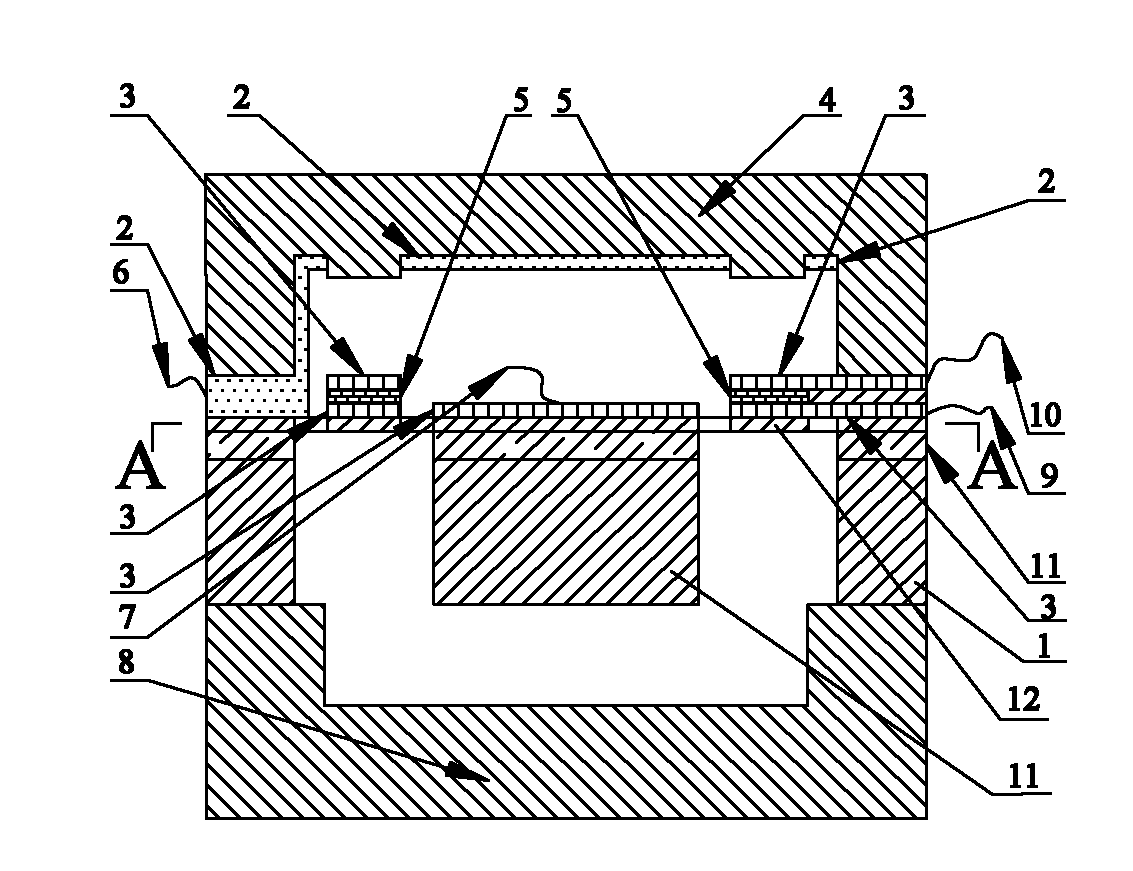

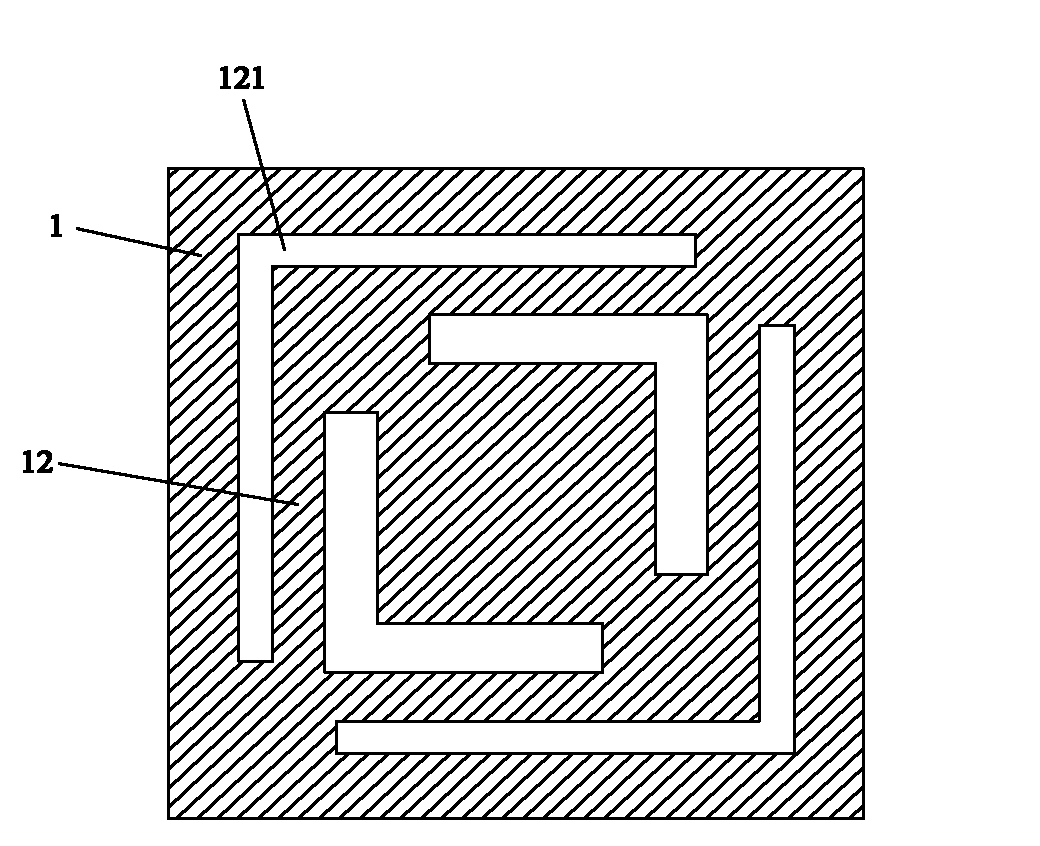

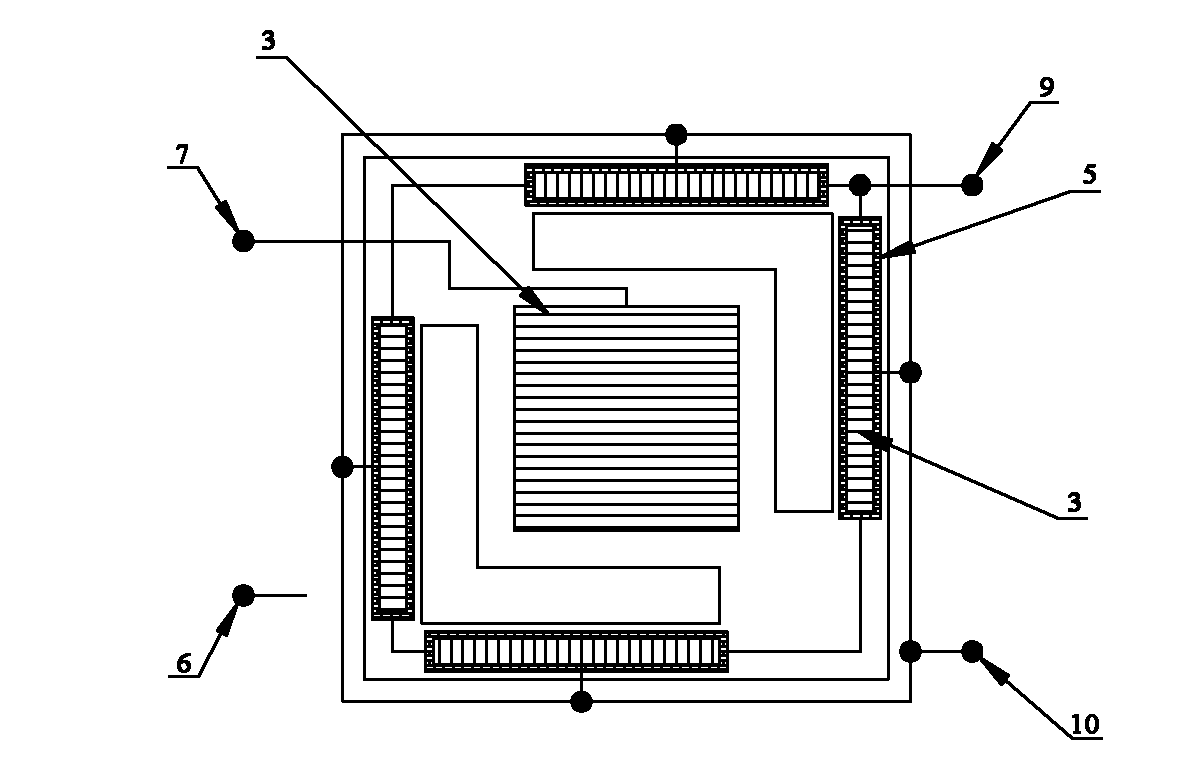

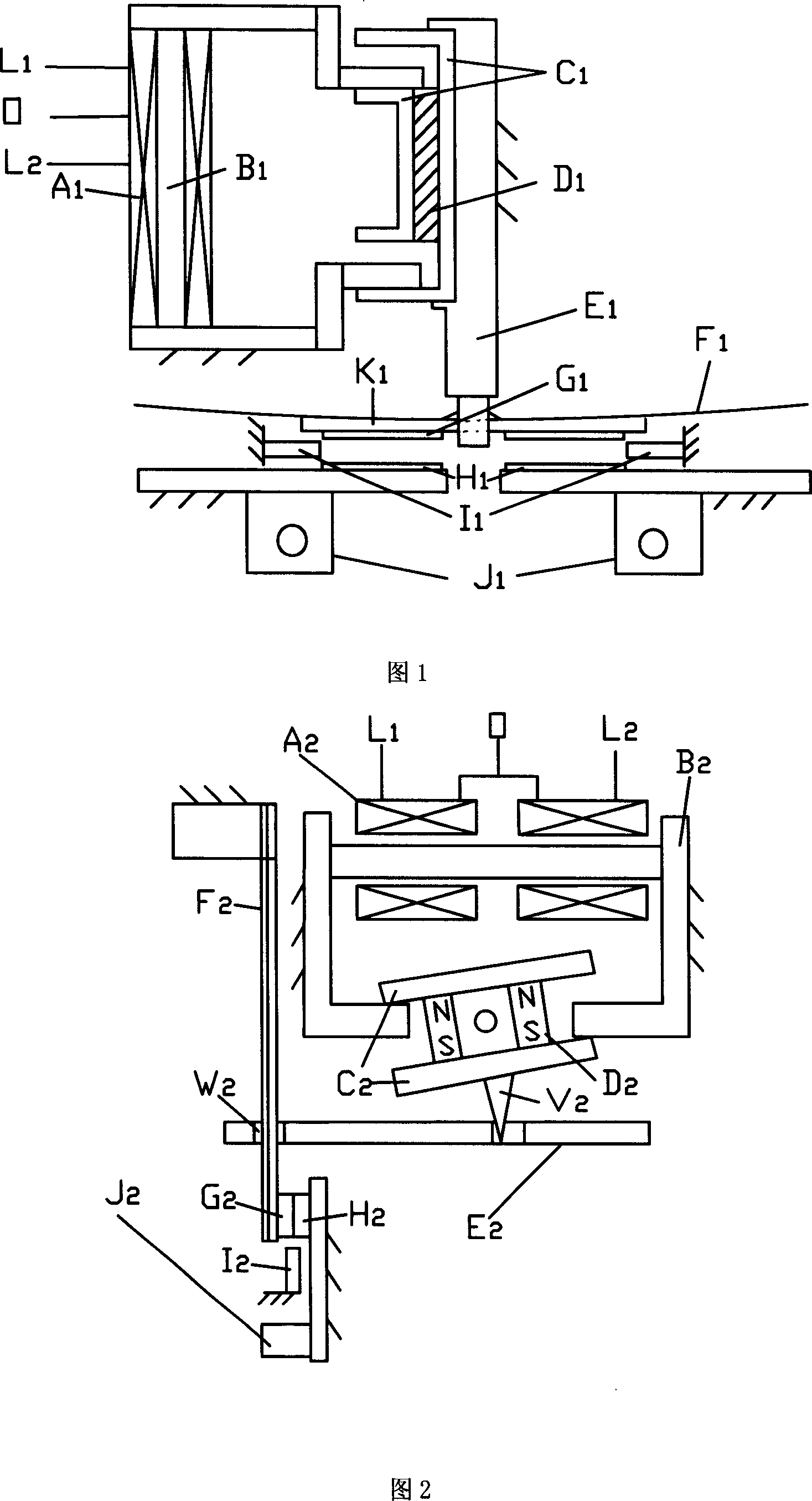

Piezoelectric-static compound micro machine vibration energy collector and manufacture method thereof

InactiveCN102570902AAvoid instabilityAchieve self-supplyPiezoelectric/electrostriction/magnetostriction machinesDecorative surface effectsCapacitanceMachining vibrations

The invention relates to a piezoelectric-static composite micro machine vibration energy collector and a manufacture method of the collector, and relates to an energy collecting device. The piezoelectric-static composite micro machine vibration energy collector comprises a chip main body and a chip external circuit, wherein the chip main body is of a three-layer laminated structure, and the chip main body comprises an upper glass piece device, an SOI (Silicon On Insulator) piece device, a lower glass piece device, a piezoelectric ceramic wafer device, a piezoelectric ceramic wafer electrode and a variable capacitance plate electrode. The chip external circuit is provided with a rectification circuit, a filter capacitor, a first switch, a second switch and an energy storage capacitor, or is provided with a rectification circuit, a filter capacitor, a first switch, a second switch and an energy storage capacitor and a variable capacitance plate starting power supply. The manufacture method comprises the following steps of: manufacturing the lower glass piece device; manufacturing the SOI piece device; manufacturing the upper glass piece device; assembling; and connecting the chip external circuit. According to the collector and the manufacture method, the process is simple, the defects of poorer device stability and performance and the like caused by,manufacturing a PZT (Piezoelectric Transducer) by using the traditional sol gel can be overcome, and wide band and high efficiency collection of energy can be realized.

Owner:XIAMEN UNIV +1

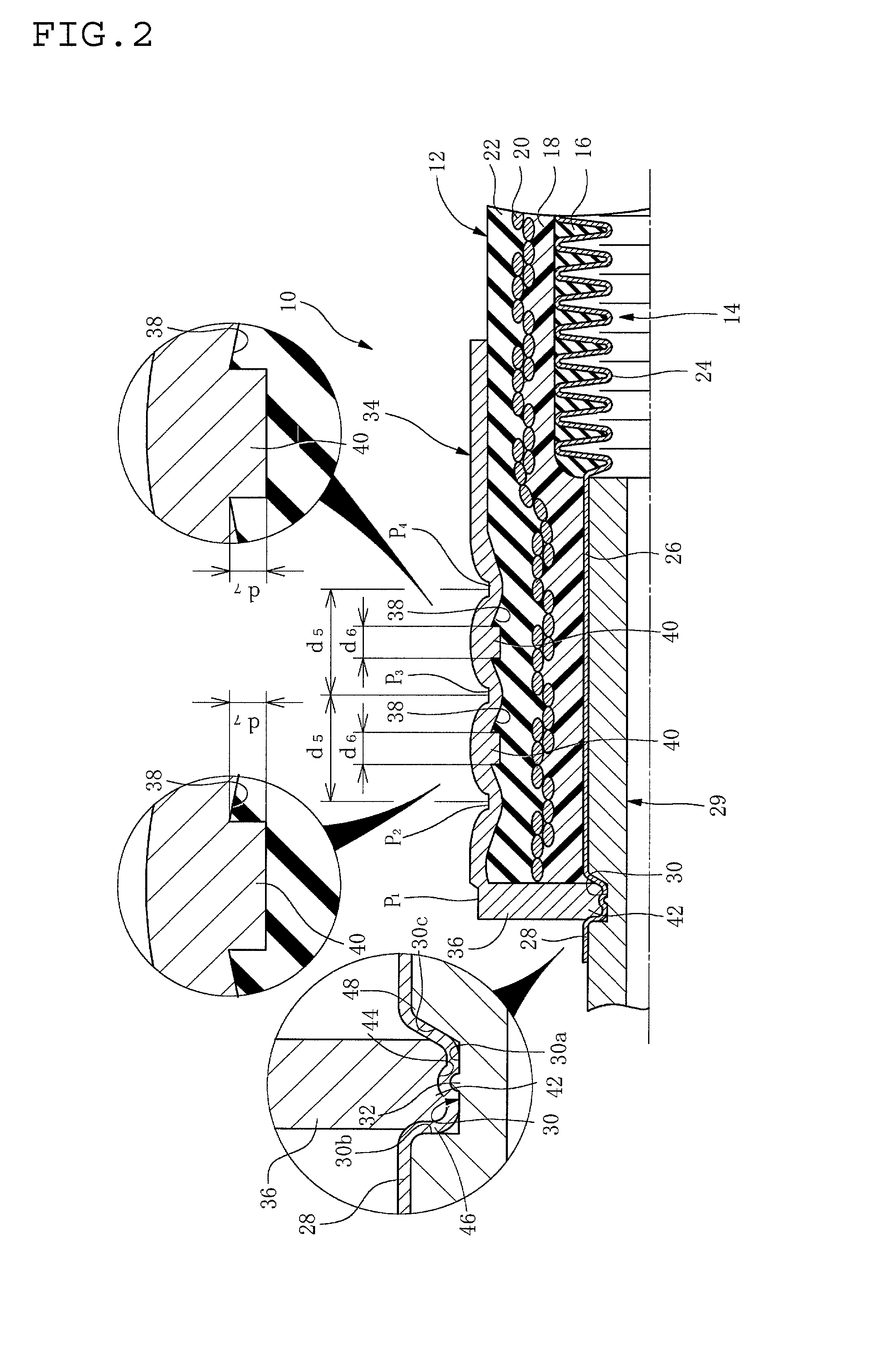

High pressure resistant vibration absorbing hose and method of producing the same

InactiveUS20060011249A1Reduce pressureReduced durabilityFlexible pipesHose connectionsVolumetric Mass DensityEngineering

A high pressure resistant vibration absorbing hose with a bursting pressure of 5 MPa or higher has a hose body and a joint fitting. The joint fitting is to be attached to a swaged portion of the hose body. The hose body has an inner surface rubber layer, a reinforcing layer of high braid or winding density of 50% or more, and an outer surface rubber layer. The swaged portion is designed to have a larger diameter than the main portion of the hose body and the inner surface rubber layer has a wall thickness equal to or larger than 1.0 mm at a swaged portion in a state before the joint fitting is securely swaged thereto. The reinforcing layer has a braid or winding angle θ of a reinforcing wire member equal to or lower than a neutral angle 54.7° and higher than 48°.

Owner:SUMITOMO RIKO CO LTD

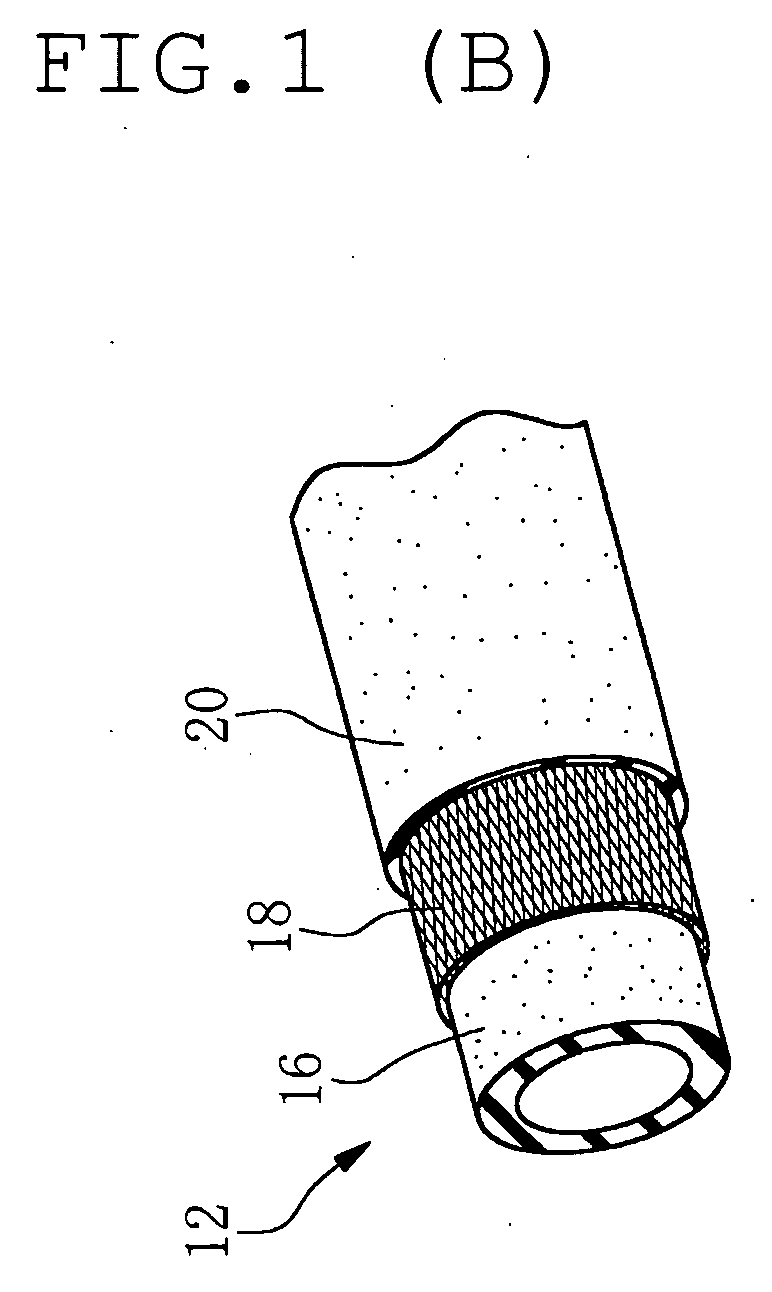

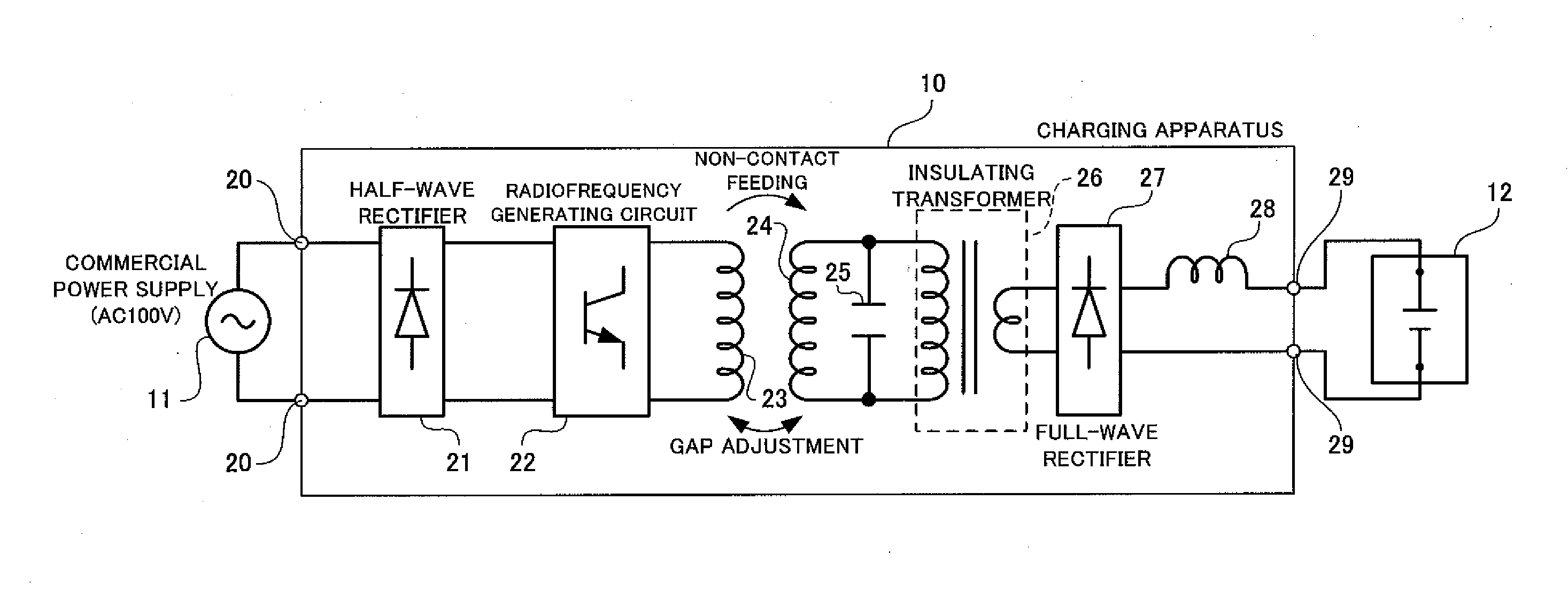

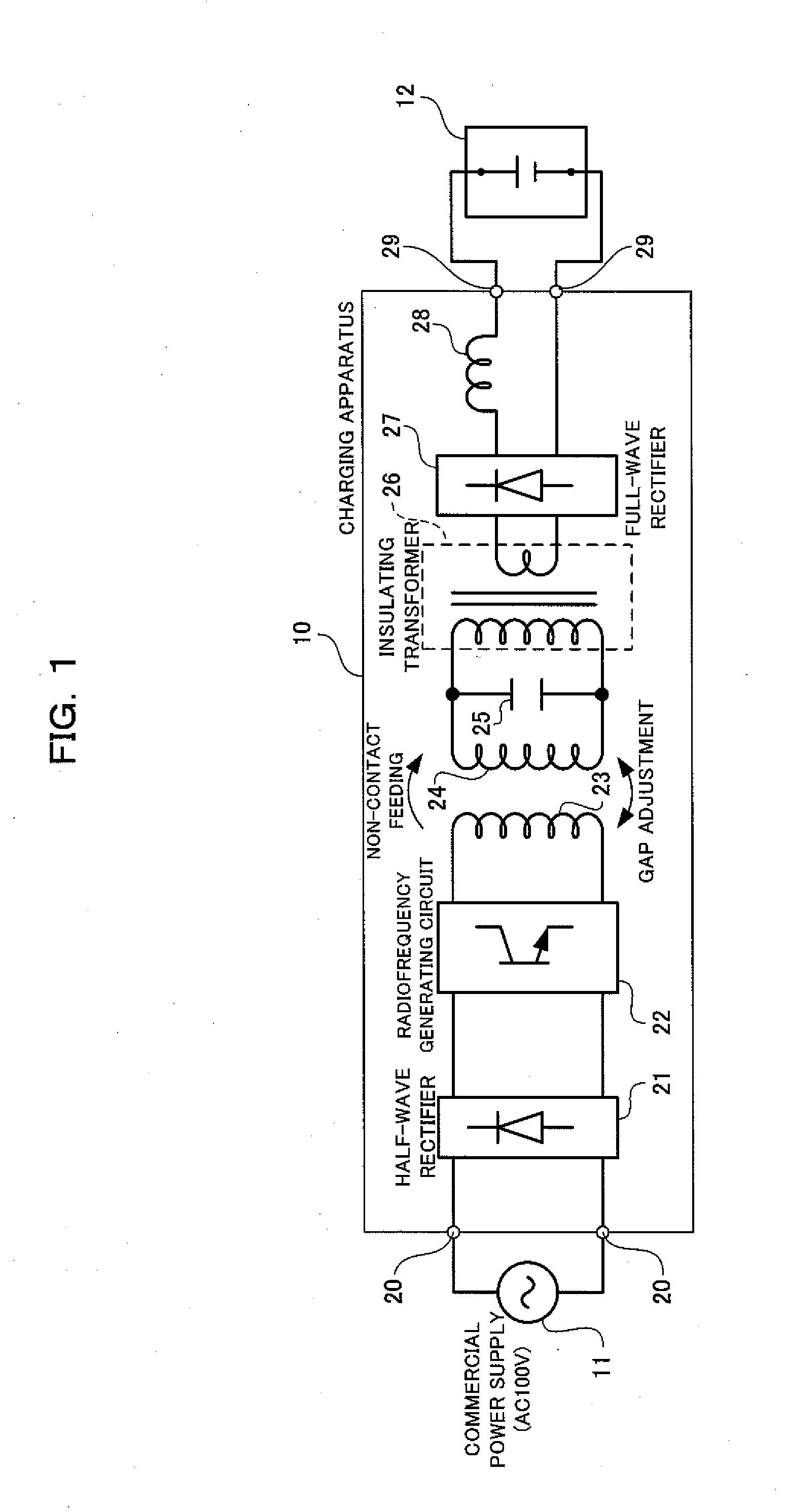

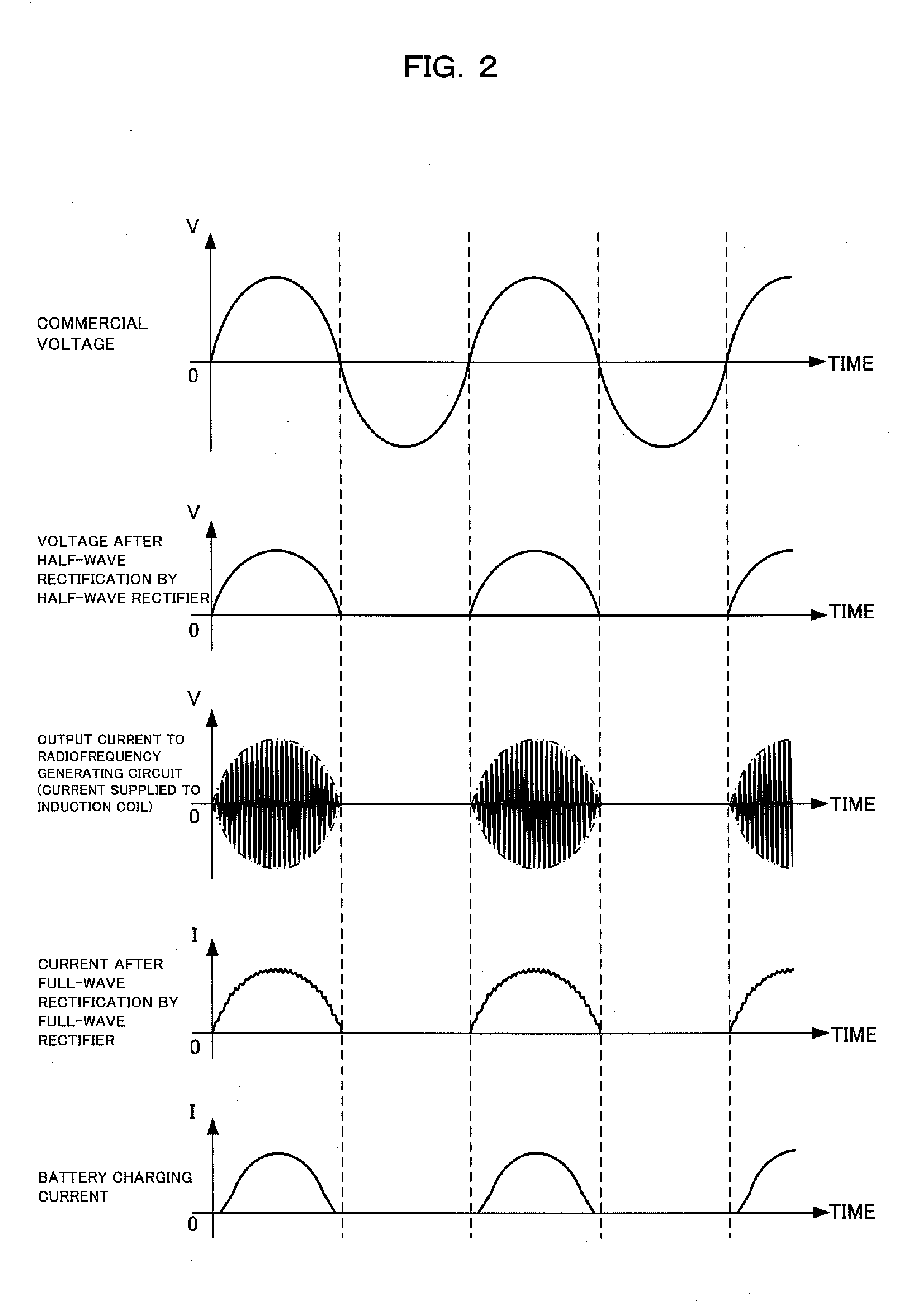

Charging apparatus for lead storage battery

ActiveUS20140028250A1Simple apparatus configurationEasy to adjustBatteries circuit arrangementsEfficient power electronics conversionFull waveElectromotive force

A charging apparatus 10 includes: a half-wave rectifier 21 that half-wave rectifies an alternating current supplied from a commercial power supply 11; a radiofrequency generating circuit 22 that converts the output current of the half-wave rectifier 21 to a radiofrequency current with a predetermined frequency and outputs the radiofrequency current; an induction coil 23 that is fed with the radiofrequency current from the radiofrequency generating circuit 22; a power receiving coil 24 that receives an electromotive force induced by a magnetic flux produced on the induction coil 23; a resonant capacitor 25 that is connected in parallel with the power receiving coil 24 and forms a resonant circuit with the power receiving coil 24 at the predetermined frequency; and a full-wave rectifier 27 that full-wave rectifies the output current of the parallel resonant circuit and supplies the current to a lead storage battery 12.

Owner:DAIFUKU CO LTD

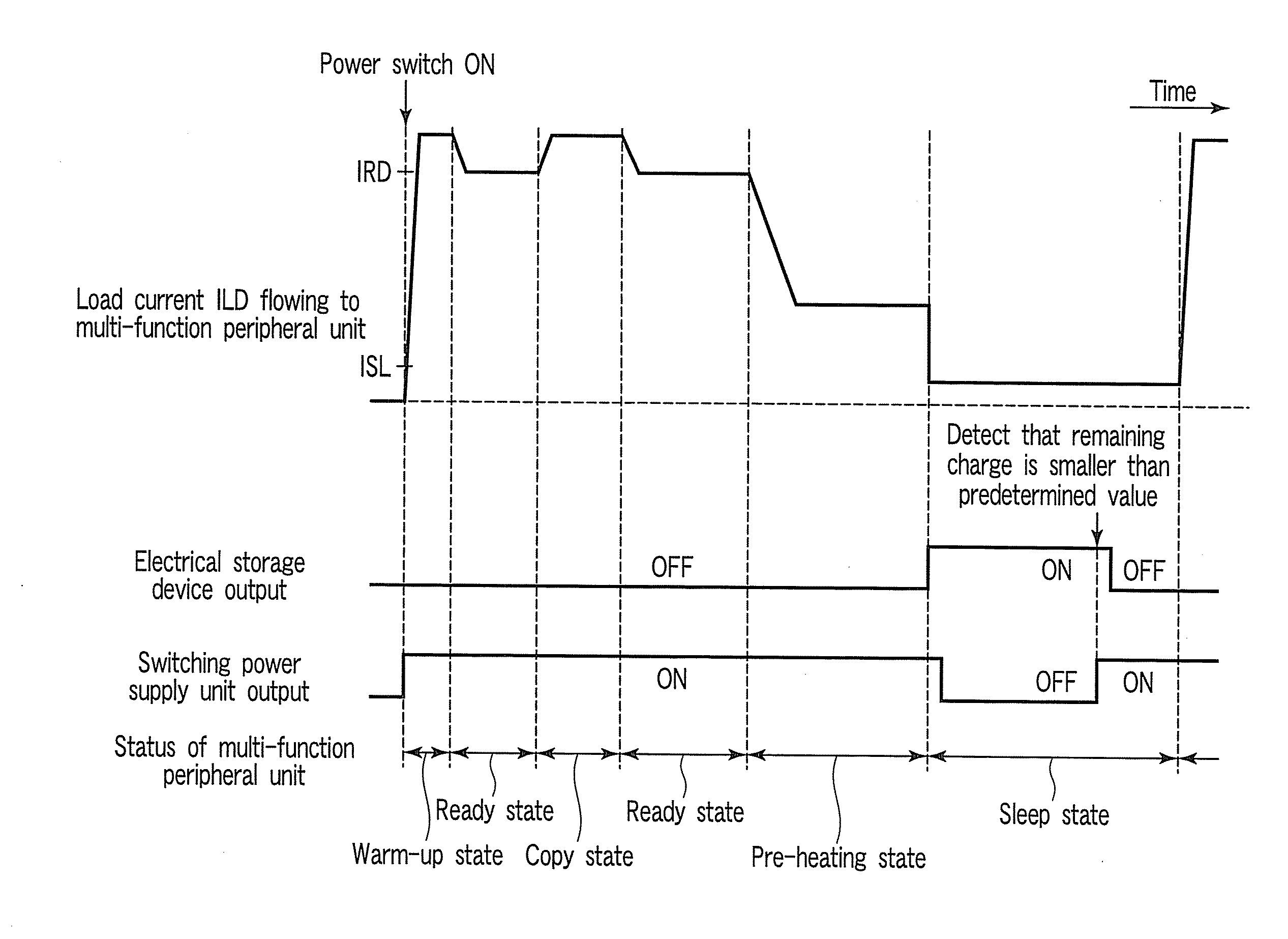

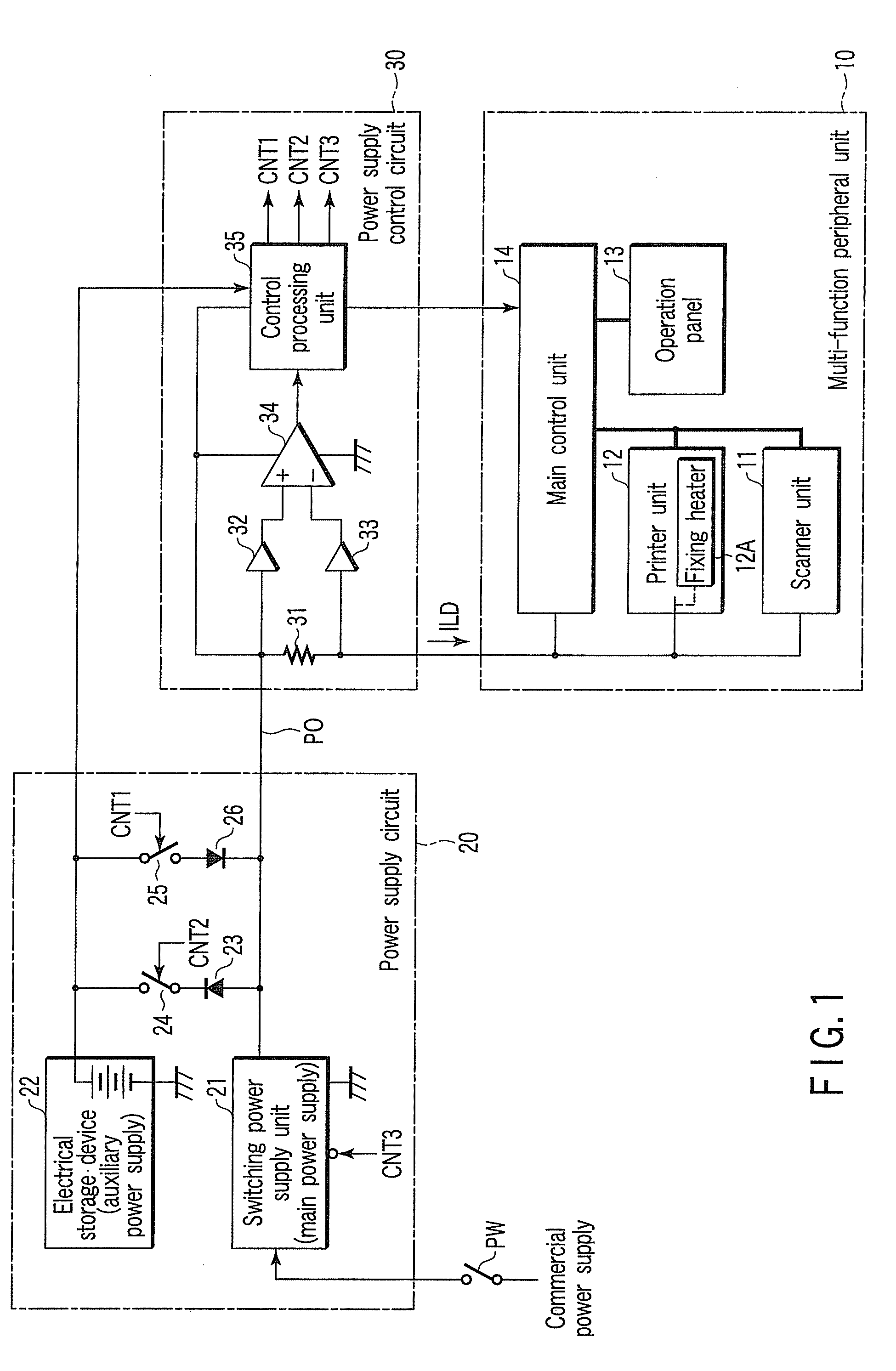

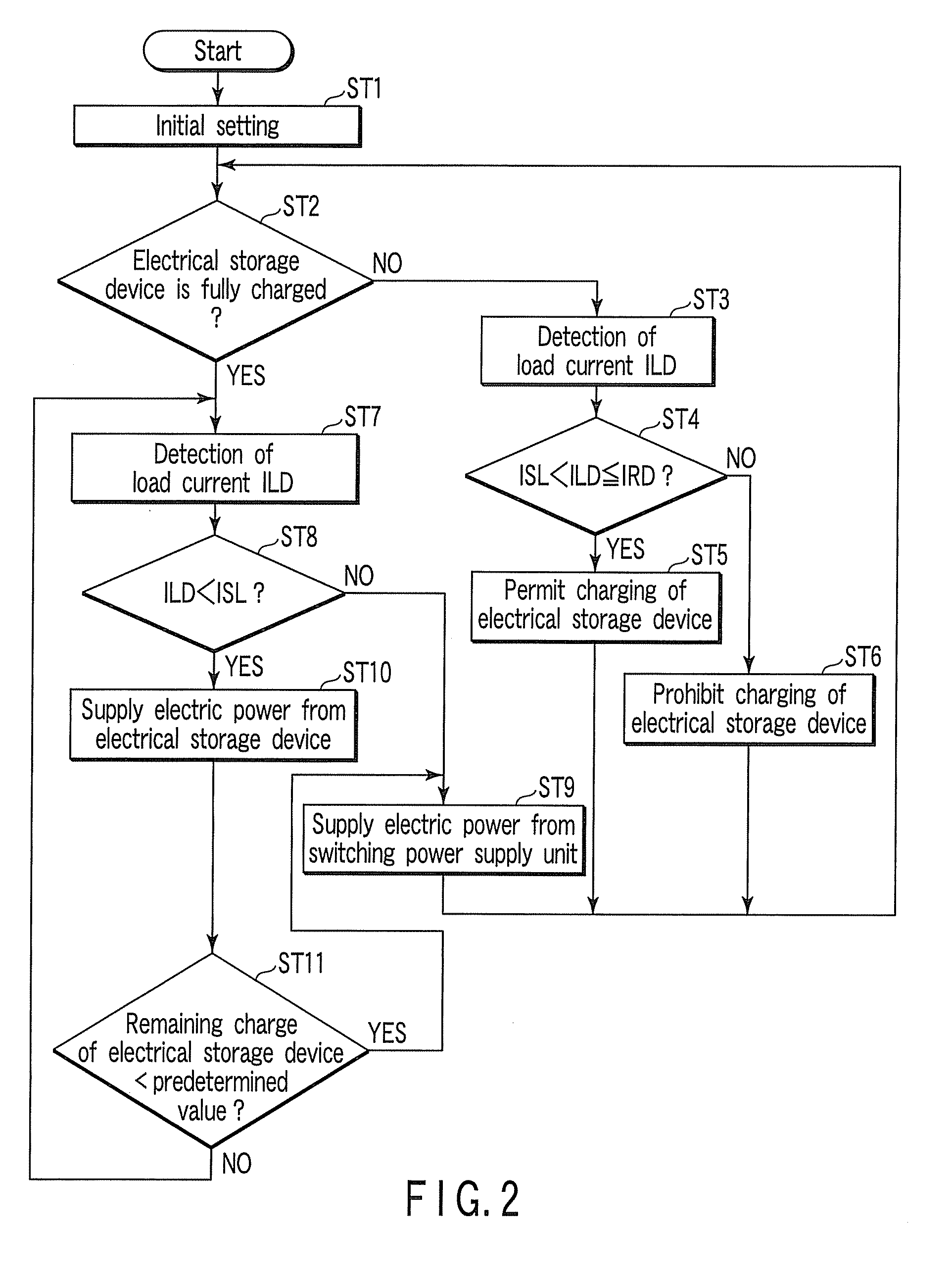

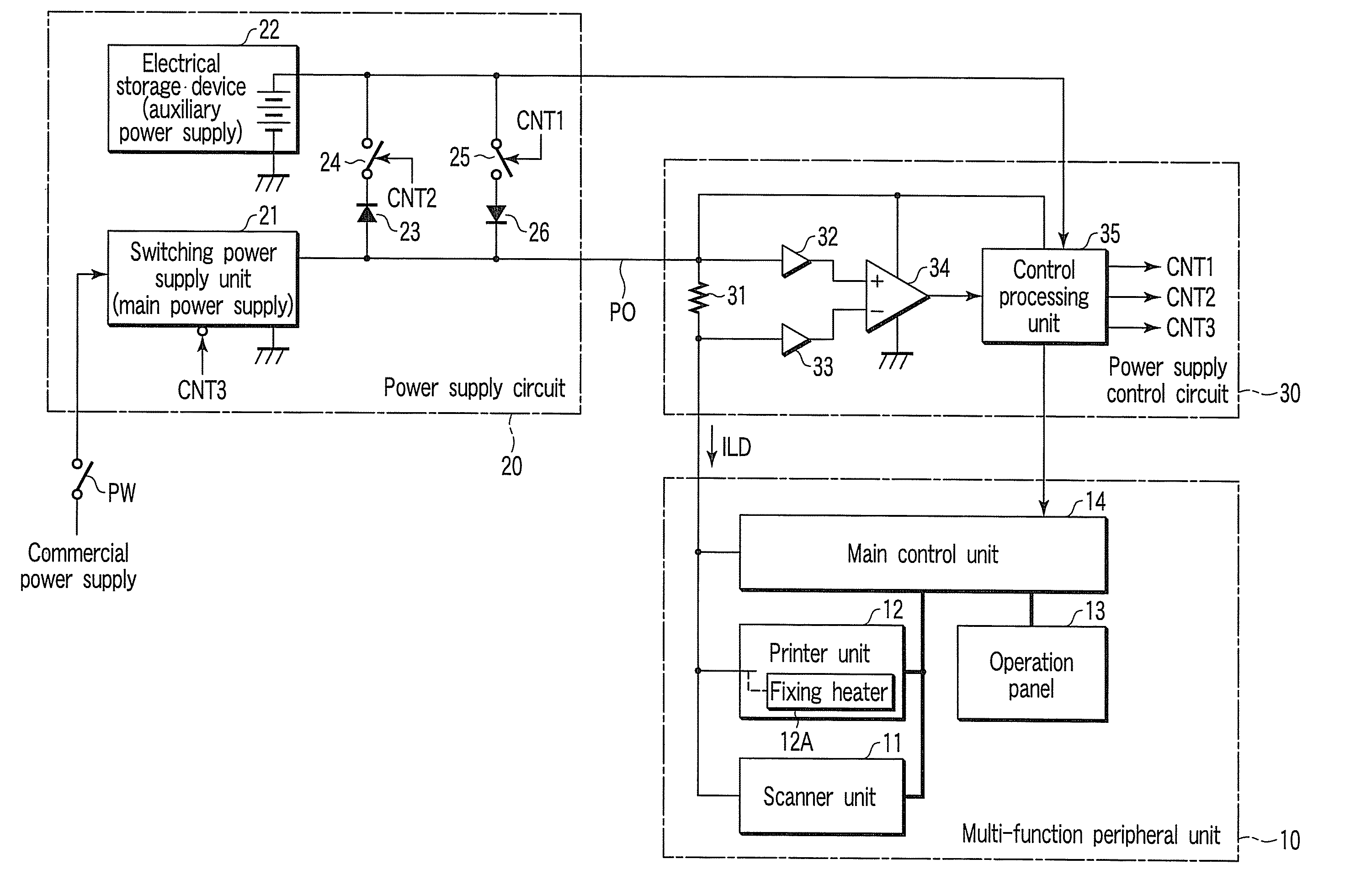

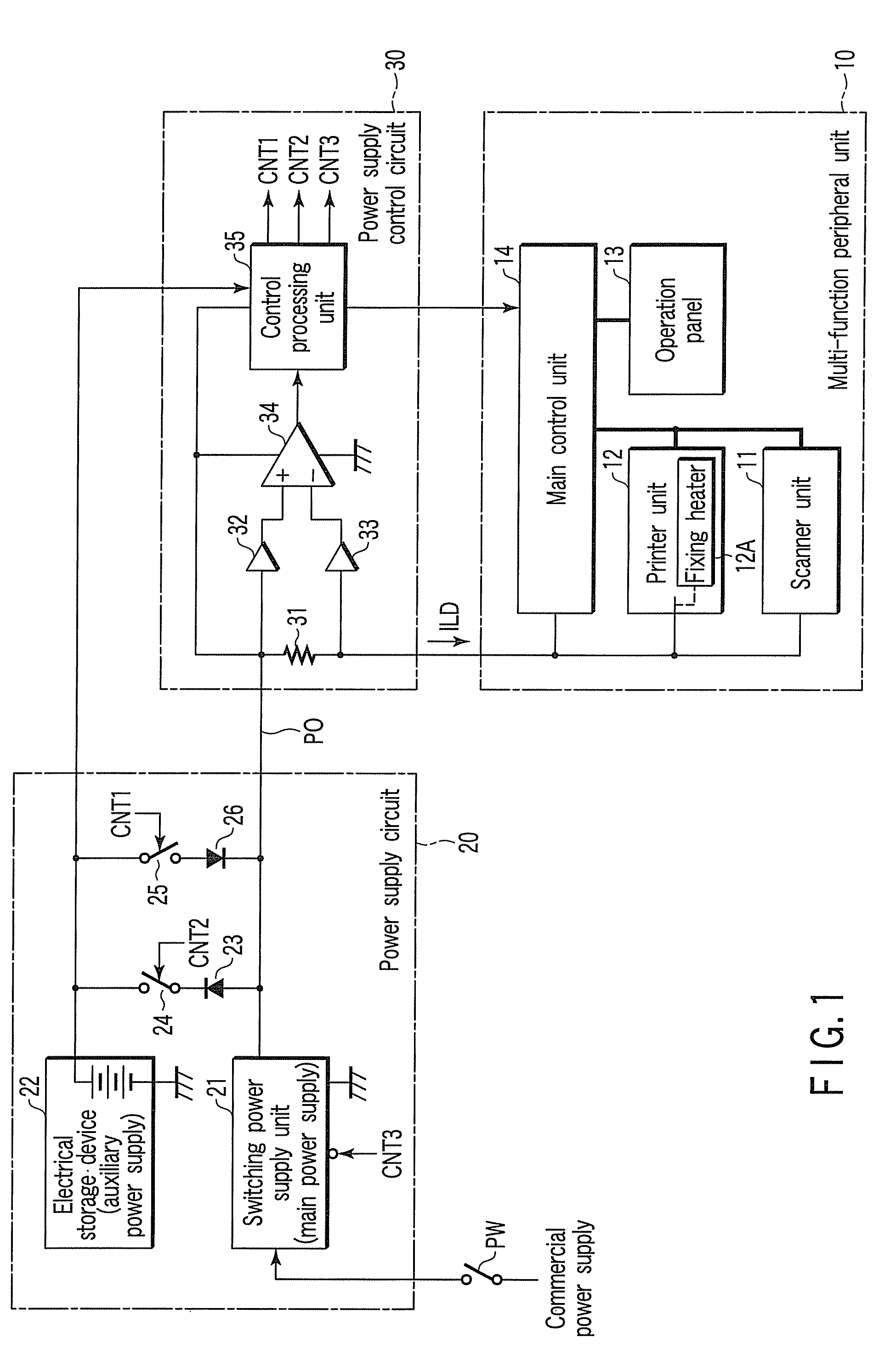

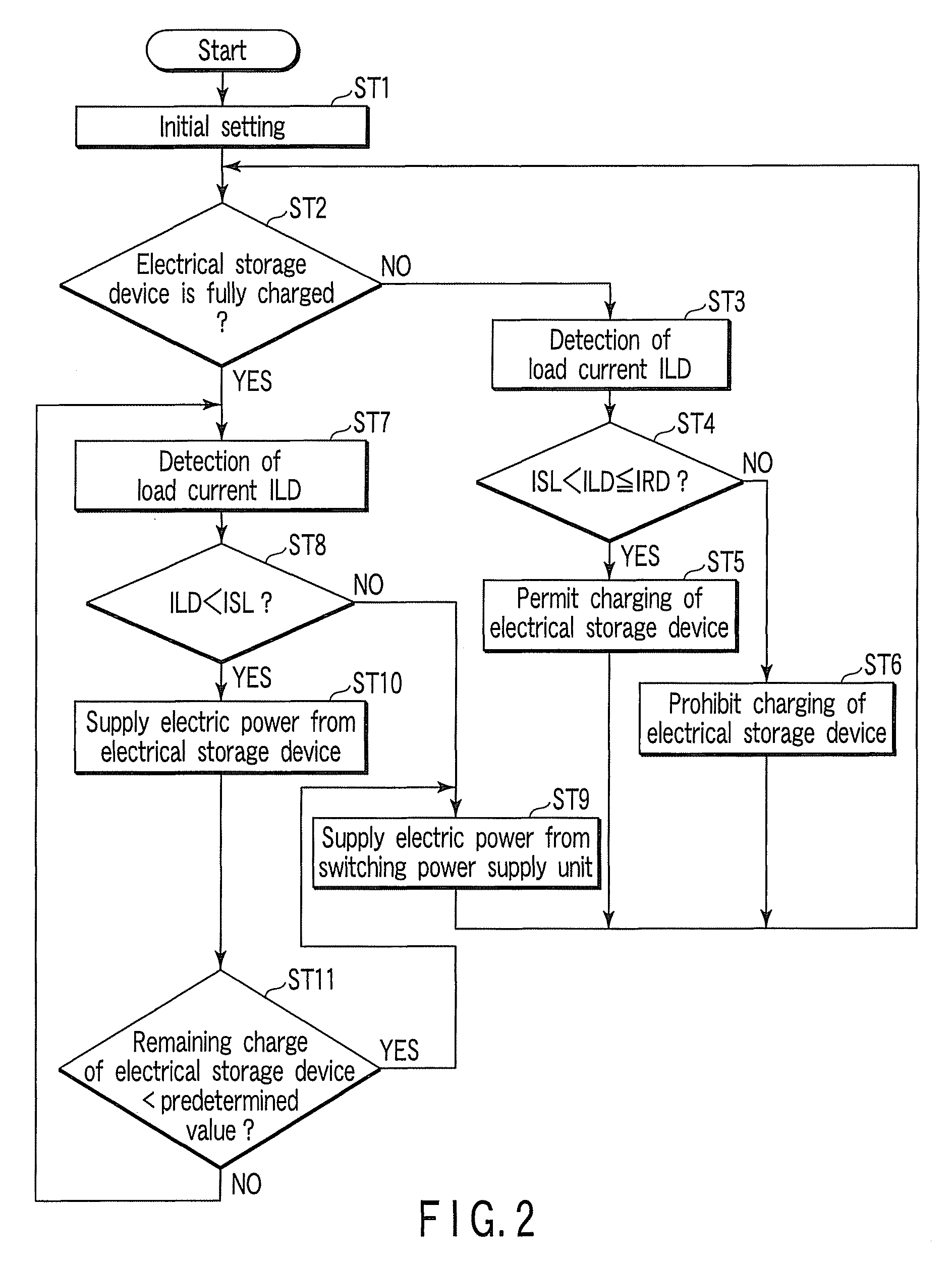

Multi-function peripheral, power supply apparatus, and power supply control method

ActiveUS20090094469A1Reduce wasteful power consumptionPower efficiency fallVolume/mass flow measurementPower supply for data processingPeripheralElectricity

A digital multi-function peripheral includes a multi-function peripheral unit that has plural functions, a switching power supply unit connected to a commercial power supply as a main power supply for the multi-function peripheral unit, and an electrical storage device charged in advance as an auxiliary power supply for the multi-function peripheral unit. The digital multi-function peripheral further includes a control circuit that monitors a load current flowing to the multi-function peripheral unit, supplies electric power from the electrical storage device to the multi-function peripheral unit instead of electric power from the switching power supply unit when the load current is smaller than a threshold set as an allowable lower limit of power efficiency of the switching power supply unit, and supplies the electric power from the switching power supply unit to the multi-function peripheral unit when the load current increases to be equal to or larger than the threshold.

Owner:KK TOSHIBA +1

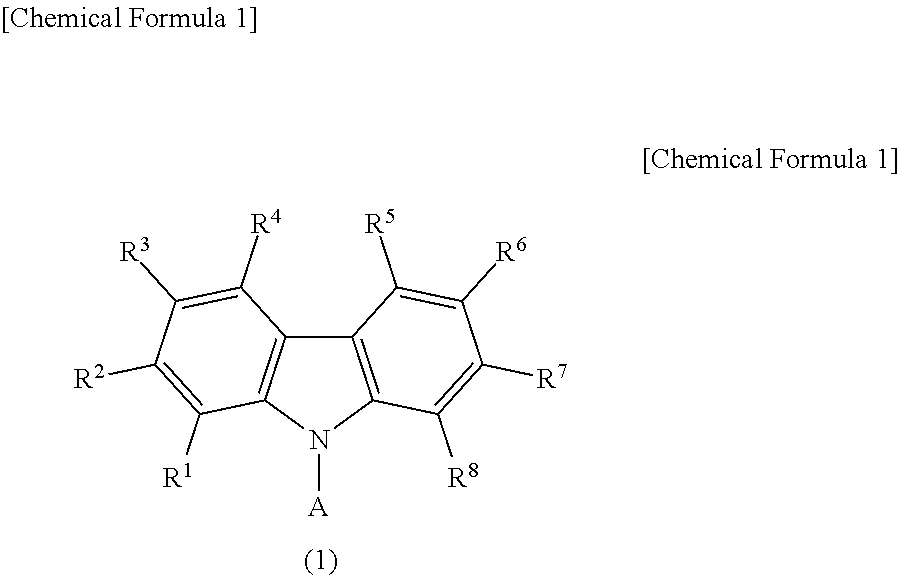

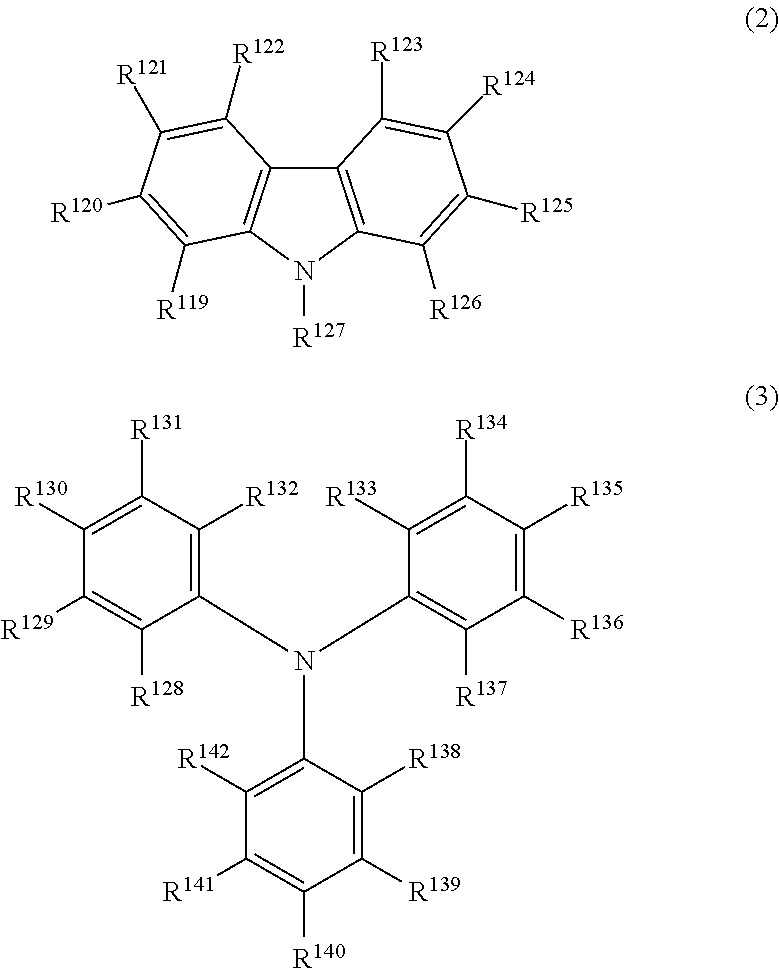

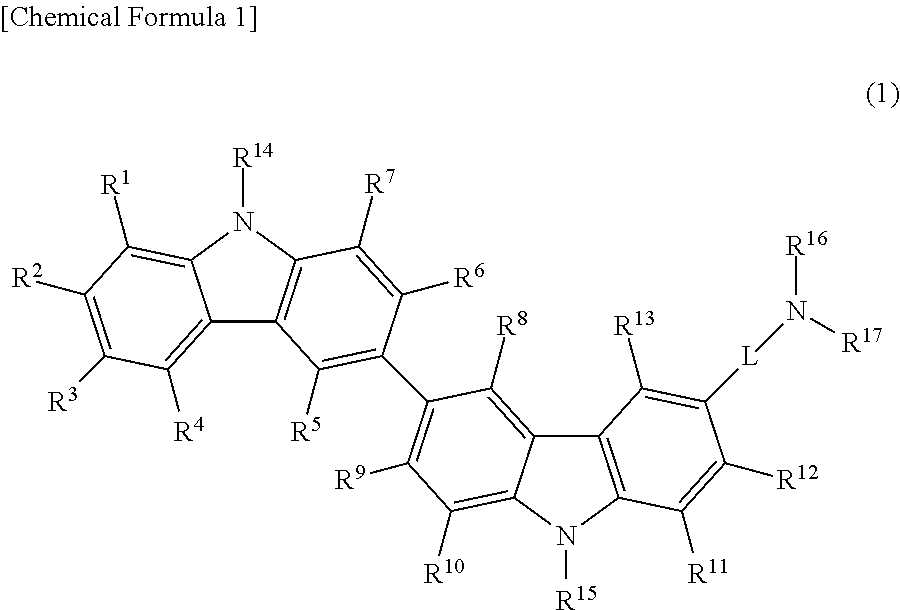

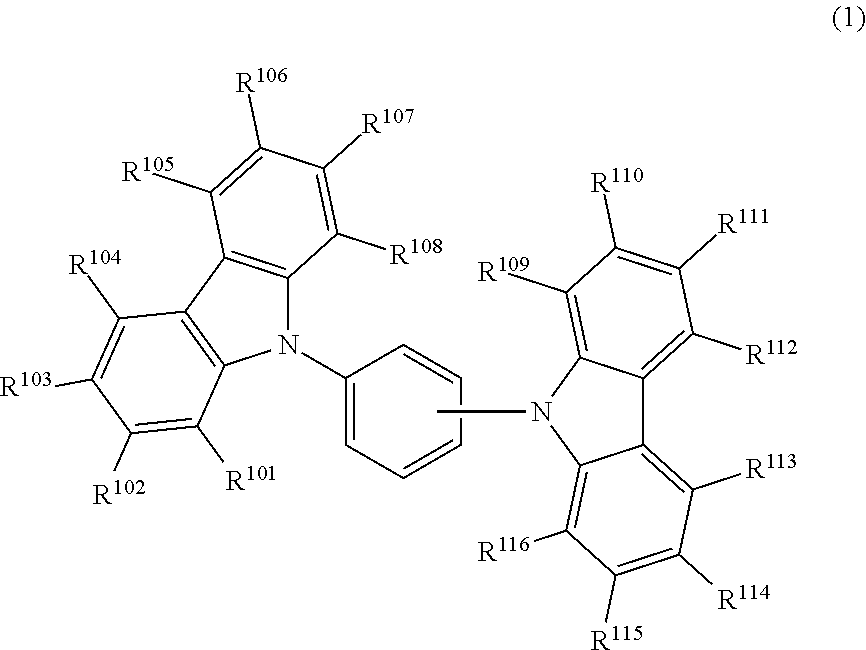

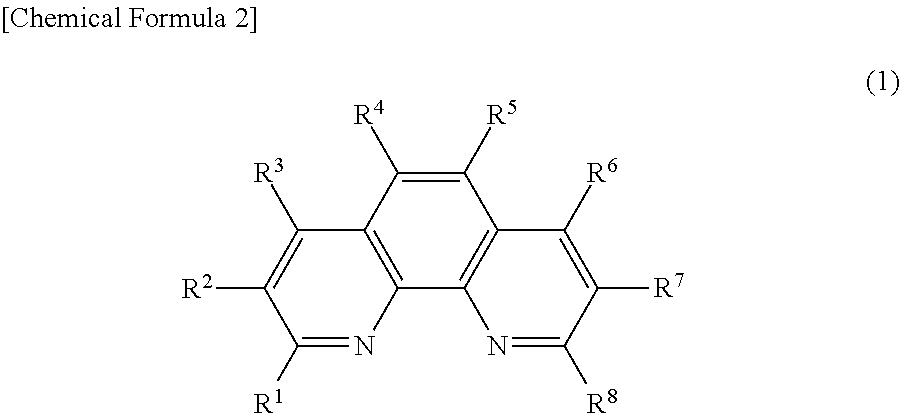

Light emitting device material and light emitting device

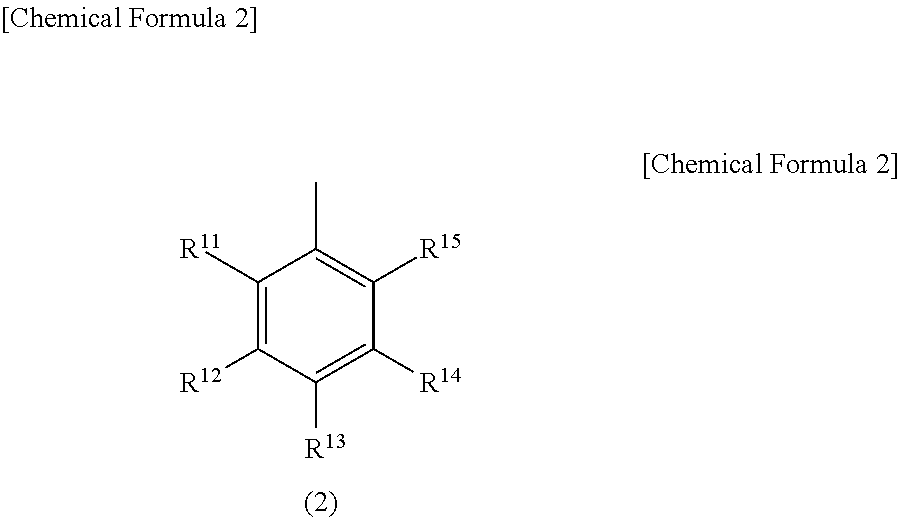

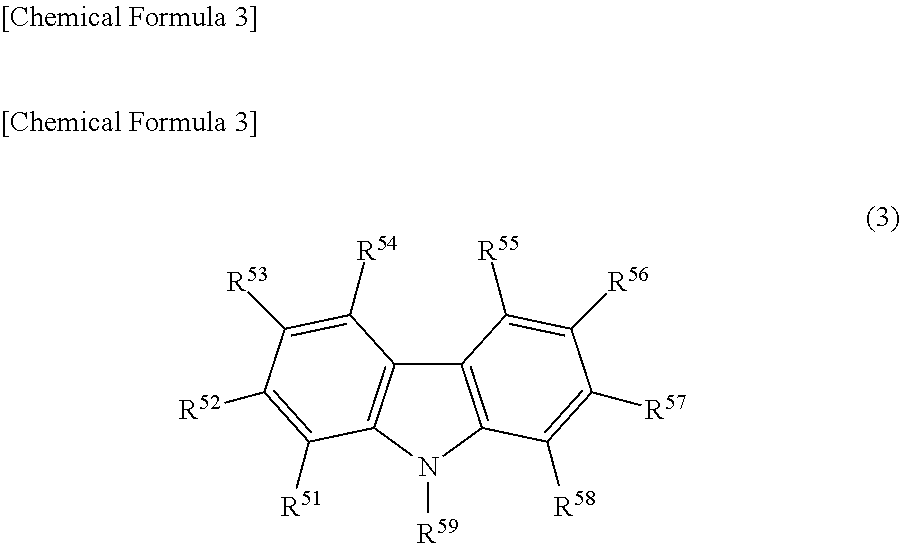

ActiveUS9391288B2Improve efficiencySufficient durable lifeOrganic chemistryElectroluminescent light sourcesCarbazoleDevice material

The present invention provides an organic thin-film light emitting device having both high luminance efficiency and durability due to the use of a light emitting device material containing a compound having a specific carbazole skeleton.

Owner:TORAY IND INC

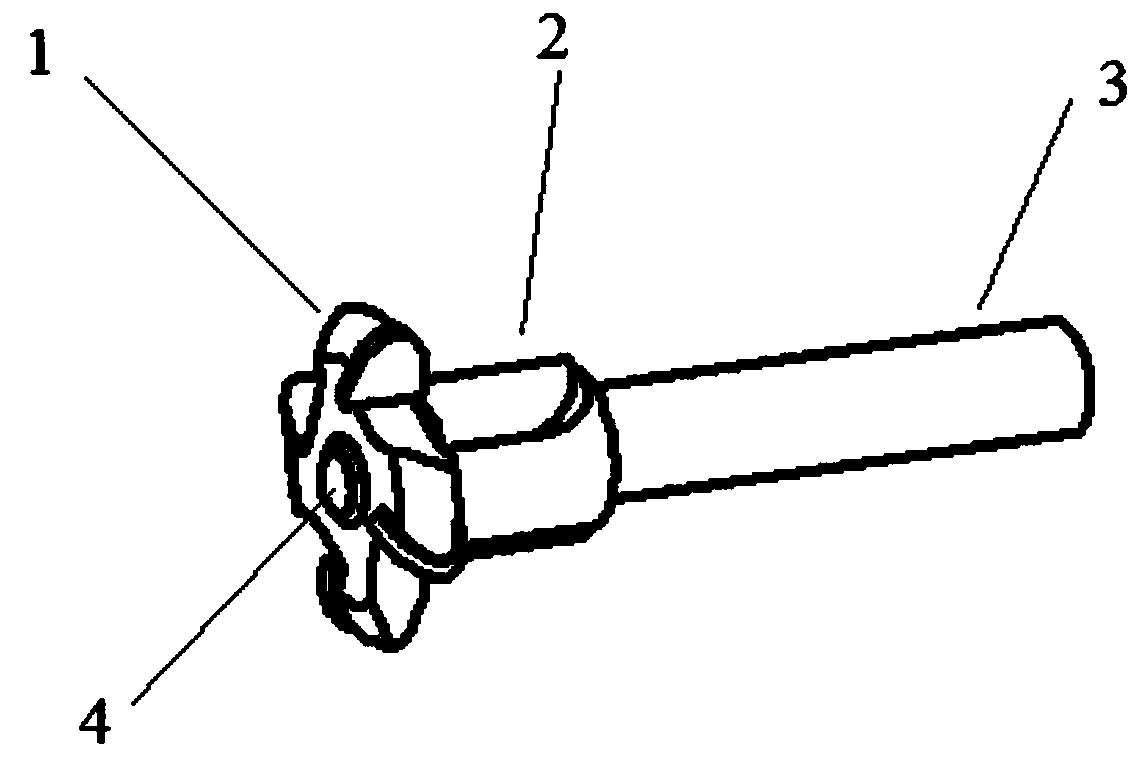

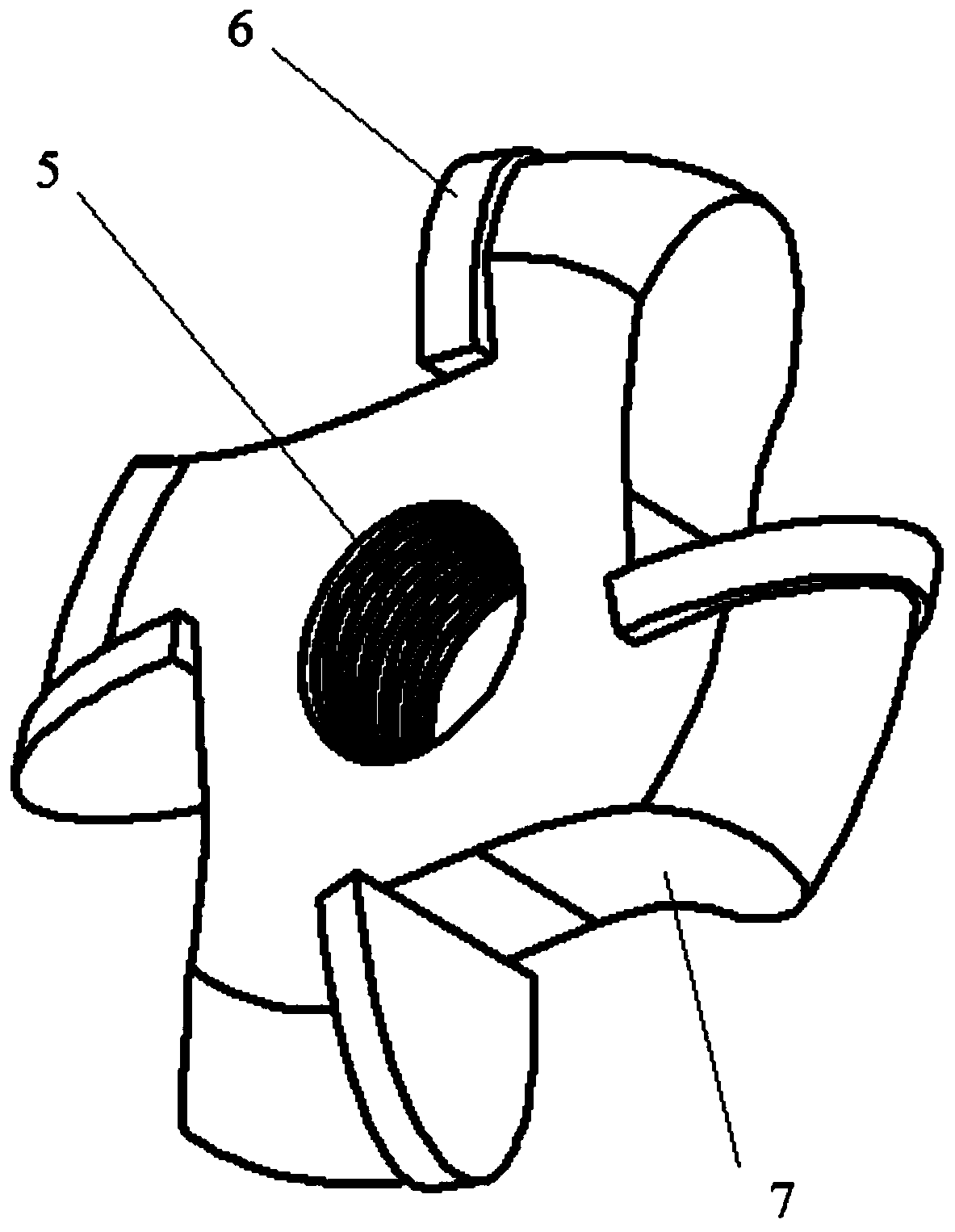

Novel tapping cutter

The invention discloses a novel tapping cutter. The novel tapping cutter comprises a cutter handle, a straight-groove milling cutter body and an oval-groove milling cutter body; one end of the straight-groove milling cutter body is integrally connected with the cutter handle, and the other end of the straight-groove milling cutter body is integrally provided with an external thread for being connected with an internal thread of the oval-groove milling cutter body; the outer diameter of the oval-groove milling cutter body is larger than that of the straight-groove milling cutter body, and the front end face of the oval-groove milling cutter body directly acts on the surface of a rubber tree trunk. The combined cutter formed by combining the two milling cutter bodies has a special shape, sothat a required guide groove is cut out to make rubber liquid flow down along the guide groove, collection is facilitated, and waste is not caused; the cutting speed of the cutter is high and stable,and the situation that saw dust residues exist in the groove and contaminate the rubber liquid can be avoided; the overall service life of the milling cutter bodies is longer than that of existing handheld tapping cutter blades, and the milling cutter bodies are more durable; limiting balls are installed at the front ends of the milling cutter bodies to limit the depth, entering the tree trunk, ofthe milling cutter bodies.

Owner:自走科技(北京)有限公司

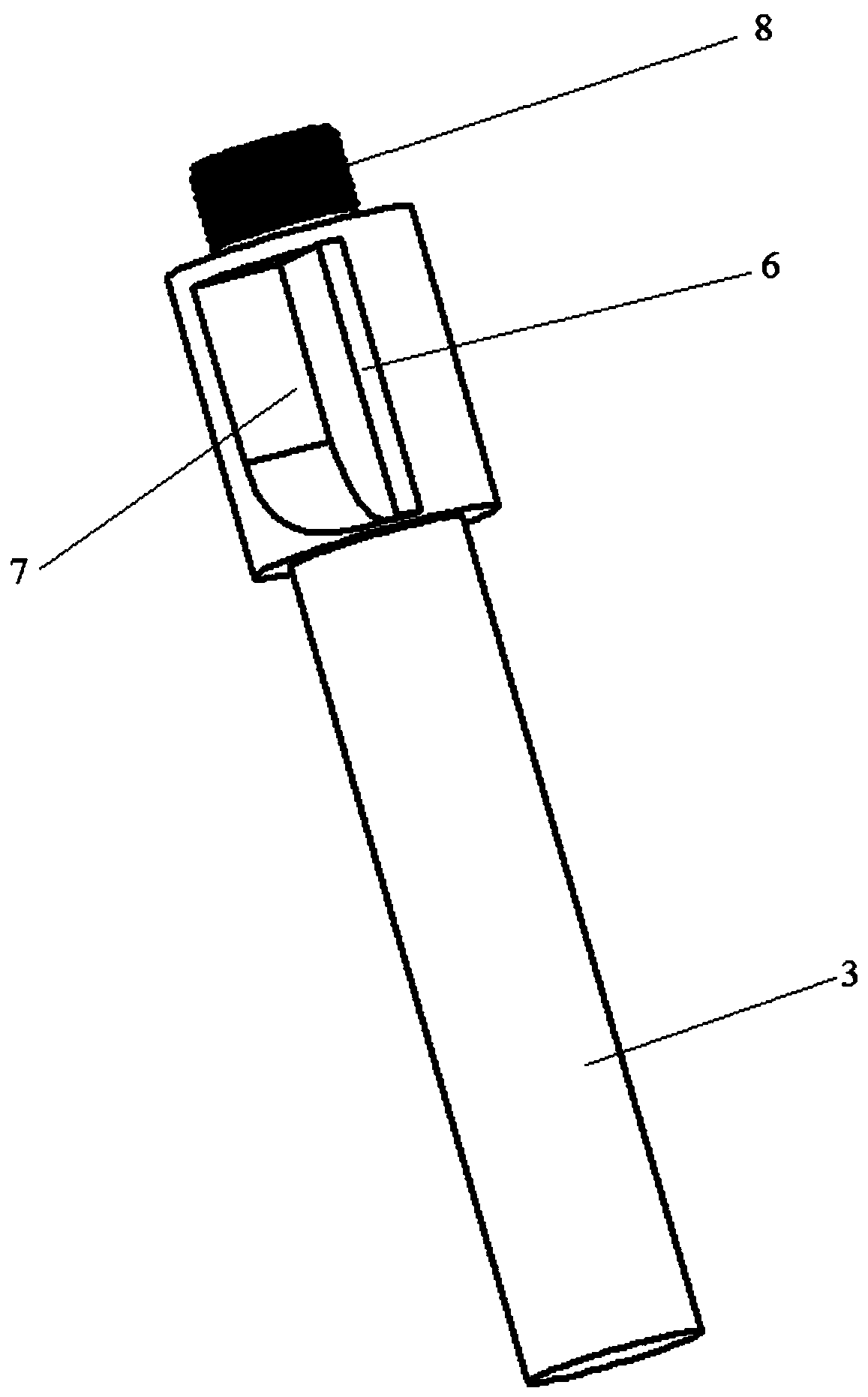

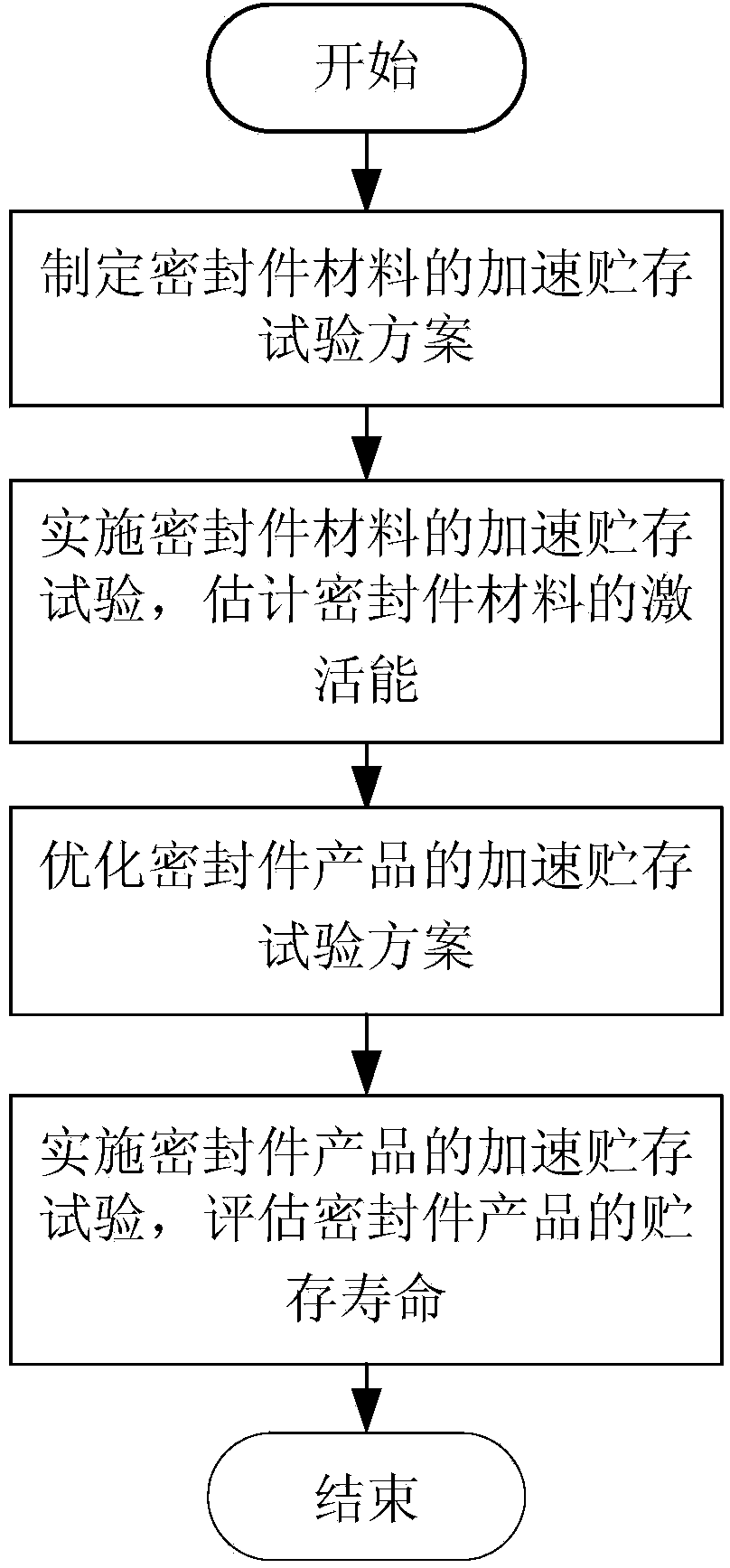

Accelerated-storage test method for on-missile sealing pieces

InactiveCN104182635ARealisticReliable lifeSpecial data processing applicationsActivation energyIndustrial engineering

The invention discloses an accelerated-storage test method for on-missile sealing pieces. The accelerated-storage test method includes the steps of 1), making an accelerated-storage test plan for sealing piece materials, implementing the accelerated-storage test for the sealing piece materials, and evaluating activation energy of the sealing piece materials; 2), optimizing the accelerated-storage test plane for sealing piece products, implementing the accelerated-storage test for the sealing piece products, and evaluating storage life of the sealing piece products. In the method, the test is divided into to steps, namely the accelerated-storage test of the materials and the accelerated-storage test of the products, so that shortcomings of high risk and inaccurate evaluation of accelerated-storage test of the products can be directly reduced. Data statistics of the accelerated-storage tests for the on-missile sealing pieces are performed, matching of the performance degradation process of the sealing pieces is performed by the adoption of multiple models, and the models with the highest matching accuracy are selected to be calculated, so that the material activation energy obtained can be more conforms to actual products.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

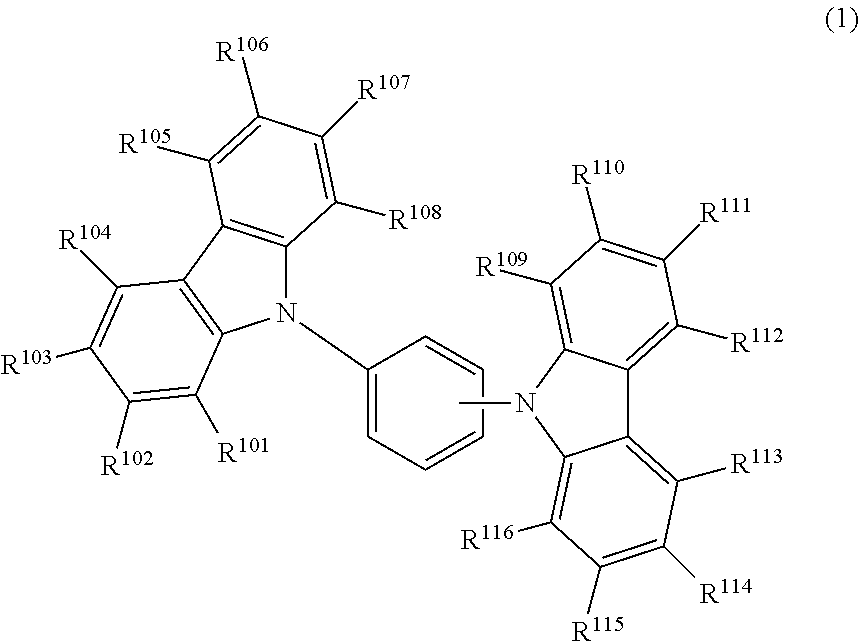

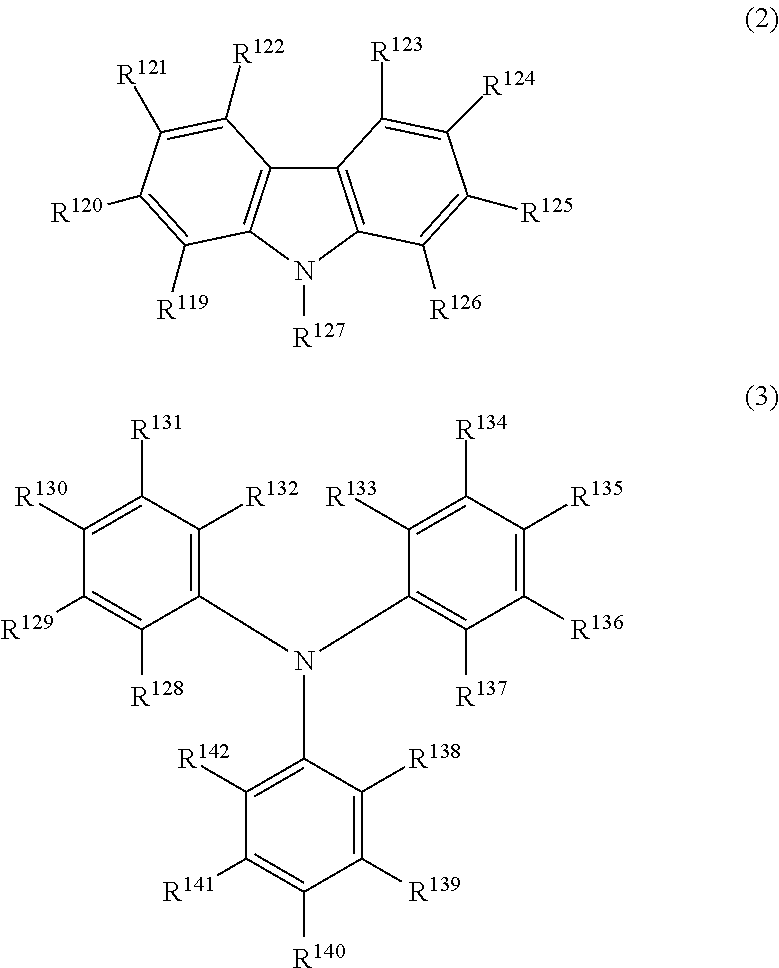

Light emitting device material and light emitting device

ActiveUS9537107B2Improve efficiencyReliable lifeOrganic chemistrySolid-state devicesDevice materialLight-emitting diode

Provided are a light emitting device material which contains a compound having a carbazole skeleton of a specific structure and which makes it possible to achieve a light emitting device having both high luminance efficiency and durability; and a light emitting device using the light emitting device material.

Owner:TORAY IND INC

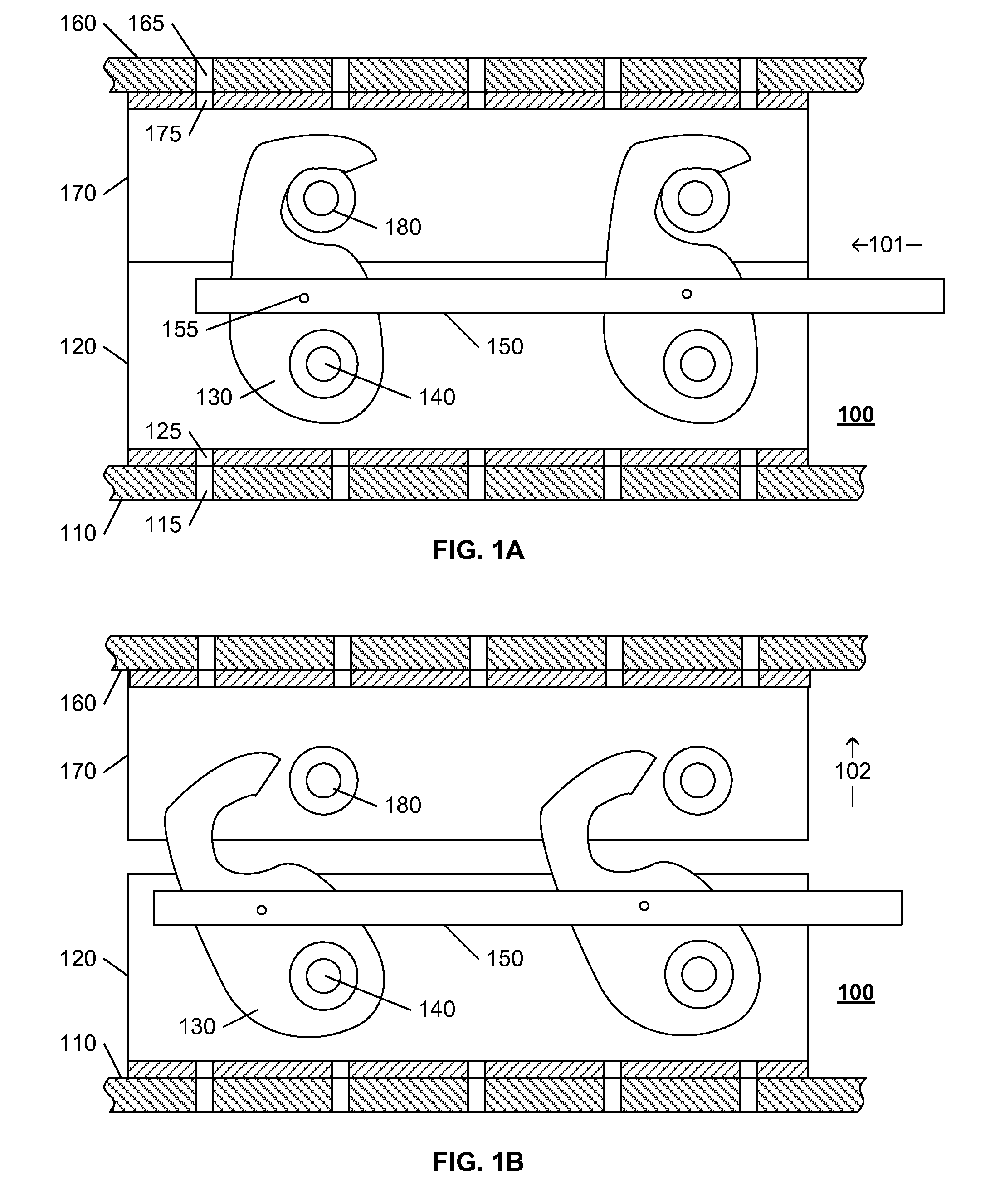

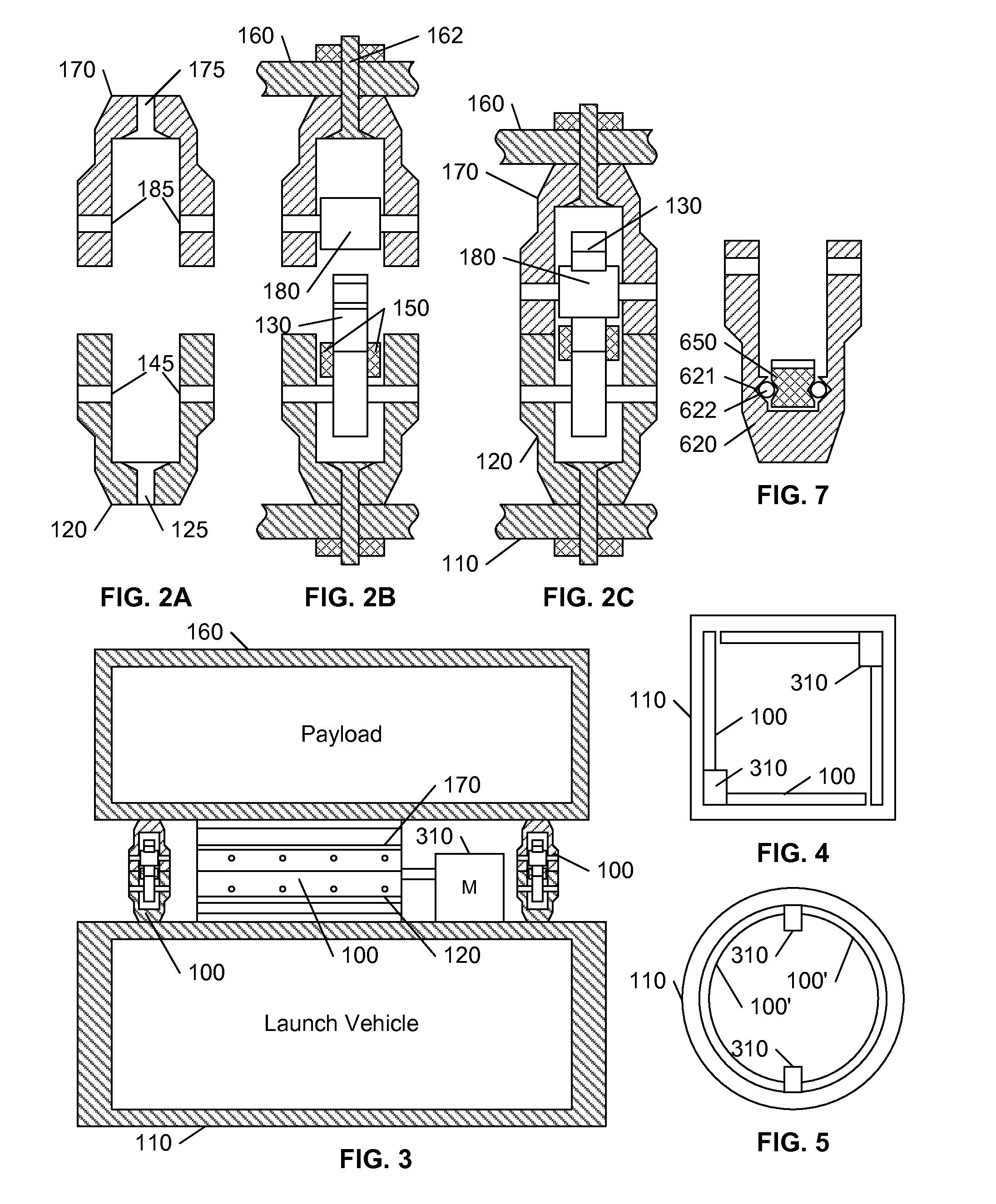

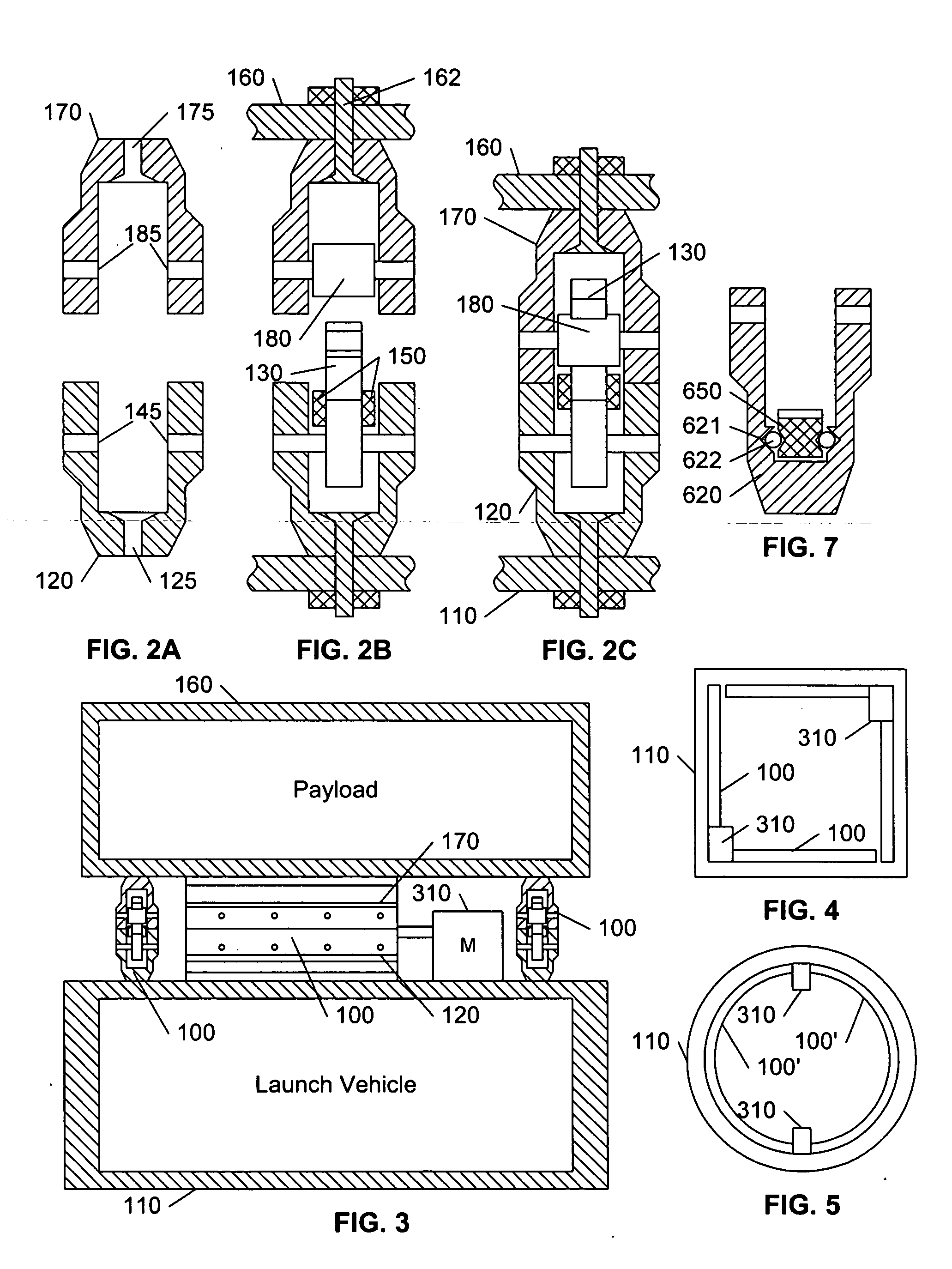

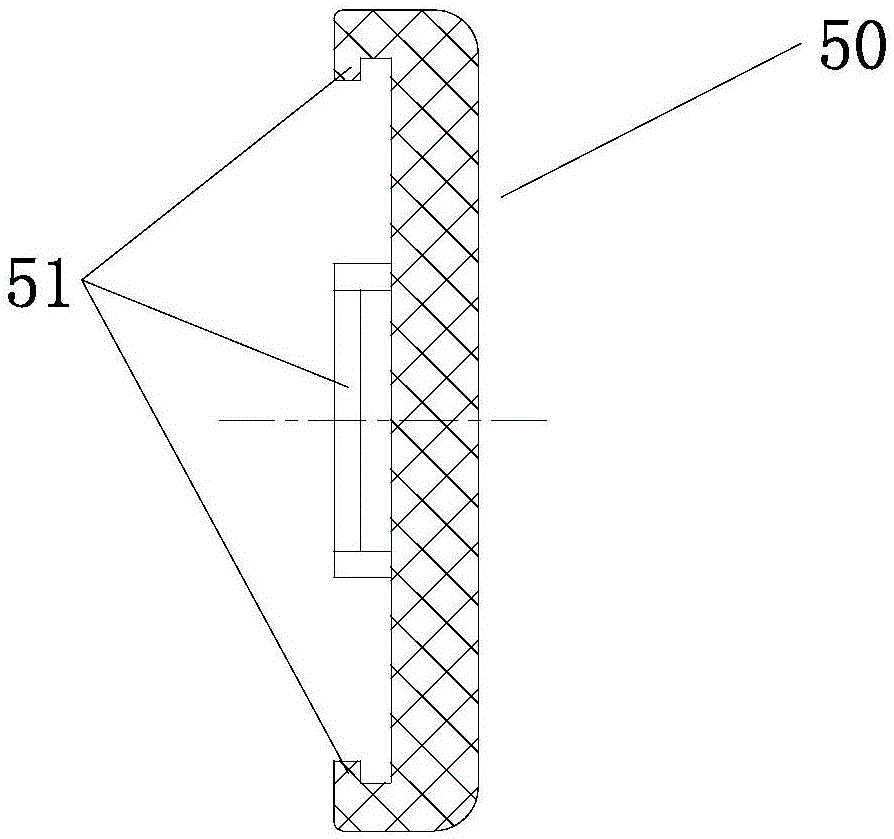

Latching separation system

InactiveUS20100090066A1Reliably and easily unfasteningRapidly fastening itemFuselage framesCosmonautic vehiclesStable stateControl system

Latching elements on a first structure are configured to securely engage corresponding bearings on a second structure, via a lateral member that drives all of the latching elements simultaneously. When engaged, or when disengaged, the system is in a stable state, requiring no active force by the controlling system to maintain the system in each state. Preferably, each latching element is coupled to the lateral member via a pinion that provides a mechanical advantage that substantially reduces the force required on the lateral member to effect the coupling or decoupling. Also preferably, the elements are formed from extruded aluminum forms, thereby providing for a relatively inexpensive and lightweight configuration that is particularly well suited for spacecraft applications.

Owner:PLANETARY SYST CORP

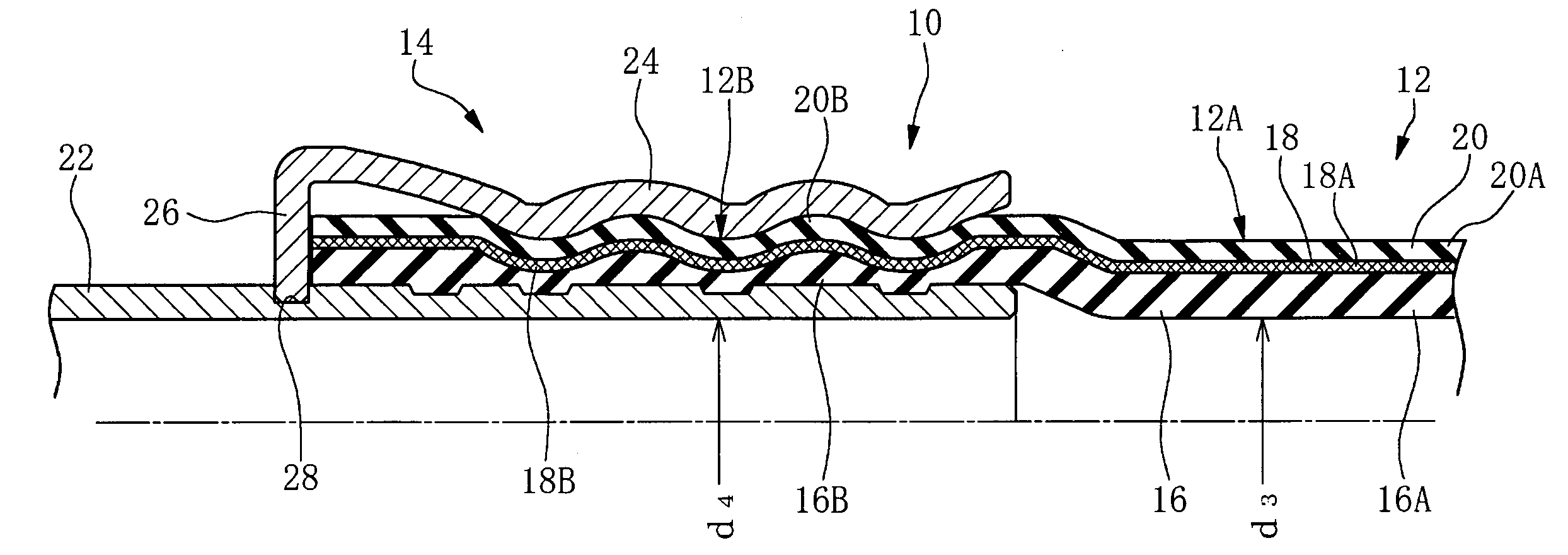

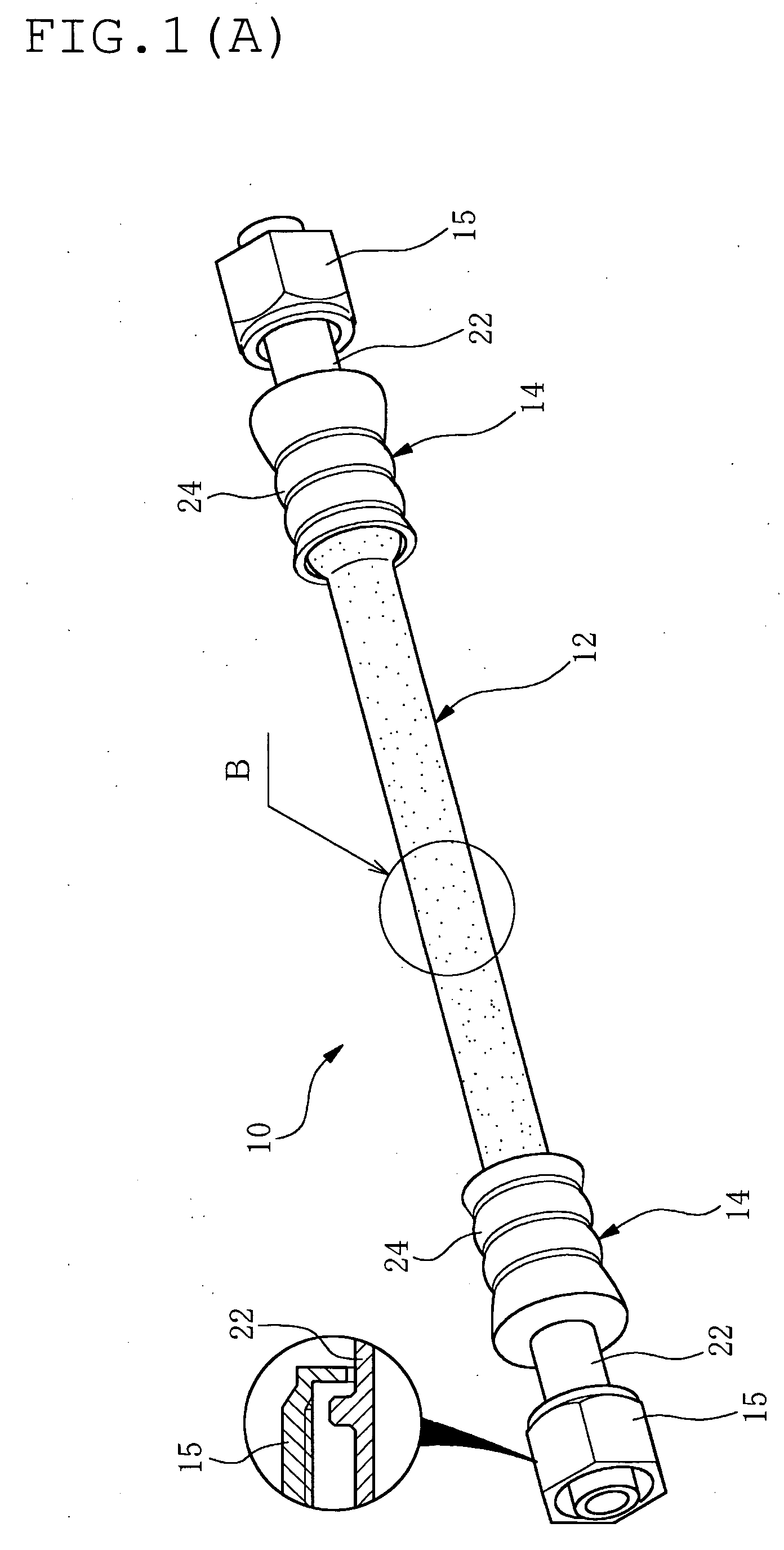

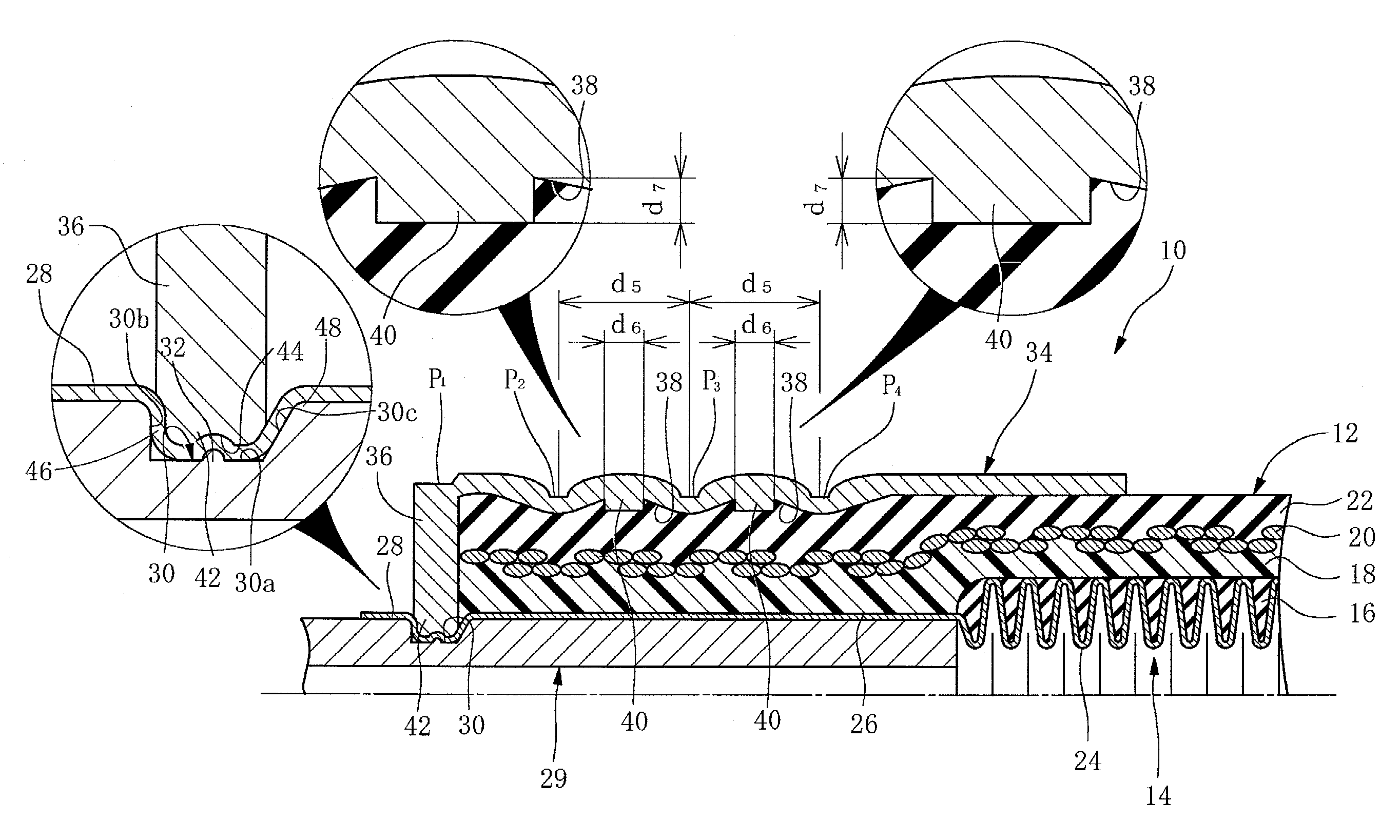

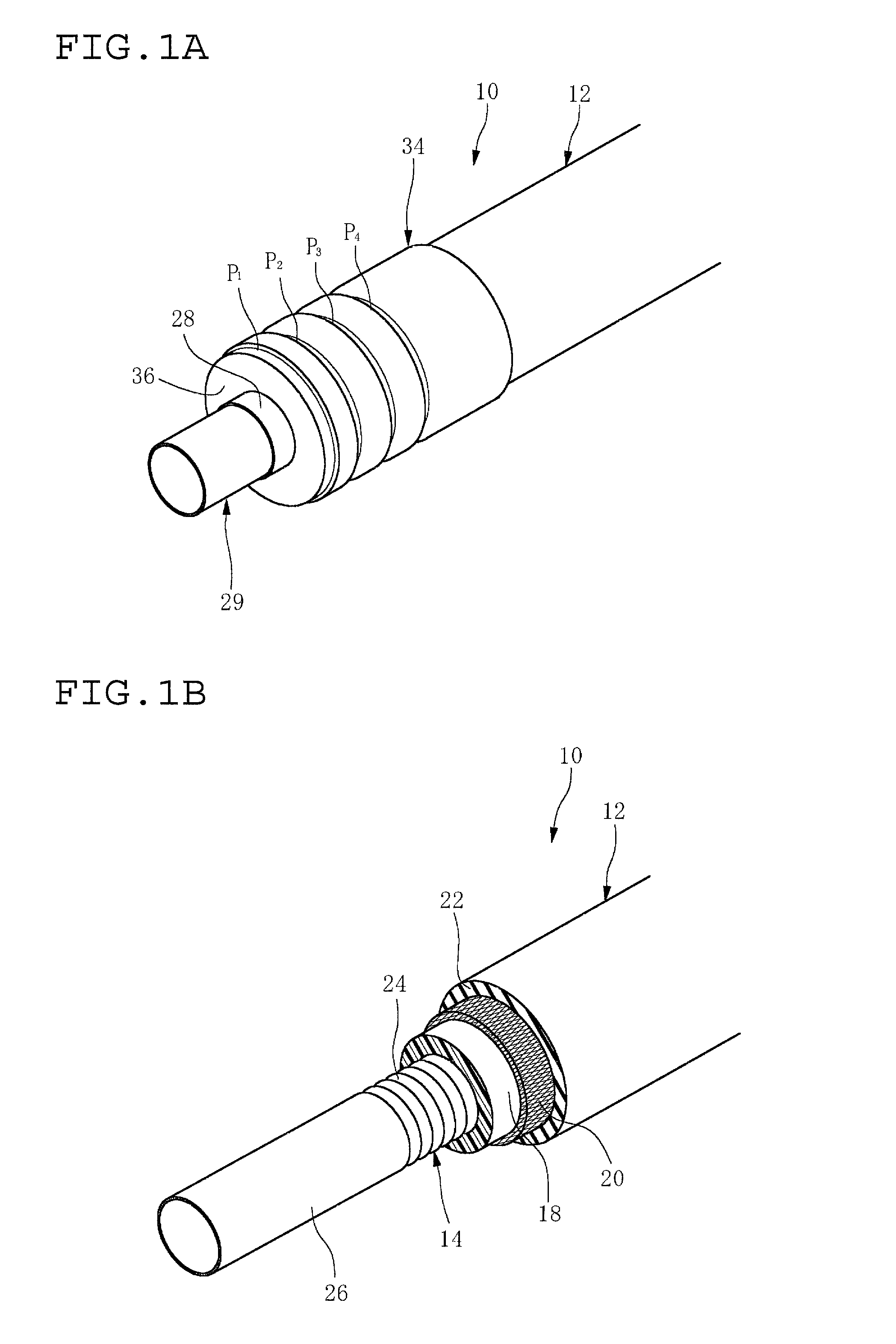

Composite hose with corrugated metal tube

InactiveUS7717138B2Avoid fracturesProlong lifeFlexible pipesHose connectionsMechanical engineeringMetal

A composite hose with a corrugated metal tube has a hose body having a corrugated metal tube and an outer layer. The corrugated metal tube includes a non-corrugated straight-walled portion on an end portion thereof, and a rigid insert pipe is inserted in the straight-walled portion. A socket fitting is fitted on the hose body by being swaged thereon radially inwardly, and an inner circumferential end portion of the collar portion and an outer circumferential surface of the insert pipe compress an extending portion of the straight-walled portion to fix the straight-walled portion onto the insert pipe and provide a seal between the outer circumferential surface of the insert pipe and an inner circumferential surface of the straight-walled portion. A fracture preventing mechanism is provided on a hose end portion for preventing fracture of the straight-walled portion.

Owner:SUMITOMO RIKO CO LTD

Magnetism keeping relay with the bar

InactiveCN101017740AImprove breaking capacityExtend your lifeElectric switchesElectromagnetic relay detailsGratingEngineering

The related magnetic latching relay with grating sheet comprises: a body; on the body, a moving and fixed contact head, an electromagnetic drive mechanism with permanent magnet to conduct or separate two contact heads. Wherein, some iron grating sheets are set between contact heads along running direction of the moving contact head. This invention generates cathode effect to accelerate arc-extinguishing, and improves performance of the relay.

Owner:FUZHOU UNIV

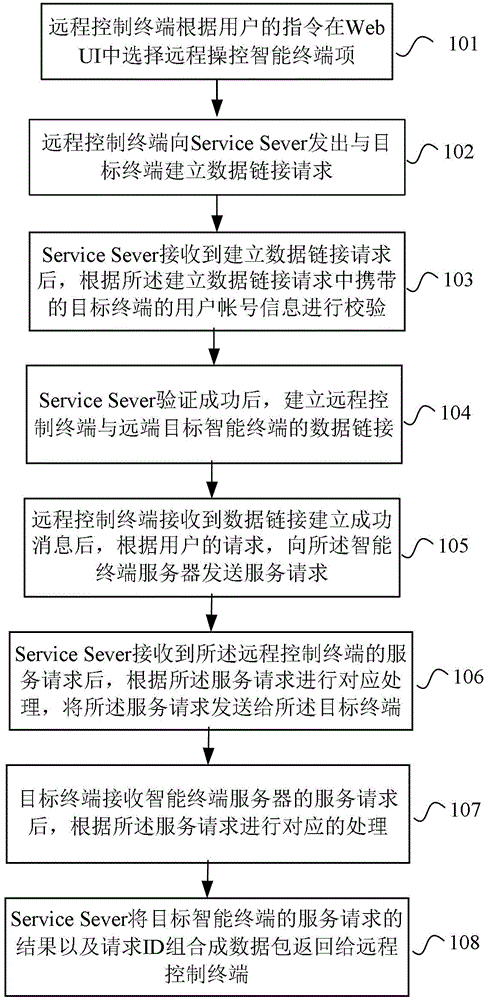

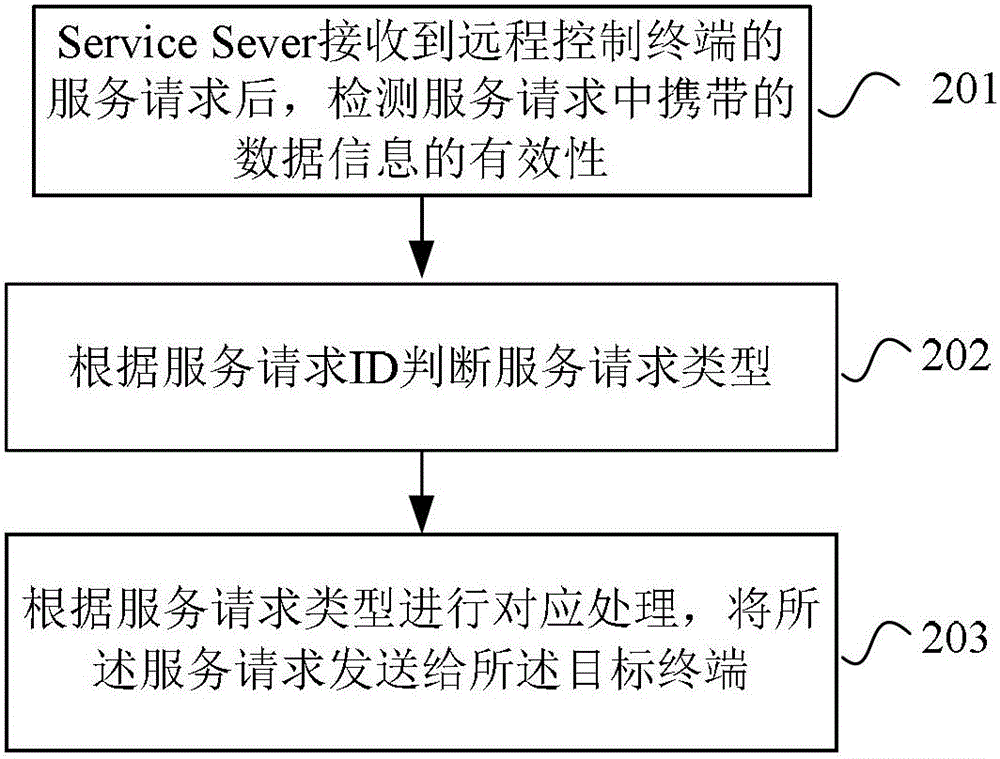

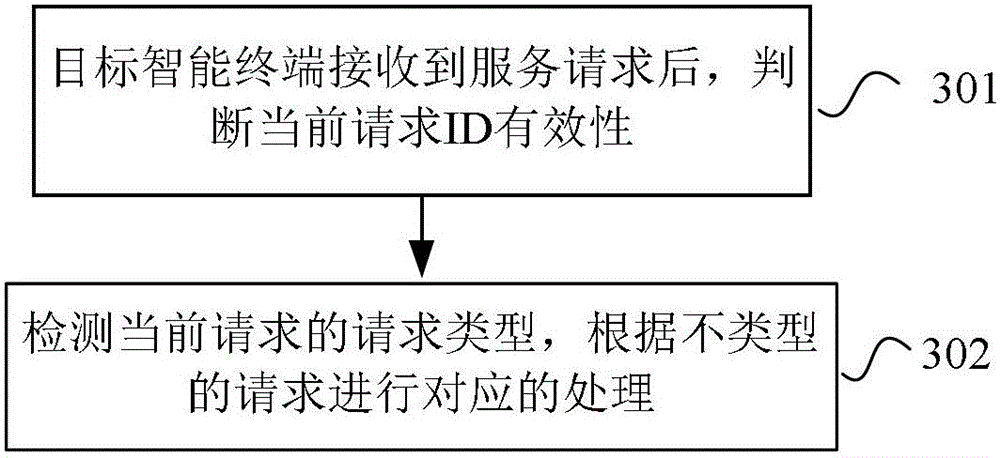

Remote control method and device

ActiveCN102724322AEnsure safetyWork lessConnection managementSubstation equipmentTerminal serverRemote control

The invention provides a remote control method and a remote control device. The method comprises the following steps that: a terminal selects an intelligent terminal remote control option from Web user interface (UI) according to an instruction of a user; the terminal transmits a request of establishing a data link with a target terminal to an intelligent terminal server, wherein the request of establishing the data link comprises the user account information of the target terminal; and after receiving a data link establishment success request, the terminal transmits a service request to the intelligent terminal server according to a request of the user. By the method and the device, intelligent terminal equipment can be conveniently and remotely controlled.

Owner:ZTE CORP

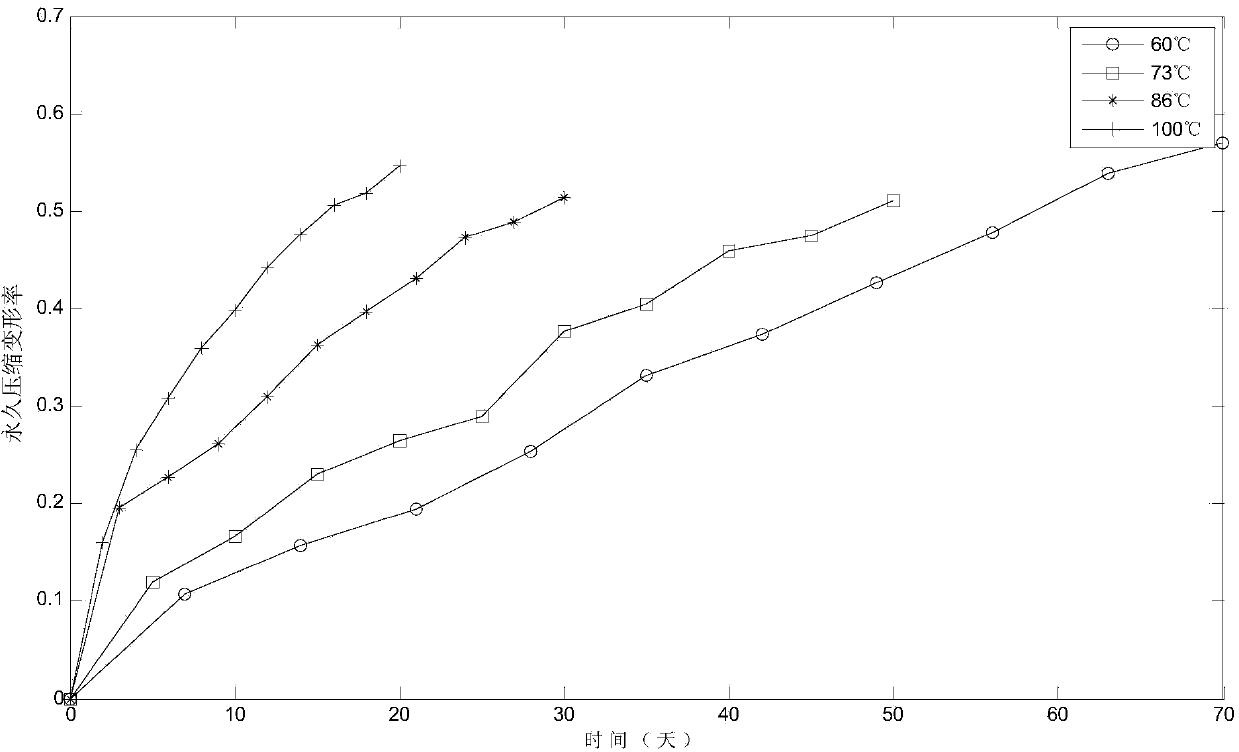

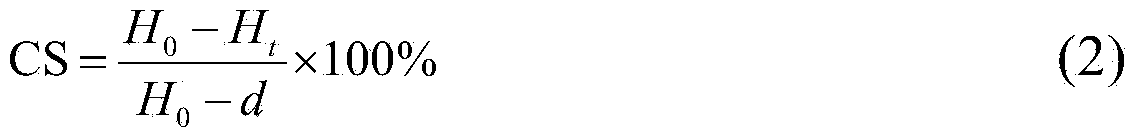

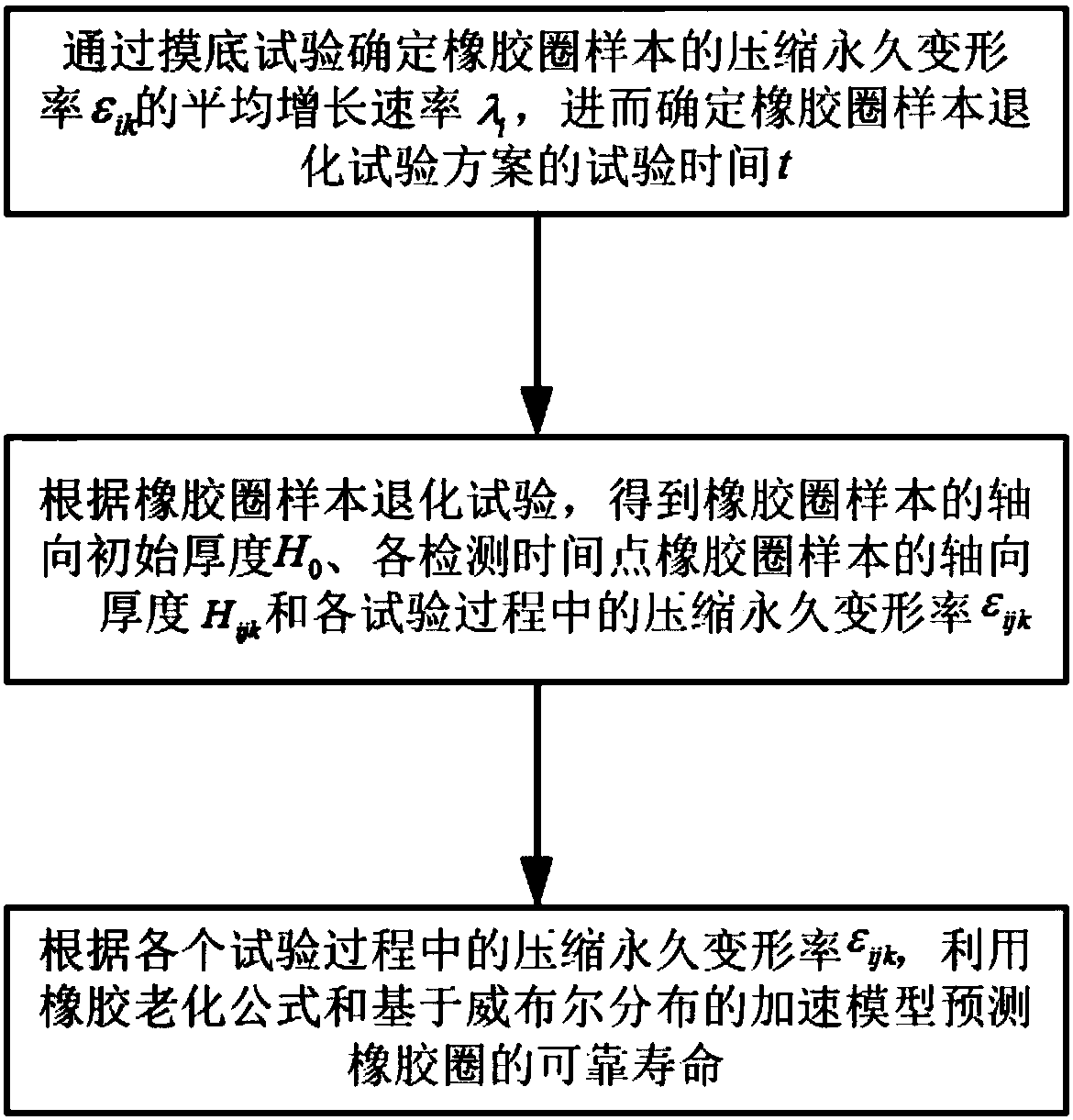

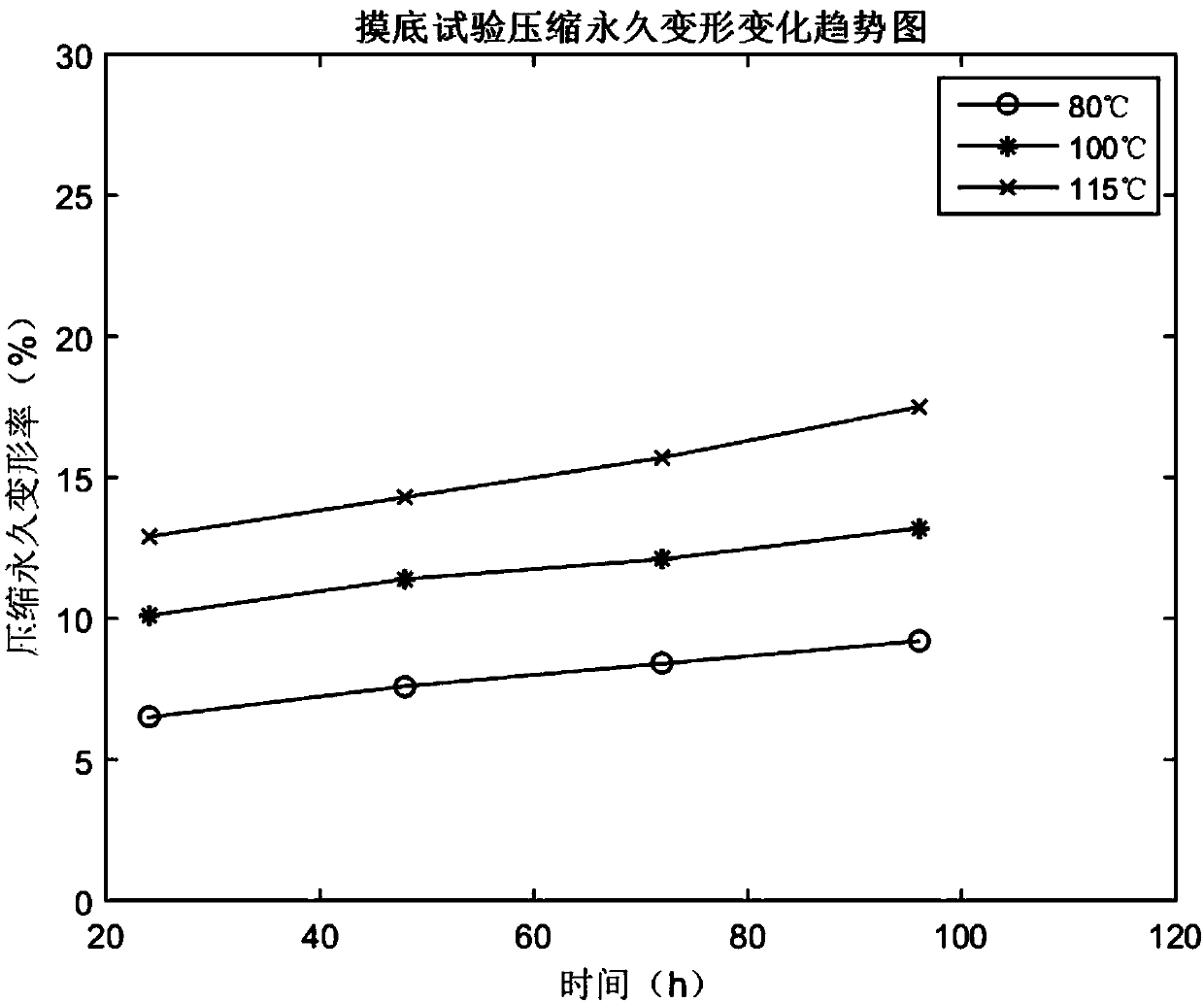

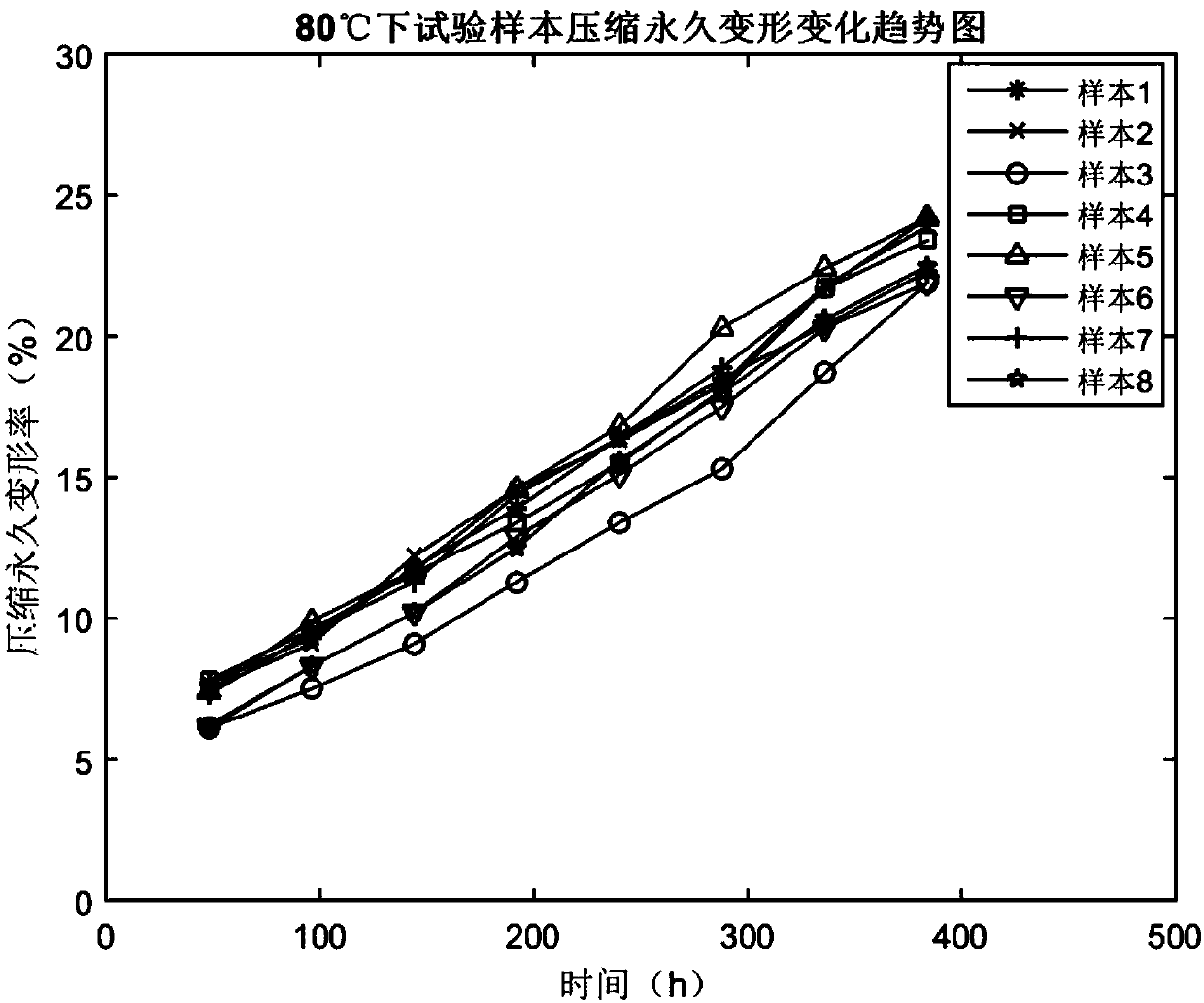

Weibull-distribution-based method for predicting reliable service life of rubber ring

InactiveCN107702905AShorten the timeHigh feasibilityMachine sealing rings testingRubber ringDegradation test

The invention discloses a Weibull-distribution-based method for predicting the reliable service life of a rubber ring. The method includes the following steps: S1, determining an average growth rate lambda i of a permanent compression deformation rate epsilon iK of a rubber ring sample through a diagnostic test and then determining test time t of a rubber ring sample degradation test plan; S2, according to the rubber ring sample degradation test, obtaining an initial axial thickness H0 of the rubber ring sample, an axial thickness HijK of the rubber ring sample at each detection time point, and a permanent compression deformation rate epsilon ijK during each test process; and S3, according to the permanent compression deformation rates epsilon ijK of all test processes, predicting a service life of the rubber ring according to a rubber degradation formula and an acceleration model based on the Weibull distribution and analyzing the reliability of the rubber ring. Compared with the traditional rubber service life prediction method capable of obtaining a single service life prediction value, the method has advantages: a reliable service life value is obtained by using a service lifedistribution function, so that the evaluation result has higher credibility.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Latching separation system

InactiveUS20050279890A1Reliably and easily unfasteningRapidly fastening itemCosmonautic vehiclesWaterborne vesselsStable stateControl system

Latching elements on a first structure are configured to securely engage corresponding bearings on a second structure, via a lateral member that drives all of the latching elements simultaneously. When engaged, or when disengaged, the system is in a stable state, requiring no active force by the controlling system to maintain the system in each state. Preferably, each latching element is coupled to the lateral member via a pinion that provides a mechanical advantage that substantially reduces the force required on the lateral member to effect the coupling or decoupling. Also preferably, the elements are formed from extruded aluminum forms, thereby providing for a relatively inexpensive and lightweight configuration that is particularly well suited for spacecraft applications.

Owner:HOLEMANS WALTER

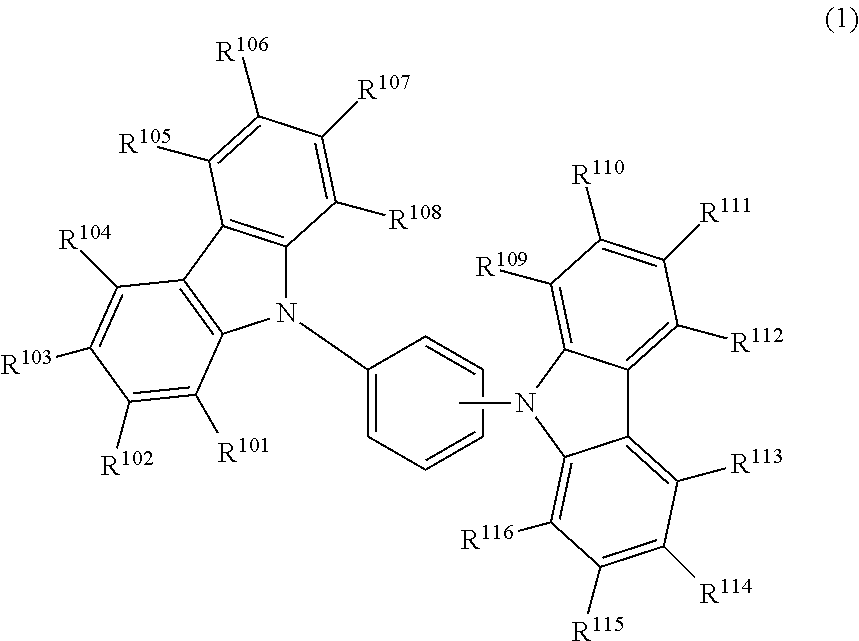

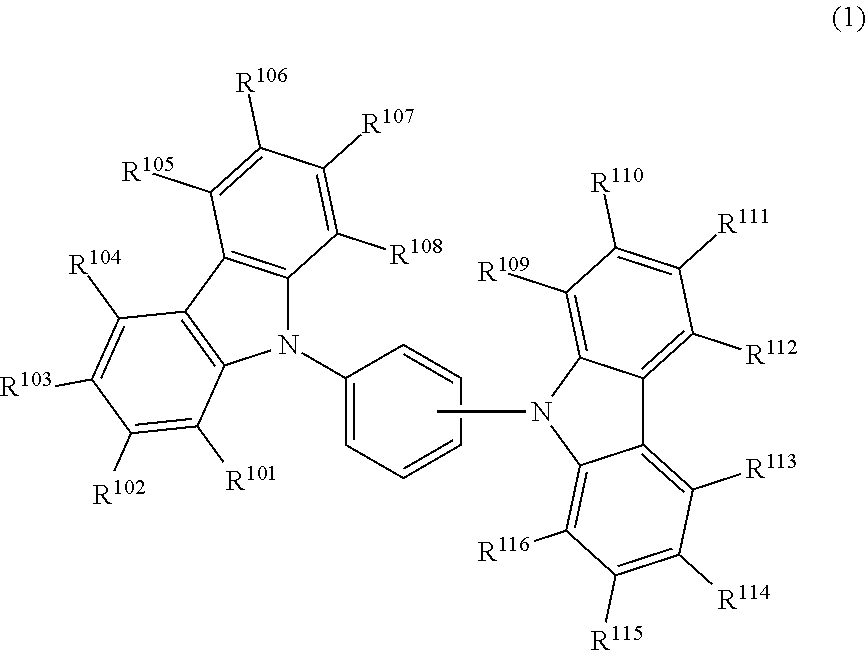

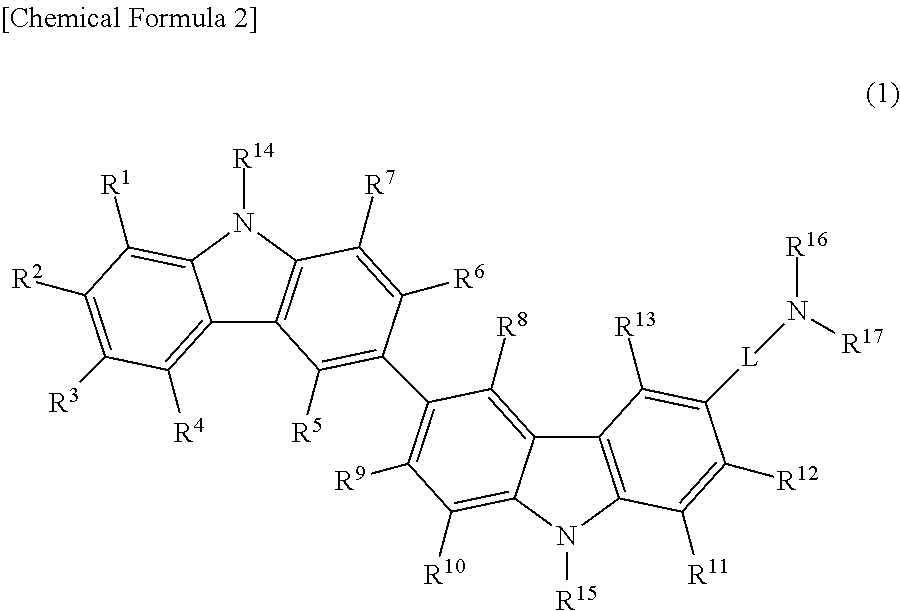

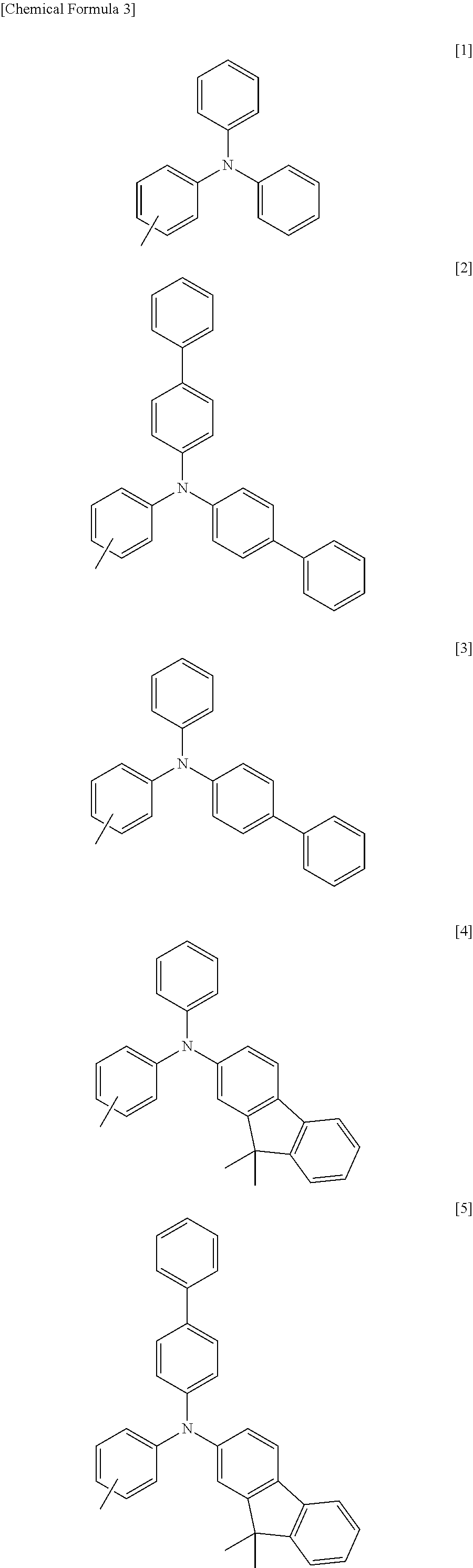

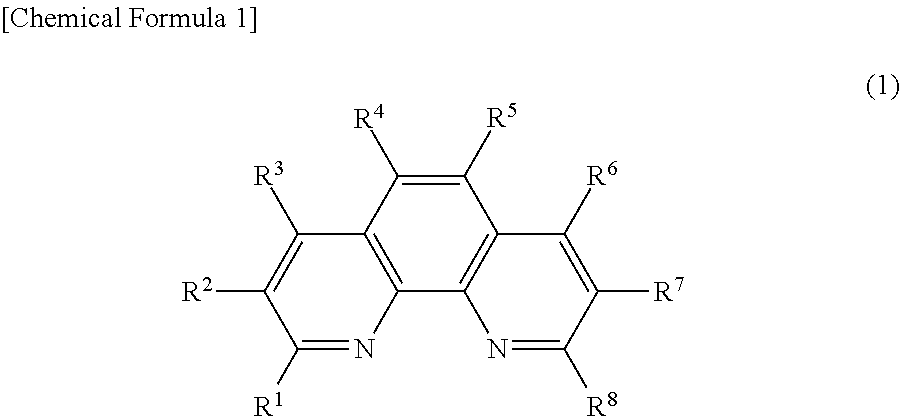

Light emitting device material and light emitting device

InactiveUS20130264558A1Reduce the driving voltageSolve low luminous efficiencyOrganic chemistryElectroluminescent light sourcesDevice materialLight emitting device

The present invention provides an organic thin-film light emitting device in which the luminance efficiency and durable life are improved while a low driving voltage is maintained by means of a light emitting device material that contains a compound represented by general formula (1).

Owner:TORAY IND INC

Light emitting device material and light emitting device

ActiveUS20130341613A1Solve low luminous efficiencySufficient durable lifeOrganic chemistrySolid-state devicesCarbazoleDevice material

Provided are a light emitting device material which contains a compound having a carbazole skeleton of a specific structure and which makes it possible to achieve a light emitting device having both high luminance efficiency and durability; and a light emitting device using the light emitting device material.

Owner:TORAY IND INC

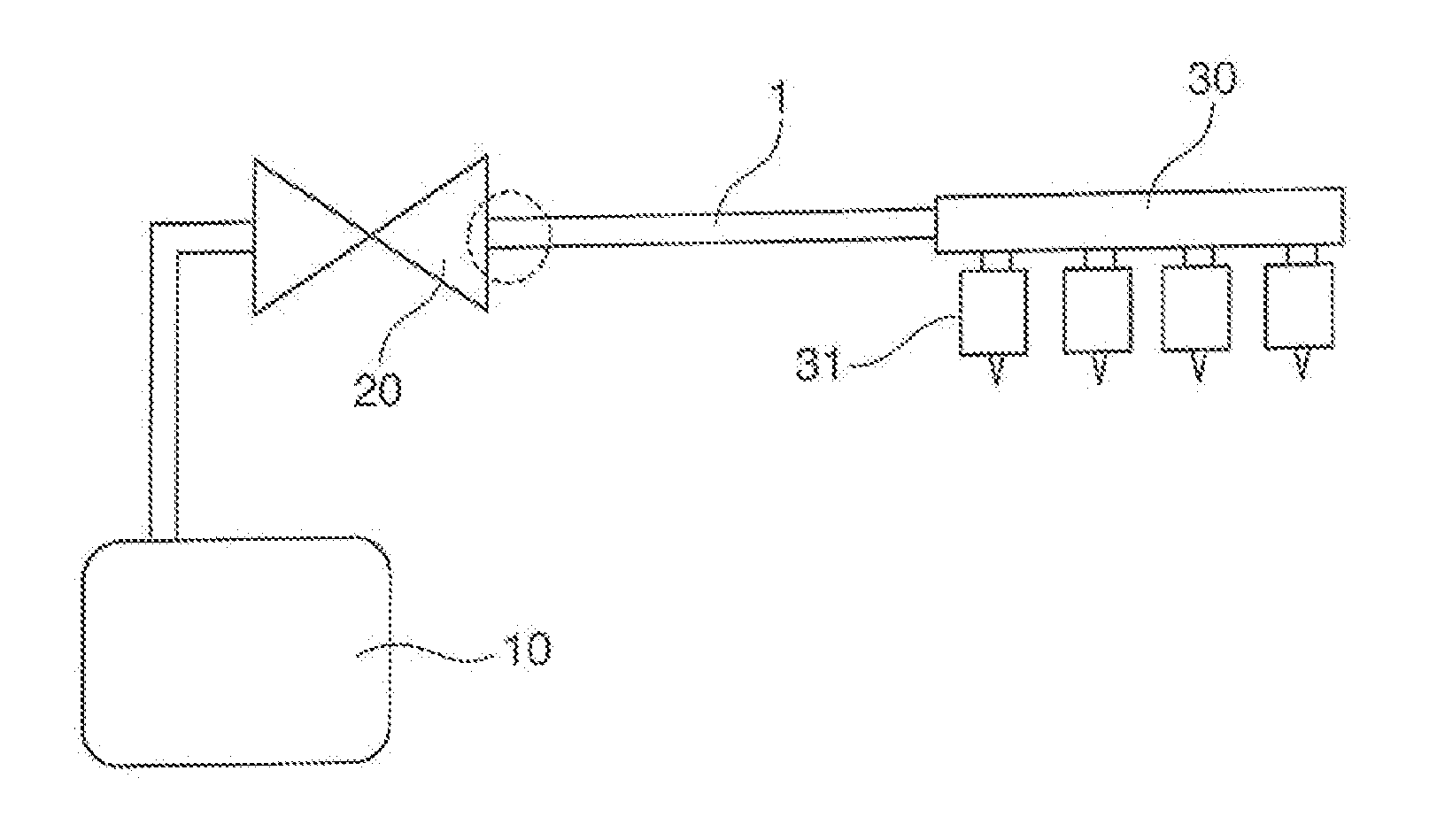

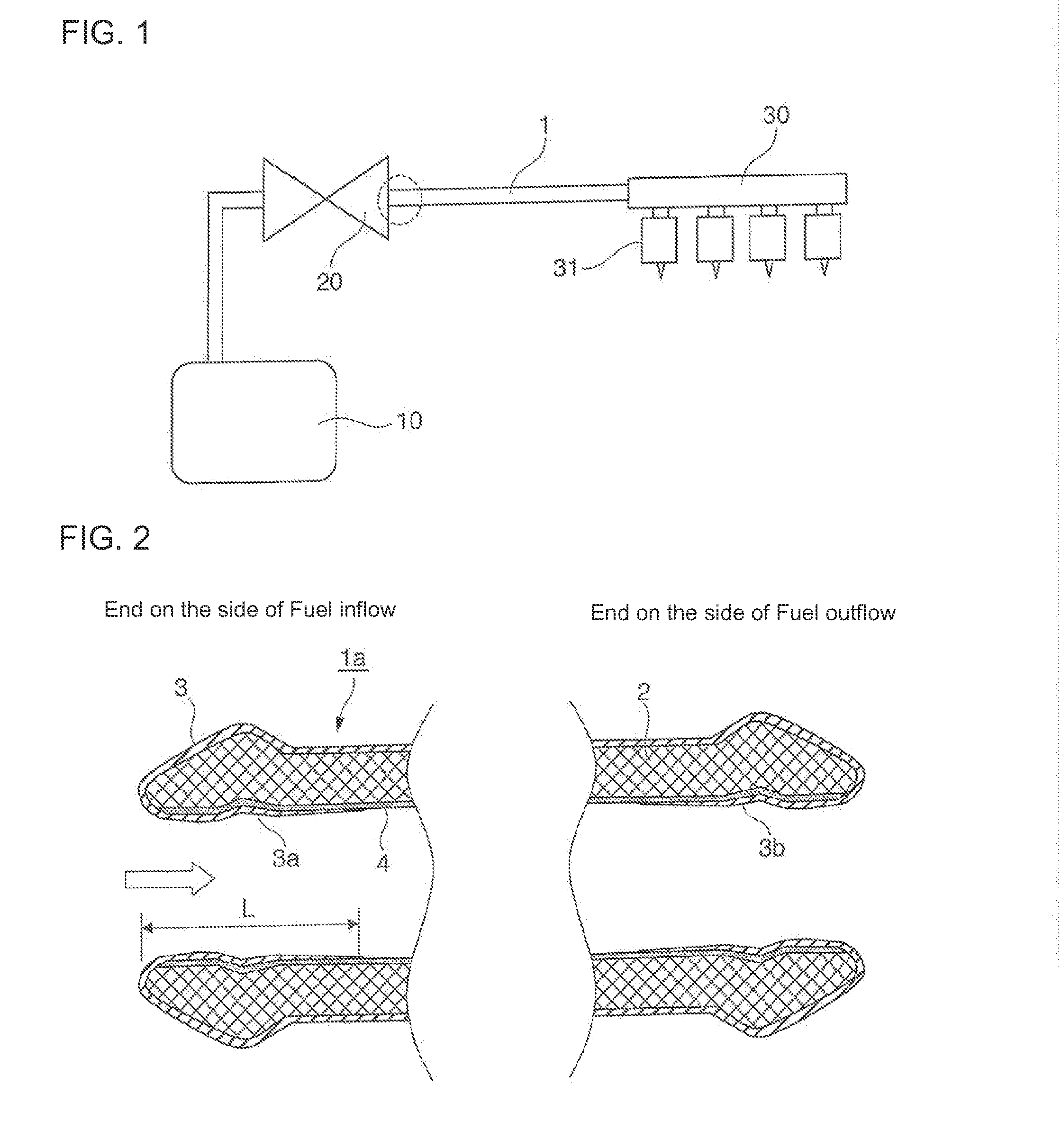

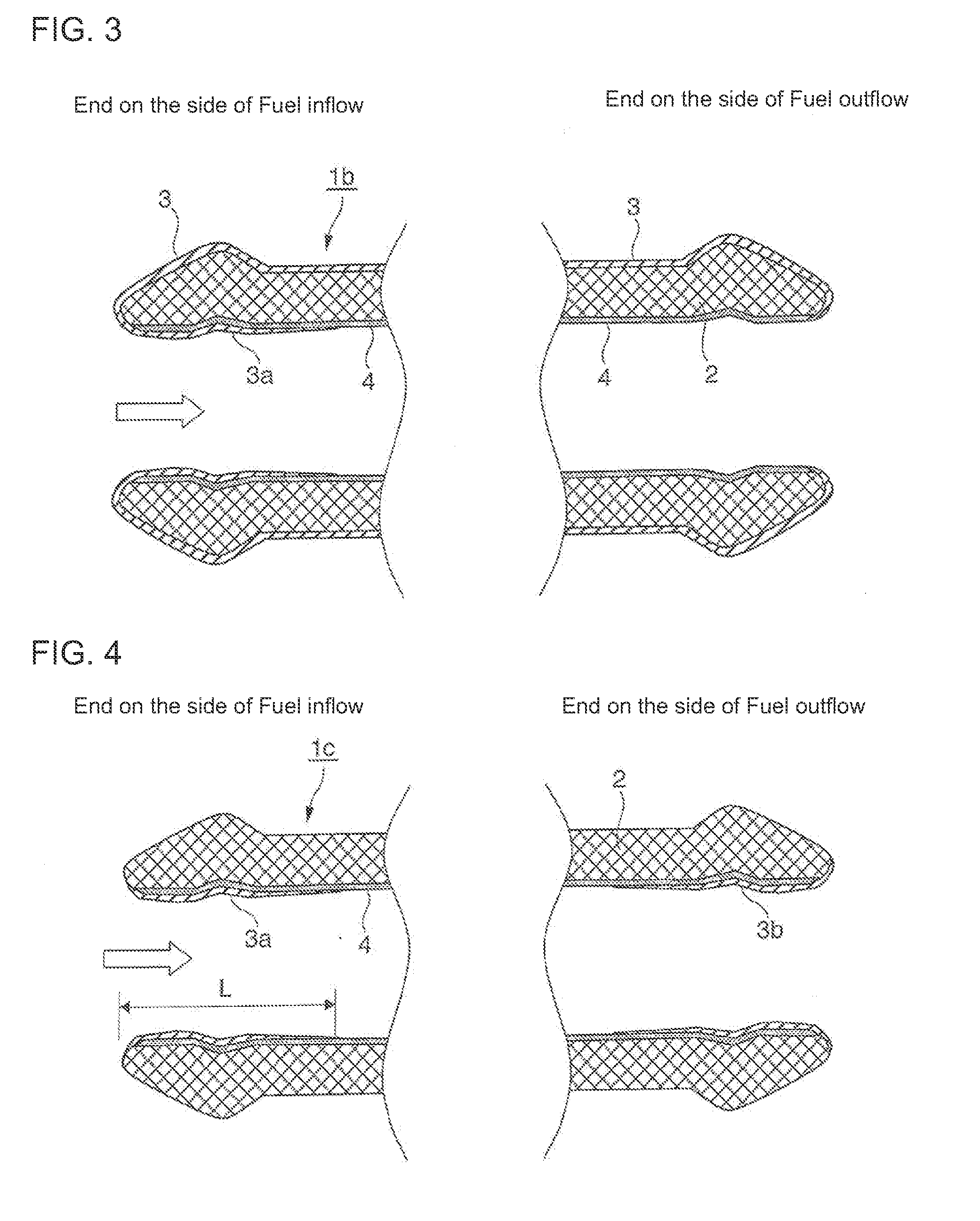

Steel fuel conveying pipe

ActiveUS20130098496A1Reliable lifeAvoid corrosionCorrosion preventing fuel injectionCorrosion preventionHigh resistanceGasoline direct injection

To provide a steel fuel conveying pipe which has high resistance to corrosive fuel and maintains reliability without damaging a direct-injection engine, and connects a high-pressure pump and a direct-injection rail with each other in a gasoline direct-injection engine system, and a fuel conveying pipe suitable as a bypass pipe for coupling direct-injection rails with each other in a V-type gasoline engine. A steel fuel conveying pipe for conveying gasoline is characterized in that a Ni-plated layer is provided on the whole inner circumferential face of the fuel conveying pipe, and an anti-rust film layer composed of a Zn-plated layer and a Zn-based alloy-plated layer is further provided on the Ni-plated layer at at least one end of the fuel conveying pipe.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Water-based paint for steel tube external protection and preparation method of water-based paint

InactiveCN104559660ALess material consumptionStrong adhesionPaints with biocidesAnti-corrosive paintsEpoxyAcrylic resin

The invention discloses a water-based paint for steel tube external protection. The water-based paint is prepared from the following raw material constituents in percentage by weight: 20.0-35.0% of an waterborne epoxy emulsion, 15.0-25.0% of water-based acrylic resin I, 15.0-25.0% of water-based acrylic resin II, 0.5-2.0% of propylene glycol, 2.0-5.0% of butyl cellosolve, 0.1-1.0% of a flash-rust inhibitor, 0.5-1.0% of a corrosion inhibitor, 0.5-2.0% of a salt spray resistant additive, 0.1-0.5% of a bactericide, 0.1-0.5% of a wetting agent, 0.05-0.5% of a defoaming agent, 0.1-1.0% of a thickening agent, and 21.3-27.5% of deionized water; the water-based paint is prepared from the following steps: (1) preparing the raw materials; (2) burdening and dispersing; (3) filtering and packaging. The water-based paint disclosed by the invention belongs to the varnish system; the dry film thickness of the paint is only 20-30 microns; the water-based paint is good in adhesive force, corrosion resistance and water penetration resistance; the surface gloss of the coating can be up to 90 degrees, the salt spray resistance property can be up to 300 hours above, and the outdoor weather resistance can be more than 1 year.

Owner:SHANGHAI HILONG PETROCHEM RES INST +3

Multi-function peripheral, power supply apparatus, and power supply control method

InactiveUS7966501B2Reduce consumptionPower efficiency fallVolume/mass flow measurementPower supply for data processingElectricityLower limit

A digital multi-function peripheral includes a multi-function peripheral unit that has plural functions, a switching power supply unit connected to a commercial power supply as a main power supply for the multi-function peripheral unit, and an electrical storage device charged in advance as an auxiliary power supply for the multi-function peripheral unit. The digital multi-function peripheral further includes a control circuit that monitors a load current flowing to the multi-function peripheral unit, supplies electric power from the electrical storage device to the multi-function peripheral unit instead of electric power from the switching power supply unit when the load current is smaller than a threshold set as an allowable lower limit of power efficiency of the switching power supply unit, and supplies the electric power from the switching power supply unit to the multi-function peripheral unit when the load current increases to be equal to or larger than the threshold.

Owner:KK TOSHIBA +1

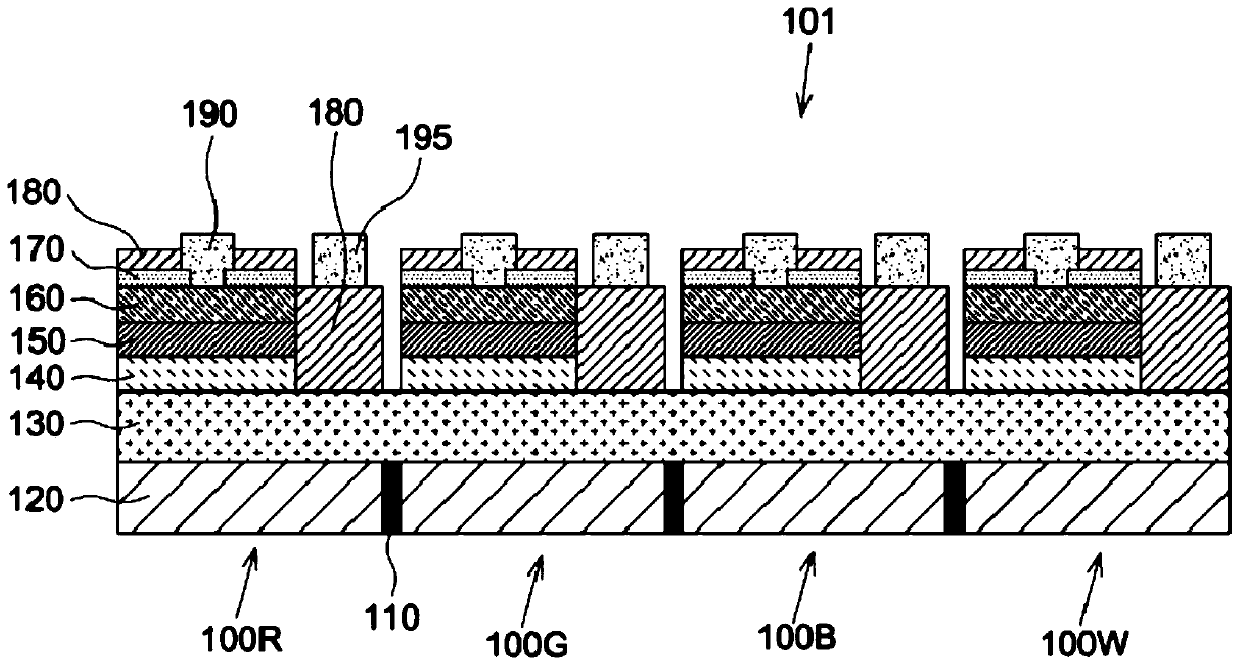

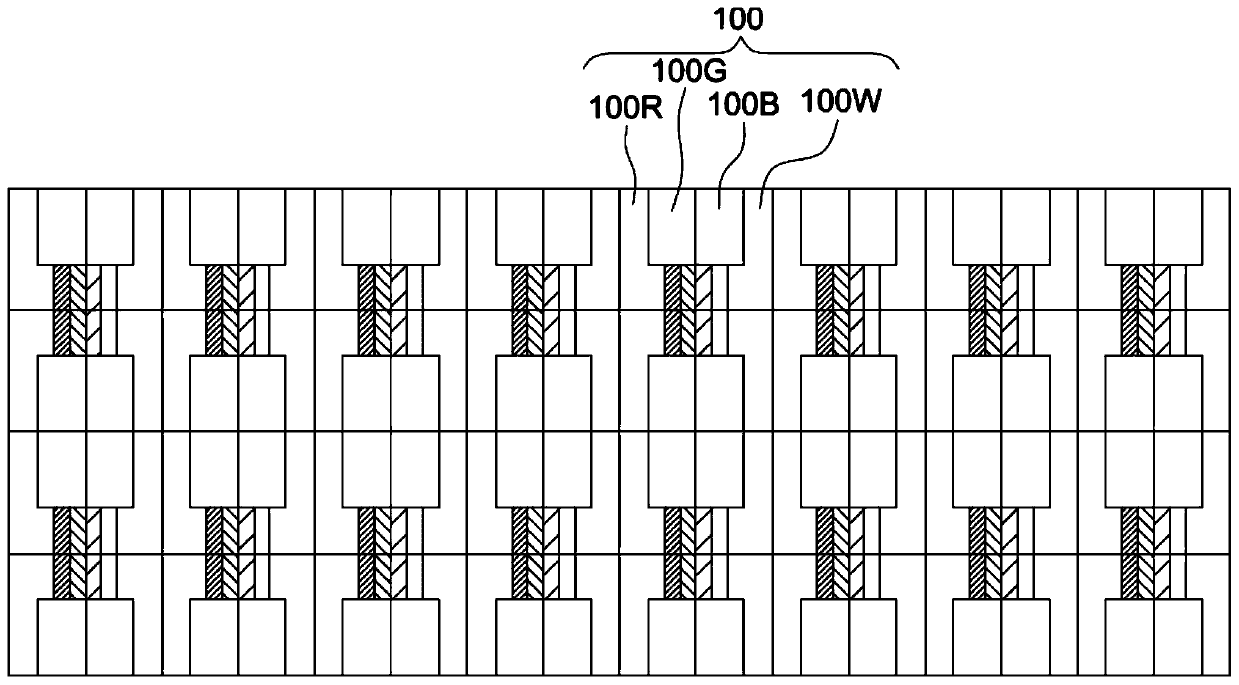

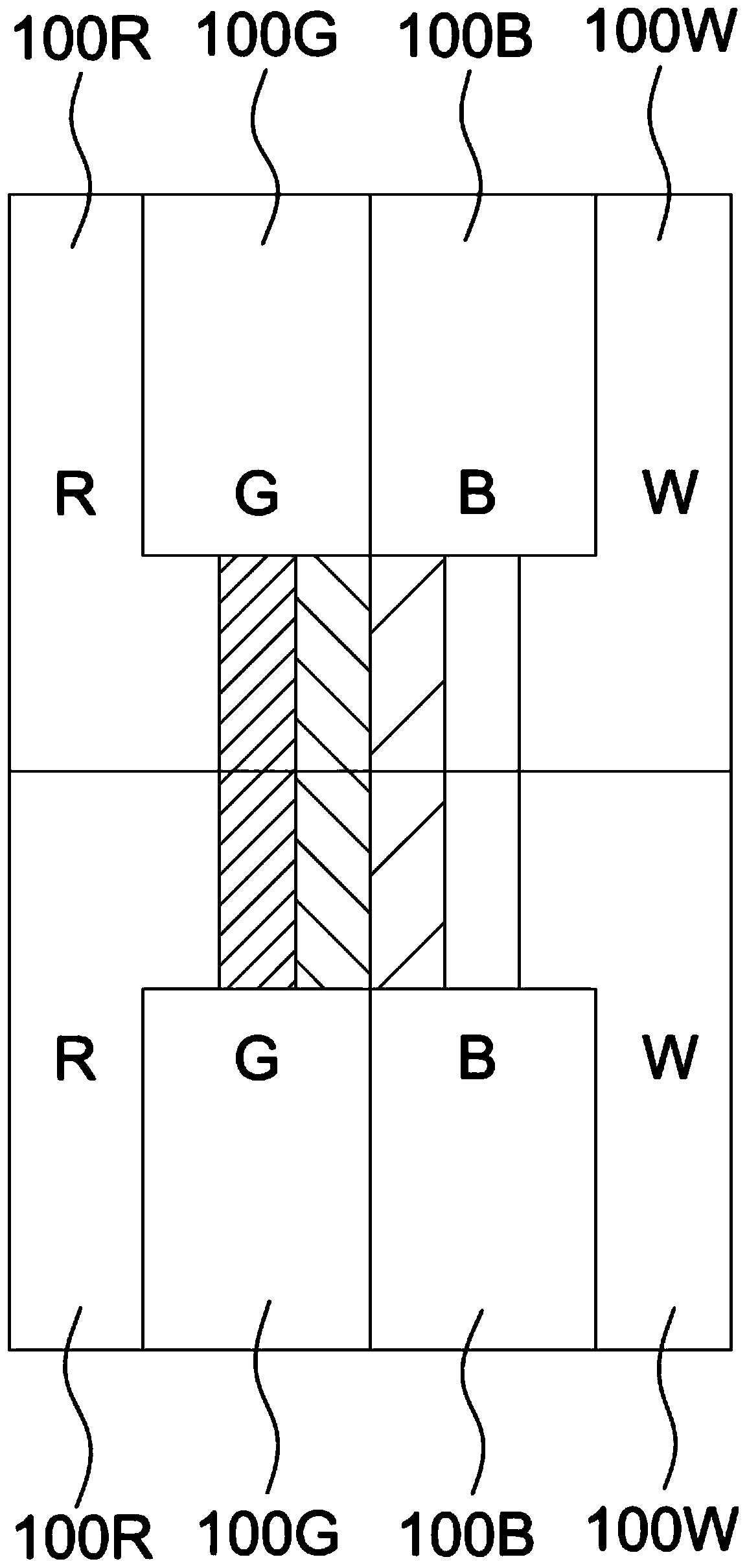

Micro light emitting diode and display panel

ActiveCN110265531AAvoid uneven displayStable lifeSolid-state devicesSemiconductor devicesElectrical conductorLight-emitting diode

The invention provides a micro light emitting diode (101) and a display panel (300). The micro light emitting diode (101) comprises a light conversion layer (120) used for converting blue light into white light, a black matrix (110) arranged in the light conversion layer (120), a buffer layer (130) arranged on the light conversion layer (120), a first semiconductor layer (140) arranged on the buffer layer (130), an indium gallium nitride layer (150) arranged on the first semiconductor layer (140), a second semiconductor layer (160) arranged on the indium gallium nitride layer (150), a current spreading layer (170) arranged on the second semiconductor layer (160) and used for widening the light-emitting area, a passivation layer (180) arranged on the current spreading layer (170) and the buffer layer (130), a first cushion (190) and a second cushion (195).

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

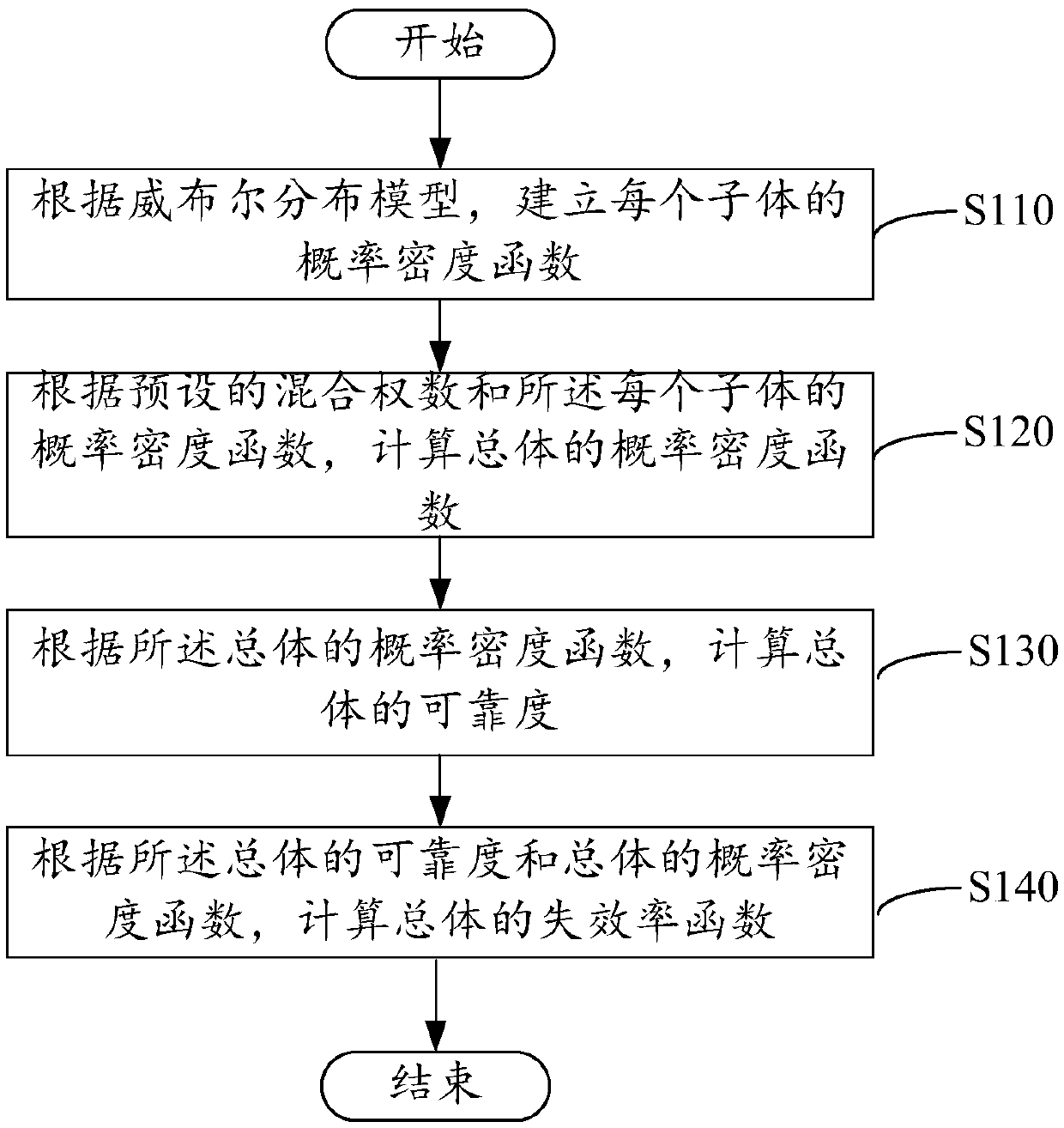

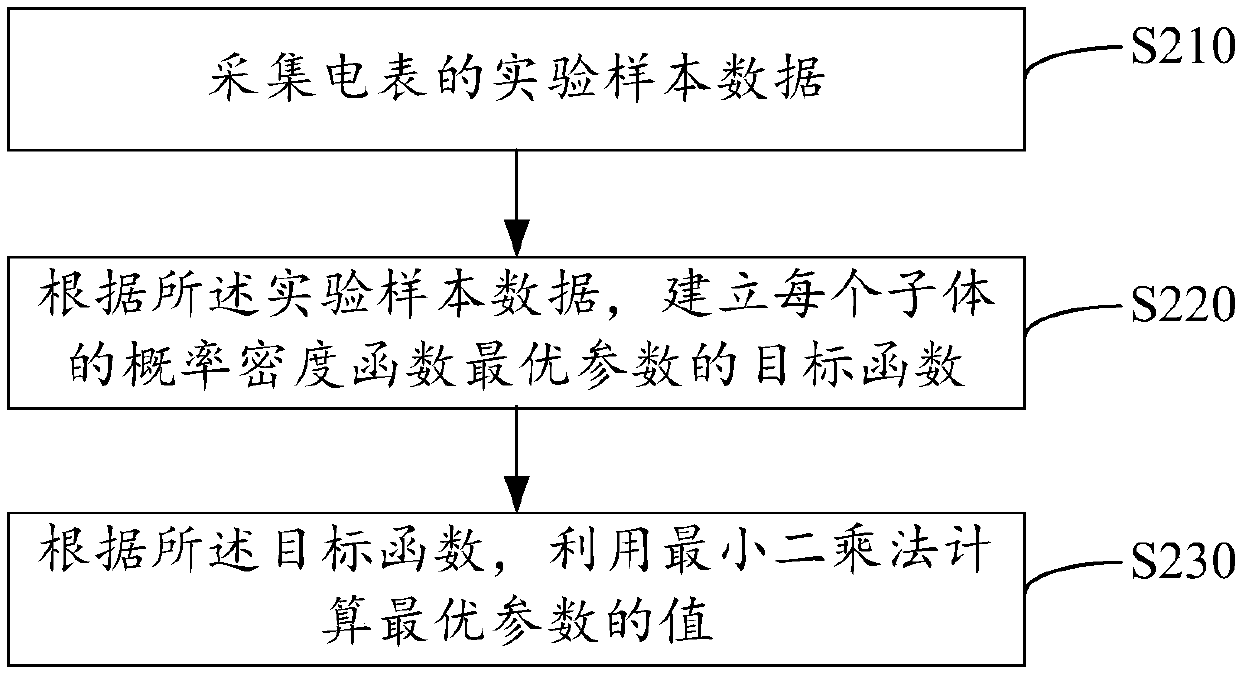

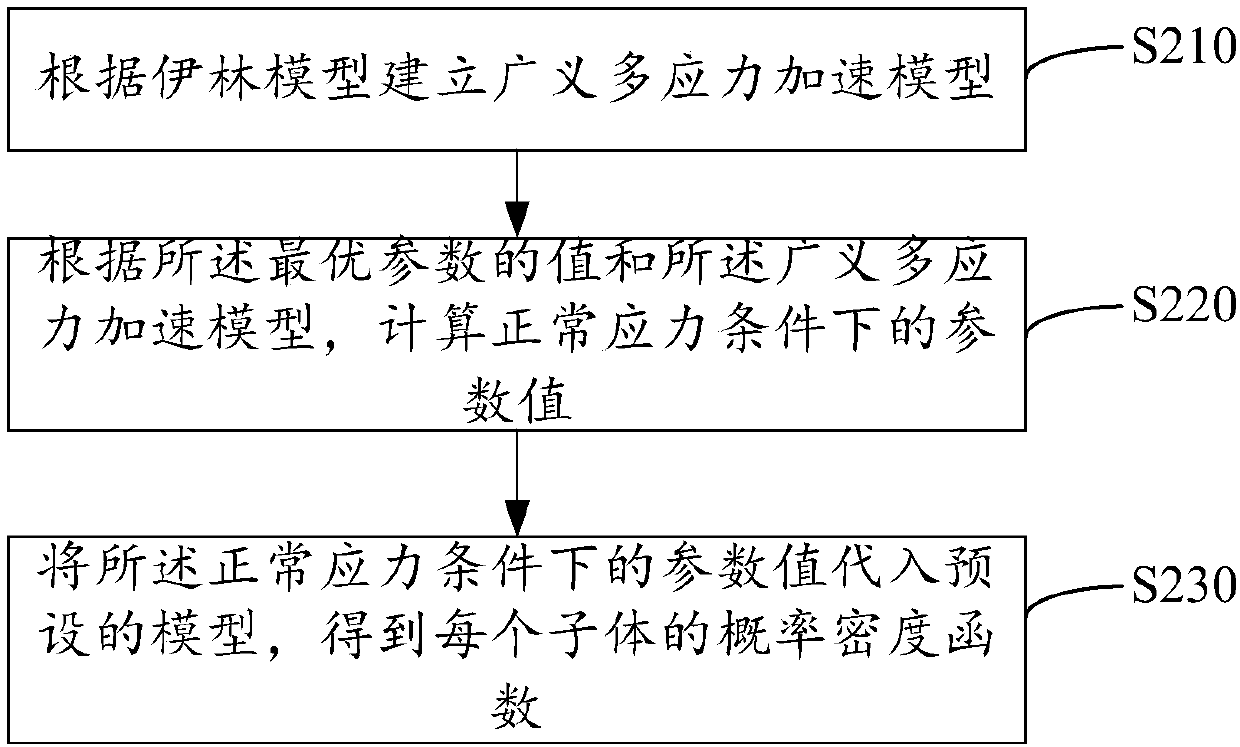

Method and a system for calculating the failure rate of an electric meter

PendingCN109522517AReliable lifeReliable resultsData processing applicationsComplex mathematical operationsFailure rateNormal density

The invention discloses a method and a system for calculating the failure rate of an electric meter. The method comprises the following steps of: establishing a probability density function of each child according to a Weibull distribution model; Calculating an overall probability density function according to a preset mixing weight and a probability density function of each child; Calculating anoverall reliability according to the overall probability density function; Calculating An overall failure rate function based on the overall reliability and the overall probability density function. This method can be used to calculate the failure rate of the meter with a variety of stresses.

Owner:CHINA ELECTRIC POWER RES INST +1

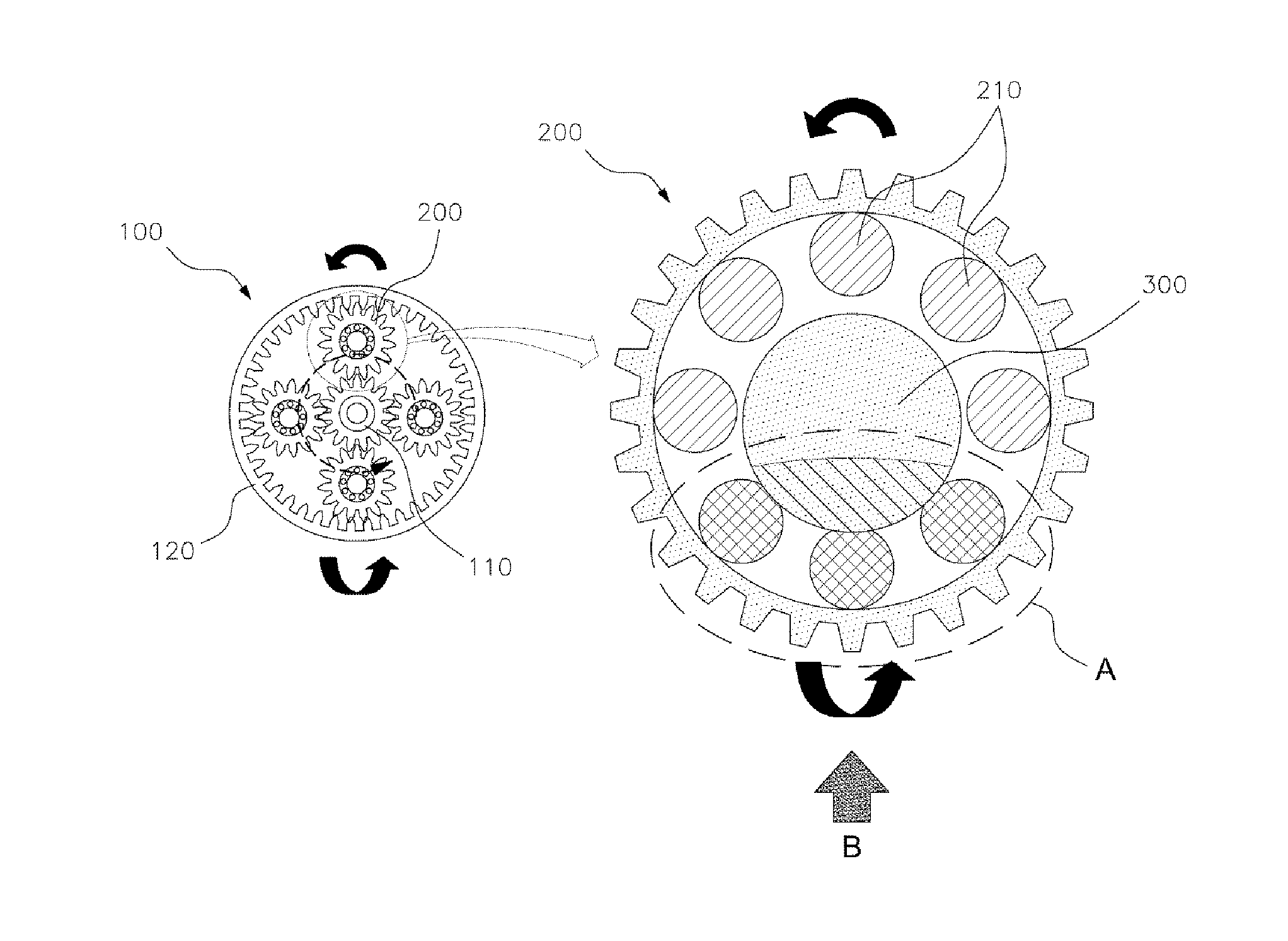

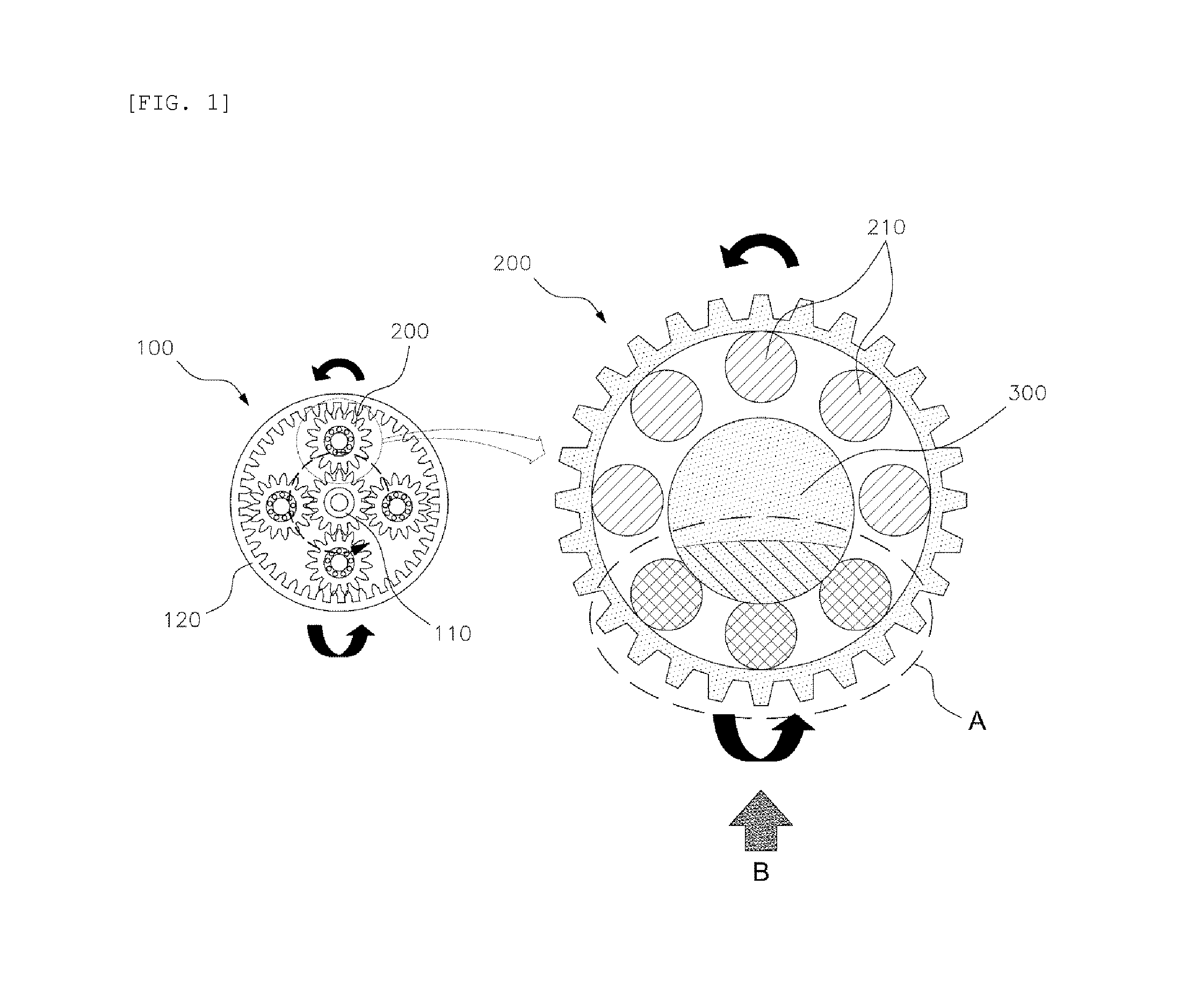

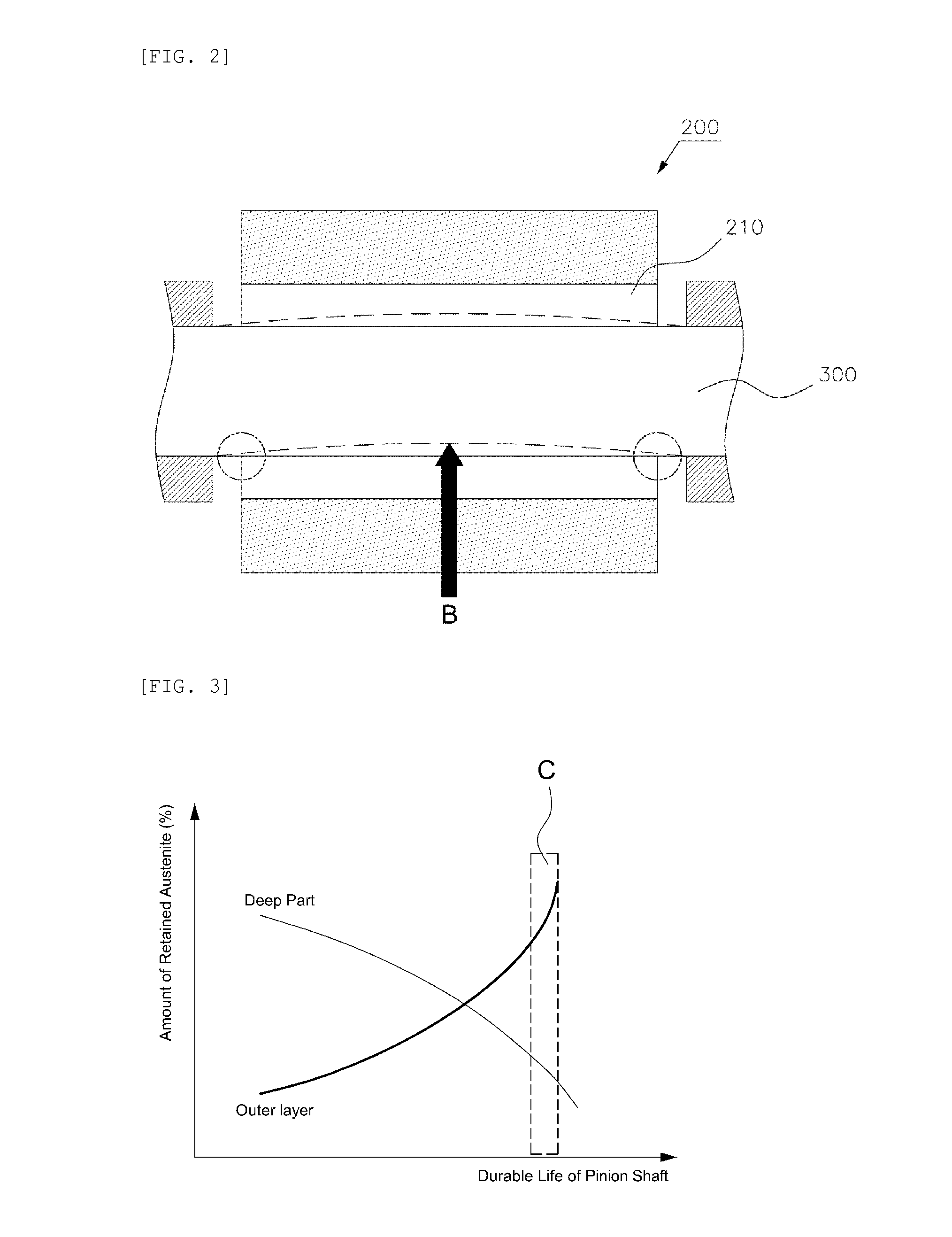

Long life pinion shaft and method for manufacturing thereof

InactiveUS20140007636A1Reliable lifeCurb bendingShaftsSolid state diffusion coatingCarbon steelCarbon alloy

Disclosed is a long life pinion shaft having improved durability by forming an outer diameter portion thereof with high carbon alloy steel and the inner diameter portion medium carbon steel. In particular, the high carbon alloy steel, is selected from the group consisting of: high carbon chromium bearing steel; high speed tool steel; alloy tool steel; and / or carbon alloy steel.

Owner:HYUNDAI MOTOR CO LTD +1

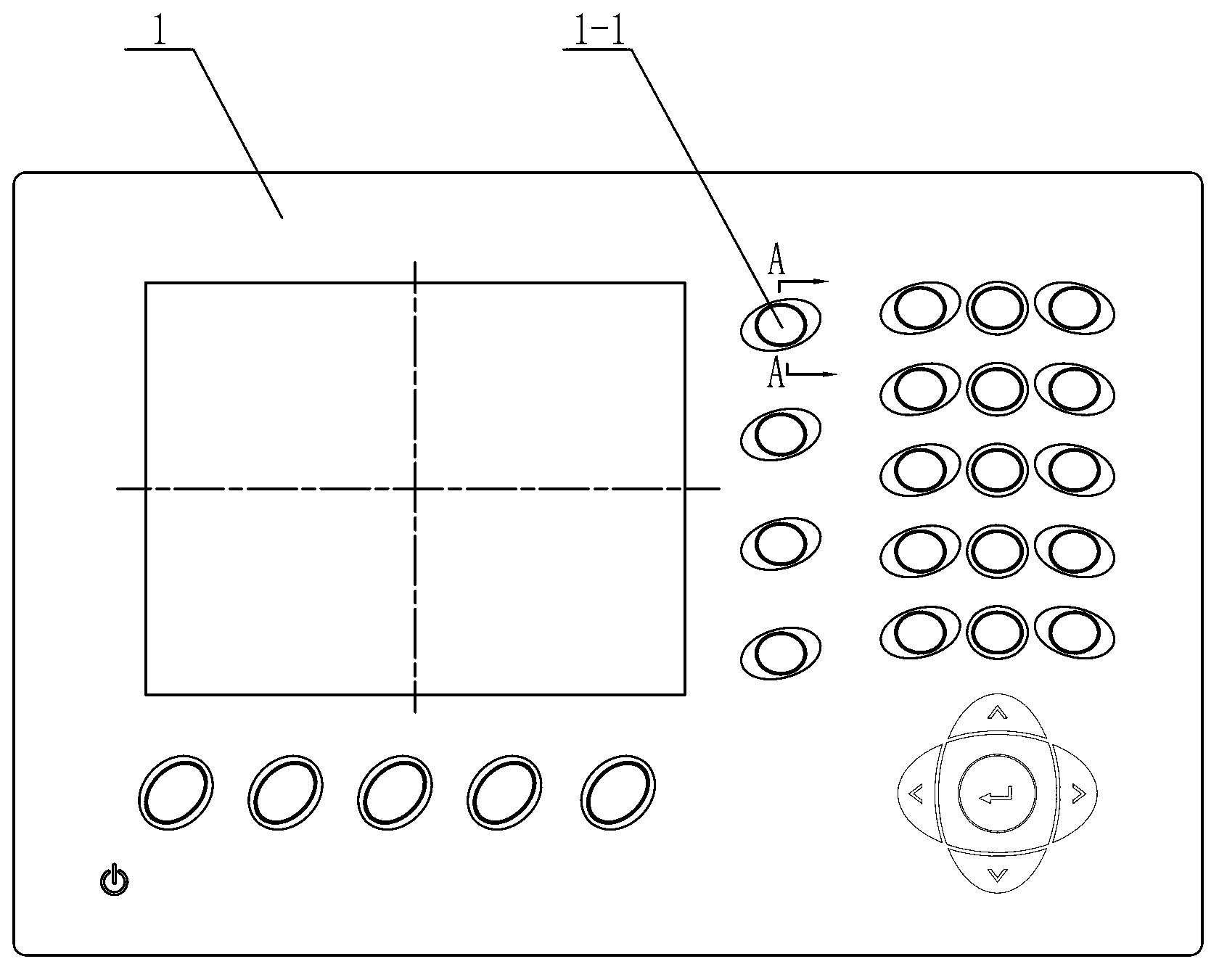

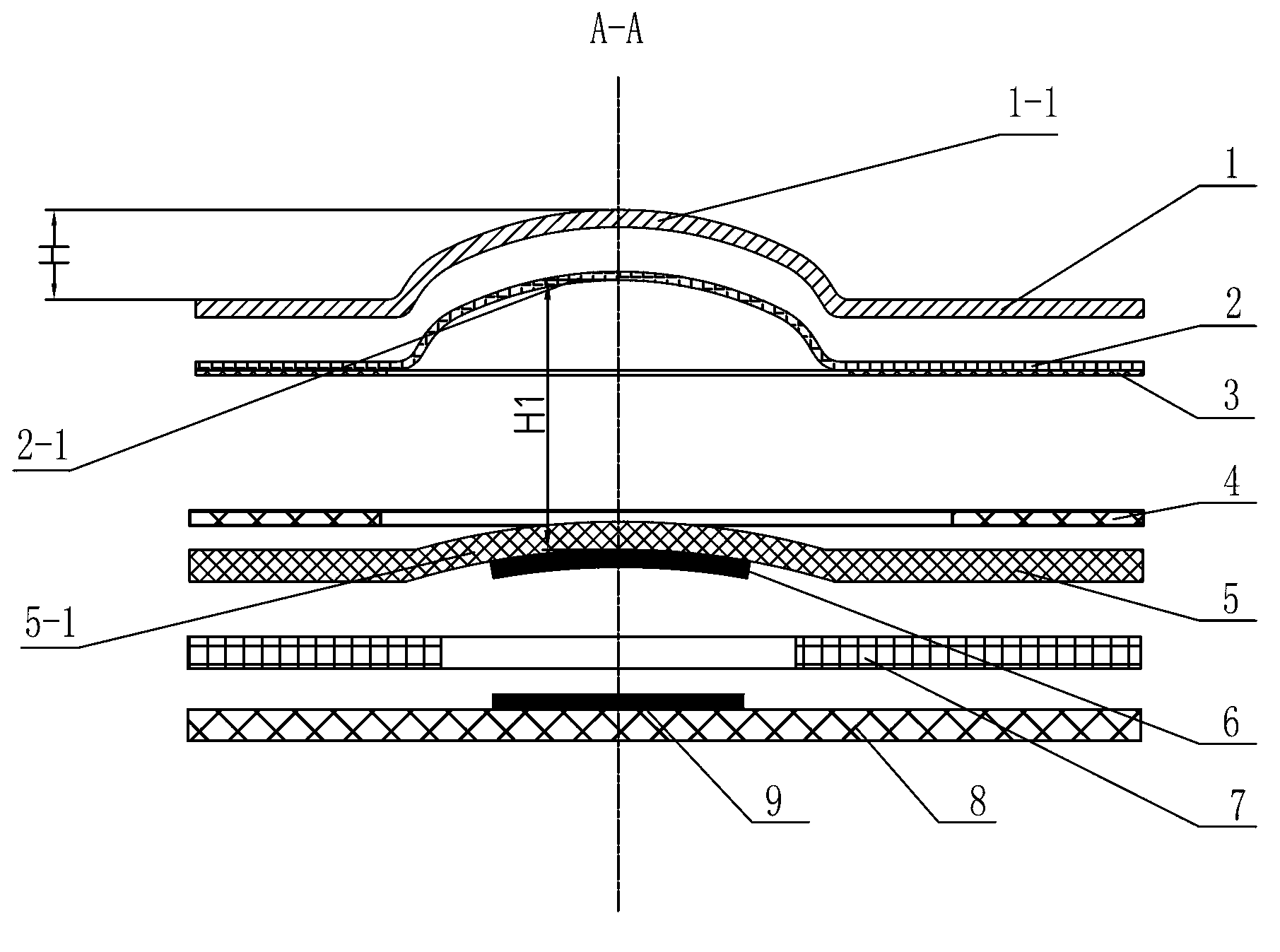

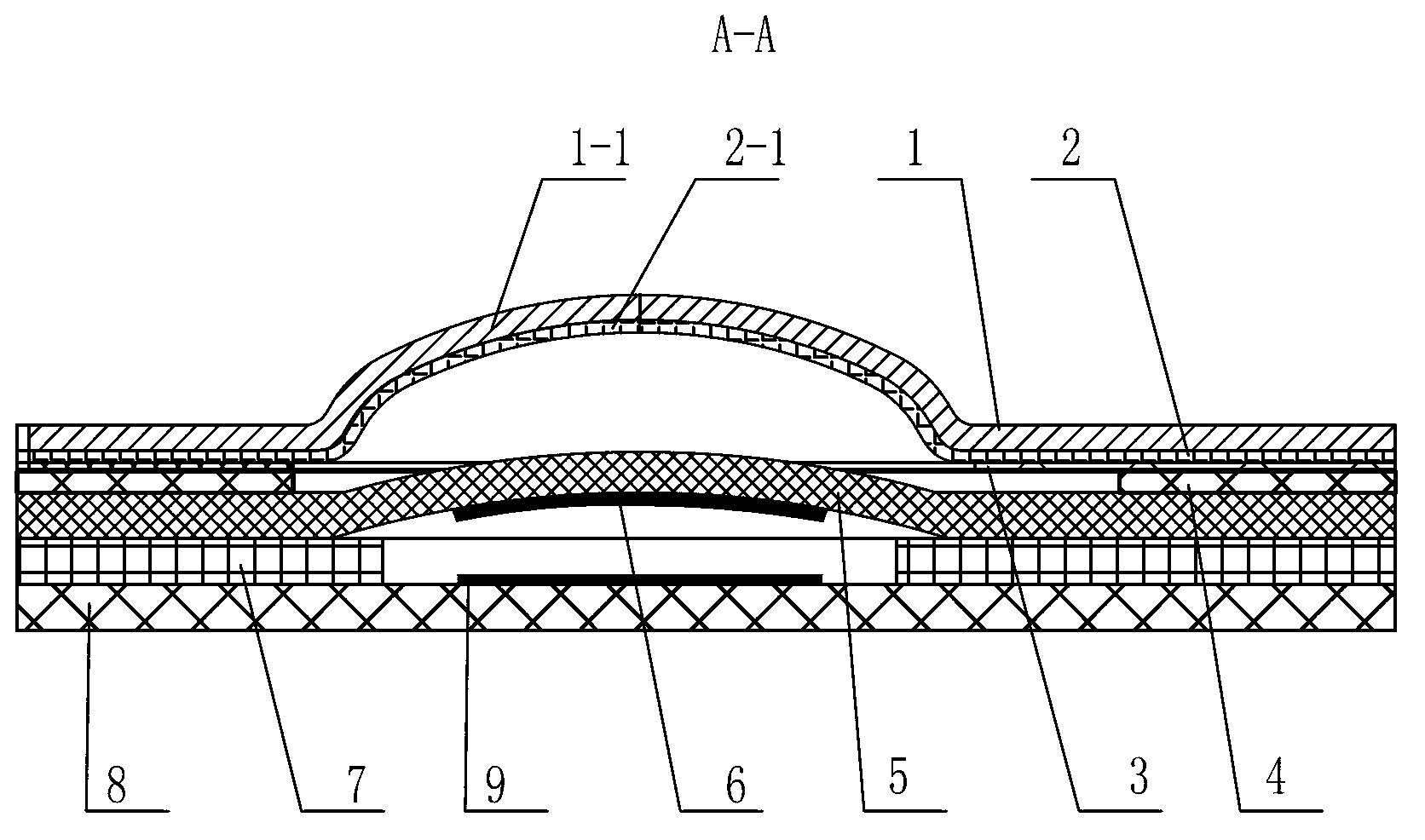

Silica film all-in-one keyboard

The invention relates to a silica film all-in-one keyboard which comprises a face plate layer, a lower substrate layer with a film circuit, an upper substrate layer with electric conduction wafers and an insulation interlayer. The face plate layer comprises a polyester film layer and a silica gel layer below the polyester film layer, the polyester film layer is connected with the silica gel layer in a hot-press mode, a plurality of upwards-plump keys on the polyester film layer are connected with corresponding upwards-plump keys on the silica gel layer, the plump heights H of the keys on the polyester film layer are 0.5-1.0mm, the lower portion of the silica gel layer is connected with a sealing gasket layer through a peelable glue layer, the sealing gasket layer is fixedly connected with the upper substrate layer, the upper substrate layer is fixedly connected with the lower substrate layer through the insulation interlayer, protrusions corresponding to the keys on the polyester film layer are arranged on the upper substrate layer, and the electric conduction wafers at the bottoms of the protrusions correspond to electric conduction strips on the film circuit. The silica film all-in-one keyboard is simple and reasonable in structure, capable of improving the hand feeling of the keyboard and small in pressing force, reduces labor intensity, brings convenience to replacement of the face plate layer, and reduces use cost of the keyboard.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +2

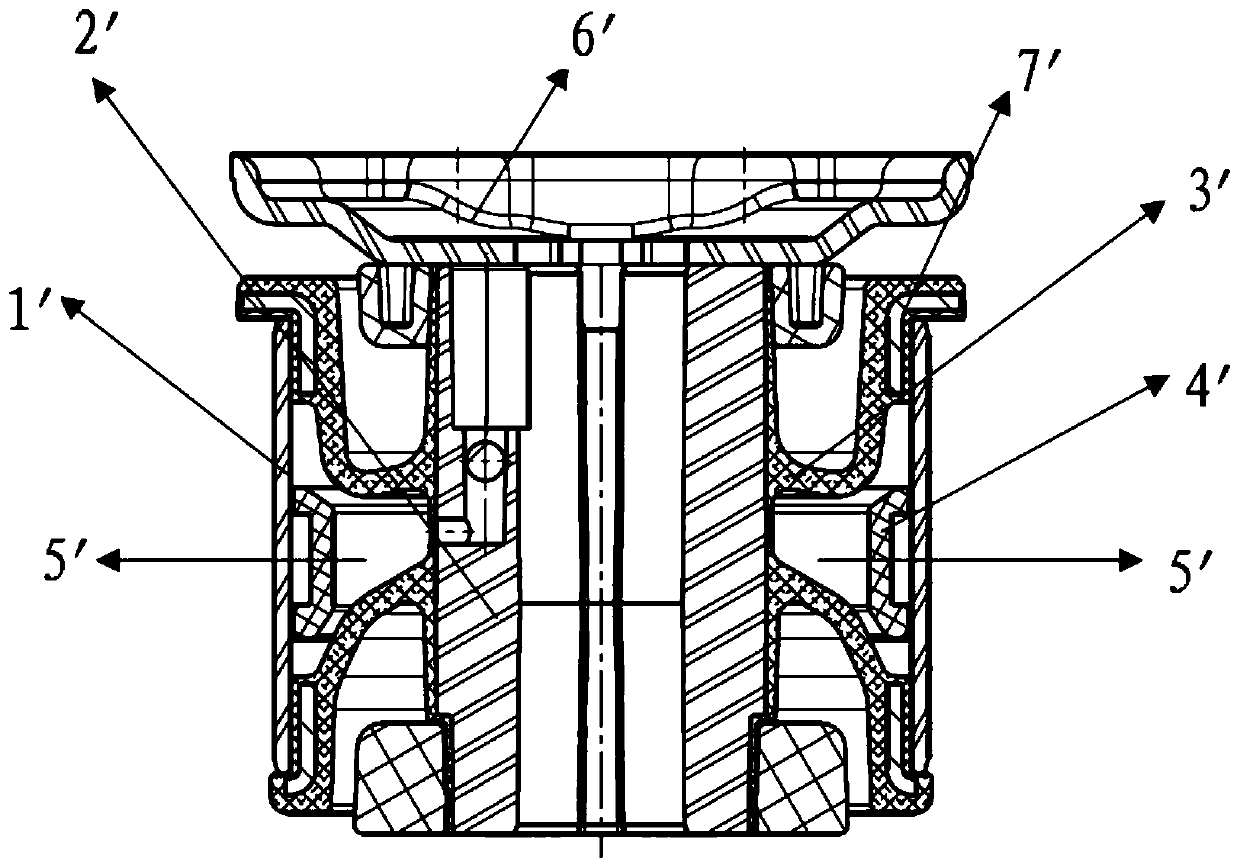

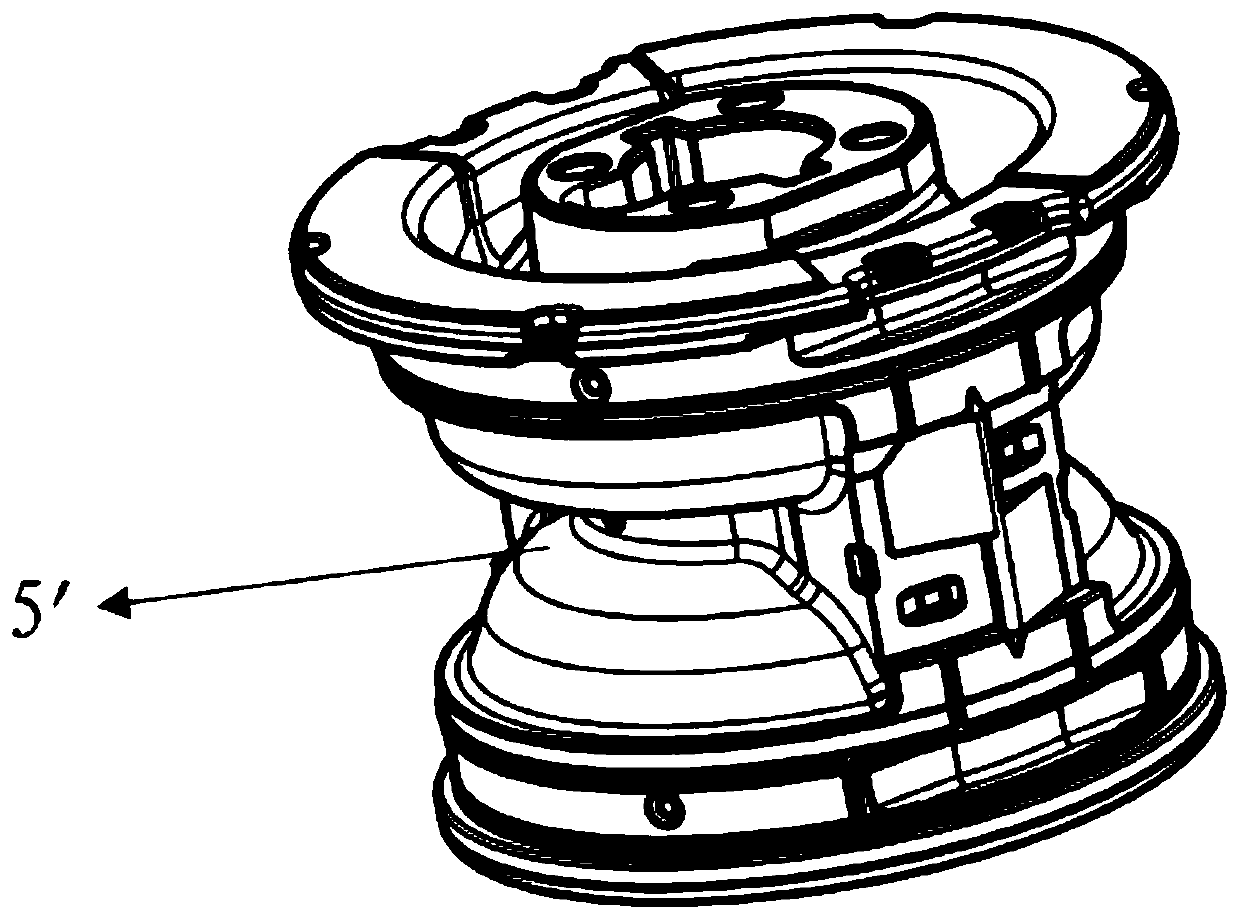

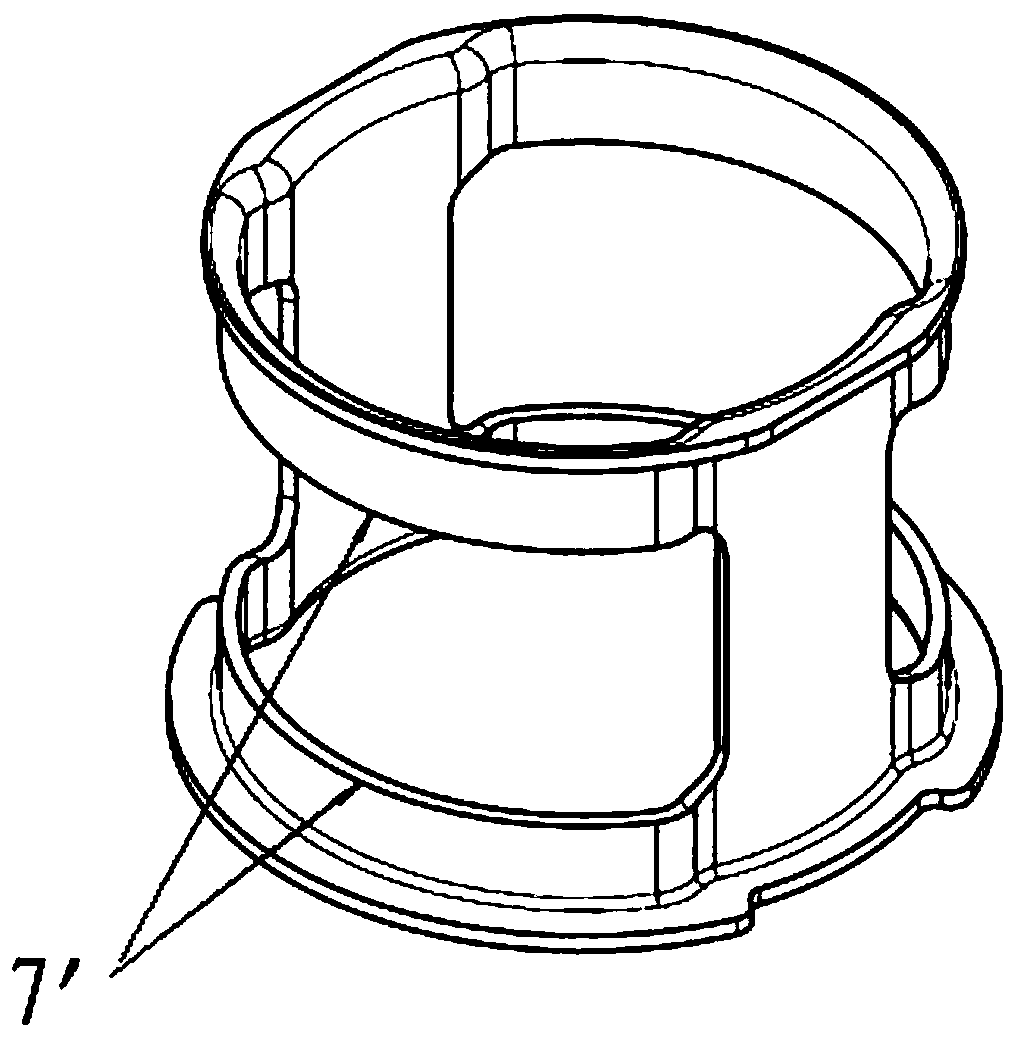

Plastic inner cage hydraulic bushing

The invention discloses a plastic inner cage hydraulic bushing. The plastic inner cage hydraulic bushing comprises an outer frame, an inner frame, a damping rubber structure, a plastic inner cage, a limiting rubber structure and a limiting gasket, wherein the inner frame, the damping rubber structure and the plastic inner cage are sequentially and coaxially arranged from inside to outside; the plastic inner cage, the damping rubber structure, and the inner frame are integrated into a first combination through vulcanized bonding; the limiting rubber structure is annular and arranged at the topend of the outer frame; the limiting rubber structure and the outer frame are integrated into a second combination through vulcanized bonding; the limiting gasket is arranged at the top end of the limiting rubber structure; the first combination is arranged in the second combination. According to the plastic inner cage hydraulic bushing, the durability of the bushing can be improved, the cost is reduced, and the quality is stable and reliable.

Owner:BOGE ELASTMETALL SHANGHAI CO LTD

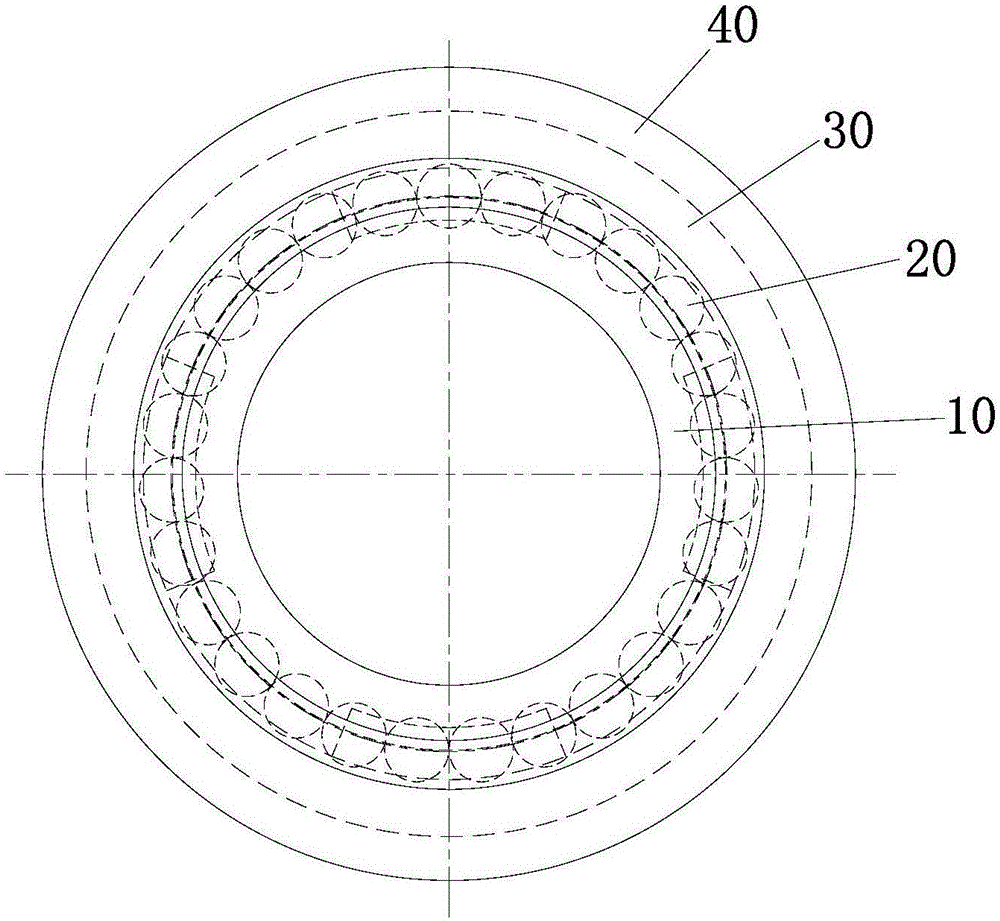

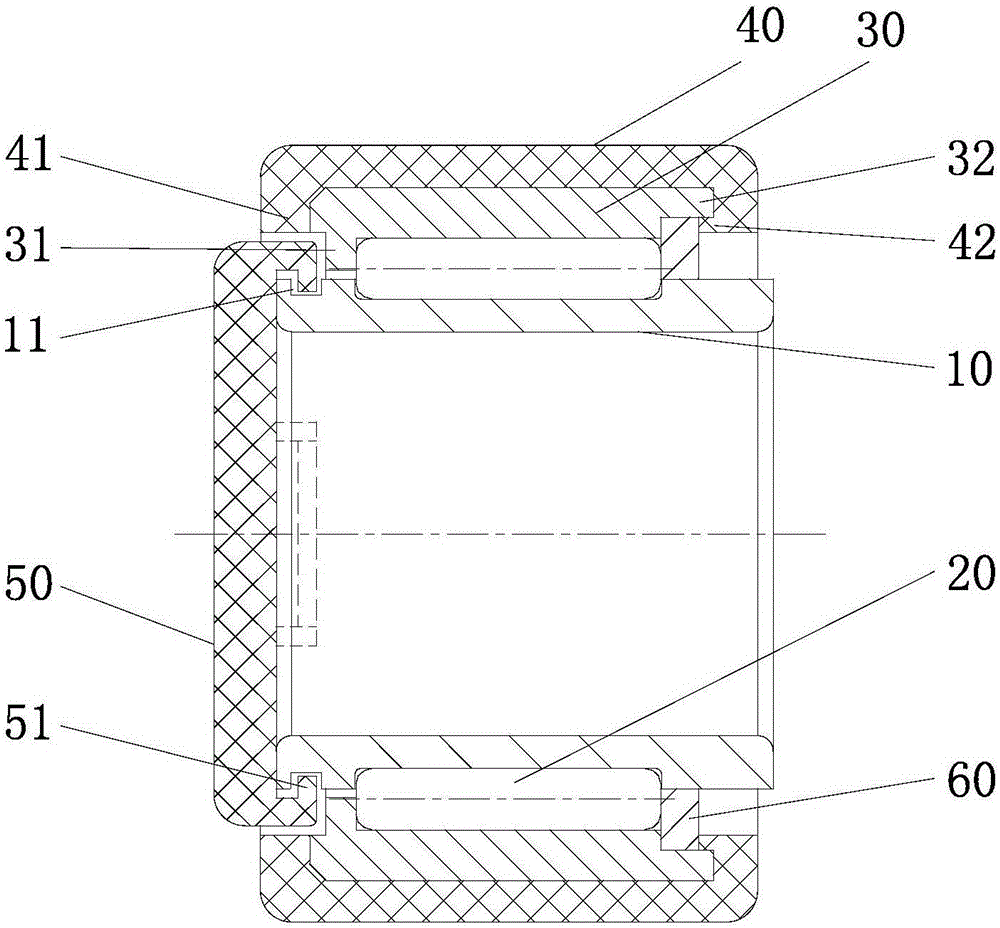

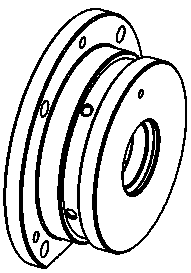

Bearing roller of seat damper

ActiveCN106194994AFlexible rotationReduce noiseBearing componentsNeedle bearingsEngineeringWear resistance

The invention belongs to the technical field of seats, and relates to a bearing roller of a seat damper. The bearing roller of the seat damper comprises a bearing inner ring, a bearing outer ring, a roller between the bearing inner ring and the bearing outer ring and a roller check ring at one end of the roller. The outer cylindrical face of the bearing ring is sleeved with an annular rolling ring, and one end of the bearing inner ring is sleeved with a side cover plate. The bearing roller of the seat damper has the advantages that a roller bearing is flexible in rotating, low in noise and long in service life. The friction force of the annular rolling ring on a sliding rail is small, the noise is low, and the abrasion resistance is good. The rolling ring and the sliding rail are combined, so that the bearing roller is flexible in overall rotation, low in noise, long in service life, and capable of enabling the seat damper to rotate smoothly and freely at any stroke position.

Owner:ZHEJIANG TIANCHENG SEAT

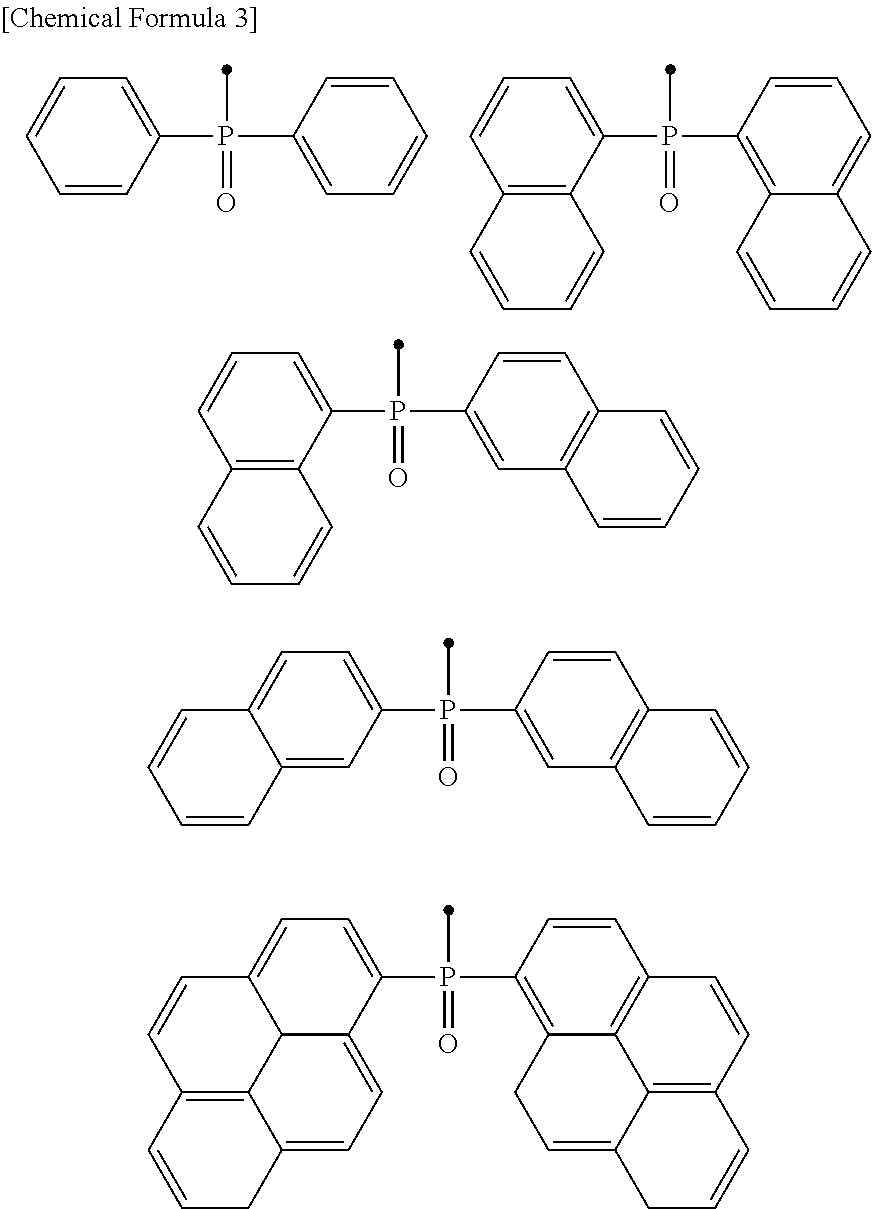

Phenanthroline derivative, electronic device containing same, light emitting element, and photoelectric conversion element

InactiveUS20180019407A1Improve efficiencyReliable lifeOrganic chemistryElectroluminescent light sourcesLithium electrodeNitrogen

Provided is a phenanthroline derivative having a specific structure. The phenanthroline derivative includes in a skeleton a substituted or unsubstituted heteroaryl group having electron-accepting nitrogen, and a substituted or unsubstituted aryl group having less than 20 ring-forming carbon atoms. The phenanthroline derivative is preferably used in electronic devices such as light emitting elements, photoelectric conversion elements, lithium ion batteries, fuel cells and transistors.

Owner:TORAY IND INC

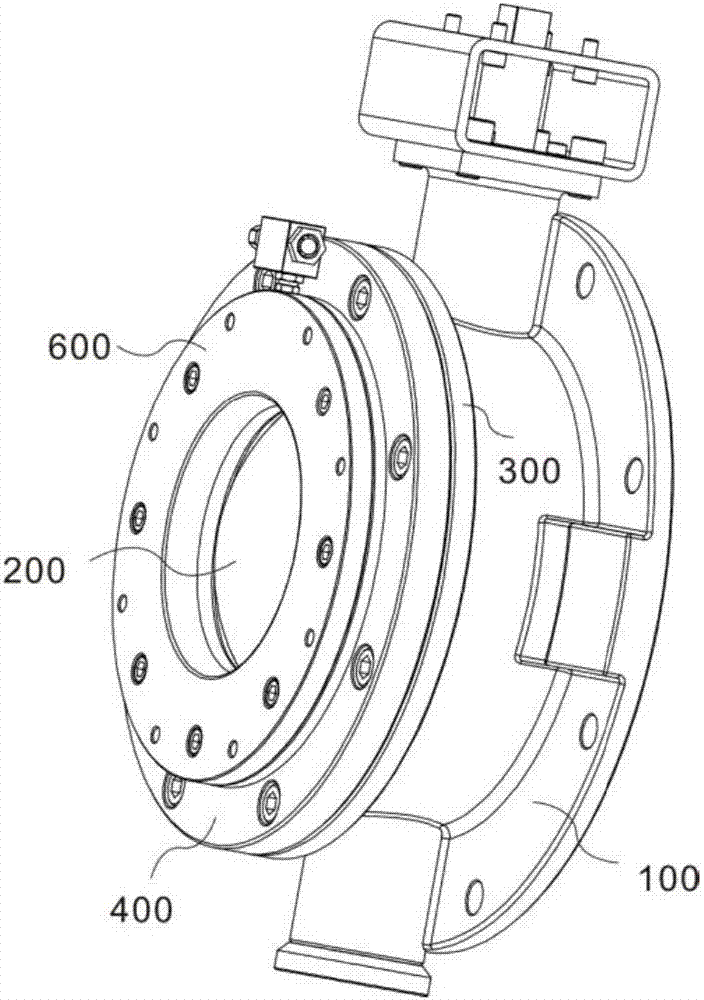

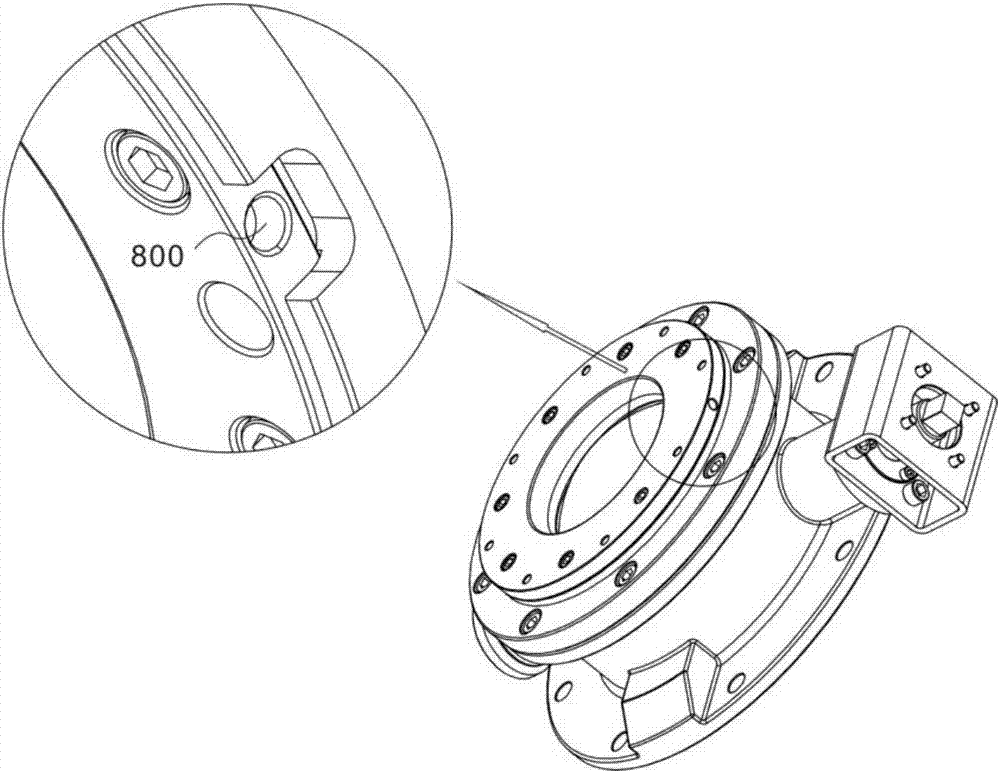

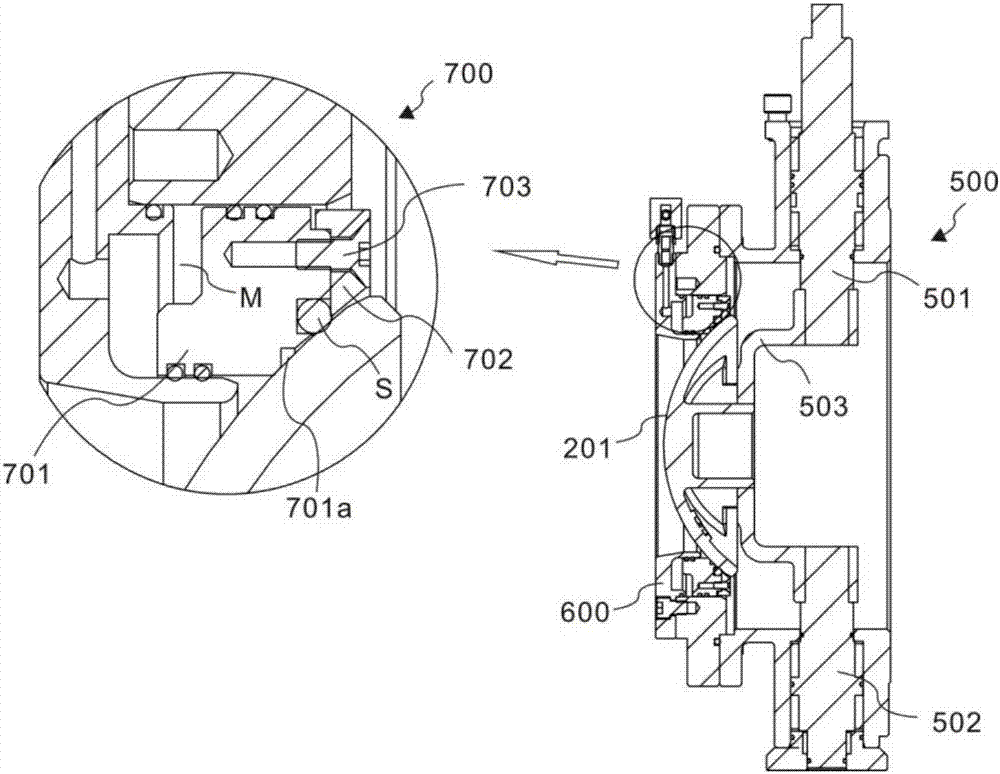

Novel dual-sealing type dome valve

A novel dual-sealing type dome valve comprises a valve body, a valve element, a valve seat and a valve deck and further comprises a gland, a sealing assembly and an air source channel. One end of the gland is connected with the valve deck, and the other end exceeds the inner side face of the valve deck so that a limiting face can be formed, then the other end of the gland extends downwards to abut against the outer end face of the valve element when the dome valve is closed, and a sealing channel is formed. The sealing assembly comprises a piston and a sealing gland. The piston and the sealing gland are arranged in the sealing channel and can move in the sealing channel. The air source channel extends from an opening of the valve deck to the sealing channel so that an air inlet and outlet channel can be formed. The novel dual-sealing type dome valve has the beneficial effects that sealing is achieved by adopting a metal material, thus, compared with traditional sealing, the performance is more reliable, and the service life is longer. Control is achieved through an air source, air in the piston is exhausted preferentially, the valve can be opened after the pressure between the valve element and the piston is reduced, abrasion due to opening of the valve is reduced, the service life of the valve is prolonged, the maintenance period is further shortened, and energy sources are saved.

Owner:JIANGSU GEN DE POWER EQUIP CO LTD

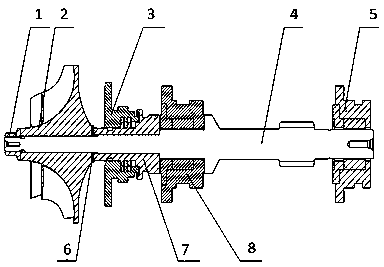

High-speed floating ring bearing and rotor system support manner

ActiveCN109027002AReduce heat generationReduce oil supplyLiquid cushion bearingsMechanical energy handlingHollow cylinderDynamic pressure

The invention discloses a high-speed floating ring bearing sleeving a rotor. The high-speed floating ring bearing comprises a bearing block and a floating ring. The bearing block is of a hollow cylinder structure. The floating ring is arranged in the hollow cylinder structure. When the rotor runs, the floating ring and the rotor relatively rotate, and the bearing block is provided with a bearing block oil passing hole and a bearing block oil passing groove. The floating ring is provided with a floating ring oil passing hole and a floating ring oil groove. Lubricating media enter the bearing block oil passing groove through the bearing block oil passing hole and enter the floating ring oil groove through the floating ring oil passing hole, and when the rotor rotates, a dynamic pressure oilfilm is formed to support the rotor. A high-speed floating ring bearing-rotor supporting system comprises the above high-speed floating ring bearing, and further comprises a floating ring and thrust combined bearing, a rotor system and an oil supply system.

Owner:湖南泛航智能装备有限公司

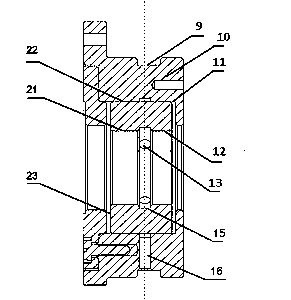

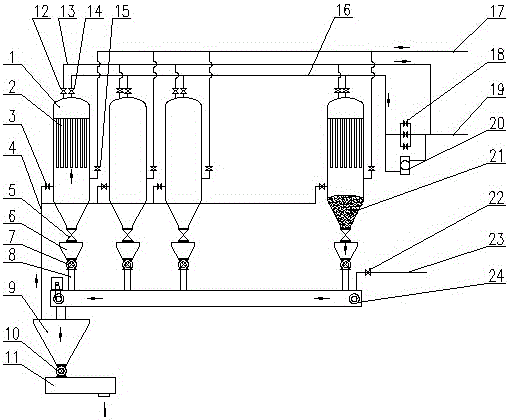

Blast furnace gas dry method bag type dust removing mechanical type pressure dust unloading process and device thereof

ActiveCN106636507ALarge flow cross-sectional areaLess load interval changesBlast furnace detailsProcess efficiency improvementEngineeringGas chamber

Disclosed is a blast furnace gas dry method bag type dust removing mechanical type pressure dust unloading process and device. A first gas pressure relief valve is arranged on a dust and gas chamber located on the lower portion of each cloth bag dust removing box body. Each first gas pressure relief valve of the corresponding cloth bag dust removing box body is connected to a concentration dust bin through a first gas pressure relief pipe, so that dust and gas with pressure in the concentration dust bin enter the dust and gas chambers located on the lower portions of the cloth bag dust removing box bodies through the first gas pressure relief valves. A second gas pressure relief valve is arranged on a gas purifying chamber located on the upper portion of each cloth bag dust removing box body. Each second gas pressure relief valve of the corresponding cloth bag dust removing box body is connected to a low pressure purified gas main pipe through a second gas pressure relief pipe, so that gas in gas purifying chambers located on the upper portions of the cloth bag dust removing box bodies enters the low pressure purified gas main pipe through the second gas pressure relief valves. Cloth bag dust removing box body dust unloading is conducted by utilizing gas pressure energy of a dust removing system. The blast furnace gas dry method bag type dust removing mechanical type pressure dust unloading process and device have the advantages that the mechanical dust unloading and conveying process is adopted and meanwhile pneumatic dust unloading and conveying are utilized, and the pneumatic dust unloading and conveying process is adopted and meanwhile mechanical power dust unloading and conveying are utilized.

Owner:LIUZHOU IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com