Silica film all-in-one keyboard

A silicone membrane, integrated technology, used in electrical components, electrical switches, circuits, etc., can solve the problems of reducing the reliability of the instrument, difficult to ensure the sealing performance of the instrument, and short service life of the panel layer, so as to reduce the service life of the instrument and improve the Reliable feel and life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

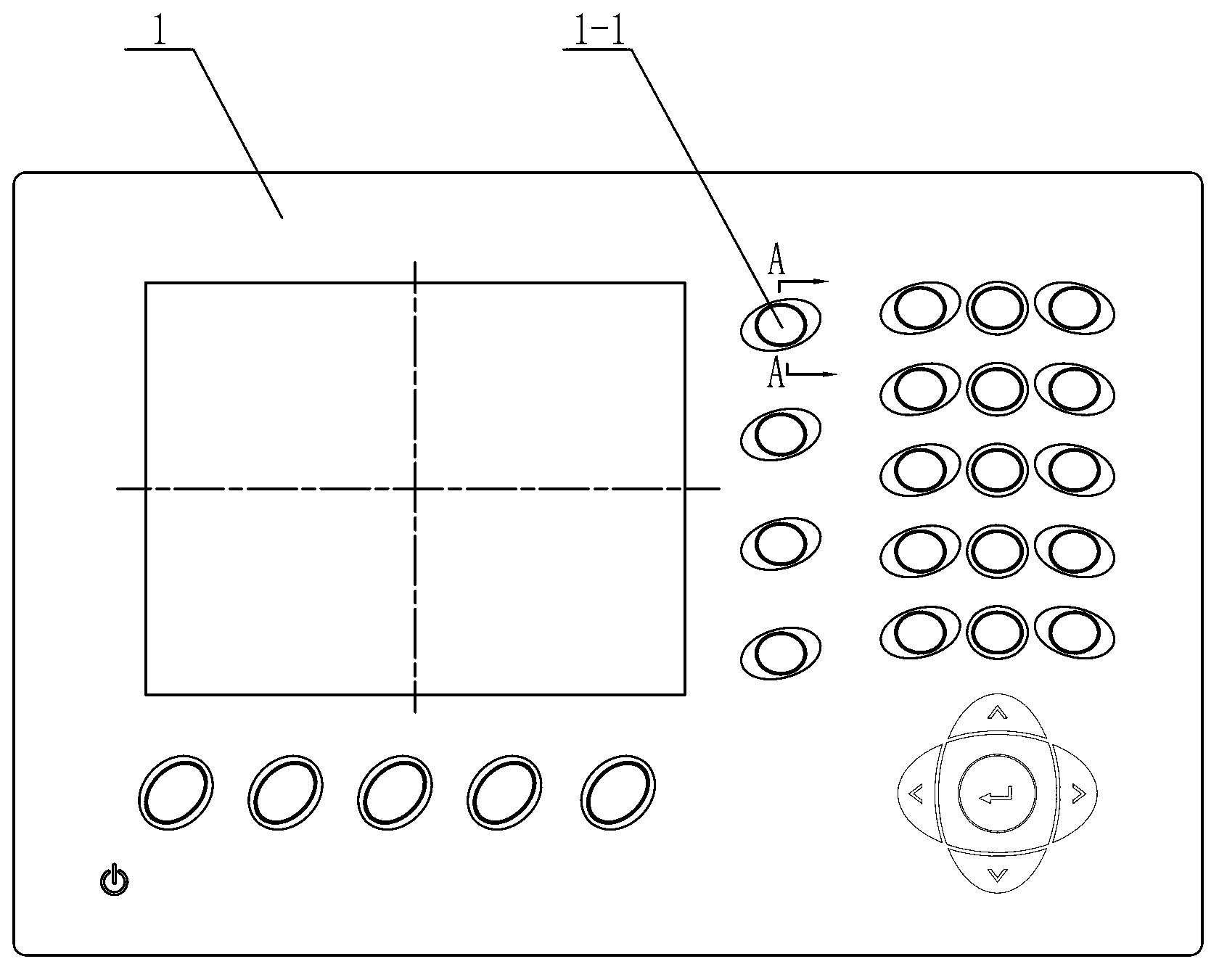

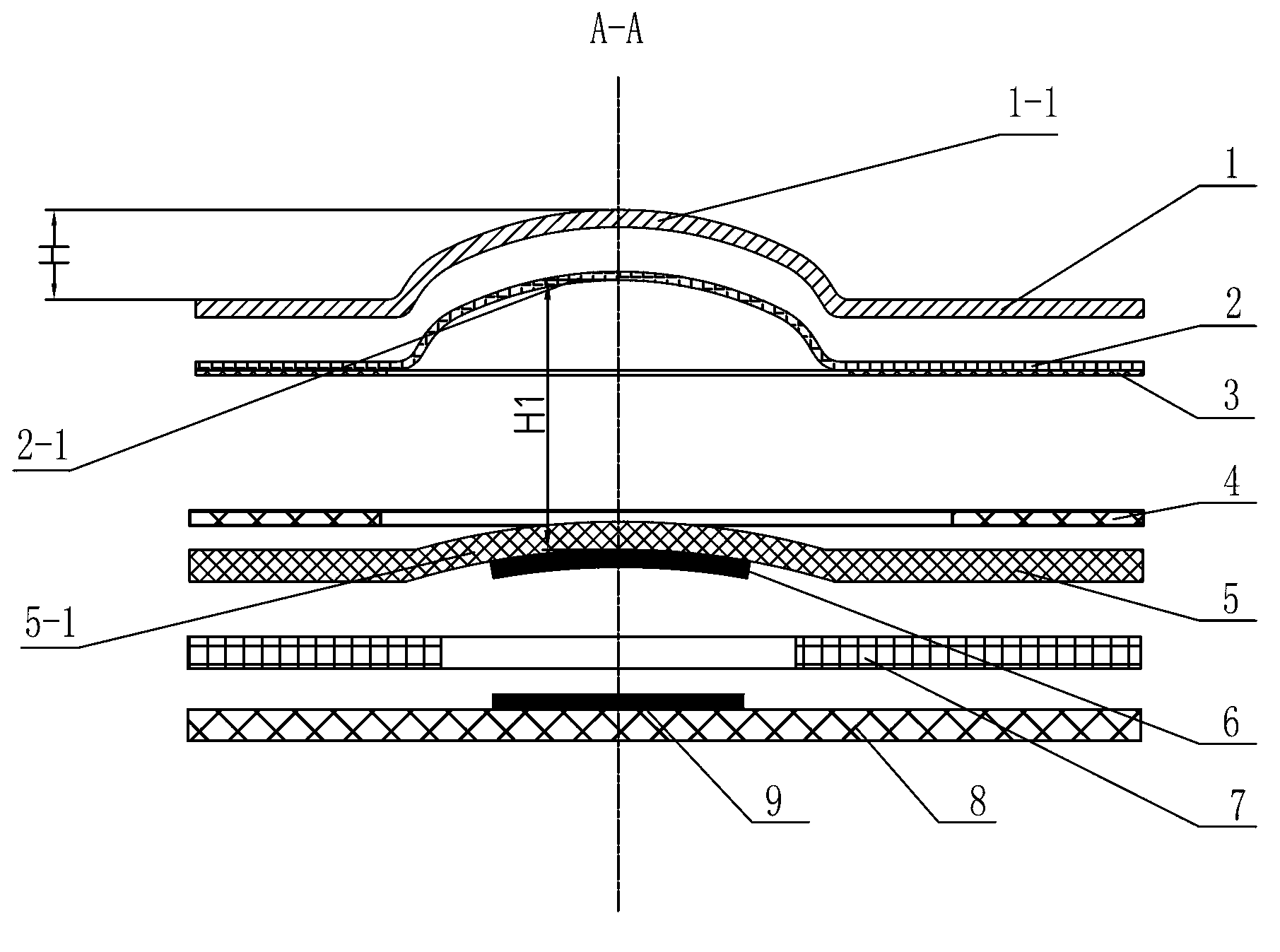

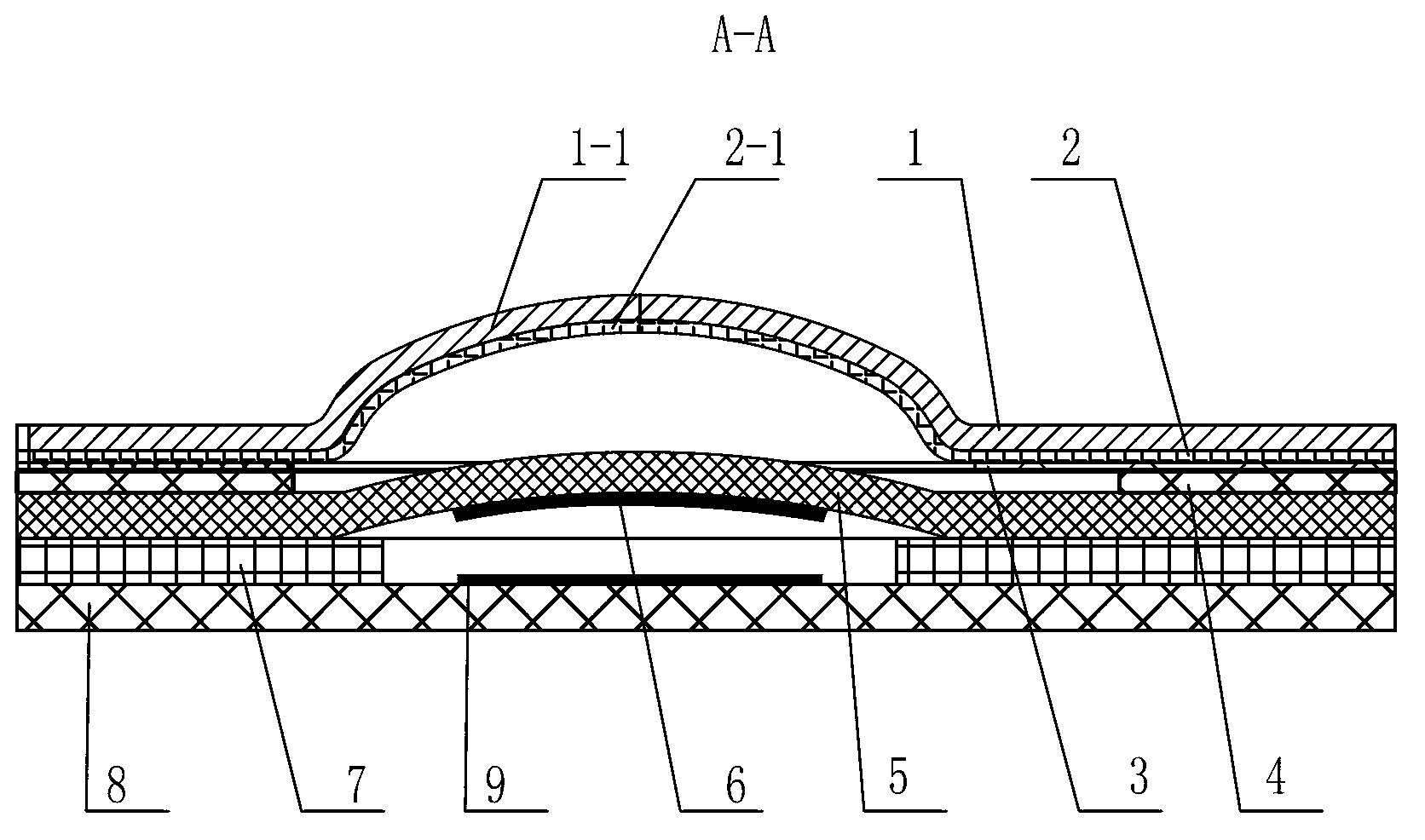

[0011] See Figure 1~3 As shown, the silicone membrane integrated keyboard of the present invention comprises a panel layer, a lower substrate layer 8 with a thin film circuit 9, an upper substrate layer 5 with a conductive contact piece 6 and an insulating interlayer 7, an upper substrate layer 5, an insulating interlayer 7 and the lower substrate layer 8 constitute the control circuit part of the keyboard.

[0012] See Figure 1~3 As shown, the panel layer of the present invention includes a polyester film layer 1 connected by thermocompression and a silica gel layer 2 located at its lower part, and the polyester film layer 1 and the silica gel layer 2 are connected into one body after thermocompression by high temperature and bonding medium. The inventive panel layer has windows and is used to mount the display. The thickness of silica gel layer 2 of the present invention is between 0.15-0.2mm, as the thickness of silica gel layer 2 is at 0.18mm, and the thickness of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com