Polyurethane reaction ball and preparing method thereof

A technology of polyurethane and reaction, which is applied in the field of polyurethane microporous elastomer hexagonal reaction ball and its preparation, can solve the problems of decreased elasticity, ozone resistance, poor aging resistance, and inability to use, and achieves improved rebound performance and good response ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation of Isocynate1: Add 450g of diphenylmethane diisocyanate (Yantai Wanhua, MDI-100) into a three-necked flask equipped with a stirrer, thermometer, and nitrogen tube, heat to 60-70°C, and then add the calculated Polyol 9142.5 g, Polyol 11142.5g, Polyol 1315g. After reacting at 80°C for 2 hours, lower the temperature to below 40°C and then add 250g of polymethylene polyphenyl polyisocyanate (Yantai Wanhua, PM-200), and control the NCO mass fraction of Isocynate1 at 21.6-22.6%;

[0060] Preparation of Isocynate2: Add 400g of diphenylmethane diisocyanate (Yantai Wanhua, MDI-100) into a three-neck flask equipped with a stirrer, thermometer, and nitrogen tube, heat to 60-70°C, and then add 10300g of calculated Polyol , Polyol 1280g, Polyol 1420g. After reacting at 80°C for 2 hours, lower the temperature to below 40°C and then add 200g of polymethylene polyphenyl isocyanate (Yantai Wanhua, PM-200), and control the NCO mass fraction of Isocynate2 at 17.8-18.8%;

[0...

Embodiment 1

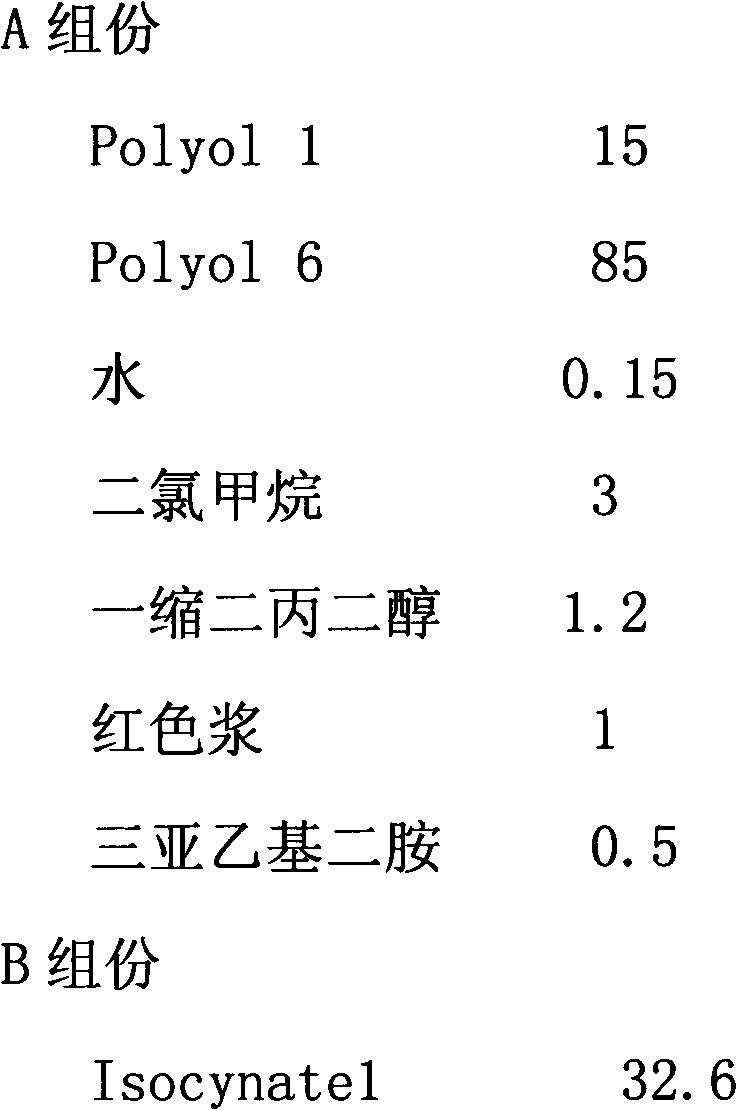

[0064] The preparation of embodiment 1 polyurethane reaction ball

[0065]

[0066] At room temperature, put the above-mentioned component A raw materials into the reaction kettle in turn, and use a high-speed shear mixer to stir for 5 minutes at a stirring speed of 1500 rpm, and the output is System1. +Put System1 and Isocynate1 into their respective storage tanks, mix and stir System1 at 25°C and Isocynate1 at 25°C, stir for 8 seconds, pour into a mold at 35°C, open the mold in 7 minutes, leave it at room temperature for 30 hours, and test the mechanical properties . The polyurethane reaction ball prepared according to the method of embodiment 1, density 520kg / m 3 , hardness ShoreA 44, free fall rebound 84%.

Embodiment 2

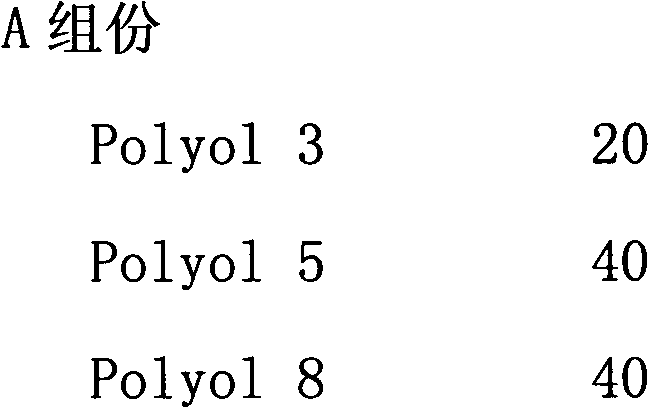

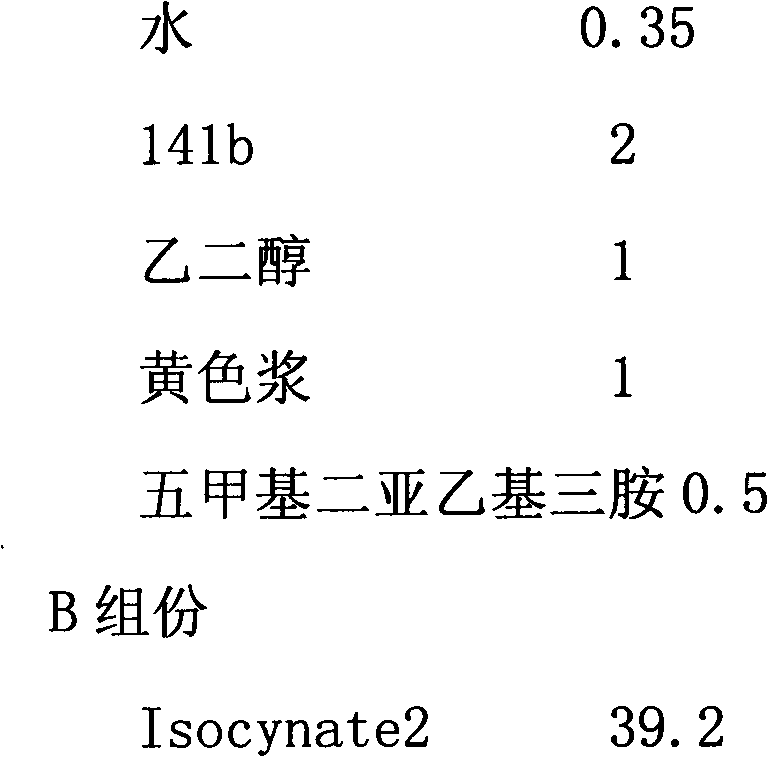

[0067] The preparation of embodiment 2 polyurethane reaction balls

[0068]

[0069]

[0070]At room temperature, put the above-mentioned component A raw materials into the reaction kettle in turn, and use a high-speed shear mixer to stir for 5 minutes at a stirring speed of 1500 rpm, and the output is System2. Put System2 and Isocynate2 into their respective storage tanks, mix and stir System1 at 24°C and Isocynate1 at 26°C, stir for 7 seconds, pour into a mold at 35°C, open the mold in 7 minutes, and test the mechanical properties after standing at room temperature for 30 hours. The polyurethane reaction ball prepared according to the method of embodiment 2, density 450kg / m 3 , hardness ShoreA 38, free fall rebound 83%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com