Patents

Literature

77results about How to "Improve heat generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal package wth heat slug for die stacks

InactiveUS20130277821A1Improve cooling effectImproved thermal connectionSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor assembly comprises a package, which in turn comprises at least one substrate, a first die stacked onto the substrate, at least one further die stacked onto the first die, at least one heat spreader in the package, and TSV:s extending through the stacked dies. The ends of the TSV:s are exposed at the further die.

Owner:SONY MOBILE COMM INC +1

Semiconductor device, power diode, and rectifier

ActiveUS20120061662A1Improve pressure resistanceLower average currentSemiconductor devicesPower semiconductor devicePower flow

An object is to provide a semiconductor device having electrical characteristics such as high withstand voltage, low reverse saturation current, and high on-state current. In particular, an object is to provide a power diode and a rectifier which include non-linear elements. An embodiment of the present invention is a semiconductor device including a first electrode, a gate insulating layer covering the first electrode, an oxide semiconductor layer in contact with the gate insulating layer and overlapping with the first electrode, a pair of second electrodes covering end portions of the oxide semiconductor layer, an insulating layer covering the pair of second electrodes and the oxide semiconductor layer, and a third electrode in contact with the insulating layer and between the pair of second electrodes. The pair of second electrodes are in contact with end surfaces of the oxide semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

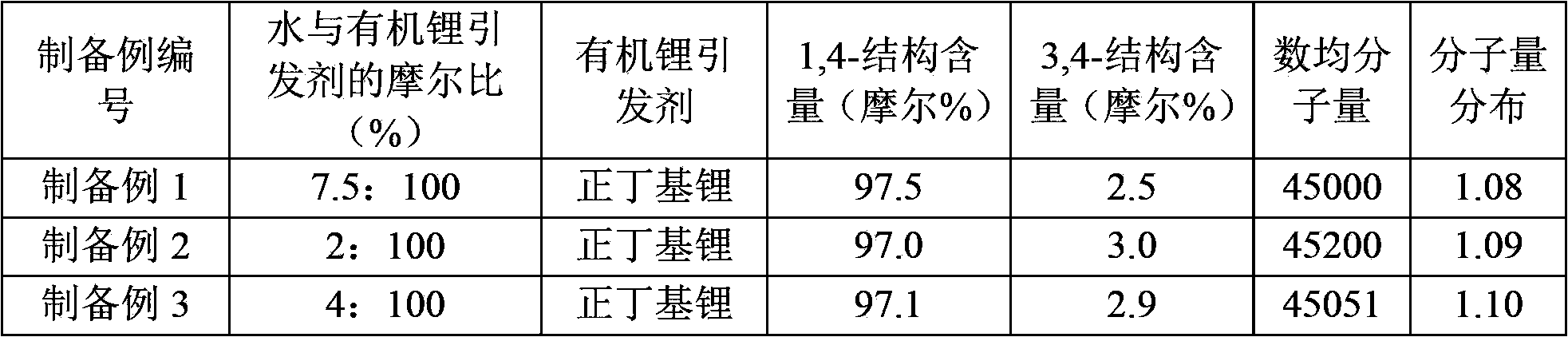

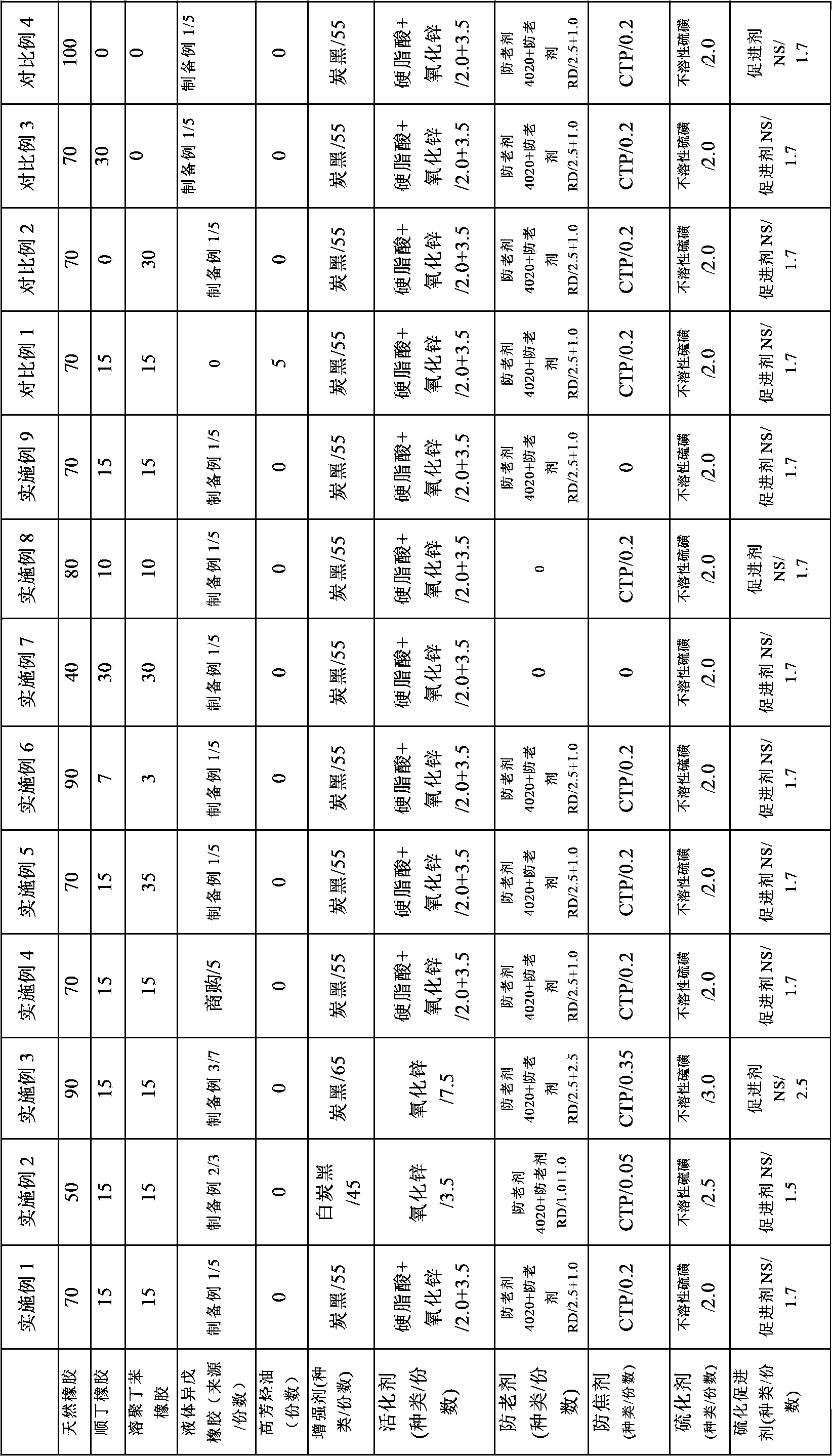

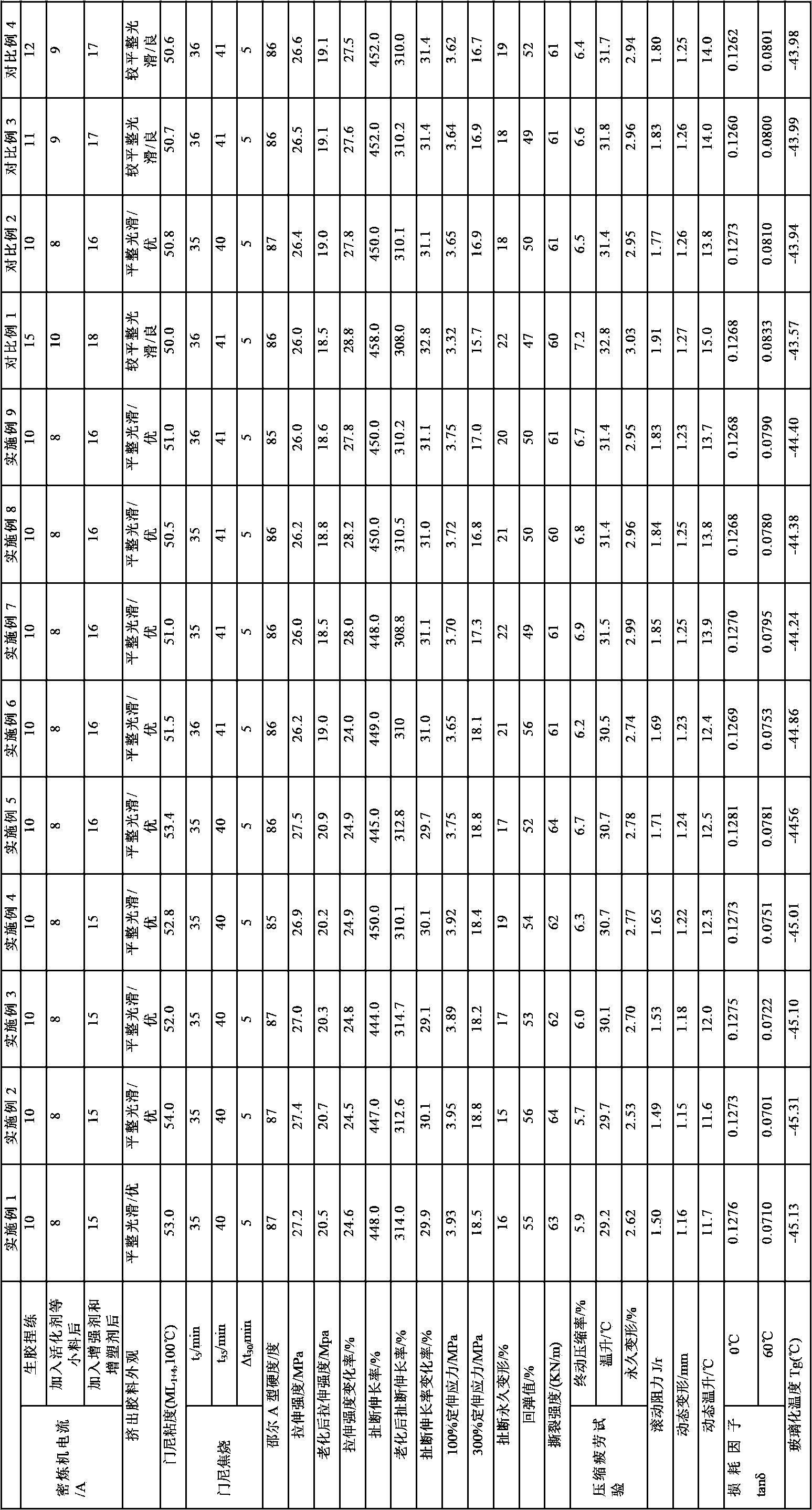

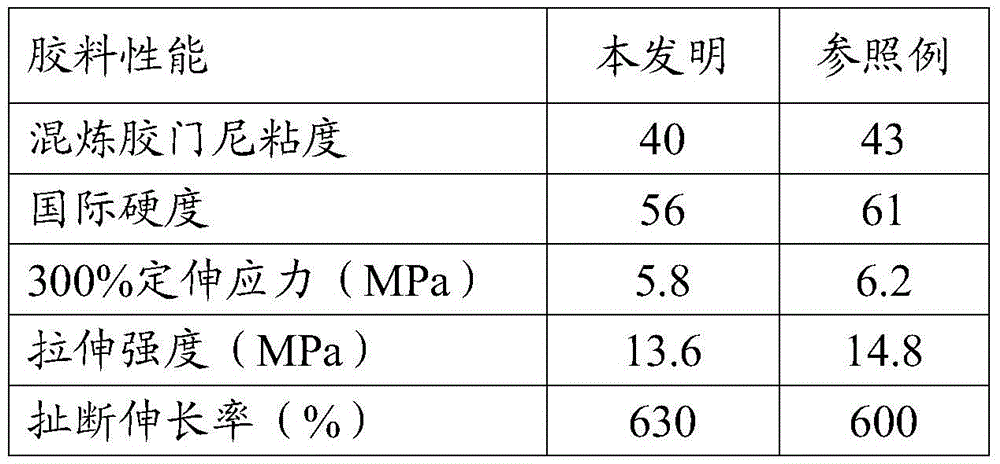

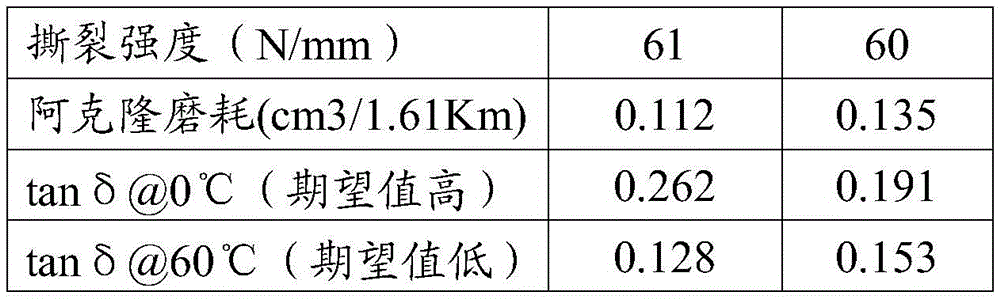

Rubber composition, tyre tread rubber and preparation method thereof

ActiveCN103788422AImprove securityEnsure safetySpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention relates to a rubber composition. The composition comprises a main body rubber, a vulcanizing agent, a vulcanization accelerator, an activator and a reinforcing agent. The composition also comprises liquid isoprene rubber. The main body rubber comprises natural rubber, butadiene rubber and solution polymerized styrene-butadiene rubber. The invention also discloses tyre tread rubber and a preparation method thereof. The tyre tread rubber provided by the invention is low in processing energy consumption, good in surface quality of extruding and calendaring rubber materials, good in physical and mechanical properties and ageing resistant property, and relatively small in compression set and heat generation, and can improve durability of the tyre and prolong the service life of the tyre. The tyre tread rubber provided by the invention has good wet skid resistance and low rolling resistance, can guarantee security of the tyre in a driving process and is benefit for energy conservation of the tyre.

Owner:CHINA PETROLEUM & CHEM CORP +1

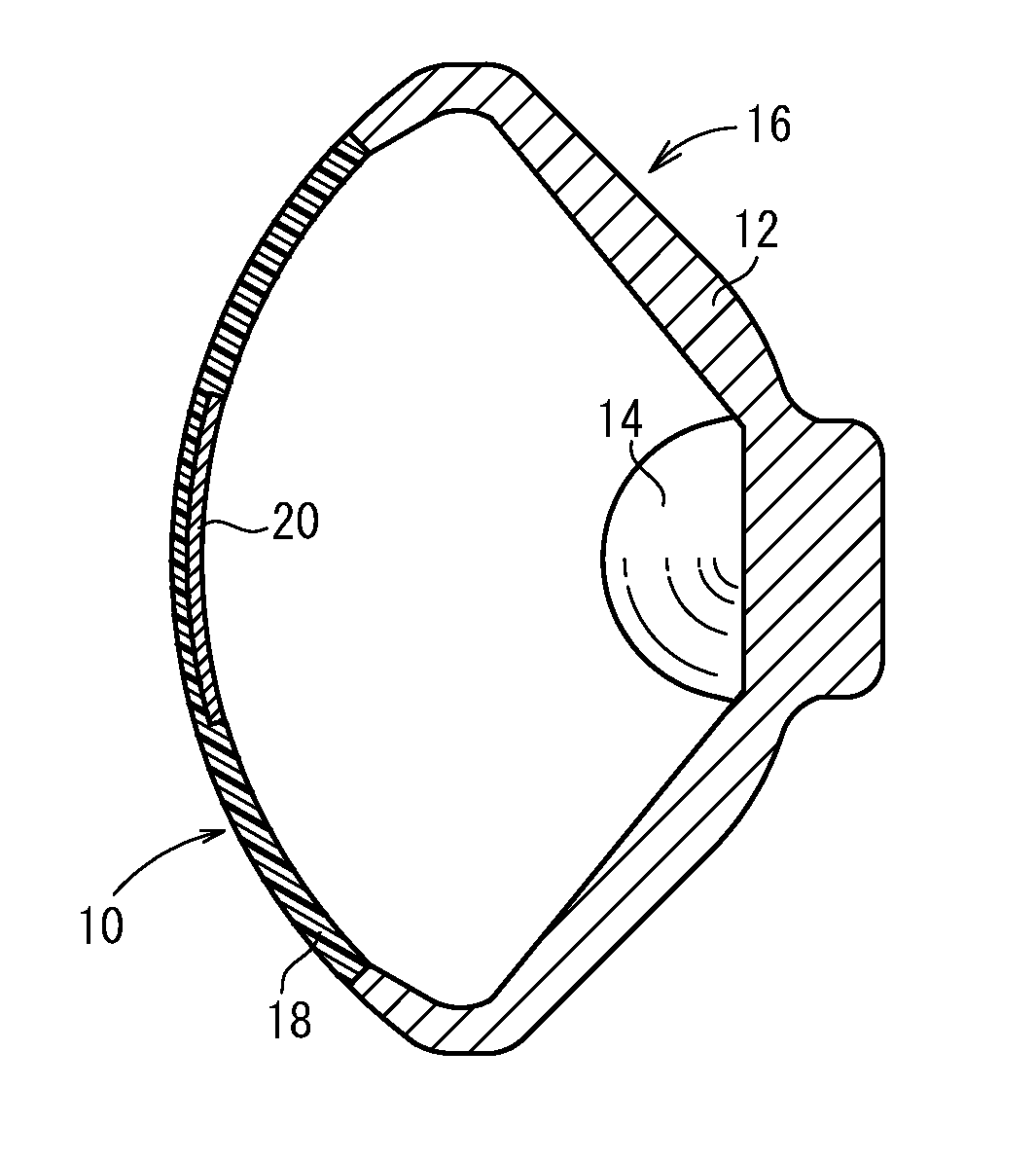

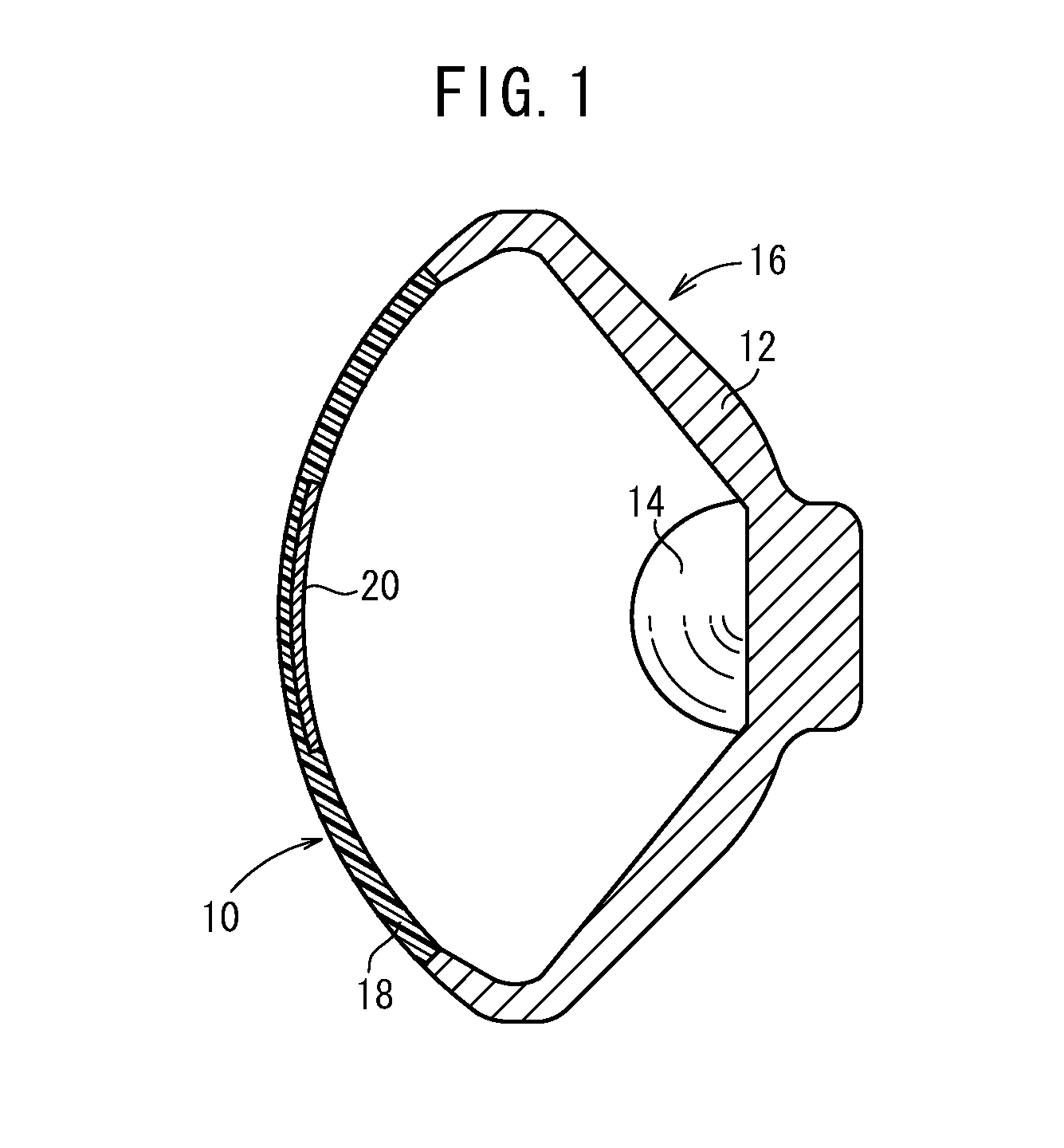

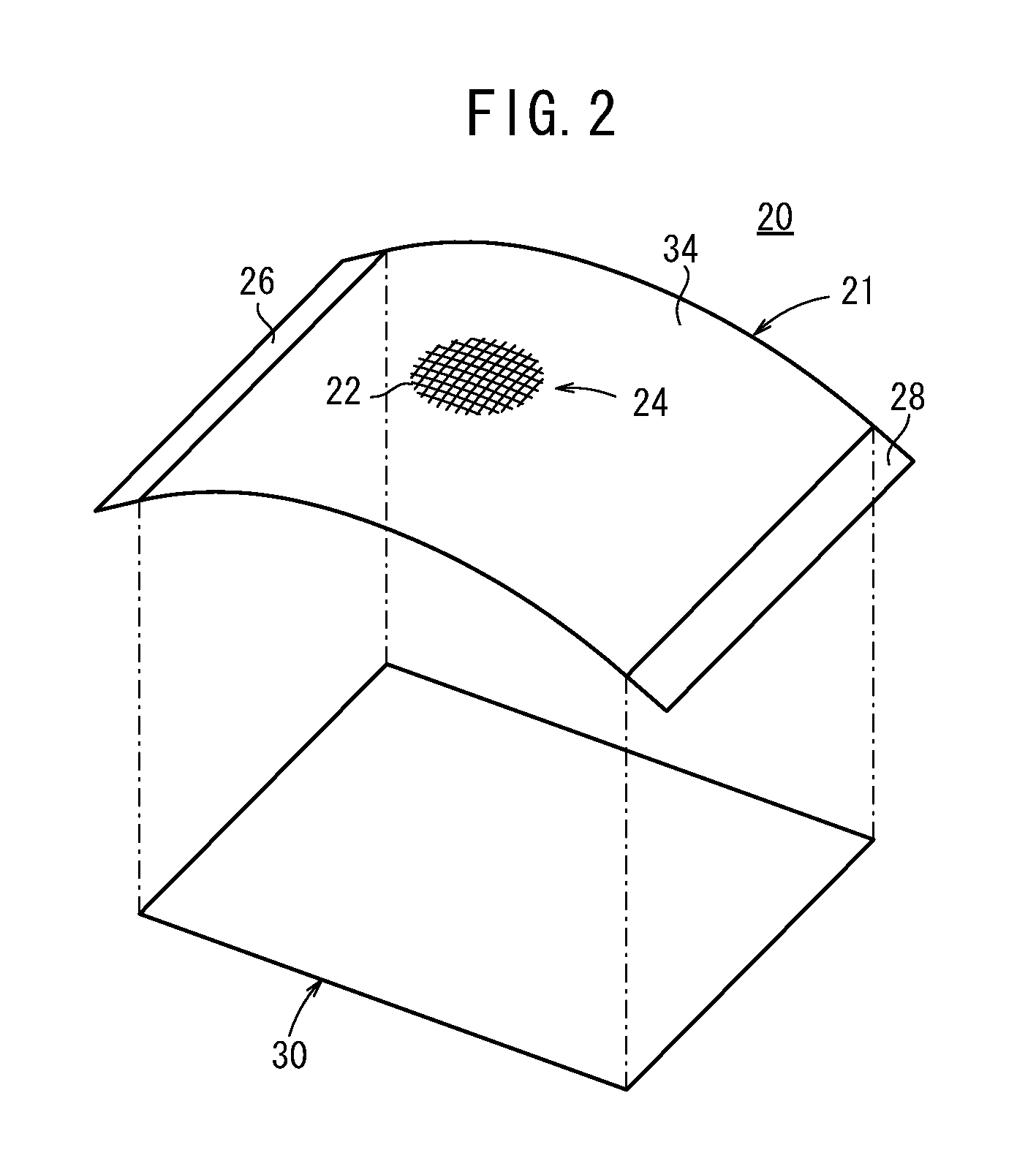

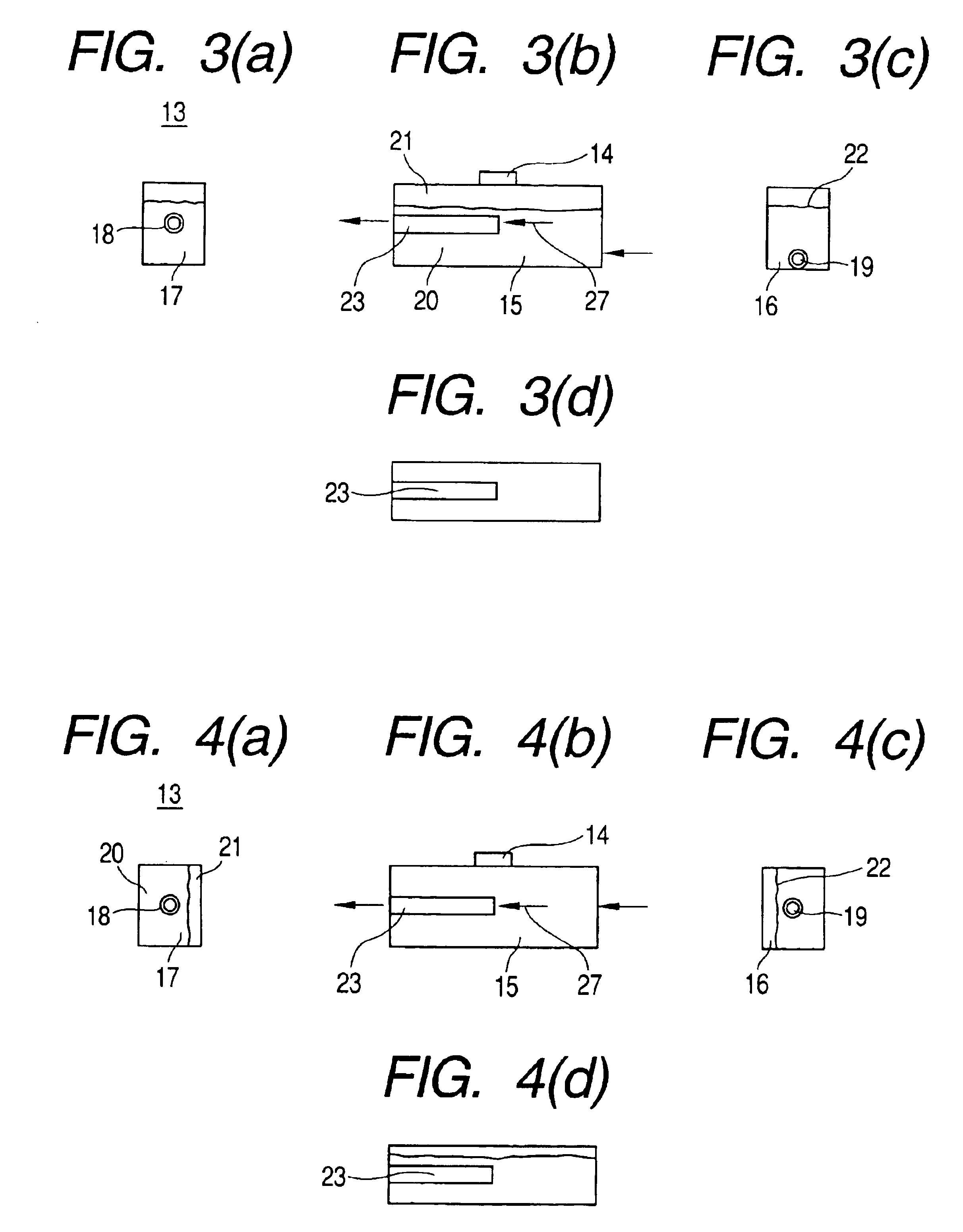

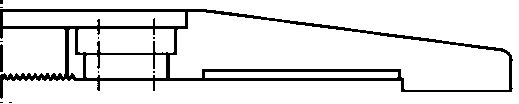

Formed body with curved surface shape, method of producing the formed body, front cover for vehicle lighting device, and method of producing the front cover

ActiveUS20110134655A1Low costImprove conductivityMaterial nanotechnologyVehicle headlampsEngineeringFront cover

A formed body having a curved surface, a method of producing the formed body, a front cover for a vehicle lighting device, and a method of producing the front cover. A front cover (10) for a vehicle lighting device, mounted to a front opening in a vehicle lighting device (16) having a lamp body (12) and a light source (14) which is provided in the lamp body (12), wherein a heat generating body (20) is provided in a substantially rectangular region of that surface of the front cover which faces the light source (14). The heat generating body (20) maintains the relationship of Ra=(2 R0), where R0 is the electric resistance value (initial value) of the heat generating body (20) before the heat generating body is elongated and Ra is the electric resistance value of the heat generating body (20) after the heat generating body is elongated 5%.

Owner:FUJIFILM CORP

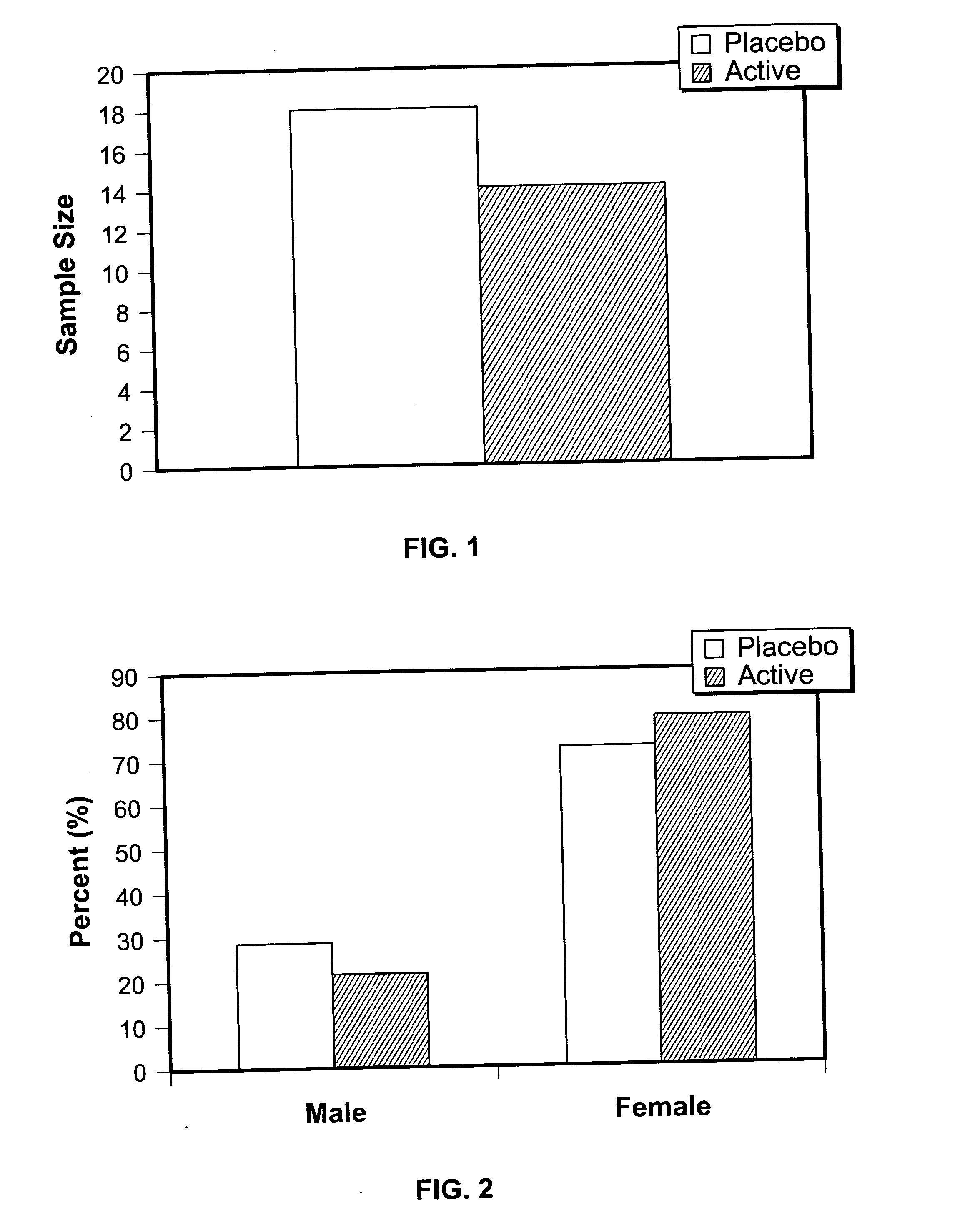

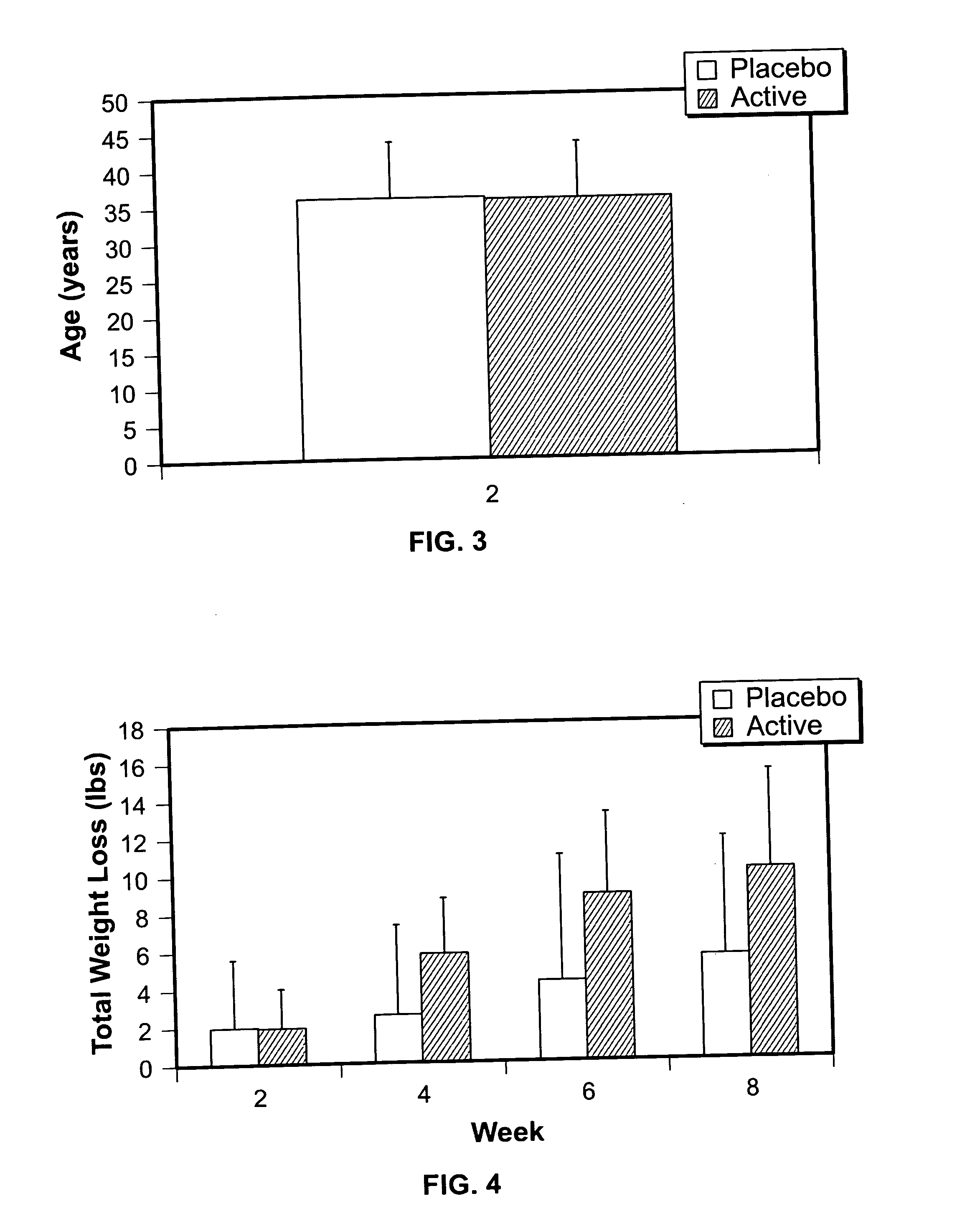

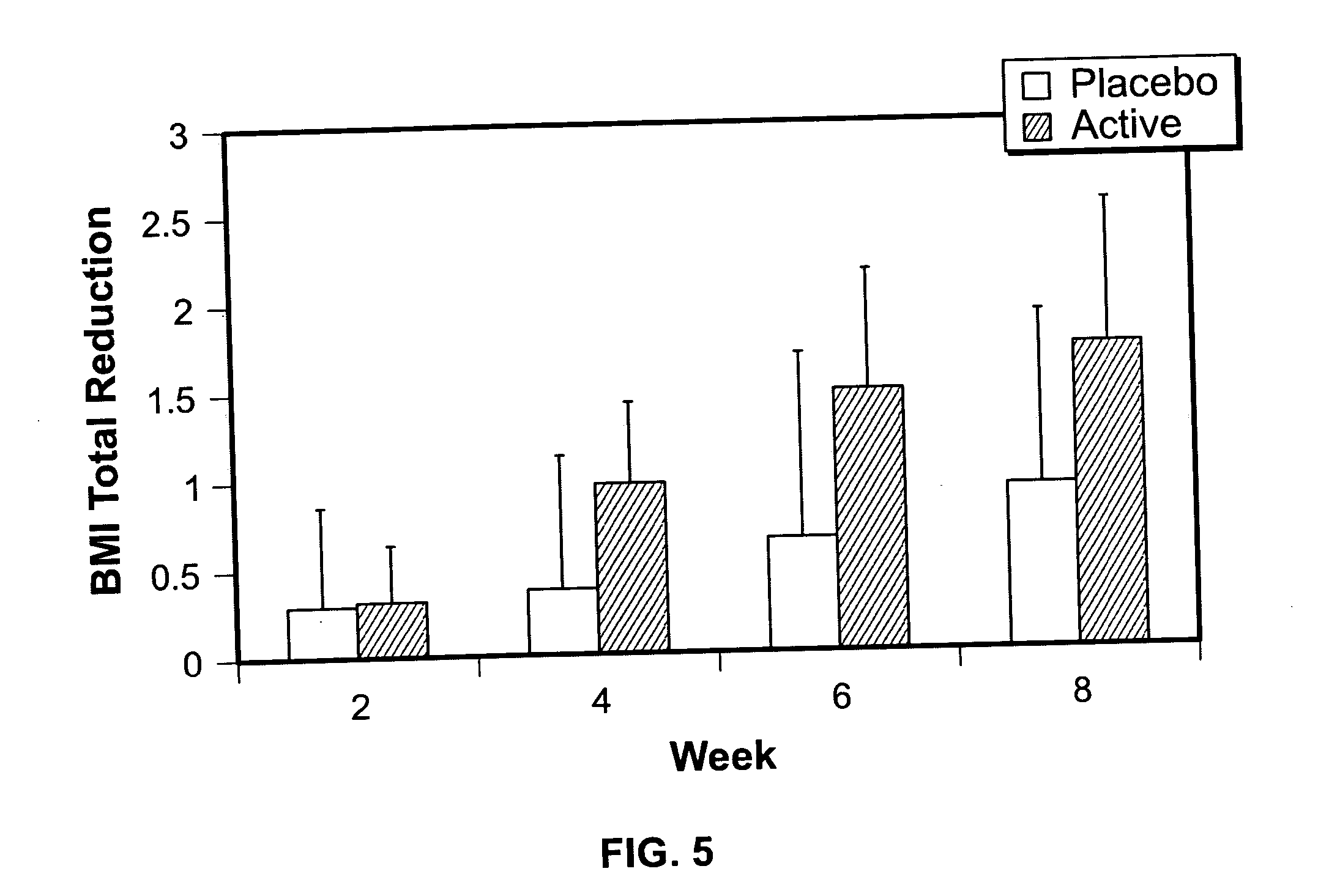

Weight-loss supplement

InactiveUS20050130933A1Reduce and control appetiteLowering indexBiocideOrganic active ingredientsEnvironmental healthAdditive ingredient

A weight-loss supplement comprising a satiety-promoting ingredient that includes a mixture of dietary fibers comprising glucomannan and a gum and; a thermogenic ingredient selected from the group consisting of caffeine, catechin-polyphenol and combinations thereof.

Owner:HALO FORMULATIONS LTD

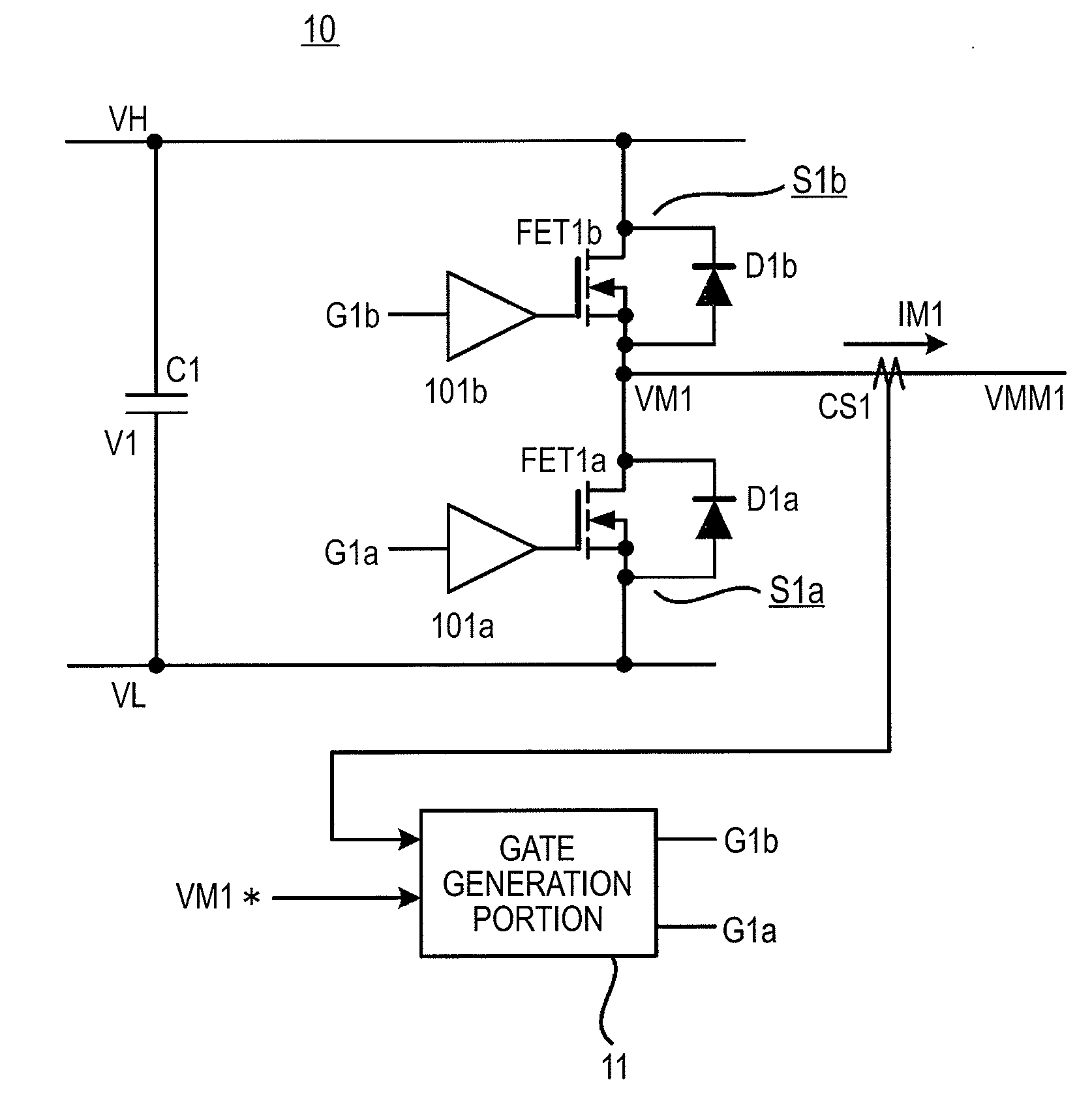

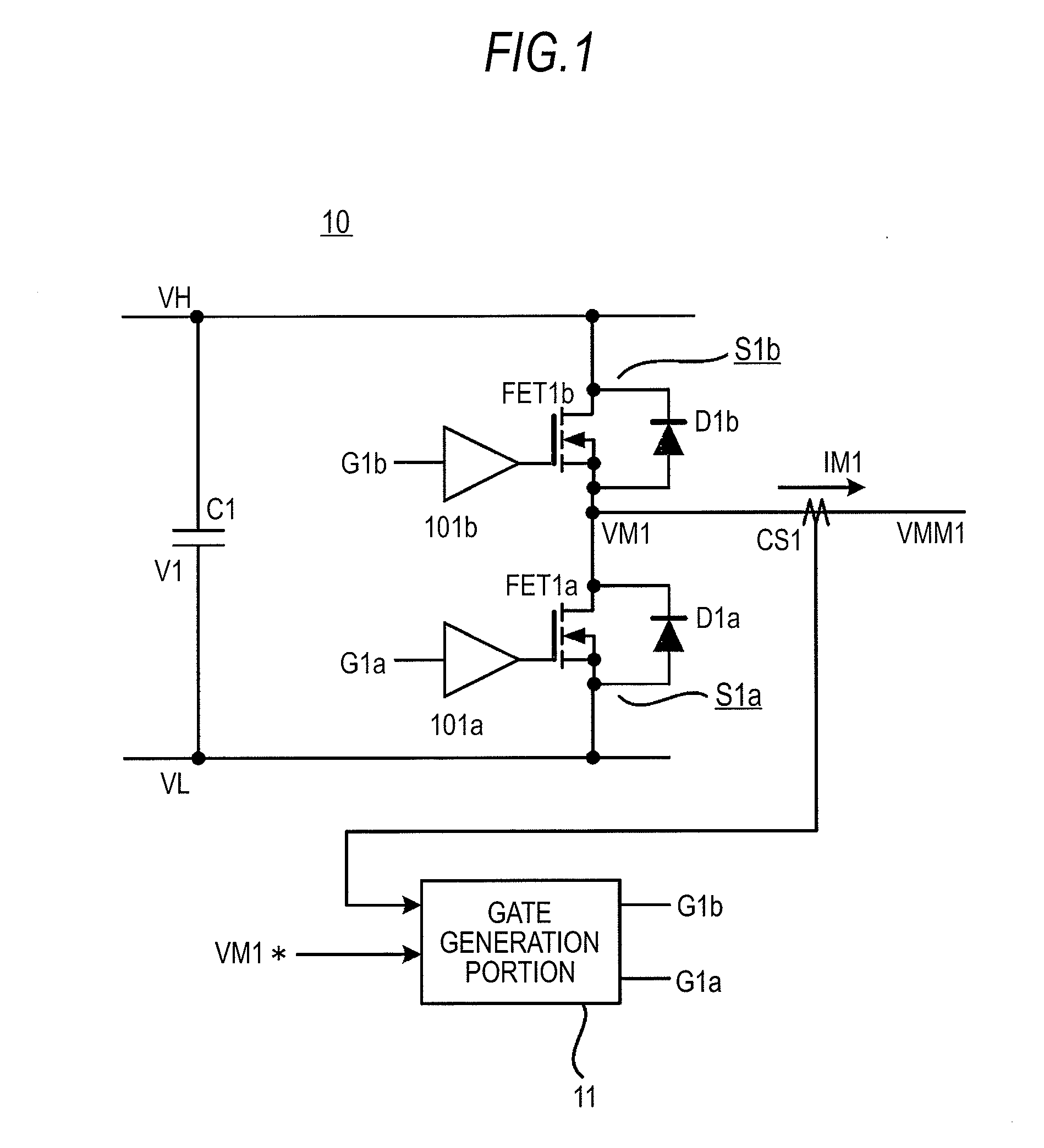

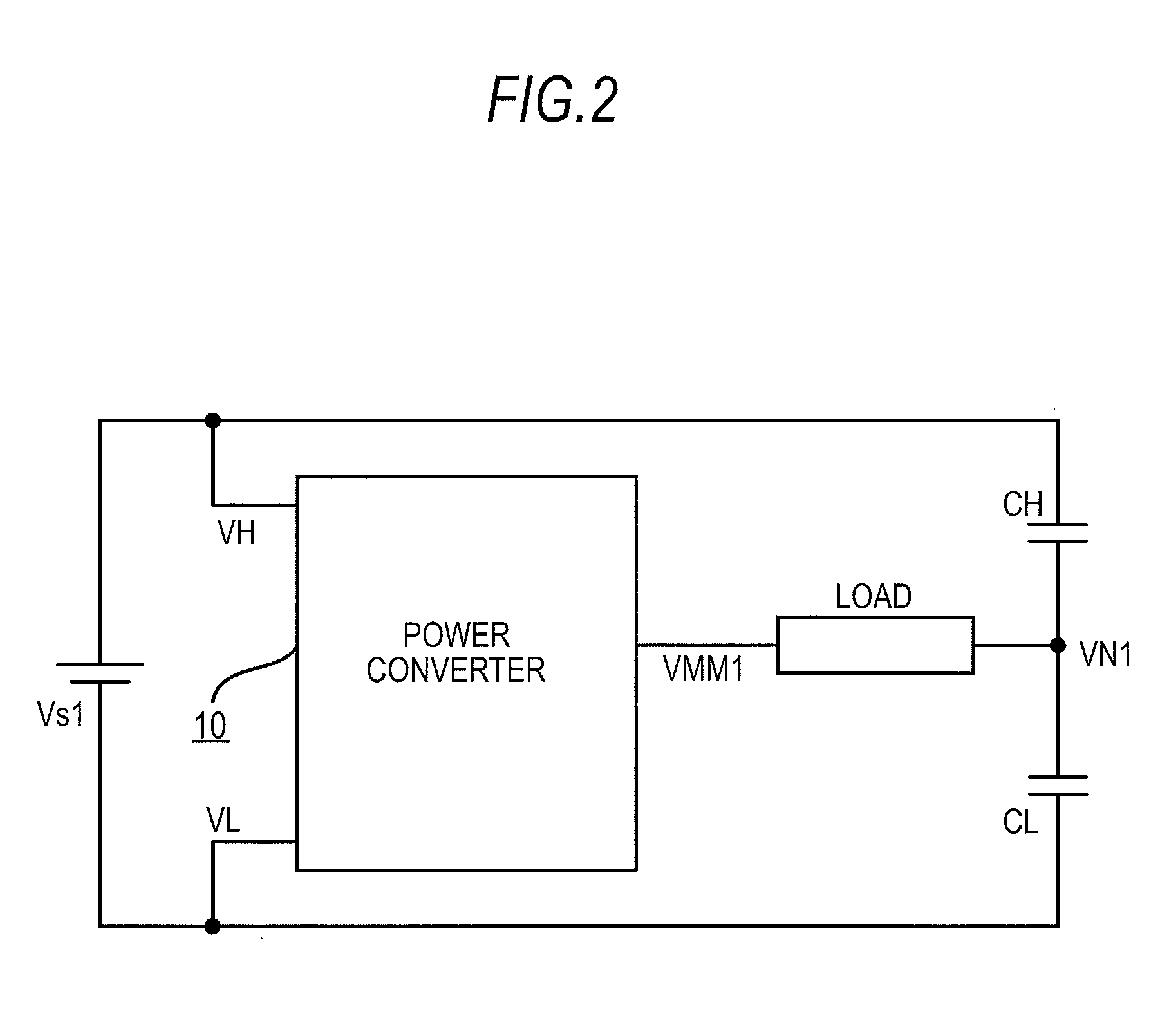

Power converter

ActiveUS20130002227A1Improve heat generationLow heat generationEfficient power electronics conversionAc-dc conversionPower flowCurrent sensor

A power converter has one set of two semiconductor switches performing switching actions, each of which is formed of an FET and a free wheel diode connected in anti-parallel to the FET, and a smoothing capacitor, and convers power by complementary switching actions of the FETs in the semiconductor switches. The power converter is provided with a current sensor that detects a direction of a current flowing through the semiconductor switches and a gate generation portion that skips ON signals of PWM gate signals of the semiconductor switches when the direction of the current flowing through the semiconductor switches is negative.

Owner:MITSUBISHI ELECTRIC CORP

Rubber material formula of car tires and production method thereof

The invention relates to a formula of tire rubber, in particular to a rubber material formula of car tires. The rubber material formula of car tires, provided by the invention, is composed of following components in parts by weight: 110-140 parts of crude rubber material, 60-110 parts of reinforcing agent, 10-15 parts of environment-friendly aromatic hydrocarbon oil, 2-3 parts of activating agent, 2-4 parts of anti-aging agent, 1-2 parts of microcrystal wax, 2-5 parts of accelerator and 2-2.5 parts of vulcanizing agent. The tires prepared by the rubber material formula disclosed by the invention have greatly improved safety and reduced oil consumption; and the design meets the requirements for environment protection, safety and energy saving of the car tires.

Owner:克劳斯玛菲股份有限公司

Chemical composition and method for enhancing metabolism

InactiveUS6932987B1Improve healthIncrease thermogenic activity and metabolismBiocideUnknown materialsChemical combinationChemistry

An innovative and synergistic chemical composition is developed for enhancing a person's metabolism. Specifically, the chemical composition aids in increasing the thermogenic activity of the body, which encourages the metabolic conversion of the foods consumed by the person. This results in a loss of body fat and weight, without adversely affecting the person's nervous or circulatory systems. In addition, a method is presented wherein the person ingests a recommended dosage of the chemical composition prior to engaging in physical exercise, thereby allowing the chemical composition to be readily utilized by many of the people who may benefit from its effects.

Owner:DIAZ JOSE A +1

Compositions and methods for promoting weight loss and increasing energy

ActiveUS20120034323A1Protection affordReduce controlBiocideOrganic chemistryChlorogenic acidCaffeine

The present invention relates to compositions comprising plants and extracts of plants with chlorogenic acids and antioxidants and / or caffeine; methods for preparing the same; and methods to promote weight loss through the administration of compositions containing these plants and plant extracts in specific proportions.

Owner:NORTHERN INNOVATIONS HLDG

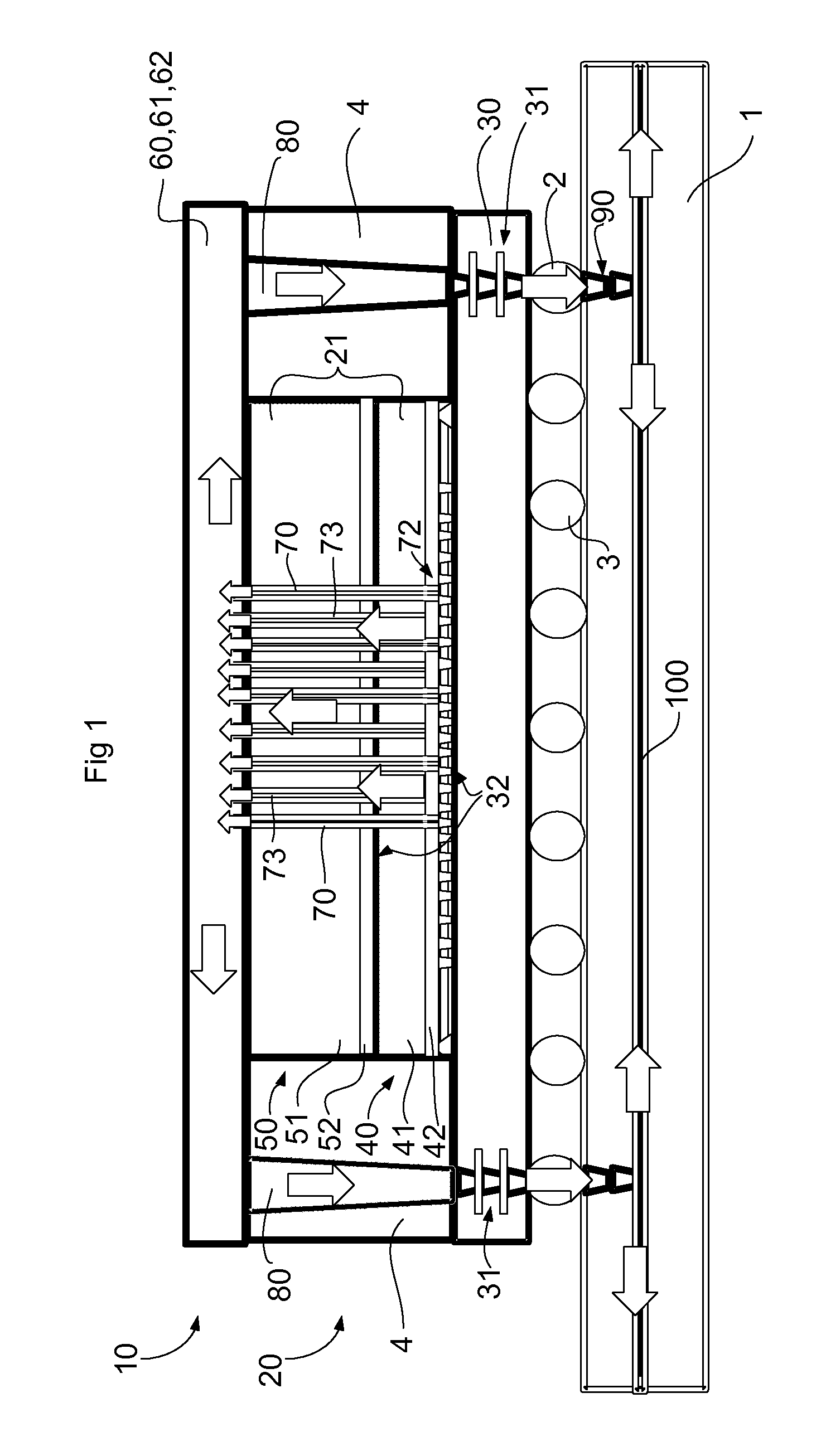

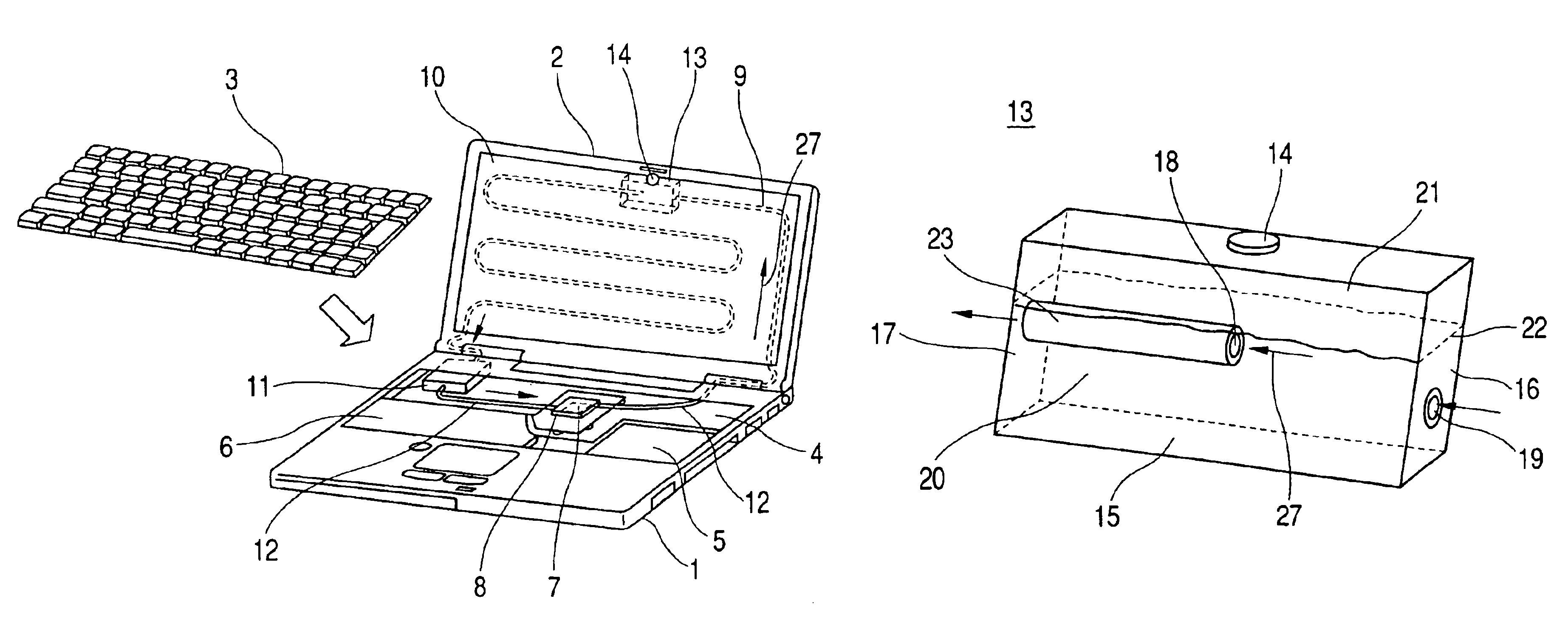

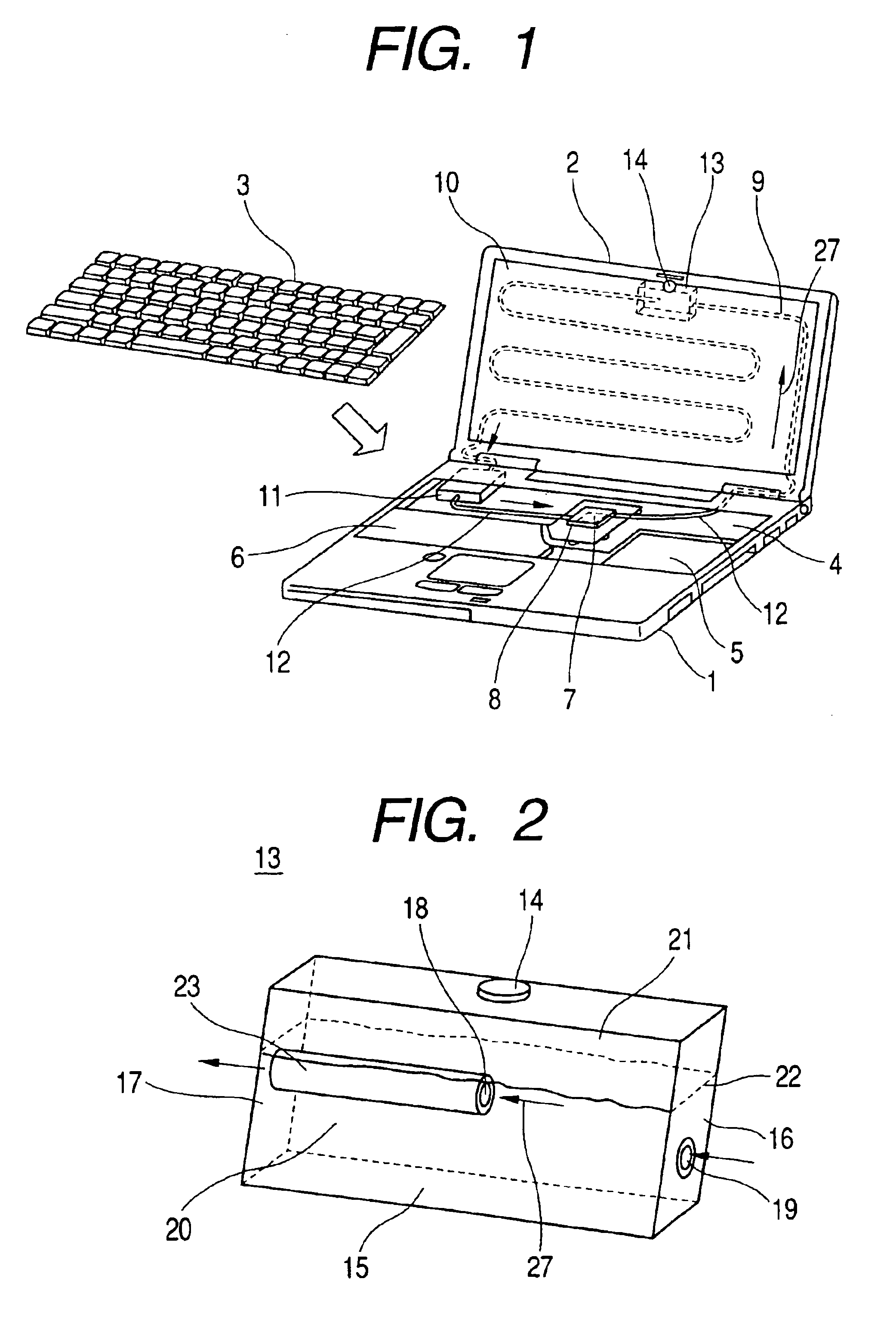

Electronic apparatus

InactiveUS6885556B2Improve heat generationEasy to processDomestic cooling apparatusLiquid organic insulatorsEngineeringThermal radiation

An electronic apparatus includes a case mounting a semiconductor element within an inside thereof, a heat-receiving member thermally connected with the semiconductor element, a heat-radiation member disposed on an inner side surface of the casing, and a liquid driver for driving a liquid coolant between the heat-radiation member and the heat-receiving member. The apparatus further includes a tank accumulating the liquid coolant therein with at least a predetermined volume of the coolant to delimit a coolant surface within the tank, wherein the tank, the heat-radiation member and the heat-receiving member are connected with tubes, and a suction end portion of a suction pipe connected into the tank is located at a position which is always below the coolant surface irrespective of change of position of the tank.

Owner:MAXELL HLDG LTD

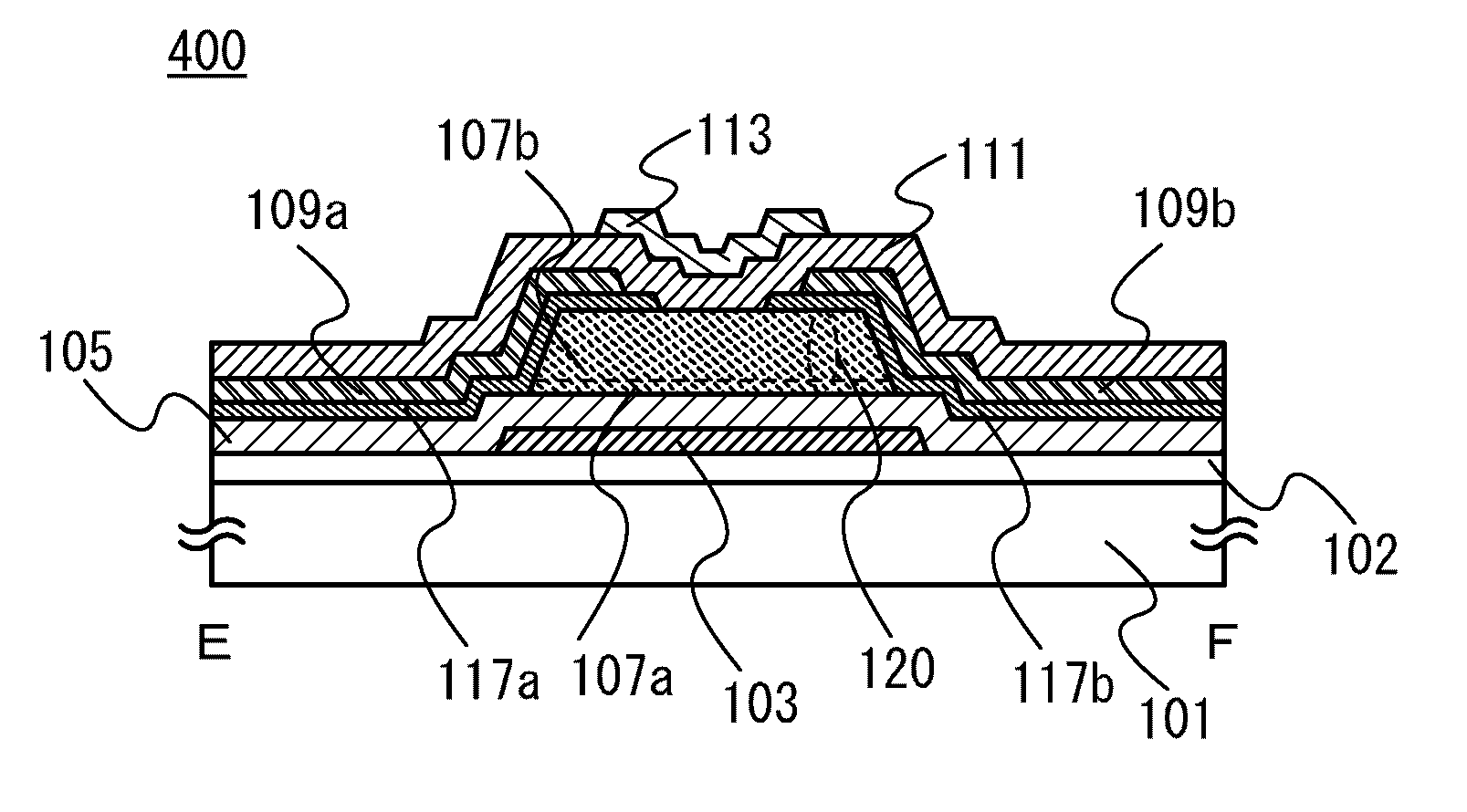

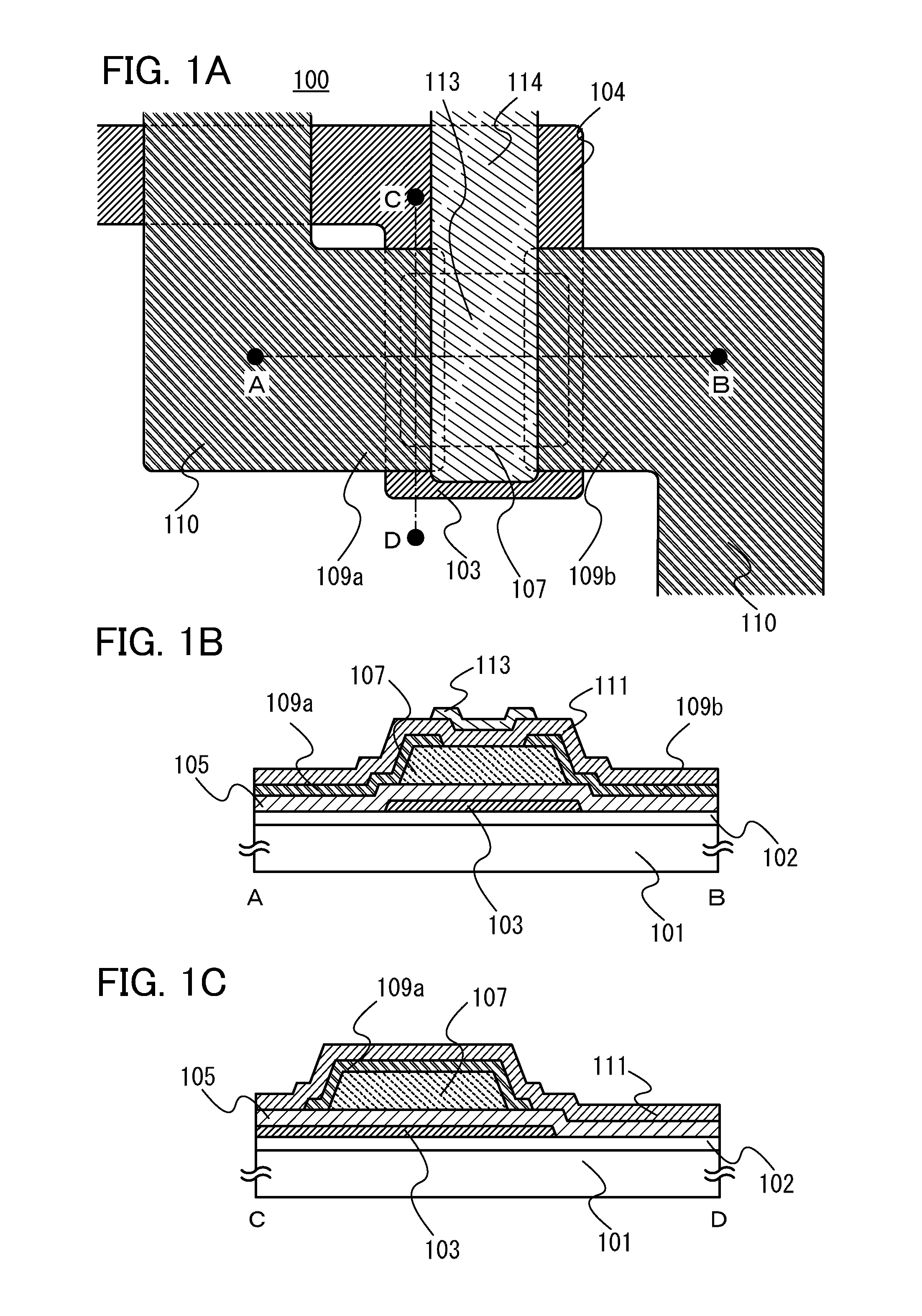

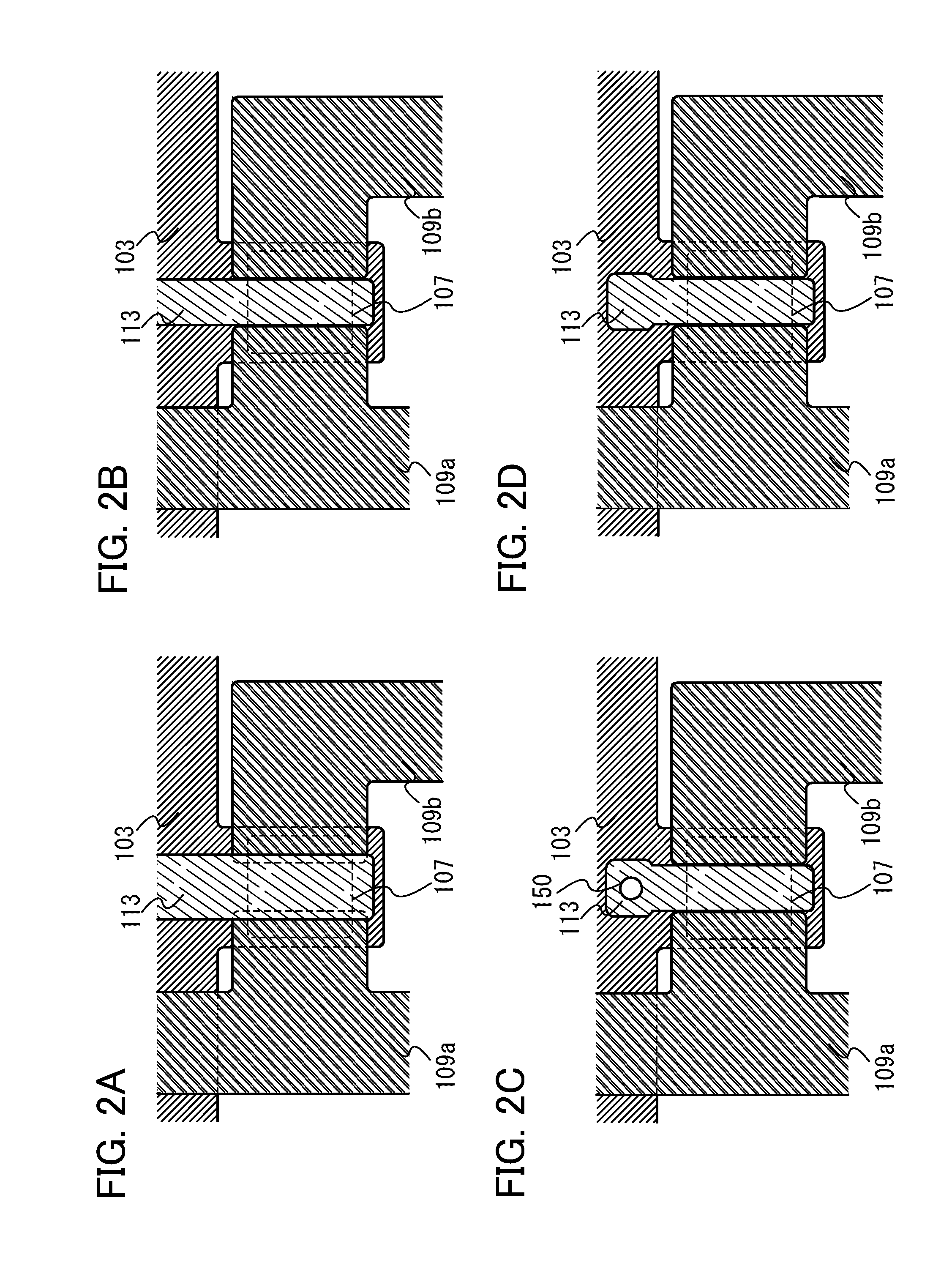

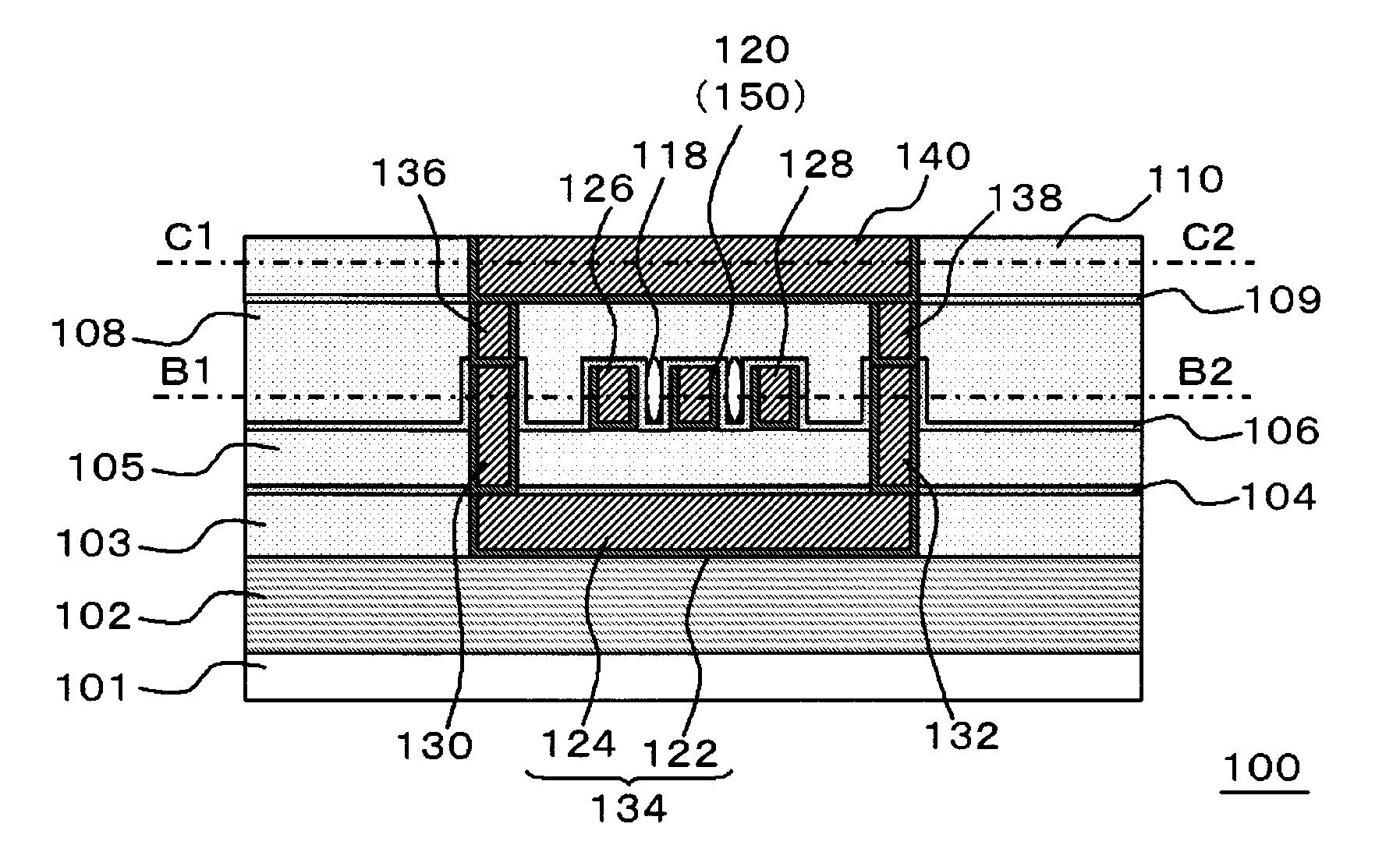

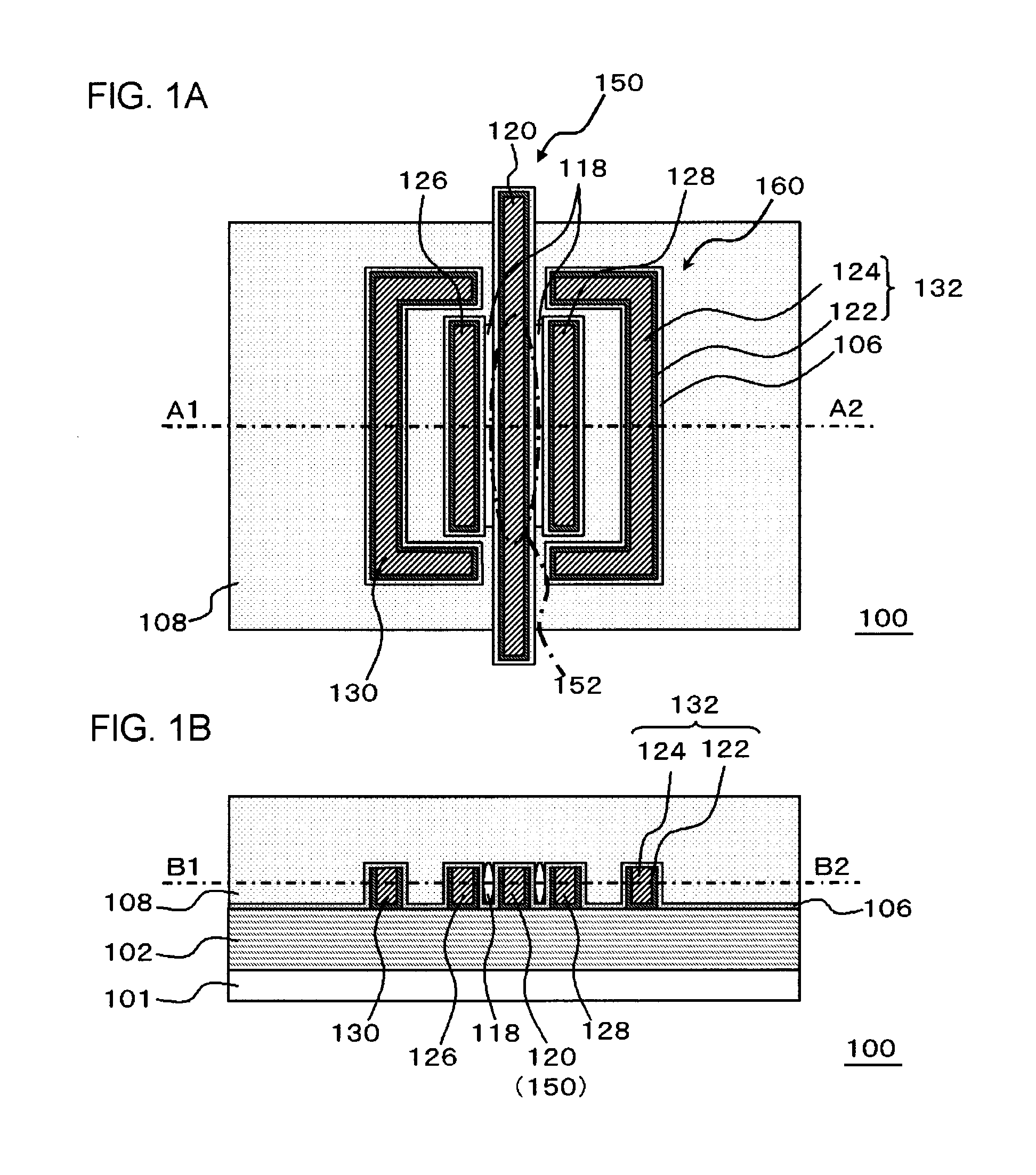

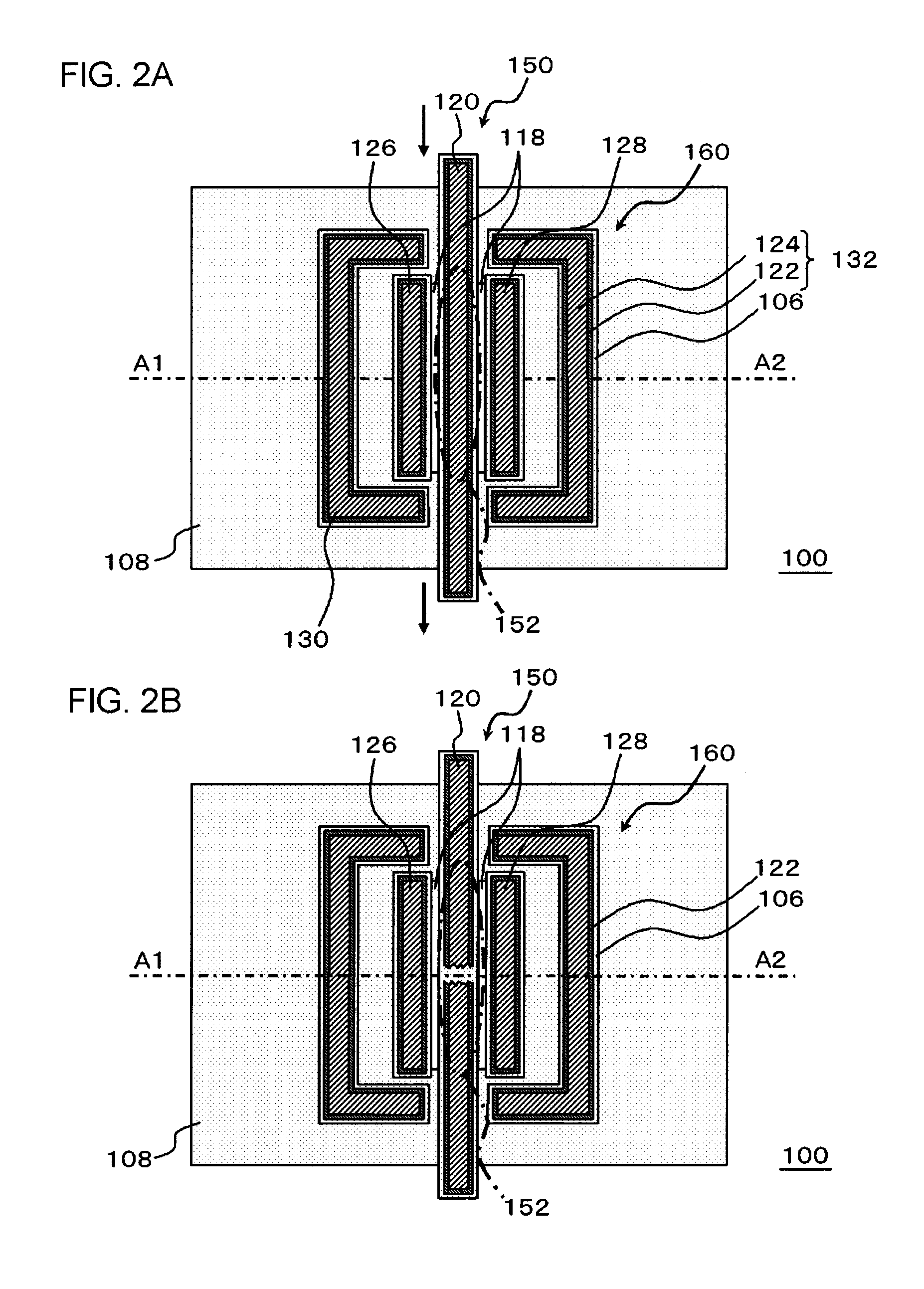

Semiconductor device and method of manufacturing semiconductor device

ActiveUS20110140235A1Easy to cutImprove heat generationSemiconductor/solid-state device detailsSolid-state devicesInter layerSemiconductor

A semiconductor device include an insulating interlayer formed over a substrate; an electrical fuse which is composed of a first wiring formed in the insulating interlayer, and has a cutting portion; and a second wiring and a third wiring, formed respectively on both sides of the cutting portion to extend along the cutting portion in the same layer as the first wiring. Air gaps formed to extend along the cutting portion are respectively provided between the cutting portion and the second wiring and between the cutting portion and the third wiring.

Owner:RENESAS ELECTRONICS CORP

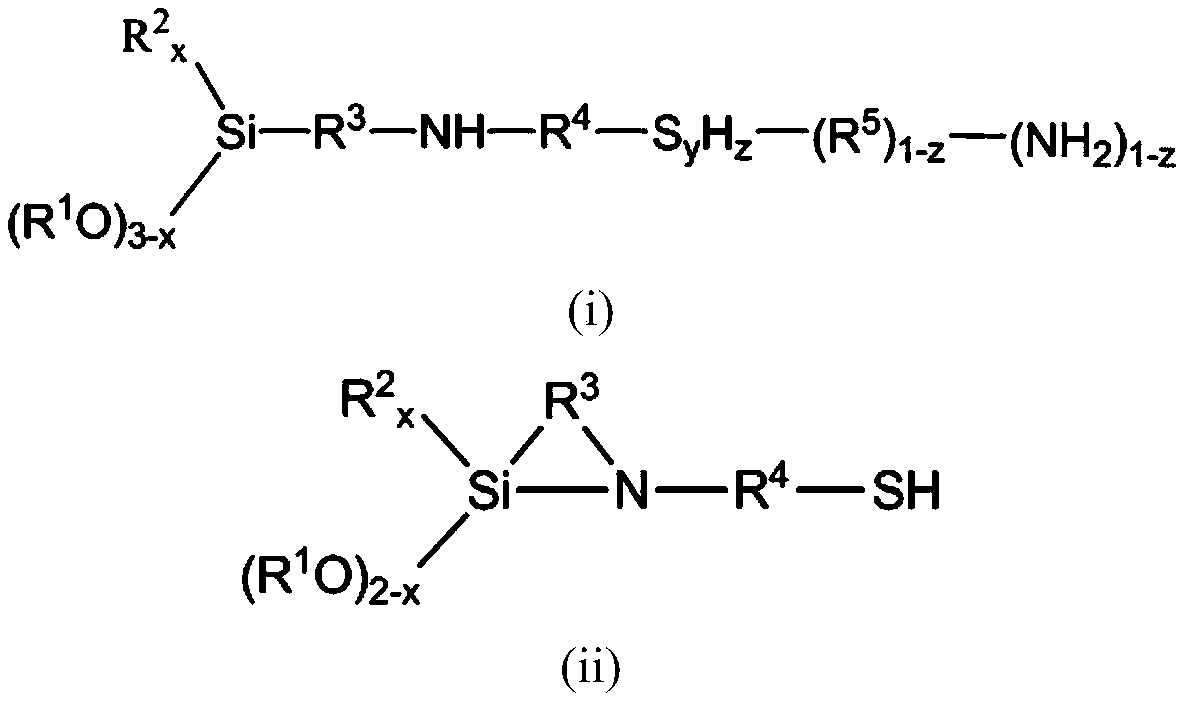

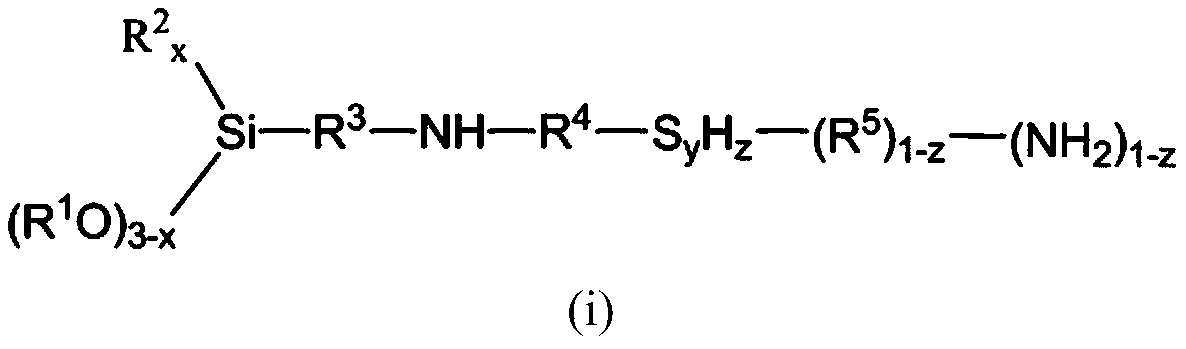

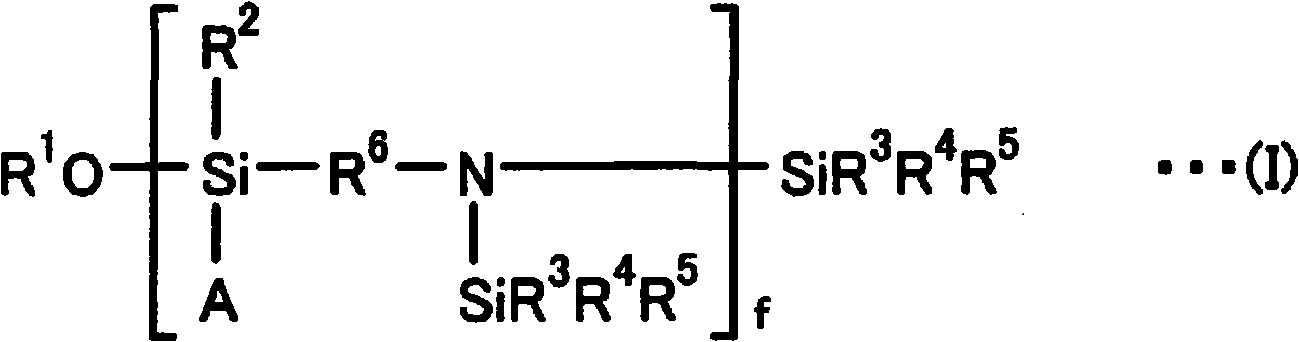

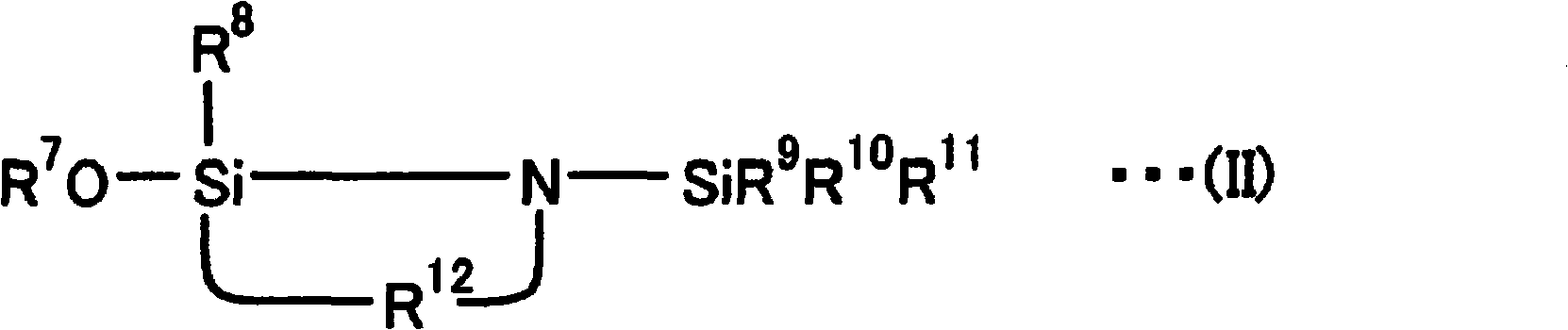

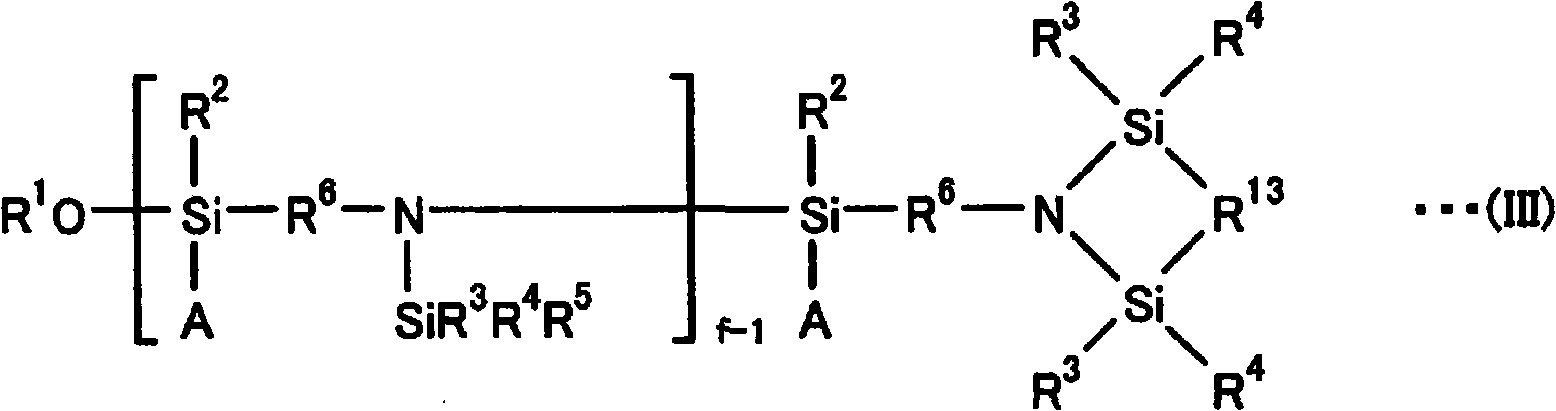

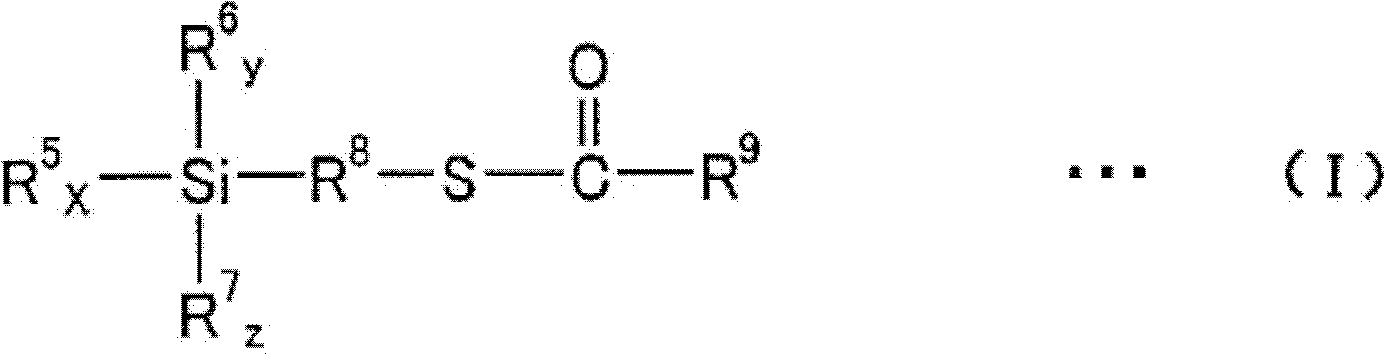

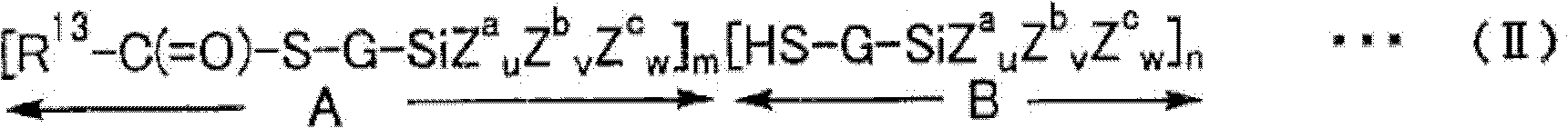

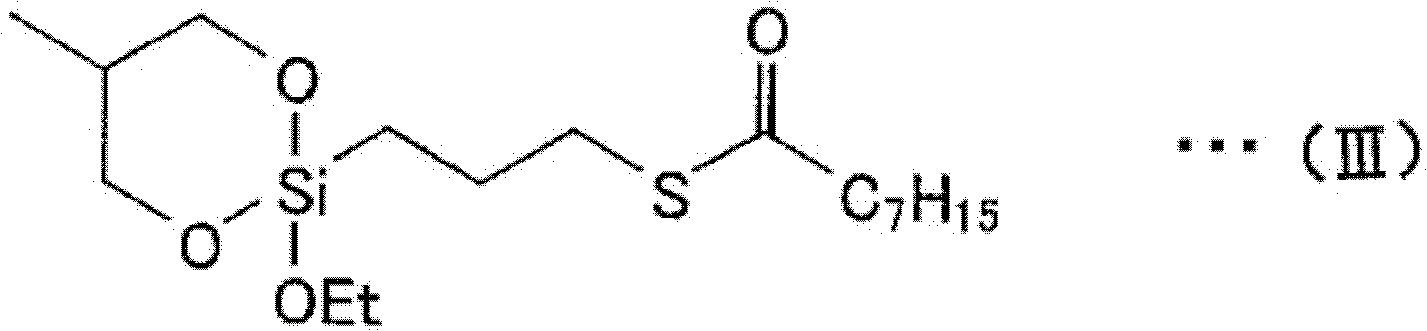

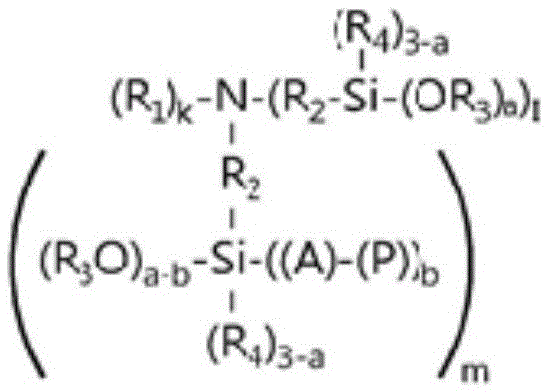

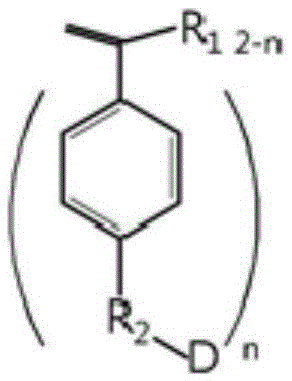

Multi-functional silane coupling agent as well as preparation method and application thereof

ActiveCN109749129AHigh tensile strengthHigh elongation at breakGroup 4/14 element organic compoundsTetraReinforced rubber

The invention relates to a multi-functional silane coupling agent. The molecular structure of the silane coupling agent simultaneously contains an amino group, an alkoxysilyl group and a sulfur-containing functional group; the amino functional group comprises one or more of an amino group, a secondary amino group and a tertiary amino group; the sulfur-containing functional group comprises one or several of sulfydryl, a mono-sulfide bond, a dis-ulfide bond, a tri-sulfide bond and a tetra-sulfide bond. The multi-functional silane coupling agent provided by the invention contains the amino group,the alkoxysilyl group and the sulfur-containing functional group and can simultaneously modify carbon black, white carbon black and rubber, fully realize the effect of carbon black and / or white carbon black mixed filling and reinforcing rubber, effectively improve the tensile strength, the elongation at break and the constant tensile stress of the rubber, significantly reduce the permanen compression deformation and significantly improve the heat generation performance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

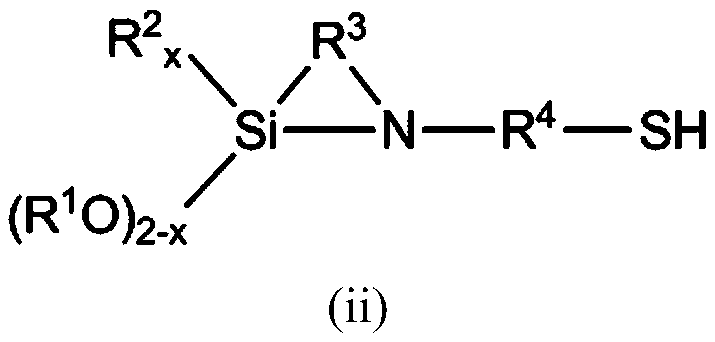

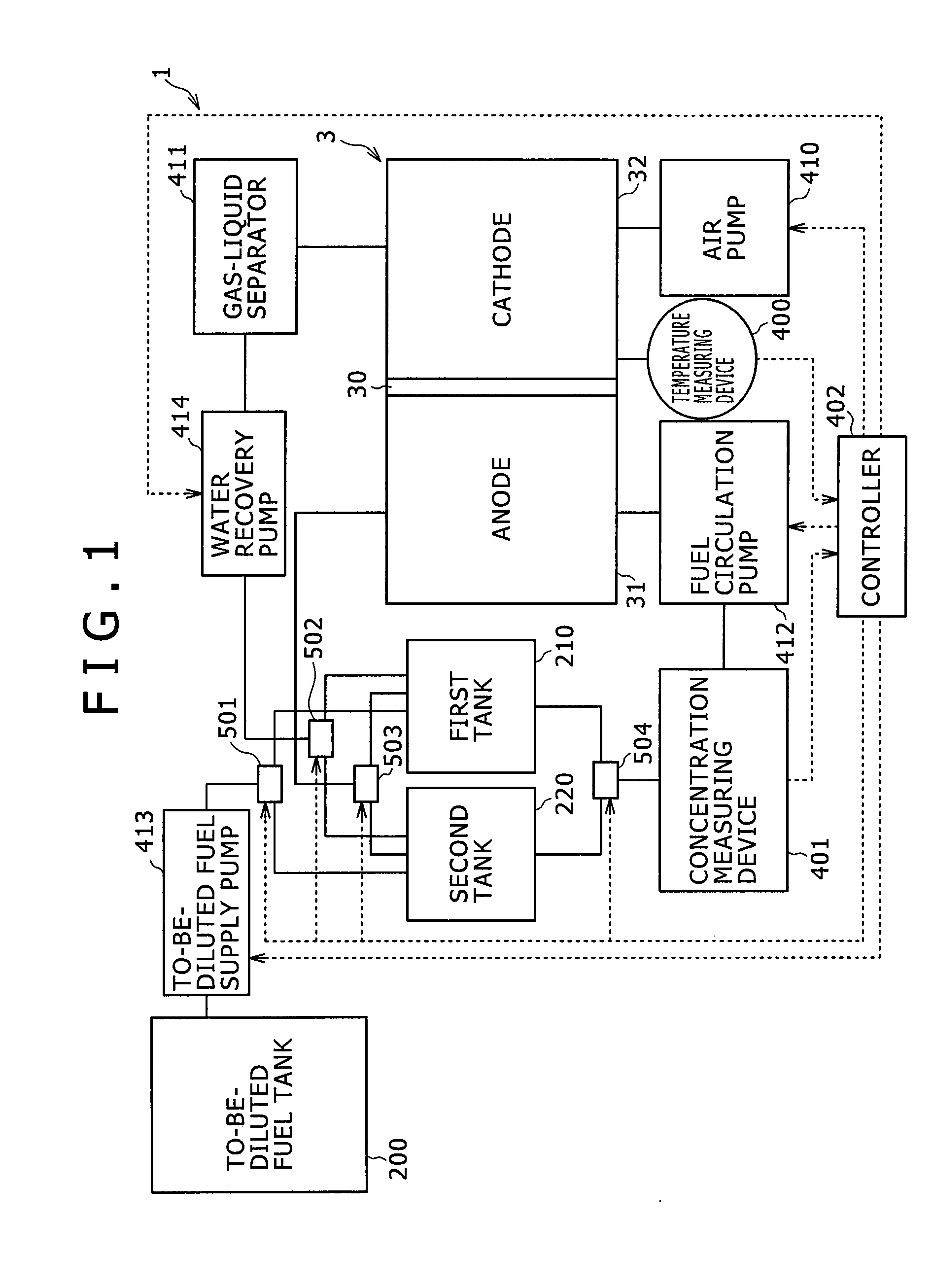

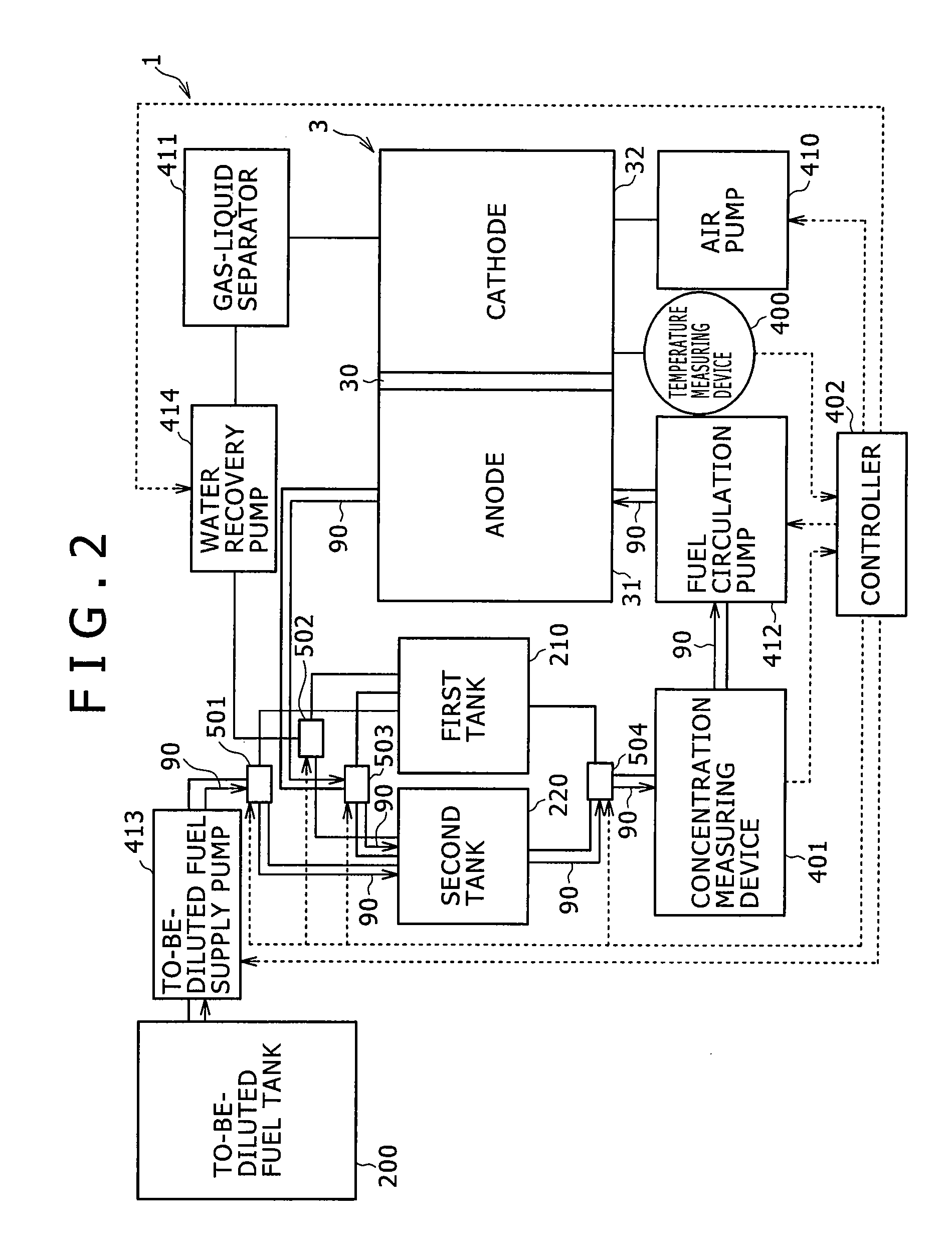

Fuel cell system and fuel cell starting method

InactiveUS20070212581A1Shorten the time periodIncrease temperatureReactant parameters controlWater management in fuel cellsHigh concentrationFuel cells

It is an object of the present invention to provide a system in which a fuel cell can be operated by use of a fuel having a constantly optimum concentration. It is another object of the present invention to shorten the time taken in starting a fuel cell. A low-concentration fuel for performing mainly a power generation reaction and a high-concentration fuel for performing mainly the power generation reaction and a reaction for raising the temperature of a power generation cell are stored respectively in separate storage vessels, whereby the fuel supplied to a negative electrode can be instantaneously changed over according to the temperature of the power generation cell. This makes it possible to perform an operation at a constantly optimum fuel concentration. In addition, since it is possible to raise the temperature of the power generation cell in a short time, it is possible to reduce the capacity of an auxiliary battery used when the temperature of the power generation cell is low, and to reduce the fuel cell system in size.

Owner:SONY CORP

Run-flat tire side support rubber, preparation method and tire structure thereof

InactiveCN109438787AGood physical and mechanical propertiesImprove heat generationTyre partsSteering wheelTear resistance

The invention relates to the technical field of tires and in particular to run-flat tire side support rubber, a preparation method and a tire structure thereof. Neodymium series butadiene rubber usedby a sizing material is polybutadiene with high cis-form-1,4-structure content obtained by using a neodymium compound as a main catalyst, so the support rubber has higher tensile property and resilience property, good carbon black dispersing performance, and more excellent aging-resistant performance. White carbon black adopts a 1115MP type with high dispersion and a low superficial area. The high-dispersion-type low-superficial-area white carbon black is capable of effectively improving tear resistance and thermal aging resistance of a support rubber part, and effectively reducing 15% of thermogenesis performance. Through a formula of the relayed sizing material, the prepared support rubber has stronger physical characteristics of tear resistance, high stretching, high strength, high temperature resistance and the like. Through a special design and a matching ratio in structure and formula aspects, the tires can be guaranteed to be continuously driven still in a speed of 80 km / h in azero air pressure state, and a steering wheel cannot be easily deviated from a driving direction in a driving process, until a next maintenance point is found out.

Owner:万达集团股份有限公司 +1

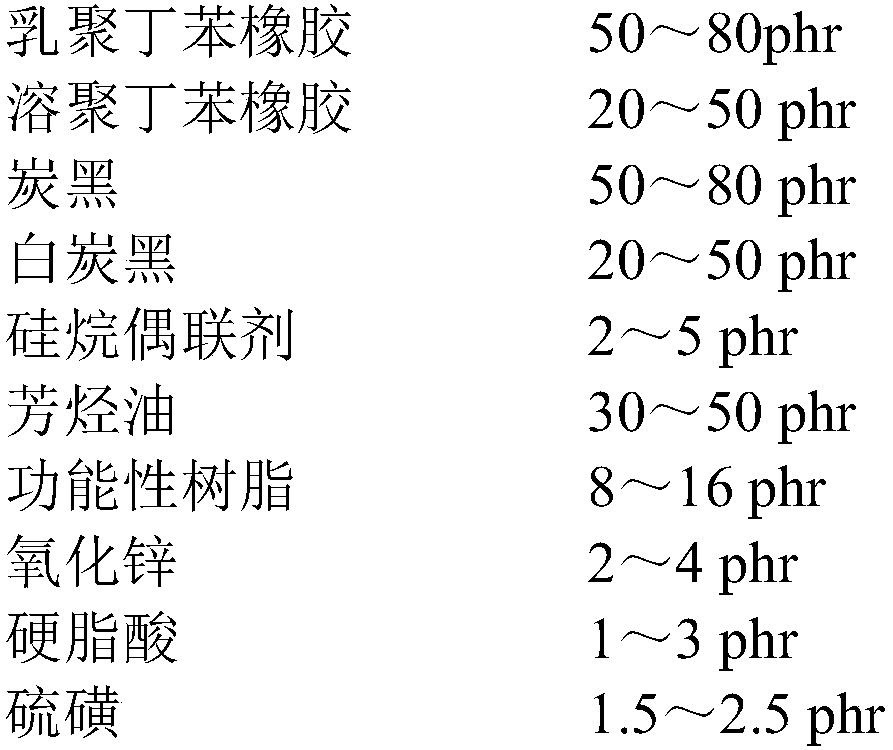

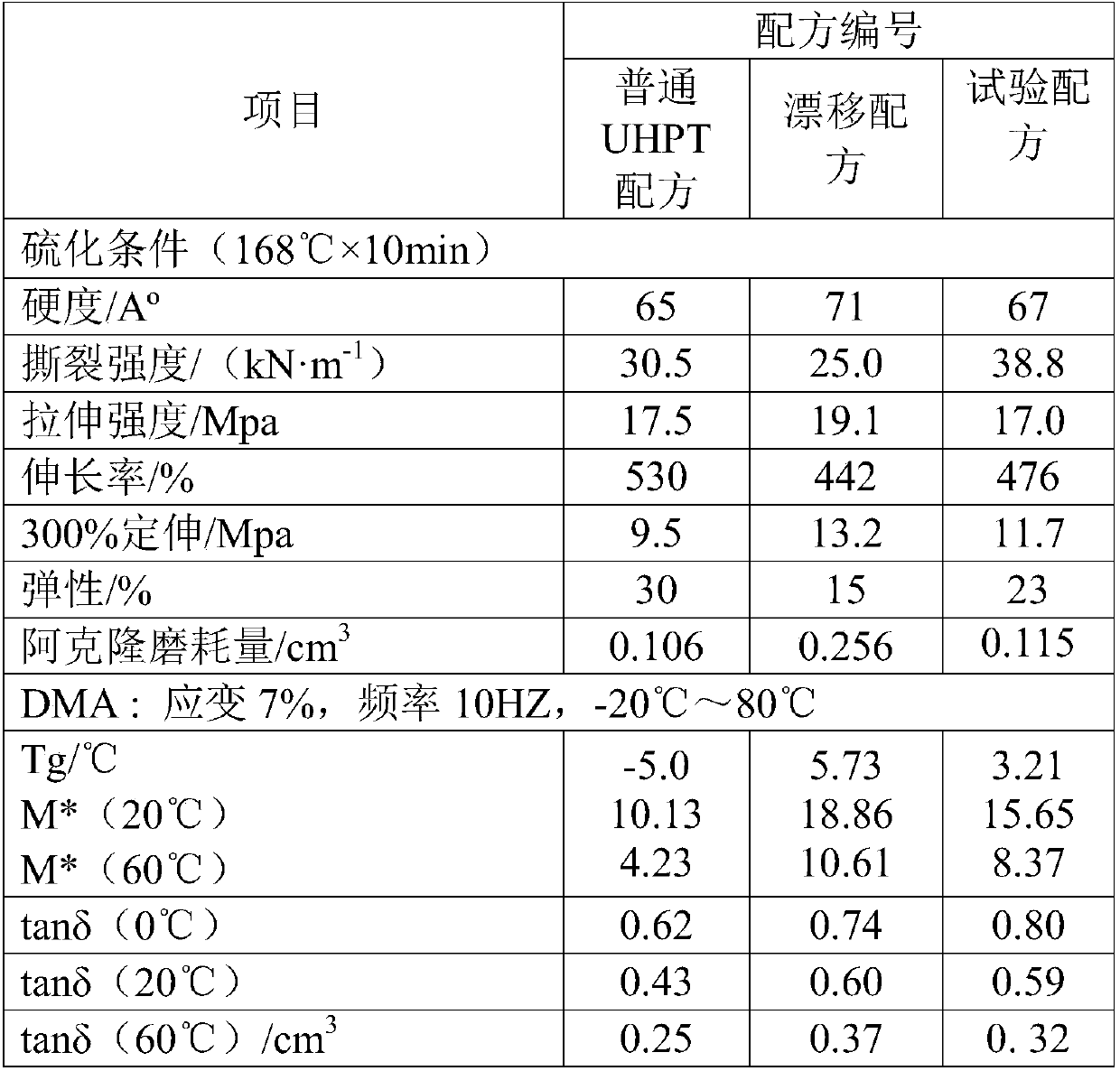

UHPT tread rubber which can be used in drifting competition

The invention discloses UHPT tread rubber which can be used in a drifting competition. The tread rubber comprises the following components: emulsion polymerized styrene-butadiene rubber 50-70 phr, solution polymerized styrene-butadiene rubber 30-50 phr, carbon black 50-80 phr, white carbon black 20-50 phr, a silane coupling agent 2-5 phr, oil 30-50 phr, functional resin 8-16 phr, zinc oxide 2-4 phr, stearic acid 1-3 phr, sulfur 1.5-2.5 phr, an accelerator 2.0-3.0 phr, and other components 4-7 phr. The formula of the tread rubber provided by the invention innovatively uses the modified solutionpolymerized styrene-butadiene rubber, the highly-dispersed white carbon black with a high specific surface area and the functional resin, also the ratio of fillers and the mixing process of the treadrubber are reasonably adjusted, and the requirements of the usage performance of daily driving and the drifting competition are taken into account: compared with ordinary UHPT tread rubber, the treadrubber provided by the invention has excellent dry ground gripping and manipulating performance; and compared with professional drifting tread rubber, the tread rubber provided by the invention has significantly-improved service life and better-improved wet ground gripping performance, and can meet multi-purpose requirements of usual driving and the drifting competition.

Owner:SAILUN GRP CO LTD

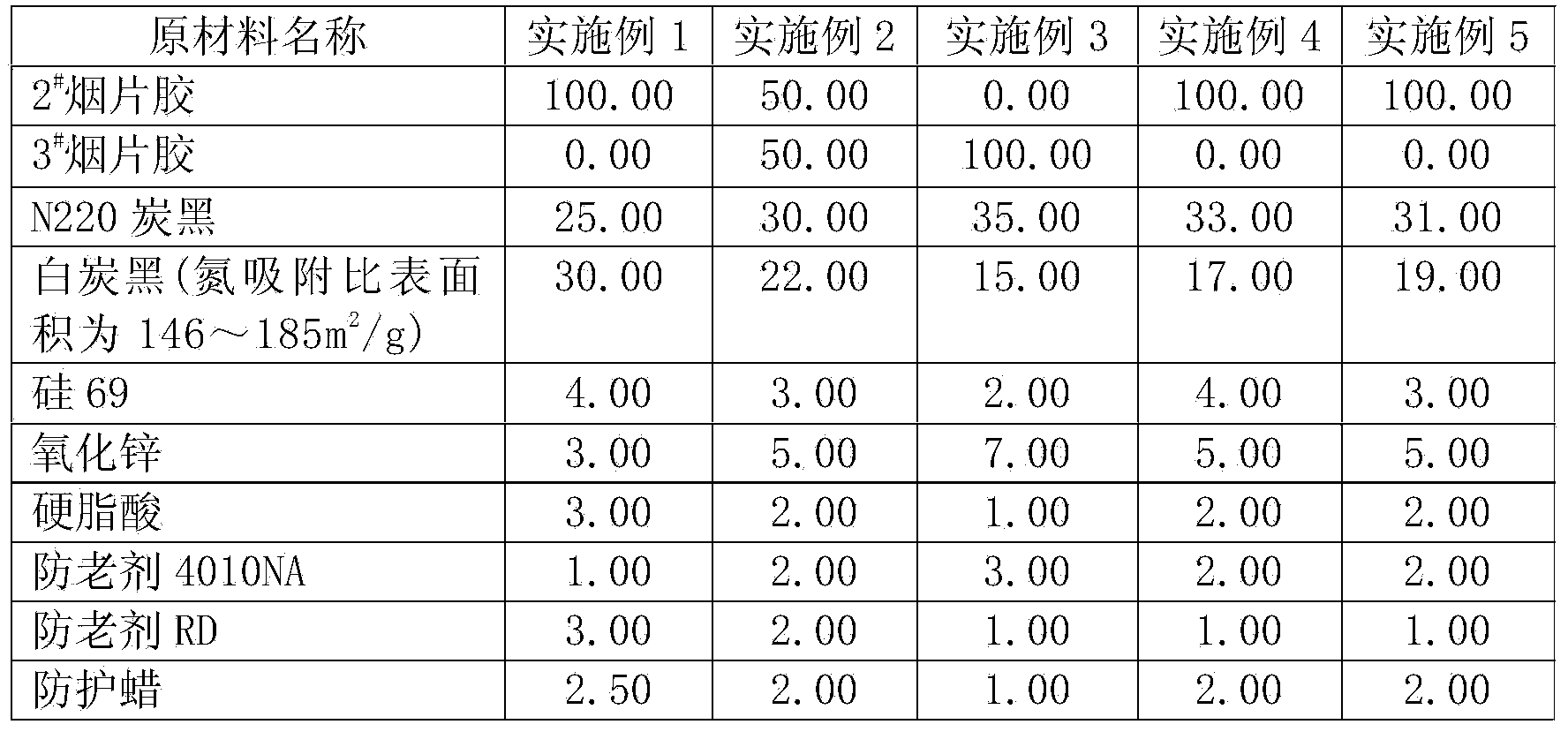

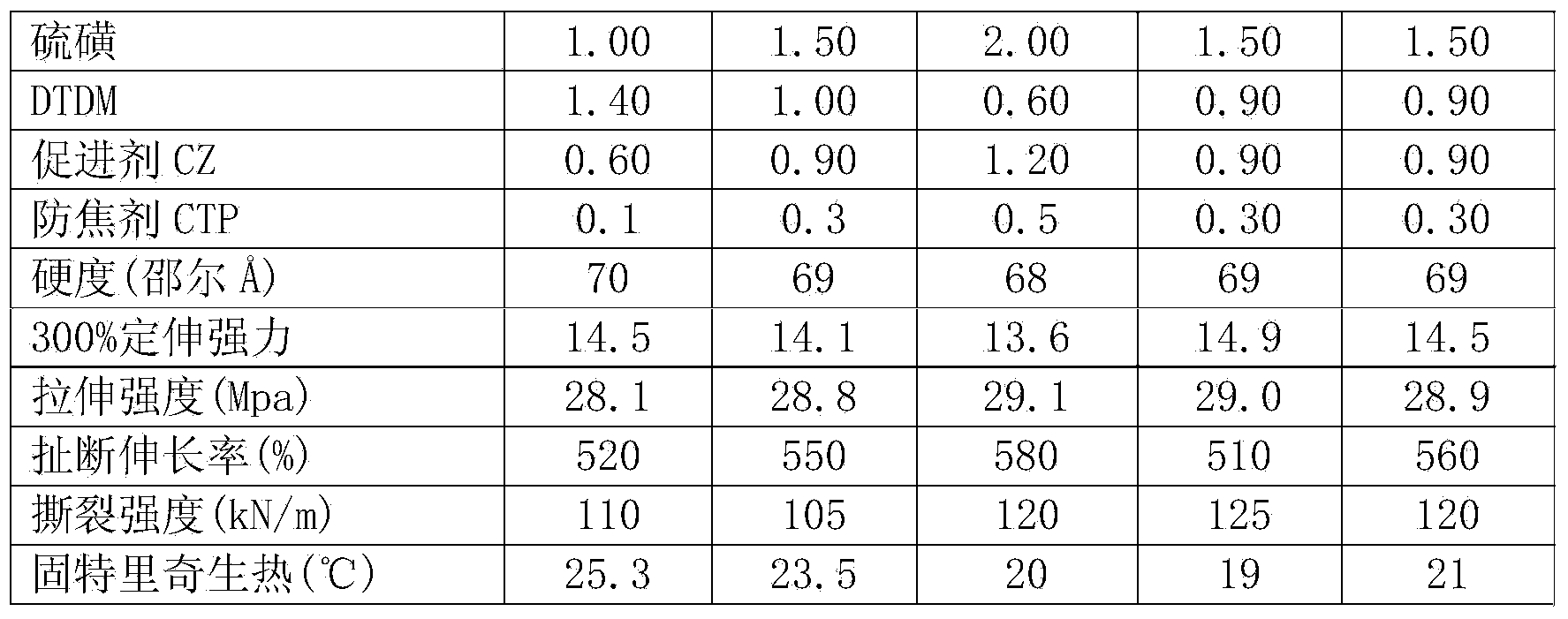

Heat-resistant tread rubber for large skew construction machinery tire

The invention discloses a heat-resistant tread rubber for large skew construction machinery tire. The heat-resistant tread rubber is prepared from the components in parts by weight: 100 parts of natural rubber, 25-35 parts of N220 carbon black, 15-30 parts of white carbon black, 2-4 parts of silane coupling agent, 3-7 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of antioxidant 4010NA, 1-3 parts of antioxidant RD, 1-2.5 parts of protective wax, 1-2 parts of sulphur, 0.5-1.2 parts of vulcanizing agent DTDM, 0.6-1.2 parts of accelerator CZ and 0.1-0.5 part of scorch retarder CTP. With the adoption of a rubber material prepared by a formula disclosed by the invention, rubber material has the excellent characteristic of thermal aging resistance when the generated heat of the rubber material is lowered.

Owner:CHEMCHINA GUILIN TIRE

Tire

InactiveCN101910279AExcellent wear propertiesImprove heat generationSpecial tyresRolling resistance optimizationRolling resistanceButadiene-styrene rubber

Provided is a tire that not only has excellent wear characteristics but also good control stability typified by wet skid resistance and reduced rolling resistance (low heat buildup). The tire is provided using as the tread a rubber composition wherein (B) 20-150 parts by weight of silica wherein the cetyltrimethylammonium bromide (CTAB) adsorption specific surface area is 60-130 (m2 / g) and the nitrogen adsorption specific surface area (N2SA) by the BET method is 70-140 m2 / g are blended with respect to (A) 100 parts by weight of a rubber component comprising 15-70 wt% of an amine functional group-modified styrene-butadiene copolymer.

Owner:BRIDGESTONE CORP

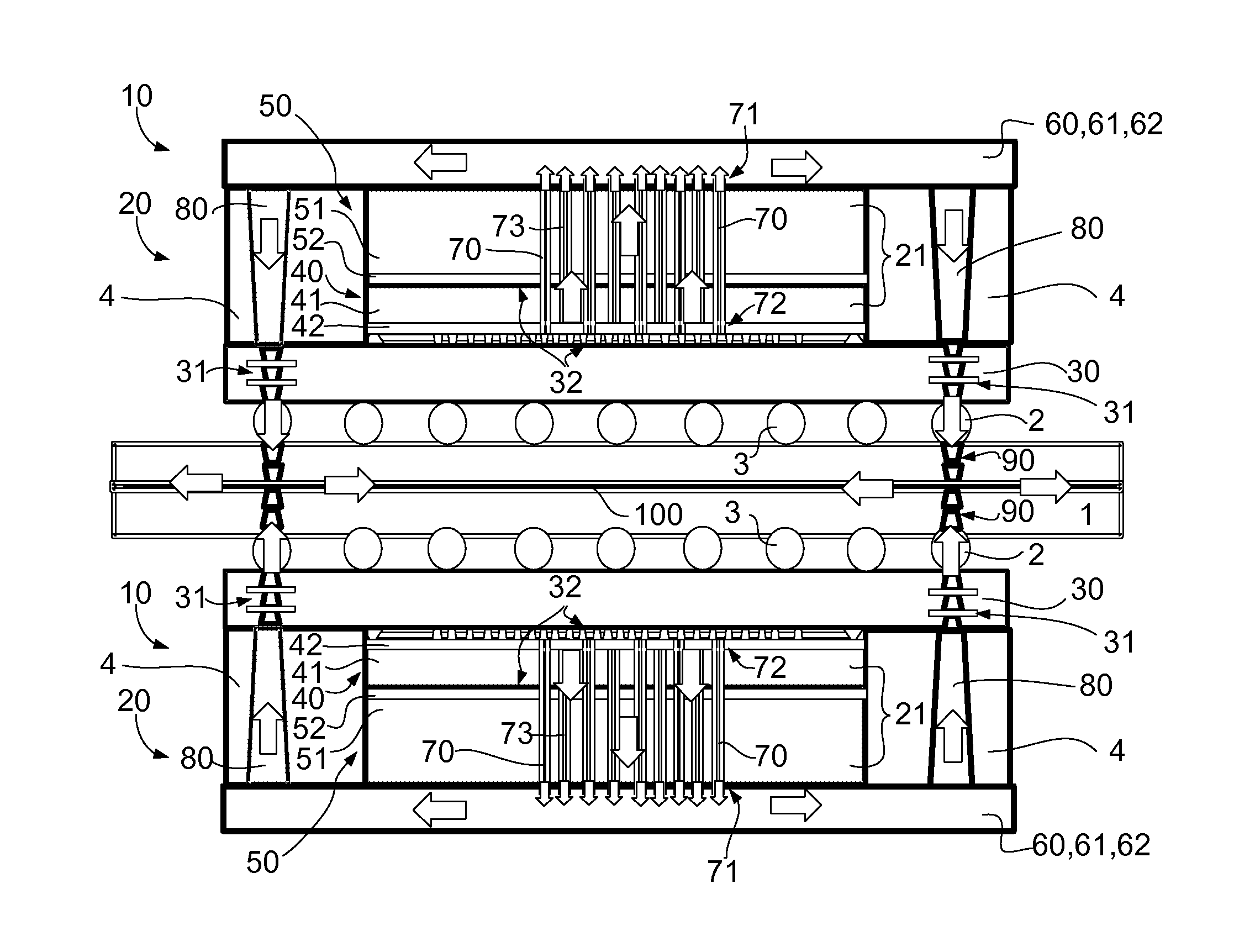

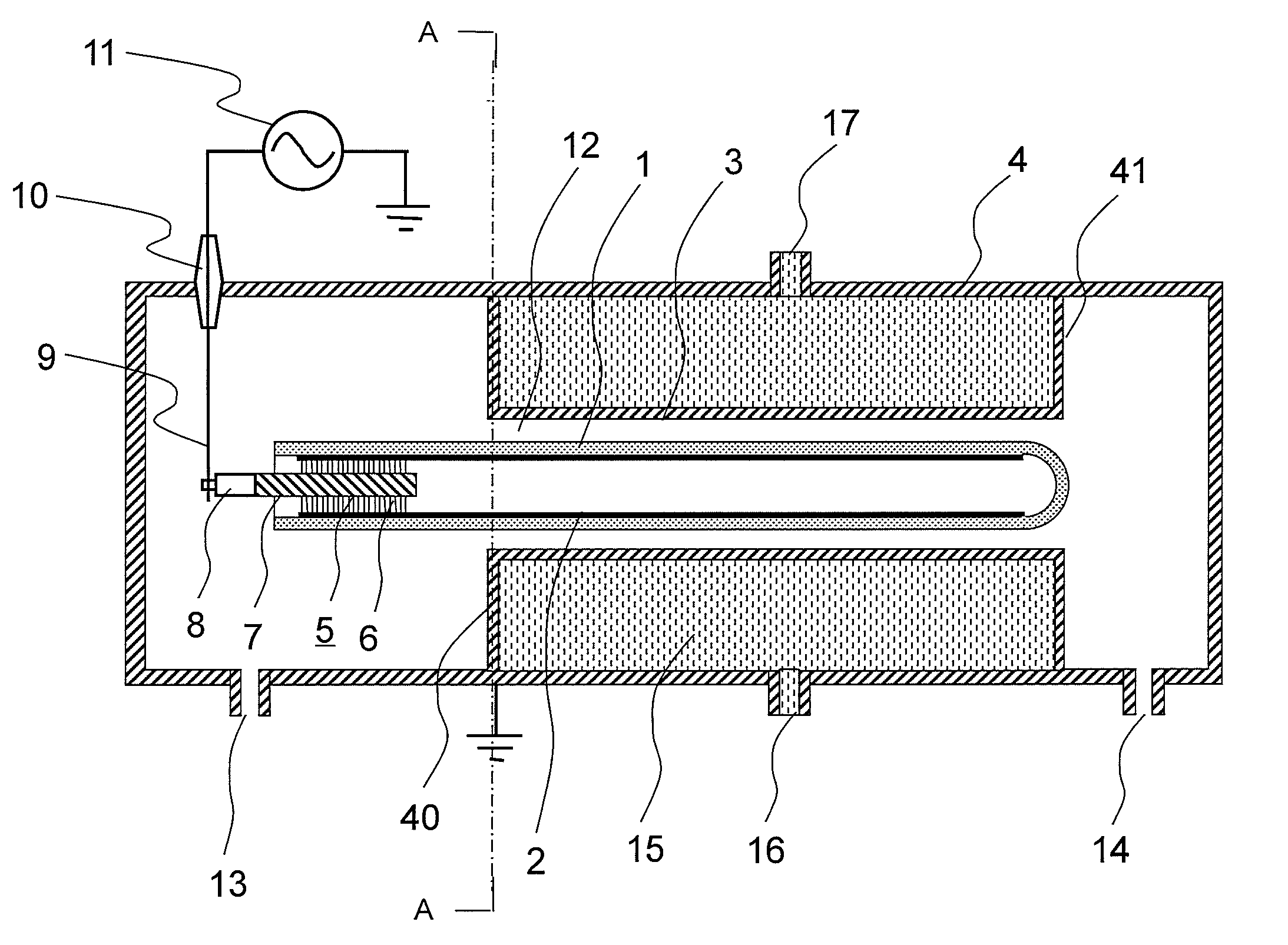

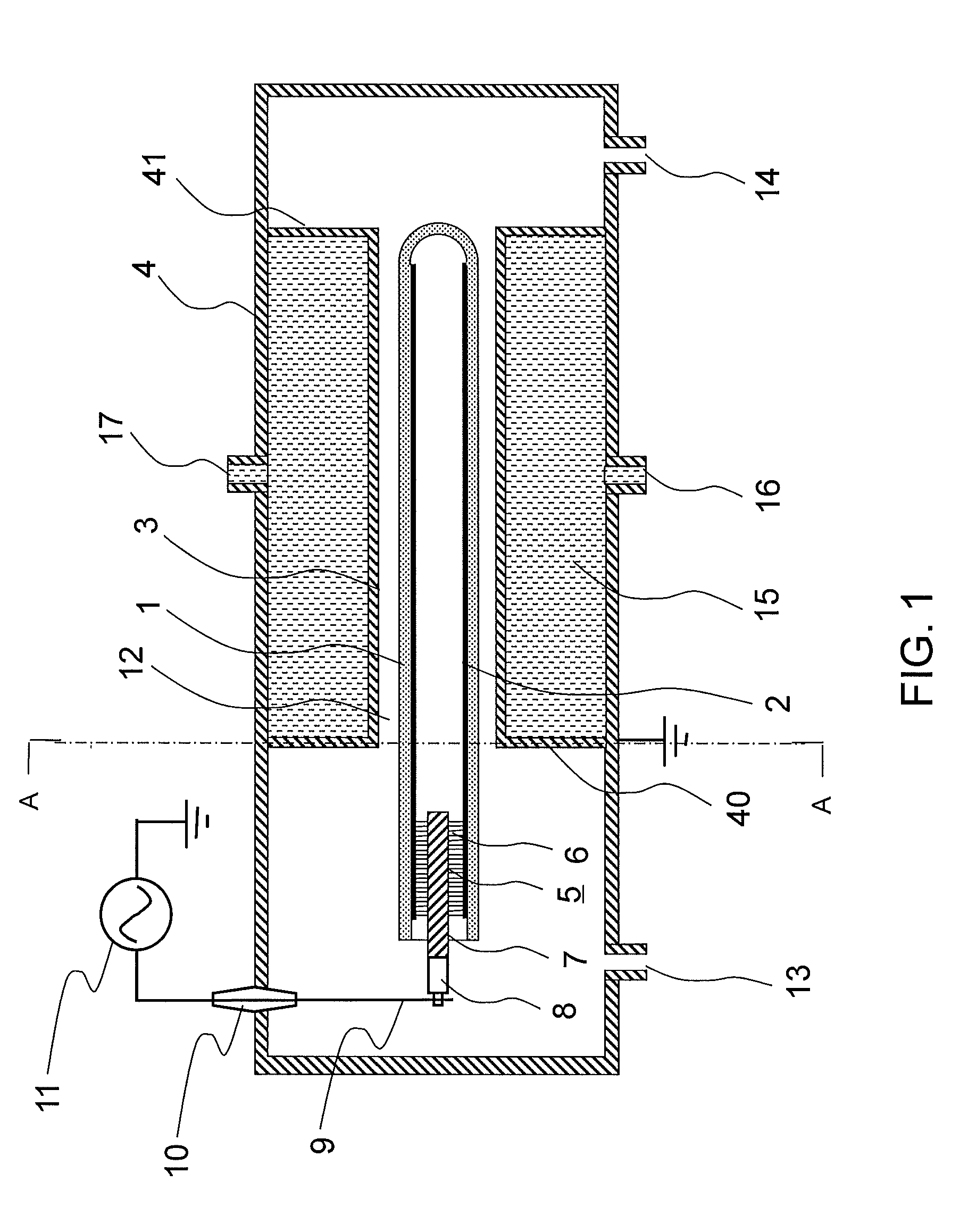

Ozone generating apparatus

ActiveUS20100296980A1Improve heat generationImprove reliabilityElectrical discharge ozone preparationElectrographic process apparatusVolumetric Mass DensityHigh pressure

An ozone generating apparatus having high reliability in which a glass tube can prevent from being damaged by melting a power feeding brush even if a large amount of short-circuit current flows. In an ozone generating apparatus using silent discharge, an alternating high voltage power is supplied from a power supply to a metal film formed in an inner wall of a glass tube by a power feeding brush comprising a brush shaft made of metal and a large number of metal thin wires fixed to the periphery of the brush shaft, the following equation satisfies.(D2 / D1)≧(1+(1 / 20 β)),wherein ‘D1’ indicates an outer diameter of a bundle of metal thin wires, ‘D2’ indicates an outer diameter of the brush shaft and ‘β’ indicates the line density of metal thin wires on a surface of the brush shaft.

Owner:MITSUBISHI ELECTRIC CORP

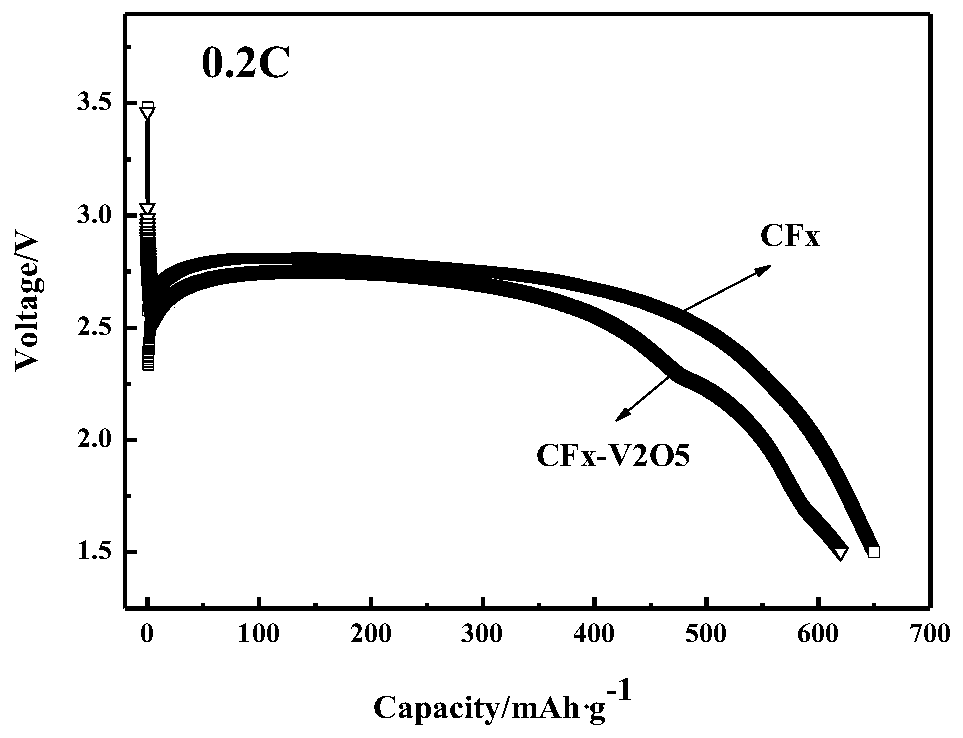

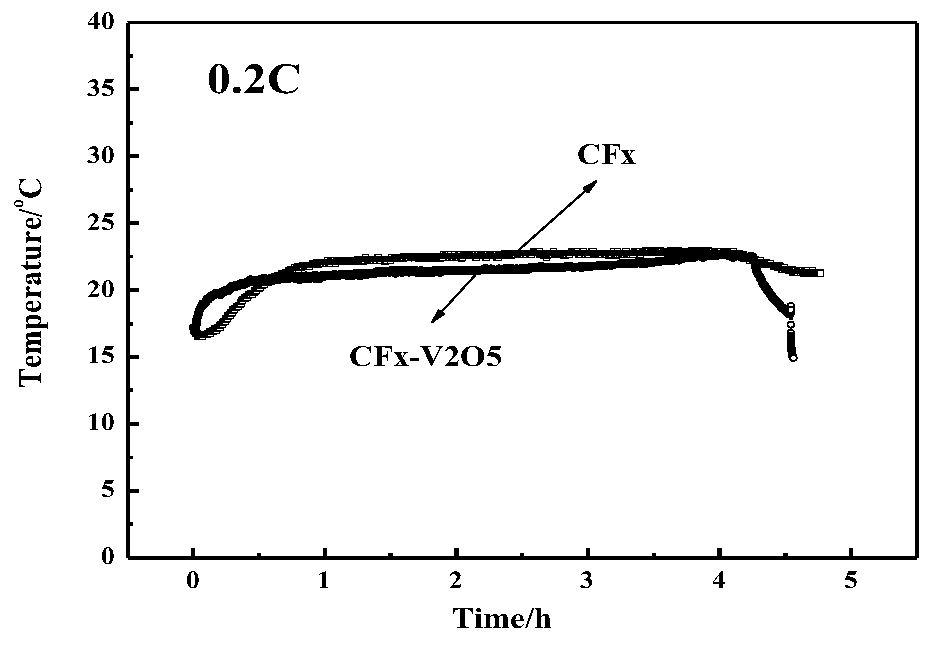

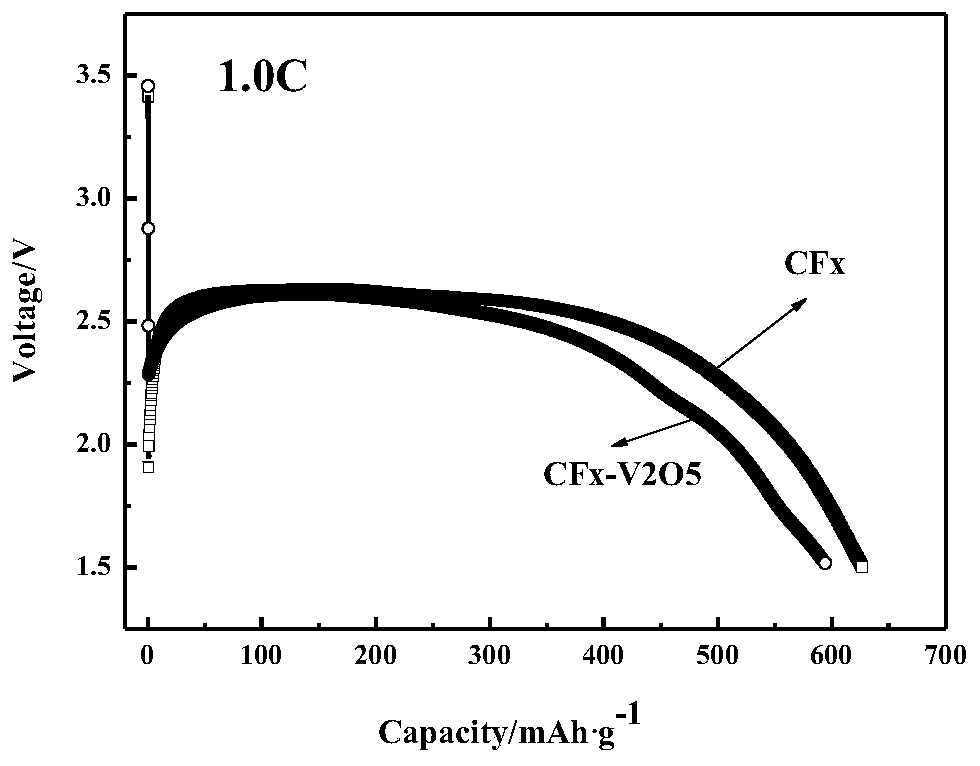

V2O5-carbon fluoride mixed positive electrode material and preparation method thereof

ActiveCN110707313AMake up for the voltage lag problemHigh voltageCell electrodesPhysical chemistryBattery cell

The invention relates to the technical field of lithium battery materials, in particular to a V2O5-carbon fluoride mixed positive electrode material and a preparation method thereof. According to theinvention, a V2O5 material is doped in a carbon fluoride positive electrode material, so that the advantages that the V2O5 material has higher discharge platform voltage, good high-current discharge capacity, very small heat generation during the discharge process and the like are fully utilized, the problem of voltage lag at the initial discharge stage of the carbon fluoride positive electrode material is solved, the large-current discharge capacity of the carbon fluoride positive electrode material is effectively improved, the rate capability of the lithium carbon fluoride battery is greatlyimproved, the temperature rise during the discharge process of the lithium carbon fluoride battery is reduced, and the application range of the lithium carbon fluoride battery is expanded. Under theaction of a dispersing agent, the two materials are mixed in a high-energy ball milling manner, so that the problem of voltage lag at the initial discharge stage of the carbon fluoride positive electrode material and the problem of high heat productivity under a high-current discharge condition are further solved. According to the present invention, the zirconium oxide balls are added during the high-energy ball milling process, so that the uniformity of the mixed materials is further improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

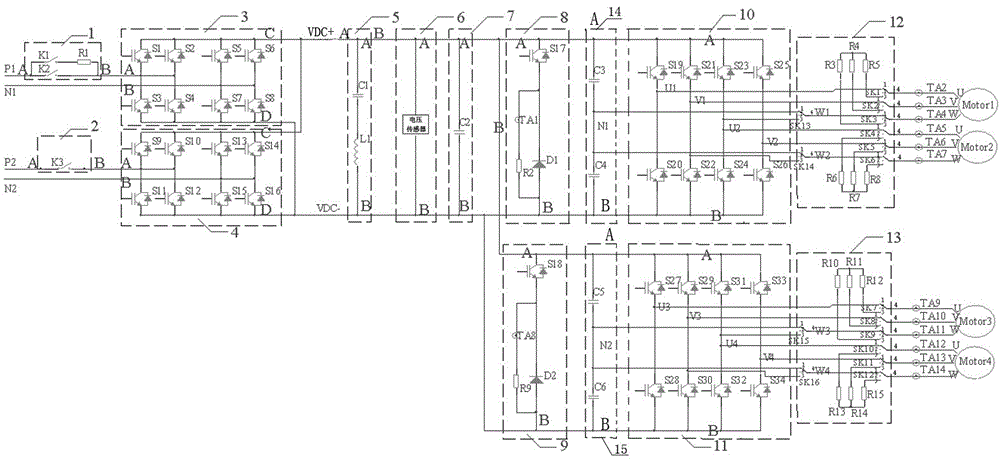

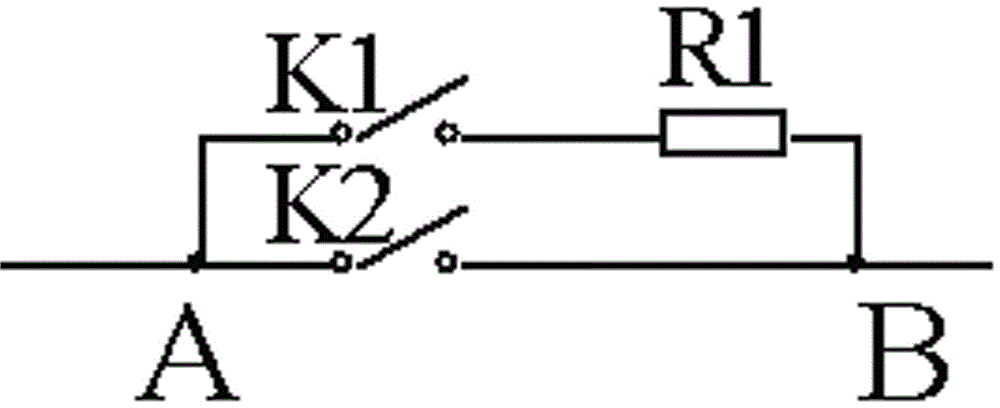

Main circuit of traction converter for high-speed motor train unit

ActiveCN105811814AAvoid damageReduce feverMultiple motor speed/torque controlCapacitanceFour quadrants

The invention relates to a traction conversion device of a motor train unit, in particular to a main circuit of a traction converter for a high-speed motor train unit. The main circuit of the traction converter of the high-speed motor train unit comprises a first input voltage / current buffer circuit, a second input voltage / current buffer circuit, a first four-quadrant rectifier, a second four-quadrant rectifier, a secondary filter circuit, a voltage sensor, a support capacitor, a first chopping circuit, a second chopping circuit, a first inverter, a second inverter, a first contactor circuit, a second contactor circuit, a first capacitance circuit and a second capacitance circuit. The main circuit of the traction converter of the high-speed motor train unit, proposed by the invention, has the advantages of energy saving, low heat generation, high protection capability, high reliability and the like, is applicable to various mode running, and the problems of high heat generation, high thermal loss and high cost of the converter of the existing permanent-magnet synchronous motor are solved.

Owner:CRRC YONGJI ELECTRIC CO LTD

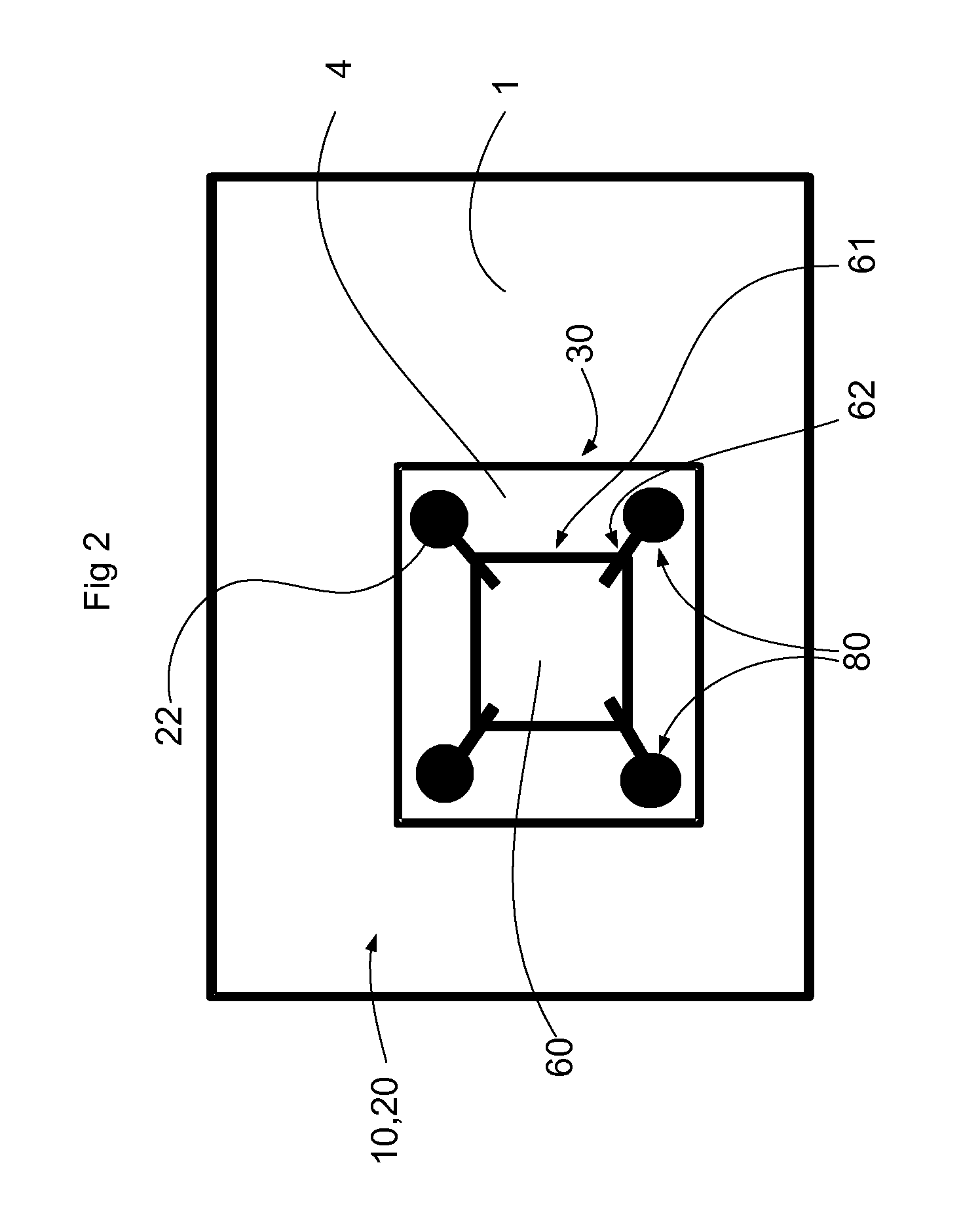

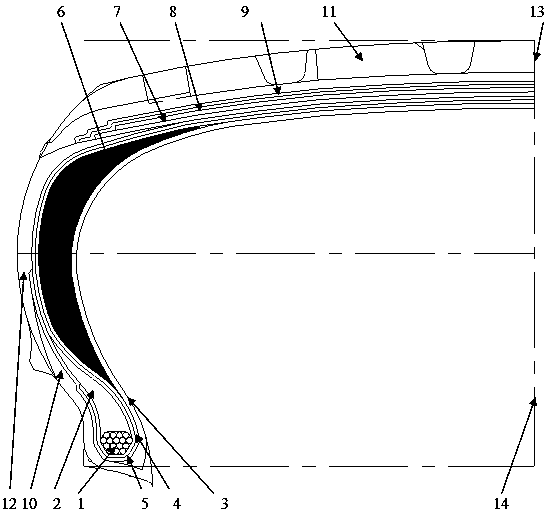

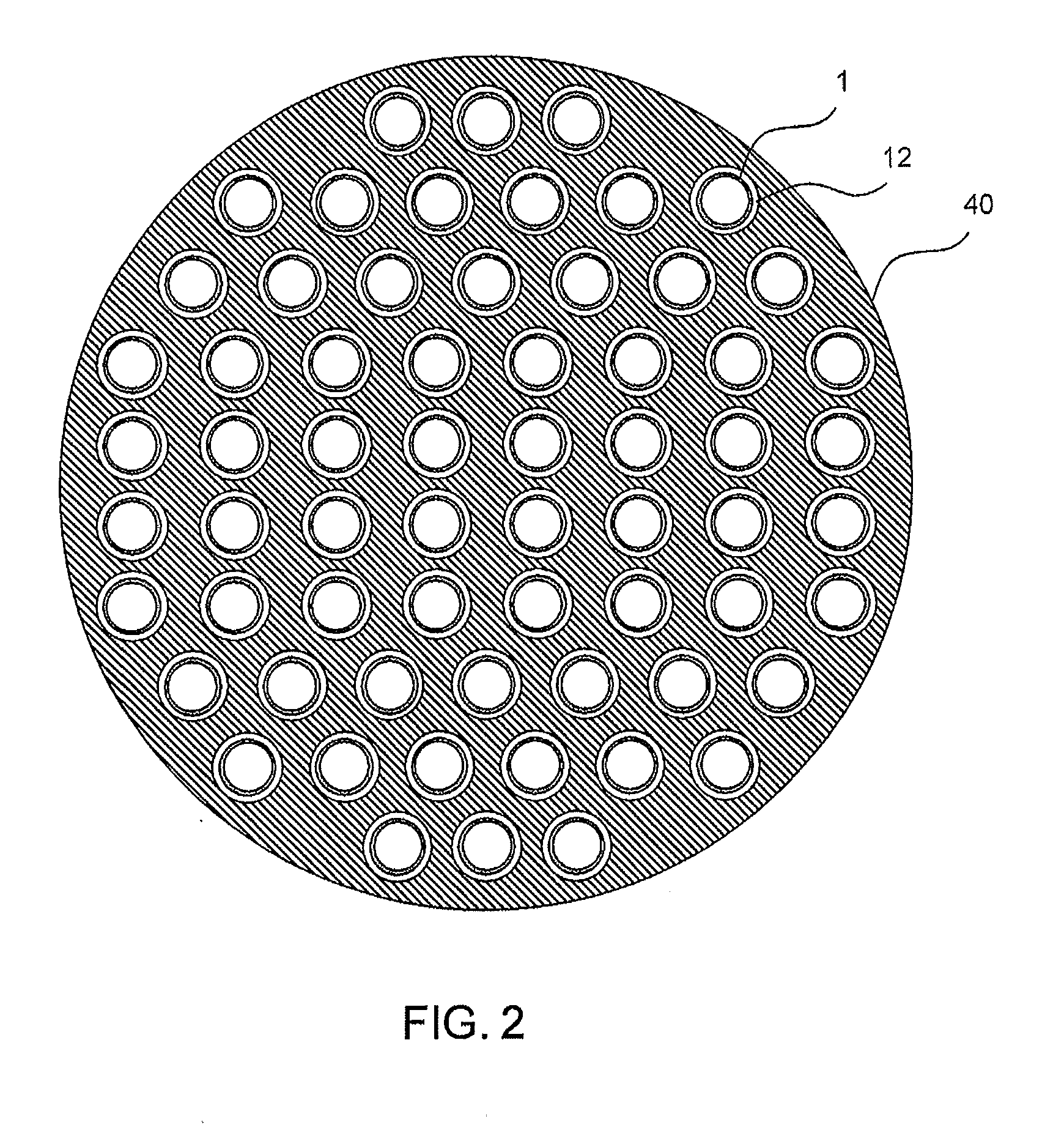

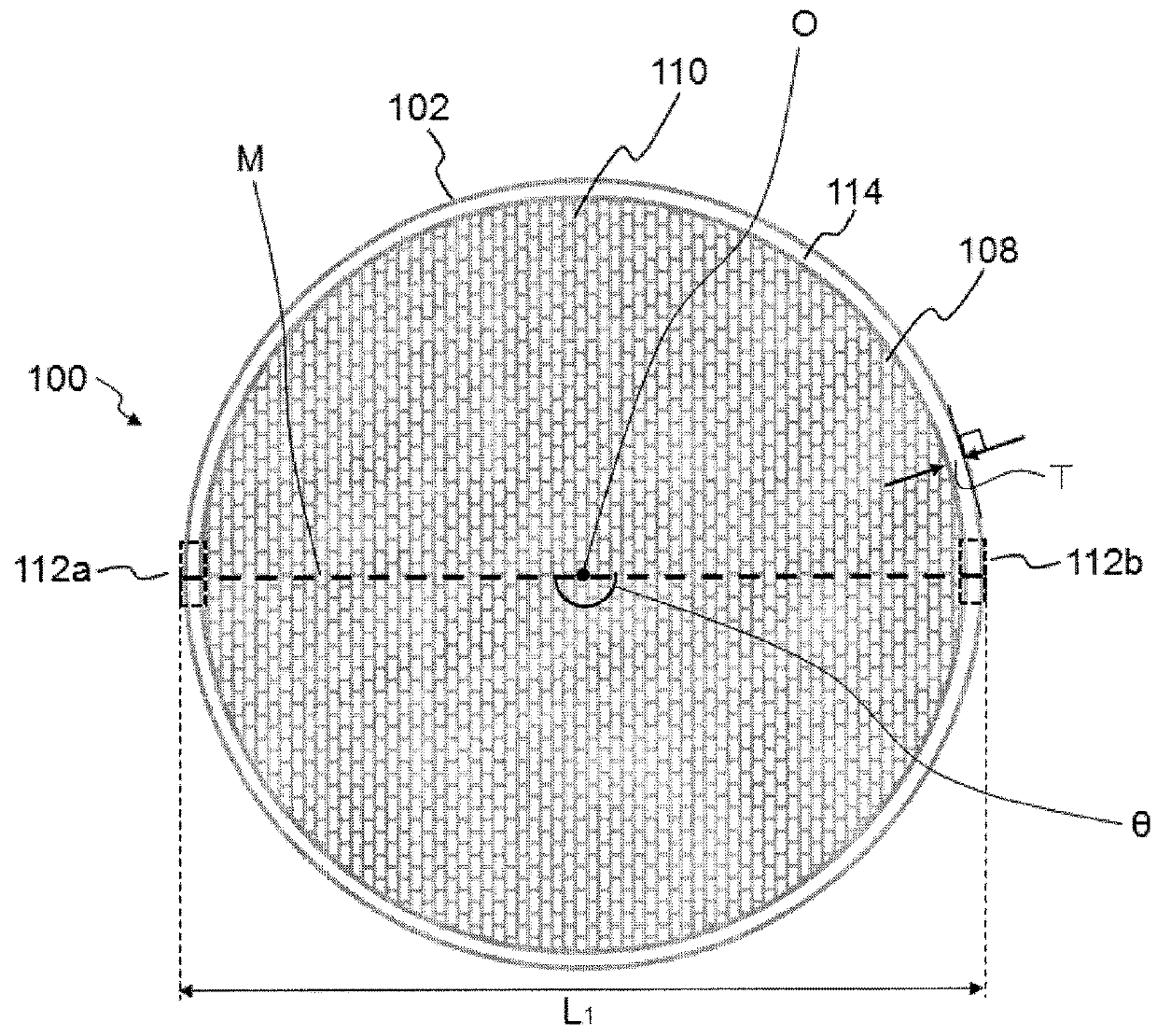

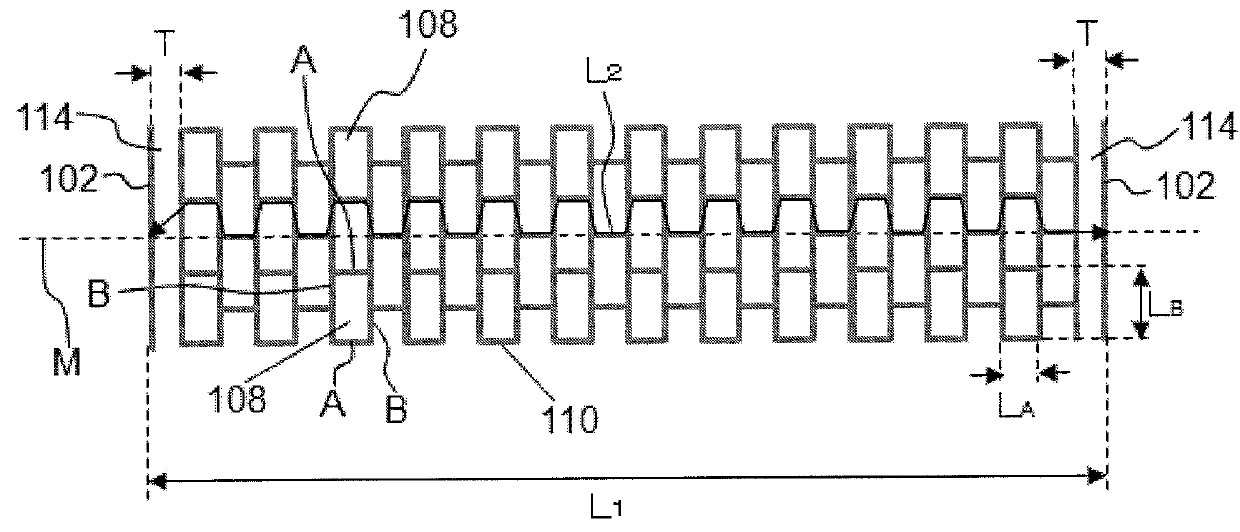

Honeycomb structure

ActiveUS20180264456A1Heat generation uniformity can be improvedSacrificing structural reliabilityPhysical/chemical process catalystsInternal combustion piston enginesEngineeringMechanical engineering

A columnar honeycomb structure comprising an outer peripheral side wall having an outer peripheral side surface; a plurality of partition walls that partition and form a plurality of cells penetrating from one bottom surface to another bottom surface to form flow paths, the plurality of partition walls being disposed inside the outer peripheral side wall; and a pair of terminal connection portions arranged so as to be opposed to each other on the outer peripheral side surface of the outer peripheral side wall, wherein the honeycomb structure satisfies a relational expression of 1.3≤L2 / L1 in which: in a cross section perpendicular to a direction of the flow paths of the cells, L1 represents a length between two points on the outer peripheral side surface intersecting with a straight line connecting circumferential centers of the pair of terminal connection portions; and L2 represents a length of a shortest path connecting the two points through the outer peripheral side wall and the partition walls.

Owner:NGK INSULATORS LTD

Pneumatic tire

A pneumatic tire using a rubber composition, comprising: per 100 parts by mass of a rubber component comprising at least one kind of natural rubber or diene-based synthetic rubber, 20-150 parts by mass of hydrous silicic acid employed as a filler, wherein the specific surface area determined based on the adsorption of cetyltrimethylammonium bromide (CTAB) (m2 / g) and the modal diameter (nm) of primary aggregates determined by the acoustic particle size distribution analysis (Aac) satisfy relationship (A), and the difference between the ignition loss (loss in mass% through 3-hour heating at 750 DEG C) and the heating loss (loss in mass% through 2-hour heating at 105 DEG C) satisfies relationship (B); and 1-25 parts by mass of at least one kind of specific sulfur-containing silane compound as a silane coupling agent. -0.76x(CTAB)+274 (A) (ignition loss)-(heating loss) is not greater than Aac and is not less than 3 (B).

Owner:BRIDGESTONE CORP

Winter tread rubber material

The invention provides a winter tread rubber material comprising, in parts by weight, 35-50 parts of natural rubber, 10-15 parts of high vinyl polybutadiene rubber, 50-60 parts of oil filled neodymium cis-butadiene rubber, 15-20 parts of mineral oil MES, 6-8 parts of high-structural carbon black, 60-75 parts of high-dispersion white carbon black, 5-7 parts of a silane coupling agent, 3-5 parts of a processing aid, 1-3 parts of zinc oxide, 1.5-3 parts of stearic acid, 2-3 parts of an anti-aging agent 4020, 1-2 parts of microcrystalline wax, 5-8 parts of aliphatic hydrocarbon tackifying resin, 0.5-1.5 parts of a sulfur powder, 1.5-2.5 parts of an accelerator, and 6-10 parts of a regenerated rubber powder. The winter tread rubber material is still in a relatively soft state under an environment of relatively low temperature, the friction between a tread and the ground is large, and the safety of a vehicle driving under the environment of low temperature is ensured; the wear resistance of the tread can be improved, the use cost is reduced, user benefits are maximized, and the pollution to the environment is reduced; and wet skid resistance and heat generation property of the rubber material both have excellent representation and fully conform to the road holding requirements of wet road surfaces.

Owner:QINGDAO LIYANG RUBBER TECH CO LTD

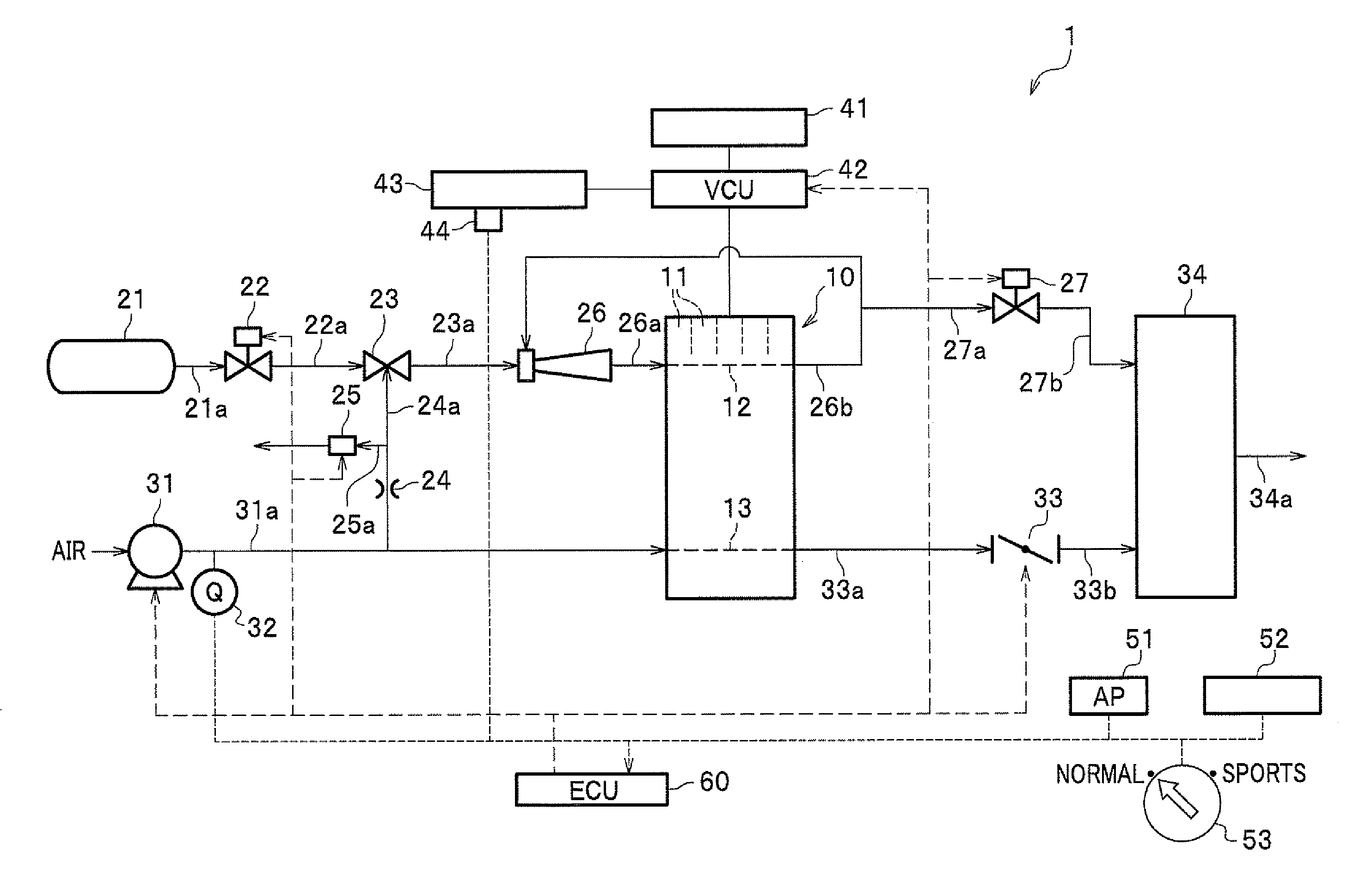

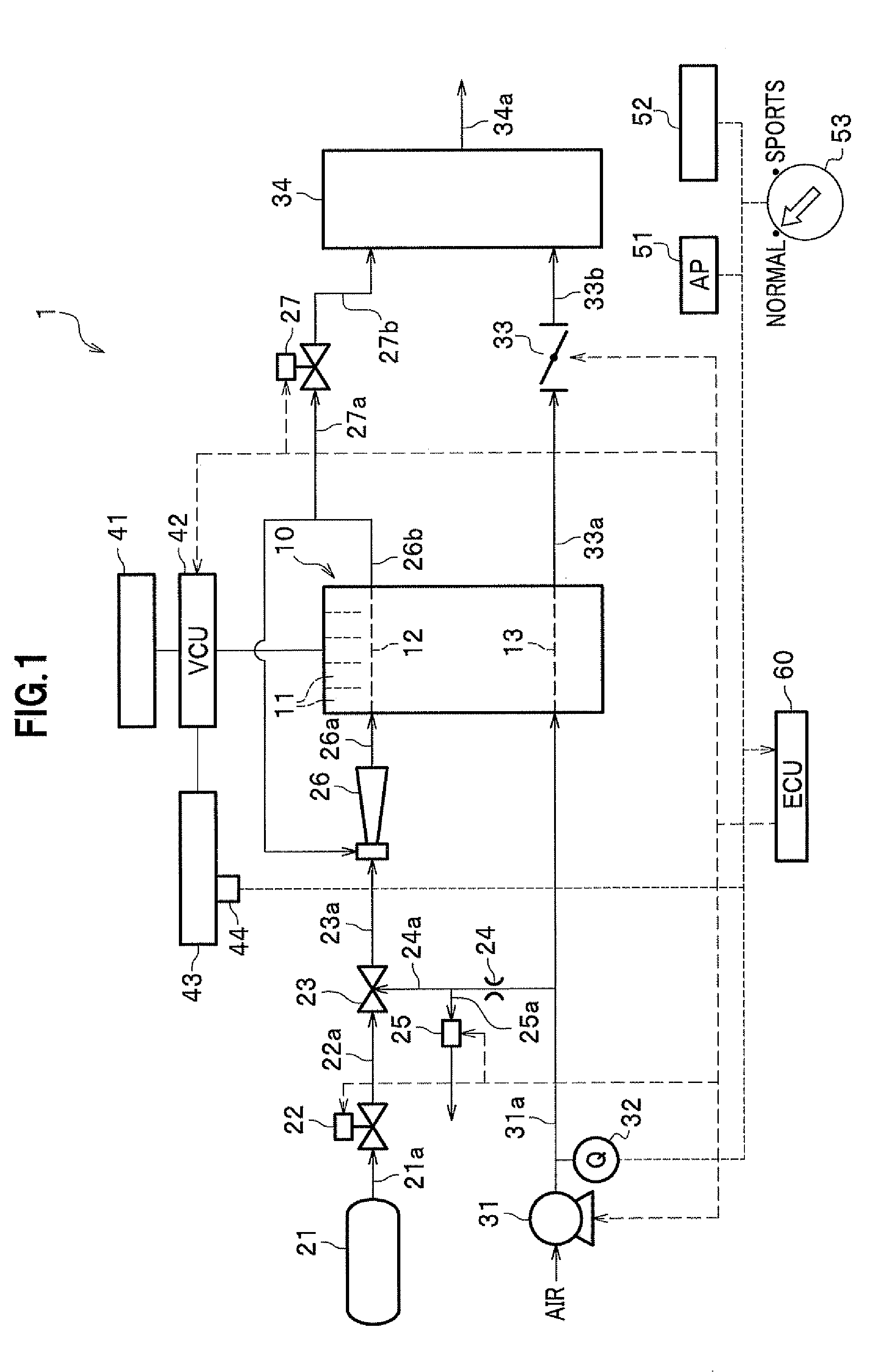

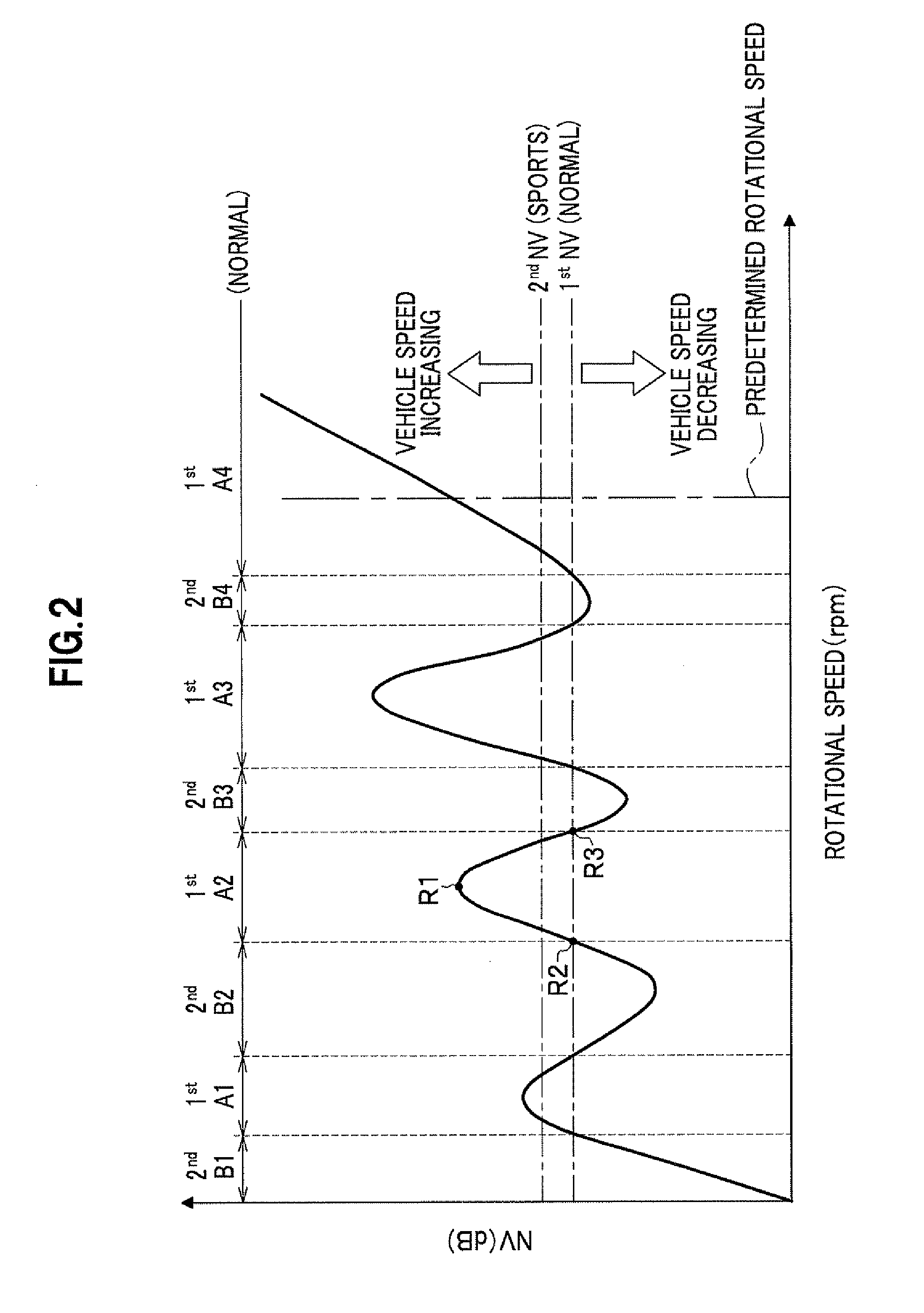

Fuel cell system

ActiveUS20090291341A1Extended battery operationEasy to changeFuel cells groupingFuel cell auxillariesFuel cellsEngineering

An object of the present invention is to provide a fuel cell system in which a noise and a vibration of a compressor can be suppressed. In order to achieve the above object, the present invention provides a fuel cell system including a fuel cell; a compressor for supplying an oxidant gas to the fuel cell, having a first rotational speed region within which as a rotational speed increases, a noise becomes greater than a predetermined value, and a second rotational speed region within which as the rotational speed increases, the noise becomes equal to or less than the predetermined value; and a compressor controller for controlling the compressor by calculating a command rotational speed for commanding the compressor based on a required amount of power generation.

Owner:HONDA MOTOR CO LTD

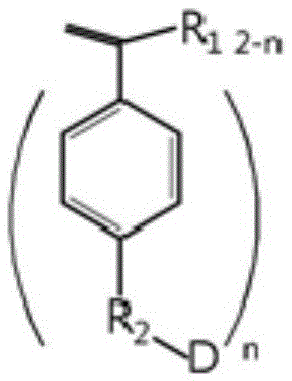

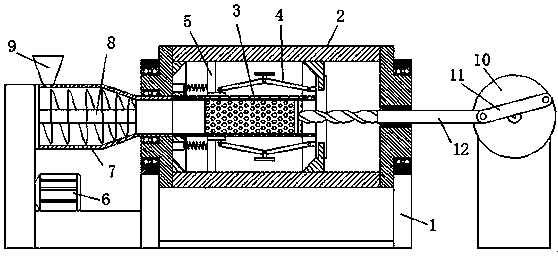

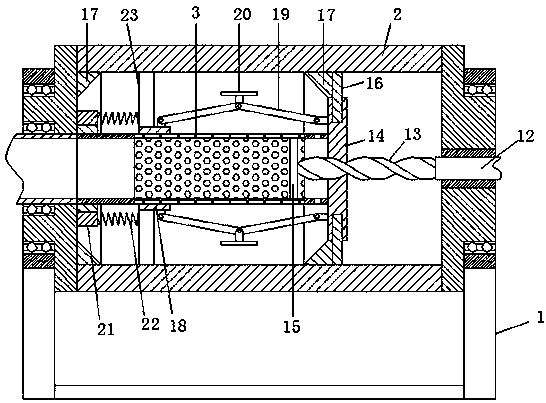

Internal rotation type biomass pyrolysis furnace

ActiveCN109796994AImprove pyrolysis efficiencyImprove heat generationGranulation in rotating drumsSpecial form destructive distillationEngineeringHeat generation

The invention relates to the field of pyrolysis furnaces, in particular to an internal rotation type biomass pyrolysis furnace, which comprises a transversely-arranged furnace body, wherein two ends of the furnace body are mounted on a support; the left end of the furnace body is connected with a feeding device; an inner cylinder is transversely arranged inside the furnace body in a coaxial manner; two ends of the inner cylinder are connected to the inner wall of the furnace body through fixing shafts in a rotary manner; the right end of the inner cylinder is connected with a driving mechanism; the left end of the inner cylinder is connected with a feeding port of the feeding device; a wall scraping mechanism is connected to the outside of the inner cylinder in a sleeved manner; the wall scraping mechanism is used for scraping the biomass adhered to the inner wall of the furnace body and simultaneously cooperating with the inner cylinder for granulating; and a shock wall mechanism is arranged between the wall scraping mechanism and the right end of the inner cylinder for crushing the biomass and vibrating the biomass adhered to the inner wall of the furnace body. According to the internal rotation type biomass pyrolysis furnace, granulation is carried out through the inner cylinder, and adhesion of biomass to the inner wall of the furnace body is avoided through the wall shaking mechanism and the wall scraping mechanism, and thus the heat generation effect of the inner wall of the furnace body is improved, and the heat inside the furnace body is uniform, so that the biomasspyrolysis efficiency and the yield of pyrolysis gas and pyrolysis oil are improved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

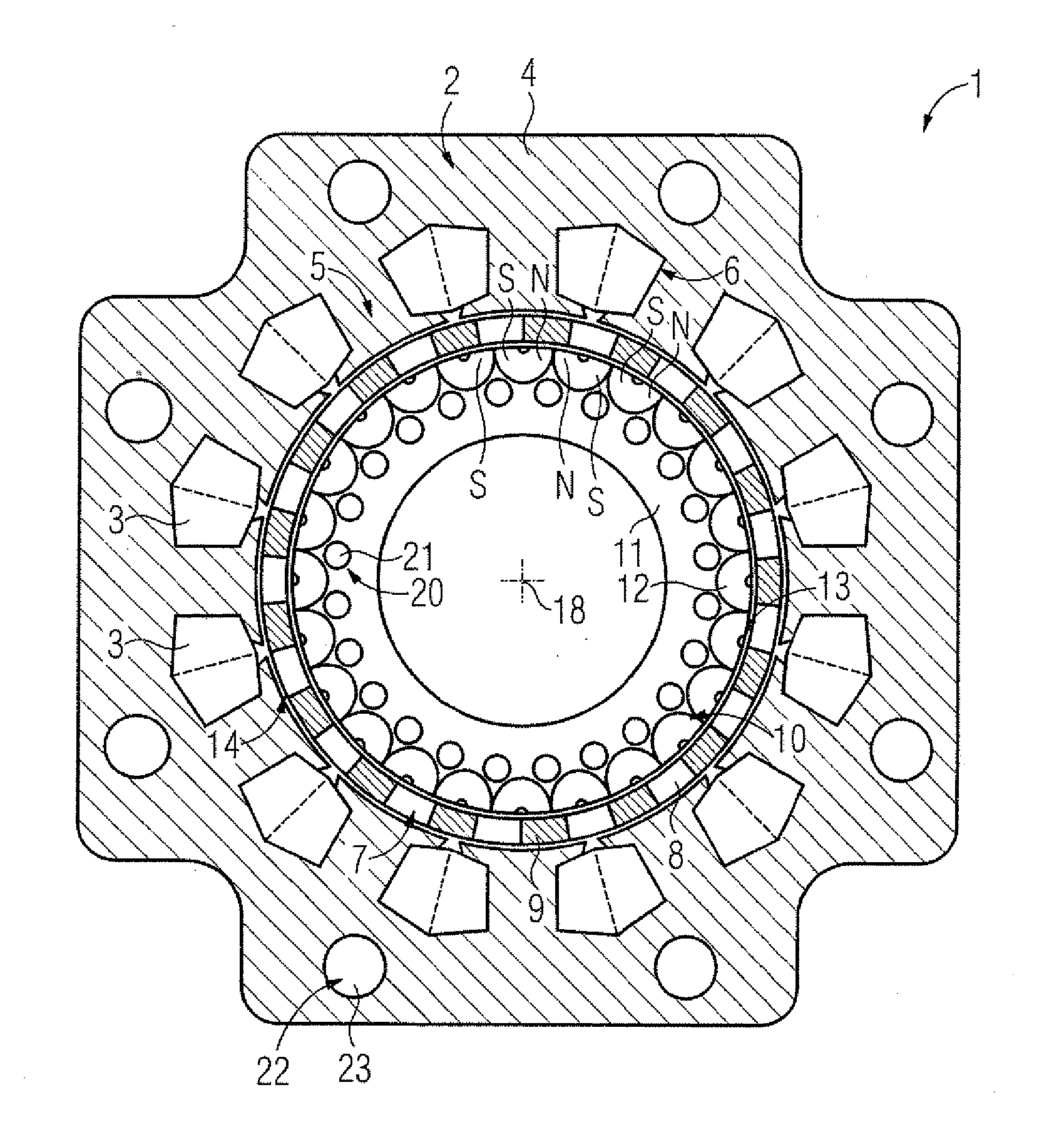

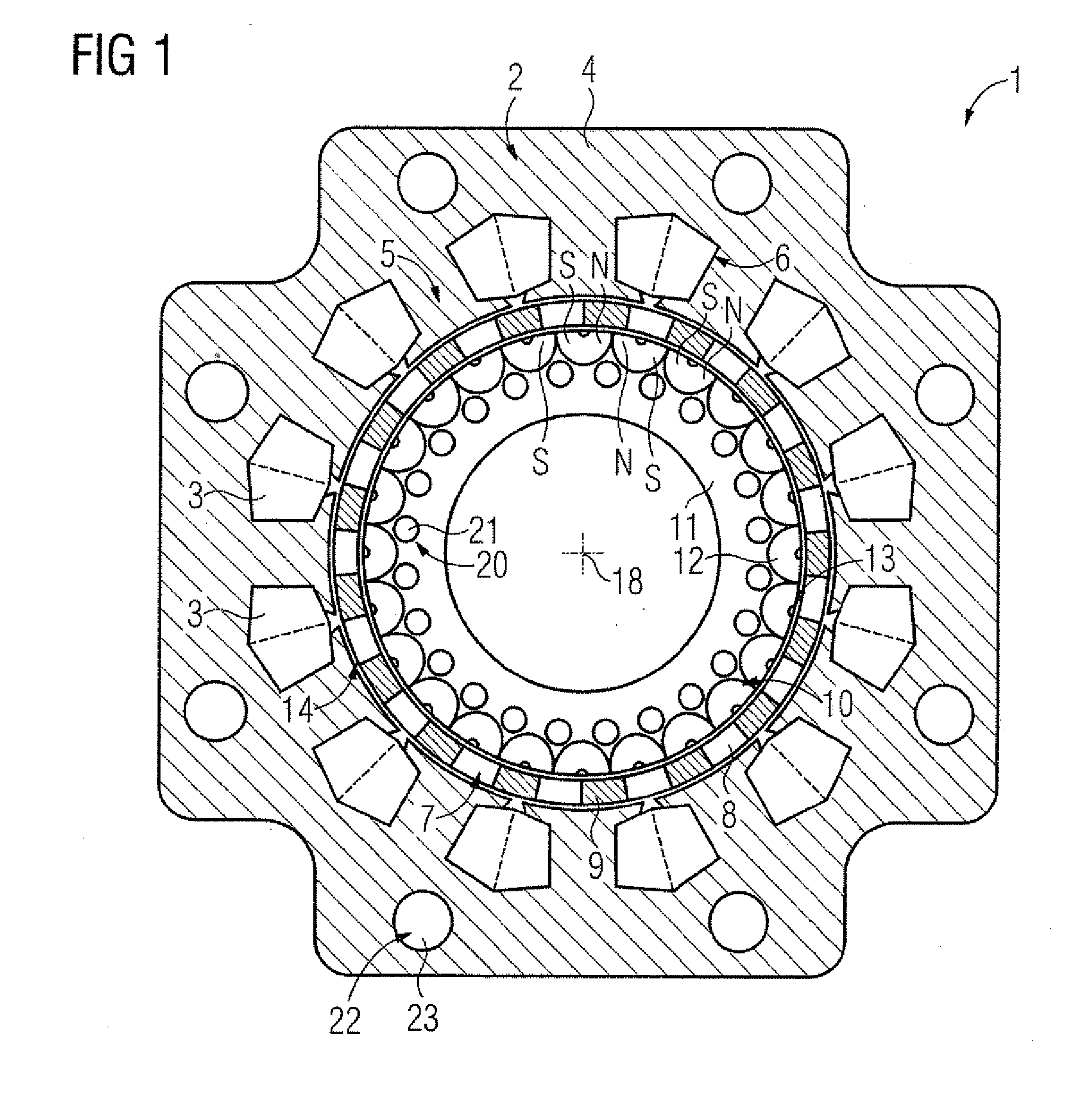

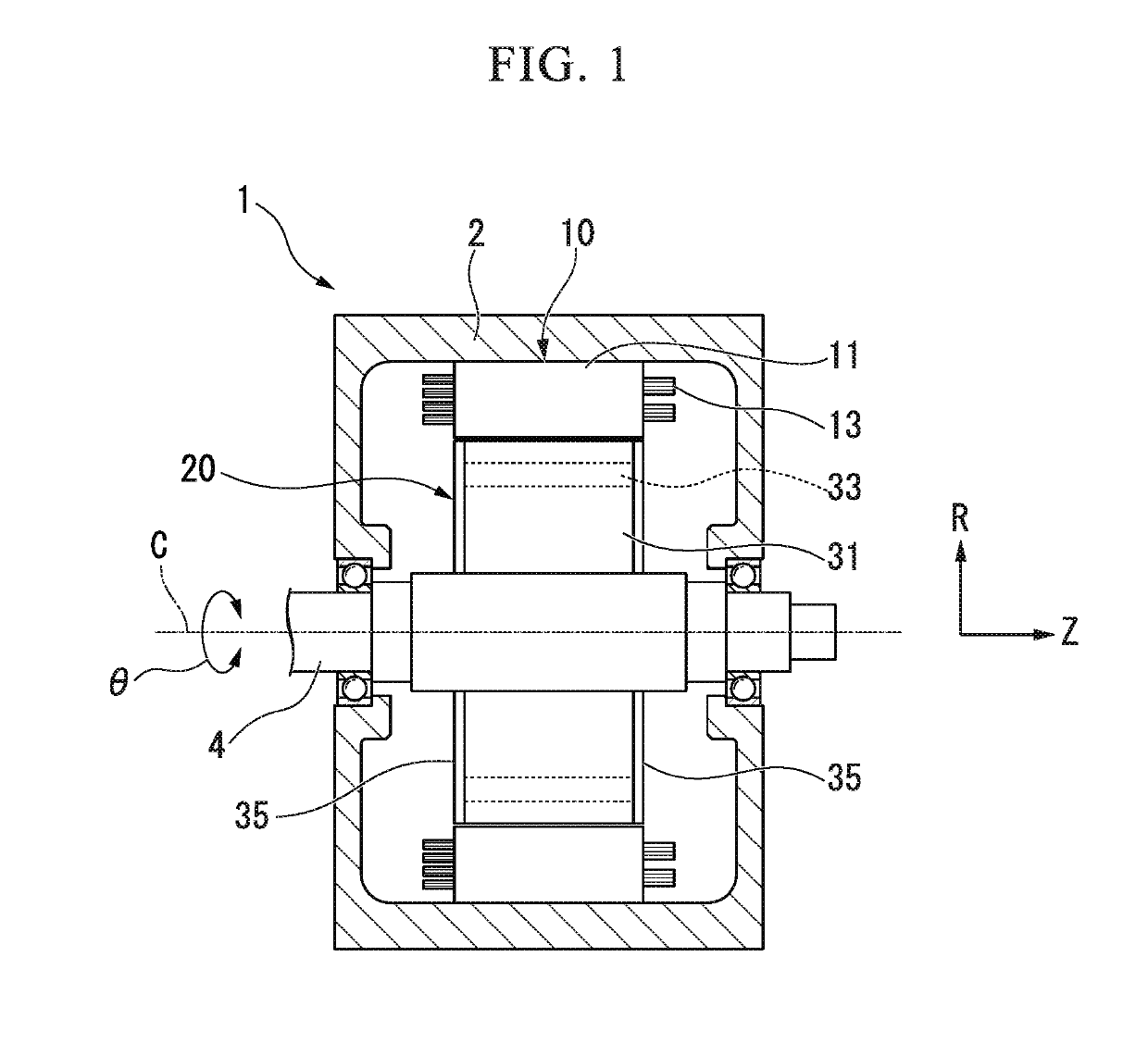

Electric rotating machine with laterally magnetized magnets

InactiveUS20160294229A1Improve heat generationLow conductivityMagnetic circuit rotating partsElectric propulsion mountingMagnetPhysics

An electric rotating machine includes an outer stator, and an inner stator arranged inside the outer stator in concentric relationship to the outer stator. The inner stator has a plurality of permanent magnets which contain iron-neodymium-boron. A rotor is arranged in concentric relationship to the outer stator and the inner stator between the outer stator and the inner stator. The rotor is configured for movement in relation to the outer stator and the inner stator and defines with the inner stator an internal air gap there between. Each permanent magnet of the inner stator has a north pole and a south pole on a side facing the internal air gap.

Owner:SIEMENS AG

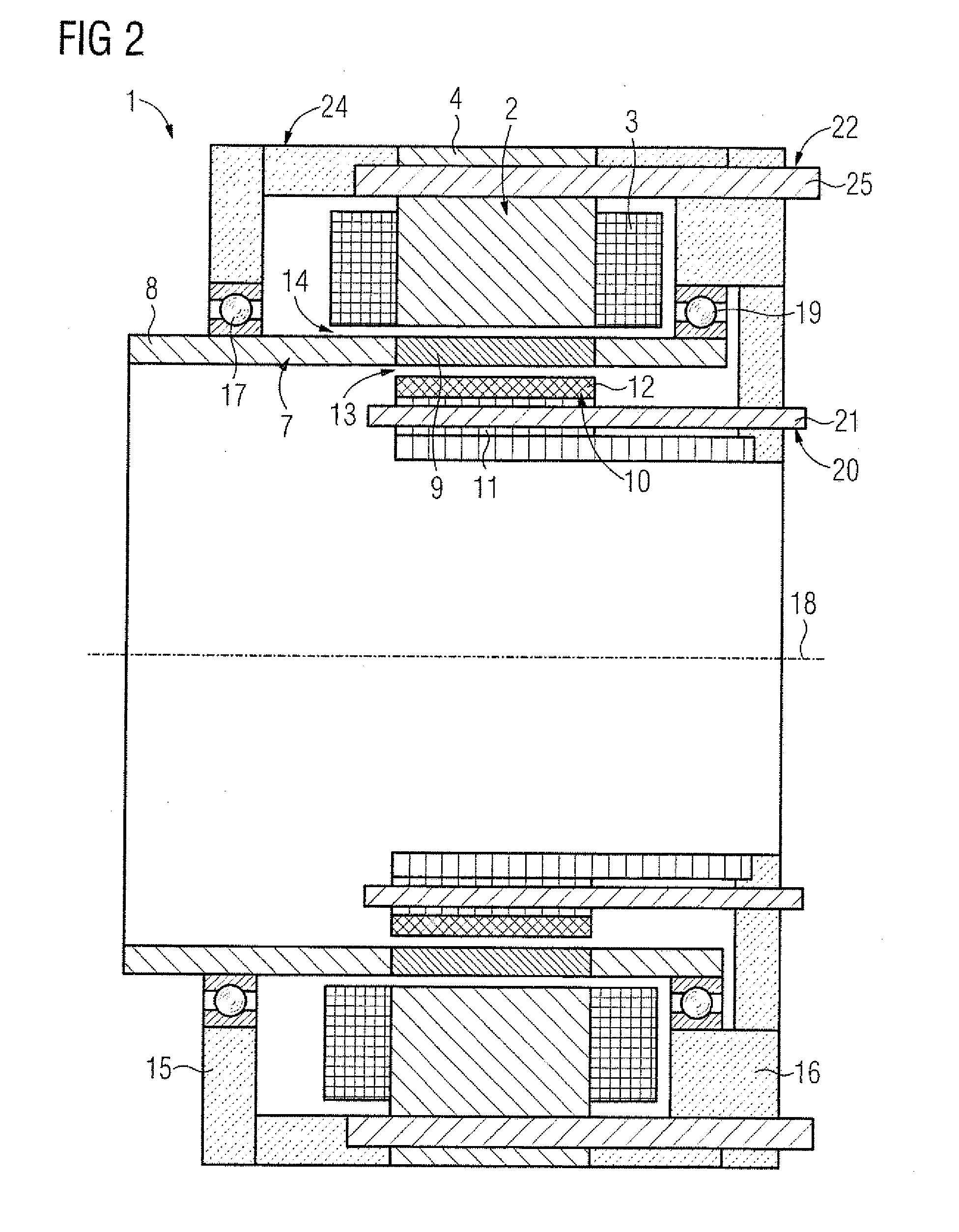

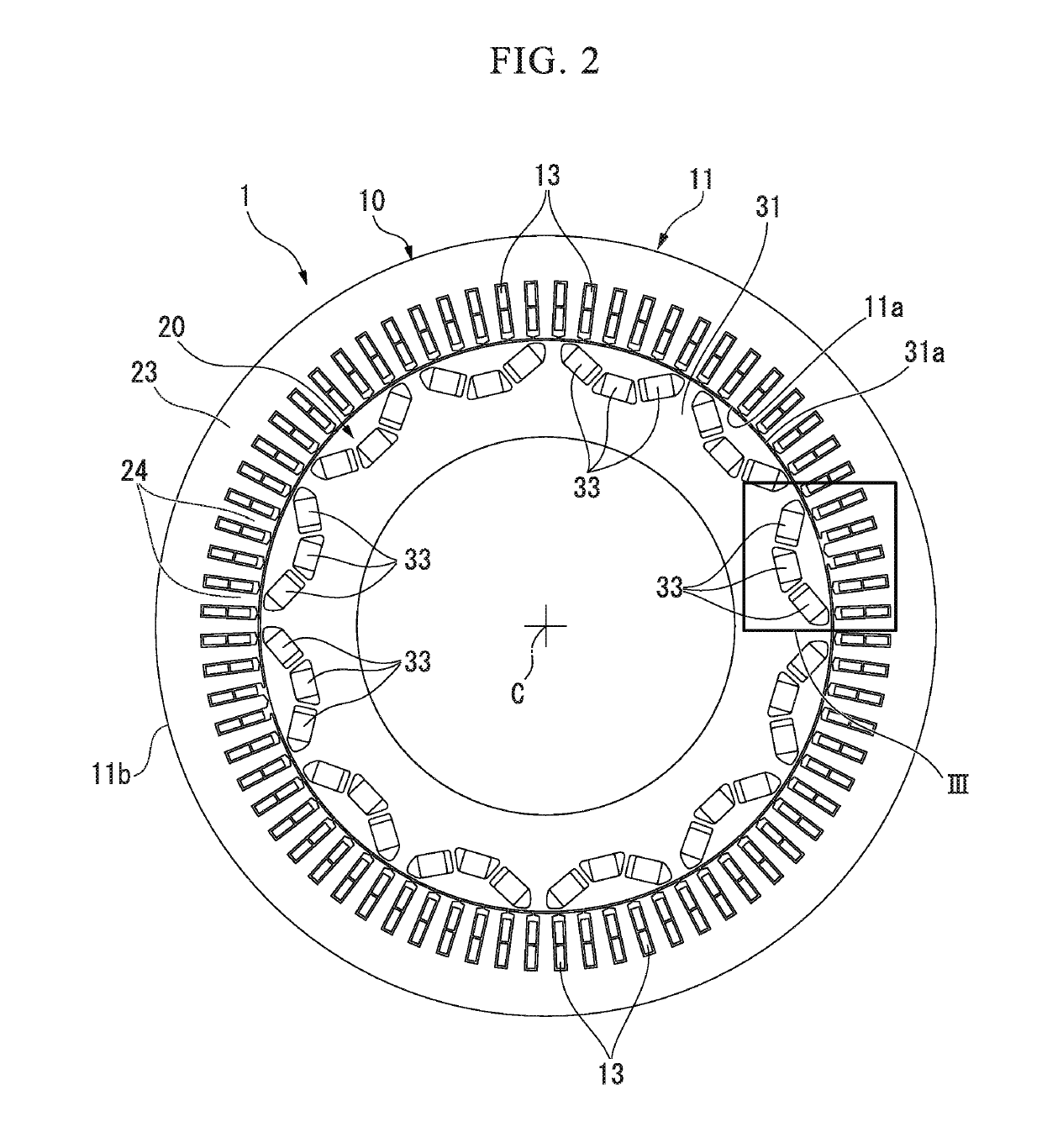

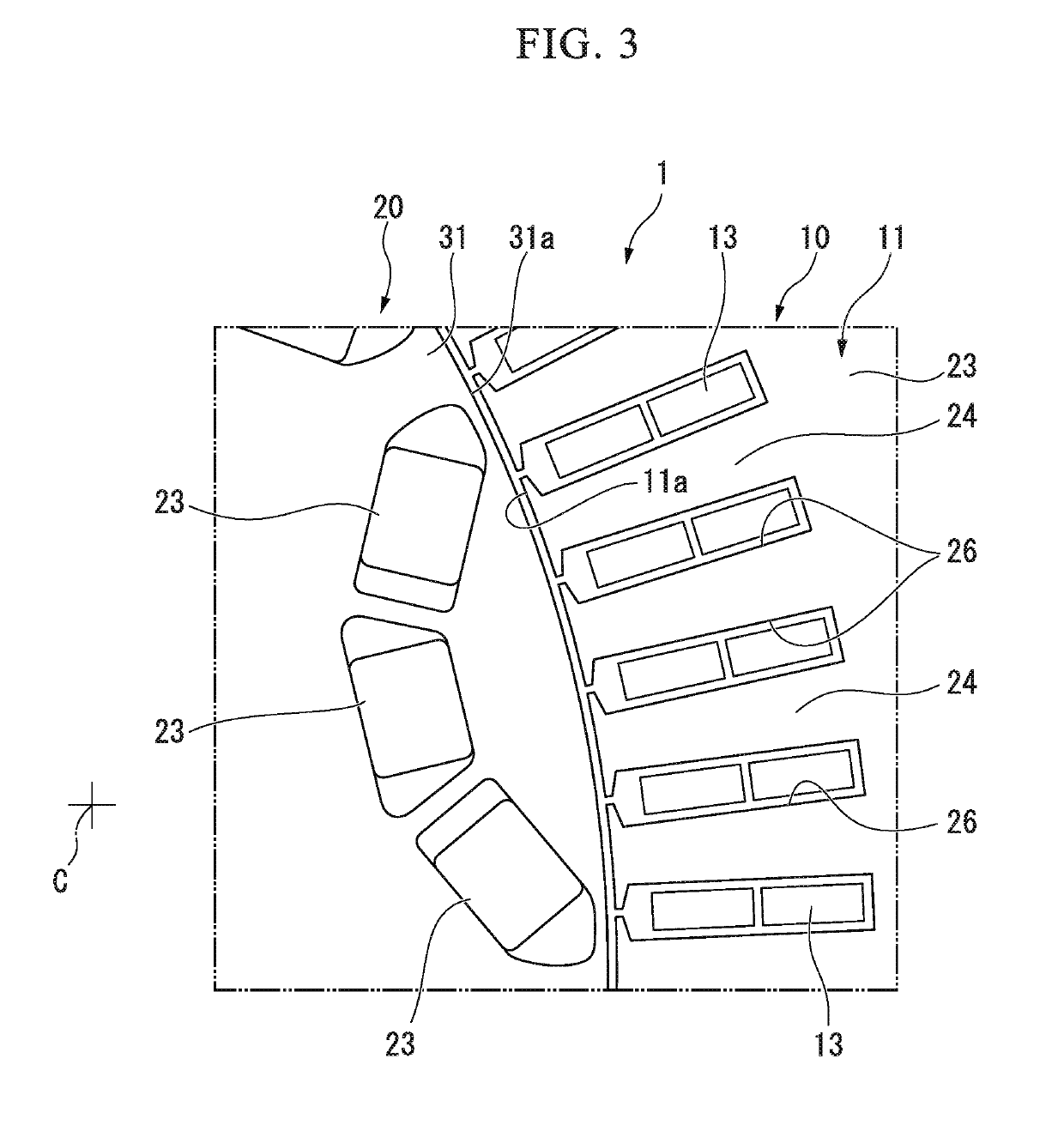

Rotary electric machine

ActiveUS20190280549A1Improve heat generationEfficient transferWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineEngineering

A rotary electric machine includes a stator. A plurality of slots are formed in a stator core of the stator, and a coil and an insulating sheet layer are inserted into the slots. A first coil side surface and a second coil side surface of the coil inserted into the slots serve as adhesive regions, which are adhered to a slot inner circumferential surface via the insulating sheet layer. In addition, a first coil end surface and a second coil end surface of the coil inserted into the slots serve as non-adhesive regions, which are maintained in a non-contact manner with respect to the slot inner circumferential surface.

Owner:HONDA MOTOR CO LTD

Compositions and methods for promoting weight loss and increasing energy

ActiveUS8372447B2Reduce controlControl food cravingsBiocideOrganic chemistryChlorogenic acidCaffeine

The present invention relates to compositions comprising plants and extracts of plants with chlorogenic acids and antioxidants and / or caffeine; methods for preparing the same; and methods to promote weight loss through the administration of compositions containing these plants and plant extracts in specific proportions.

Owner:NORTHERN INNOVATIONS HLDG

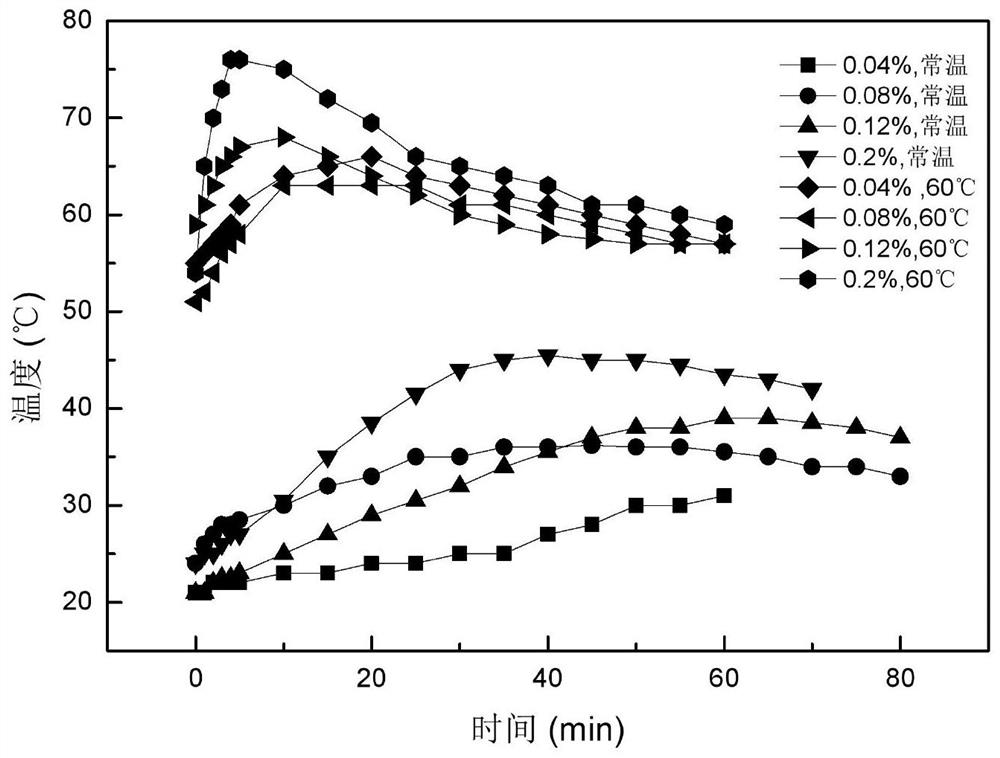

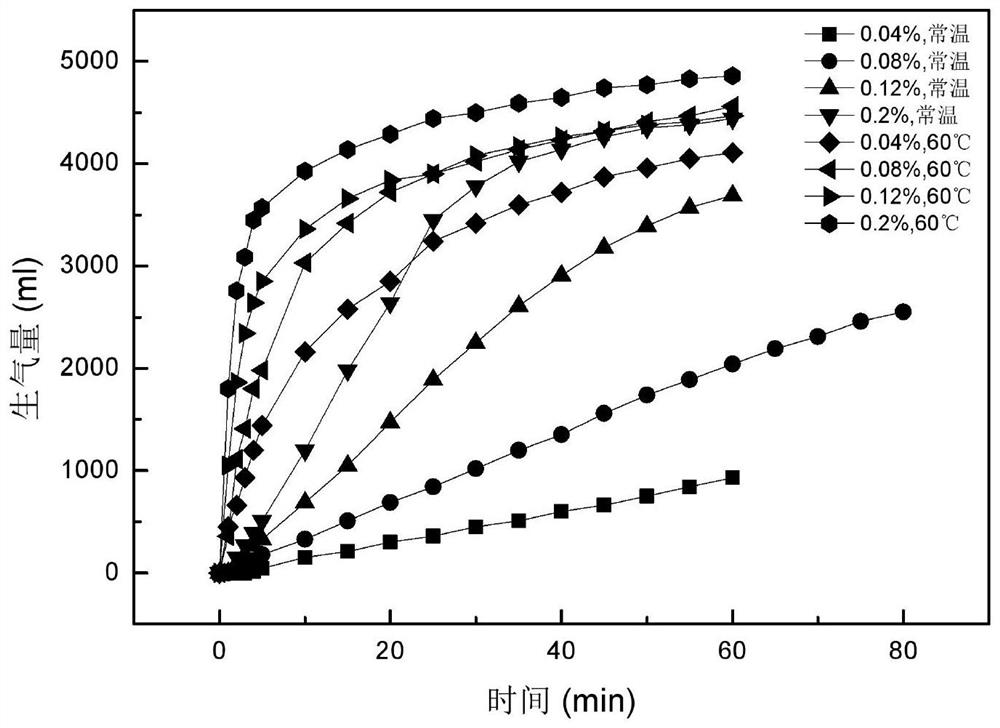

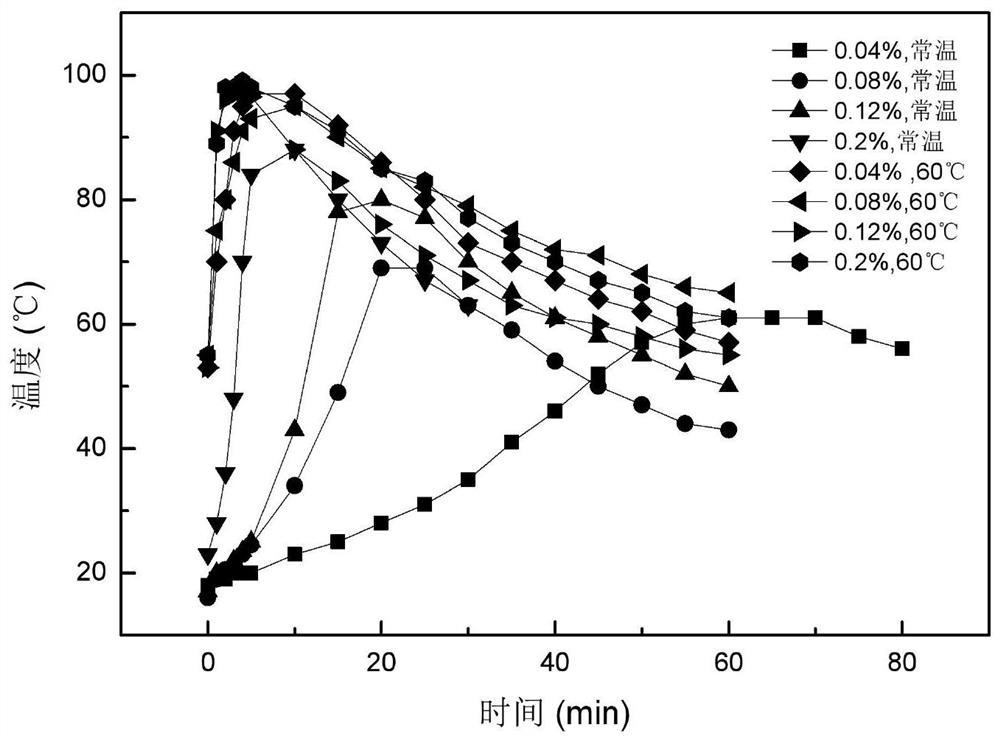

Self-heating fracturing fluid with controllable peak temperature, and preparation method and application of self-heating fracturing fluid

ActiveCN111849451AReduce cold damageImprove heat generationDrilling compositionNitrate saltsPhysical chemistry

The invention discloses a self-heating fracturing fluid with controllable peak temperature, and a preparation method and application of the self-heating fracturing fluid. The self-heating fracturing fluid is prepared by mixing a self-heating fracturing fluid base fluid and an activator solution according to a mass ratio of (18-22): (0.8-1.2). According to the self-heating fracturing fluid, a urea / nitrite / ammonium salt / low-concentration acidic activator system is adopted; according to the system, after a low-concentration activator is added, HNO2, NH4<+> and NH3.H2O undergo a thermochemical reaction, so a good heat generation effect is achieved and the cold damage of the fracturing fluid to a stratum is reduced; meanwhile, when the use concentration of an activator solution is 0.005%-0.04%,time for reaching the peak temperature is 1-5 hours, and the peak temperature reaches 48-105 DEG C, so the temperature for reservoir development is controllable, the cold damage of the fracturing fluid to the stratum is reduced, the gel breaking of the fracturing fluid can be enhanced by increasing the temperature, and secondary damage to the stratum is reduced; and therefore, the fracturing fluid is suitable for yield increase and transformation of high-pour-point oil reservoirs and low-temperature reservoirs.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com