Winter tread rubber material

A technology of tread rubber and rubber, which is applied in the field of tire rubber, can solve the problems of easy hardening of tread rubber, traffic accidents, and large rolling resistance, so as to improve winter performance, maximize benefits, and increase friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

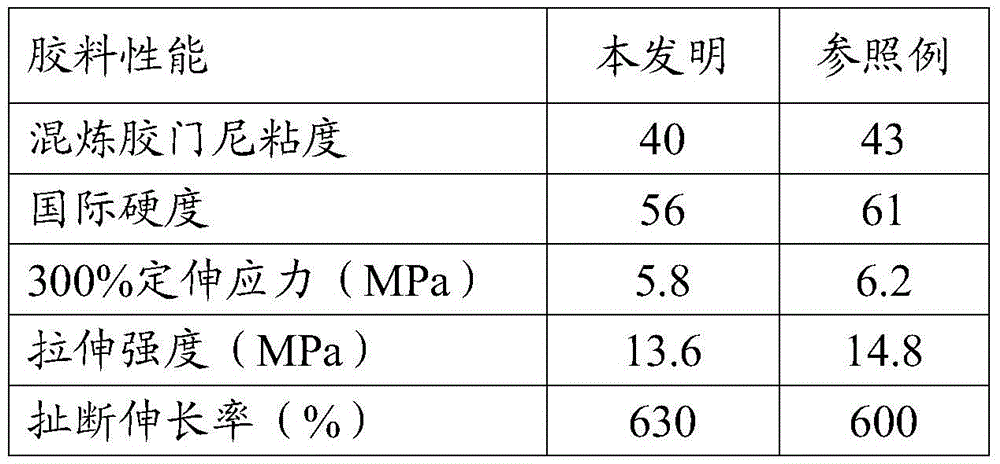

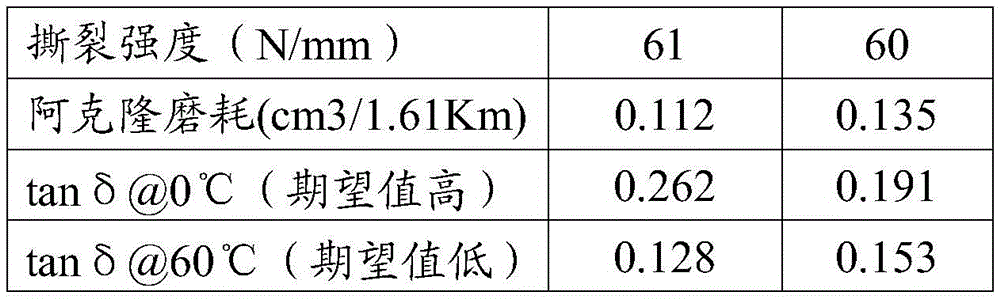

Examples

Embodiment 1

[0016] A kind of winter tread rubber material, according to parts by weight, including 45 parts of natural rubber, 15 parts of high vinyl polybutadiene rubber, 55 parts of oil-extended neodymium-based butadiene rubber, 18 parts of mineral oil MES, and 7 parts of high-structure carbon black 65 parts of highly dispersed silica, 6 parts of silane coupling agent, 164 parts of processing aid WB, 2 parts of zinc oxide, 2.5 parts of stearic acid, 2.5 parts of antioxidant 4020, 1.5 parts of microcrystalline wax, aliphatic hydrocarbon 7 parts of viscose resin, 1 part of sulfur powder, 2 parts of accelerator, 8 parts of reclaimed rubber powder. The natural rubber in this embodiment can be SMR20, STR20, SIR20 natural rubber commonly used in the tire industry, which is convenient to obtain materials and reduces production costs. In this embodiment, high-vinyl polybutadiene rubber is selected. This polymer has good wet skid resistance, low rolling resistance and heat generation, and is the...

Embodiment 2

[0021] It is basically the same as Example 1, the difference is that: the winter tread rubber material, in parts by weight, includes 35 parts of natural rubber, 10 parts of high vinyl polybutadiene rubber, 50 parts of oil-extended neodymium-based butadiene rubber, mineral 20 parts of oil MES, 8 parts of high-structure carbon black, 60 parts of high-dispersion white carbon black, 5 parts of silane coupling agent, 163 parts of processing aid WB, 3 parts of zinc oxide, 1.5 parts of stearic acid, 40203 parts of anti-aging agent, microcrystalline 1 part wax, 5 parts aliphatic hydrocarbon tackifying resin, 1.5 parts sulfur powder, 2.5 parts accelerator, 6 parts reclaimed rubber powder.

Embodiment 3

[0023] It is basically the same as Example 1, the difference is that: the winter tread rubber material, in parts by weight, includes 50 parts of natural rubber, 13 parts of high vinyl polybutadiene rubber, 60 parts of oil-extended neodymium-based butadiene rubber, mineral 15 parts of oil MES, 6 parts of high-structure carbon black, 75 parts of high-dispersion white carbon black, 7 parts of silane coupling agent, 165 parts of processing aid WB, 1 part of zinc oxide, 3 parts of stearic acid, 40202 parts of anti-aging agent, microcrystalline 2 parts of wax, 8 parts of aliphatic hydrocarbon tackifying resin, 0.5 parts of sulfur powder, 1.5 parts of accelerator, 10 parts of reclaimed rubber powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com