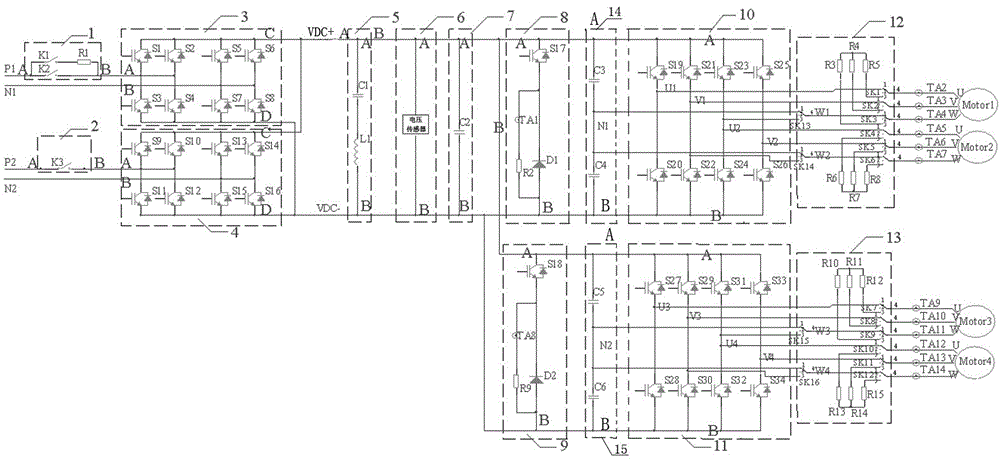

Main circuit of traction converter for high-speed motor train unit

A technology for traction converters and high-speed EMUs, applied in electrical components, electronic commutation motor control, multiple motor speed/torque control, etc. High loss and other problems, to achieve the effect of reducing damage, good reliability, and reducing total loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

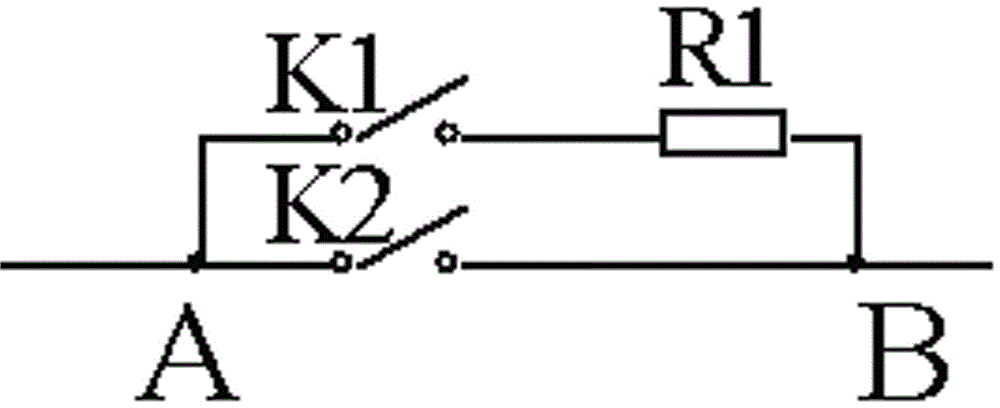

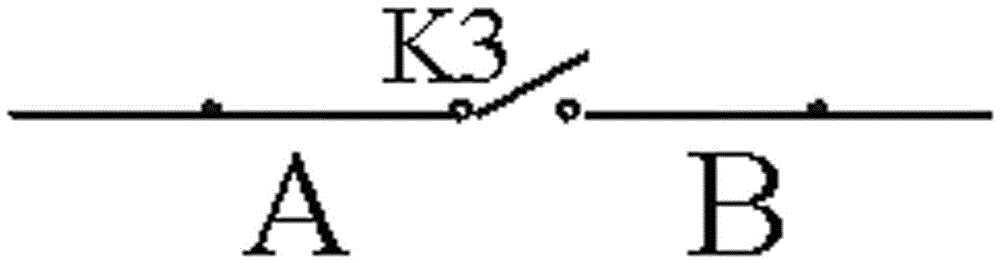

[0022] Such as figure 1 As shown, a high-speed EMU traction converter main circuit includes a first input voltage and current buffer circuit 1, a second input voltage and current buffer circuit 2, a first four-quadrant rectifier 3, a second four-quadrant rectifier 4, Secondary filter circuit 5, voltage sensor 6, support capacitor 7, first chopper circuit 8, second chopper circuit 9, first inverter 10, second inverter 11, first contactor circuit 12, second Two contactor circuits 13 , a first capacitor circuit 14 and a second capacitor circuit 15 .

[0023] The secondary side output winding P1 of the traction transformer is connected to the A terminal of the first voltage and current buffer circuit 1, the B terminal of the first voltage and current buffer circuit 1 is connected to the A terminal of the first four-quadrant rectifier 3, and the secondary side ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com