End-functional conjugated diene-based polymer and manufacturing method therefor

一种共轭二烯、聚合物的技术,应用在制备该聚合物领域,能够解决高滞后损耗、低分散性、效果不够等问题,达到优异相容性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

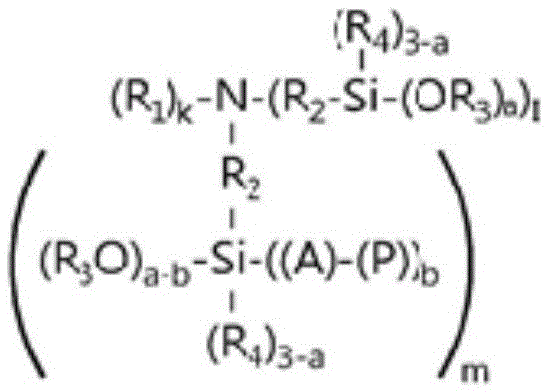

Method used

Image

Examples

preparation example Construction

[0078] In the method of preparing an end-functionalized conjugated diene-based polymer according to the present invention, the polymerization in (a) may be performed additionally using a polar additive.

[0079] The polar additive may be a base. Alternatively, the polar additive may be an ether, an amine, or a mixture thereof, or may be selected from tetrahydrofuran, di(tetrahydrofuryl)propane, diethyl ether, cyclopentyl ether, dipropyl ether, ethylene glycol dimethyl ether, ethylene glycol dimethyl ether, Alcohol dimethyl ether, diethylene glycol, dimethyl ether, tert-butoxyethoxyethane bis(2-dimethylaminoethyl) ether, (dimethylaminoethyl) ether, trimethylamine, triethylamine , tripropylamine and tetramethylethylenediamine. Alternatively, the polar additive may be di(tetrahydrofuryl)propane, triethylamine or tetramethylethylenediamine.

[0080] The polar additive may be used in an amount of 0.001 to 50 g, preferably 0.001 to 10 g, more preferably 0.005 to 1 g, and most pref...

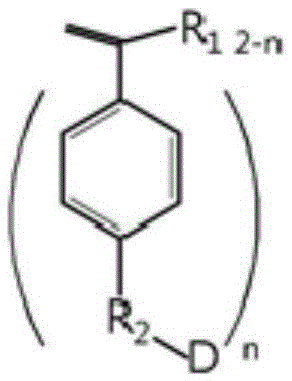

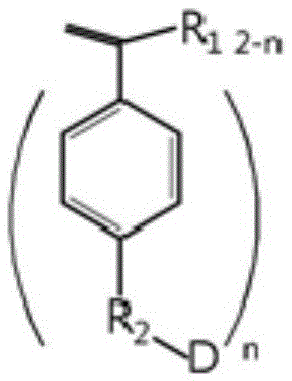

Embodiment 1

[0116] In a 20L autoclave reactor, 260g of styrene, 720g of 1,3-butadiene, 5000g of n-hexane and 1.3g of 2,2-bis(2-tetrahydrofuryl)propane as a polar additive were placed, and the reaction The internal temperature of the vessel rose to 40 °C. When the internal temperature of the reactor reached 40° C., 4 mmol of n-butyllithium was placed in the reactor to perform an adiabatic reaction until stable. 20 minutes after the completion of the adiabatic reaction, 20 g of 1,3-butadiene was added, thereby forming a living polymer having a lithium terminal. Then, 0.5 g of 3- or 4-pyrrolidineethylstyrene was added, and the reaction was performed for 30 minutes, thereby capping the living polymer.

[0117] Subsequently, 5 mmol of bis(methyldiethoxysilylpropyl)-N-methylamine was added and the reaction was allowed to proceed for 15 minutes. Thereafter, the polymerization reaction was terminated using ethanol, and 5 ml of a solution in which 0.3 wt % of butylated hydroxytoluene (BHT) as an...

Embodiment 2

[0120] An end-functionalized conjugated diene-based polymer was prepared in the same manner as in Example 1 except that 3- or 4-pyrrolidineethylstyrene was added in an amount of 1 g instead of 0.5 g. The analysis results of the end-functionalized conjugated diene-based polymer thus prepared are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com