Self-heating fracturing fluid with controllable peak temperature, and preparation method and application of self-heating fracturing fluid

A peak temperature and self-generated technology, applied in the field of fracturing fluid, can solve the problems of unsuitable high pour point oil reservoirs, etc., achieve good heat generation effect, improve development effect, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also protects a method for preparing fracturing fluid with controllable peak temperature and self-generated heat, which includes the following steps:

[0064] S1, preparing self-generating heat fracturing fluid base fluid;

[0065] S2, preparing an activator solution, pouring the formulated amount of the activator into the formulated amount of water, at a rate of 1-2 ml / min, stirring and mixing evenly at a rotating speed of 400-600 r / min, to obtain an activator solution;

[0066] S3, fully mix the self-generating fracturing fluid base fluid obtained in S1 with the activator solution obtained in S2 in proportion to obtain the self-generating fracturing fluid with controllable peak temperature.

[0067] Further, the specific method for preparing self-generating heat fracturing fluid base fluid in the S1 includes the following steps:

[0068] S101, add the formulated amount of nitrite into the formulated amount of water, stir and mix evenly under the...

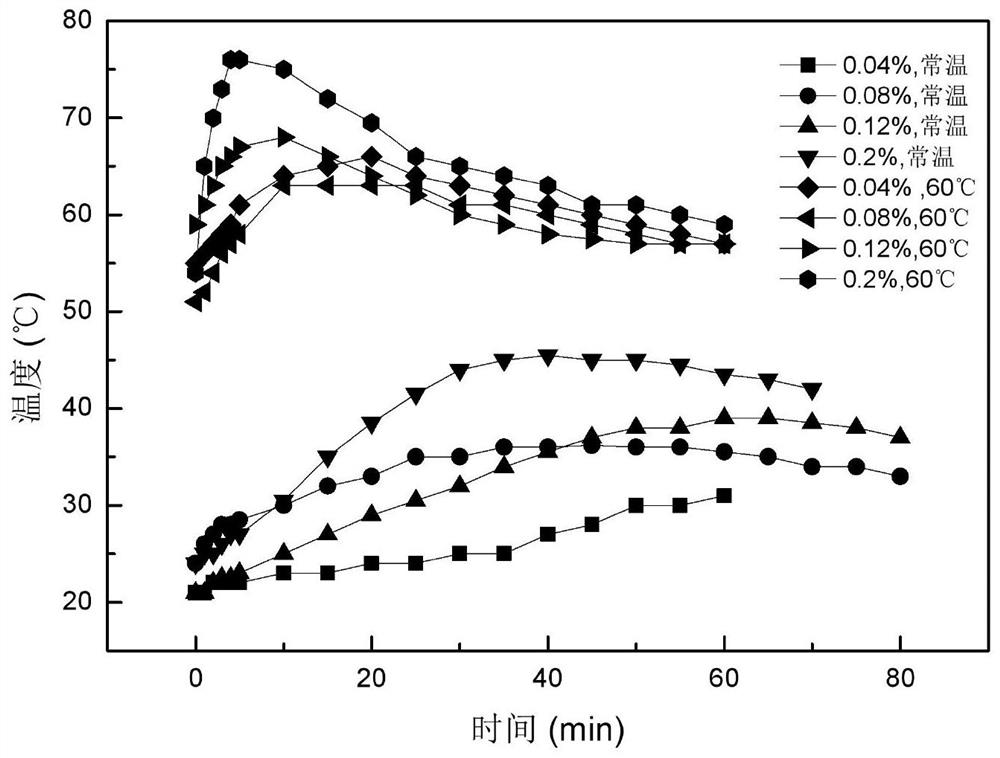

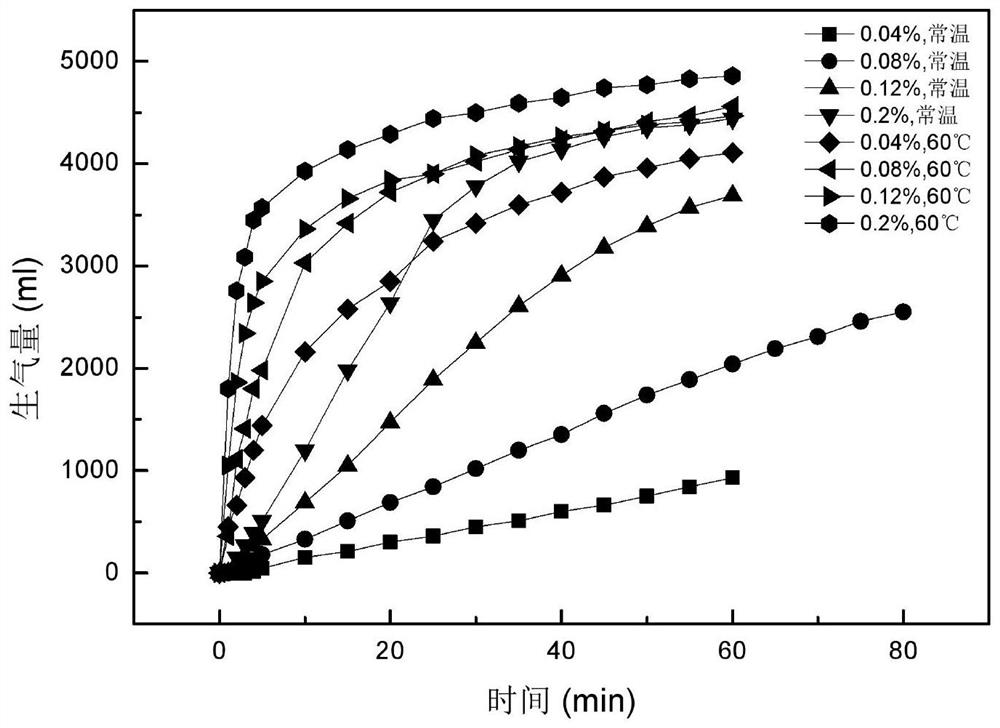

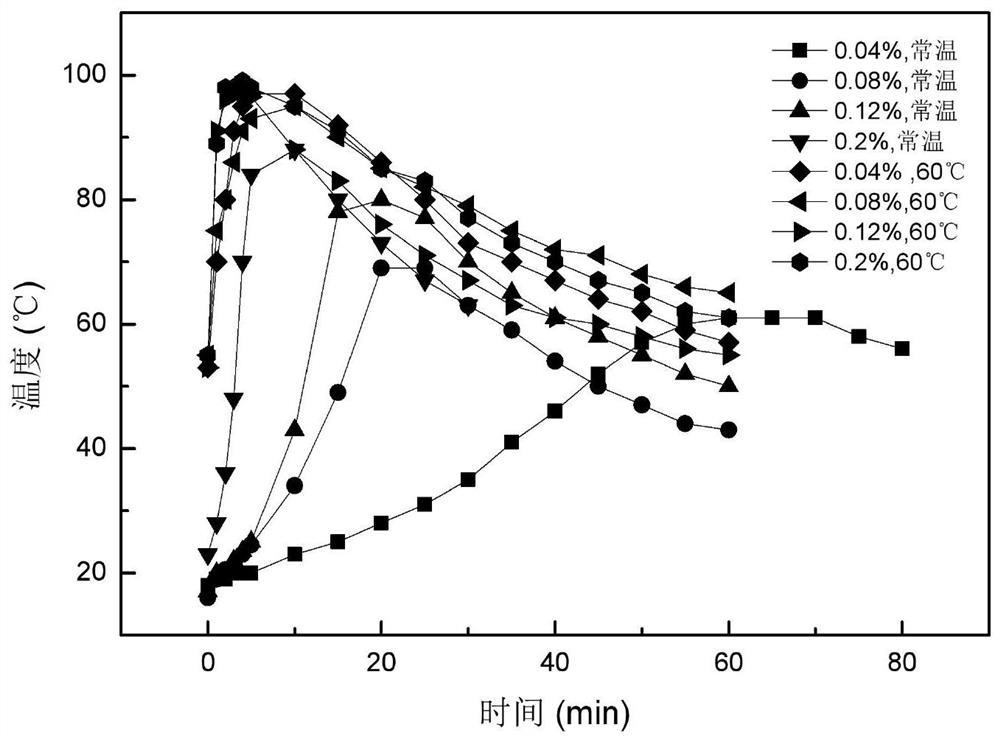

Embodiment 1

[0079] This embodiment provides a self-generating heat fracturing fluid with controllable peak temperature, which is prepared by mixing the self-generating heat fracturing fluid base fluid and the activator solution at a mass ratio of 20:1.

[0080] Further, the raw material composition of the self-generating heat fracturing fluid base fluid is as follows:

[0081] Urea 2g, sodium nitrite 6.9g, ammonium chloride 5.35g, thickener hydroxypropyl guar gum 0.3g, crosslinking agent (crosslinking agent JL-13) 1g, regulator sodium hydroxide solution 1g, drainage aid Sodium lauryl sulfate 0.5g, fungicide formaldehyde 0.1g, gel breaker ammonium persulfate 0.06g, clay stabilizer potassium chloride 0.3g, water 82.49g.

[0082]The raw material composition of described activator solution is as follows:

[0083] Hydrochloric acid 1.6g, water 98.4g; oxalic acid 1.6g, water 98.4g; citric acid 1.6g, water 98.4g.

[0084] Specifically, the crosslinking agent JL-13 is to mix glycerol and water ...

Embodiment 2

[0095] A self-generating heat fracturing fluid with controllable peak temperature is prepared by mixing a self-generating heat fracturing fluid base fluid and an activator solution at a mass ratio of 20:1.

[0096] Further, the raw material composition of the self-generating heat fracturing fluid base fluid is as follows:

[0097] Urea 2g, sodium nitrite 6.9g, ammonium chloride 5.35g, thickener hydroxypropyl guar gum 0.3g, crosslinking agent JL-131g, conditioner 1g, drainage aid 0.5g, fungicide formaldehyde 0.1g, Glue ammonium persulfate 0.06g, clay stabilizer potassium chloride 0.3g, water 82.49g.

[0098] The cross-linking agent JL-13 is to mix glycerol and water uniformly according to the mass ratio of 1:4, and add 4g sodium hydroxide and 26g borax in sequence, and raise the temperature to 40°C at 400r / min-500r / min Stir continuously at a rotating speed, add 5g of sodium gluconate after it is completely dissolved, and heat it in a water bath at 60°C for 3-4h to obtain it. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com