UHPT tread rubber which can be used in drifting competition

A technology for tread rubber and compounded rubber is applied in the field of automobile tire materials, which can solve the problems that the grip and handling performance cannot meet the needs of drifting driving, the safety of driving on wet and slippery roads cannot be guaranteed, and the ordinary people are insurmountable, etc. The effect of soil and abrasion performance, large molecular weight and excellent abrasion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

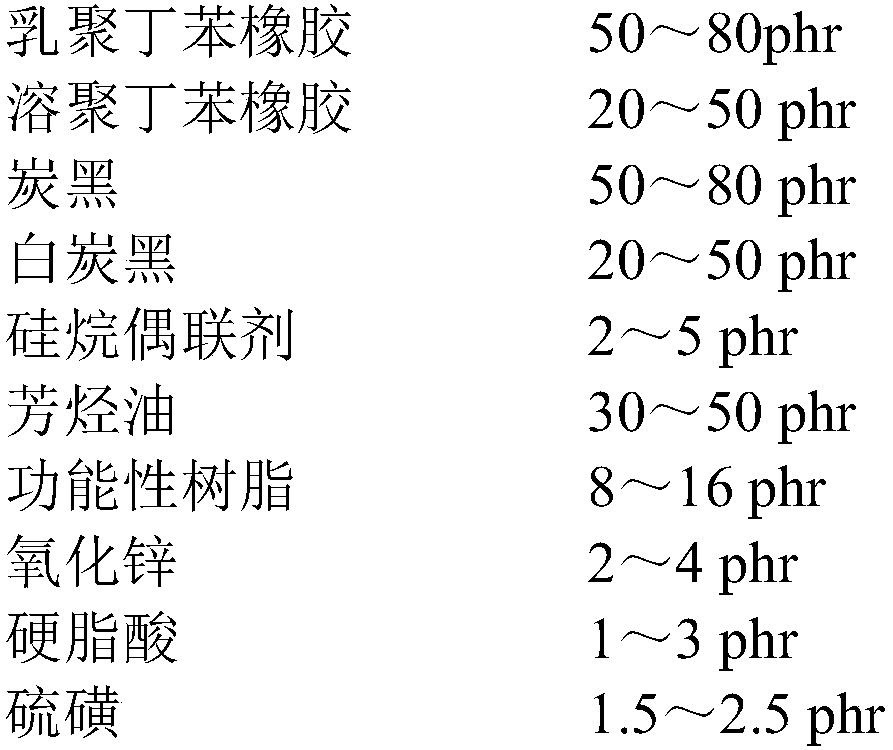

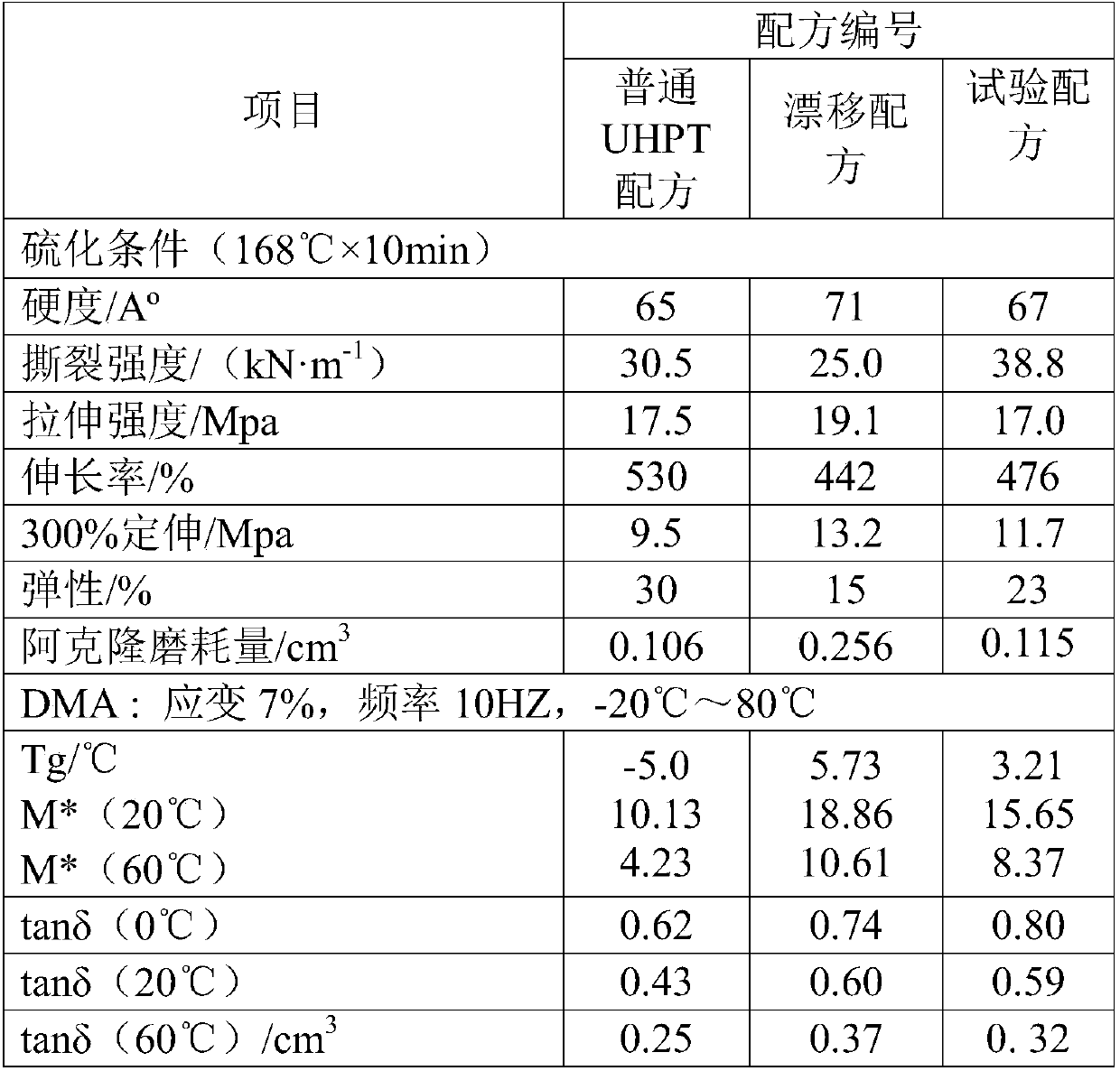

[0028] A kind of UHPT tread rubber that can be used for drifting competitions. The mixed rubber is composed as follows according to parts by weight: 55 phr of emulsion polystyrene butadiene rubber, 45 phr of solution polystyrene butadiene rubber, 60 phr of carbon black, 40 phr of white carbon black, silane coupling Agent 4phr, aromatic oil 35phr, functional resin 10phr, zinc oxide 3phr, stearic acid 2phr, sulfur 2phr, accelerator 3.0phr, other components 5phr.

Embodiment 2

[0030]A kind of UHPT tread rubber that can be used for drifting competitions. The mixed rubber is composed as follows according to parts by weight: 60 phr of emulsion polystyrene butadiene rubber, 40 phr of solution polystyrene butadiene rubber, 70 phr of carbon black, 30 phr of white carbon black, silane coupling Agent 3phr, aromatic oil 40phr, functional resin 8phr, zinc oxide 3phr, stearic acid 2phr, sulfur 2phr, accelerator 3.0phr, other components 5phr.

Embodiment 3

[0032] A kind of UHPT tread rubber that can be used for drifting competitions. The mixed rubber is composed as follows according to parts by weight: emulsion polystyrene butadiene rubber: 50phr, solution polystyrene butadiene rubber 20phr, carbon black 50phr, white carbon black 20phr, silane Joint agent 2phr, aromatic oil 30phr, functional resin 8phr, zinc oxide 2phr, stearic acid 1phr, sulfur 1.5phr, accelerator 2.5phr, other components 4phr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com