Perovskite nanocrystal with stable morphology at high temperature and preparation method thereof

A nanocrystal and perovskite technology, applied in the fields of nanotechnology, nanotechnology, nanooptics, etc. for materials and surface science, can solve problems such as application obstacles, agglomeration growth, and limitation of perovskite nanocrystals. Good monodispersity, enhanced bonding, good monochromatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of synthetic method of high temperature stable perovskite nanocrystal, comprising the following steps:

[0022] a. Cs(CH 3 COOH), octadecene and oleic acid were mixed, heated to 150°C under a nitrogen atmosphere, and reacted for 30 minutes to obtain a cesium precursor, which was kept at 150°C for use;

[0023] b. Dissolve lead halide in a mixture of octadecene, oleic acid and oleylamine at 180~200°C under nitrogen protection to obtain a lead precursor, and keep it at 180~200°C for use;

[0024] c. Dissolve metal-doped halides in octadecene, oleic acid, and oleylamine at a high temperature of 150-170°C under nitrogen protection to obtain a transparent metal-doped precursor solution, which is kept at 100°C for use;

[0025] d. First inject the cesium precursor obtained in step a into the lead precursor obtained in step b, and after reacting for 1 minute, inject the doped metal halide precursor obtained in step c, and react for 5 to 180 minut...

Embodiment 1

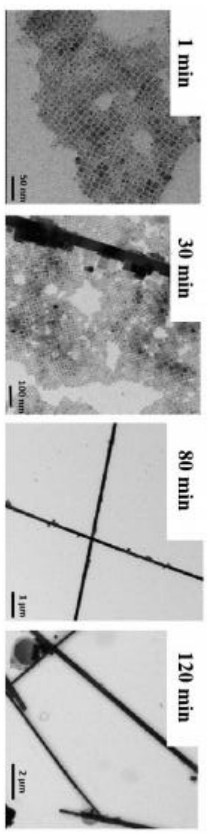

[0038] This example mainly demonstrates the instability of the morphology of perovskite nanocrystals doped with metal ions according to the present invention at high temperature.

[0039] 1. Weigh Cs(CH 3 COOH) powder 0.12 g, oleic acid 0.3 ml, octadecene 5 ml, put into a 25 ml three-necked flask. where Cs(CH 3The molar ratio of COOH) to oleic acid is 1:1.5, and the molar concentration of cesium ions is 0.12 mmol / ml. Nitrogen was introduced while magnetically stirring, and after deoxygenation for 30 minutes, the flask was heated to 150°C and kept for 30 minutes to obtain a light yellow transparent cesium precursor solution, which was kept at 150°C for use.

[0040] 2. Weigh PbCl 2 Add 0.069 g of powder, 0.011 g of ZnCl2 powder, 0.5 ml of oleic acid, 0.5 ml of oleylamine and 5 ml of octadecene into a 25 ml three-necked flask. where PbCl 2 The molar ratio of oleic acid to oleic acid is 1:1, and the molar ratio of oleic acid to oleylamine is 1.08:1. The molar concentration ...

Embodiment 2

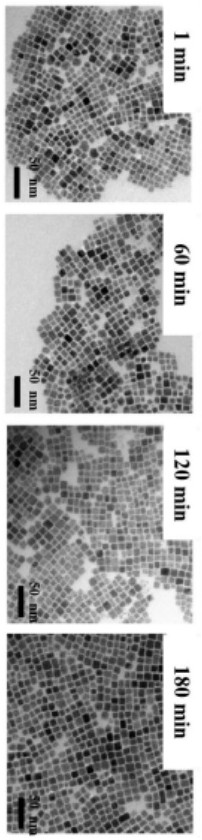

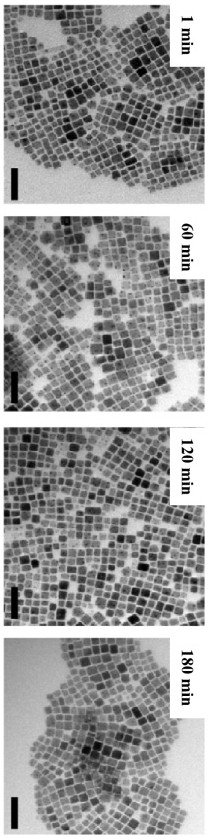

[0044] This example is used to demonstrate that the doped perovskite nanocrystals prepared by the method of the present invention have good shape stability at high temperature.

[0045] 1. Weigh Cs(CH 3 COOH) powder 0.12 g, oleic acid 0.3 ml, octadecene 5 ml, put into a 25 ml three-necked flask. where Cs(CH 3 The molar ratio of COOH) to oleic acid is 1:1.5, and the molar concentration of cesium ions is 0.12 mmol / ml. Nitrogen was introduced while magnetically stirring, and after deoxygenation for 30 minutes, the flask was heated to 150°C and kept for 30 minutes to obtain a light yellow transparent cesium precursor solution, which was kept at 150°C for use.

[0046] 2. Weigh PbCl 2 Add 0.069 g of powder, 0.5 ml of oleic acid, 0.5 ml of oleylamine and 5 ml of octadecene into a 25 ml three-necked flask. where PbCl 2 The molar ratio of oleic acid to oleic acid is 1:1, and the molar ratio of oleic acid to oleylamine is 1.08:1. The molar concentration of lead ions is 0.4 mmol / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com