Semi-flexible heavy-duty pavement paving structure

A semi-flexible, pavement technology, applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of low fatigue resistance, inability to interweave, small fluidity, etc., to improve rutting resistance and fatigue resistance , Prevent early water damage and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

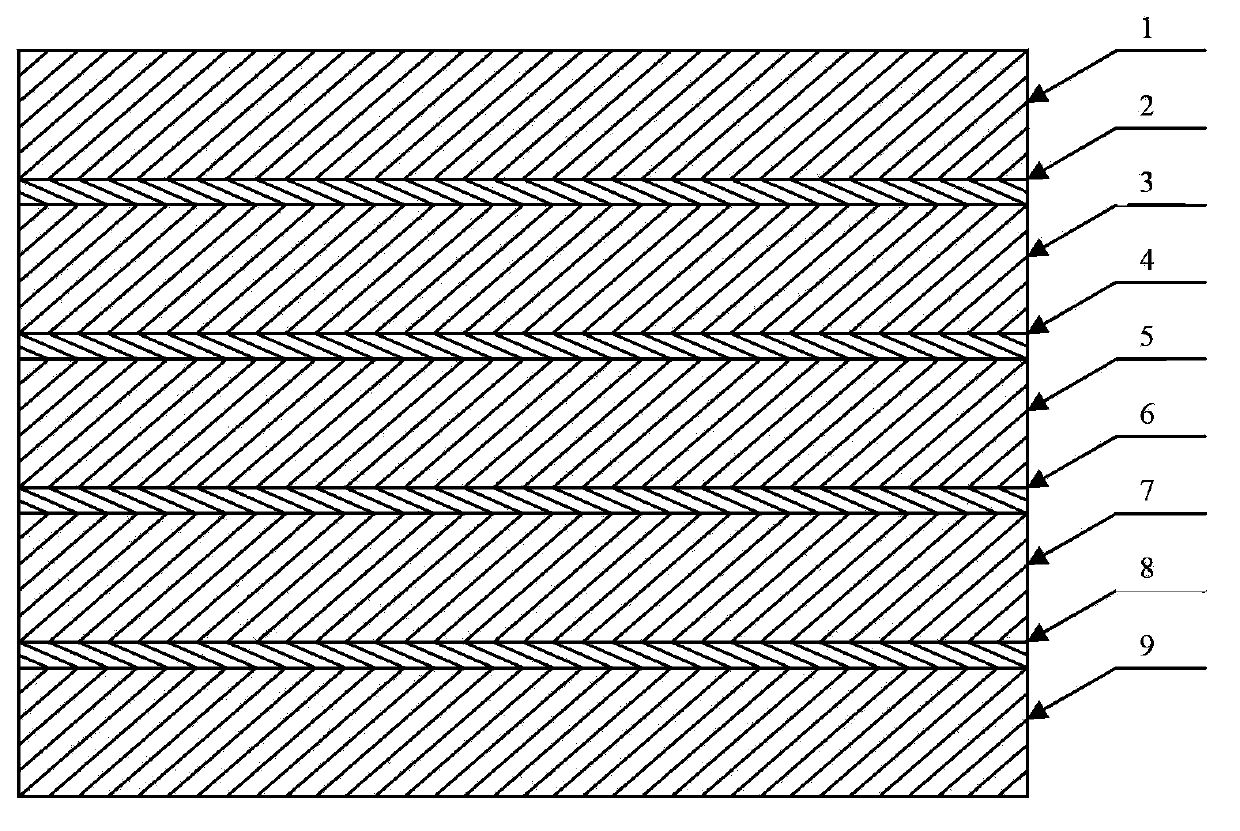

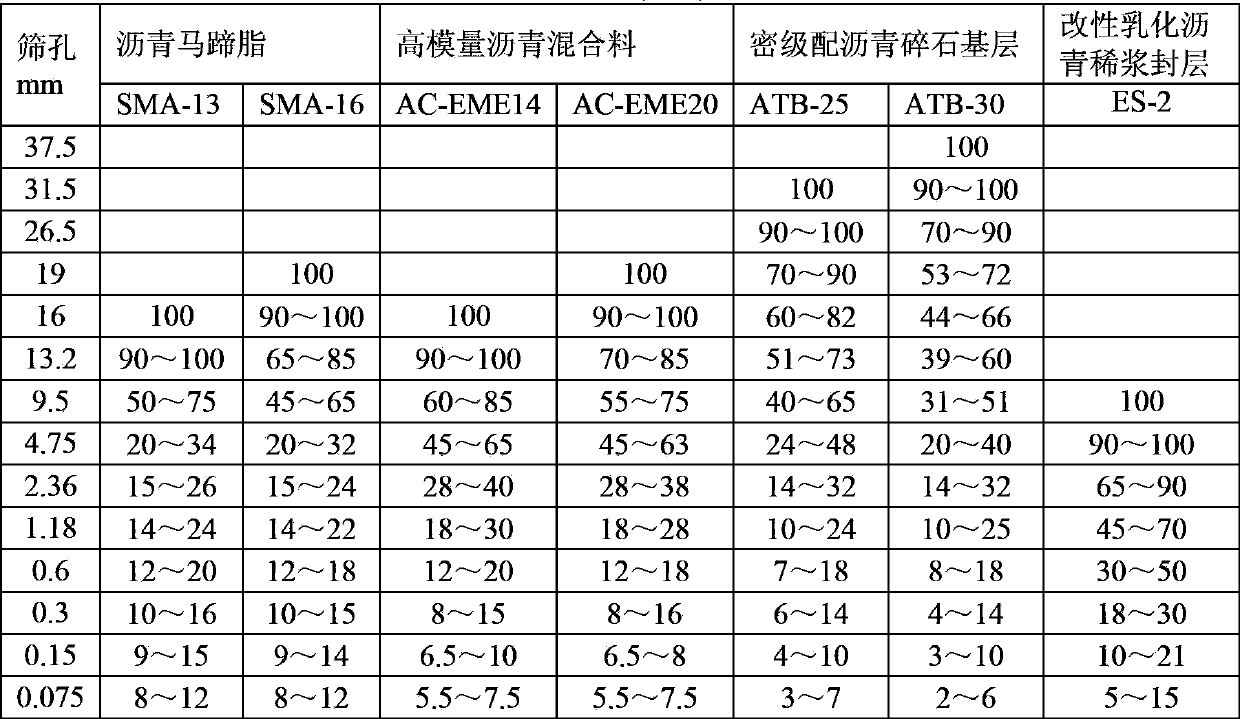

[0067] 1) Determination of mineral material gradation

[0068] The basalt mineral materials are selected for crushing and screening, and the various grades of mineral materials are mixed in a certain proportion to obtain the synthetic gradation of different structural layers in the following table 4:

[0069] Table 4 Mineral gradation of pavement structure layer

[0070]

[0071] Among them, the physical and chemical properties of basalt coarse aggregate, fine aggregate and limestone powder are as follows:

[0072] Table 5 Physical and chemical properties of aggregate and mineral powder

[0073]

[0074] 2) Preparation of cement

[0075] ① Preparation of high viscosity modified asphalt

[0076] Choose AH-50 bitumen, heat it to melt, add SBS791, waste rubber powder, APAO modifier, Hersbit858, carbon 9 petroleum resin in mass ratio 100:7:5:4:5:3, and cut at 175℃ Cut for 30 minutes and react at 180°C for 3 hours to obtain a high-viscosity modified asphalt binder. The properties of the high-...

Embodiment 2

[0110] 1) Determination of mineral material gradation

[0111] Select limestone mineral material for crushing and screening, and mix each grade of mineral material in a certain proportion to obtain the synthetic gradation of different structural layers in the following table 13:

[0112] Table 13 Mineral gradation of pavement structure layer

[0113]

[0114]

[0115] Among them, the physical and chemical properties of limestone coarse aggregate, fine aggregate and limestone powder are as follows:

[0116] Table 14 Physical and chemical properties of aggregate and mineral powder

[0117]

[0118] 2) Preparation of cement

[0119] ① Preparation of high viscosity modified asphalt

[0120] Select AH-70 bitumen, heat it to melt, add SBS791, waste rubber powder, APAO modifier, Hersbit858, carbon 9 petroleum resin in mass ratio 100:10:12:3:3:3, and cut at 175℃ Cut for 30 minutes and react at 180°C for 3 hours to obtain a high-viscosity modified asphalt binder. The properties of the high-viscos...

Embodiment 3

[0154] 1) Determination of mineral material gradation

[0155] Diabase mineral material is selected for crushing and screening, and each grade of mineral material is mixed in a certain proportion to obtain the synthetic gradation of different structural layers in the following table 20:

[0156] Table 20 Mineral gradation of pavement structure layer

[0157]

[0158] Among them, the physical and chemical properties of diabase coarse aggregate, fine aggregate and limestone ore powder are shown in Table 21:

[0159] Table 21 Physical and Chemical Properties of Aggregate and Mineral Powder

[0160]

[0161] 2) Preparation of cement

[0162] ① Preparation of high viscosity modified asphalt

[0163] Select AH-90 bitumen, heat it to melt, add SBS791, waste rubber powder, APAO modifier, Hersbit858, carbon 9 petroleum resin in mass ratio 100:10:12:3:3:3, and cut at 175℃ Cut for 30 minutes and react at 180°C for 3 hours to obtain a high-viscosity modified asphalt binder. The properties of the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com