Asphalt mixture and production method thereof

A kind of technology of asphalt mixture and production process, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problem of affecting the safety of pavement operation, service life and economic benefits, affecting the high temperature stability and crack resistance of pavement, pavement Use performance damage and destruction to achieve the ability to strengthen the moisture stripping effect, reduce the probability of cracking of the road surface, and increase the effect of anti-rutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

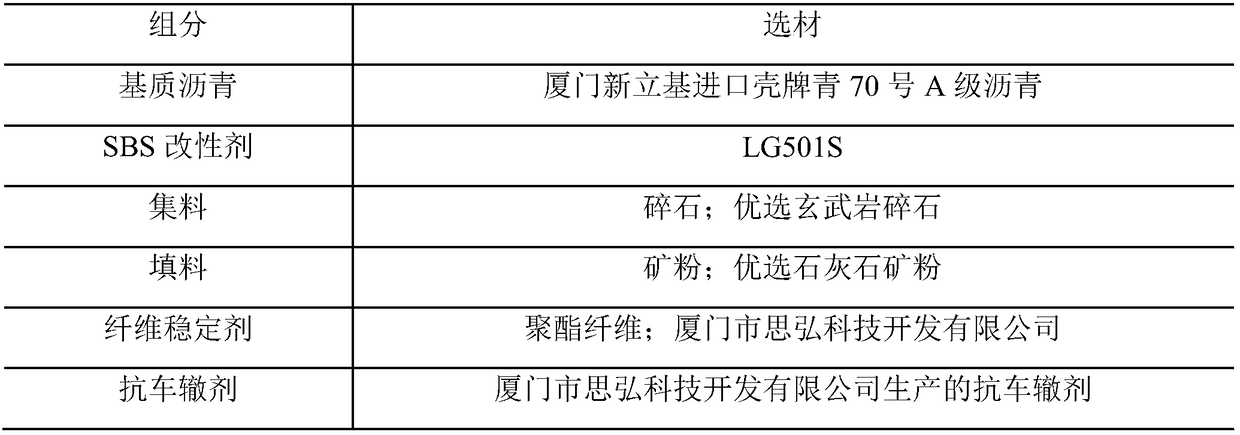

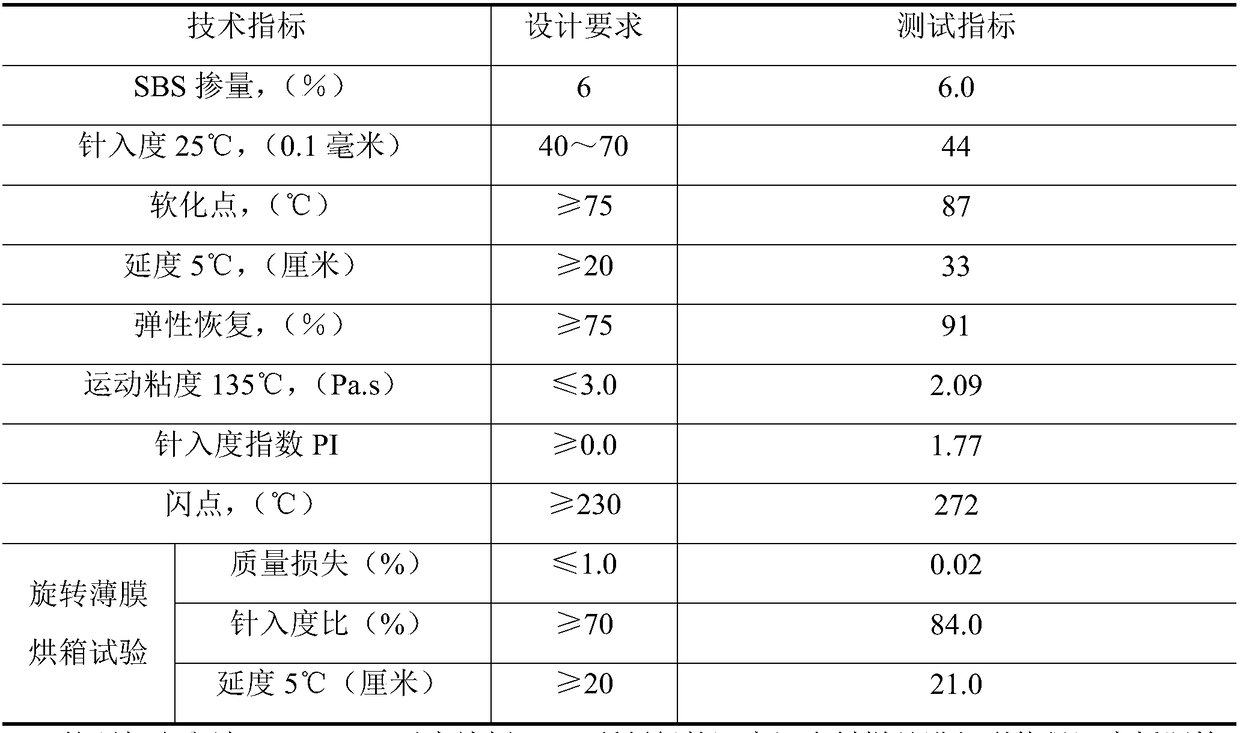

Method used

Image

Examples

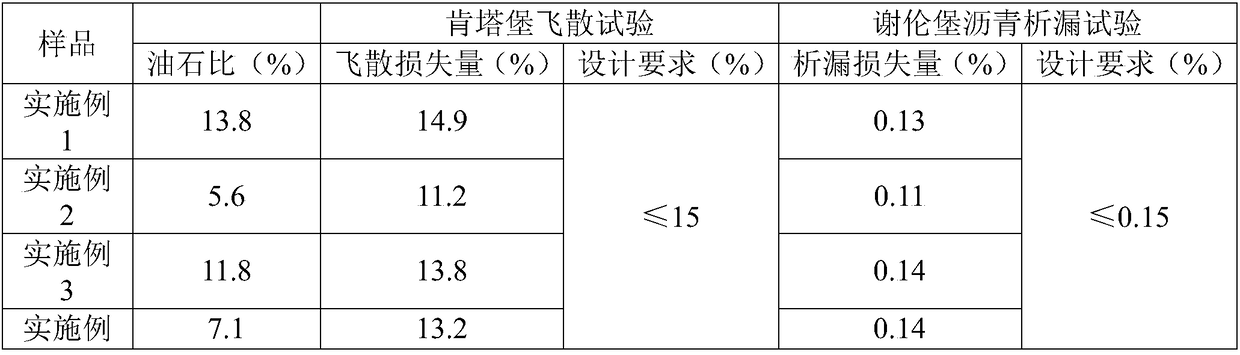

Embodiment 1

[0032] Modified asphalt was prepared as follows:

[0033] Weigh 10.4kg of base asphalt and 0.6kg of SBS, heat the base asphalt to 182°C, then slowly add the weighed SBS into the base asphalt, and stir at 180°C for 42min to obtain modified asphalt.

[0034] A production process of asphalt mixture, comprising the steps of:

[0035] Step 1: Weigh 21kg of the first aggregate, 28kg of the second aggregate, 20kg of the third aggregate and 8kg of the fourth aggregate, and weigh the first aggregate, the second aggregate, the third aggregate and the fourth aggregate at 175°C Four aggregates are heated, and the heated first aggregate, second aggregate, third aggregate, fourth aggregate and 0.5kg polyester fiber are evenly mixed, and dry mixed for 8s to obtain the first mixture;

[0036] Step 2: Weigh 12kg of modified asphalt, heat the modified asphalt at 170°C, add the heated modified asphalt and 0.5kg of anti-rutting agent into the first mixture in step 1, and mix for 60s to obtain t...

Embodiment 2

[0040] Modified asphalt was prepared as follows:

[0041] Weigh 4.71kg of base asphalt and 0.29kg of SBS, heat the base asphalt to 183°C, then slowly add the weighed SBS into the base asphalt, and stir at 188°C for 43min to obtain modified asphalt.

[0042] A production process of asphalt mixture, comprising the steps of:

[0043] Step 1: Weigh 22.5kg of the first aggregate, 25kg of the second aggregate, 20.5kg of the third aggregate and 11kg of the fourth aggregate, and weigh the first aggregate, the second aggregate, and the third aggregate at 177°C Heating with the fourth aggregate, and uniformly mixing the heated first aggregate, second aggregate, third aggregate, fourth aggregate and 3kg polyester fiber, and dry mixing for 9s to obtain the first mixture;

[0044] Step 2: Weigh 6kg of modified asphalt, heat the modified asphalt at 172°C, add the heated modified asphalt and 3kg of anti-rutting agent into the first mixture in step 1, and mix for 62s to obtain the first mixt...

Embodiment 3

[0048] Modified asphalt was prepared as follows:

[0049] Weigh 9.43kg of base asphalt and 0.57kg of SBS, heat the base asphalt to 184°C, then slowly add the weighed SBS into the base asphalt, and stir at 182°C for 44min to obtain modified asphalt.

[0050] A production process of asphalt mixture, comprising the steps of:

[0051] Step 1: Weigh 23kg of the first aggregate, 26kg of the second aggregate, 22kg of the third aggregate and 7kg of the fourth aggregate, and weigh the first aggregate, the second aggregate, the third aggregate and the fourth aggregate at 179°C Four aggregates are heated, and the heated first aggregate, second aggregate, third aggregate, fourth aggregate and 2kg polyester fiber are mixed evenly, and dry mixed for 10s to obtain the first mixture;

[0052] Step 2: Weigh 10kg of modified asphalt, heat the modified asphalt at 174°C, add the heated modified asphalt and 3kg of anti-rutting agent into the first mixture in step 1, and mix for 70s to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com