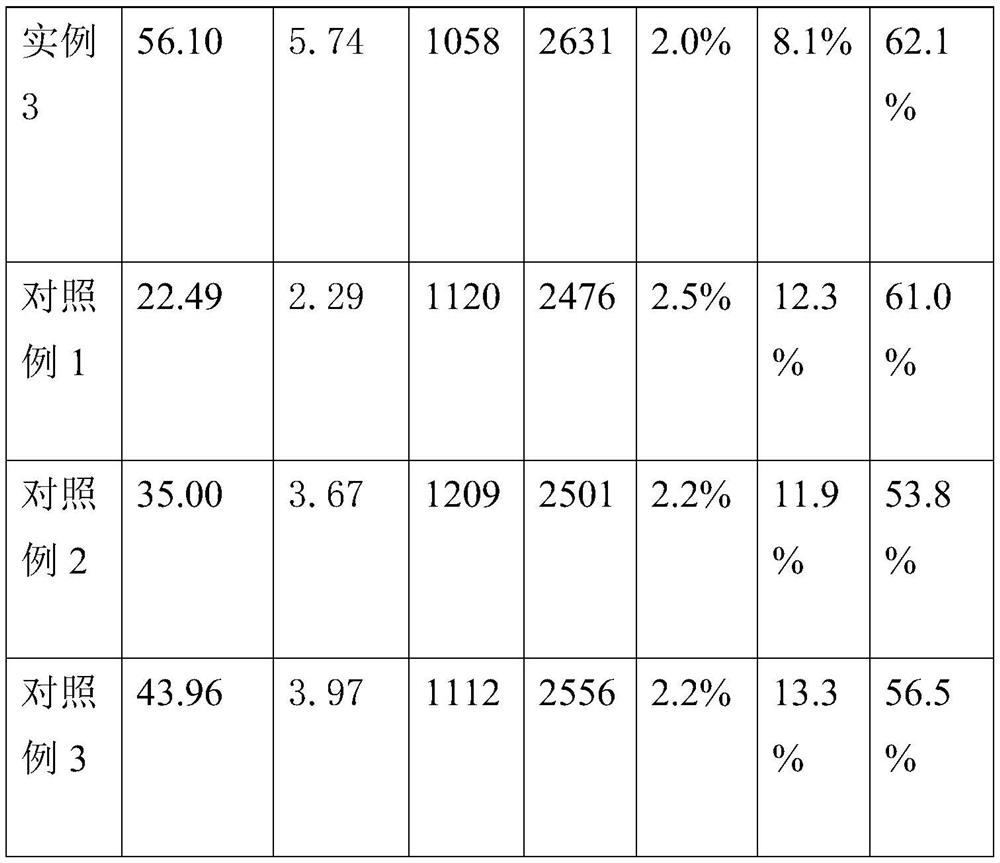

Patents

Literature

44results about How to "Low crush value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for reinforcing recycled concrete fine aggregate by using carbon dioxide

ActiveCN105174766AImprove water absorptionLow water absorptionSolid waste managementCALCIUM HYDROXIDE SOLUTIONCalcification

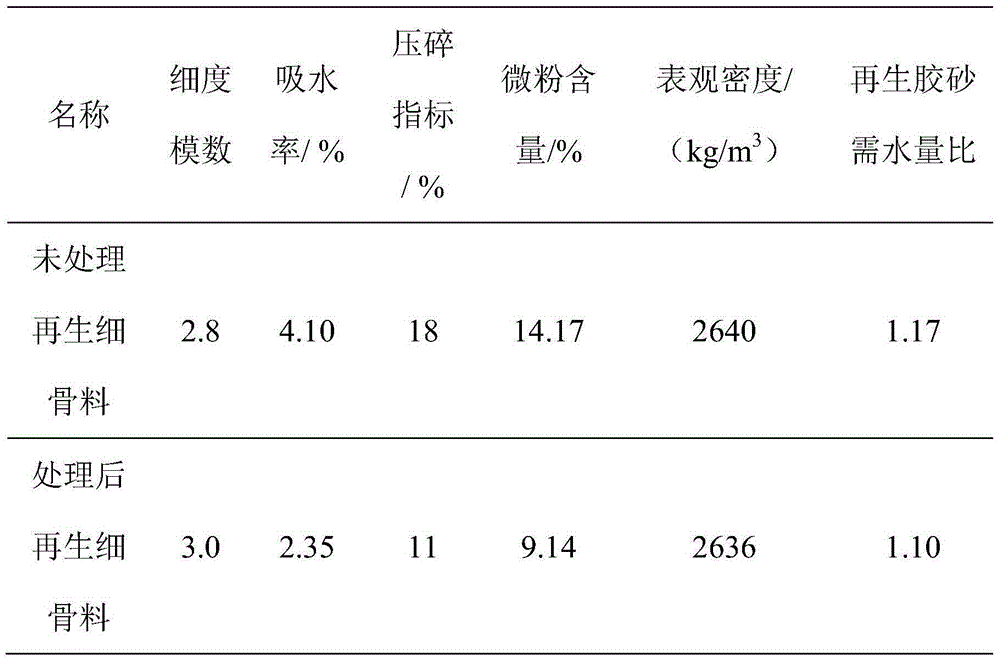

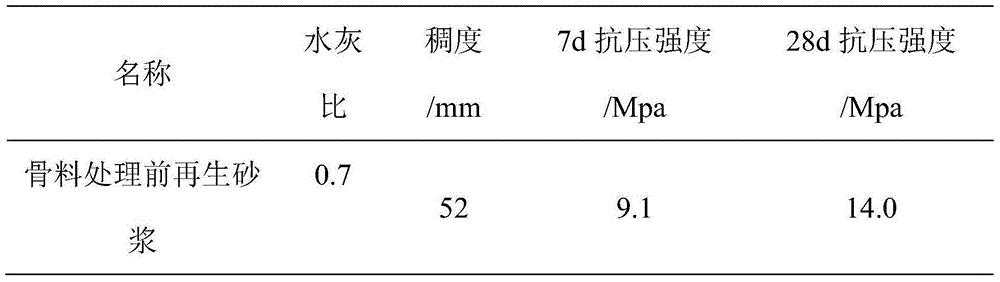

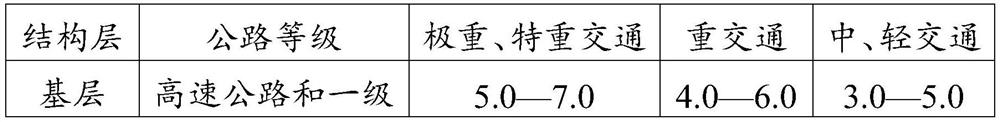

The invention discloses a method for reinforcing recycled concrete fine aggregate by using carbon dioxide, which comprises the following steps: (1) calcium hydroxide solution or calcium salt calcification treatment: spreading recycled fine aggregate prepared from construction waste on a tray, spraying a calcium hydroxide or calcium salt solution, and stirring uniformly; (2) CO2 curing: putting the recycled fine aggregate subjected to calcium hydroxide solution or calcium salt calcification treatment in a closed carbonization box, and carrying out carbonization curing until the surface is completely carbonized; and (3) recycled mortar preparation: preparing recycled mortar with the substitution rate of 100% by using the treated recycled fine aggregate. Compared with the unreinforced recycled aggregate, the crushing value of the recycled fine aggregate prepared by the method is lowered by nearly 45%, and the water absorptivity is lowered by nearly 53%. Compared with the recycled mortar prepared from the unreinforced recycled aggregate, the consistency of the recycled mortar prepared by the method is enhanced by 42% or so, the 7d strength of the mortar is enhanced by 15-26%, and the 28d strength can be enhanced by 17-24%.

Owner:SOUTHEAST UNIV +1

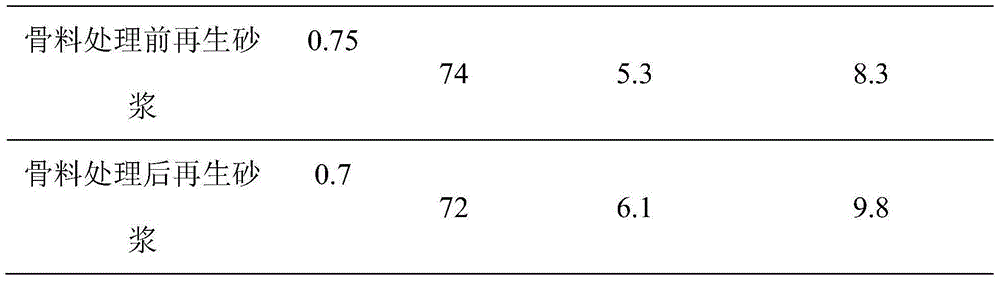

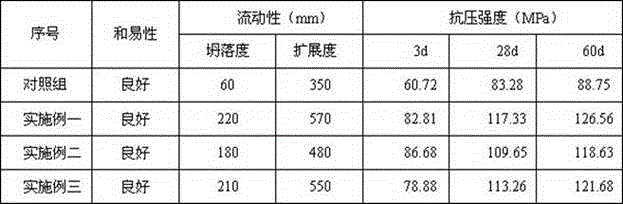

Ferronickel slag ultrahigh-strength concrete and preparation method thereof

The invention provides a ferronickel slag ultrahigh-strength concrete and a preparation method thereof. Every cubic meter of ferronickel slag ultrahigh-strength concrete contains 550-700kg of cementing material, 900-1000kg of coarse aggregate, 800-900kg of fine aggregate, 8-20kg of polycarboxylic-acid high efficiency water reducing agent and 160-170kg of water. The cementing material is composed of the following components in percentage by mass: 50-60% of P.O 52.5 Portland cement, 15-20% of ore powder, 5% of silica fume and 20-30% of ferronickel slag micropowder. The ferronickel slag is used as crude aggregate, fine aggregate and a mineral admixture respectively instead of natural gravel, sand and part of cement. Besides, the ferronickel slag has favorable water-reducing actions, can greatly improve the placeability of concrete, and obviously increases the slump constant. The 25-day compression strength of the ferronickel slag ultrahigh-strength concrete can reach 110 MPa or above, which is much higher than the non-ferronickel-slag concrete.

Owner:徐州经济技术开发区诚意商品混凝土有限公司

Method for recovering and reinforcing concrete aggregate

InactiveCN105884230AConserve waterIncrease the content of carbonizable substancesSolid waste managementCALCIUM HYDROXIDE SOLUTIONReinforced concrete

The invention discloses a method for recovering and reinforcing concrete aggregate. According to the method, waste concrete discharged during cleaning of a stirring vehicle is scientifically and effectively utilized, and water for separating cement and sand is saved. When the content of carbonatable substances in recycled aggregate is increased during treatment of a calcium hydroxide solution or a calcium salt solution with the method, calcium carbonate formed after carbonization treatment effectively fills microcracks, the porosity of the recycled aggregate is effectively reduced, and the crushing value and the water absorption of the aggregate are further reduced.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Waste concrete regeneration method

InactiveCN105884308ASolving RecyclingShorten the production cycleSolid waste managementEnvironmental engineeringConstruction waste

The invention discloses a waste concrete regeneration method. By means of the provided concrete preparation method, the problem about recycling of building waste can be effectively solved, the production cycle of regenerated concrete prepared with the method is short, the porosity of recycled aggregate is effectively reduced through microorganism deposition treatment, the crushing value of the aggregate is reduced, the water absorption of the aggregate is reduced, the strength of the produced regenerated concrete can reach C50, and the performance of the concrete in all aspects is stable.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Preparation method of regenerated concrete

InactiveCN105924053ASolve the recycling problemShort production cycleSolid waste managementEnvironmental geologyArchitectural engineering

The invention discloses a preparation method of regenerated concrete. The provided method can effectively solve the problem of construction waste recovery and reutilization. Moreover, the concrete production period is short, the microbial treatment can effectively reduce the porosity of regenerated aggregate, thus the crushing value and water absorption of aggregate are reduced, the strength of produced regenerated concrete can reach C50, and the properties of regenerated concrete become more stable.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Environment-protective type plant cover concrete

InactiveCN101323517ALow water absorptionSolve the problem of stacking affecting the ecological environmentSolid waste managementEcological environmentCarboxylic acid

The invention discloses an environment-friendly plant concrete, consisting of water, cement, waste concrete aggregate, concrete antalkali and poly carboxylic acid water reducing agent. The detailed matching proportion is as follows: the ratio of water / cement / waste concrete aggregate is 0.28 to 0.32:1:5; the quantity of adopted concrete antalkali is 10 to 20 percent of the cement quantity; the quantity of the poly carboxylic acid water reducing agent is 1 to 2 percent of the cement quantity. Compared with the existing similar product of the prior technology, the invention not only can solve the contamination to ecological environment by stacked waste concrete but also can avoid the damage to ecological environment by extreme exploitation to aggregate and realize the purpose of planting plants on concrete, thus achieving the effects of recycling sources, regulating ecological balance and beautifying environment; the intensity of the concrete is high, the concrete can be pre-cast into various shapes as requirements, and the construction is convenient.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Concrete aggregate recycling and modifying method

InactiveCN105884229AReduce porosityLow water absorptionSolid waste managementMicroorganismMagnetic separator

The invention discloses a concrete aggregate recycling and modifying method. According to the method, needle-like, flaky and powdery particles in waste concrete are removed by means of a grating type vibrating feeder, metal impurities are removed through a magnetic separator, high-density powdery impurities are removed and low-density plastics, wood, grass roots and bark are separated through a precipitation separation cleaning tank, the working efficiency is high, and the operation is convenient; through microorganism deposition modification treatment, the porosity of recycled aggregate is effectively reduced, and the crushing value and the water absorption of aggregate are further reduced.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

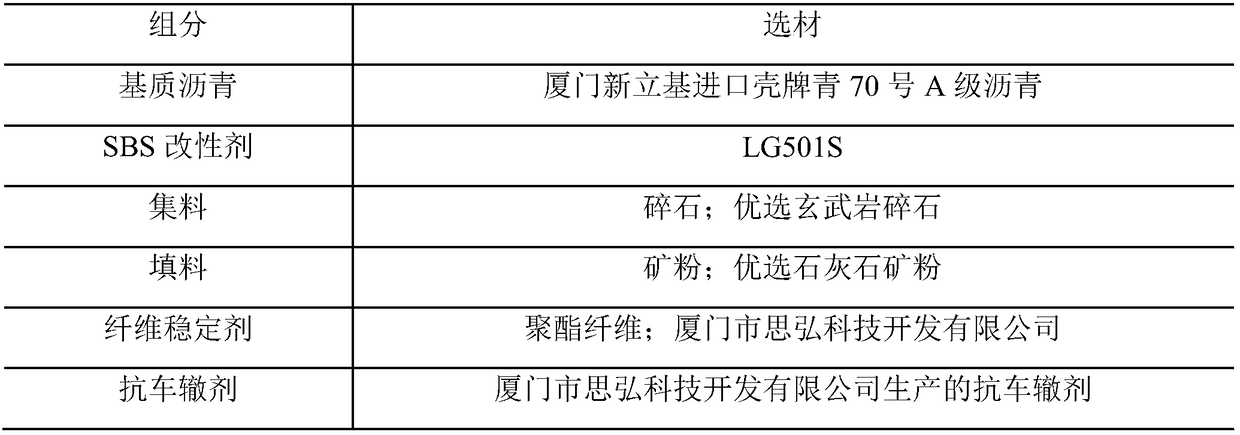

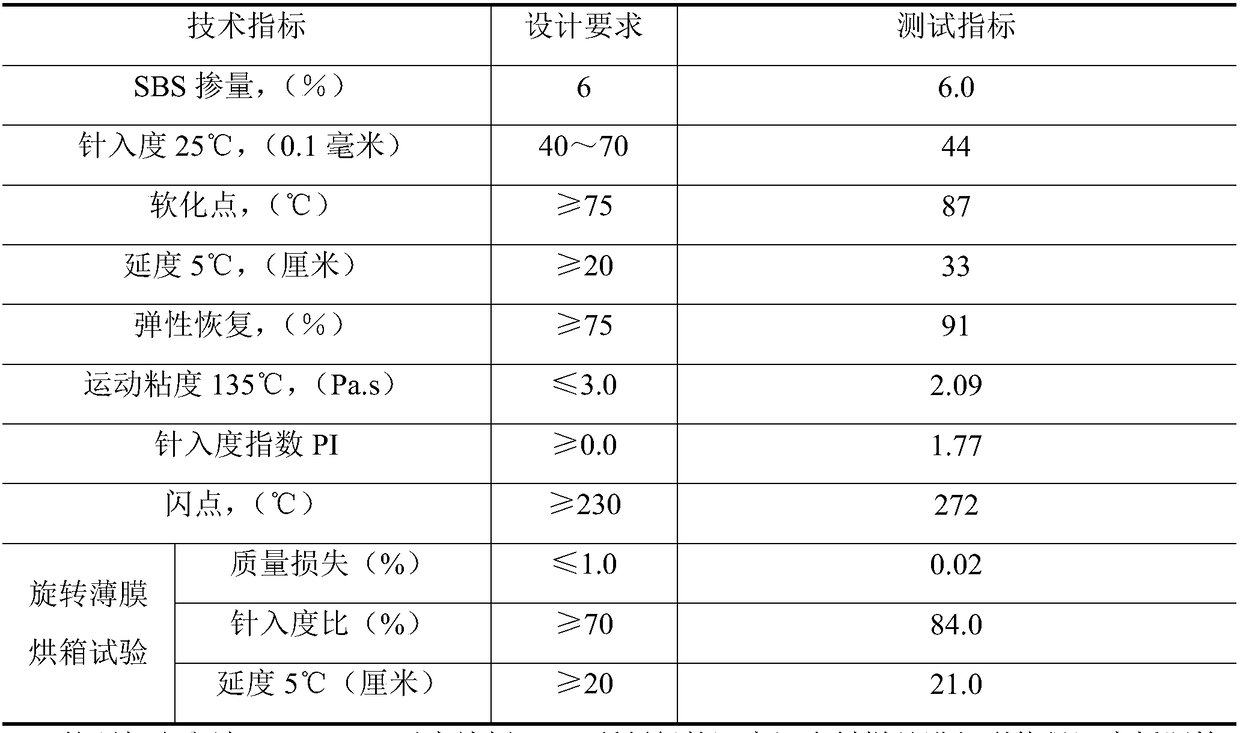

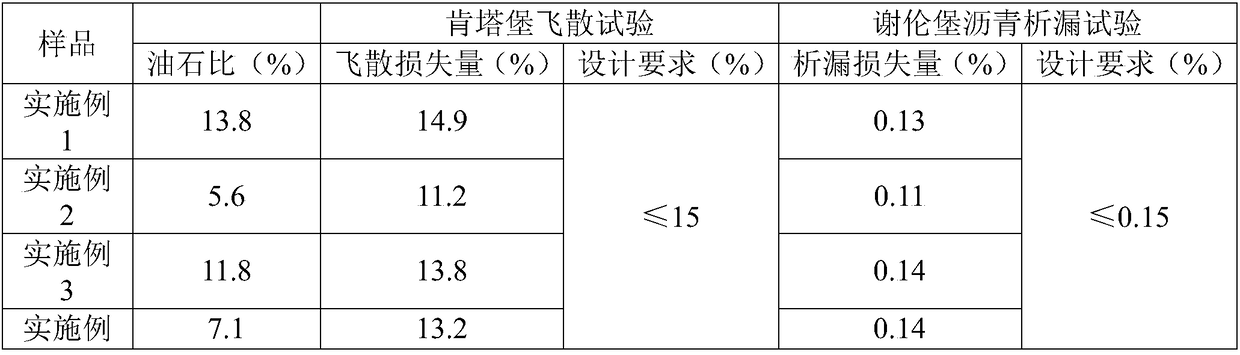

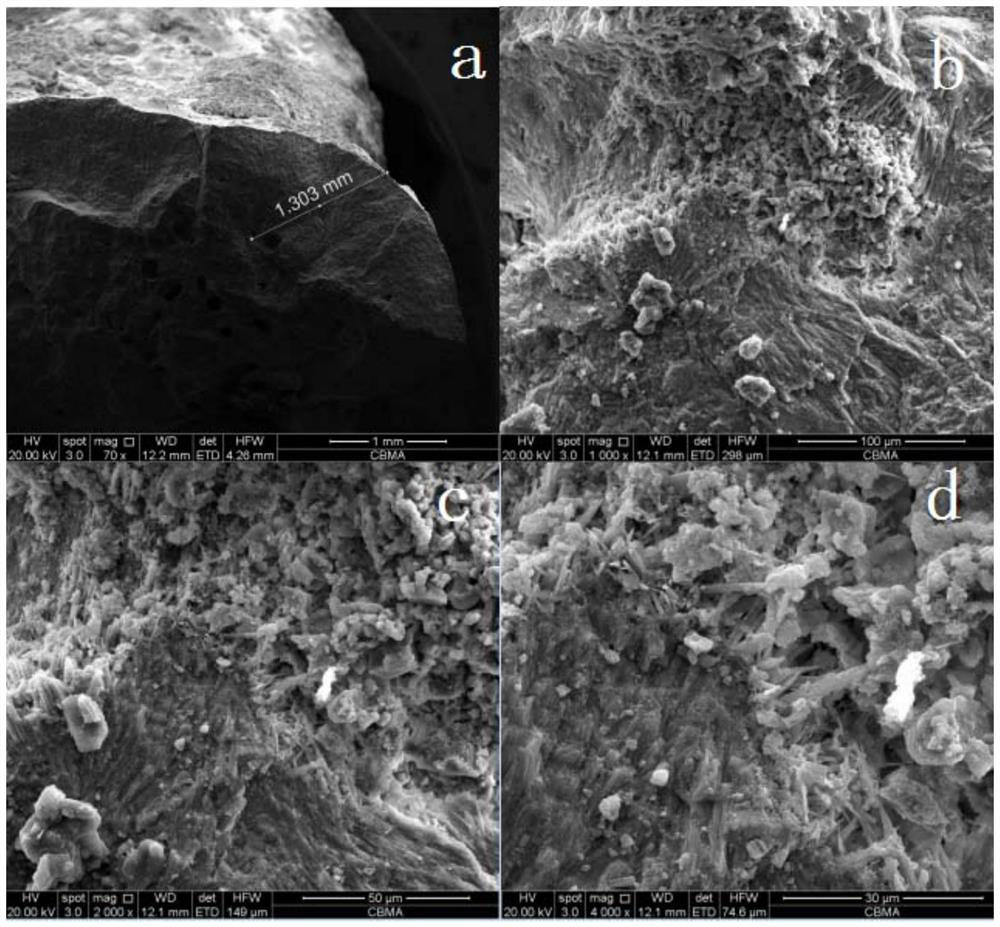

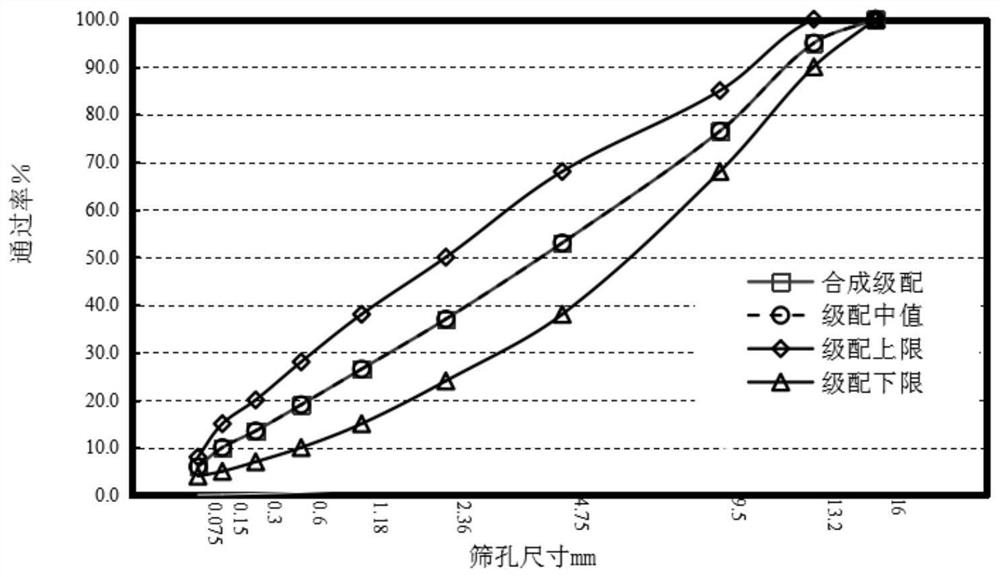

Asphalt mixture and production method thereof

ActiveCN109180077AImproves rutting resistanceImprove stress resistanceBuilding insulationsAsphaltPolymer chemistry

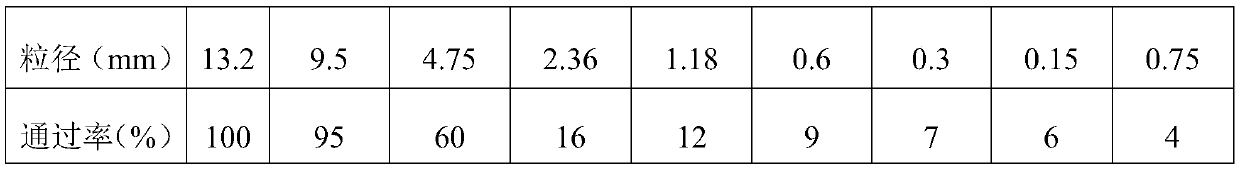

The invention discloses an asphalt mixture and a production method thereof and relates to the field of building materials. The asphalt mixture solves the problem that the existing asphalt mixture forthe airport runway has poor stability and anti-rutting ability, and comprises 4 to 12 wt% of modified asphalt, 72 to 88 wt% of aggregate, 5 to 10 wt% of a filler, 0.5 to 3 wt% of a fiber stabilizer and 0.5 to 3 wt% of an anti-rutting agent and has an asphalt-aggregate ratio of 5.6 to 14%. The modified asphalt comprises matrix asphalt and SBS and the weight of the SBS is 5-8 wt% that of the matrixasphalt. The asphalt mixture has the advantages of high dynamic stability, high temperature stability, strong rutting resistance and good water stability, and is suitable for airport runways.

Owner:厦门市政沥青工程有限公司 +2

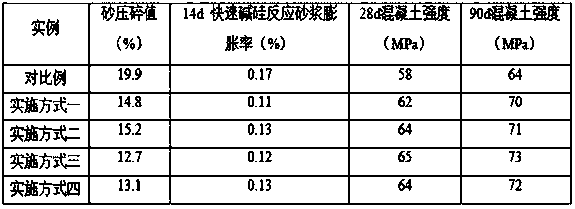

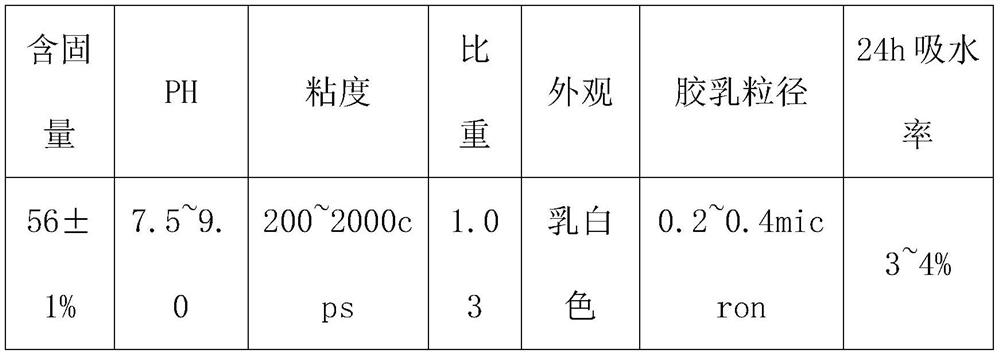

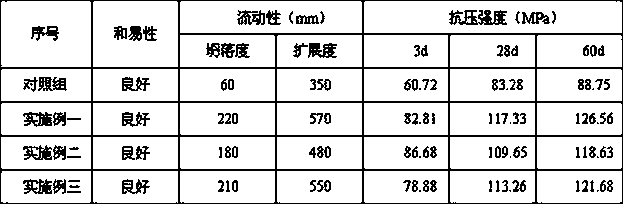

Modified material and treatment method of low-quality aggregate

The invention belongs to the technical field of building materials, and specifically relates to a modified material and treatment method of a low-quality aggregate. The modified material of the low-quality aggregate provided by the invention comprises the following components in percentage by mass: 46-50% of cement, 10-15% of a mineral admixture, 2-5% of an active powder, 0.2-0.6% of a water reducing agent, 0.001-0.004% of a viscosity adjusting agent, 0-3.2% of an expanding agent, 0-0.12% of an air entraining agent, and 0-0.0007% of a defoaming agent. The modified material provided by the invention can realize effective filling and coating modification of the low-quality aggregate through the cooperation between the components, and the adjustment of the use amount, and especially through the cooperation of the specific use amount of the cement, active powder and viscosity adjusting agent, the surface tension and viscosity of the modified material can be effectively adjusted, and a porepenetration amount and a shell coating thickness are coordinately optimized. The combined use of the inorganic and organic components promotes the secondary hydration / chemical bonding of a slurry layer, and improves the strength of an interface between the aggregate and the slurry layer. The cylindrical compress strength of the aggregate after modification treatment is increased by 40% or more, acrushing value is reduced by 30% or more, and a water absorption rate in 24 h is reduced by 15% or more.

Owner:CHINA BUILDING MATERIALS ACAD

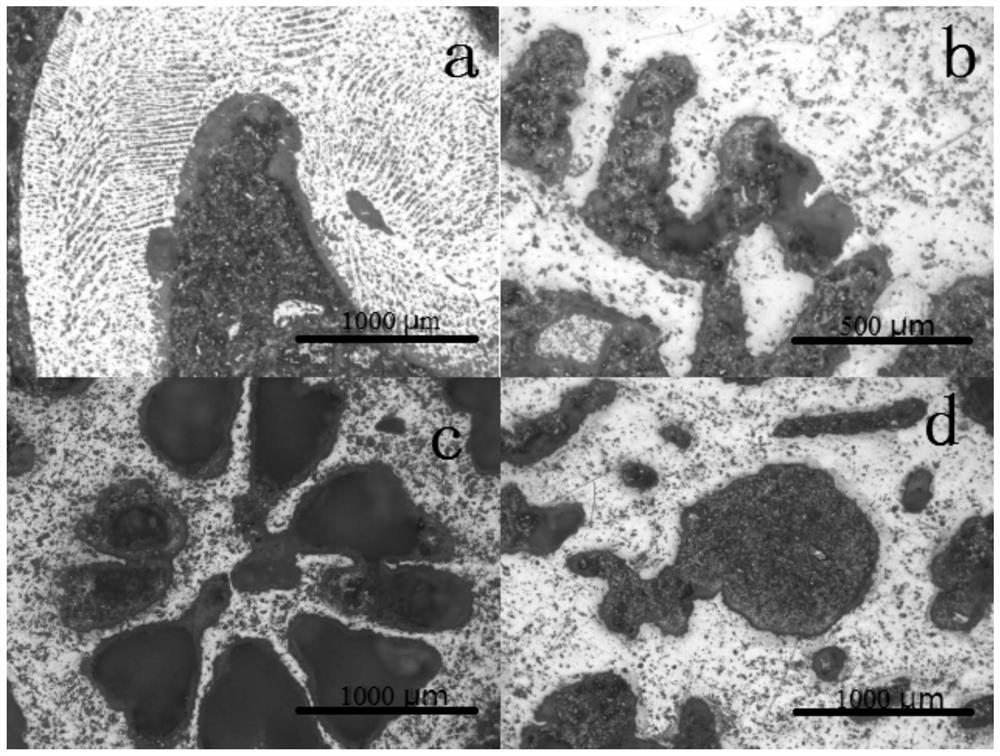

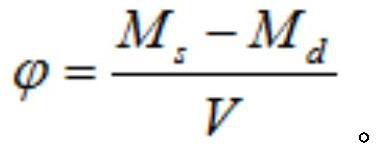

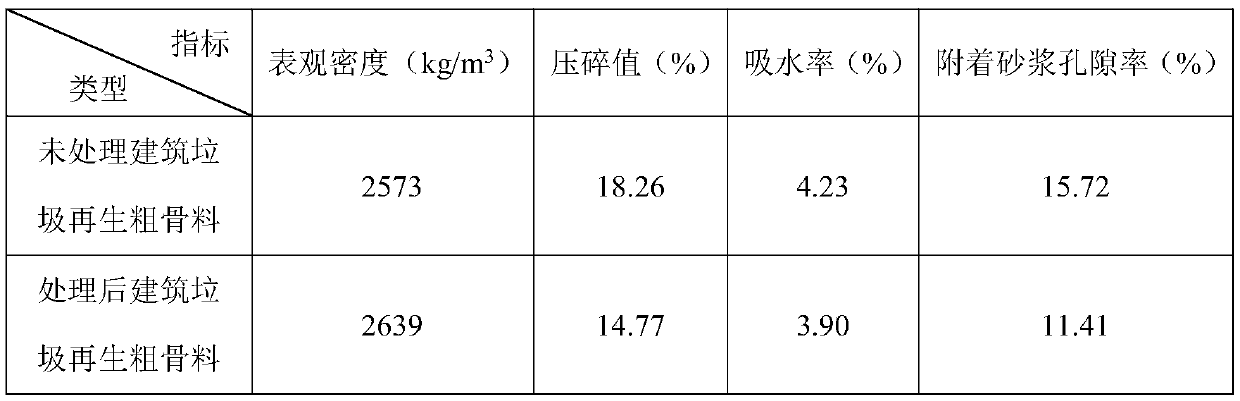

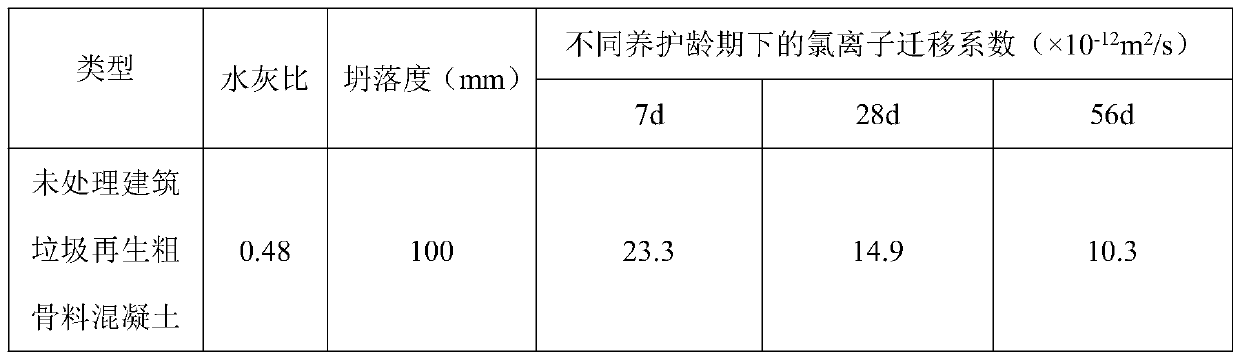

Aggregate treatment method for enhancing chlorine salt erosion resistance of construction waste recycled concrete

InactiveCN109851266ALess investment in equipmentLow power consumptionSolid waste managementEmulsionAir drying

The invention discloses an aggregate treatment method for enhancing chlorine salt erosion resistance of construction waste recycled concrete, which comprises the following steps: (1) carrying out processes of coarse separation, separation and impurity removal, crushing and screening and the like on waste concrete construction waste to obtain construction waste recycled coarse aggregate, and naturally air-drying the recycled coarse aggregate for later use; (2) impregnating the recycled coarse aggregate obtained in the step (1) into a slaked lime emulsion, stirring the liquid once every 10 minutes, taking out the recycled coarse aggregate, airing the recycled coarse aggregate indoors for 24 hours, and transferring the recycled coarse aggregate into a drying box for drying; (3) spreading therecycled coarse aggregate obtained in the step (2) on a tray, and moving the recycled coarse aggregate into a concrete carbonization box for neutralization treatment; (4) completely replacing the natural macadam aggregate with the recycled coarse aggregate obtained in the step (3) to prepare the recycled concrete. The treatment method has a remarkable improvement effect on the chlorine salt erosion resistance of the recycled concrete.

Owner:BEIJING UNIV OF TECH

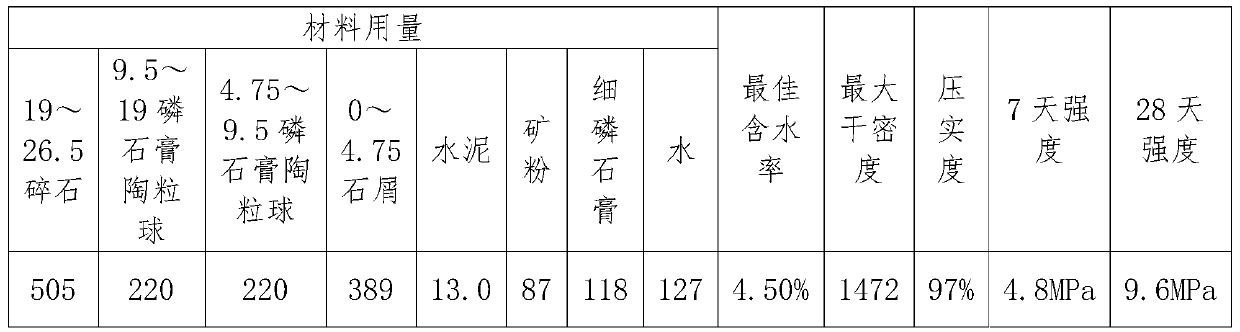

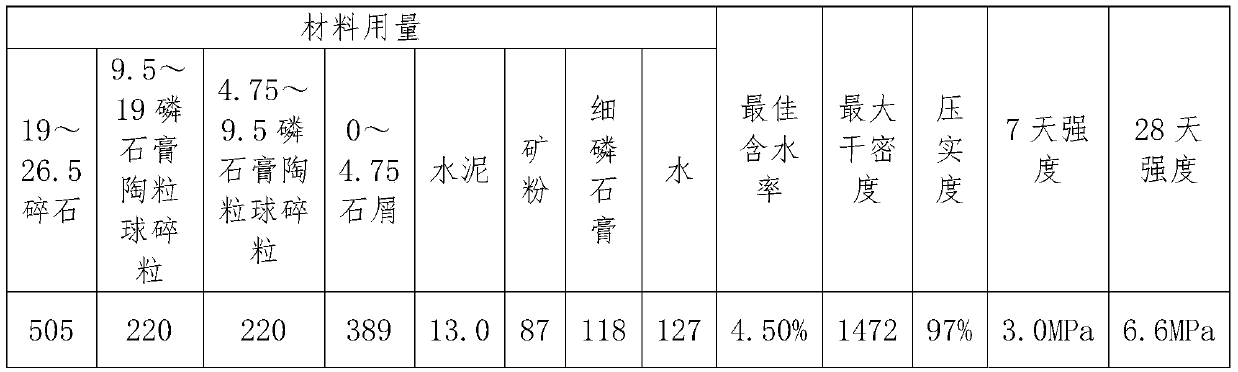

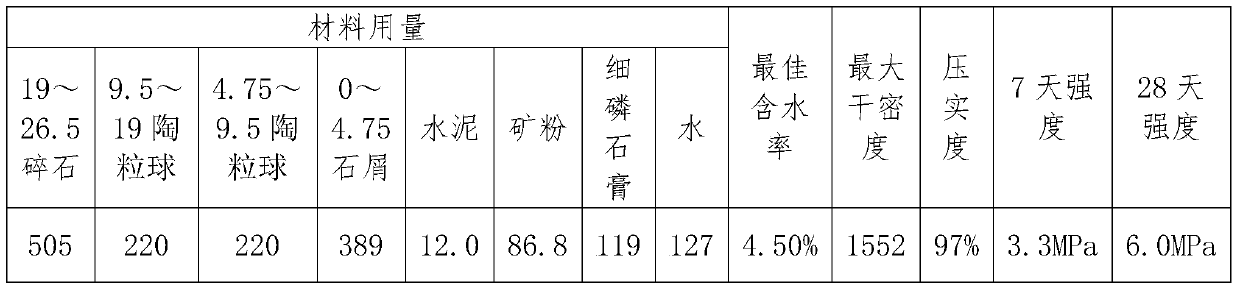

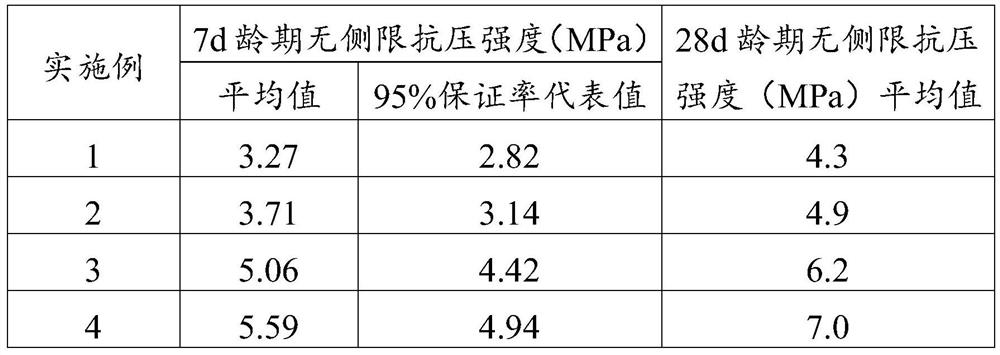

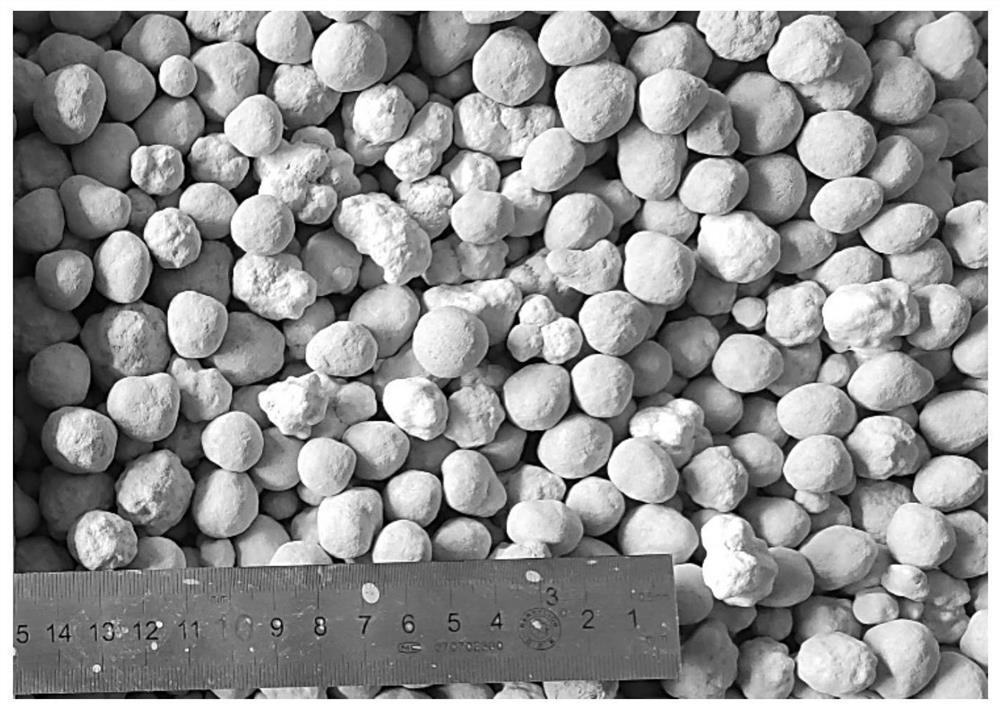

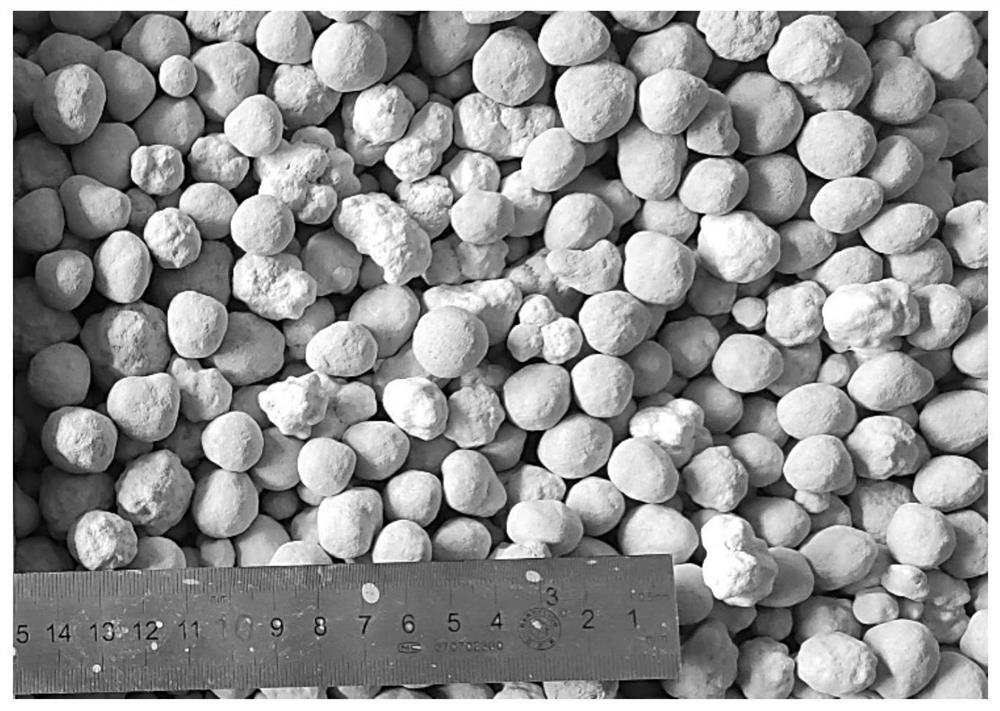

Phosphogypsum ceramsite ball and spherical and gravel type phosphogypsum ceramsite ball light aggregate water stable layer

The invention provides a phosphogypsum ceramsite ball. The phosphogypsum ceramsite ball comprises a phosphogypsum core, an oversulfated phosphogypsum layer wrapping the phosphogypsum core, and a cement layer wrapping the oversulfated phosphogypsum layer. The phosphogypsum core is formed by granulating original phosphogypsum, calcium oxide, cement clinker, mineral powder and residual slurry of theelectric pole, and the over-sulfur phosphogypsum layer is formed by mixing fine phosphogypsum, slag and cement clinker. Meanwhile, the invention further provides two kinds of water stable layers obtained by applying the phosphogypsum ceramsite ball, the 7-day unconfined compressive strength can reach 3-4.8 MPa, and the phosphogypsum ceramsite ball can be used for base structures of heavy traffic in expressways and first-grade highways.

Owner:HUBEI CHANG YAOXIN MATERIALS LIMITED BY SHARE

A method of using carbon dioxide to strengthen recycled concrete fine aggregate

ActiveCN105174766BReduce porosityImprove water absorptionSolid waste managementCALCIUM HYDROXIDE SOLUTIONCarbonization

The invention discloses a method for reinforcing recycled concrete fine aggregate by using carbon dioxide, which comprises the following steps: (1) calcium hydroxide solution or calcium salt calcification treatment: spreading recycled fine aggregate prepared from construction waste on a tray, spraying a calcium hydroxide or calcium salt solution, and stirring uniformly; (2) CO2 curing: putting the recycled fine aggregate subjected to calcium hydroxide solution or calcium salt calcification treatment in a closed carbonization box, and carrying out carbonization curing until the surface is completely carbonized; and (3) recycled mortar preparation: preparing recycled mortar with the substitution rate of 100% by using the treated recycled fine aggregate. Compared with the unreinforced recycled aggregate, the crushing value of the recycled fine aggregate prepared by the method is lowered by nearly 45%, and the water absorptivity is lowered by nearly 53%. Compared with the recycled mortar prepared from the unreinforced recycled aggregate, the consistency of the recycled mortar prepared by the method is enhanced by 42% or so, the 7d strength of the mortar is enhanced by 15-26%, and the 28d strength can be enhanced by 17-24%.

Owner:SOUTHEAST UNIV +1

Reinforced and regenerated coarse concrete aggregate, preparation method and application

InactiveCN106220064AReduce adhesion rateLow crush valueSolid waste managementPolymer scienceConstruction aggregate

The invention discloses a reinforced and regenerated coarse aggregate, a preparation method and application of the reinforced and regenerated coarse concrete aggregate in concrete preparation. The reinforced and regenerated coarse aggregate is prepared by mixing an aggregate which is obtained by crushing waste concrete and screening the broken waste concrete and has the particle size of 5 mm to 15 mm with an aggregate which is obtained by crushing the waste concrete and screening the broken waste concrete and has the particle size of 15 mm to 31 mm according to the mass ratio of 4:3 and then reinforcing the mixture. The preparation method comprises the steps that 10, the waste concrete is crushed and screened to obtain the two regenerated aggregates with the different particle sizes; 20, 3 parts of the regenerated aggregate with the particle size of 15 mm to 31 mm is taken, stirred for 30 seconds to 50 seconds in the positive direction through a forced stirrer and then stirred for 30 seconds to 50 seconds in the negative direction through the forced stirrer; 30, 4 parts of the regenerated aggregate with the particle size of 5 mm to 15 mm is taken, added into the forced stirrer, stirred for 40 seconds to 60 seconds in the positive direction and then stirred for 40 seconds to 60 seconds in the negative direction, discharging is conducted, and then the reinforced and regenerated coarse aggregate is obtained. Accordingly, the regenerated coarse aggregate with the low crushing value and mortar adhesion rate is obtained through the simple operation technology and the low production cost.

Owner:YANGZHOU UNIV

Recycled concrete aggregate reinforced by using construction waste micro powder and preparation method of recycled concrete aggregate

PendingCN113651549AImprove performancePromote resource utilizationSolid waste managementCarbideSlurry

The invention discloses a recycled concrete aggregate reinforced by using construction waste micro-powder, the recycled concrete aggregate is composed of a matrix, a modified wrapping layer and a surface reinforced layer, the matrix is a recycled aggregate, the modified wrapping layer is reinforced slurry, and the surface reinforced layer is carbide; wherein the recycled aggregate accounts for 80%-95% by mass, the reinforced slurry accounts for 4%-15% by mass, and the carbide accounts for 1%-5% by mass. The invention also provides a preparation method of the recycled concrete aggregate. According to the method, the raw materials are easy to obtain, the waste concrete aggregate and the micro powder thereof are utilized to the maximum extent, waste utilization and environmental protection are achieved, the cost is low, the technological process is simple, engineering practice application is facilitated, and the prepared modified recycled concrete aggregate is excellent in physical and mechanical property and wide in application prospect.

Owner:SUN YAT SEN UNIV +1

Permeable asphalt mixture and preparation method thereof

ActiveCN114315232ALow water absorptionLow crush valueSolid waste managementFiberBituminous materials

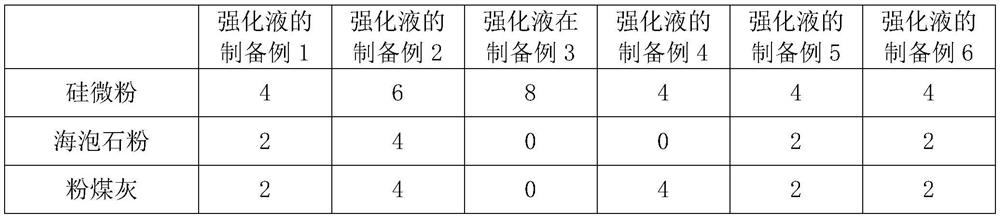

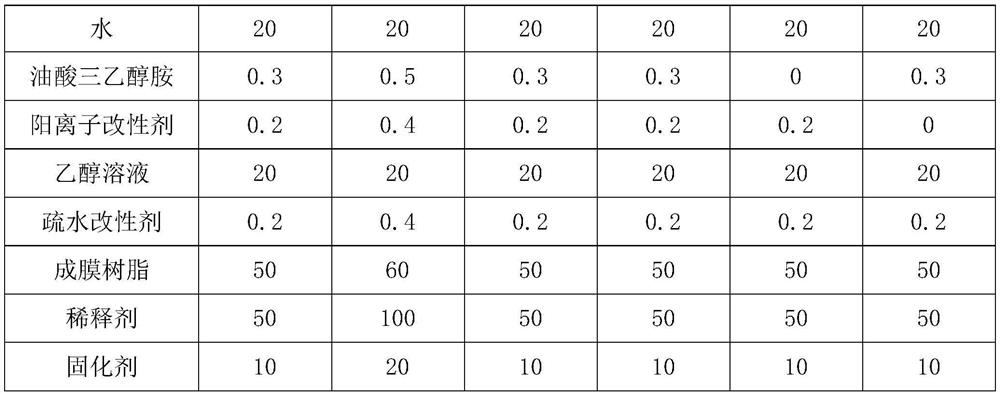

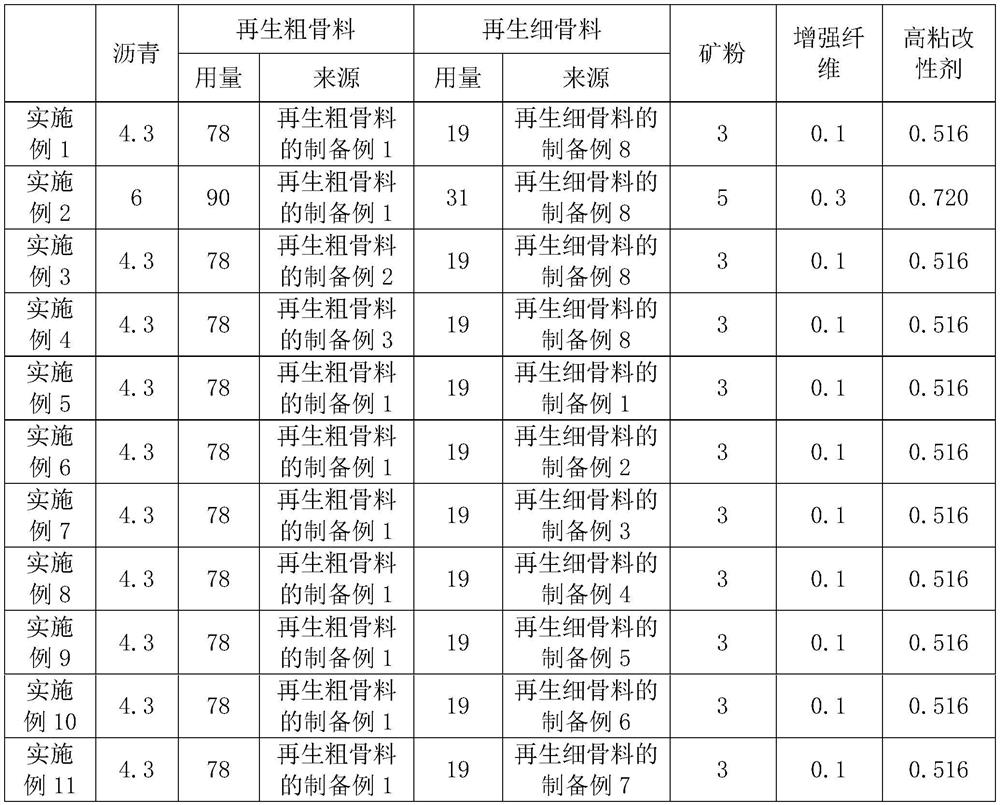

The invention relates to the field of pavement asphalt materials, and particularly discloses a permeable asphalt mixture and a preparation method thereof. The invention relates to a permeable asphalt mixture, which is prepared from the following raw materials in parts by weight: 4.3 to 6 parts of asphalt, 78 to 90 parts of recycled coarse aggregate, 19 to 31 parts of recycled fine aggregate, 3 to 5 parts of mineral powder, 0.1 to 0.3 part of reinforced fiber and 0.516 to 0.72 part of high-viscosity modifier, the recycled coarse aggregate is obtained by crushing, acidifying and carbonizing waste concrete. The permeable asphalt mixture can be used for permeable pavements, and has the advantages of good water permeability, good water damage resistance, high strength, large bearing capacity and good high temperature resistance.

Owner:苏州东振路桥工程有限公司

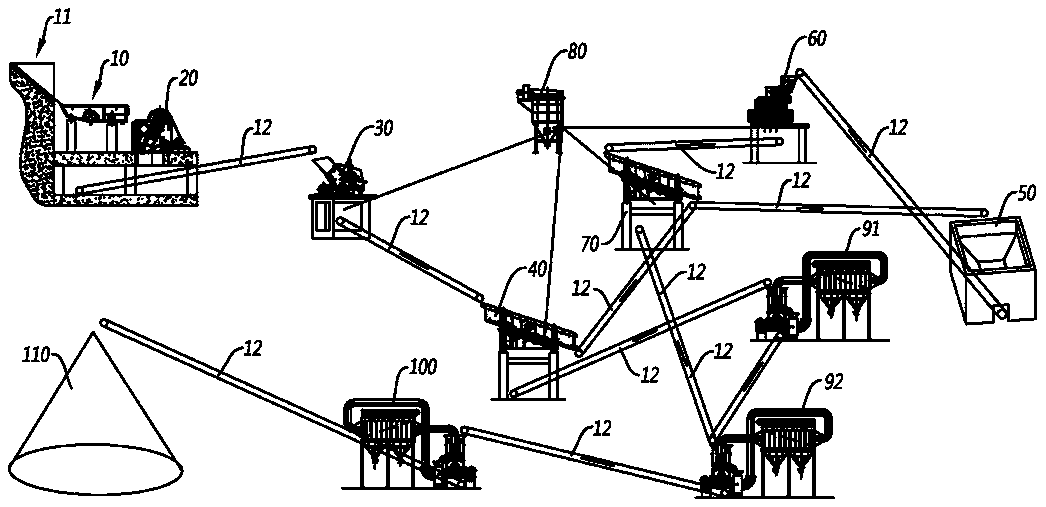

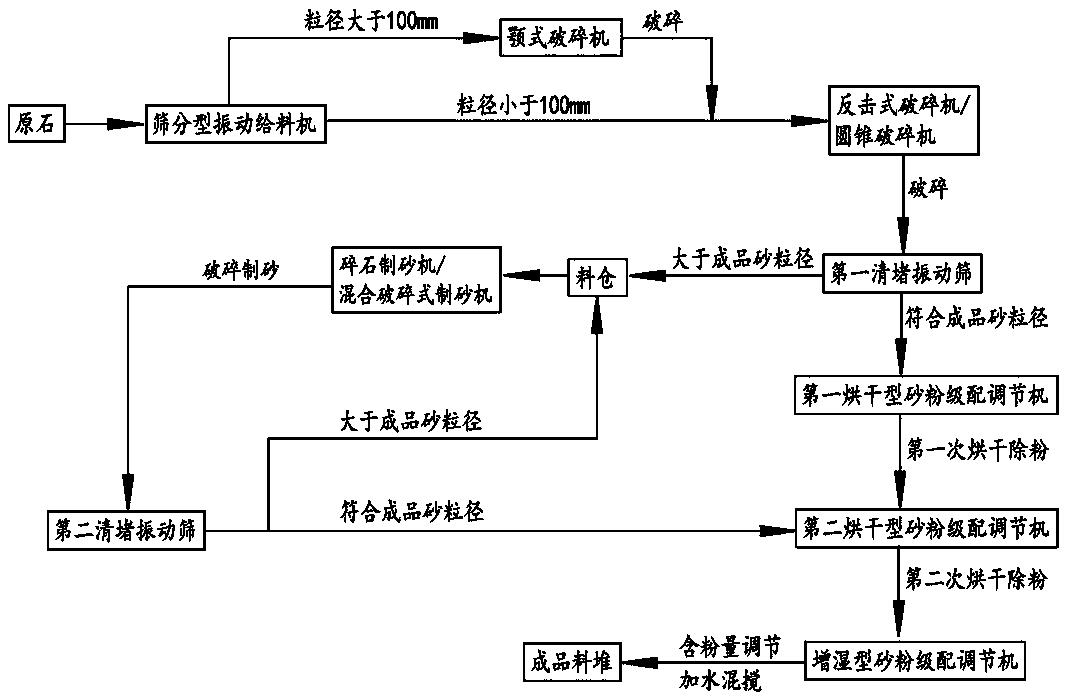

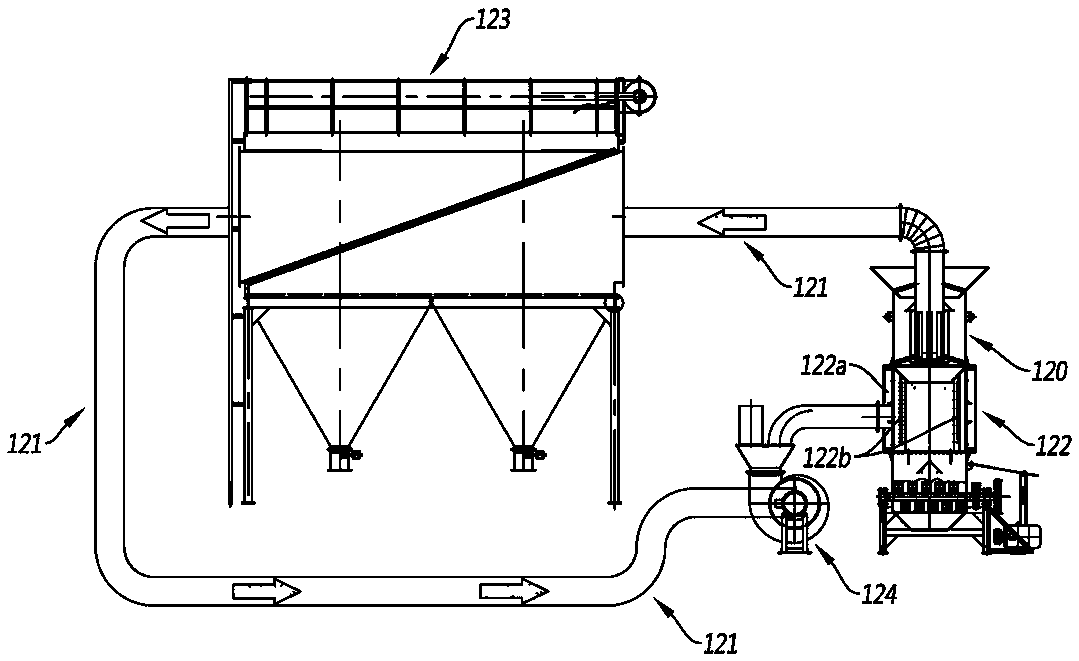

Dry-type sand production line and dry-type sand making process

PendingCN110102393AQuality improvementGood for the environmentTransportation and packagingMixersCrusherMaterials science

The invention relates to the technical field of dry-type sand making, and discloses a dry-type sand production line. The dry-type sand production line comprises a screening type vibration feeder for screening raw stone materials and a jaw crusher communicating with the screening type vibration feeder; an impact crusher or a cone crusher communicating with the jaw crusher through a belt conveyor isused for crushing the stone materials crushed by the jaw crusher; and subsequently, the quality of sand powder is improved through sand making by crushing, power removing by drying, powder content adjusting and mixed stirring by adding water. The dry-type sand making process comprises the steps of screening the raw stone materials, crushing the raw stone materials for the first time, crushing theraw stone materials for the second time, crushing the raw stone materials for sand making, drying to remove the powder, controlling the sand powder content by humidifying the sand powder and adjusting the powder content after drying and removing powder, adding water for mixing and stirring, and bonding the powder and the sand into a whole to obtain a finished product. According to the productionline and the process, the powder content of sand particles is reduced through multi-stage crushing; and drying instead of water washing is used for powder removal, and the heat of drying for powder removal is recycled, so that energy saving, environment-friendliness as well as high production efficiency are achieved.

Owner:SHAOGUAN HELI HEAVY IND MACHINERY

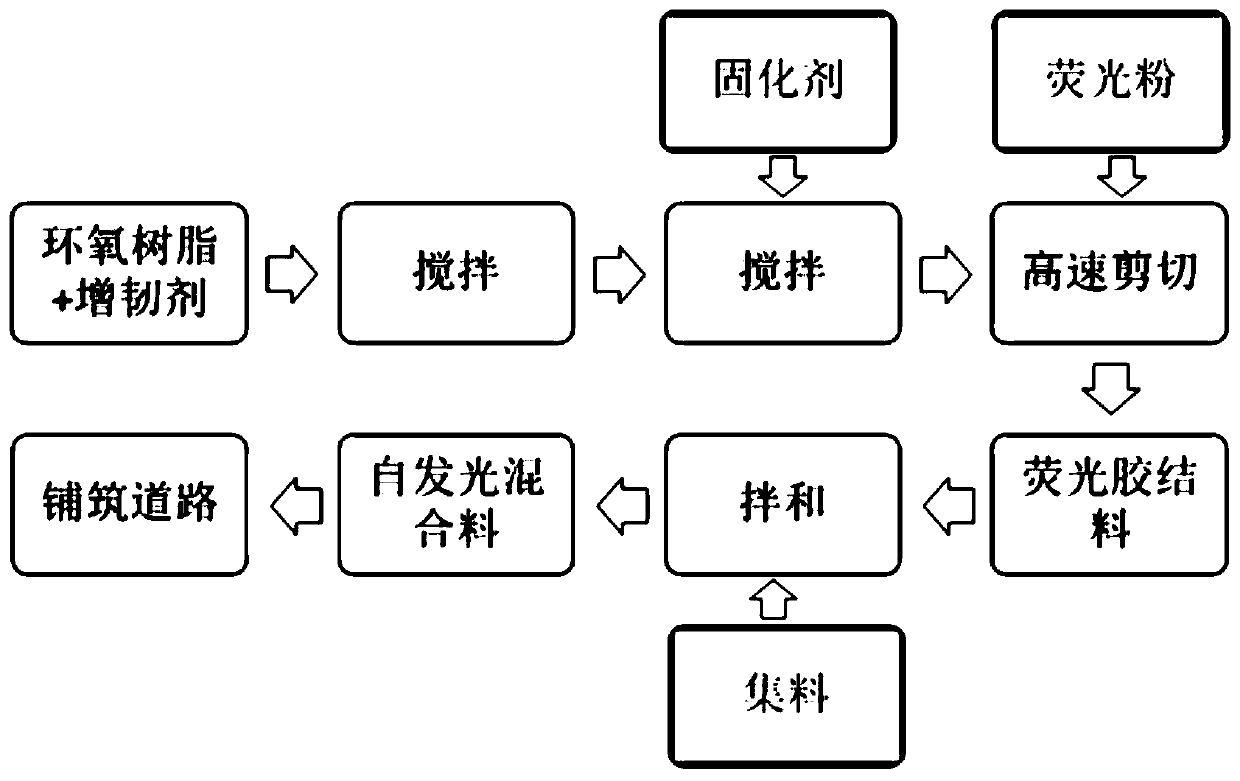

Energy-storage self-luminous epoxy resin mixture for road, preparation method and application

ActiveCN111138114AFully protect the luminosityIncrease stickinessIn situ pavingsPolymer scienceFirming agent

The invention discloses an energy-storage self-luminous epoxy resin mixture for roads as well as a preparation method and application thereof. The energy-storage self-luminous epoxy resin mixture comprises the following components: coarse aggregate, fine aggregate, epoxy resin, a toughening agent, a curing agent and fluorescent powder, wherein the nominal particle size of the coarse aggregate is greater than 2.36 mm, the nominal particle size of the fine aggregate is 0.15-2.36 mm, and the nominal particle size of the fluorescent powder is less than 0.15 mm; wherein the epoxy resin accounts for6.0%-10.0% of the total mass of the coarse aggregate and the fine aggregate, the flexibilizer accounts for 0.4%-1.0% of the total mass of the coarse aggregate and the fine aggregate, the curing agentaccounts for 1.0%-2.5% of the total mass of the coarse aggregate and the fine aggregate, and the fluorescent powder accounts for 5.0%-10.0% of the total mass of the coarse aggregate and the fine aggregate. The advantages of the fluorescent powder are achieved by applying the colorless and transparent epoxy resin, so that the epoxy resin mixture is good in light transmission and ideal in luminouseffect, and the proportion of the epoxy resin can meet the requirement of pavement performance and has a protection effect on the fluorescent powder; the fluorescent powder with the nominal particle size smaller than 0.15 mm is adopted for replacing fine aggregate with the particle size smaller than 0.15 mm, so that the mechanical property of the pavement structure is not affected, and the beneficial effects of energy storage and light emitting are achieved.

Owner:CHANGAN UNIV

Environment-protective type plant cover concrete

InactiveCN101323517BLow water absorptionSolve the problem of stacking affecting the ecological environmentSolid waste managementEcological environmentCarboxylic acid

The invention discloses an environment-friendly plant concrete, consisting of water, cement, waste concrete aggregate, concrete antalkali and poly carboxylic acid water reducing agent. The detailed matching proportion is as follows: the ratio of water / cement / waste concrete aggregate is 0.28 to 0.32:1:5; the quantity of adopted concrete antalkali is 10 to 20 percent of the cement quantity; the quantity of the poly carboxylic acid water reducing agent is 1 to 2 percent of the cement quantity. Compared with the existing similar product of the prior technology, the invention not only can solve the contamination to ecological environment by stacked waste concrete but also can avoid the damage to ecological environment by extreme exploitation to aggregate and realize the purpose of planting plants on concrete, thus achieving the effects of recycling sources, regulating ecological balance and beautifying environment; the intensity of the concrete is high, the concrete can be pre-cast into various shapes as requirements, and the construction is convenient.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Environment-friendly concrete sidewalk brick

InactiveCN105541228AGood water permeabilityHigh strengthSolid waste managementCeramic shaping apparatusBrickPortland cement

The invention discloses an environment-friendly concrete sidewalk brick. The brick is prepared from water, cement, waste concrete aggregate or tailings, and a concrete antalkali, wherein the specific mix proportion is that water to cement to waste concrete aggregate or tailings is (0.4 to 0.46) to 1 to 4; the using amount of the concrete antalkali is 22 to 25 percent of that of the cement; the concrete antalkali is prepared from 55 to 65 percent by weight of kieselguhr, 20 to 40 percent by weight of zeolite, and 5 to 15 percent of echinacea extract, the cement is ordinary portland cement with a mark number of 52.5R. Compared with the prior art, the brick provided by the invention has the characteristics that the overall performance is good and environmental friendliness is realized and protective effect is realized.

Owner:周琴霞

Ferronickel slag aggregate treatment method

The invention discloses a ferronickel slag aggregate treatment method. The ferronickel slag aggregate treatment method comprises the steps of: (1) soaking ferronickel slag aggregate in a mixed aqueoussolution of sodium hydroxide and water glass; (2) adjusting the temperature of the mixed solution obtained in the step (1) to 40-60 DEG C, and keeping the temperature for 1-6 hours; (3) after the heat preservation is finished, quickly stirring the solution for 10-60 seconds; (4) adding sodium carbonate and cement powder, and performing uniform stirring; (5) standing and precipitating the solutionfor 1-2 hours, and performing separating to obtain precipitate and clarified liquid; and (6) screening out ferronickel slag aggregate with the particle size of more than 5mm in the precipitate, naturally air-drying the ferronickel slag aggregate to be used as concrete aggregate, drying and grinding the part with the particle size of less than 5mm in the precipitate to be used as a concrete admixture, and using the clarified liquid as alkali-activated material mixing water. Through treatment of the method, air holes and active ingredients on the surface of the ferronickel slag aggregate are destroyed, and the problems that the ferronickel slag aggregate is high in crushing value and has potential alkali aggregate reaction are solved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

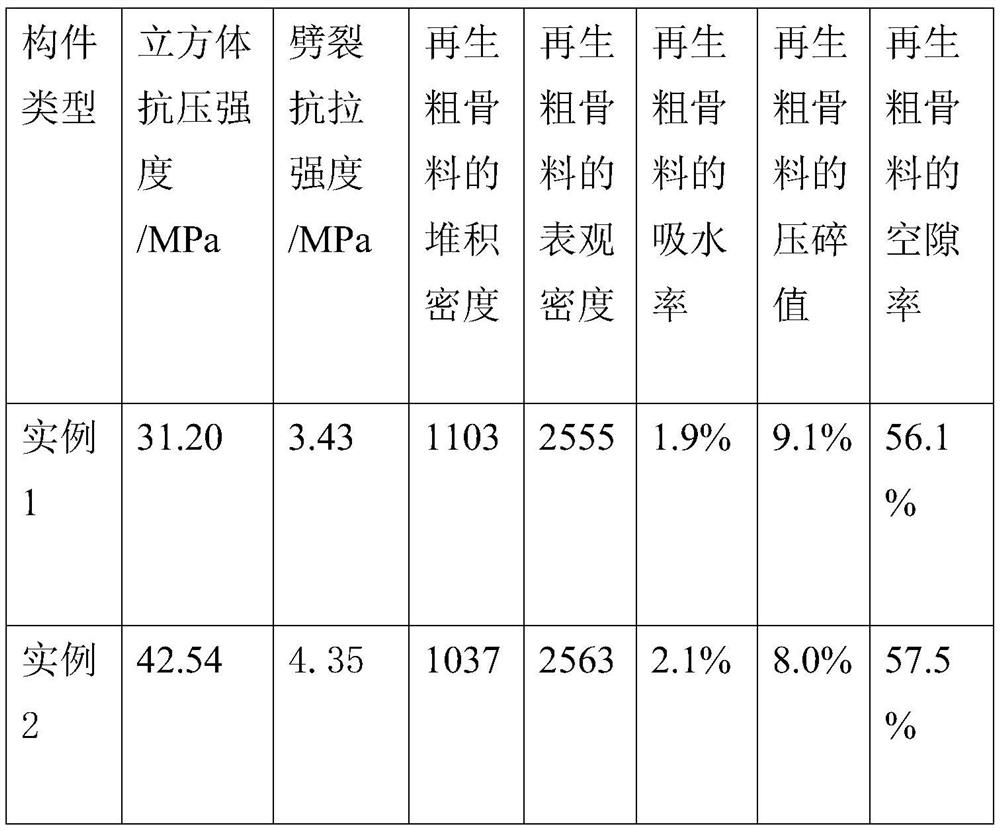

Recycled concrete with high interface bonding performance and preparation method thereof

The invention discloses recycled concrete with high interface bonding performance and a preparation method thereof. The recycled concrete comprises the following components in parts: 190-210 parts ofwater, 223.5-608.7 parts of cement, 405-665 parts of sand, 991.6-1290.9 parts of reinforced recycled coarse aggregate, 11.2-30.4 parts of silica fume, 33.5-91.3 parts of fly ash, 22.4-60.9 parts of mineral powder and 0-15.2 parts of water reducer. The invention disadvantages of low strength, low elasticity modulus, poor crack resistance, poor durability and the like of recycled concrete caused bythe defects of low density, high crushing value, high porosity, high water absorption rate and poor interface bonding performance of coarse aggregate and mortar in common recycled concrete. Therefore,the recycling of the waste concrete generated by dismantling the old building is realized, and the recycled concrete has great significance for saving resources and protecting the ecological environment.

Owner:HEFEI CEMENT RES DESIGN INST +1

High-strength concrete prepared from river pebbles

InactiveCN114180914AConducive to reasonable accumulationSmall amount of flaky particlesSoil scienceCrushed stone

The invention discloses high-strength concrete prepared from river pebbles, and belongs to the technical field of concrete, and the high-strength concrete comprises the following components: 520-600 Kg / m of a cementing material, 130-140 Kg / m of water, 660-760 Kg / m of sand, 960-1060 Kg / m of pebble gravel and an additive, the cementing material comprises 5-10% of fly ash, 8-20% of mineral powder, 5-10% of silica fume and the balance of cement; and the admixture accounts for 1.5-2.5% of the total amount of the cementing material. The river pebbles with particle size defects eliminated through crushing and shaping are adopted as coarse aggregates, the crushed and shaped pebbles are small in needle-sheet-shaped particle content and good in particle shape, the crushing value is smaller than 10%, reasonable accumulation of aggregates in concrete and reasonable stress distribution are facilitated, overall material particle grading distribution in the high-strength concrete tends to be more reasonable, and the strength of the high-strength concrete is improved. The working performance of a concrete mixture and the strength of concrete are improved, so that resources are saved, and the environment is protected.

Owner:河北冀超新型建材有限公司

Preparation method and application of biological calcium carbonate uniformly reinforced recycled aggregate

ActiveCN114772968AImprove distribution uniformityUniform reinforcement of recycled aggregateSolid waste managementEnvironmental chemistryCalcium carbonate

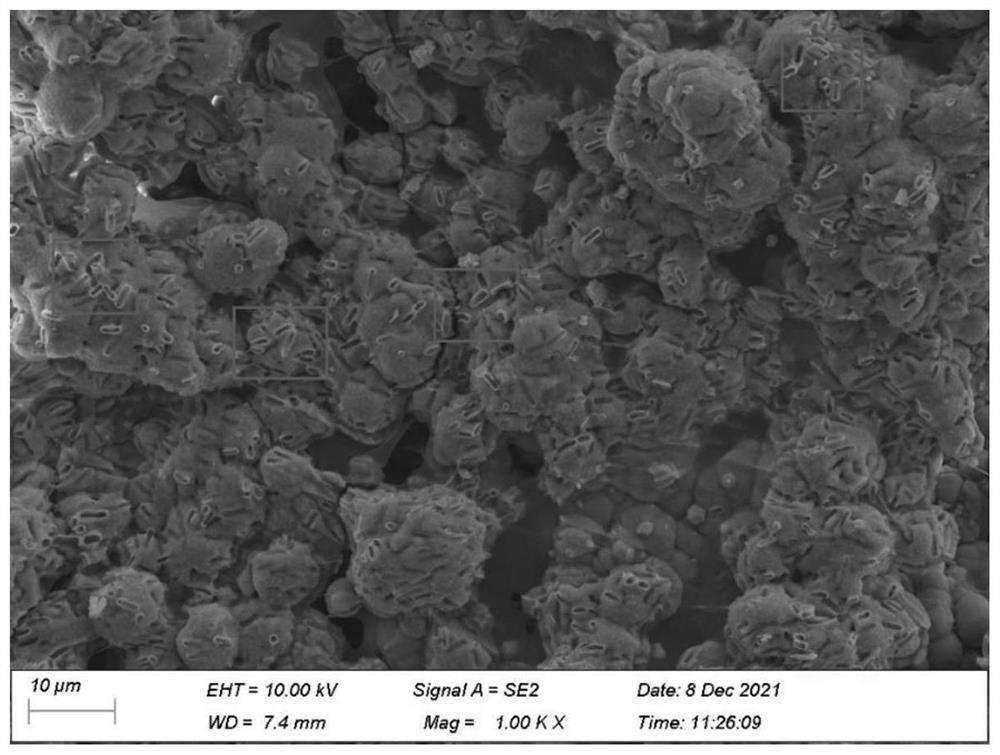

The invention provides a preparation method of a biological calcium carbonate uniformly reinforced recycled aggregate. The preparation method comprises the following steps: (1) pretreating the recycled aggregate; (2) uniformly fixing carbonate mineralizing bacteria on the whole surface of the recycled aggregate; (3) depositing biological calcium carbonate on the whole surface of the recycled aggregate; and (4) drying. A network structure formed after the thickening agent and calcium ions are chelated is used for effectively wrapping bacteria, carbonate mineralizing bacteria are uniformly fixed on the whole surface of the recycled aggregate, and biological calcium carbonate is formed by taking the mineralizing bacteria as nucleation sites, so that in-situ deposition of the biological calcium carbonate on the surface of the recycled aggregate is realized; the distribution uniformity of the biological calcium carbonate on the surface of the recycled aggregate is improved, and the water absorption rate and the crushing value of the recycled aggregate are further reduced, so that the utilization rate of the recycled aggregate in the concrete is improved, the sustainable development of the concrete is realized, and the large-scale application of the recycled aggregate in the concrete field is promoted.

Owner:XI AN JIAOTONG UNIV

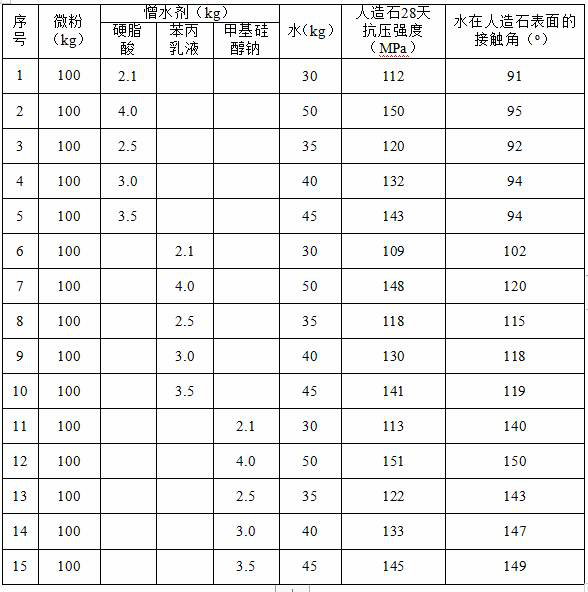

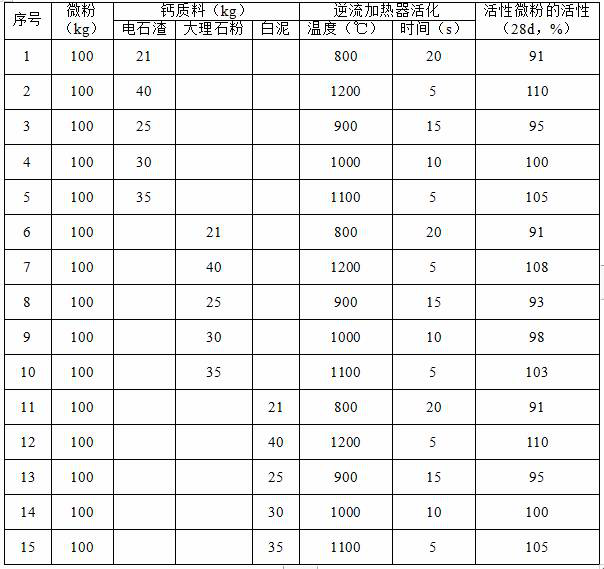

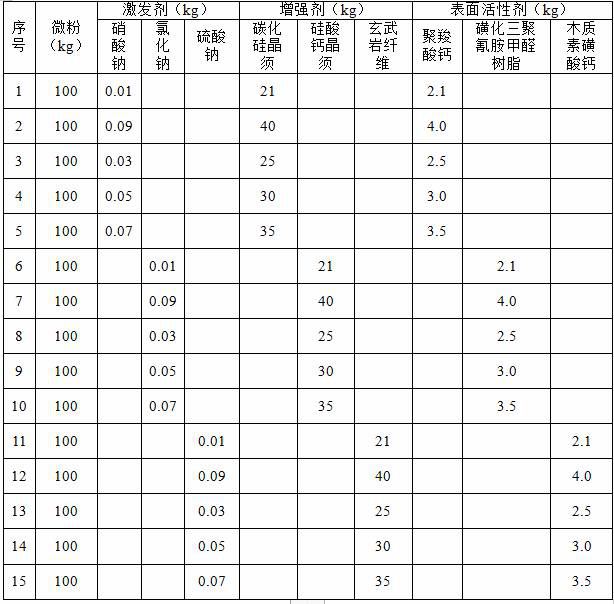

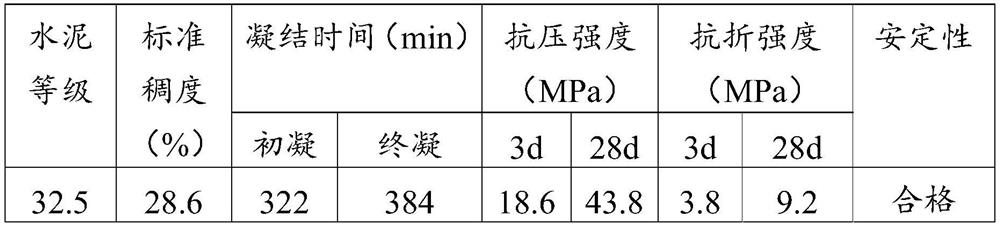

Method for preparing high-strength fabricated artificial stone from construction waste

The invention discloses a method for preparing high-strength fabricated artificial stone from construction waste, which comprises the following steps: reselecting and separating brick concrete construction waste, and grinding concrete in a hot air autogenous mill to obtain recycled aggregate and micro powder; adding a calcareous material into the micro powder, grinding by using steam kinetic energy, and then carrying out rapid thermal activation in a countercurrent heater to obtain active micro powder; and adding an excitant, a reinforcing agent, a surfactant, a water repellent and water intothe active micro powder, uniformly stirring, molding and curing to obtain the high-strength fabricated artificial stone. The method is low in production cost and high in efficiency, and high-quality cyclic utilization of resources is achieved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

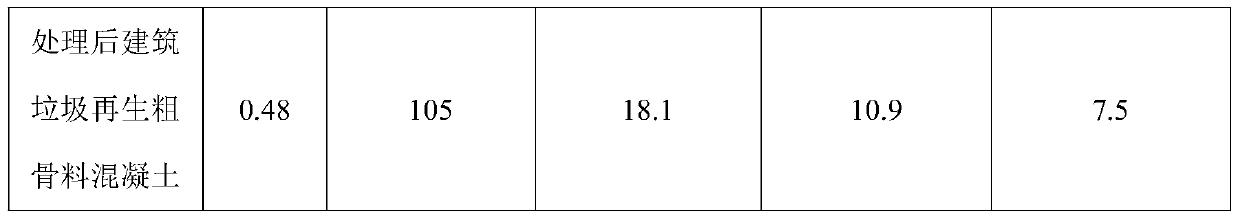

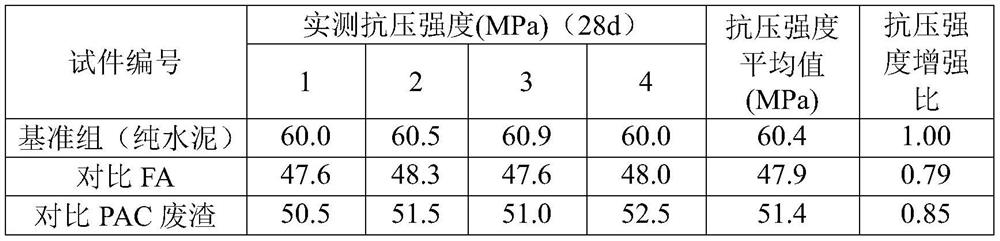

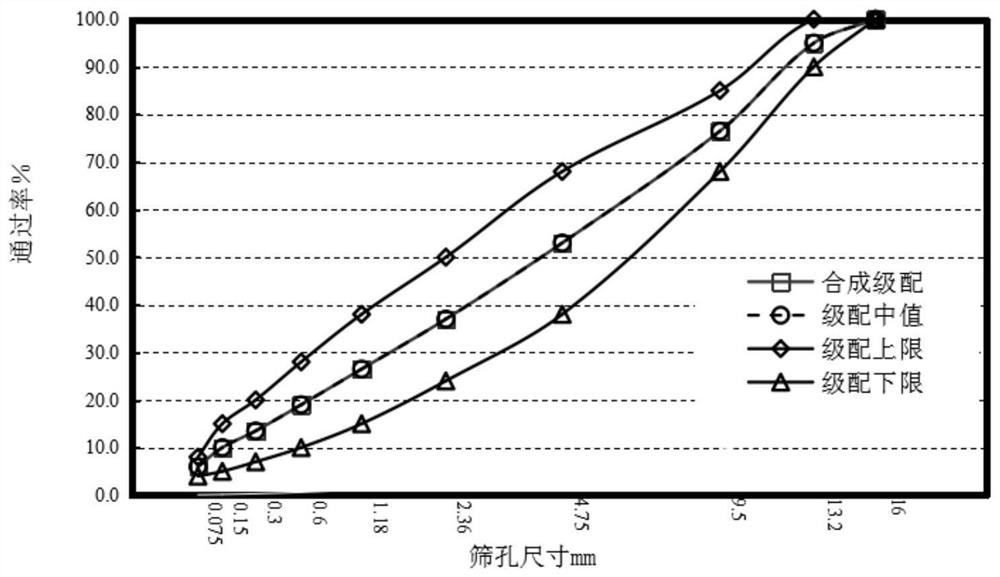

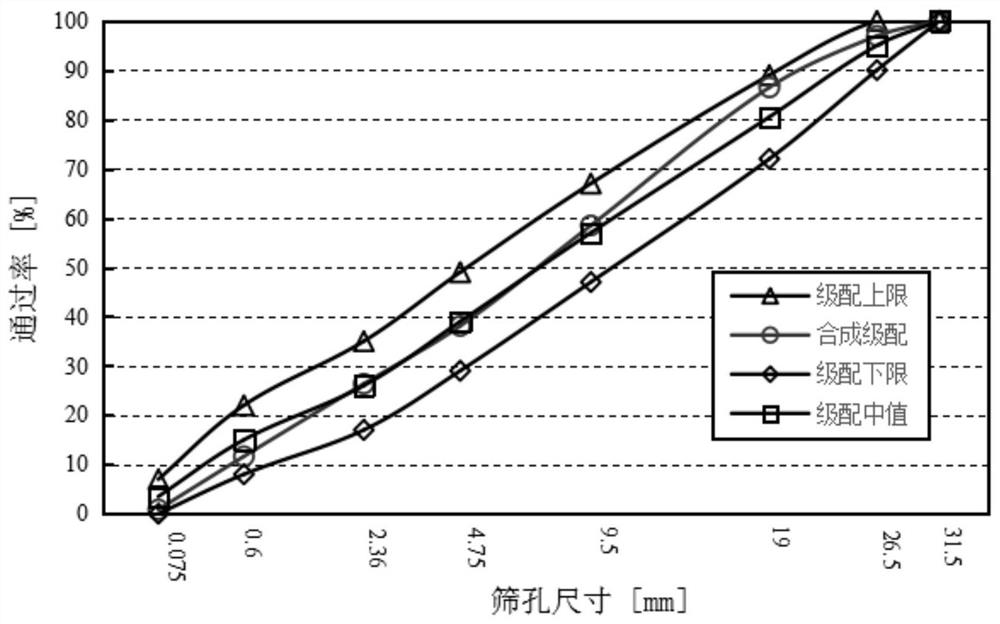

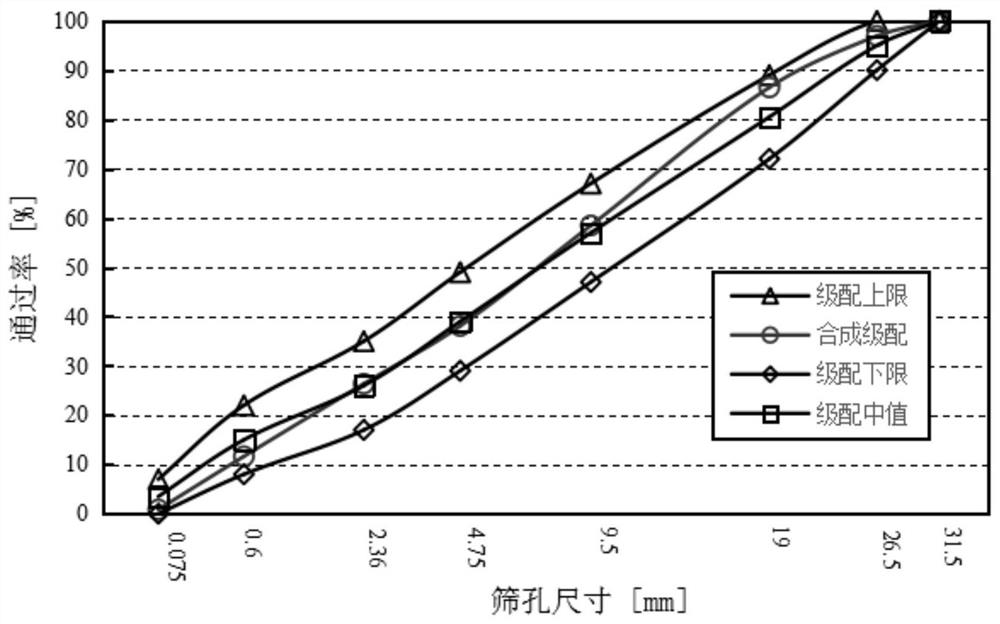

Inorganic mixture prepared from construction waste recycled aggregate and preparation method thereof

InactiveCN113582641ALower requirementLow crush valueSolid waste managementEnvironmental engineeringUltimate tensile strength

The invention discloses an inorganic mixture prepared from construction waste recycled aggregate. The inorganic mixture is prepared from the following raw materials in percentage by weight: 93-96 wt% of recycled aggregate and 4-7 wt% of cement. The recycled aggregate with the particle size of 20-31.5 mm is 10%, the recycled aggregate with the particle size of 10-20 mm is 25%, the recycled aggregate with the particle size of 5-10 mm is 30%, and the recycled aggregate with the particle size of 0-5 mm is 35%. By further improving the combination of the recycled aggregate, the cement consumption can be further reduced, the utilization scale of the recycled aggregate is increased, and the strength requirement of the existing road base is met.

Owner:BCEG RESOURCES RECYCLING CO LTD

A kind of ferronickel slag ultra-high strength concrete and preparation method thereof

Owner:徐州经济技术开发区诚意商品混凝土有限公司

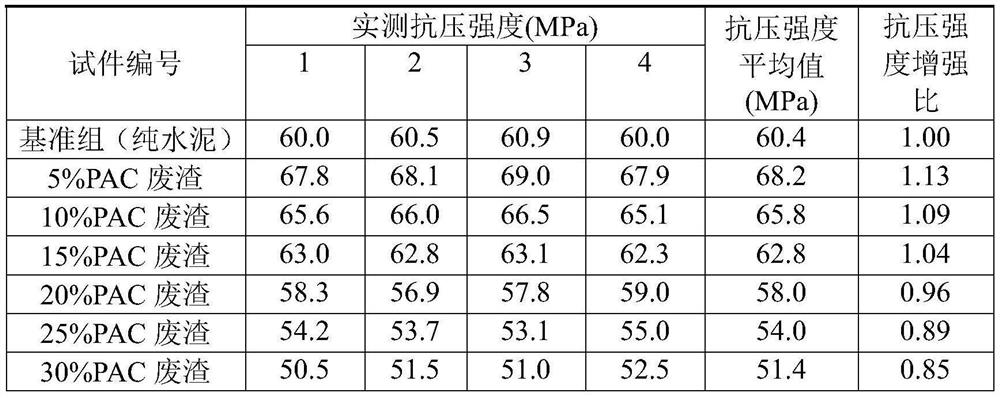

A kind of polyaluminum chloride waste slag recycled concrete curb and its preparation method

ActiveCN112159180BPotentially chemically active and effectivePotential chemical activationAluminium chlorideSlag

The invention discloses a polyaluminum chloride waste slag regenerated concrete curb and a preparation method thereof. The raw materials include: sand 600-690kg / m in terms of mass per unit volume 3 , recycled coarse aggregate 375 ~ 400kg / m 3 , natural coarse aggregate 750~800kg / m 3 , Thermally activated polyaluminum chloride waste residue 40-80kg / m 3 , Cement 220~260kg / m 3 , Fly ash 40~80kg / m 3 , the water-to-cement ratio is 0.40-0.45; the amount of water-reducing agent is 0.30-0.55% of the gelling material, the amount of defoamer is 0.10-0.15% of the gelling material, and the amount of alkali activator is 2.5-0.5% of the gelling material 5.3%. The present invention adopts industrial waste polyaluminum chloride waste slag and recycled aggregate to make road curbs. The production method is simple and the cost is low, which can effectively reduce the large amount of polyaluminum chloride waste slag and construction waste piled up, and can also reduce the waste of high energy consumption cement. The amount used is of great significance to reduce construction costs and reduce environmental pollution, and has good social and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

A kind of phosphogypsum-based aggregate and preparation method thereof

ActiveCN113354376BHigh strengthShorten the maintenance periodSolid waste managementCelluloseSodium phosphates

The invention discloses a phosphogypsum-based aggregate and a preparation method thereof, belonging to the technical field of road building materials. The phosphogypsum-based aggregate is prepared by mixing A powder and B solution into a ball; the A powder includes: 50%-80% of phosphogypsum, 15%-45% of waste residue powder, and 3%- of alkaline activator 6%; the solution B includes sodium hexametaphosphate 1%-2%, cellulose ether 0.1%-0.2%, and the rest is water. The preparation method includes: 1) mixing phosphogypsum, slag powder, and alkaline activator to obtain A powder; 2) adding sodium hexametaphosphate and cellulose ether to water to dissolve to obtain B solution; 3) preparing step 1) The obtained A powder is put into the pelletizing machine, and the B solution is continuously sprayed into the pelletizing machine to be mixed with the A powder, and the pellets are formed to obtain aggregates; 4) after the aggregates are solidified, water immersion curing is performed to obtain the described aggregates. Phosphogypsum based aggregates. The invention realizes short curing period and high strength of phosphogypsum-based aggregate.

Owner:WUHAN UNIV OF TECH

Phosphogypsum-based aggregate and preparation method thereof

The invention discloses phosphogypsum-based aggregate and a preparation method thereof, and belongs to the technical field of road building materials. The phosphogypsum-based aggregate is prepared by mixing and balling powder A and a solution B; the powder A comprises 50%-80% of phosphogypsum, 15%-45% of waste residue powder and 3%-6% of an alkaline activator; and the solution B comprises 1%-2% of sodium hexametaphosphate, 0.1%-0.2% of cellulose ether and the balance being water. The preparation method comprises the steps: 1) mixing phosphogypsum, slag powder and the alkaline activator to obtain the powder A; 2) adding sodium hexametaphosphate and cellulose ether in water, and dissolving to obtain the solution B; (3) putting the powder A prepared in the step (1) into a ball forming mill, continuously spraying the solution B into the ball forming mill, mixing the solution B with the powder A, and carrying out ball forming to obtain aggregate; and 4) curing the aggregate, soaking in water, and curing to obtain the phosphogypsum-based aggregate. The phosphogypsum-based aggregate is short in curing period and high in strength.

Owner:WUHAN UNIV OF TECH

Preparation method of radioactive waste magmatite glass ceramic solidified body

InactiveCN110845143AStable chemical and physical propertiesStrong weather resistanceRadioactive decontaminationMetallurgyHeat stability

The invention discloses a preparation method of a radioactive waste magmatite glass ceramic solidified body. The preparation method is characterized by comprising the following steps: taking the following raw materials in percentage by mass: 44-99% of natural magmatite and 1-56% of simulated radioactive waste which is ZrO2, CeO2 or La2O3; mixing and grinding; heating an obtained mixed material at1400-1500 DEG C for 3-4.5 hours to obtain a melt; cooling the melt to 730-1250 DEG C, and keeping the temperature for 2-3 hours to obtain a magmatite glass ceramic solidified body; and keeping the temperature at 600 DEG C for 1-2 hours, and cooling to room temperature to obtain the radioactive waste magmatite glass ceramic solidified body. The prepared radioactive waste magmatite glass ceramic solidified body is good in chemical stability and thermal stability, the mechanical stability and the radioactive waste package capacity are superior to those of glass solidified bodies, the simulated radioactive waste element weightlessness rate is small, and practicability is high.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com